Bosch GCL 25 PROFESSIONAL: English

English: Bosch GCL 25 PROFESSIONAL

OBJ_BUCH-1546-002.book Page 11 Monday, July 9, 2012 10:30 AM

English | 11

Tel. Kundenberatung: +49 (1803) 33 57 99

f Caution – The use of other operating or adjusting

(Festnetzpreis 9 ct/min, höchstens 42 ct/min aus Mobil-

equipment or the application of other processing meth-

funknetzen)

ods than those mentioned here, can lead to dangerous

Fax: +49 (711) 7 58 19 30

radiation exposure.

E-Mail: kundenberatung.ew@de.bosch.com

f The measuring tool is provided with a warning label in

Österreich

English (marked with number 10 in the representation

Tel.: +43 (01) 7 97 22 20 10

of the measuring tool on the graphics page).

Fax: +43 (01) 7 97 22 20 11

E-Mail: service.elektrowerkzeuge@at.bosch.com

Schweiz

Tel.: +41 (044) 8 47 15 11

Fax: +41 (044) 8 47 15 51

f Do not direct the laser beam at persons or animals and

do not stare into the laser beam yourself. This measur-

Luxemburg

ing tool produces laser class 2 laser radiation according to

Tel.: +32 2 588 0589

IEC 60825-1. This can lead to persons being blinded.

Fax: +32 2 588 0595

E-Mail: outillage.gereedschap@be.bosch.com

f Do not use the laser viewing glasses as safety goggles.

The laser viewing glasses are used for improved visualisa-

Entsorgung

tion of the laser beam, but they do not protect against laser

Messwerkzeuge, Zubehör und Verpackungen sollen einer

radiation.

umweltgerechten Wiederverwertung zugeführt werden.

f Do not use the laser viewing glasses as sun glasses or in

Werfen Sie Messwerkzeuge und Akkus/Batterien nicht in den

traffic. The laser viewing glasses do not afford complete

Hausmüll!

UV protection and reduce colour perception.

Nur für EU-Länder:

f Have the measuring tool repaired only through quali-

Gemäß der europäischen Richtlinie

fied specialists using original spare parts. This ensures

2002/96/EG müssen nicht mehr ge-

that the safety of the measuring tool is maintained.

brauchsfähige Messwerkzeuge und gemäß

f Do not allow children to use the laser measuring tool

der europäischen Richtlinie 2006/66/EG

without supervision. They could unintentionally blind

müssen defekte oder verbrauchte Akkus/

other persons or themselves.

Batterien getrennt gesammelt und einer

f Do not operate the measuring tool in explosive environ-

umweltgerechten Wiederverwendung zu-

ments, such as in the presence of flammable liquids,

geführt werden.

gases or dusts. Sparks can be created in the measuring

Nicht mehr gebrauchsfähige Akkus/Batterien können direkt

tool which may ignite the dust or fumes.

abgegeben werden bei:

Keep the laser target plate 13 away

Deutschland

from cardiac pacemakers. The magnets

Recyclingzentrum Elektrowerkzeuge

on the laser target plate generate a field

Osteroder Landstraße 3

that can impair the function of cardiac

37589 Kalefeld

pacemakers.

Schweiz

Batrec AG

f Keep the laser target plate 13 away from magnetic data

3752 Wimmis BE

medium and magnetically-sensitive equipment. The ef-

Änderungen vorbehalten.

fect of the magnets on the laser target plate can lead to ir-

reversible data loss.

Product Description and

English

Specifications

Please unfold the fold-out page with the representation of the

Safety Notes

measuring tool and leave it unfolded while reading the operat-

Working safely with the measuring tool is

ing instructions.

possible only when the operating and safety

information are read completely and the

Intended Use

instructions contained therein are strictly

The measuring tool is intended for determining and checking

followed. Never make warning labels on the

horizontal and vertical lines as well as plumb points.

measuring tool unrecognisable. SAVE

THESE INSTRUCTIONS.

Bosch Power Tools 1 618 C00 50R | (9.7.12)

OBJ_BUCH-1546-002.book Page 12 Monday, July 9, 2012 10:30 AM

12 | English

Product Features

Point and line laser GCL 25

The numbering of the product features shown refers to the

Battery life for the operating

illustration of the measuring tool on the graphic page.

modes

1 Exit opening for laser beam

– Cross and point-line operation

12 h

2 Operating mode button

– 5-point operation

24 h

3 Battery low indicator

– Line operation

30 h

4 On/Off switch

Weight according to

EPTA-Procedure 01/2003

0.6 kg

5 Magnets

Dimensions

6 Tripod mount 5/8"

(length x width x height)

155x56x118mm

7 Tripod mount 1/4"

Degree of protection

IP 54 (dust and splash

8 Latch of battery lid

water protected)

9 Battery lid

1) The working range can be decreased by unfavourable environmental

10 Laser warning label

conditions (e.g. direct sun irradiation).

11 Serial number

The measuring tool can be clearly identified with the serial number 11

12 Laser viewing glasses*

on the type plate.

13 Laser target plate

14 Measuring plate with stand*

Assembly

15 Universal holder*

Inserting/Replacing the Battery

16 Tripod*

Alkali-manganese batteries are recommended for the meas-

17 Case

uring tool.

* The accessories illustrated or described are not included as

To open the battery lid 9, slide the latch 8 in the direction of

standard delivery.

the arrow and fold the battery lid up. Insert the batteries.

When inserting, pay attention to the correct polarity accord-

Technical Data

ing to the representation on the inside of the battery lid.

Point and line laser GCL 25

When the batteries are low, the battery low indicator 3 flashes

Article number

3 601 K66 B00

red. Additionally, the laser beams flash for approx. 5 s every

10 minutes. When the flashing initially begins, the measuring

Working range

1)

tool can be operated for approx. 1 more hour. When the bat-

– Laser lines

10 m

teries become empty, the laser beams flash one more time di-

– Horizontal point beams

30 m

rectly prior to the automatic shut-off.

– Point beam, upward

10 m

Always replace all batteries at the same time. Only use batter-

– Point beam, downward

5m

ies from one brand and with the identical capacity.

Levelling accuracy

f Remove the batteries from the measuring tool when

– Laser lines and horizontal

not using it for extended periods. When storing for ex-

point beams

±0.3 mm/m

tended periods, the batteries can corrode and discharge

– Vertical point beams

±0.5 mm/m

themselves.

Self-levelling range, typically

± 4°

Levelling duration, typically

<4s

Operation

Operating temperature

–10 °C ... +50 °C

Initial Operation

Storage temperature

–20 °C ... +70 °C

f Protect the measuring tool against moisture and direct

Relative air humidity, max.

90 %

sun light.

Laser class

2

f Do not subject the measuring tool to extreme tempera-

Laser type

635 nm, <1 mW

tures or variations in temperature. As an example, do

C

not leave it in vehicles for long time. In case of large varia-

6

1

tions in temperature, allow the measuring tool to adjust to

Tripod mount

1/4", 5/8"

the ambient temperature before putting it into operation.

Batteries

4x1.5VLR06(AA)

In case of extreme temperatures or variations in tempera-

1) The working range can be decreased by unfavourable environmental

ture, the accuracy of the measuring tool can be impaired.

conditions (e.g. direct sun irradiation).

f Avoid heavy impact or falling of the measuring tool.

The measuring tool can be clearly identified with the serial number 11

After heavy exterior impact on the measuring tool, an accu-

on the type plate.

racy check should always be carried out before continuing

to work (see “Levelling Accuracy”).

1 618 C00 50R | (9.7.12) Bosch Power Tools

OBJ_BUCH-1546-002.book Page 13 Monday, July 9, 2012 10:30 AM

English | 13

f Switch the measuring tool off during transport. When

Automatic Levelling

switching off, the levelling unit, which can be damaged in

case of intense movement, is locked.

Working with Automatic Levelling (see figures C–E)

Position the measuring tool on a level and firm support, attach

Switching On and Off

it to the holder 15 or to the tripod 16.

To switch on the measuring tool, slide the On/Off switch 4 to

When working with automatic levelling, push the On/Off

the “on” position (when working without automatic level-

switch 4 to the “ on” position.

ling) or to the “on” position (when working with automat-

ic levelling). Immediately after switching on, the measuring

After switching on, the automatic levelling function automati-

tool sends laser beams out of the exit openings 1.

cally compensates irregularities within the self-levelling range

of ± 4°. The levelling is finished as soon as the laser points or

f Do not point the laser beam at persons or animals and

laser lines do not move any more.

do not look into the laser beam yourself, not even from

a large distance.

If the automatic levelling function is not possible, e.g. be-

cause the surface on which the measuring tool stands devi-

To switch off the measuring tool, slide the On/Off switch 4 to

ates by more than 4° from the horizontal plane, the laser

the “off” position. When switching off, the levelling unit is

beams flash. This alarm is deactivated within 10 s after

locked.

switching on, in order to allow adjustment of the measuring

Deactivating the Automatic Shut-off

tool.

When no button on the measuring tool is pressed for approx.

Set up the measuring tool in level position and wait for the

30 minutes, the measuring tool automatically switches off to

self-levelling to take place. As soon as the measuring tool is

save the batteries.

within the self-levelling range of ±4°, the laser beams light up

To switch on the measuring tool after automatic shut-off, either

continuously.

slide the On/Off switch 4 to the “off” position and then switch

In case of ground vibrations or position changes during oper-

the measuring tool on again or press the operating mode button

ation, the measuring tool is automatically levelled in again. To

2 once.

avoid errors by moving the measuring tool, check the position

To deactivate the automatic shut-off, keep the operating

of the laser beams with regard to the reference points upon

mode button 2 pressed for at least 3 s (while the measuring

re-levelling.

tool is switched on). Deactivation of the automatic shut-off is

confirmed by brief flashing of the laser beams.

Working without Automatic Levelling (see figure F)

For work without automatic levelling, push the On/Off switch

f Do not leave the switched on measuring tool unattend-

4 to the “ on” position. When the automatic levelling is

ed and switch the measuring tool off after use. Other

switched off, the laser lines flash continuously.

persons could be blinded by the laser beam.

When automatic levelling is switched off, you can hold the

To activate the automatic shut-off, switch the measuring tool

measuring tool freely in your hand or place it on an inclinded

off and then on again.

surface. The laser beams no longer necessarily run vertical to

Operating Modes

each other.

The measuring tool has several operating modes between

which you can switch at any time:

Levelling Accuracy

– Cross and point-line operation: The measuring tool gener-

Influences on Accuracy

ates a horizontal and a vertical laser line facing toward the

The ambient temperature has the greatest influence. Espe-

front as well as a vertical point beam each facing upward

cially temperature differences occurring from the ground

and downward, and a horizontal point beam each facing

upward can divert the laser beam.

toward the front and to both sides.

As thermal fluctuation is largest close to the ground, the

– 5-point operation: The measuring tool generates a vertical

measuring tool, if possible, should be mounted on a commer-

point beam each facing upward and downward, as well as

cially available tripod and placed in the centre of the working

a horizontal point beam each facing toward the front and to

area.

both sides.

– Horizontal line operation: The measuring tool generates a

Apart from exterior influences, device-specific influences

horizontal laser line facing frontward.

(such as heavy impact or falling down) can lead to deviations.

– Vertical line operation: The measuring tool generates a ver-

Therefore, check the accuracy of the measuring tool each

tical laser line facing frontward.

time before starting your work.

All point beams run at a 90° angle to each other; the laser

When the accuracy of the horizontal point beams is within the

lines also cross each other at a 90° angle.

maximum allowed deviation, then the accuracy of the vertical

point beams and the laser lines is thus also checked.

After switching on, the measuring tool is in cross-line and

point-line operation. To change the operating mode, press

Should the measuring tool exceed the maximum deviation

the operating mode button 2.

during one of the tests, please have it repaired by a Bosch af-

ter-sales service.

All operating modes can be selected both with and without au-

tomatic levelling.

Bosch Power Tools 1 618 C00 50R | (9.7.12)

OBJ_BUCH-1546-002.book Page 14 Monday, July 9, 2012 10:30 AM

14 | English

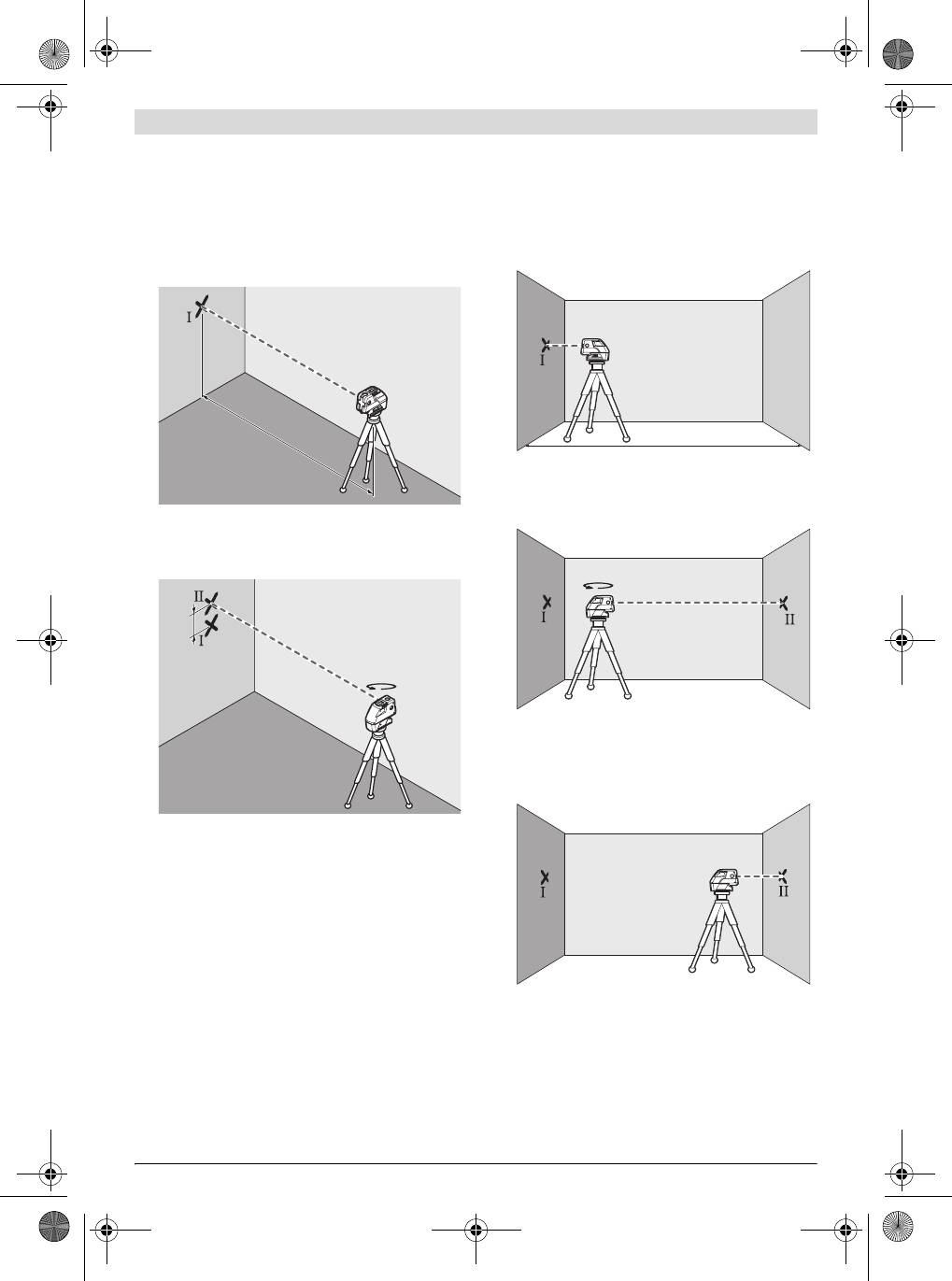

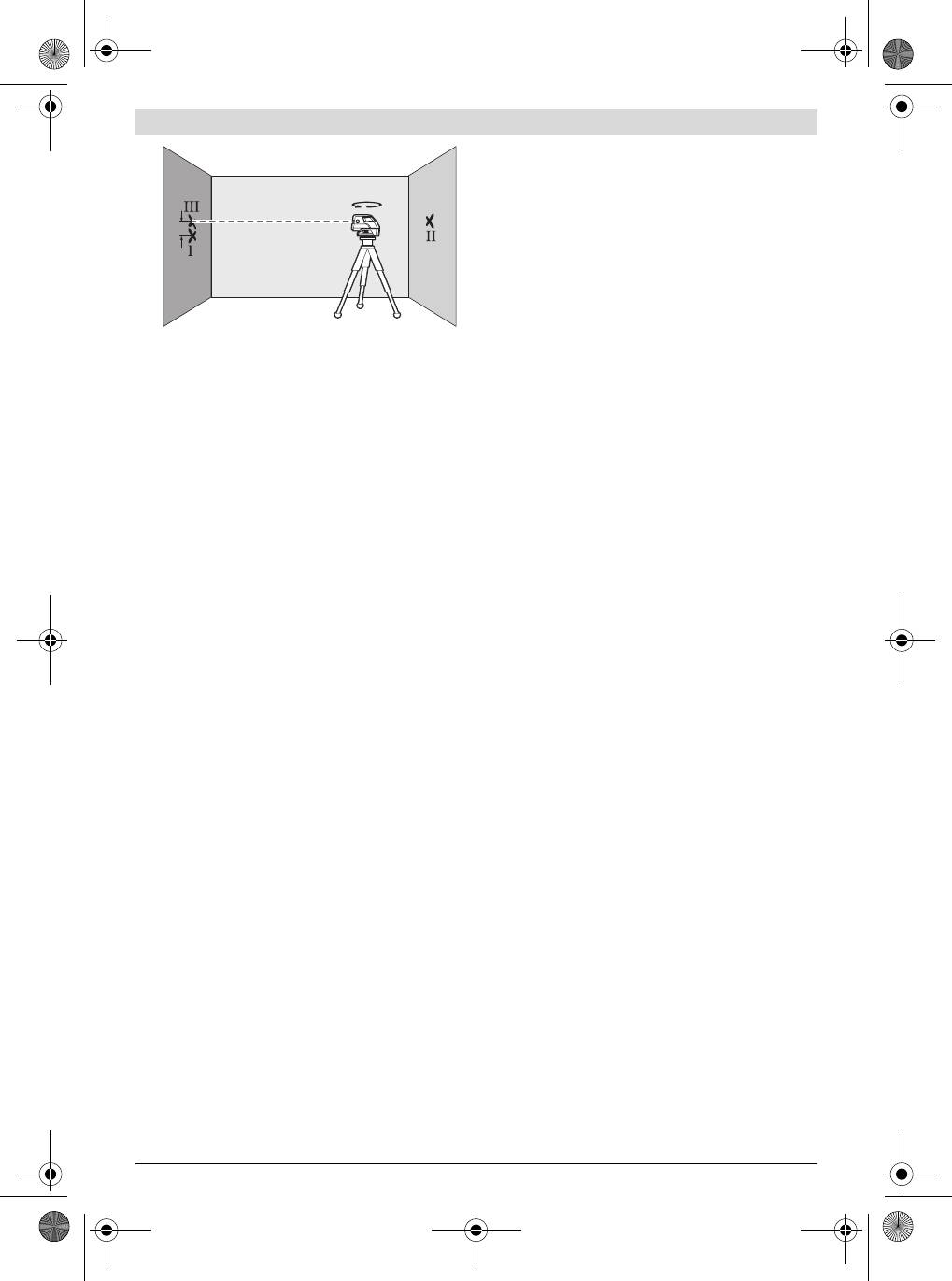

Checking the Horizontal Levelling Accuracy of the Lateral

Checking the Horizontal Levelling Accuracy of the Longi-

Axis

tudinal Axis

A free measuring distance of 20 m on a firm surface in front of

A free measuring distance of 20 m on a firm surface between

a wall is required for the check.

two walls A and B is required for the check.

– Mount the measuring tool onto the holder or a tripod, or

– Mount the measuring tool onto the holder or a tripod, or

place it on a firm and level surface at a distance of 20 m to

place it on a firm and level surface close to wall A. Switch

the wall. Switch the measuring tool on and select 5-point

the measuring tool on and select 5-point operation.

operation.

A

B

20 m

20 m

– Direct the horizontal laser beam, which runs parallel to the

longitudinal axis of the measuring tool, at the close wall A.

Allow the measuring tool to level in. Mark the centre of the

– Direct one of the two lateral laser beams, that run along-

laser beam on the wall (point I).

side the lateral axis of the measuring tool, at the wall. Allow

the measuring tool to level in. Mark the centre of the laser

beam on the wall (point I).

A

180°

B

d

180°

– Turn the measuring tool around by 180°, allow it to level in

and mark the centre point of the laser beam on the oppo-

site wall B (point II).

– Without turning the measuring tool, position it close to wall

B. Switch the measuring tool on and allow it to level in.

– Rotate the measuring tool by approx. 180° without chang-

ing its height. Allow it to level in and mark the centre point

A

B

of the other lateral laser beam on the wall (point II). Take

care that point II is as vertical as possible above or below

point I.

– The difference d of both marked points I and II on the wall

results in the actual height deviation of the measuring tool

alongside the lateral axis.

On the measuring distance of 2 x 20 m = 40 m, the maximum

allowable deviation is:

40 m x ± 0.3 mm/m = ± 12 mm.

– Align the height of the measuring tool (using the tripod or

Thus, the difference d between points I and II may not exceed

by underlaying, if required) in such a manner that the cen-

12 mm (max.).

tre point of the laser beam is projected exactly against the

previously marked point II on wall B.

1 618 C00 50R | (9.7.12) Bosch Power Tools

OBJ_BUCH-1546-002.book Page 15 Monday, July 9, 2012 10:30 AM

English | 15

Working with the Laser Target Plate

The laser target plate 13 increases the visibility of the laser

A

B

180°

beam under unfavourable conditions and at large distances.

The reflective part of the laser target plate 13 improves the

d

visibility of the laser line. Thanks to the transparent part, the

laser line is also visible from the back side of the laser target

plate.

Laser Viewing Glasses (Accessory)

The laser viewing glasses filter out the ambient light. This

makes the red light of the laser appear brighter for the eyes.

– Rotate the measuring tool by 180° without changing the

f Do not use the laser viewing glasses as safety goggles.

height. Allow it to level in and mark the centre point of the

The laser viewing glasses are used for improved visualisa-

laser beam on wall A (point III). Take care that point III is

tion of the laser beam, but they do not protect against laser

as vertical as possible above or below point I.

radiation.

– The difference d of both marked points I and III on wall A

f Do not use the laser viewing glasses as sun glasses or in

results in the actual height deviation of the measuring tool

traffic. The laser viewing glasses do not afford complete

alongside the Longitudinal axis.

UV protection and reduce colour perception.

On the measuring distance of 2 x 20 m = 40 m, the maximum

Work Examples (see figures C – F)

allowable deviation is: 40 m x ± 0.3 mm/m = ± 12 mm.

Applicational examples for the measuring tool can be found

Thus, the difference d between points I and III may not ex-

on the graphics pages.

ceed 12 mm (max.).

Always position the measuring tool close to the surface or

Working Advice

edge subject to checking, and allow it to level in prior to each

measurement.

f For marking, always use only the centre of the laser

point or the laser line. The size of the laser point as well as

Always measure the distances between laser beam or laser

the width of the laser line change with distance.

line and a surface or edge at two points as far as possible away

from each other (e.g. with the measurment plate 14).

Working with the Tripod (Accessory)

A tripod offers a stable, height-adjustable measuring support.

Maintenance and Service

Position the measuring tool with the 1/4" tripod mount 7 onto

the thread of the tripod 16 or a commercially available cam-

Maintenance and Cleaning

era tripod. For fastening to a commercially available construc-

Store and transport the measuring tool only in the supplied

tion tripod, use the 5/8" tripod mount 6. Tighten the measur-

case.

ing tool with the tripod mounting stud.

Keep the measuring tool clean at all times.

Adjust the tripod roughly before switching on the measuring

Do not immerse the measuring tool in water or other fluids.

tool.

Wipe off debris using a moist and soft cloth. Do not use any

Fastening with the Universal Holder (Accessory)

cleaning agents or solvents.

With the universal holder 15, you can fasten the measuring

Regularly clean the surfaces at the exit opening of the laser in

tool, e.g., to vertical surfaces, pipes or magnetizable materials.

particular, and pay attention to any fluff of fibres.

The universal holder is also suitable for use as a ground tripod

If the measuring tool should fail despite the care taken in man-

and makes the height adjustment of the measuring tool easier.

ufacturing and testing procedures, repair should be carried

Adjust the universal holder roughly before 15 switching on

out by an authorised after-sales service centre for Bosch

the measuring tool.

power tools. Do not open the measuring tool yourself.

Working with the Measuring Plate (Accessory)

In all correspondence and spare parts orders, please always

(see figures A–B)

include the 10-digit article number given on the type plate of

With the measuring plate 14, it is possible to project the laser

the measuring tool.

mark onto the floor or the laser height onto a wall.

For repairs, only send in the measuring tool in the case.

With the zero field and the scale, the offset or drop to the

After-sales Service and Customer Assistance

required height can be measured and projected at another

location. This eliminates the necessity of precisely adjusting

Our after-sales service responds to your questions concern-

the measuring tool to the height to be projected.

ing maintenance and repair of your product as well as spare

parts. Exploded views and information on spare parts can

The measuring plate 14 has a reflective coating that enhances

also be found under:

the visibility of the laser beam at greater distances or in

www.bosch-pt.com

intense sunlight. The brightness intensification can be seen

Our customer service representatives can answer your ques-

only when viewing, parallel to the laser beam, onto the meas-

tions concerning possible applications and adjustment of

uring plate.

products and accessories.

Bosch Power Tools 1 618 C00 50R | (9.7.12)

OBJ_BUCH-1546-002.book Page 16 Monday, July 9, 2012 10:30 AM

16 | English

Great Britain

Bosch Headquarters

Robert Bosch Ltd. (B.S.C.)

Midrand, Gauteng

P.O. Box 98

Tel.: +27 (011) 6 51 96 00

Broadwater Park

Fax: +27 (011) 6 51 98 80

North Orbital Road

E-Mail: rbsa-hq.pts@za.bosch.com

Denham

People’s Republic of China

Uxbridge

China Mainland

UB 9 5HJ

Bosch Power Tools (China) Co., Ltd.

Tel. Service: +44 (0844) 736 0109

567, Bin Kang Road

Fax: +44 (0844) 736 0146

Bin Jiang District 310052

E-Mail: boschservicecentre@bosch.com

Hangzhou, P.R.China

Ireland

Service Hotline: 400 826 8484

Origo Ltd.

Fax: +86 571 8777 4502

Unit 23 Magna Drive

E-Mail: contact.ptcn@cn.bosch.com

Magna Business Park

www.bosch-pt.com.cn

City West

HK and Macau Special Administrative Regions

Dublin 24

Robert Bosch Hong Kong Co. Ltd.

Tel. Service: +353 (01) 4 66 67 00

21st Floor, 625 King’s Road

Fax: +353 (01) 4 66 68 88

North Point, Hong Kong

Australia, New Zealand and Pacific Islands

Customer Service Hotline: +852 2101 0235

Robert Bosch Australia Pty. Ltd.

Fax: +852 2590 9762

Power Tools

E-Mail: info@hk.bosch.com

Locked Bag 66

www.bosch-pt.com.hk

Clayton South VIC 3169

Indonesia

Customer Contact Center

PT. Multi Mayaka

Inside Australia:

Kawasan Industri Pulogadung

Phone: +61 (01300) 307 044

Jalan Rawa Gelam III No. 2

Fax: +61 (01300) 307 045

Jakarta 13930

Inside New Zealand:

Indonesia

Phone: +64 (0800) 543 353

Tel.: +62 (21) 46 83 25 22

Fax: +64 (0800) 428 570

Fax: +62 (21) 46 82 86 45/68 23

Outside AU and NZ:

E-Mail: sales@multimayaka.co.id

Phone: +61 (03) 9541 5555

www.bosch-pt.co.id

www.bosch.com.au

Philippines

Republic of South Africa

Robert Bosch, Inc.

Customer service

28th Floor Fort Legend Towers,

Hotline: +27 (011) 6 51 96 00

3rd Avenue corner 31st Street,

Gauteng – BSC Service Centre

Fort Bonifacio Global City,

35 Roper Street, New Centre

1634 Taguig City, Philippines

Johannesburg

Tel.: +63 (2) 870 3871

Tel.: +27 (011) 4 93 93 75

Fax: +63 (2) 870 3870

Fax: +27 (011) 4 93 01 26

matheus.contiero@ph.bosch.com

E-Mail: bsctools@icon.co.za

www.bosch-pt.com.ph

KZN – BSC Service Centre

Bosch Service Center:

Unit E, Almar Centre

9725-27 Kamagong Street

143 Crompton Street

San Antonio Village

Pinetown

Makati City, Philippines

Tel.: +27 (031) 7 01 21 20

Tel.: +63 (2) 899 9091

Fax: +27 (031) 7 01 24 46

Fax: +63 (2) 897 6432

E-Mail: bsc.dur@za.bosch.com

rosalie.dagdagan@ph.bosch.com

Western Cape – BSC Service Centre

Democracy Way, Prosperity Park

Milnerton

Tel.: +27 (021) 5 51 25 77

Fax: +27 (021) 5 51 32 23

E-Mail: bsc@zsd.co.za

1 618 C00 50R | (9.7.12) Bosch Power Tools

Оглавление

- Deutsch

- English

- Français

- Español

- Português

- Italiano

- Nederlands

- Dansk

- Svenska

- Norsk

- Suomi

- ÅëëçíéêÜ

- Türkçe

- Polski

- Česky

- Slovensky

- Magyar

- Ðóññêèé

- Óêðà¿íñüêà

- Română

- Áúëãàðñêè

- Srpski

- Slovensko

- Hrvatski

- Eesti

- Latviešu

- Lietuviškai

- 日本語

- 中文

- กฎระเบียบเพื่อความปลอดภัย

- รายละเอียดผลิตภัณฑและขอมูลจําเพาะ

- การประกอบ

- การบํารุงรักษาและการบริการ

- Bahasa Indonesia

- Tiøng Vi·t