Bosch GSA 1300 PCE Professional: English

English: Bosch GSA 1300 PCE Professional

OBJ_BUCH-1366-005.book Page 11 Thursday, August 8, 2013 10:18 AM

English | 11

Prevent unintentional starting. Ensure the switch is in

English

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or en-

Safety Notes

ergising power tools that have the switch on invites acci-

dents.

General Power Tool Safety Warnings

Remove any adjusting key or wrench before turning

WARNING

Read all safety warnings and all in-

the power tool on. A wrench or a key left attached to a ro-

structions. Failure to follow the warnings

tating part of the power tool may result in personal injury.

and instructions may result in electric shock, fire and/or seri-

ous injury.

Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool in

Save all warnings and instructions for future reference.

unexpected situations.

The term “power tool” in the warnings refers to your mains-

Dress properly. Do not wear loose clothing or jewel-

operated (corded) power tool or battery-operated (cordless)

lery. Keep your hair, clothing and gloves away from

power tool.

moving parts. Loose clothes, jewellery or long hair can be

Work area safety

caught in moving parts.

Keep work area clean and well lit. Cluttered or dark areas

If devices are provided for the connection of dust ex-

invite accidents.

traction and collection facilities, ensure these are con-

Do not operate power tools in explosive atmospheres,

nected and properly used. Use of dust collection can re-

such as in the presence of flammable liquids, gases or

duce dust-related hazards.

dust. Power tools create sparks which may ignite the dust

Power tool use and care

or fumes.

Do not force the power tool. Use the correct power tool

Keep children and bystanders away while operating a

for your application. The correct power tool will do the

power tool. Distractions can cause you to lose control.

job better and safer at the rate for which it was designed.

Electrical safety

Do not use the power tool if the switch does not turn it

Power tool plugs must match the outlet. Never modify

on and off. Any power tool that cannot be controlled with

the plug in any way. Do not use any adapter plugs with

the switch is dangerous and must be repaired.

earthed (grounded) power tools. Unmodified plugs and

Disconnect the plug from the power source and/or the

matching outlets will reduce risk of electric shock.

battery pack from the power tool before making any

Avoid body contact with earthed or grounded surfaces,

adjustments, changing accessories, or storing power

such as pipes, radiators, ranges and refrigerators.

tools. Such preventive safety measures reduce the risk of

There is an increased risk of electric shock if your body is

starting the power tool accidentally.

earthed or grounded.

Store idle power tools out of the reach of children and

Do not expose power tools to rain or wet conditions.

do not allow persons unfamiliar with the power tool or

Water entering a power tool will increase the risk of electric

these instructions to operate the power tool. Power

shock.

tools are dangerous in the hands of untrained users.

Do not abuse the cord. Never use the cord for carrying,

Maintain power tools. Check for misalignment or bind-

pulling or unplugging the power tool. Keep cord away

ing of moving parts, breakage of parts and any other

from heat, oil, sharp edges and moving parts. Damaged

condition that may affect the power tool’s operation. If

or entangled cords increase the risk of electric shock.

damaged, have the power tool repaired before use.

When operating a power tool outdoors, use an exten-

Many accidents are caused by poorly maintained power

sion cord suitable for outdoor use. Use of a cord suitable

tools.

for outdoor use reduces the risk of electric shock.

Keep cutting tools sharp and clean. Properly maintained

If operating a power tool in a damp location is unavoid-

cutting tools with sharp cutting edges are less likely to bind

able, use a residual current device (RCD) protected

and are easier to control.

supply. Use of an RCD reduces the risk of electric shock.

Use the power tool, accessories and tool bits etc. in ac-

Personal safety

cordance with these instructions, taking into account

the working conditions and the work to be performed.

Stay alert, watch what you are doing and use common

Use of the power tool for operations different from those

sense when operating a power tool. Do not use a power

intended could result in a hazardous situation.

tool while you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention while op-

Service

erating power tools may result in serious personal injury.

Have your power tool serviced by a qualified repair per-

Use personal protective equipment. Always wear eye

son using only identical replacement parts. This will en-

protection. Protective equipment such as dust mask,

sure that the safety of the power tool is maintained.

non-skid safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

Bosch Power Tools 1 609 92A 0CN | (8.8.13)

OBJ_BUCH-1366-005.book Page 12 Thursday, August 8, 2013 10:18 AM

12 | English

Safety Warnings for Sabre Saws

Product Description and

Hold power tool by insulated gripping surfaces, when

Specifications

performing an operation where the cutting accessory

may contact hidden wiring or its own cord. Cutting ac-

Read all safety warnings and all instruc-

cessory contacting a “live” wire may make exposed metal

tions. Failure to follow the warnings and in-

parts of the power tool “live” and could give the operator an

structions may result in electric shock, fire

electric shock.

and/or serious injury.

Keep hands away from the sawing range. Do not reach

While reading the operating instructions, unfold the graphics

under the workpiece. Contact with the saw blade can

page for the machine and leave it open.

lead to injuries.

Apply the machine to the workpiece only when

Intended Use

switched on. Otherwise there is danger of kickback when

The machine is intended for sawing wood, plastic, metal and

the cutting tool jams in the workpiece.

building materials while resting firmly on the workpiece. It is

suitable for straight and curved cuts. When using the appropri-

When sawing, the adjustable footplate 2 must always

ate bimetal saw blades, it is possible to cut flush to the work-

faces against the workpiece. The saw blade can become

piece surface. The saw blade recommendations must be ob-

wedged and lead to loss of control over the machine.

served.

When the cut is completed, switch off the machine and

The light of this power tool is intended to illuminate the power

then pull the saw blade out of the cut only after it has

tool’s direct area of working operation and is not suitable for

come to a standstill. In this manner you can avoid kick-

household room illumination.

back and can place down the machine securely.

Use only undamaged saw blades that are in perfect con-

Product Features

dition. Bent or dull saw blades can break, negatively influ-

The numbering of the product features refers to the illustra-

ence the cut, or lead to kickback.

tion of the machine on the graphics page.

Do not brake the saw blade to a stop by applying side

1 Saw blade*

pressure after switching off. The saw blade can be dam-

2 Adjustable footplate

aged, break or cause kickback.

3 Saw blade holder

Clamp material well. Do not support the workpiece

4 Locking sleeve for saw blade

with your hand or foot. Do not touch objects or the floor

5 Stroke rod

with the the saw running. Danger of kickback.

6 Utility hook

Use suitable detectors to determine if utility lines are

7 On/Off switch

hidden in the work area or call the local utility company

8 Lock-off button for On/Off switch

for assistance. Contact with electric lines can lead to fire

9 Footplate release button

and electric shock. Damaging a gas line can lead to explo-

10 “PowerLight”

sion. Penetrating a water line causes property damage or

11 Handle (insulated gripping surface)

may cause an electric shock.

*Accessories shown or described are not part of the standard de-

When working with the machine, always hold it firmly

livery scope of the product. A complete overview of accessories

with both hands and provide for a secure stance. The

can be found in our accessories program.

power tool is guided more secure with both hands.

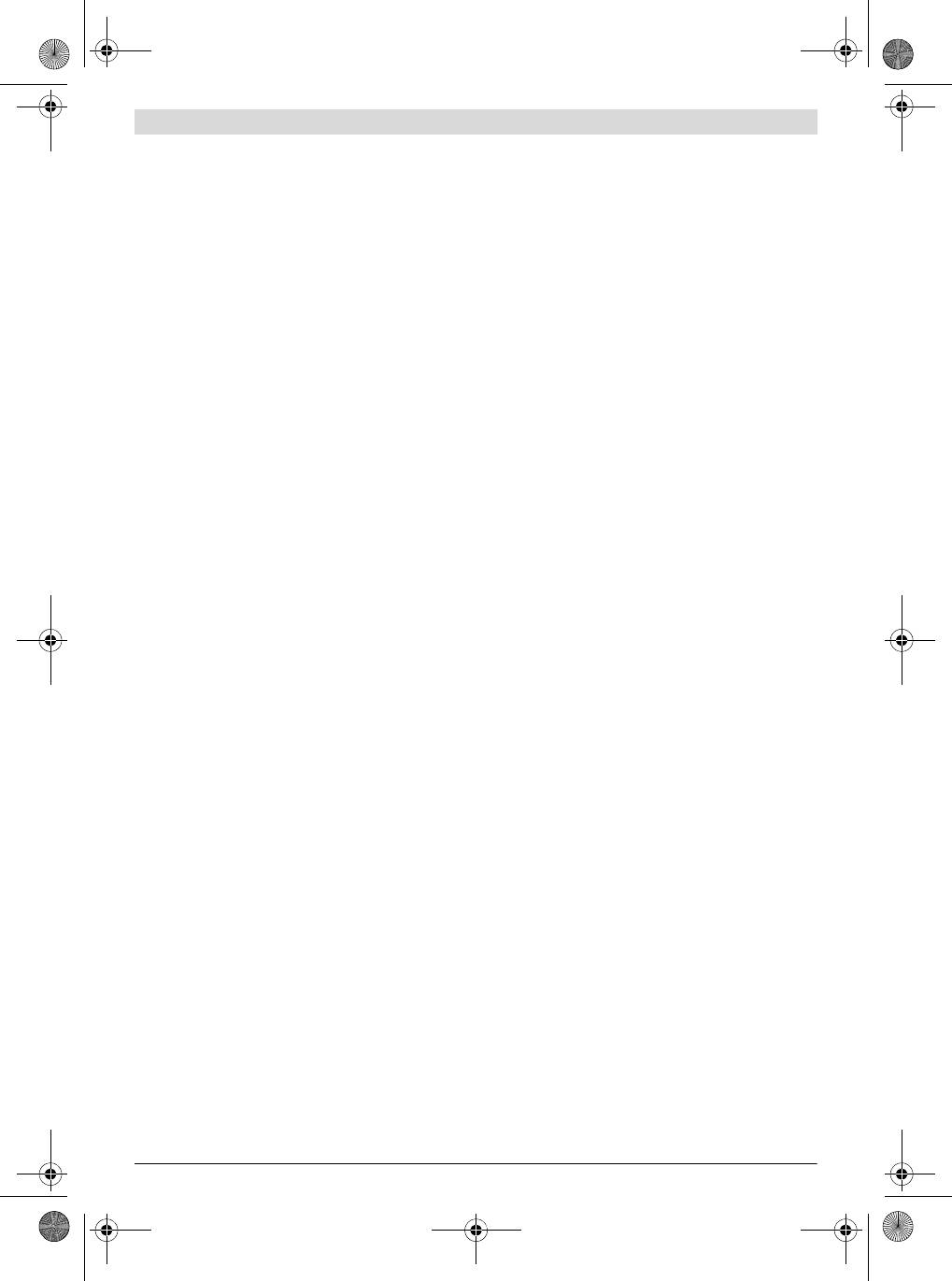

Technical Data

Secure the workpiece. A workpiece clamped with clamp-

Sabre saw GSA 1300 PCE

ing devices or in a vice is held more secure than by hand.

Article number

3 601 F4E 2..

Always wait until the machine has come to a complete

Rated power input

W1300

stop before placing it down. The tool insert can jam and

-1

lead to loss of control over the power tool.

Stroke rate at no load n

0

min

0–2900

Products sold in GB only: Your product is fitted with an

Tool holder

SDS

BS 1363/A approved electric plug with internal fuse

Orbital action

(ASTA approved to BS 1362).

Constant electronic control

If the plug is not suitable for your socket outlets, it should

Stroke

mm 28

be cut off and an appropriate plug fitted in its place by an

authorised customer service agent. The replacement plug

Cutting depth, max.

should have the same fuse rating as the original plug.

–in wood

mm

220

The severed plug must be disposed of to avoid a possible

– in non-alloy steel

mm

20

shock hazard and should never be inserted into a mains

– Pipe diameter

mm

175

socket elsewhere.

Weight according to

Products sold in AUS and NZ only: Use a residual current

EPTA-Procedure 01/2003

kg 4.1

device (RCD) with a rated residual current of 30 mA or

Protection class

/II

less.

The values given are valid for a nominal voltage [U] of 230 V. For differ-

ent voltages and models for specific countries, these values can vary.

1 609 92A 0CN | (8.8.13) Bosch Power Tools

OBJ_BUCH-1366-005.book Page 13 Thursday, August 8, 2013 10:18 AM

English | 13

Noise/Vibration Information

Selecting a Saw Blade

Measured sound values determined according to EN 60745.

An overview of recommended saw blades can be found at the

Typically the A-weighted noise levels of the product are:

beginning of these instructions. Use only ½" universal shank

Sound pressure level 95 dB(A); Sound power level

saw blades. The saw blade should not be longer than required

106 dB(A). Uncertainty K =3 dB.

for the intended cut.

Wear hearing protection!

Use a thin saw blade for narrow curve cuts.

Vibration total values a

h

(triax vector sum) and uncertainty K

Inserting the Saw Blade (see figure A)

determined according to EN 60745:

Cutting board: a

2

, K=1.5 m/s

2

Turn the locking sleeve 4 approx. 90° in the direction of the

h

=17.5m/s

,

Cutting wooden beam: a

=23.5m/s

2

, K=1.5 m/s

2

arrow and hold. Push the saw blade 1 into the saw blade hold-

h

.

er 3. Release the locking sleeve 4 again.

The vibration emission level given in this information sheet has

Check the tight seating of the saw blade. A loose saw

been measured in accordance with a standardised test given in

blade can fall out and lead to injuries.

EN 60745 and may be used to compare one tool with another.

It may be used for a preliminary assessment of exposure.

For certain work, the saw blade 1 can also be turned through

The declared vibration emission level represents the main ap-

180° (with the teeth pointed upwards) and re-inserted again.

plications of the tool. However if the tool is used for different

Removing the Saw Blade (see figure B)

applications, with different accessories or poorly maintained,

the vibration emission may differ. This may significantly in-

Before removing, allow the saw blade to cool down.

crease the exposure level over the total working period.

Danger of injury when touching the hot saw blade.

An estimation of the level of exposure to vibration should also

Turn the locking sleeve 4 approx. 90° in the direction of the

take into account the times when the tool is switched off or

arrow and hold. Remove the saw blade 1.

when it is running but not actually doing the job. This may signif-

icantly reduce the exposure level over the total working period.

Dust/Chip Extraction

Identify additional safety measures to protect the operator

Dusts from materials such as lead-containing coatings,

from the effects of vibration such as: maintain the tool and the

some wood types, minerals and metal can be harmful to

accessories, keep hands warm, organise work patterns.

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

Declaration of Conformity

the user or bystanders.

We declare under our sole responsibility that the product de-

Certain dusts, such as oak or beech dust, are considered

scribed under “Technical Data” is in conformity with the fol-

as carcinogenic, especially in connection with wood-treat-

lowing standards or standardisation documents: EN 60745

ment additives (chromate, wood preservative). Materials

according to the provisions of the directives 2009/125/EC

containing asbestos may only be worked by specialists.

(Regulation 1194/2012), 2011/65/EU, 2004/108/EC,

– Provide for good ventilation of the working place.

2006/42/EC.

– It is recommended to wear a P2 filter-class respirator.

Technical file (2006/42/EC) at:

Observe the relevant regulations in your country for the

Robert Bosch GmbH, PT/ETM9,

materials to be worked.

D-70745 Leinfelden-Echterdingen

Prevent dust accumulation at the workplace. Dusts can

Henk Becker

Helmut Heinzelmann

easily ignite.

Executive Vice President

Head of Product Certification

Engineering

PT/ETM9

Operation

Operating Modes

Before any work on the machine itself, pull the mains

Robert Bosch GmbH, Power Tools Division

plug.

D-70745 Leinfelden-Echterdingen

Leinfelden, 08.07.2013

Pivoting and Retractable Footplate (see figure C)

Due to its movability, the adjustable footplate 2 adapts to the

Assembly

required angular position of the surface.

Replacing/Inserting the Saw Blade

Depending on the saw blade being used and the application,

the footplate 2 can be moved in lengthway direction in three

Before any work on the machine itself, pull the mains

steps. Press the release button for the footplate 9 and slide

plug.

the footplate 2 to the required position. Release the footplate

When mounting the saw blade, wear protective gloves.

release button 9 and check that the footplate 2 is firmly

Danger of injury when touching the saw blade.

latched. Slide the footplate 2 as required until it is firmly

When changing the saw blade, take care that the saw

latched.

blade holder is free of material residue, e.g. wood or

metal shavings.

Bosch Power Tools 1 609 92A 0CN | (8.8.13)

OBJ_BUCH-1366-005.book Page 14 Thursday, August 8, 2013 10:18 AM

14 | English

Utility Hook (see figure D)

Switch the machine on and guide it toward the workpiece.

Your tool is equipped with a utility hook 6 for hanging it, e.g.,

Position the footplate 2 onto the surface of the work and saw

to a ladder, etc. Simply fold out the utility hook 6 to the re-

through the material applying uniform contact pressure and

quired position.

feed. After completing the working procedure, switch the

When the tool is hanging by the utility hook, ensure

machine off.

that the saw blade is protected against unintended

If the saw blade should jam, switch the machine off immedi-

contact. Danger of injury.

ately. Widen the gap somewhat with a suitable tool and pull

Fold the utility hook 6 back in again when you are ready to

out the machine.

continue working.

Plunge Cutting (see figure E)

The plunge cutting procedure is only suitable for treat-

Starting Operation

ing soft materials such as wood, plaster board or simi-

Observe correct mains voltage! The voltage of the pow-

lar! Do not work metal materials with the plunge cut-

er source must agree with the voltage specified on the

ting procedure!

nameplate of the machine. Power tools marked with

Use only short saw blades for plunge cutting.

230 V can also be operated with 220 V.

Place the machine with the edge of the footplate 2 onto the

The “PowerLight” 10 is lit when the mains plug is inserted,

workpiece and switch on. For power tools with stroke speed

and allows for illumination of the working range under unfa-

control, set the maximum stroke speed. Press the power tool

vourable light conditions.

firmly against the workpiece and allow the saw blade to slowly

Switching On and Off

plunge into the workpiece.

To start the machine, first push the lock-off button for the

As soon as the footplate 2 fully lays on the surface of the work-

On/Off switch 8 and then press the On/Off switch 7 and keep

piece, continue sawing alongside the desired cutting line.

it pressed.

For certain work, the saw blade 1 can also be inserted turned

To switch off the machine, release the On/Off switch 7.

through by 180° and the sabre saw can be guided accordingly

Note: For safety reasons, the On/Off switch 7 cannot be

in a reversed manner.

locked; it must remain pressed during the entire operation.

Flush Cuts (see figure F)

To save energy, only switch the power tool on when using it.

Using elastic bimetal saw blades, items still attached to a wall

Orbital action

(e.g. projecting building elements such as water pipes, etc.)

To achieve a high cutting speed, the orbital action is continu-

can be sawn off flush at the wall.

ously in operation.

Pay attention that the saw blade always extends be-

yond the diameter of the material being worked. There

Constant Electronic Control

is danger of kickback.

The constant electronic control keeps the stroke rate almost

Position the saw blade directly against the wall and apply

constant at no-load and under load, and ensures uniform

some lateral pressure via the tool until the footplate faces

working performance.

against the wall. Switch the power tool on and saw through

Controlling/Presetting the Stroke Rate

the workpiece, applying constant lateral pressure.

Increasing or reducing the pressure on the On/Off switch 7

Coolant/Lubricant

enables stepless stroke-rate control of the switched-on ma-

When sawing metal, coolant/lubricant should be applied

chine.

alongside cutting line because of the material heating up.

Light pressure on the On/Off switch 7 results in a low stroke

rate. Increasing the pressure also increases the stroke rate.

Maintenance and Service

The required stroke rate is dependent on the material and the

working conditions and can be determined by a practical trial.

Maintenance and Cleaning

Reducing the stroke rate is recommended when the saw

Before any work on the machine itself, pull the mains

blade engages in the material as well as when sawing plastic

plug.

and aluminium.

For safe and proper working, always keep the machine

and ventilation slots clean.

Working Advice

Clean the saw blade holder preferably with compressed air or

Before any work on the machine itself, pull the mains

a soft brush. Remove the saw blade from the power tool for

plug.

this. Ensure proper operation of the saw blade holder by ap-

Tips

plying a suitable lubricant.

When sawing light building materials, observe the stat-

Heavy contamination of the machine can lead to malfunc-

utory provisions and the recommendations of the ma-

tions. Therefore, do not saw materials that produce a lot of

terial suppliers.

dust from below or overhead.

Check wood, press boards, building materials, etc. for foreign

If the replacement of the supply cord is necessary, this has to

objects such as nails, screws or similar, and always use the

be done by Bosch or an authorized Bosch service agent in or-

correct sawblade.

der to avoid a safety hazard.

1 609 92A 0CN | (8.8.13) Bosch Power Tools