Bosch FCS-320-TP Series Conventional Aspirating Smoke Detectors: Installation

Installation: Bosch FCS-320-TP Series Conventional Aspirating Smoke Detectors

24

en

FCS-320-TP1 | FCS-320-TP2 | FCS-320-TT1 | FCS-320-TT2

F.01U.130.927 | 2.0 | 2010.12

Bosch Sicherheitssysteme GmbH

Installation

FCS-320-TP1 and FCS-320-TP2 System Overview

See

Figure 1, Page 4

FCS-320-TT1 and FCS-320-TT2 System Overview

See

Figure 2, Page 4

Jumper Assignment

See

Figure 4, Page 5

CAUTION!

Installation must only be performed by authorized and specialized personnel!Switch off the

unit before carrying out the following work.Do not connect or disconnect the detector module

while switched on!

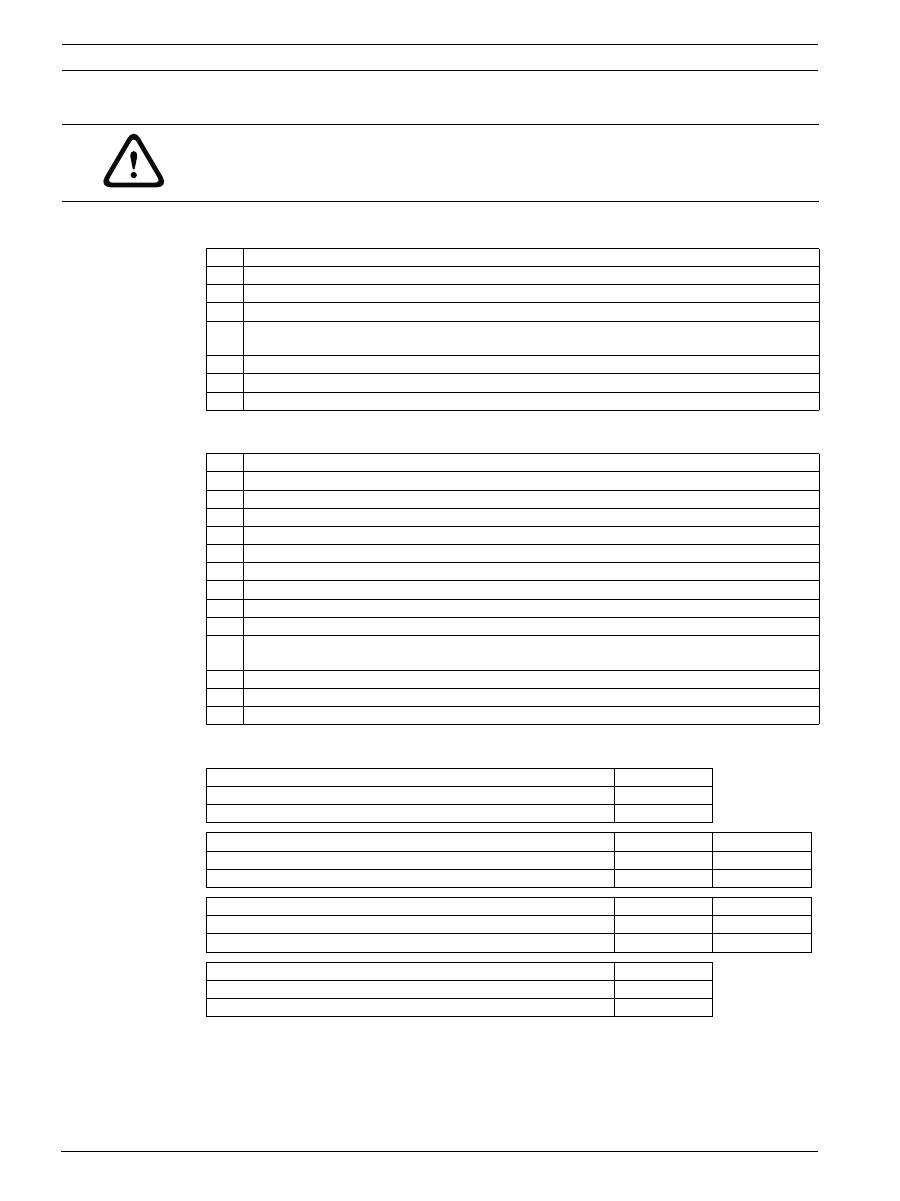

1

Operating LED

2

Alarm LED for detector module 1

3

Alarm LED for detector module 2 (for FCS-320-TP2 only)

4

Collective fault LED

5

Pre-punched cable entries for connection to the fire panel and power supply

(input/output)

6

Pipe system 1 connection

7

Pipe system 2 connection (required for FCS-320-TP2 only)

8

Connection for air return pipe

1

Operating LED

2

Collective fault LED

3

Info alarm LED for detector module 1

4

Pre-alarm LED for detector module 1

5

Main alarm LED for detector module 1

6

Smoke level display in ten levels, detector module 1

7

Info alarm LED for detector module 2 (for FCS-320-TT2 only)

8

Pre-alarm LED for detector module 2 (for FCS-320-TT2 only)

9

Main alarm LED for detector module 2 (for FCS-320-TT2 only)

10

Smoke level display in ten levels, detector module 2 (for FCS-320-TT2 only)

11

Pre-punched cable entries for connection to the fire panel and power supply (input/

output)

12

Pipe system 1 connection

13

Pipe system 2 connection (required for FCS-320-TT2 only)

14

Connection for air return pipe

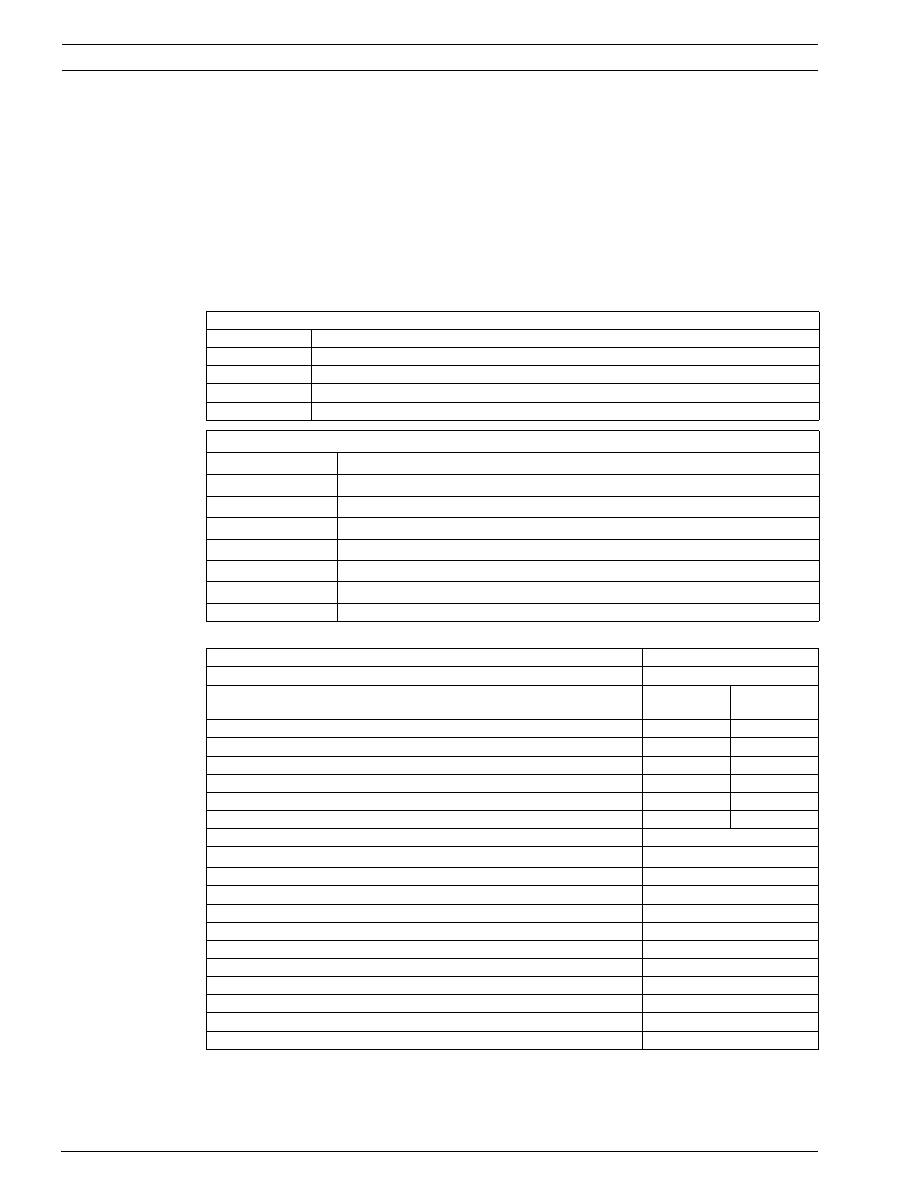

Jumper JU1: fan voltage

Pin 1+2

6.9 V

Bypassed

9 V

Open

Jumper JU2: collective fault contact for detector module 1 Pin 1+2

Pin 2+3

NC contact

Bypassed

Open

NO contact

Open

Bypassed

Jumper JU3: collective fault contact for detector module 2 Pin 1+2

Pin 2+3

NC contact

Bypassed

Open

NO contact

Open

Bypassed

Jumper JU4: number of detector modules

Pin 1+2

1 detector module

Bypassed

2 detector modules

Open

FCS-320-TP1 | FCS-320-TP2 | FCS-320-TT1 | FCS-320-TT2

en

25

Bosch Sicherheitssysteme GmbH

F.01U.130.927 | 2.0 | 2010.12

Installing the Detector Module

See

Figure 3, Page 4

:

1.

Open the unit by carefully unlocking the housing cover's quick-release locks with a

screwdriver and then removing the housing cover.

2.

Carefully disconnect the display board connection cable from the motherboard ("DISPL."

connection) and remove the housing cover.

1.

Spread the brackets provided for fixing the detector module slightly apart.

2.

Carefully insert the detector module until you hear it click into place. Make sure that the

used detector module is fixed tightly and securely by the bracket by additionally pushing

together the brackets by hand.

3.

Connect detector module 1 to the "HEAD1" connection on the motherboard using the

flatband cable.

FCS-320-TP2 and FCS-320-TT2 variants:

Connect detector module 2 to the "HEAD 2" connection on the motherboard using the

flatband cable.

4.

Reconnect the display board connection cable to the "DISPL." connection on the

motherboard.

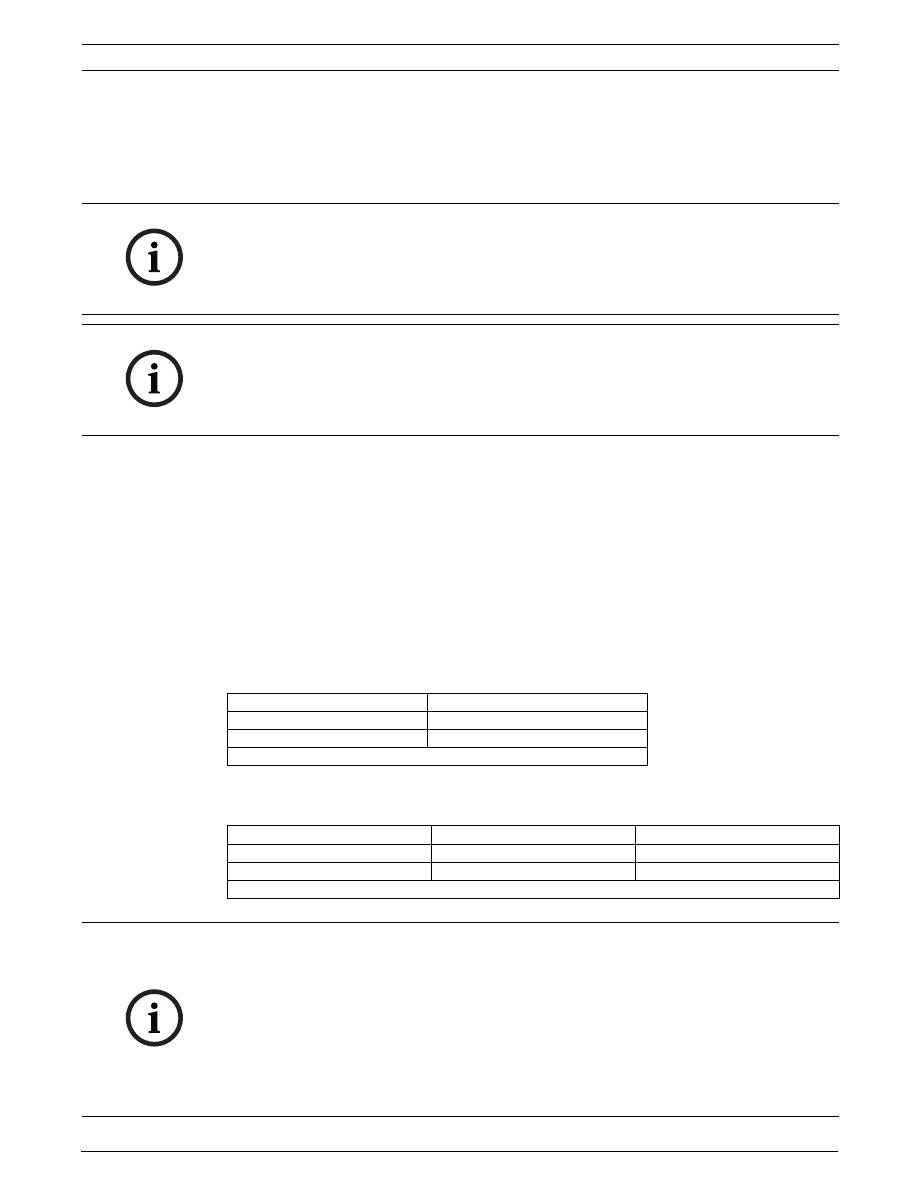

Setting the Fan Voltage

See

Figure 4, Page 5

: with jumper JU1, the fan voltage is set on the motherboard. The default

setting is marked in bold.

Number of Detector Modules

See

Figure 4, Page 5

: The number of populated detector modules is factory set in line with the

model variant (jumper JU4 on the unit's motherboard).

Installing the Unit

NOTICE!

Only DM-TP-50(80), DM-TP-10(25) and DM-TP-01(05) detector modules certified to VdS may

be used in the FCS-320-TP1/TP2. Only DM-TT-50(80), DM-TT-10(25) and DM-TT-01(05)

detector modules certified to VdS may be used in the FCS-320-TT1/TT2.The detector module

settings are configured via the DIP switch on the detector module.The sensitivity value is

based on measurements with standard test fires (old value in brackets).

NOTICE!

FCS-320-TP2

and

FCS-320-TT2

variants

:

These units are factory prepared for the installation of two detector modules:

-

The fan covers for both aspiration pipes are removed.

-

The two pipe system connections are cut out.

-

The pin pair on jumper JU4 is open (see

Figure 4, Page 5

).

Fan voltage

Jumper JU1, pin no. 1+2

6.9 V X

9 V

O

X = pin pair bypassed / O = pin pair open

Variant

Number of detector modules Jumper JU4, pin no. 1+2

FCS-320-TP1 / FCS-320-TT1

1 detector module

X

FCS-320-TP2 / FCS-320-TT2

2 detector modules

O

X = pin pair bypassed / O = pin pair open

NOTICE!

-

When selecting the installation location, ensure that the unit displays are easily visible.

-

Remember when planning that the unit fans generate a noise level of approx. 45 dB(A).

-

The air outlet on the unit must not be obstructed. The distance between the air outlet

and adjacent components, e.g. a wall, must be at least 10 cm (4 inches).

-

The aspirating smoke detector can be installed with the suction device pointing up or

down (to do this, rotate the housing cover through 180°). If the aspiration pipe points

down, make sure no impurities enter the air return pipe, which will be pointing up.

-

The aspirating smoke detector is either screwed directly to the installation wall by the

rear panel or installed using unit mounting type MT-1, e.g. on frames (see

Figure 5,

Page 5

: 1 = horizontal installation, 2 = vertical installation).

26

en

FCS-320-TP1 | FCS-320-TP2 | FCS-320-TT1 | FCS-320-TT2

F.01U.130.927 | 2.0 | 2010.12

Bosch Sicherheitssysteme GmbH

1.

First, clearly mark the fixing points on the installation position provided on the

equipment. Use the supplied drilling jig as an aid. To guarantee a firm, low-vibration hold,

the unit must be secured with four screws (max. 6 mm

∅

(0.4 inches) for wall mounting,

max. 4 mm

∅

(0.2 inches) for MT-1 unit mounting).

2.

Using four screws appropriate for the installation method, attach the unit securely to the

surface or to the unit mounting. Ensure that the unit is not fixed under mechanical stress

and that the screws are not tightened too tightly, otherwise damage or undesirable

resonance noises could occur.

To balance out unevenness and/or prevent vibrations, vibration absorbers (subject to

separate order) must be used.

3.

Using a screwdriver, carefully punch out the required cable entries on the housing (max.

5 x M20 and 2 x M25).

4.

Fit the cable entry/entries as required with M20 or M25 connections (2 x M25 and 1 x

M20 included in the delivery) by pushing them into the cable entry/entries.

5.

Route the connection cable(s) (max. 2.5 mm

2

) through the prepared M20 or M25

connections and into the unit. Cut them to the required length inside the unit.

6.

Wire the unit according to the connection information described below.

Connecting the FCS-320-TP/-TT series

See

Figure 4, Page 5

:

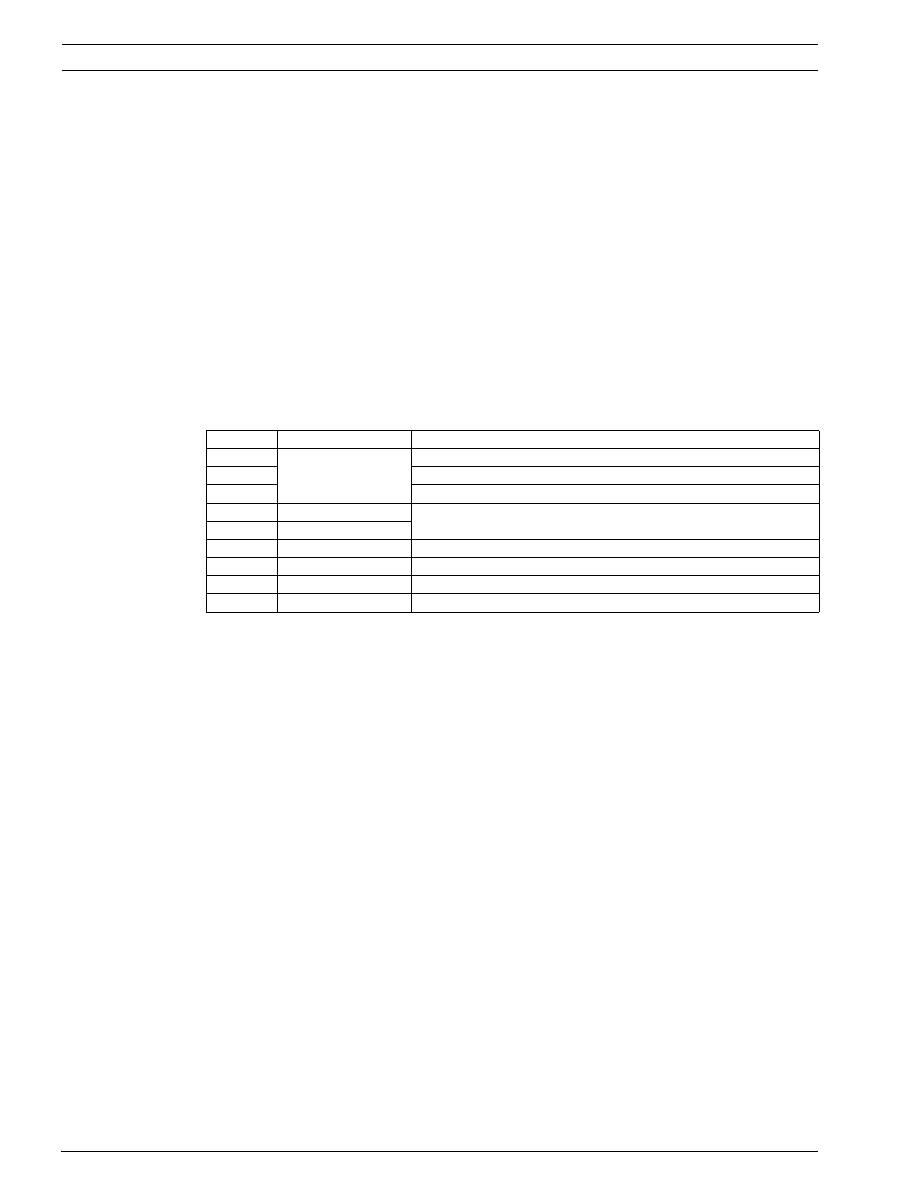

Terminal Terminal block X6 Function

1

Al 1

NO contact for 1st alarm relay

2

C contact for 1st alarm relay

3

NC contact for 1st alarm relay

4

+ Ext. Displ.1

Remote indicator for 1st detector module

5

- Ext. Displ.1

6

+ Reset

+24 V reset input

7

- Reset

0 V reset input

8

+ 24V

+24 V power supply

9

- 24V

0 V power supply

FCS-320-TP1 | FCS-320-TP2 | FCS-320-TT1 | FCS-320-TT2

en

27

Bosch Sicherheitssysteme GmbH

F.01U.130.927 | 2.0 | 2010.12

Connecting the FCS-320-TP/-TT series

See

Figure 4, Page 5

:

Parameter Settings Using the DIP Switch

The aspirating smoke detector parameters are set using the DIP switch on the detector

modules. The default settings are marked in bold in each case. Select all other parameters

(see tables).

Commissioning

See

Figure 5, Page 5

:

Terminal Terminal block X7

1

Fault 2

Fault contact for 2nd detector module

2

3

Al 2

NO contact for 2nd alarm relay

4

C contact for 2nd alarm relay

5

NC contact for 2nd alarm relay

6

+ Ext. Displ.2

Remote indicator for 2nd detector module

7

- Ext. Displ.2

8

Fault 1

Fault contact for 1st detector module

9

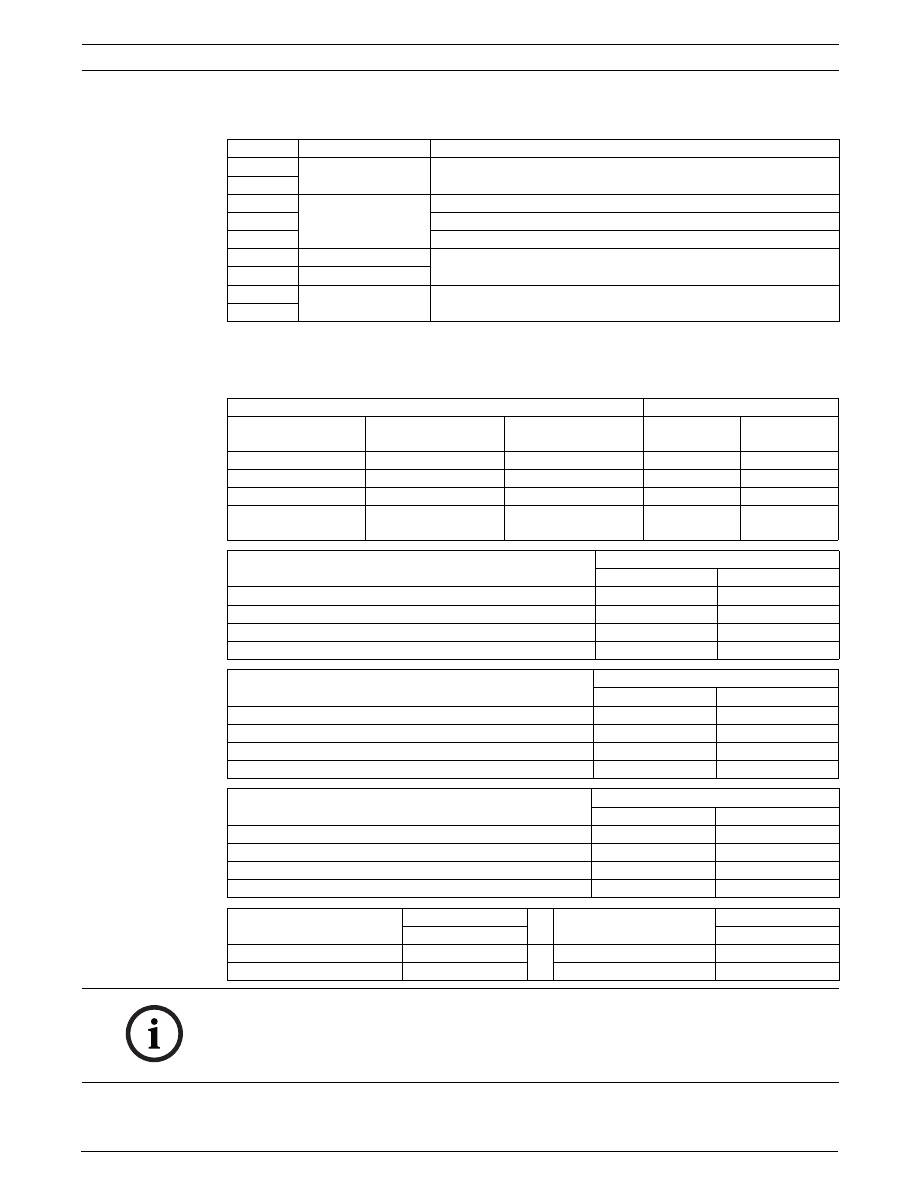

Sensitivity

DIP settings

DM-TP-01(05)

DM-TT-01(05)

DM-TP10(25)

DM-TT-10(25)

DM-TP50(80)

DM-TT-50(80)

Switch 1

Switch 2

0,12 %/m(0,4 %/m) 0,8 %/m(2 %/m)

on

on

0,06 %/m(0,2 %/m) 0,4 %/m(1 %/m)

off

on

0,03 %/m(0,1 %/m) 0,2 %/m(0,5 %/m)

1,0 %/m(1,6 %/m)

on

off

0,015 %/m(0,05 %/

m)

0,1 %/m(0,25 %/m)

0,5 %/m(0,8 %/m)

off

off

Alarm delay

DIP settings

Switch 3

Switch 4

0 seconds

off

off

10 seconds

on

off

30 seconds

off

on

60 seconds

on

on

Activation threshold for airflow malfunction

DIP settings

Switch 5

Switch 6

Low (+/- 10% volume flow change)

on

off

Average (+/- 20% volume flow change)

off

on

High (+/- 30% volume flow change)

off

off

Very high (+/- 50% volume flow change)

on

on

Airflow fault delay

DIP settings

Switch 7

Switch 8

30 seconds

off

on

2 minutes

on

off

15 minutes

on

on

60 minutes

off

off

Trouble logging

DIP settings

LOGIC·SENS filter

DIP settings

Switch 9

Switch 10

not saving

off

off

off

saving

on

on

on

NOTICE!

The sensitivity value is based on measurements with standard test fires (old value in

brackets).

The activation threshold for the airflow malfunction is set to 20% volume flow change by

default. Higher values are not permitted within EN 54-20.

28

en

FCS-320-TP1 | FCS-320-TP2 | FCS-320-TT1 | FCS-320-TT2

F.01U.130.927 | 2.0 | 2010.12

Bosch Sicherheitssysteme GmbH

1.

Check the system after installation using the FAS-ASD-DIAG Diagnostic Software.

2.

The unit must be operated for at least 30 min prior to the airflow being initialized to bring

it up to operating temperature.

3.

To initialize the connected pipe system, press the S2 flow-init button (see

Figure 5,

Page 5

) on the detector module concerned until the green operating LED on the unit

starts to flash. Initialization is complete after approx. 10 seconds. Following successful

initialization, the operating LED lights up permanently.

4.

No further modifications may be made to the pipe system during or after initialization.

The unit's fan voltage must also remain unchanged following initialization. Otherwise, the

initialization procedure must be repeated.

Troubleshooting Using Flash Codes

Malfunctions and unit statuses are indicated via the flash codes of the detector module LEDs:

Technical data

Flash code of detector module LEDs

1 flash

Airflow initialization (flow-init) active

2 x flashes

Airflow too small (obstruction)

3 x flashes

Airflow too great (break)

4 x flashes

Unit upload (approx. 2 minutes)

Permanently lit Hardware defect in the detector module

LED flash code on the motherboard (LED1/LED2)

1 flash

Error: internal voltage monitoring 1

2 flashes

Error: internal voltage monitoring 2

3 flashes

Error: fan voltage monitoring

4 flashes

Error: air pressure correction voltage monitoring

5 flashes

Software error

6 flashes

Internal error 1

7 flashes

Internal error 2

8 flashes

Unit upload (approx. 2 min)

Power supply

14 V DC to 30 V DC

Rated supply voltage

24 V DC

Max. current consumption (at 24 V)

FCS-320

-TP1/-TT1

FCS-320

-TP2/-TT2

-

Starting current 6.9 V (without reset board)

300/300 mA 320/330 mA

-

Starting current 9 V (without reset board)

300/300 mA 320/330 mA

-

In standby, fan voltage 6.9 V (without reset board)

200/200 mA 220/230 mA

-

In standby, fan voltage 9 V (without reset board)

275/260 mA 295/310 mA

-

On alarm, fan voltage 6.9 V (without reset board)

210/230 mA 240/290 mA

-

On alarm, fan voltage 9 V (without reset board)

285/290 mA 315/370 mA

Reset board current consumption

Max. 20 mA

Max. wire gauge

2.5 mm

2

Housing material

Plastic (ABS)

Housing color

Papyrus white, RAL 9018

Protection category according to EN 60529

IP 20

Permissible temperature range

-

FCS-320 series Aspirating Smoke Detector

-20 °C to +60 °C

-

PVC pipe system

-10 °C to +60 °C

-

ABS pipe system

-40 °C to +80 °C

Permissible relative humidity (non-condensing)

10 to 95%

Sound power level

45 dB(A)

Life cycle of the fan (12 V)

43,500 hrs at 24 °C