Bosch GNA 16 (SDS) Professional: English

English: Bosch GNA 16 (SDS) Professional

English |

7

Bosch Power Tools

1 619 929 J61 | (25.7.11)

Wartung und Service

Wartung und Reinigung

f

Ziehen Sie vor allen Arbeiten am Elektrowerkzeug den

Netzstecker aus der Steckdose.

f

Halten Sie das Elektrowerkzeug und die Lüftungs-

schlitze sauber, um gut und sicher zu arbeiten.

Reinigen und ölen Sie alle 3 Betriebsstunden Stempel

3

und

Matrize

5

.

Wechseln Sie Stempel und Matrize bei Verschleiß rechtzeitig,

denn nur scharfe Werkzeuge bringen gute Schnittleistung und

schonen das Elektrowerkzeug.

Der Stempel

3

und die Matrize

5

dürfen nicht nachgeschliffen

werden.

Matrize wechseln

Schrauben Sie die Rändelschraube

7

aus dem Matrizenhalter

4

. Entnehmen Sie die Matrize

5

.

Reinigen Sie gegebenenfalls den Matrizenhalter

4

.

Setzen Sie eine neue, gut geölte Matrize

5

in den Matrizenhal-

ter. Achten Sie dabei auf die Ausrichtung der abgeflachten

Seite.

Schrauben Sie die Rändelschraube

7

mit aufgesetztem Gummi-

ring

6

wieder ein. Ziehen Sie die Schraube gegen den Wider-

stand des Gummirings gut fest.

Stempel wechseln

Lösen Sie die Schraube

2

und ziehen Sie den Matrizenhalter

4

vollständig aus dem Gehäuse.

Schieben Sie den Stempel

3

seitlich aus der Nut am Matrizen-

halter

4

und ziehen Sie ihn nach unten heraus.

Setzen Sie einen neuen, gut geölten Stempel

3

in die Nut am

Matrizenhalter

4

und richten Sie ihn mittig aus.

Schieben Sie den Matrizenhalter

4

vorsichtig über den Stem-

pel

3

in das Gehäuse zurück. Drehen Sie den Matrizenhalter in

eine der drei möglichen Positionen (siehe „Schnittrichtung

wechseln“, Seite 6). Ziehen Sie die Schraube

2

gut fest.

Sollte das Elektrowerkzeug trotz sorgfältiger Herstellungs-

und Prüfverfahren einmal ausfallen, ist die Reparatur von ei-

ner autorisierten Kundendienststelle für Bosch-Elektrowerk-

zeuge ausführen zu lassen.

Geben Sie bei allen Rückfragen und Ersatzteilbestellungen

bitte unbedingt die 10-stellige Sachnummer laut Typenschild

des Elektrowerkzeuges an.

Kundendienst und Kundenberatung

Der Kundendienst beantwortet Ihre Fragen zu Reparatur und

Wartung Ihres Produkts sowie zu Ersatzteilen. Explosions-

zeichnungen und Informationen zu Ersatzteilen finden Sie

auch unter:

www.bosch-pt.com

Das Bosch-Kundenberater-Team hilft Ihnen gerne bei Fragen

zu Kauf, Anwendung und Einstellung von Produkten und Zu-

behören.

www.powertool-portal.de

, das Internetportal für Handwer-

ker und Heimwerker.

www.ewbc.de

, der Informations-Pool für Handwerk und Aus-

bildung.

Deutschland

Robert Bosch GmbH

Servicezentrum Elektrowerkzeuge

Zur Luhne 2

37589 Kalefeld – Willershausen

Tel. Kundendienst: +49 (1805) 70 74 10*

Fax: +49 (1805) 70 74 11*

(*Festnetzpreis 14 ct/min, höchstens 42 ct/min aus Mobil-

funknetzen)

E-Mail: Servicezentrum.Elektrowerkzeuge@de.bosch.com

Tel. Kundenberatung: +49 (1803) 33 57 99

(Festnetzpreis 9 ct/min, höchstens 42 ct/min aus Mobilfunk-

netzen)

Fax: +49 (711) 7 58 19 30

E-Mail: kundenberatung.ew@de.bosch.com

Österreich

Tel.: +43 (01) 7 97 22 20 10

Fax: +43 (01) 7 97 22 20 11

E-Mail: service.elektrowerkzeuge@at.bosch.com

Schweiz

Tel.: +41 (044) 8 47 15 11

Fax: +41 (044) 8 47 15 51

Luxemburg

Tel.: +32 2 588 0589

Fax: +32 2 588 0595

E-Mail: outillage.gereedschap@be.bosch.com

Entsorgung

Elektrowerkzeuge, Zubehör und Verpackungen sollen einer

umweltgerechten Wiederverwertung zugeführt werden.

Werfen Sie Elektrowerkzeuge nicht in den Hausmüll!

Nur für EU-Länder:

Gemäß der Europäischen Richtlinie

2002/96/EG über Elektro- und Elektronik-

Altgeräte und ihrer Umsetzung in nationales

Recht müssen nicht mehr gebrauchsfähige

Elektrowerkzeuge getrennt gesammelt und

einer umweltgerechten Wiederverwertung

zugeführt werden.

Änderungen vorbehalten.

English

Safety Notes

General Power Tool Safety Warnings

Read all safety warnings and all in-

structions.

Failure to follow the warnings

and instructions may result in electric shock, fire and/or seri-

ous injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-

operated (corded) power tool or battery-operated (cordless)

power tool.

WARNING

OBJ_DOKU-9160-002.fm Page 7 Monday, July 25, 2011 2:04 PM

8

| English

1 619 929 J61 | (25.7.11)

Bosch Power Tools

Work area safety

f

Keep work area clean and well lit.

Cluttered or dark areas

invite accidents.

f

Do not operate power tools in explosive atmospheres,

such as in the presence of flammable liquids, gases or

dust.

Power tools create sparks which may ignite the dust

or fumes.

f

Keep children and bystanders away while operating a

power tool.

Distractions can cause you to lose control.

Electrical safety

f

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools.

Unmodified plugs and

matching outlets will reduce risk of electric shock.

f

Avoid body contact with earthed or grounded surfaces,

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is

earthed or grounded.

f

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

f

Do not abuse the cord. Never use the cord for carrying,

pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges and moving parts.

Damaged

or entangled cords increase the risk of electric shock.

f

When operating a power tool outdoors, use an exten-

sion cord suitable for outdoor use.

Use of a cord suitable

for outdoor use reduces the risk of electric shock.

f

If operating a power tool in a damp location is unavoid-

able, use a residual current device (RCD) protected

supply.

Use of an RCD reduces the risk of electric shock.

Personal safety

f

Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use a power

tool while you are tired or under the influence of drugs,

alcohol or medication.

A moment of inattention while op-

erating power tools may result in serious personal injury.

f

Use personal protective equipment. Always wear eye

protection.

Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing protection used

for appropriate conditions will reduce personal injuries.

f

Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Car-

rying power tools with your finger on the switch or energis-

ing power tools that have the switch on invites accidents.

f

Remove any adjusting key or wrench before turning

the power tool on.

A wrench or a key left attached to a ro-

tating part of the power tool may result in personal injury.

f

Do not overreach. Keep proper footing and balance at

all times.

This enables better control of the power tool in

unexpected situations.

f

Dress properly. Do not wear loose clothing or jewel-

lery. Keep your hair, clothing and gloves away from

moving parts.

Loose clothes, jewellery or long hair can be

caught in moving parts.

f

If devices are provided for the connection of dust ex-

traction and collection facilities, ensure these are con-

nected and properly used.

Use of dust collection can re-

duce dust-related hazards.

Power tool use and care

f

Do not force the power tool. Use the correct power tool

for your application.

The correct power tool will do the

job better and safer at the rate for which it was designed.

f

Do not use the power tool if the switch does not turn it

on and off.

Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

f

Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools.

Such preventive safety measures reduce the risk of

starting the power tool accidentally.

f

Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool.

Power

tools are dangerous in the hands of untrained users.

f

Maintain power tools. Check for misalignment or bind-

ing of moving parts, breakage of parts and any other

condition that may affect the power tool’s operation. If

damaged, have the power tool repaired before use.

Many

accidents are caused by poorly maintained power tools.

f

Keep cutting tools sharp and clean.

Properly maintained

cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

f

Use the power tool, accessories and tool bits etc. in ac-

cordance with these instructions, taking into account

the working conditions and the work to be performed.

Use of the power tool for operations different from those

intended could result in a hazardous situation.

Service

f

Have your power tool serviced by a qualified repair per-

son using only identical replacement parts.

This will en-

sure that the safety of the power tool is maintained.

Safety Warnings for Nibblers

f

Secure the workpiece.

A workpiece clamped with clamp-

ing devices or in a vice is held more secure than by hand.

f

Products sold in GB only

: Your product is fitted with a

BS 1363/A approved electric plug with internal fuse

(ASTA approved to BS 1362).

If the plug is not suitable for your socket outlets, it should

be cut off and an appropriate plug fitted in its place by an

authorised customer service agent. The replacement plug

should have the same fuse rating as the original plug.

The severed plug must be disposed of to avoid a possible

shock hazard and should never be inserted into a mains

socket elsewhere.

Products sold in AUS and NZ only

: Use a residual current

device (RCD) with a rated residual current of 30 mA or

less.

OBJ_BUCH-480-002.book Page 8 Monday, July 25, 2011 9:39 AM

English |

9

Bosch Power Tools

1 619 929 J61 | (25.7.11)

Product Description and Specifica-

tions

Read all safety warnings and all instruc-

tions.

Failure to follow the warnings and in-

structions may result in electric shock, fire

and/or serious injury.

While reading the operating instructions, unfold the graphics

page for the machine and leave it open.

Intended Use

The machine is intended for cutting sheet metal without de-

forming the material and is suitable for straight cuts, cut-outs

and narrow curves.

Product Features

The numbering of the product features refers to the illustra-

tion of the machine on the graphics page.

1

On/Off switch

2

Die holder screw

3

Punch

4

Die holder

5

Die

6

Rubber ring for knurled screw

7

Knurled screw for die

Accessories shown or described are not part of the standard deliv-

ery scope of the product. A complete overview of accessories can

be found in our accessories program.

Technical Data

Noise/Vibration Information

Measured sound values determined according to EN 60745.

Typically the A-weighted sound pressure level of the product

is 79 dB(A). Uncertainty K=3 dB.

The noise level when working can exceed 80 dB(A).

Wear hearing protection!

Vibration total values a

h

(triax vector sum) and uncertainty K

determined according to EN 60745:

a

h

=9 m/s

2

, K<3 m/s

2

.

The vibration emission level given in this information sheet

has been measured in accordance with a standardised test

given in EN 60745 and may be used to compare one tool with

another. It may be used for a preliminary assessment of expo-

sure.

The declared vibration emission level represents the main ap-

plications of the tool. However if the tool is used for different

applications, with different accessories or poorly maintained,

the vibration emission may differ. This may significantly in-

crease the exposure level over the total working period.

An estimation of the level of exposure to vibration should also

take into account the times when the tool is switched off or

when it is running but not actually doing the job. This may sig-

nificantly reduce the exposure level over the total working pe-

riod.

Identify additional safety measures to protect the operator

from the effects of vibration such as: maintain the tool and the

accessories, keep the hands warm, organisation of work pat-

terns.

Declaration of Conformity

We declare under our sole responsibility that the product de-

scribed under “Technical Data” is in conformity with the fol-

lowing standards or standardization documents: EN 60745

according to the provisions of the directives 2004/108/EC,

2006/42/EC.

Technical file (2006/42/EC) at:

Robert Bosch GmbH, PT/ESC,

D-70745 Leinfelden-Echterdingen

Robert Bosch GmbH, Power Tools Division

D-70745 Leinfelden-Echterdingen

Leinfelden, 08.06.2011

Operation

Starting Operation

f

Observe correct mains voltage! The voltage of the pow-

er source must agree with the voltage specified on the

nameplate of the machine. Power tools marked with

230 V can also be operated with 220 V.

Switching On and Off

To

start

the machine, press the On/Off switch

1

.

For

locking

the On/Off switch

1

hold it down and push it back.

To

switch off

the machine, release the On/Off switch

1

. When

the On/Off switch

1

is locked, press it first and then release it.

Nibbler

GNA 16

Professional

Article number

0 601 529 2..

Rated power input

W

350

Output power

W

160

Stroke rate at no load n

0

min

-1

2200

Stroke speed under load

min

-1

1600

Max. steel sheet cutting capacity*

mm

1.6

Cutting width

mm

5

Smallest curve radius

mm

40

Weight according to

EPTA-Procedure 01/2003

kg

1.7

Protection class

/

II

* to 400 N/mm

2

with reference to steel sheet

The values given are valid for a nominal voltage [U] of 230 V. For differ-

ent voltages and models for specific countries, these values can vary.

Please observe the article number on the type plate of your machine.

The trade names of the individual machines may vary.

Dr. Egbert Schneider

Senior Vice President

Engineering

Dr. Eckerhard Strötgen

Head of Product

Certification

OBJ_BUCH-480-002.book Page 9 Monday, July 25, 2011 9:39 AM

10

| English

1 619 929 J61 | (25.7.11)

Bosch Power Tools

Changing the Cutting Direction

For changing the cutting direction, the die holder

4

can be

turned to three positions, each offset by 90°. Cutting toward

the rear (toward the housing of the machine) is not possible.

For turning the die holder

4

loosen the screw

2

until you can

turn the die holder. Turn it 90 ° to the right or the left in rela-

tion to the longitudinal axle of the power tool.

Make sure that the screw

2

engages into the borehole of the

die holder

4

. Tighten the screw

2

.

Working Advice

f

Before any work on the machine itself, pull the mains

plug.

f

The power tool is not suitable for stationary operation.

For example, it may not be clamped in a vice or fastened on

a workbench.

f

Wear protective gloves while working and pay particu-

lar attention to the mains cable.

Sharp burrs develop at

the cut steel sheet and can cause injuries to the operator or

damage the mains cable.

f

Exercise caution when handling the cutting chips.

The

chips have sharp tips that can cause injuries.

Apply the machine to the workpiece only when switched on.

Always hold the machine vertical to the surface of the steel

sheet and do not tilt it.

The cut takes place during the downward motion of the

punch. Guide the machine evenly and with moderate feed in

the cutting direction. A high feed rate significantly reduces

the service life of the cutting tools and can damage the ma-

chine.

The machine operates more quietly when it is raised slightly

during cutting. If the punch should become wedged during

cutting, switch the machine off, relubricate the punch and re-

lease the tension of the steel sheet. Do not exert force, other-

wise the punch and the die will become damaged.

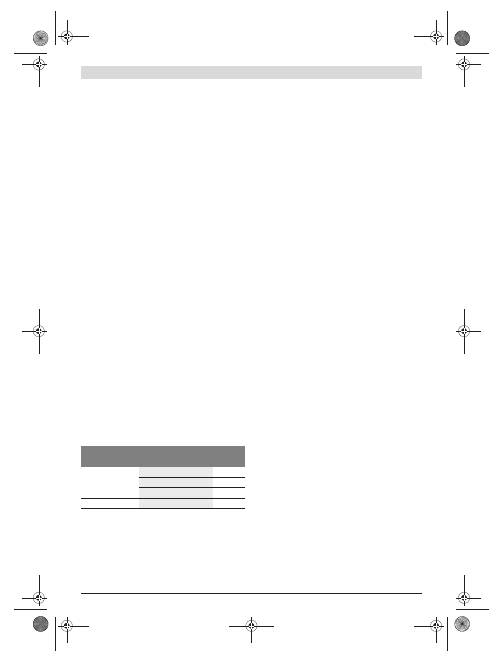

Maximum Steel Sheet Cutting Capacity

The maximum steel sheet cutting capacity d

max

depends on

the strength properties of the material to be cut.

The machine allows for straight and deformation-free cutting

of metal sheets to the following thicknesses:

Lubricating/Cooling the Punch

To extend the service life of the punch

3

, a lubricating agent

with good cooling properties (e.g. cutting oil) should be used.

Apply a trail of lubricant beads onto the top side of the metal

sheet alongside the intended cutting line. For long periods of

continual use or for work with high frictional wear (e.g. when

cutting aluminium), the cutting head should be immersed into

a container with lubricant in regular intervals.

Cutting along a Cutting Mark or with a Guide

Straight cuts are carried out easier when the machine is guid-

ed alongside a rule.

Contours can be cut by guiding the machine along a template.

For inside cuts, pre-drilling a hole with a diameter of 21 mm is

necessary.

Maintenance and Service

Maintenance and Cleaning

f

Before any work on the machine itself, pull the mains

plug.

f

For safe and proper working, always keep the machine

and ventilation slots clean.

Clean and lubricate the punch

3

and die

5

every 3 operating

hours.

Change the punch and die in good time when worn. Only

sharp tools produce a good cutting quality and make the ma-

chine last longer.

The punch

3

and the die

5

may not be reground.

Changing the Die

Unscrew the knurled screw

7

of the die holder

4

. Take out the

die

5

.

Il necessary, clean the die holder

4

.

Put a new, well greased die

5

into the die holder. Pay attention

to the alignment of the flat side.

Tighten the knurled screw

7

again, the rubber ring placed on-

to it

6

. Tighten the screw against the resistance of the rubber

ring.

Changing the Punch

Loosen the screw

2

and pull the die holder und

4

completely

out of the housing.

Push the punch

3

laterally out of the slot in the die holder

4

and pull it down and out.

Place a new, well greased punch

3

into the slot in the die hold-

er

4

and align it centrally.

Push the die holder

4

with caution over the punch

3

back into

the housing. Turn the die holder into one of the three possible

positions (see “Changing the Cutting Direction”, page 10).

Tighten the screw

2

.

If the machine should fail despite the care taken in manufac-

turing and testing procedures, repair should be carried out by

an after-sales service centre for Bosch power tools.

In all correspondence and spare parts order, please always in-

clude the 10-digit article number given on the type plate of

the machine.

After-sales Service and Customer Assistance

Our after-sales service responds to your questions concern-

ing maintenance and repair of your product as well as spare

parts. Exploded views and information on spare parts can al-

so be found under:

www.bosch-pt.com

Material

Max. strength property

[N/mm

2

]

d

max

[mm]

Steel

400

1.6

600

1.0

800

0.7

Aluminium

200

2.0

OBJ_BUCH-480-002.book Page 10 Monday, July 25, 2011 9:39 AM

English |

11

Bosch Power Tools

1 619 929 J61 | (25.7.11)

Our customer service representatives can answer your ques-

tions concerning possible applications and adjustment of

products and accessories.

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham

Uxbridge

UB 9 5HJ

Tel. Service: +44 (0844) 736 0109

Fax: +44 (0844) 736 0146

E-Mail: boschservicecentre@bosch.com

Ireland

Origo Ltd.

Unit 23 Magna Drive

Magna Business Park

City West

Dublin 24

Tel. Service: +353 (01) 4 66 67 00

Fax: +353 (01) 4 66 68 88

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: +61 (01300) 307 044

Fax: +61 (01300) 307 045

Inside New Zealand:

Phone: +64 (0800) 543 353

Fax: +64 (0800) 428 570

Outside AU and NZ:

Phone: +61 (03) 9541 5555

www.bosch.com.au

Republic of South Africa

Customer service

Hotline: +27 (011) 6 51 96 00

Gauteng – BSC Service Centre

35 Roper Street, New Centre

Johannesburg

Tel.: +27 (011) 4 93 93 75

Fax: +27 (011) 4 93 01 26

E-Mail: bsctools@icon.co.za

KZN – BSC Service Centre

Unit E, Almar Centre

143 Crompton Street

Pinetown

Tel.: +27 (031) 7 01 21 20

Fax: +27 (031) 7 01 24 46

E-Mail: bsc.dur@za.bosch.com

Western Cape – BSC Service Centre

Democracy Way, Prosperity Park

Milnerton

Tel.: +27 (021) 5 51 25 77

Fax: +27 (021) 5 51 32 23

E-Mail: bsc@zsd.co.za

Bosch Headquarters

Midrand, Gauteng

Tel.: +27 (011) 6 51 96 00

Fax: +27 (011) 6 51 98 80

E-Mail: rbsa-hq.pts@za.bosch.com

People’s Republic of China

China Mainland

Bosch Power Tools (China) Co., Ltd.

567, Bin Kang Road

Bin Jiang District 310052

Hangzhou, P.R.China

Service Hotline: 400 826 8484

Fax: +86 571 8777 4502

E-Mail: contact.ptcn@cn.bosch.com

www.bosch-pt.com.cn

HK and Macau Special Administrative Regions

Robert Bosch Hong Kong Co. Ltd.

21st Floor, 625 King’s Road

North Point, Hong Kong

Customer Service Hotline: +852 (21) 02 02 35

Fax: +852 (25) 90 97 62

E-Mail: info@hk.bosch.com

www.bosch-pt.com.hk

Indonesia

PT. Multi Mayaka

Kawasan Industri Pulogadung

Jalan Rawa Gelam III No. 2

Jakarta 13930

Indonesia

Tel.: +62 (21) 46 83 25 22

Fax: +62 (21) 46 82 86 45/68 23

E-Mail: sales@multimayaka.co.id

www.bosch-pt.co.id

Philippines

Robert Bosch, Inc.

28th Floor Fort Legend Towers,

3rd Avenue corner 31st Street,

Fort Bonifacio Global City,

1634 Taguig City, Philippines

Tel.: +63 (2) 870 3871

Fax: +63 (2) 870 3870

matheus.contiero@ph.bosch.com

www.bosch-pt.com.ph

Bosch Service Center:

9725-27 Kamagong Street

San Antonio Village

Makati City, Philippines

Tel.: +63 (2) 899 9091

Fax: +63 (2) 897 6432

rosalie.dagdagan@ph.bosch.com

OBJ_BUCH-480-002.book Page 11 Monday, July 25, 2011 9:39 AM