Panasonic EY7541: III

III: Panasonic EY7541

original options and sockets to the

square drive on the body. The cushion

rubber in the square drive to push up

the ball may get hard under freezing

point. This requires extra force in

detaching and attaching sockets.

Attaching or Removing Bat-

tery Pack

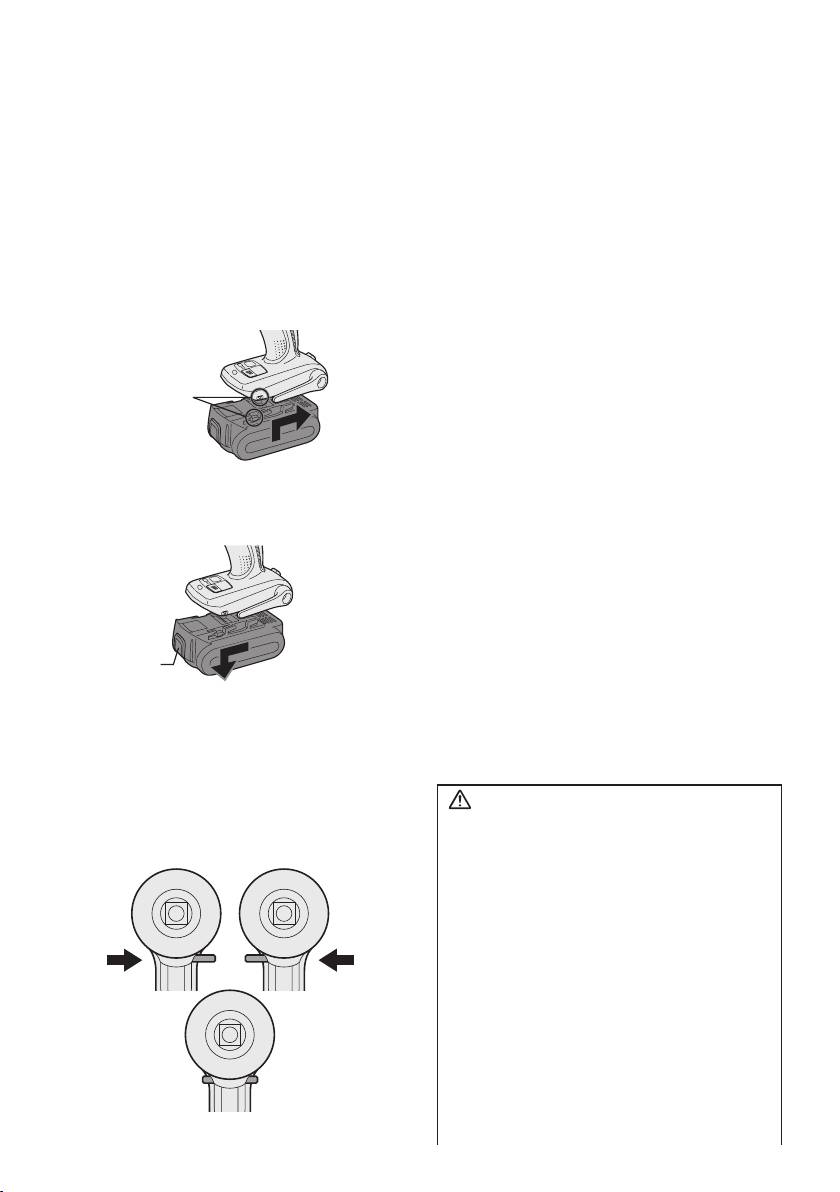

1. To connect the battery pack:

Line up the alignment marks and attach

the battery pack.

•

Slide the battery pack until it locks into

position.

Alignment

marks

2. To remove the battery pack:

Push on the button from the front to re-

lease the battery pack.

Button

III

. OPERATION

[Main Body]

Switch and Forward/Reverse

Lever Operation

-

6

-

Forward Reverse

Switch lock

CAUTION:

To prevent damage, do not operate

Forward/Reverse lever until the bit

comes to a complete stop.

Forward Rotation Switch

Operation

1. Push the lever for forward rotation.

2. Depress the trigger switch slightly to start

the tool slowly.

3. The speed increases with the amount of

depression of the trigger for efficient tight-

ening of screws. The brake operates and

the bit stops immediately when the trigger

is released.

4. After use, set the lever to its center posi

-

tion (switch lock).

Reverse Rotation Switch

Operation

1.

Push the lever for reverse rotation. Check

the

direction of rotation before use.

2.

Depress the trigger switch slightly to start the

tool slowly.

3. After use, set the lever to its center posi-

tion (switch lock).

CAUTION:

• To eliminate excessive temperature

increase of the tool surface, do not

operate the tool continuously using two

or more battery packs. Tool needs cool

off time before switching to another

pack.

How to Use the Belt Hook

WARNING!

• Be sure to attach the belt hook securely

to the main unit with the screw firmly fas-

tened. When the belt hook is not firmly

attached to the main unit, the hook may

disconnect and the main unit may fall.

This may result in an accident or injury.

• Periodically check screw for tightness. If

found to be loose, tighten firmly.

•

Be sure to attach the belt hook firmly and

securely onto a waist belt or other belt. Pay

attention that the unit does not slip off the

belt.

This may result in an accident or injury.

• When the main unit is held by the belt

hook, avoid jumping or running with it.

Doing so may cause the hook to slip and

the main unit may fall.

This may result in an accident or injury.

• When the belt hook is not used, be sure

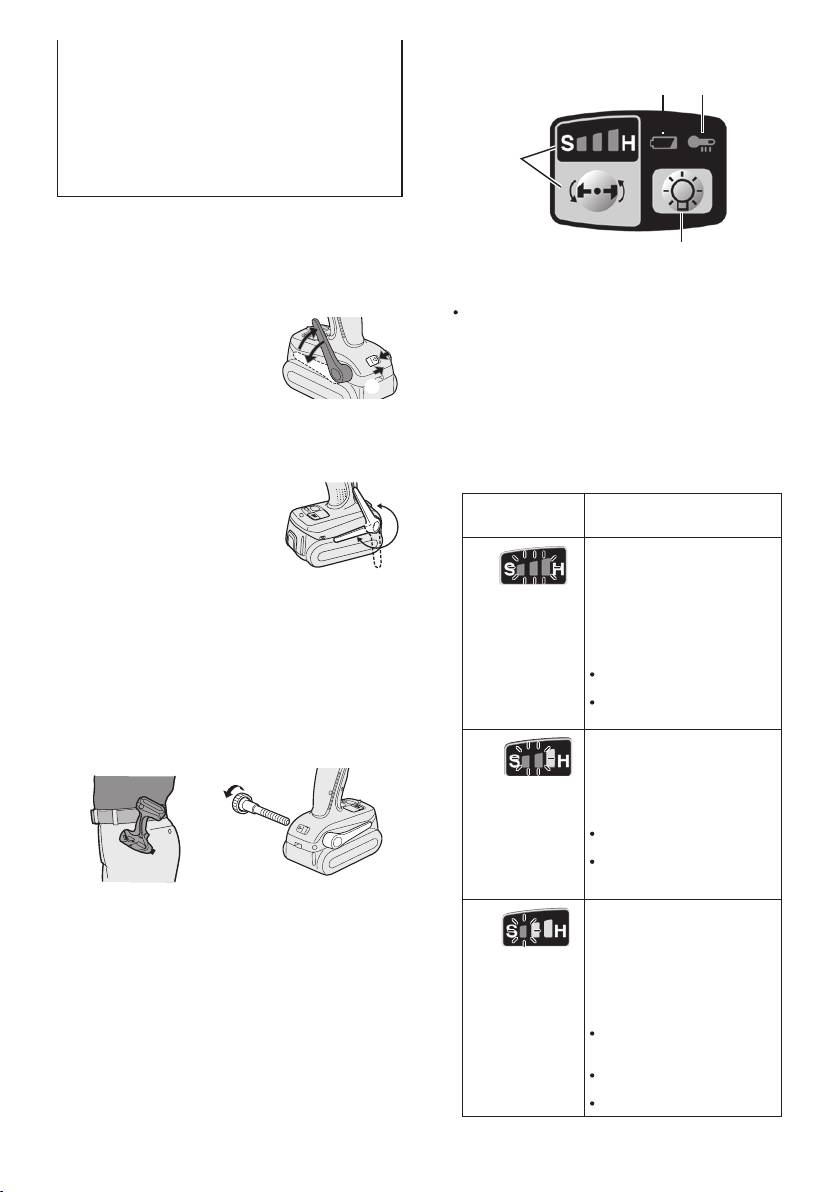

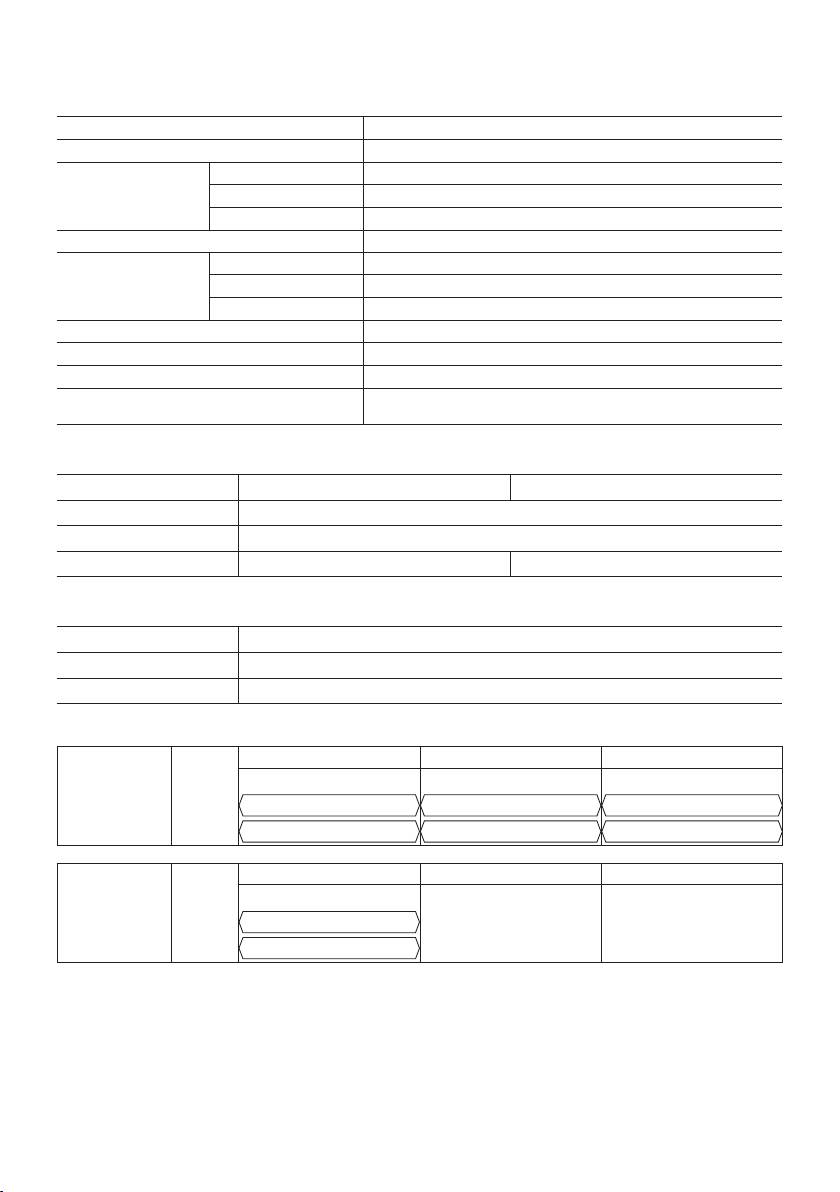

Control Panel

to return it to the storing position. The belt

(4) (3)

hook may catch on something.

This may result in an accident or injury.

•

When the unit is hooked onto the waist belt

by the belt hook, do not attach driver bits

(1)

to the unit. A sharp edge object, such as a

drill bit, may cause injury or an accident.

To Set the Belt Hook Angle

(2)

Position

1. Slide the belt hook lock lever 1 and hold

(1) Impact Power Mode Select

it to unlock the belt hook.

Selecting the impact power among 3

2

2. Pull the belt hook from

modes (Soft, Medium, Hard).

1

storing position 2 and

Press the impact power mode button to set

set it.

it. The mode changes to hard, medium, or

3.

Release the belt hook

3

soft each time the button is pressed.

lock lever to

lock the

The driver is preset to “hard” impact mode

angle of belt hook.

setting when shipped from the manufac-

4.

Make sure the belt hook is firmly locked.

turer.

Also make sure the belt hook is firmly

Recommended work guideline table

locked into position

3

.

Impact

• The belt hook cannot

Power mode

Recommended Application

be locked in this posi-

Display

tion. Firmly lock it into

Jobs requiring a high level

position before use.

of torque where there is

H

no possibility of the bolts

To return the belt hook to the storing position,

or screw breaking, its top

Follow step 1. and 2. above, then lower the

shearing off, or the bit coming

belt hook.

loose. (This setting provides

0 – 2300 r.p.m.

To secure the lock, follow 3 and 4 above.

maximum torque.) Suitable

and

applications include:

0 – 3000 i.p.m.

Tightening M8 and larger

To Change the Belt Hook

bolts

Tightening long screws

Location Side

during interior finishing work

The belt hook can be attached to either

Jobs requiring limited torque

side of the unit.

where there is a possibility of

M

the screw breaking or its top

shearing off. (This setting limits

torque.) Suitable applications

include:

0 – 1400 r.p.m.

Tightening bolts with

and

smaller diameters (M6)

0 – 2800 i.p.m.

Tightening metalwork

screws when installing

fixtures

1. Set the belt hook at storing position.

Jobs requiring limited torque

2. Loosen the screw turning it counter-

where there is a possibility

S

clockwise, using a flat metal or a flat

of the screw breaking, its

top shearing off, or the bit

blade screw driver.

coming loose and damaging

3. Take out the belt hook and insert into

anishedexteriorsurface.

the other side of the slot on the main

(This setting limits torque.)

0 – 1000 r.p.m.

unit.

Suitable applications include:

and

Tightening bolts smaller

4. Fasten the screw firmly, turning it clock

-

0 – 2000 i.p.m.

than M6 that may shear

wise.

easily

Tightening screws into

The belt hook can be taken out from the

molded plastic

main unit only when it is at storing posi-

Installing gypsum wallboard

tion.

* i.p.m. = Impact per minute.

-

7

-

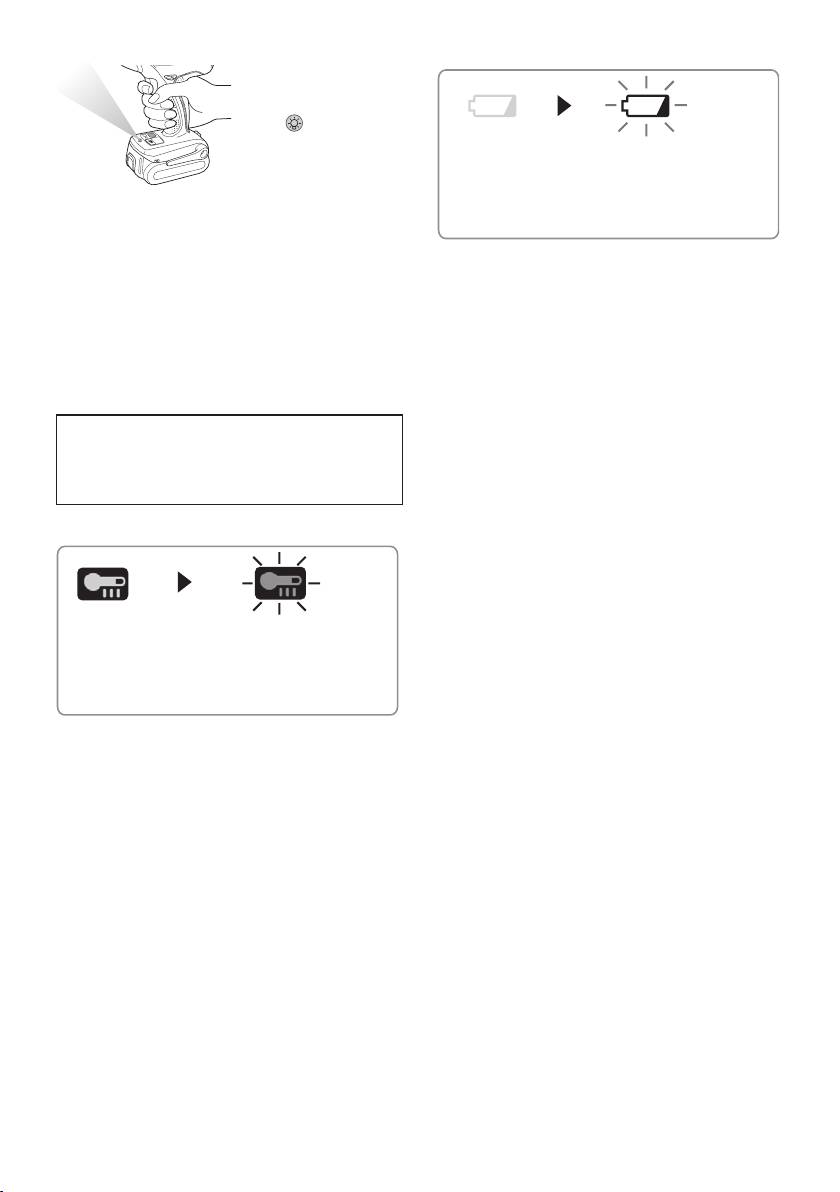

(2) LED light

(4) Battery low warning lamp

Before the use of LED

light, always pull the

power switch once.

Press the LED light

on button.

The light illuminates

Off (normal

Flashing (No charge)

operation)

with very low cur-

Battery protection

rent, and it does not

feature active

adversely affect the performance of the tool

during use or its battery capacity.

Excessive (complete) discharging of Li-

CAUTION:

ion batteries shortens their service life

• The built-in LED light is designed to illu-

dramatically. The driver includes a battery

minate the small work area temporarily.

protection feature designed to prevent

•

Do not use it as a substitute for a regular

excessive discharging of the battery pack.

flashlight, since it does not have enough

• The battery protection feature activates

brightness.

immediately before the battery loses its

•

LED light turns off when the tool has not

charge, causing the battery low warning

been used for 5 minutes.

lamp to flash.

Caution : DO NOT STARE INTO BEAM.

• If you notice the battery low warning

lamp flashing, charge the battery pack

Use of controls or adjustments or performance

immediately.

ofproceduresotherthanthosespeciedherein

may result in hazardous radiation exposure.

[Battery Pack]

(3) Overheat warning lamp

For Appropriate Use of Bat-

tery Pack

Li-ion Battery Pack (EY9L40/

Off (normal

Flashing: Overheat

EY9L41)

operation)

Indicates operation has

• For optimum battery life, store the Li-ion

been halted due to motor

battery pack following use without charging

or battery overheating.

it.

The overheating protection feature halts

• When charging the battery pack, confirm

driver operation to protect the motor and

that the terminals on the battery charger

battery pack in the event of overheating.

are free of foreign substances such as

The overheat warning lamp on the control

dust and water etc. Clean the terminals

panel flashes when this feature is active.

before charging the battery pack if any

•

If the overheating protection feature acti-

foreign substances are found on the ter-

vates, allow the driver to cool thoroughly

minals.

(at least 30 minutes). The driver is ready

The life of the battery pack terminals may

for use when the overheat warning lamp

be affected by foreign substances such as

goes out.

dust and water etc. during operation.

•

Avoid using the driver in a way that

• When battery pack is not in use, keep it

causes the overheating protection fea-

away from other metal objects like: paper

ture to activate repeatedly.

clips, coins, keys, nails, screws, or other

small metal objects that can make a con-

nection from one terminal to another.

Shorting the battery terminals together

may cause sparks, burns or a fire.

•

When operating the battery pack, make

sure the work place is well ventilated.

-

8

-

• When the battery pack is removed from the

CAUTION:

main body of the tool, replace the battery

To prevent the risk of fire or damage to

pack cover immediately in order to prevent

the battery charger.

dust or dirt from contaminating the battery

• Do not use power source from an

terminals and causing a short circuit.

engine generator.

• Do not cover vent holes on the charger

and the battery pack.

• Unplug the charger when not in use.

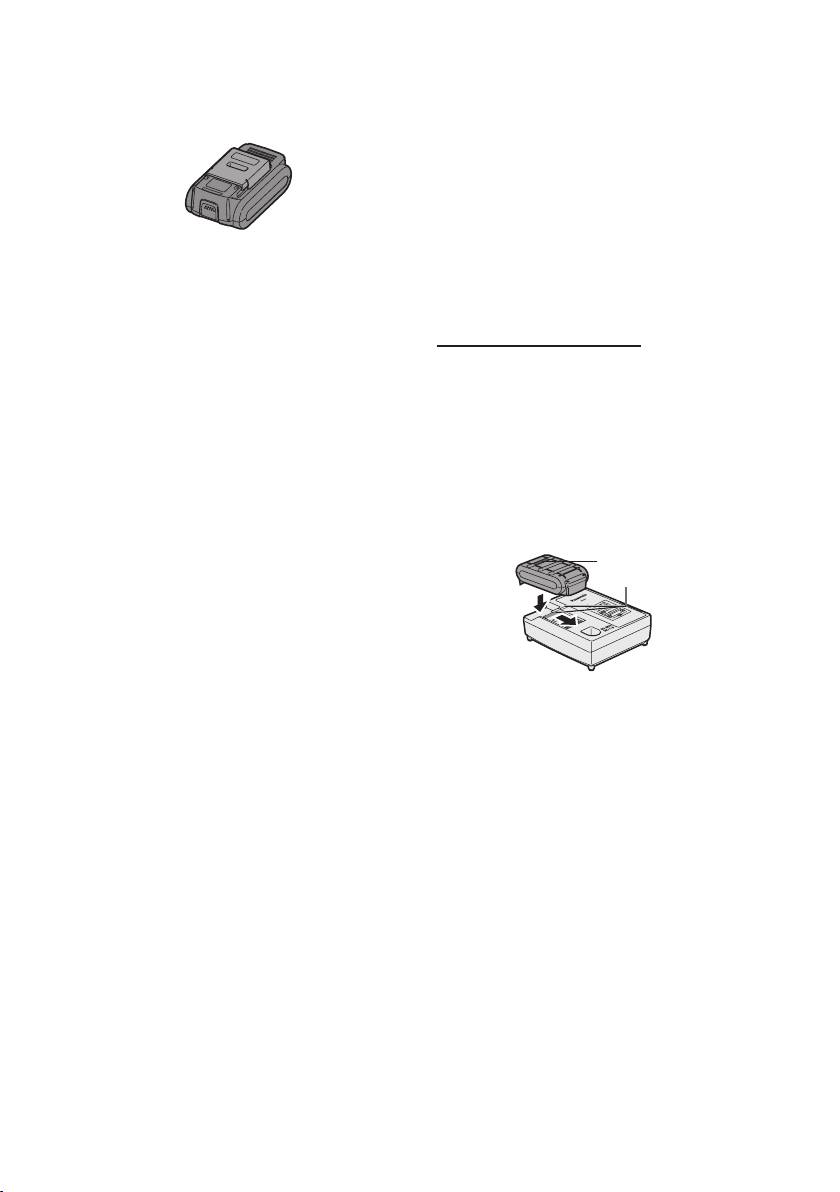

Li-ion Battery Pack

NOTE:

Battery Pack Life

Your battery pack is not fully charged at

The rechargeable batteries have a lim-

the time of purchase. Be sure to charge

ited life. If the operation time becomes

the battery before use.

extremely short after recharging, replace

the battery pack with a new one.

Battery charger (EY0L80)

1. Plug the charger into the AC outlet.

Battery Recycling

NOTE:

ATTENTION:

Sparks may be produced when the plug

For environmental protection and recy-

is inserted into the AC power supply, but

cling of materials, be sure that it is dis-

this is not a problem in terms of safety.

posed of at an officially assigned loca-

2.

Insert the battery pack firmly into the charger.

tion, if there is one in your country.

1 Line up the alignment marks and place the

battery onto the dock on the charger.

[Battery Charger]

2 Slide forward in the direction of the arrow.

Alignment marks

Charging

Cautions for the Li-ion Battery

Pack

• If the temperature of the battery pack falls

approximately below −10°C (14°F),charg

-

3.

During charging, the charging lamp will be

ing will automatically stop to prevent degra-

lit.

dation of the battery.

When charging is completed, an internal

electronic switch will automatically be trig-

Common Cautions for the Li-

gered to prevent overcharging.

ion/Ni-MH/Ni-Cd Battery Pack

• Charging will not start if the battery

• The ambient temperature range is between

pack is warm (for example, immediately

0°C (32°F) and 40°C (104°F).

after heavy-duty operation).

If the battery pack is used when the bat

-

The orange standby lamp will be flash

-

tery temperature is below 0°C (32°F),

ing until the battery cools down.

the tool may fail to function properly.

Charging will then begin automatically.

• When charging a cool battery pack (below

4.

The charge lamp (green) will flash slowly

0°C (32°F)) in a warm place, leave the

once the battery is approximately 80%

battery pack at the place and wait for

charged.

more than one hour to warm up the bat-

5.

When charging is completed, the charging

tery to the level of the ambient tempera-

lamp will start flashing quickly in green color.

ture.

6. If the temperature of the battery pack is

•

Cool down the charger when charging more

0°C or less, charging takes longer to fully

than two battery packs consecutively.

charge the battery pack than the standard

• Do not insert your fingers into contact

charging time.

hole, when holding charger or any other

occasions.

-

9

-

Even when the battery is fully charged, it

5.

If the charging lamp does not light imme-

will have approximately 50% of the power

diately after the charger is plugged in, or if

of a fully charged battery at normal operat-

after the standard charging time the charg-

ing temperature.

ing lamp does not flash quickly in green,

consult an authorized dealer.

7.

If the power lamp does not light immediately

after the charger is plugged in, or if after the

6. If a fully charged battery pack is inserted

standard charging time the charging lamp

into the charger again, the charging lamp

does not flash quickly in green, consult an

lights up. After several minutes, the charg-

authorized dealer.

ing lamp may flash quickly to indicate the

charging is completed.

8. If a fully charged battery pack is inserted

into the charger again, the charging lamp

lights up. After several minutes, the charg-

ing lamp may flash quickly to indicate the

charging is completed.

Ni-MH/Ni-Cd Battery Pack

NOTE:

When you charge the battery pack for

the first time, or after prolonged stor-

age, charge it for about 24 hours to

bring the battery up to full capacity.

Battery charger (EY0L80)

1. Plug the charger into the AC outlet.

NOTE:

Sparks may be produced when the plug

is inserted into the AC power supply, but

this is not a problem in terms of safety.

2.

Insert the battery pack firmly into the charger.

3.

During charging, the charging lamp will be

lit.

When charging is completed, an internal

electronic switch will automatically be trig-

gered to prevent overcharging.

• Charging will not start if the battery

pack is warm (for example, immediately

after heavy-duty operation).

The orange standby lamp will be

flashing until the battery cools down.

Charging will then begin automatically.

4.

When charging is completed, the charg-

ing lamp will start flashing quickly in green

color.

-

10

-

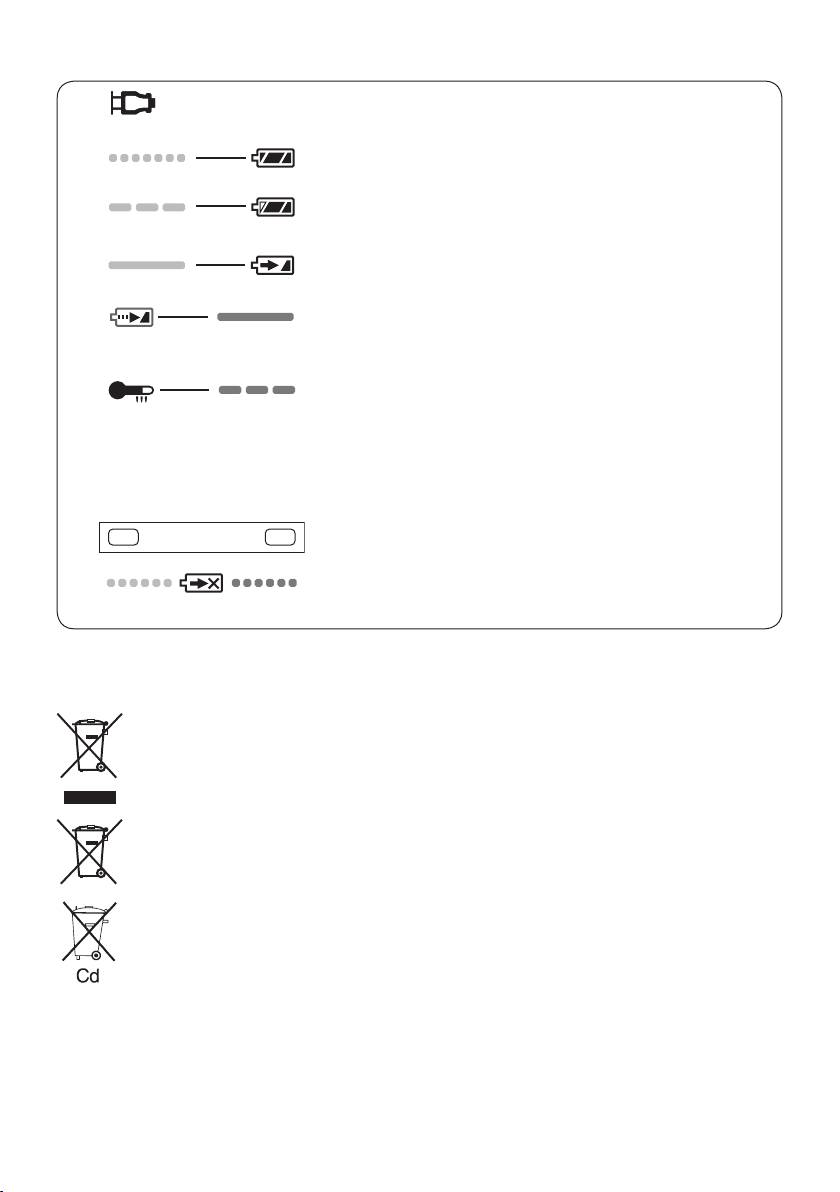

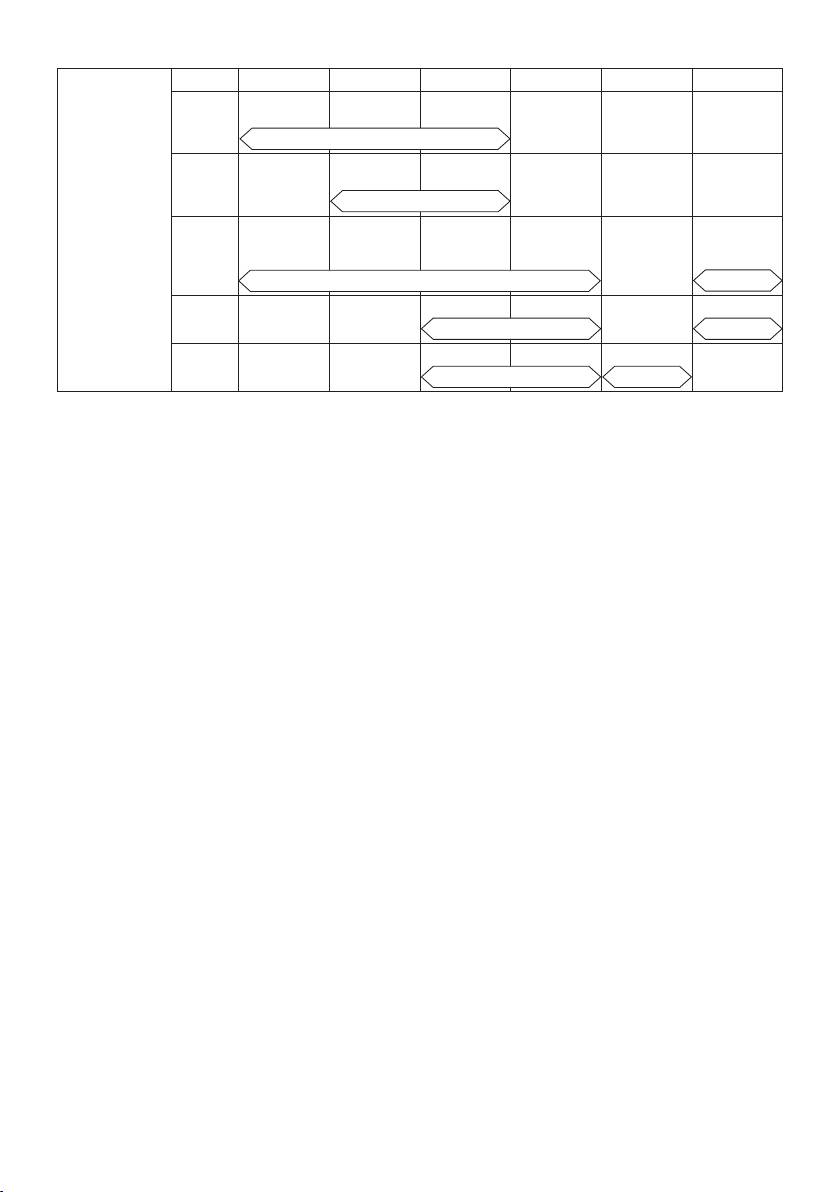

LAMP INDICATIONS

Green Lit

Charger is plugged into the AC outlet.

Ready to charge.

Green Flashing Quickly

Charging is completed. (Full charge.)

Green Flashing

Battery is approximately 80% charged (Usable charge. Li-ion

only).

Green Lit

Now charging

Orange Lit

Battery pack is cool.

The battery pack is being charged slowly to reduce the load on

the battery. (Li-ion only)

Orange Flashing

Battery pack is warm. Charging will begin when temperature of

battery pack drops.

If the temperature of the battery pack is −10°C or less, the

chargingstatuslamp(orange)willalsostartashing.Charg

-

ing will begin when the temperature of the battery pack goes

up (Li-ion only).

Charging Status Lamp

Left: green Right: orange will be displayed.

Both Orange and Green Flashing Quickly

Charging is not possible. Clogged with dust or malfunction of

the battery pack.

Information for Users on Collection and Disposal of Old Equip-

ment and used Batteries

These symbols on the products, packaging, and/or accompanying documents mean

that used electrical and electronic products and batteries should not be mixed with

general household waste.

For proper treatment, recovery and recycling of old products and used batteries, please

take them to applicable collection points, in accordance with your national legislation

and the Directives 2002/96/EC and 2006/66/EC.

By disposing of these products and batteries correctly, you will help to save valuable

resources and prevent any potential negative effects on human health and the

environment which could otherwise arise from inappropriate waste handling.

For more information about collection and recycling of old products and batteries,

please contact your local municipality, your waste disposal service or the point of sale

where you purchased the items.

Penalties may be applicable for incorrect disposal of this waste, in accordance with

national legislation.

For business users in the European Union

If you wish to discard electrical and electronic equipment, please contact your dealer or

supplier for further information.

-

11

-

[Information on Disposal in other Countries outside the European

Union]

These symbols are only valid in the European Union. If you wish to discard these items,

please contact your local authorities or dealer and ask for the correct method of disposal.

Note for the battery symbol (bottom two symbol examples):

This symbol might be used in combination with a chemical symbol. In this case it complies

with the requirement set by the Directive for the chemical involved.

IV

. MAINTENANCE

Use only a dry, soft cloth for wiping the unit. Do not use a damp cloth, thinner, benzine, or other

volatile solvents for cleaning.

V

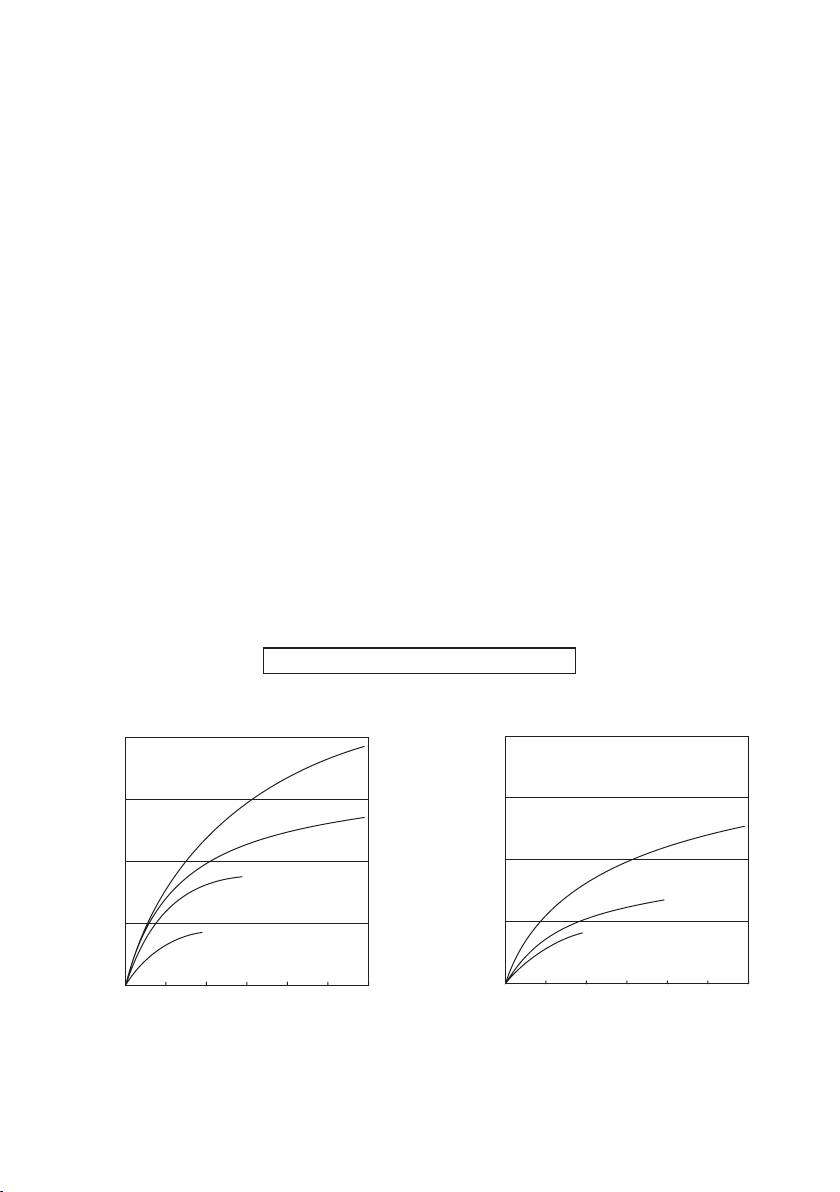

. TIGHTENING TORQUE

The power required for tightening a bolt will vary, according to bolt material and size, as well as

the material being bolted. Choose the length of tightening time accordingly.

Reference values are provided below.

(They may vary according to tightening conditions.)

Factors Affecting Tightening Torque

The tightening torque is affected by a wide variety of factors including the followings. After

tightening, always check the torque with a torque wrench.

1) Voltage

When the battery pack becomes nearly discharged, the voltage decreases and the tighten-

ing torque drops.

Bolt Tightening Conditions

-

12

-

196.0

(2000)

M16

147.0

(1500)

M14

98.0

(1000)

M12

49.0

(500)

M10

0.0 0.5 1.0 1.5 2.0 2.5 3.0

N·m

M10×35 mm M12, M14, M16×45 mm

(kgf-cm)

Standard bolt

Tightening torque

Tightening time (Sec.)

196.0

(2000)

147.0

(1500)

M12

98.0

(1000)

M10

49.0

(500)

M8

0.0 0.5 1.0 1.5 2.0 2.5 3.0

N·m

M8, M10×35 mm M12×45 mm

(kgf-cm)

High tensile bolt

Tightening torque

Tightening time (Sec.)

Washer

Bolt

Steel plate

thickness10 mm (3/8")

Washer

Nut

Spring washer

Tightening conditions

• The following bolts are used.

Standard bolts: Strength type 4.8

High tensile type 12.9

-

13

-

4.8

Explanation of the strength type

Bolt yield point

(80% of tensile strength)

2

32 kgf/mm

(45000psi)

Bolt tensile strength

2

40 kgf/mm

(56000psi)

4) Tightening conditions

Tightening torque will vary, even with the

same bolt, according to grade, length, and

torque coefficient (the fixed coefficient indi-

cated by the manufacturer upon produc-

tion).

Tightening torque will vary, even with the

same bolting material (e.g. steel), accord-

ing to the surface finish.

Torque is greatly reduced when the bolt

and nut start turning together.

5) Socket play

Torque is lowered as the six-sided configu-

ration of the socket of the wrong size is

used to tighten a bolt.

6) Switch (Variable speed control trigger)

Torque is lowered if the unit is used with

the switch not fully depressed.

2) Tightening time

7) Effect of connecting adaptor

Longer tightening time results in increased

The tightening torque will be lowered

tightening torque. Excessive tightening, how-

through the use of a universal joint or a

ever, adds no value and reduces the life of

connecting adaptor.

the tool.

3) Different bolt diameters

The size of the bolt diameter affects the tight-

ening torque.

Generally, as the bolt diameter increases,

tightening torque rises.

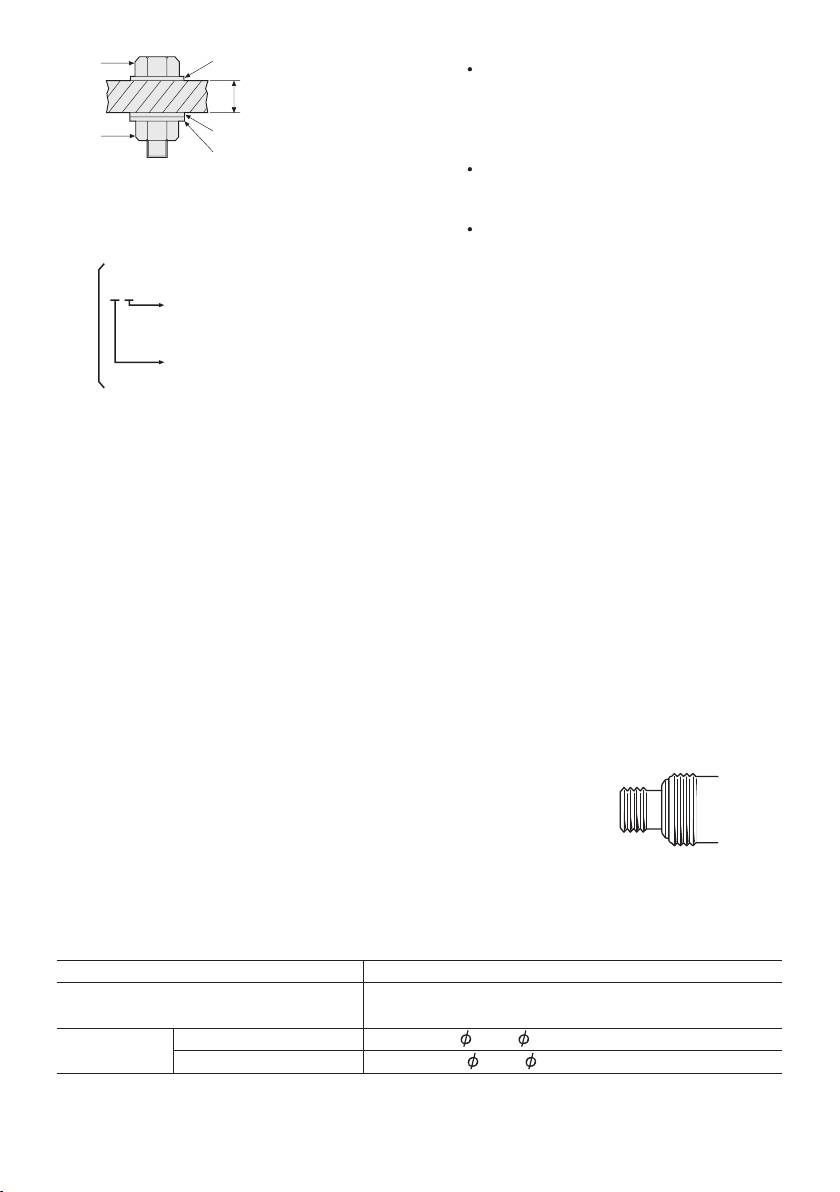

VI

. ACCESSORIES

Use only bits suitable for size of drill’s chuck.

Use Panasonic original Optional Quick change chuck

(EY9HX110E) for maximum performance.

(EY9HX110E)

VII

. APPENDIX

MAXIMUM RECOMMENDED CAPACITIES

Model

EY7541

Standard bolt: M6 – M16

Bolt fastening

High tensile bolt

: M6 – M12

Wood screw

3.5 – 9.5 mm (1/8" – 3/8")

Screw driving

Self-drilling screw

3.5 – 6 mm (1/8" – 1/4")

VIII

. SPECIFICATIONS

MAIN UNIT

Model EY7541

Motor 14.4 V DC

-1

soft mode 0 – 1000 min

(rpm)

-1

No load speed

medium mode 0 – 1400 min

(rpm)

-1

hard mode 0 – 2300 min

(rpm)

Maximum torque 185 N·m (1890 kgf-cm, 1640 in-lbs)

-1

soft mode 0 – 2000 min

(ipm)

-1

Impact per minute

medium mode 0 – 2800 min

(ipm)

-1

hard mode 0 – 3000 min

(ipm)

Overall length 167 mm (6-9/16")

Weight (with battery pack: EY9L40) 1.5 kg (3.3 lbs)

Weight (with battery pack: EY9L41) 1.55 kg (3.4 lbs)

Noise

See the included sheet.

Vibration

BATTERY PACK

Model EY9L40 EY9L41

Storage battery Li-ion Battery

Battery voltage 14.4 V DC (3.6 V × 4 cells)

Capacity 3 Ah 3,3 Ah

BATTERY CHARGER

Model EY0L80

Rating See the rating plate on the bottom of the charger.

Weight 0.95 kg (2.1 lbs)

[Li-ion battery pack]

14.4 V 21.6 V 28.8 V

EY9L40 EY9L60 EY9L80

Charging time

3 Ah

Usable: 35 min. Usable: 45 min. Usable: 55 min.

Full: 50 min. Full: 60 min. Full: 70 min.

14.4 V

EY9L41

Charging time

3,3 Ah

Usable: 45 min.

Full: 60 min.

-

14

-

[Ni-Cd/Ni-MH battery pack]

7.2 V

9.6 V 12 V 15.6 V 18 V 24 V

EY9065

EY9080

EY9001

1.2 Ah

EY9066

EY9086

20 min.

EY9180

EY9101

1.7 Ah

EY9182

EY9103

25 min.

EY9106

Charging time

EY9116

EY9168 EY9188

EY9107

EY9136

2 Ah

EY9117

EY9108

30 min.

60 min.

EY9200 EY9230 EY9210

3 Ah

45 min. 90 min.

EY9201 EY9231 EY9251

3.5 Ah

55 min. 65 min.

NOTE: This chart may include models that are not available in your area.

Please refer to the latest general catalogue

.

NOTE: For the dealer name and address, please see the included warranty card.

-

15

-

IMPORTANT:

ONLY FOR U. K.

The wires in this mains lead are

coloured in accordance with the follow-

ing code:

IX

. ELECTRICAL PLUG

Blue: Neutral

INFORMATION

Brown: Live

As the colours of the wire in the mains lead

FOR YOUR SAFETY PLEASE READ

of this appliance may not correspond with

THE FOLLOWING TEXT CAREFULLY

the coloured markings identifying the termi-

This appliance is supplied with a moulded

nals in your plug, proceed as follows.

three pin mains plug for your safety and

The wire which is coloured BLUE must be

convenience.

connected to the terminal in the plug which

A5ampfuseisttedinthisplug.

is marked with the letter N or coloured

Should the fuse need to be replaced please

BLACK.

ensure that the replacement fuse has a rat-

The wire which is coloured BROWN must be

ing of 5 amp and that it is approved by ASTA

connected to the terminal in the plug which is

or BSI to BS1362.

marked with the letter L or coloured RED.

Check for the ASTA mark or the BSI

Under no circumstances should either of

mark on the body of the fuse.

these wires be connected to the earth ter-

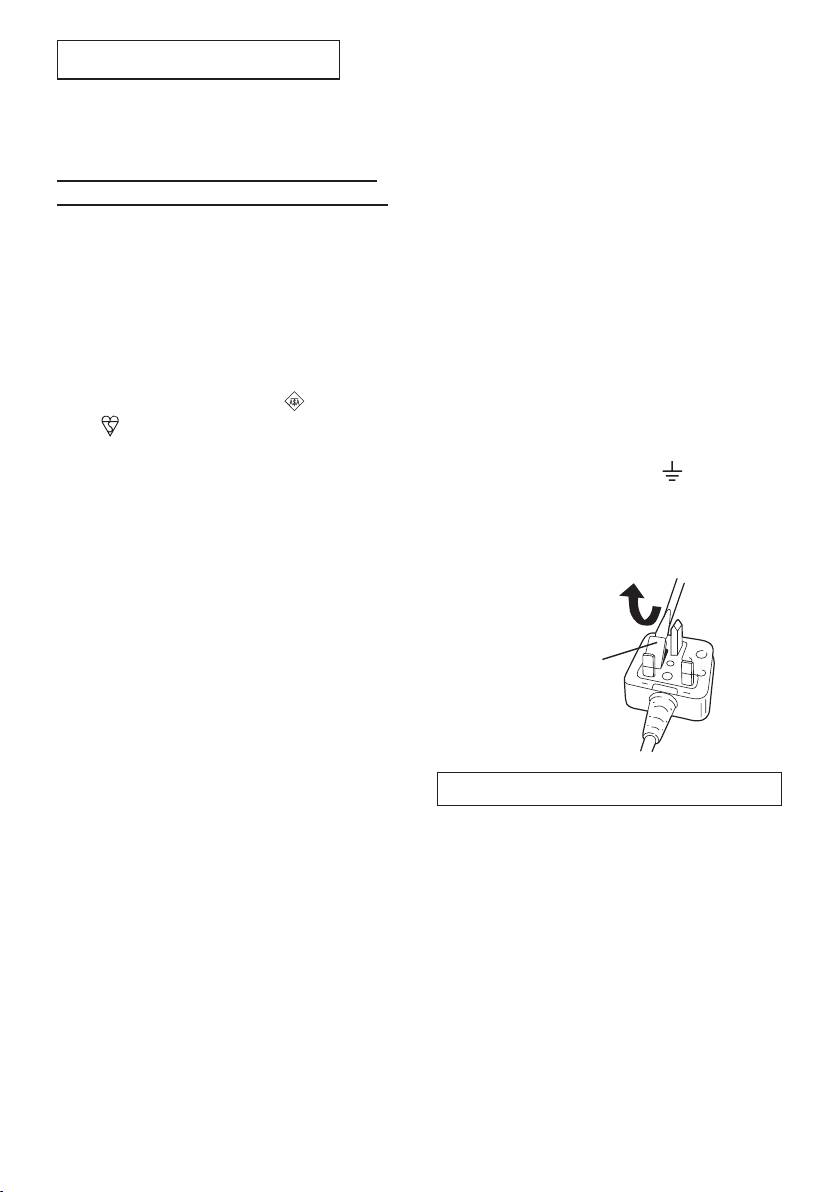

If the plug contains a removable fuse cover

minal of the three pin plug, marked with the

youmustensurethatitisrettedwhenthe

letter E or the Earth Symbol .

fuse is replaced.

If you lose the fuse cover the plug must

How to replace the fuse: Open the fuse

not be used until a replacement cover is

compartment with a screwdriver and replace

obtained.

the fuse and fuse cover if it is removable.

A replacement fuse cover can be purchased

from your local Panasonic Dealer.

IF THE FITTED MOULDED PLUG IS UN-

SUITABLE FOR THE SOCKET OUTLET IN

Fuse Cover

YOUR HOME THEN THE FUSE SHOULD

BE REMOVED AND THE PLUG CUT OFF

AND DISPOSED OF SAFELY.

THERE IS A DANGER OF SEVERE

ELECTRICAL SHOCK IF THE CUT OFF

PLUG IS INSERTED INTO ANY 13 AMP

This apparatus was produced to BS800.

SOCKET.

Ifanewplugistobettedpleaseobserve

the wiring code as shown below.

If in any doubt please consult a qualied

electrician.

-

16

-

-

17

-