Panasonic EYFLA3: IV

IV: Panasonic EYFLA3

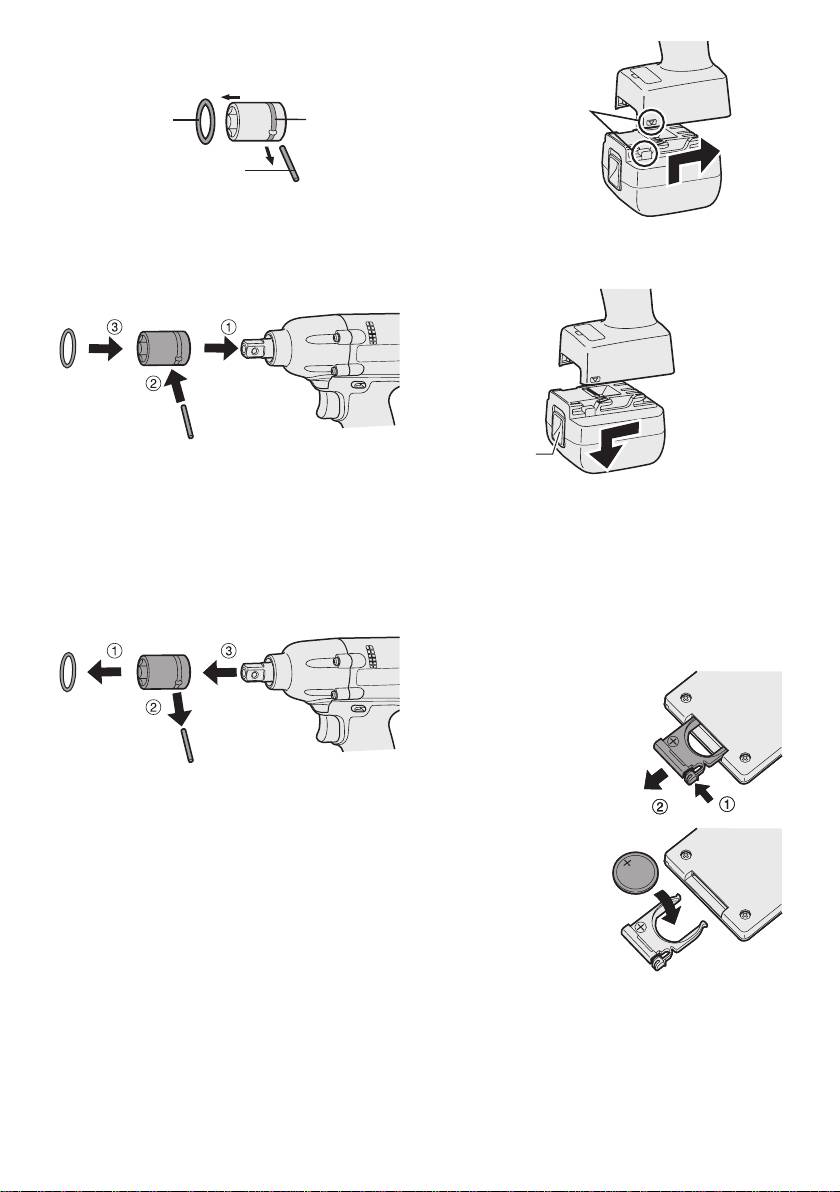

Attaching Socket

• Remove the socket’s rubber ring and pin.

Alignment

rubber

ring

groove

marks

pin

1 Attach the socket to the tool.

2 Insert

the pin. (Taking care to align the pin

2. To remove the battery pack:

holes on the socket and tool.)

Push up on the button from the front to re-

3 A

ttach the rubber ring by sliding it into place

lease the battery pack.

over the groove.

Button

NOTE:

Be sure to attach the rubber ring to prevent

the pin from falling out.

IV

. OPERATION

Removing Socket

Before Using the Remote

1 Remove the rubber ring.

2 Remove the pin.

Control (Available as an

3 R

emove the socket from the tool.

optional accessory)

Insert the battery

1. Pull out the battery holder.

1 P

ush in on the fas-

tener as indicated by

the arrow.

2 Pull out the holder

.

NOTE:

Keep the temperature of the tool above

the

freezing point (0°C/32°F) when attach-

2. Insert the battery and

ing sockets to or detaching them from

push the holder

the square drive on the tool. Do not use

back in.

excessive

force when attaching or detach-

ing sockets.

Attaching or Removing Bat-

tery Pack

NOTE:

1. To connect the battery pack:

•

If the tool does not respond to the wire-

Line up the alignment marks and attach

less remote control even when the remote

the battery pack.

control is operated close to the tool, the

battery (CR2025) is dead. Replace it with

•

Slide the battery pack until it locks into

a fresh battery.

position.

•

The included battery is provided for sam-

ple use and may not last as long as com-

mercially available batteries.

-

7

-

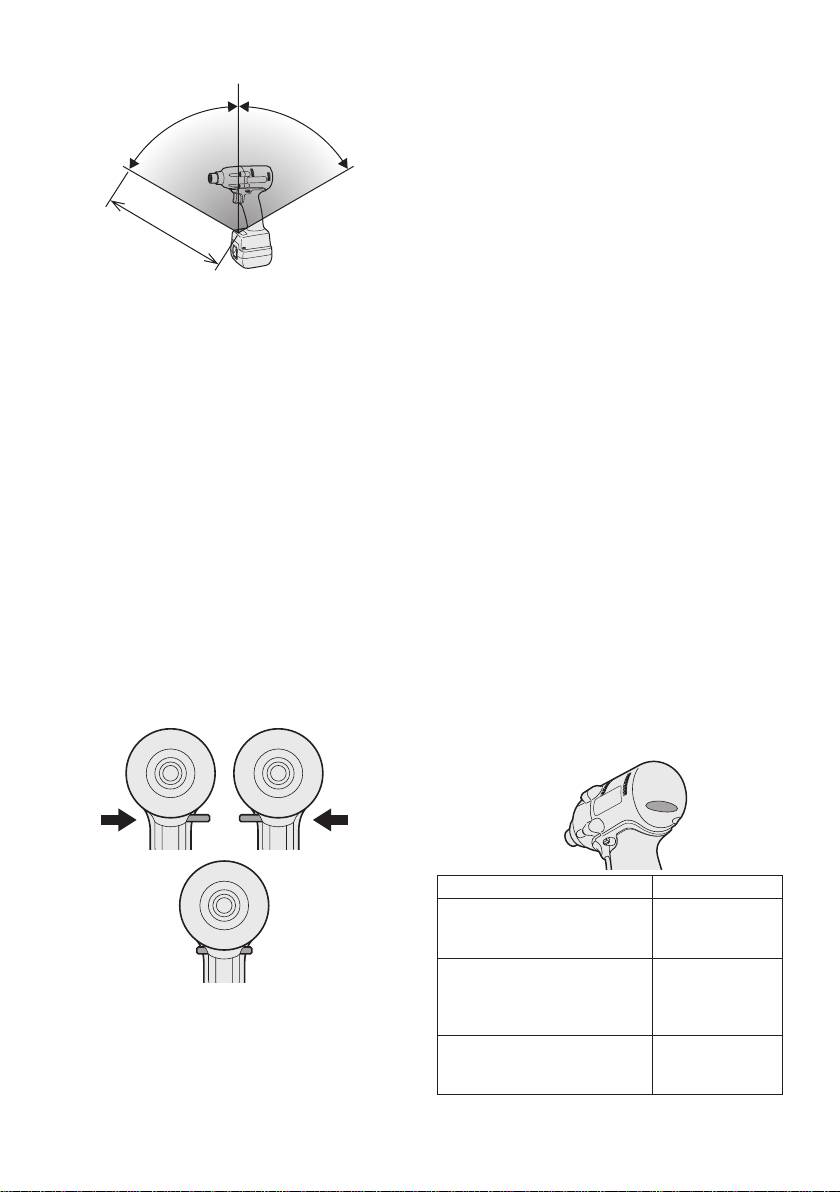

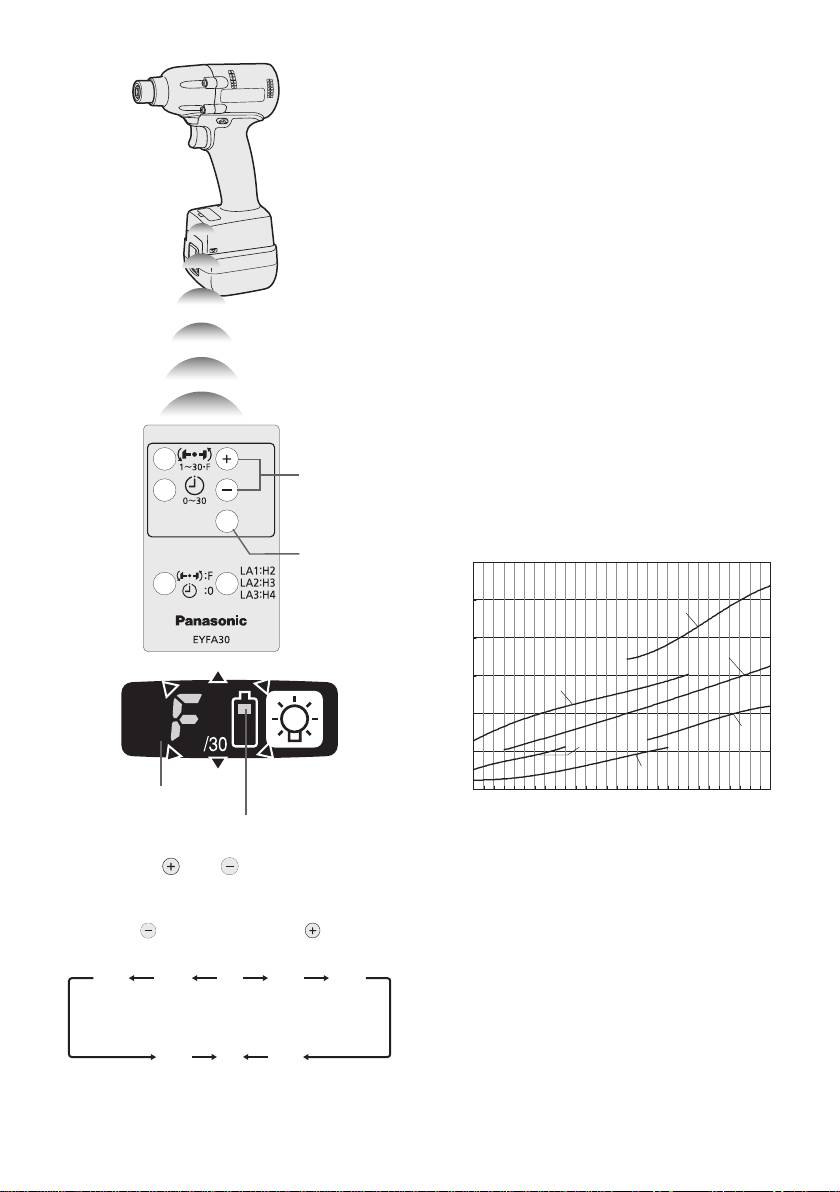

Wireless remote control range

-

8

-

Vertically

A

p

6

0

°

p

r

o

.

x

x

.

o

6

r

0

p

°

p

A

Approx. 50 cm

The remote control should be operated within

approximately 50 cm and approximately 60°

vertically and horizontally of the perpendicular

relative to the infrared receiver on the tool.

•

Under the following circumstances, you may

not be able to operate the tool, even within

this range.

•

If there is an object between the remote

control’s transmitter and the tool’s receiver.

•

Use outdoors or in other environments

where the remote control receiver is

exposed to a strong light source, or when

the remote control transmitter or receiver is

dirty may cause the tool to fail to respond,

even when the remote control is used within

the operating range.

[Main Body]

Switch and Forward/Reverse

Lever Operation

Forward Reverse

Switch lock

Forward Rotation Switch

Operation

1. Push the lever for forward rotation.

2. Depress the trigger switch slightly to start

the tool slowly.

3.

The speed increases with the amount of

depression of the trigger for efficient tight-

ening of screws. The brake operates and

the bit stops immediately when the trigger

is released.

4.

After use, set the lever to its center posi-

tion (switch lock).

Reverse Rotation Switch

Operation

1.

Push the lever for reverse rotation. Check

the

direction of rotation before use.

2.

Depress the trigger switch slightly to start the

tool slowly.

3. After use, set the lever to its center posi-

tion (switch lock).

CAUTION:

•

To eliminate excessive temperature

increase of the tool surface, do not

operate the tool continuously using two

or more battery packs. Tool needs cool

off time before switching to another

pack.

Tightening confirmation lamp

• The tightening confirmation lamp can be

used to check whether the torque control

function was activated.

Tool status Lamp display

Tightening complete

Green

(with torque control

(For approx. 2

function operation)

seconds)

•

Tightening not complete

Red

• Tightening complete

(For approx. 2

with retightening within 1

seconds)

CAUTION:

second

To prevent damage, do not operate

The automatic stop

Red

Forward/Reverse lever until the bit comes

function has been

(For approx. 5

to a complete stop.

activated.

minutes)

CAUTION:

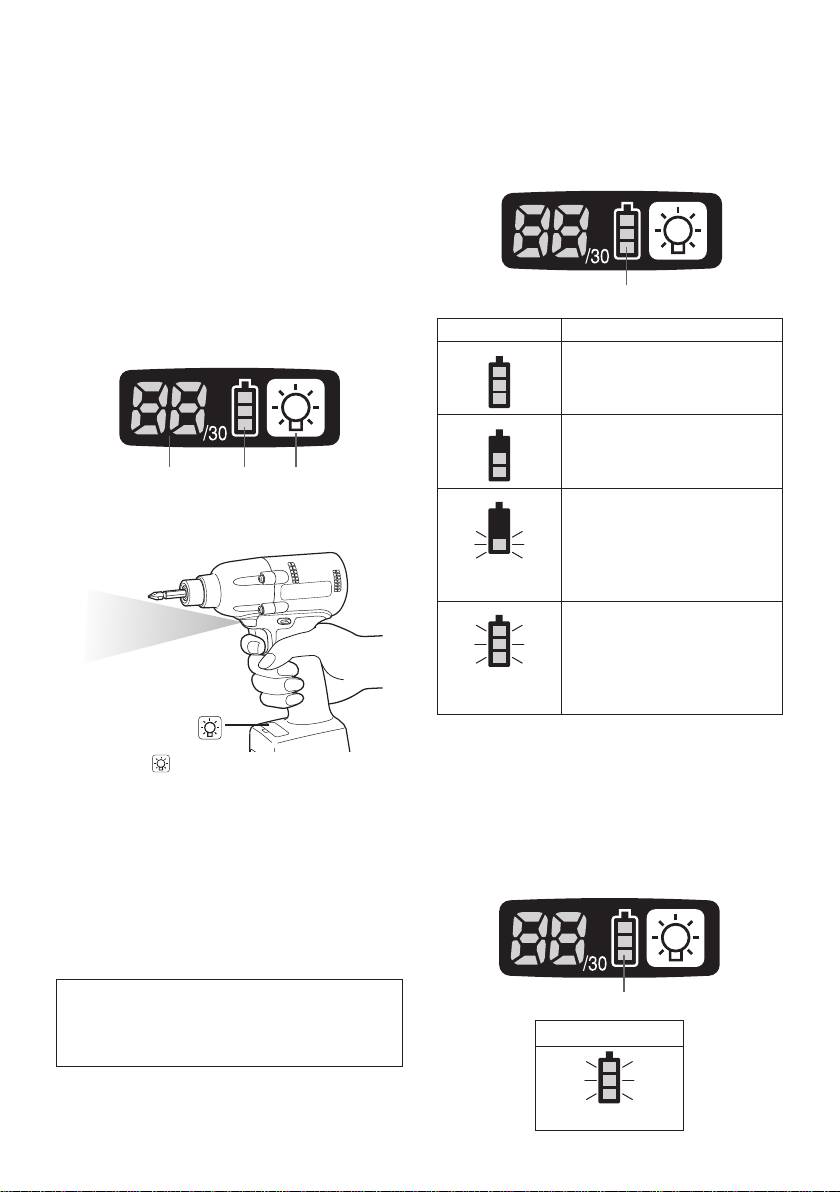

(2) The battery indication lamp

• When the tool stops automatically after

• Use the battery indication lamp to check

the switch is released during impact-

how much power is left in the battery.

mode tightening and then reengaged

within 1 second, the red lamp will light up

•

Battery life varies slightly with ambient tem-

to indicate the risk of excessive torque

perature and battery characteristics. The

application as a result of retightening.

lamp is designed to provide a rough indica-

tion of remaining battery life.

NOTE

•

The tightening confirmation lamp will not

turn on under the following conditions:

•

When the torque clutch is set to “F”

• During reverse rotation operation

• The lamp turns off when the tool is in

Battery indication lamp

operation.

Indicator Battery status

Control Panel

Fully charged

Approx. 40% or less

remaining

(1) (2) (3)

Flashing

(1) LED light

Approx. 20% or less

remaining (indicates need

to recharge battery)

The battery pack will need

Flashing

to be charged soon.

No charge

The battery pack needs to

be charged.

(The tool’s automatic

power-off function will

Flashing

activate at this stage.)

Automatic power-off function

Pressing the button toggles the LED light on

• The automatic power-off function is designed

and off.

to prevent a loss of tightening torque due

The light illuminates with very low current, and

to reduced battery voltage. Once it has

it does not adversely affect the performance

of

been activated, the tool will not operate until

the

tool during use or its battery capacity.

the battery pack has been charged (or re-

CAUTION:

placed with a fresh unit), even if the trigger is

•

The built-in LED light is designed to illu-

depressed.

minate the small work area temporarily.

•

Do not use it as a substitute for a regu-

lar

flashlight, since it does not have

enough brightness

.

Caution : DO NOT STARE INTO BEAM.

Battery indication lamp

Use of controls or adjustments or performance

of procedures other than those specied herein

Indicator

may result in hazardous radiation exposure.

Flashing

-

9

-

NOTE:

2

) Other

• All 3 bars on the battery indication lamp

• Bit and socket condition: Material,

will flash when the automatic power-off

amount of play, etc.

function is activated.

•

Use of a universal joint or socket

•

When the battery indication lamp begins

adapter

flashing, the battery pack should be

•

User: Manner in which the tool is

charged (or replaced with a fresh unit)

applied to the bolt, strength with which

immediately.

the tool is held, manner in which the

•

Be sure to fully charge the battery pack

tool’s switch is engaged

in question after activation of the auto-

•

Condition of object being tightened: Ma-

matic power-off function. Failure to do

terial, seating surface finish

so may prevent the automatic power-off

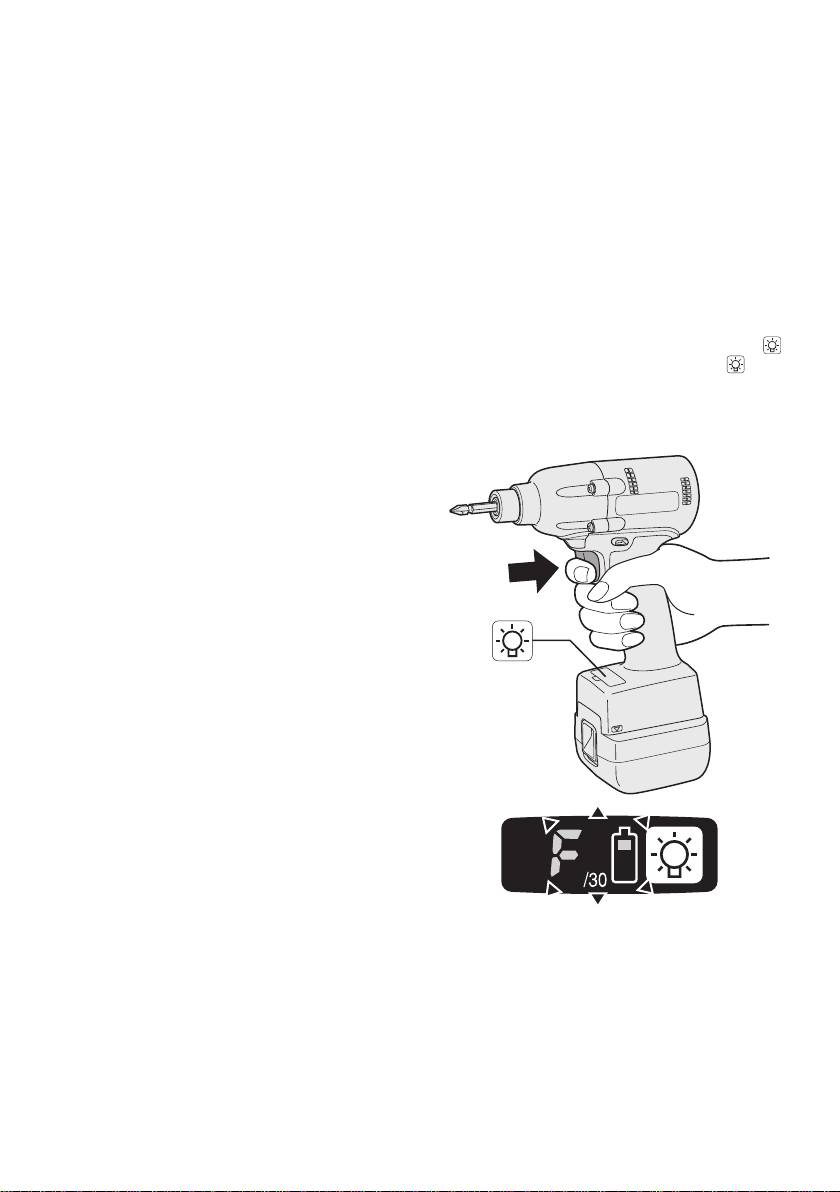

Setting the tool to configuration mode

function from being properly deactivated.

1.

Turn off the control panel.

(3) The torque control function

• If the control panel is on, remove and

then reinsert the battery pack.

• The torque control function calculates the

2.

Engage the switch while pushing the

load from the motor’s rotational angle during

button and then release both the

but-

the hammer impact and determines that the

ton and the switch.

bolt has been properly seated when a pre-

•

After all the LED lamps have turned off,

set load value is exceeded. Driving is then

the control panel will flash and change

automatically stopped after a preset number

to configuration mode.

of impacts have been delivered to the bolt.

CAUTION:

•

Always check the tool’s tightening torque

before use. Improper tool operation may

result in excessive or inadequate tight-

ening.

CAUTION:

•

Always operate the tool with the switch

fully engaged. The torque control func-

tion will not operate when the switch is

not sufficiently engaged, preventing the

tool from stopping automatically.

•

In work where a heavy load comes to

bear during tightening, the load may be

interpreted as the seating of the bolt,

preventing the bolt from being com-

pletely tightened.

•

Repeated tightening of the same bolt

may break the bolt or deform the mate-

rial into which the bolt is being driven as

a result of excessive tightening.

•

The tightening torque value and preci-

sion vary with factors such as the mate-

rial into which the bolt is being driven

and the condition of the socket being

NOTE:

used. Adjust the torque as necessary

• Tools ship from the factory set to “F”

for the work being performed. Bolt tight-

mode (torque control function off).

ening torque varies due to the factors

•

The control panel will turn off if the tool

described below.

is not operated for a period of 5 min-

1) Bolt

utes.

•

Bolt diameter: Tightening torque gener-

ally increases with bolt diameter.

•

Torque coefficient (indicated by the bolt

manufacturer), grade, length, etc.

-

10

-

Configuring the torque clutch setting

(1)

(2)

Display

Battery indication lamp

1. Press the and buttons to select the

clutch setting that is appropriate for the

work being performed.

-

11

-

1F30 229

3…28

•

You can select from 30 torque clutch

settings (1 to 30).

•

Use figures from the Tightening Torque

Chart to guide your selection of torque

clutch setting. (See the following tighten-

ing torque chart)

2.

Press the OK button to accept the select-

ed torque clutch setting.

•

The control panel will stop flashing and

light up.

CAUTION:

•

You must press the OK button in order

for the selected setting to take effect.

•

Be sure to verify the new value after

changing the setting. (See page 12.)

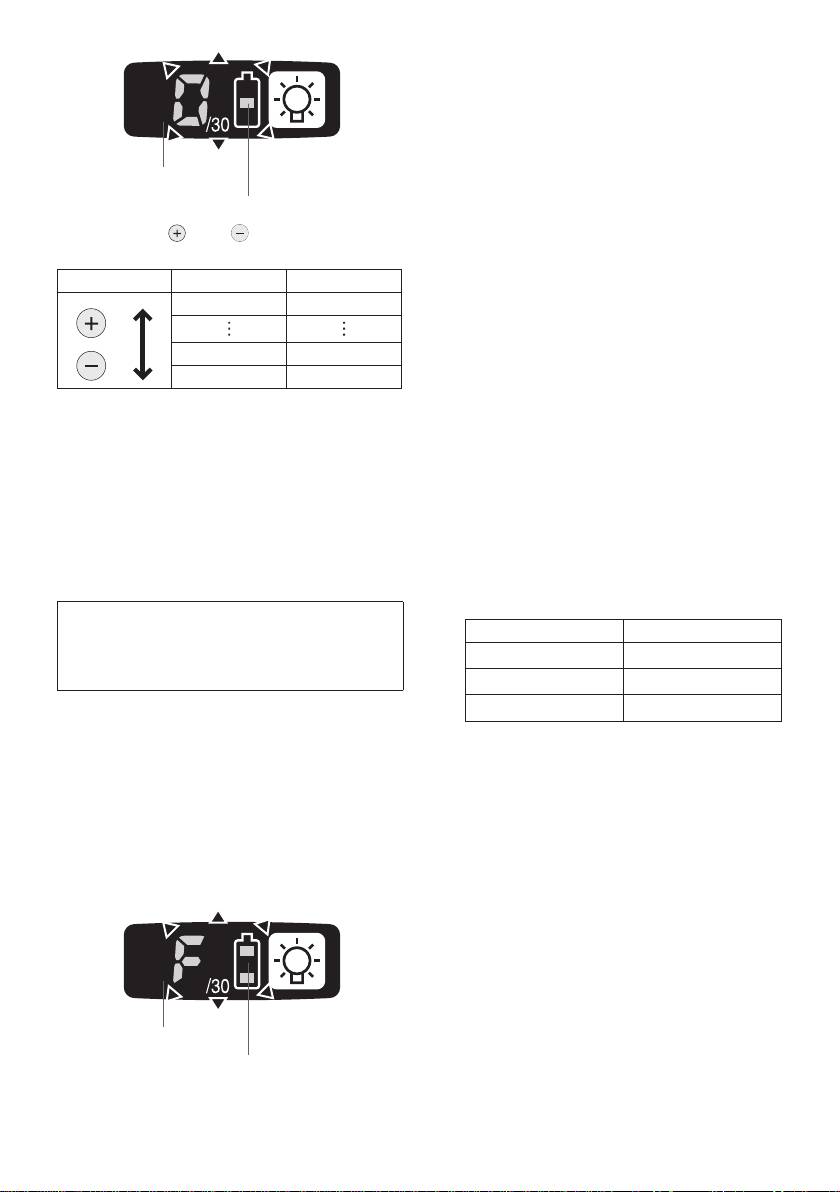

Tightening Torque Chart (for Reference

Use)

The values illustrated on this chart were mea-

sured under the conditions described below

and are provided for reference purposes.

Actual tightening torque varies with ambient

conditions (the particular bolt being tightened,

hardware being used, method of holding the

bolt in place, etc.).

As the button

As the button

is pressed

is pressed

• “F” indicates that the torque control func-

tion is off.

N • m

60

50

EYFLA3 (M10)

40

EYFLA2 (M8)

30

EYFLA3 (M8)

20

EYFLA1 (M8)

EYFLA2 (M6)

10

EYFLA1 (M6)

0

1 2 3 4 5 6 7 8 9 101112131415161718192021222324252627282930

Measurement conditions

• Temperature: Room temperature (20°C/68°F)

Using the Interval Set

•

The interval set operates to prevent the tool

from operating after it automatically stops as

a result of the torque control function, even if

the switch is engaged.

1.

Set the tool to configuration mode.

(See page 10.)

2. Press the interval set button.

• The control panel will begin flashing.

Display: The number 0 ashes on and off.

Battery indication lamp: The middle bar

of the battery ashes on and off.

•

The control panel will stop flashing and

light up.

Checking Tool Settings

•

This section describes how to have the tool

display current settings for approximately 3

seconds when the tool is stopped.

Display

•

You cannot check tool settings when the

control panel is turned off. First, engage

Battery indication lamp

the switch briefly to reactivate the display.

3. Press the and buttons to set the

Checking the torque clutch setting

desired time.

1.

Press the torque set button.

Buttons Display Seconds

• Control panel display

30 3

Display: The torque set lights up.

Battery indication lamp: The upper bar of

the battery ashes on and off.

1 0.1

0 Off

Checking the interval

1.

Press the interval set button.

4.

Press the OK button to accept the selected

• Control panel display

setting.

Display: The interval set lights up.

•

The control panel will stop flashing and

Battery indication lamp: The middle bar

light up, and the torque clutch setting

of the battery ashes on and off.

will be displayed.

Checking tool circuits

CAUTION:

1.

Press the torque set button.

•

Be sure to verify the new value after

• Control panel display

changing the setting.

Display: The torque set display lights up.

Battery indication lamp: The middle and

Initializing All Settings

lower bars of the battery ash on and off.

Factory settings

Display Tool circuit

• Torque clutch setting: “F” (torque con-

trol function off)

H2 EYFLA1

•

Interval setting: 0 (off)

H3 EYFLA

2

• This section explains how to revert all tool

H4 EYFLA3

settings to their default values at the time of

shipment from the factory.

NOTE:

•

The error display will be turned off.

• If you engage the switch while a setting

is being displayed, the control panel will

1. Set the tool to configuration mode.

revert to the torque clutch setting dis-

(See page 10.)

play.

2. Press the format button.

• The control panel will begin flashing.

CAUTION:

Display: The letter “F” ashes on and off.

•

The torque set display is not intended

Battery indication lamp: The upper and

to be used to identify the type of drive

lower bars of the battery ash on and off.

component parts (hammer, etc.) used

in a particular tool.

Display

Battery indication lamp

3. Press the OK button to accept the select-

ed setting.

-

12

-

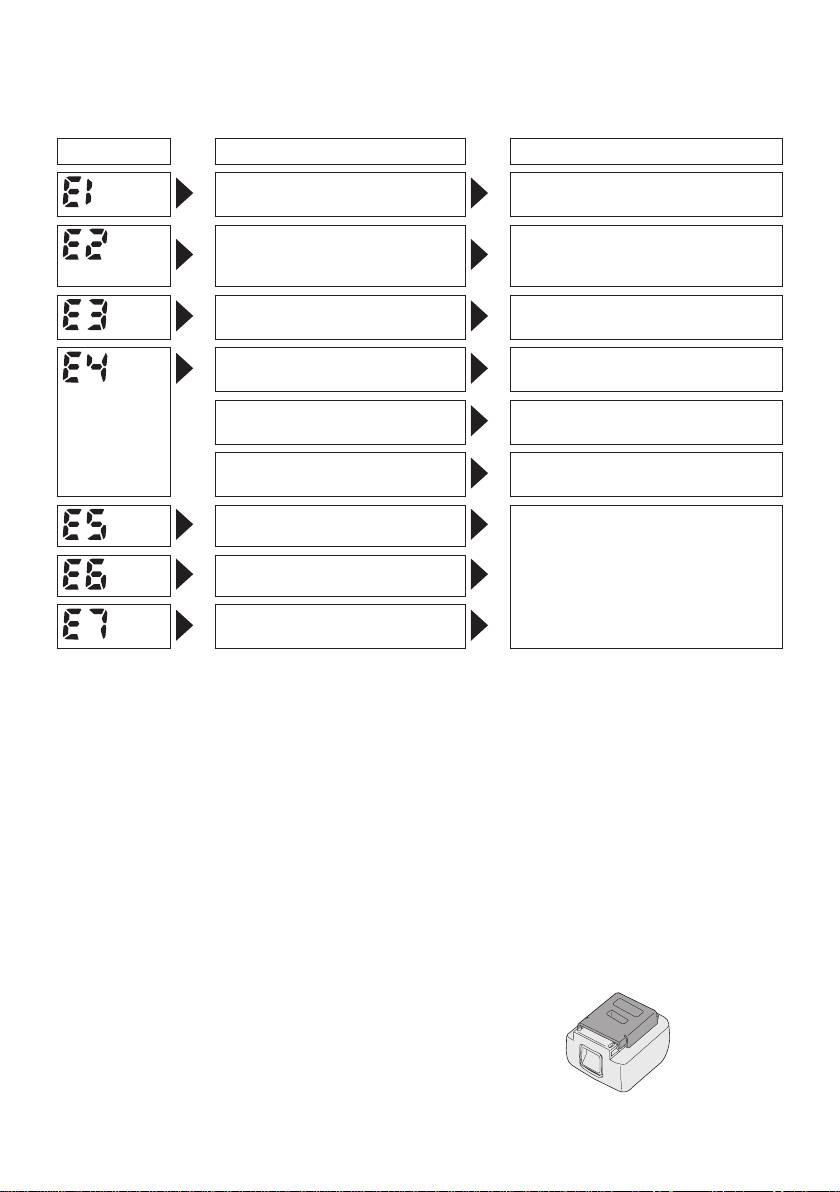

Error Display

In the event of a tool or battery pack malfunction, the control panel will display an error message.

Please check the tool or battery pack as described in the following chart before having them

serviced.

Display Likely cause Corrective action

Setting error Re-initialize the tool using the

remote control. (See page 12.)

The battery pack is too hot. Stop work and allow the battery

pack to cool before resuming use

of the tool.

The tool is too hot to operate. Stop work and allow the tool to

cool before resuming use.

The contacts that connect the

Remove any dirt.

battery pack and tool are dirty.

The battery pack has not been

Insert the battery pack rmly into

properly inserted into the tool.

the tool.

The pins on either the tool or

Replace the battery pack.

battery pack have worn down.

Motor failure, etc. Stop using the tool immediately.

Sensor malfunction, failure, etc.

Tool circuit malfunction, failure,

etc.

• When battery pack is not in use, keep it

[Battery Pack]

away from other metal objects like: paper

clips, coins, keys, nails, screws, or other

For Appropriate Use of Bat-

small metal objects that can make a con-

tery Pack

nection from one terminal to another.

Shorting

the battery terminals together may

cause sparks, burns or a fire.

Li-ion Battery Pack (EYFB30)

•

When operating the battery pack, make sure

• For optimum battery life, store the Li-ion bat-

the work place is well ventilated.

tery pack following use without charging it.

•

When the battery pack is removed from the

•

When charging the battery pack, confirm

main body of the tool, replace the battery

that the terminals on the battery charger

pack cover immediately in order to prevent

are free of foreign substances such as dust

dust or dirt from contaminating the battery

and water etc. Clean the terminals before

terminals and causing a short circuit.

charging the battery pack if any foreign sub-

stances are found on the terminals.

T

he life of the battery pack terminals may be

affected by foreign substances such as dust

and water etc. during operation.

-

13

-

Battery Pack Life

[Battery Charger]

The rechargeable batteries have a limited life.

If the operation time becomes extremely short

Charging

after recharging, replace the battery pack with

Read the operating manual for Panasonic battery

a new one.

charger for the battery pack before charging.

Battery Recycling

Before charging the battery

ATTENTION:

For environmental protection and recycling

When charging EYFB30:

of materials, be sure that it is disposed of

Charge the battery at a temperature of 5°C

at an ofcially assigned location, if there is

(41°F) to 40°C (104°F).

one in your country.

T

he battery pack cannot be charged at a tem-

perature of less than 5°C (41°F)

. If the tem-

perature of the battery pack is less than 5°C

(41°F), rst remove the battery pack from

the charger and allow it to sit for an hour in a

location where the temperature is 5°C (41°F) or

warmer. Then charge the battery pack again.

Information for Users on Collection and Disposal of Old Equip-

ment and used Batteries

These symbols on the products, packaging, and/or accompanying documents

mean that used electrical and electronic products and batteries should not be

mixed with general household waste.

F

or proper treatment, recovery and recycling of old products and used batteries,

please take them to applicable collection points, in accordance with your national

legislation and the Directives 2002/96/EC and 2006/66/EC.

By disposing of these products and batteries correctly, you will help to save valuable

resources and prevent any potential negative effects on human health and the

e

nvironment which could otherwise arise from inappropriate waste handling.

For more information about collection and recycling of old products and batteries,

please contact your local municipality, your waste disposal service or the point of

sale where you purchased the items.

P

enalties may be applicable for incorrect disposal of this waste, in accordance with

national legislation.

For business users in the European Union

If you wish to discard electrical and electronic equipment, please contact your dealer or

supplier for further information.

[Information on Disposal in other Countries outside the Euro-

pean Union]

These symbols are only valid in the European Union. If you wish to discard these items,

please contact your local authorities or dealer and ask for the correct method of disposal.

Note for the battery symbol (bottom two symbol examples):

This symbol might be used in combination with a chemical symbol. In this case it complies

with the requirement set by the Directive for the chemical involved.

-

14

-