AEG MFE1500 4935413605: 18 19ENGLISH ENGLISH

18 19ENGLISH ENGLISH: AEG MFE1500 4935413605

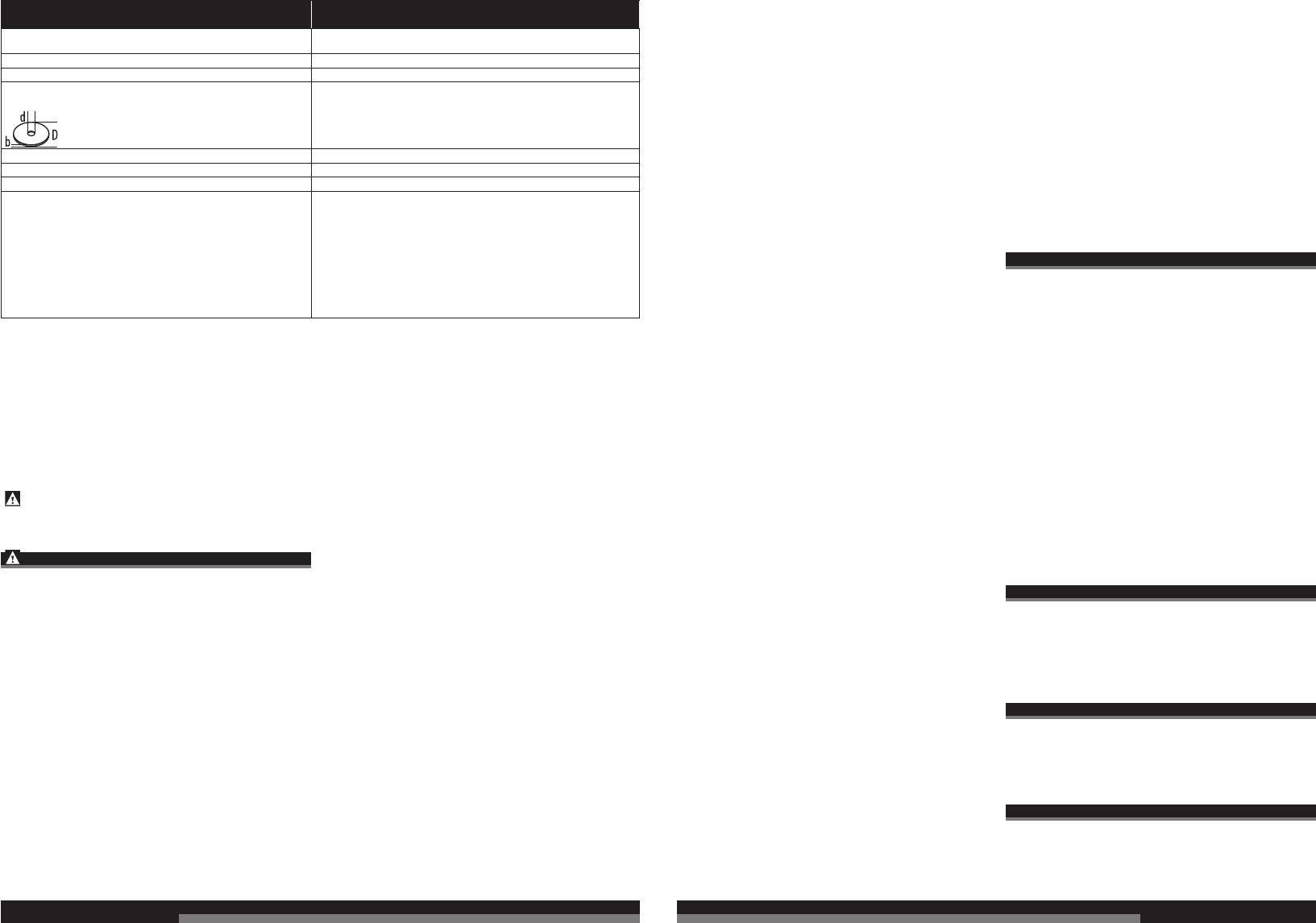

TECHNICAL DATA MFE 1500

of a broken wheel may fl y away and cause injury beyond

g) When wheel is binding or when interrupting a cut for

Wall Chaser

immediate area of operation.

any reason, switch off the power tool and hold the pow-

er tool motionless until the wheel comes to a complete

Production code 4136 06 02...

l) Hold the power tool by insulated gripping surfaces

stop. Never attempt to remove the wheel from the cut

...000001-999999

only, when performing an operation where the cutting

while the wheel is in motion otherwise kickback may oc-

Rated input 1500 W

accessory may contact hidden wiring or its own cord.

cur. Investigate and take corrective action to eliminate the

-1

Cutting accessory contacting a „live“ wire may make expo-

Rated speed 8600 min

cause of wheel binding.

sed metal parts of the power tool „live“ and could give the

D=Diamond cutting disk diameter max.

125 mm

operator an electric shock.

h) Do not restart the cutting operation in the workpiece.

d=hole diameter

22,2 mm

Let the wheel reach full speed and carefully re-enter the

m) Position the cord clear of the spinning accessory. If

cut. The wheel may bind, walk up or kickback if the power

you lose control, the cord may be cut or snagged and your

b=Cutting disk thickness min. / max.

2,4 / 2,6 mm

tool is restarted in the workpiece.

hand or arm may be pulled into the spinning accessory.

i) Support panels or any oversized workpiece to

n) Never lay the power tool down until the accessory

Cutting depth 8-30 mm

minimize the risk of wheel pinching and kickback. Large

has come to a complete stop. The spinning wheel may

workpieces tend to sag under their own weight. Supports

Cutting width 8-26 mm

grab the surface and pull the power tool out of your control.

must be placed under the workpiece near the line of cut and

Weight according EPTA-Procedure 01/2003 4,1 kg

o) Do not run the power tool while carrying it at your

near the edge of the workpiece on both sides of the wheel.

Noise/Vibration Information

side. Accidental contact with the spinning accessory could

j) Use extra caution when making a “pocket cut” into

Measured values determined according to EN 60 745.

snag your clothing, pulling the accessory into your body.

existing walls or other blind areas. The protruding wheel

Typically, the A-weighted noise levels of the tool are:

p) Regularly clean the power tool’s air vents. The

may cut gas or water pipes, electrical wiring or objects that

Sound pressure level (K=3dB(A)) 98 dB(A)

motor’s fan will draw the dust inside the housing and exces-

can cause kickback.

Sound power level (K=3dB(A)) 109 dB(A)

sive accumulation of powdered metal may cause electrical

hazards.

Wear ear protectors!

WALL CHASER & DUST EXTRACTOR TOOL SYSTEM

Vibration total values (triaxial vector sum) determined

q) Do not operate the power tool near fl ammable materi-

Use only dust extractors for dust class M with the wall

according to EN 60745.

als. Sparks could ignite these materials.

chaser. Dust capture and separation may not be as good

2

Vibration emission value a

7,0 m/s

r) Do not use accessories that require liquid coolants.

with other combinations.

h,SG

2

Uncertainty K 1,5 m/s

Using water or other liquid coolants may result in electrocu-

Observe the instructions for operating, maintaining and

tion or shock.

cleaning the dust extractor, including the fi lters. Empty the

dust container immediately when it becomes full.

WARNING

Further safety instructions for abrasive cutting-off

Use only the designated suction hose. Do not modify the

The vibration emission level given in this information sheet has been measured in accordance with a standardised test given

operations

suction hose. If masonry chunks enter the suction hose,

in EN 60745 and may be used to compare one tool with another. It may be used for a preliminary assessment of exposure.

stop work and clear the suction hose immediately. Avoid

Kickback and related warnings

The declared vibration emission level represents the main applications of the tool. However if the tool is used for different

kinking the suction hose.

applications, with different accessories or poorly maintained, the vibration emission may differ. This may signifi cantly increase

Kickback is a sudden reaction to a pinched or snagged

Clean and exchange fi lters regularly. Do not remove any

the exposure level over the total working period.

rotating wheel. Pinching or snagging causes rapid stalling of

fi lters or fi lter components.

the rotating wheel which in turn causes the uncontrolled

An estimation of the level of exposure to vibration should also take into account the times when the tool is switched off or

power tool to be forced in the direction opposite of the

Select wall chasers and cutting discs to suit the substrate

when it is running but not actually doing the job. This may signifi cantly reduce the exposure level over the total working period.

wheel’s rotation at the point of the binding.

material. Various types of cutting disc are available for

Identify additional safety measures to protect the operator from the effects of vibration such as: maintain the tool and the

different substrates.

For example, if an abrasive wheel is snagged or pinched by

accessories, keep the hands warm, organisation of work patterns.

the workpiece, the edge of the wheel that is entering into the

Use only diamond-tipped cutting discs. Segmented diamond

pinch point can dig into the surface of the material causing

discs may only be used if they have negative rake and the

the wheel to climb out or kick out. The wheel may either

gap between segments is no wider than 10 mm.

WARNING! Read all safety warnings and all

not suitable for the higher speed of a smaller tool and may

jump toward or away from the operator, depending on

burst.

Replace or resharpen cutting discs promptly whenever

instructions. Failure to follow the warnings and instructions

direction of the wheel’s movement at the point of pinching.

necessary. When cutting performance decreases, check

may result in electric shock, fi re and/or serious injury.

g) The outside diameter and the thickness of your

Abrasive wheels may also break under these conditions.

whether the cutting discs are worn and need to be replaced

Save all warnings and instructions for future reference.

accessory must be within the capacity rating of your

Kickback is the result of power tool misuse and/or incorrect

or resharpened.

power tool. Incorrectly sized accessories cannot be ade-

operating procedures or conditions and can be avoided by

CUT-OFF MACHINE SAFETY WARNINGS

quately guarded or controlled.

Start and continue grooves as described in the operating

taking proper precautions as given below.

instructions.

a) The guard provided with the tool must be securely

h) The arbour size of wheels and fl anges must properly

a) Maintain a fi rm grip on the power tool and position

attached to the power tool and positioned for maximum

fi t the spindle of the power tool. Wheels and fl anges with

your body and arm to allow you to resist kickback

WORKPLACE

safety, so the least amount of wheel is exposed towards

arbour holes that do not match the mounting hardware of

forces. Always use auxiliary handle, if provided, for

the operator. Position yourself and bystanders away

the power tool will run out of balance, vibrate excessively

Ensure compliance with the general requirements for

maximum control over kickback or torque reaction

from the plane of the rotating wheel. The guard helps to

and may cause loss of control.

construction work sites (provide adequate lighting, avoid fall

during start-up. The operator can control torque reactions

protect operator from broken wheel fragments and acciden-

hazards, etc.). Follow safety instructions.

i) Do not use damaged wheels. Before each use,

or kickback forces, if proper precautions are taken.

tal contact with wheel.

inspect the wheels for chips and cracks. If power tool

Ensure good ventilation.

b) Never place your hand near the rotating accessory.

b) Use only bonded reinforced or diamond cut-off

or wheel is dropped, inspect for damage or install an

Accessory may kickback over your hand.

Keep the work area clear and unobstructed. With relatively

wheels for your power tool. Just because an accessory

undamaged wheel. After inspecting and installing the

long grooves, the dust extractor must be able to move freely

can be attached to your power tool, it does not assure safe

wheel, position yourself and bystanders away from

c) Do not position your body in line with the rotating

with the chaser and/or travel directly after it.

operation.

the plane of the rotating wheel and run the power tool

wheel. Kickback will propel the tool in direction opposite to

at maximum no load speed for one minute. Damaged

the wheel’s movement at the point of snagging.

c) The rated speed of the accessory must be at least

WORK ORGANIZATION

wheels will normally break apart during this test time.

equal to the maximum speed marked on the power tool.

d) Use special care when working corners, sharp edges

Use hearing protection, eye protection, respiratory

Accessories running faster than their rated speed can break

j) Wear personal protective equipment. Depending on

etc. Avoid bouncing and snagging the accessory. Cor-

protection and (if necessary) gloves. At minimum, use a

and fl y apart.

application, use face shield, safety goggles or safety

ners, sharp edges or bouncing have a tendency to snag the

class FFP2 half-face particulate mask for respiratory

glasses. As appropriate, wear dust mask, hearing

rotating accessory and cause loss of control or kickback.

d) Wheels must be used only for recommended applica-

protection.

protectors, gloves and shop apron capable of stopping

tions. For example: do not grind with the side of cut-off

e) Do not attach a saw chain, woodcarving blade,

small abrasive or workpiece fragments. The eye protec-

Use a dust extractor to keep the workplace clean. To avoid

wheel. Abrasive cut-off wheels are intended for peripheral

segmented diamond wheel with a peripheral gap greater

tion must be capable of stopping fl ying debris generated

stirring up dust, do not sweep up dust deposits.

grinding, side forces applied to these wheels may cause

than 10 mm or toothed saw blade. Such blades create

by various operations. The dust mask or respirator must be

them to shatter.

frequent kickback and loss of control.

capable of fi ltrating particles generated by your operation.

TRANSPORT, HANDLING AND STORAGE

e) Always use undamaged wheel fl anges that are of

Prolonged exposure to high intensity noise may cause

f) Do not “jam” the wheel or apply excessive pressure.

correct diameter for your selected wheel. Proper wheel

Diamond cutting discs must be handled and transported

hearing loss.

Do not attempt to make an excessive depth of cut. Over-

fl anges support the wheel thus reducing the possibility of

stressing the wheel increases the loading and susceptibility

with care. Use the original packaging if possible, or use

k) Keep bystanders a safe distance away from work

wheel breakage.

to twisting or binding of the wheel in the cut and the possibi-

other suitable packaging.

area. Anyone entering the work area must wear per-

lity of kickback or wheel breakage.

f) Do not use worn down reinforced wheels from larger

Store the discs in a dry location where they are not exposed

sonal protective equipment. Fragments of workpiece or

power tools. Wheels intended for a larger power tool are

to mechanical damage.

18 19ENGLISH

ENGLISH

Оглавление

- 2 3

- 4 5

- 6 7

- 8 9

- 10 11

- 12 13

- 14 15

- 16 17

- 18 19ENGLISH ENGLISH

- 20 21 ENGLISH

- 22 23 DEUTSCH DEUTSCH

- 24 25 DEUTSCH DEUTSCH

- 26 27 FRANÇAIS FRANÇAIS

- 28 29 FRANÇAIS FRANÇAIS

- 30 31 ITALIANO ITALIANO

- 32 33 ITALIANO ITALIANO

- 34 35 ESPAÑOL ESPAÑOL

- 36 37 ESPAÑOL ESPAÑOL

- 38 39 PORTUGUES PORTUGUES

- 40 41 PORTUGUES PORTUGUES

- 42 43 NEDERLANDS NEDERLANDS

- 44 45 NEDERLANDS NEDERLANDS

- 46 47 DANSK DANSK

- 48 49 DANSK DANSK

- 50 51 NORSK NORSK

- 52 53 NORSK NORSK

- 54 55 SVENSKA SVENSKA

- 56 57 SVENSKA SVENSKA

- 58 59 SUOMI SUOMI

- 60 61 SUOMI SUOMI

- 62 63 ΕΛΛΗΝΙΚΑΕΛΛΗΝΙΚΑ

- 64 65 ΕΛΛΗΝΙΚΑΕΛΛΗΝΙΚΑ

- 66 67 TÜRKÇE TÜRKÇE

- 68 69 TÜRKÇE TÜRKÇE

- 70 71 ČESKY ČESKY

- 72 73 ČESKY ČESKY

- 74 75

- 76 77

- 78 79 POLSKI POLSKI

- 80 81 POLSKI POLSKI

- 82 83 MAGYAR MAGYAR

- 84 85 MAGYAR MAGYAR

- 86 87 SLOVENSKO SLOVENSKO

- 88 89 SLOVENSKO SLOVENSKO

- 90 91 HRVATSKIHRVATSKI HRVATSKI

- 92 93 HRVATSKI HRVATSKI

- 94 95 LATVISKI LATVISKI

- 96 97 LATVISKI LATVISKI

- 98 99

- 100 101

- 102 103 EESTI EESTI

- 104 105 EESTI EESTI

- 106 107 РУССКИЙРУССКИЙ

- 108 109 РУССКИЙРУССКИЙ

- 110 111 БЪЛГАРСКИ БЪЛГАРСКИ

- 112 113 БЪЛГАРСКИ БЪЛГАРСКИ

- 114 115 ROMÂNIA ROMÂNIA

- 116 117 ROMÂNIA ROMÂNIA

- 118 119 МАКЕДОНСКИ МАКЕДОНСКИ

- 120 121 МАКЕДОНСКИ МАКЕДОНСКИ

- 122 123 中文 中文

- 124 125

- 126 127 한국어 한국어