AEG WS13-125SXEK 4935451310: инструкция

Раздел: Строительство и ремонт

Тип: Сетевая угловая шлифовальная машина

Характеристики, спецификации

Инструкция к Сетевой угловой шлифовальной машиной AEG WS13-125SXEK 4935451310

WS 10-115 S, WS 10-115 SK, WS 10-125 S,

WS 10-125 SK, WS 12-125 S, WS 12-125 SK,

WS 13-125 SXE, WS 13-125 SXEK

Original instructions

Instrukcją oryginalną

Originalbetriebsanleitung

Eredeti használati utasítás

Notice originale

Izvirna navodila

Istruzioni originali

Originalne pogonske upute

Manual original

Instrukcijâm oriěinâlvalodâ

Manual original

Originali instrukcija

Oorspronkelijke gebruiksaanwijzing

Algupärane kasutusjuhend

Original brugsanvisning

Оригинальное руководство по

Original bruksanvisning

эксплуатации

Bruksanvisning i original

Оригинално ръководство за

експлоатация

Alkuperäiset ohjeet

Instrucţiuni de folosire originale

Πρωτότυπο οδηγιών χρήσης

Оригинален прирачник за работа

Orijinal işletme talimatı

Оригінал інструкції з експлуатації

Původním návodem k používání

Pôvodný návod na použitie

Technical Data,Safety Instructions, Specied Conditions of Use,

Please read and save

English

15

EC-Declaration of Conformity, Mains connection, Maintenance, Symbols

these instructions!

Technische Daten, Sicherheitshinweise, Bestimmungsgemäße Verwendung,

Bitte lesen und

Deutsch

20

CE-Konformitätserklärung, Netzanschluss, Wartung, Symbole

aufbewahren!

Caractéristiques techniques, Instructions de sécurité, Utilisation conforme aux

A lire et à conserver

Français

25

prescriptions, Déclaration CE de Conformité, Branchement secteur, Entretien, Symboles

soigneusement

Dati tecnici,Norme di sicurezza,Utilizzo conforme, Dicharazione di Conformità CE,

Si prega di leggere e

Italiano

30

Collegamento alla rete, Manutenzione, Simboli

conservare le istruzioni!

Datos técnicos, Instrucciones de seguridad, Aplicación de acuerdo a la nalidad,

Lea y conserve estas

Español

35

Declaracion de Conformidad CE, Conexión eléctrica, Mantenimiento, Símbolos

instrucciones por favor!

Características técnicas, Instruções de segurança, Utilização autorizada,

Por favor leia e conserve

Português

40

Declaração de Conformidade CE, Ligação à rede, Manutenção, Symbole

em seu poder!

Technische gegevens, Veiligheidsadviezen, Voorgeschreven gebruik van het

Lees en let goed

Nederlands

45

systeem, EC-Konformiteitsverklaring, Netaansluiting,Onderhoud, Symbolen

op deze adviezen!

Tekniske data, Sikkerhedshenvisninger, Tiltænkt formål,

Vær venlig at læse

Dansk

50

CE-Konformitetserklæring, Nettilslutning, Vedligeholdelse, Symboler

og Opbevare!

Tekniske data, Spesielle sikkerhetshenvisninger, Formålsmessig bruk,

Vennligst les og oppbevar!

Norsk

55

CE-Samsvarserklæring, Nettilkopling, Vedlikehold, Symboler

Tekniska data, Säkerhetsutrustning, Använd maskinen Enligt anvisningarna,

Läs igenom och spara!

Svenska

60

CEFörsäkran, Nätanslutning, Skötsel, Symboler

Tekniset arvot, Turvallisuusohjeet, Tarkoituksenmukainen käyttö,

Lue ja säilytö!

Suomi

65

Todistus CE-standardinmukaisuudesta, Verkkoliitäntä, Huolto, Symbolit

Τεχνικά στοιχεία, Ειδικές υποδείξεις ασφάλειας, Χρήση σύμφωνα με το σκοπό

Ελληνικά

70

προορισμού, Δήλωση πιστότητας ΕΚ, Μπαταρίες, Χαρακτηριστικά, Συντήρηση, Σύμβολα.

Teknik veriler, Güvenliğiniz için talimatlar, Kullanim, CE uygunluk beyanice,

Lütfen okuyun ve saklayın

Türkçe

75

Şebeke bağlantisi, Bakim, Semboller

Technická data, Speciální bezpečnostní upozornění, Oblast využití,

Po přečtení uschovejte

Česky

80

Ce-prohlášení o shodě, Připojení na sít, Údržba, Symboly

Technické údaje, Špeciálne bezpčènostné pokyny, Použitie podl’a predpisov,

Prosím prečítať a uschovať!

Slovensky

85

CE-Vyhlásenie konformity, Siet’ová prípojka, Údrzba, Symboly

Dane techniczne, Specjalne zalecenia dotyczące bezpiecze´nstwa, Użytkowanie zgodne z

Należy uważnie przeczytać i

Polski

90

przeznaczeniem, Świadectwo zgodności ce, Podłączenie do sieci, Gwarancja, Symbole

zachować do wglądu!

Műszaki adatok, Különleges biztonsági tudnivalók, Rendeltetésszerű használat,

Olvassa el és őrizze meg

Magyar

95

Ce-azonossági nyilatkozat, Hálózati csatlakoztatás, Karbantartás, Szimbólumok

Tehnični podatki, Specialni varnostni napotki, Uporaba v skladu z namembnostjo,

Prosimo preberite

Slovensko

100

Ce-izjava o konformnosti, Omrežni priključek, Vzdrževanje, Simboli

in shranite!

Tehnički podaci, Specijalne sigurnosne upute, Propisna upotreba,

Molimo pročitati i sačuvati

Hrvatski

105

CE-Izjava konformnosti, Priključak na mrežu, Održavanje, Simboli

Tehniskie dati, Speciālie drošības noteikumi, Noteikumiem atbilstošs izmantojums,

Pielikums lietošanas pamācībai

Latviski

110

Atbilstība CE normām, Tīkla pieslēgums, Apkope, Simboli

Techniniai duomenys, Ypatingos saugumo nuorodos, Naudojimas pagal paskirti,

Prašome perskaityti

Lietuviškai

115

CE Atitikties pareiškimas, Elektros tinklo jungtis, Techninis aptarnavimas, Simboliai

ir neišmesti!

Tehnilised andmed, Spetsiaalsed turvajuhised, Kasutamine vastavalt otstarbele,

Palun lugege läbi ja hoidke alal!

Eesti

120

EÜ Vastavusavaldus, Võrku ühendamine, Hooldus, Sümbolid

Òåõíè÷åñêèå äàííûå, Ðåêîìåíäàöèè ïî òåõíèêå áåçîïàñíîñòè,

Пожалуйста прочтите и

Pусский

125

Èñïîëüçî- âàíèå, Ïîäêëþ÷åíèå ê ýëåêòðîñåòè, Îáñëóæèâàíèå, Ñèìâîëû

сохраните эту инструкцию.

Òåõíè÷åñêè äàííè, Ñïåöèàëíè óêàçàíèÿ çà áåçîïàñíîñò, Èçïîëçâàíå ïî ïðåäíàçíà÷åíèå,

Моля прочетете и запазете!

Български

131

ÑÅ-Äåêëàðàöèÿ çà ñúîòâåòñòâèå, Ñâúðçâàíå êúì ìðåæàòà, Ïîääðúæêà, Ñèìâîëè

Date tehnice, Instrucţiuni de securitate, Condiţii de utilizare specifcate,

Va rugăm citiţi şi păstraţi

Română

136

Declaraţie de conformitate, Acumulatori, Intreţinere, Simboluri

aceste instrucţiuni

Òåõíè÷êè Ïîäàòîöè, Óïàòñòâî Çà Óïîòðåáà, Ñïåöèôèöèðàíè Óñëîâè Íà

Ве мoлиме прочитаjте го и

Мaкeдohcки

141

Óïîòðåáà, Åó-äåêëàðàöè¼à Çà Ñîîáðàçíîñò, БАТЕРИИ, Îäðæóâàњå, Ñèìáîëè

чувајте го ова упатство!

Технічні характеристики, Вказівки З Техніки Безпеки, Використання за призначенням,

Прочитайте та збережіть

Українська

146

Сертифікат Відповідності Вимогам Єс, Підключення до мережі, Обслуговування, Символи

цю інструкцію.

155

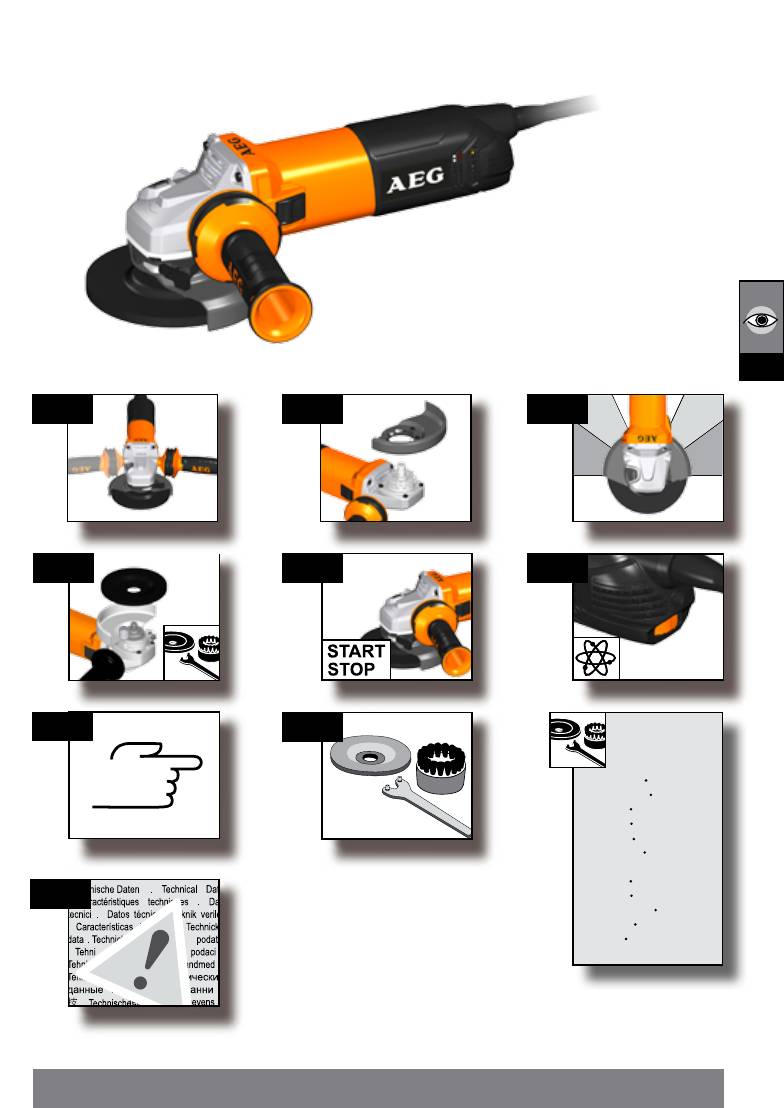

VII

TIP

I II III

IV

V

VI

Accessory

VIII

Zubehör

Accessoires

Accessorio

Accessorio Acessório

Toebehoren

Tilbehør

Tilbehør

Tillbehör

Lisälaite

Aksesuar

Příslušenství

Príslušenstv

Azokat a tartozékokat

Oprema

Piederumi

IX

Priedas

Tarvikud

Äîïîëíèòåëü

Accesoriu

A B

I

2

II

1.

2.

4.3.

2

1

3

60

°

°

60

0°

30

°

°

30

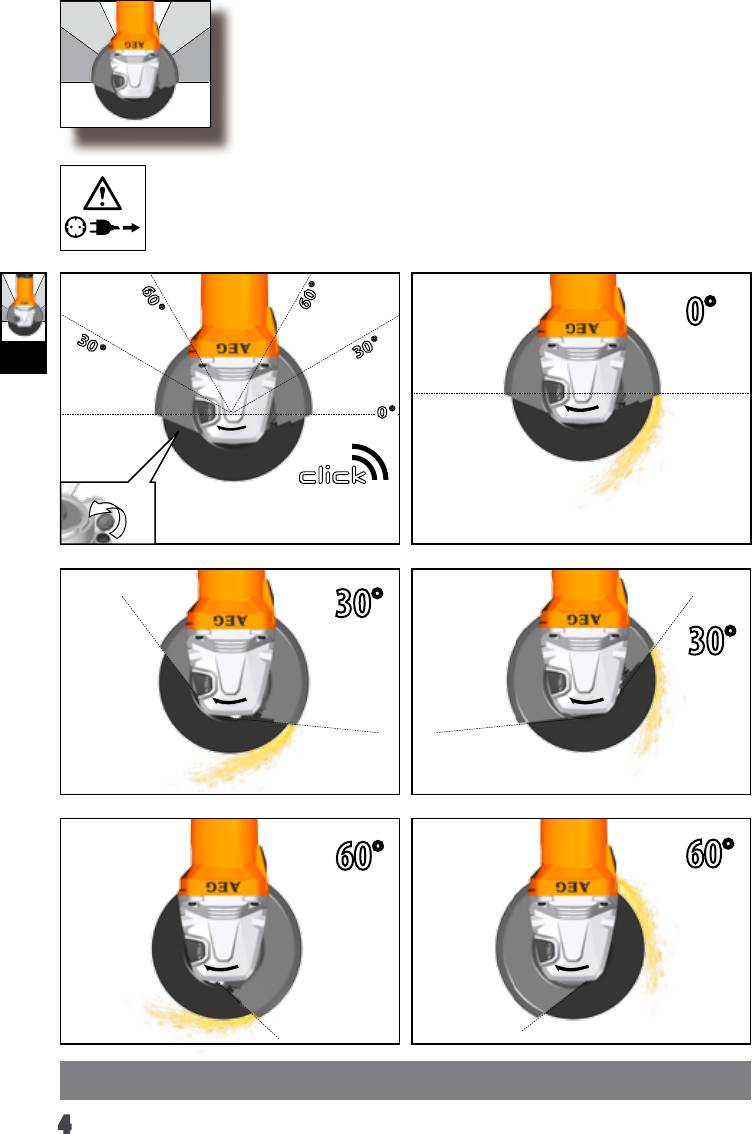

III

0

°

30°

30°

60°

60°

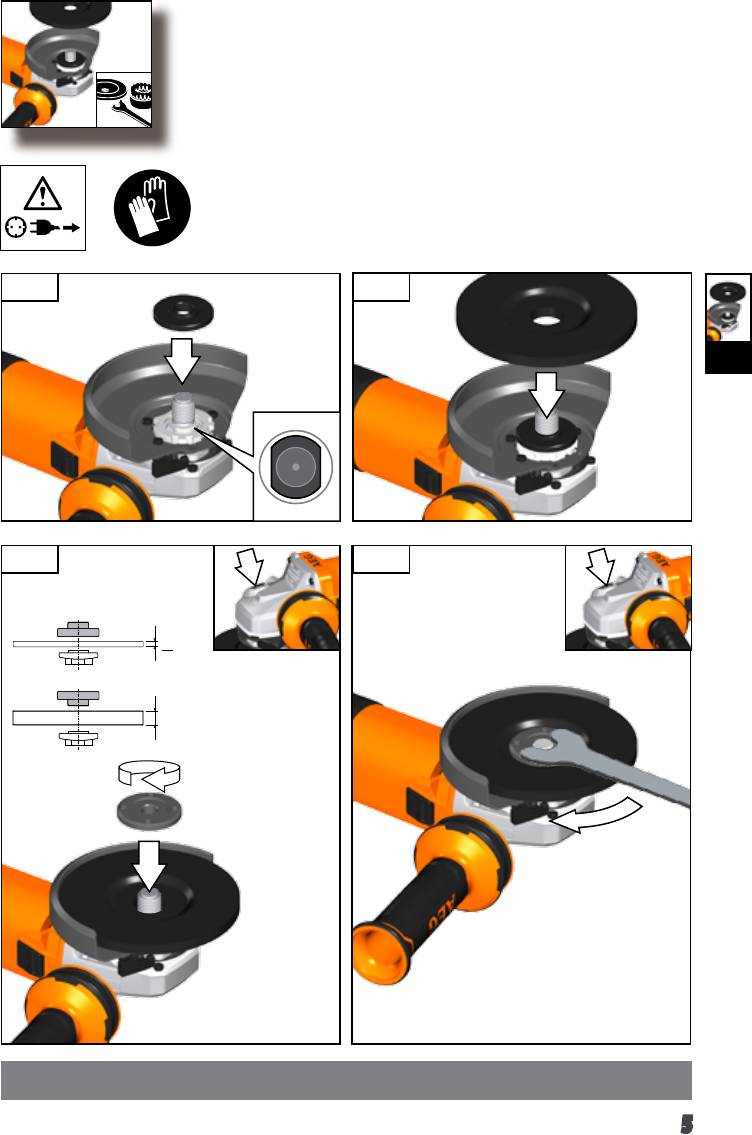

4

1.

2.

IV

3.

4.

< 6 mm

> 6 mm

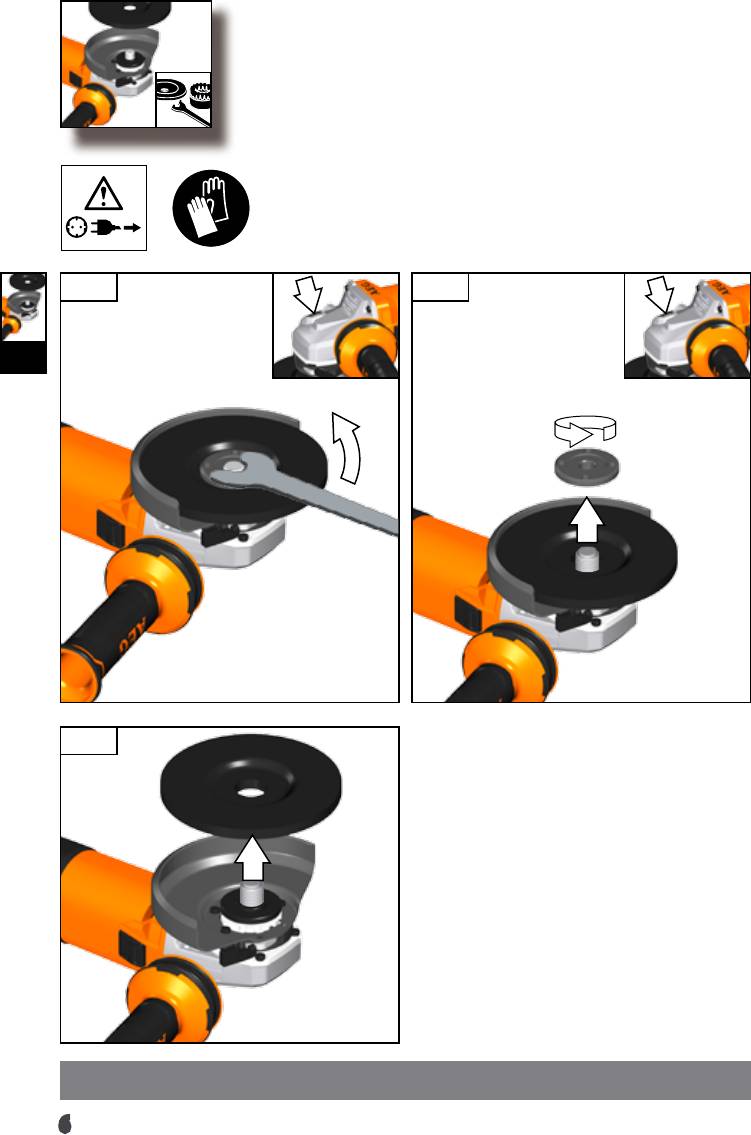

5

2.1.

IV

3.

6

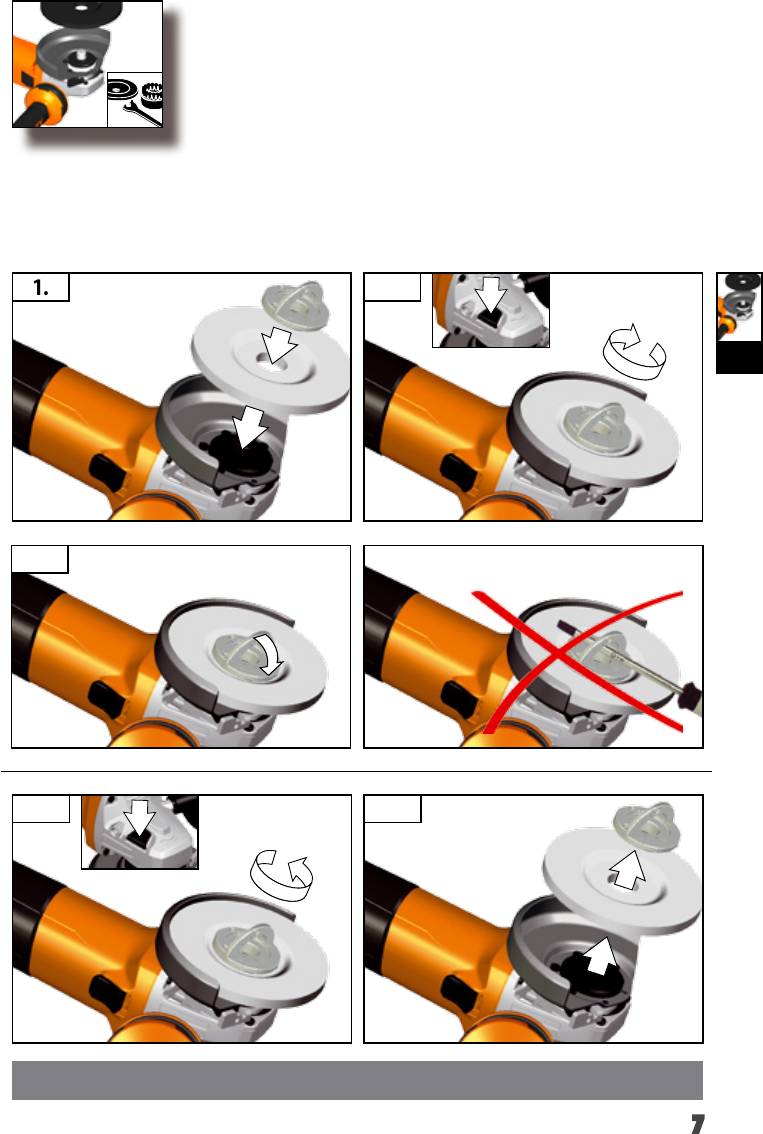

WS ...-... X...

1. 2.

IV

3.

1. 2.

7

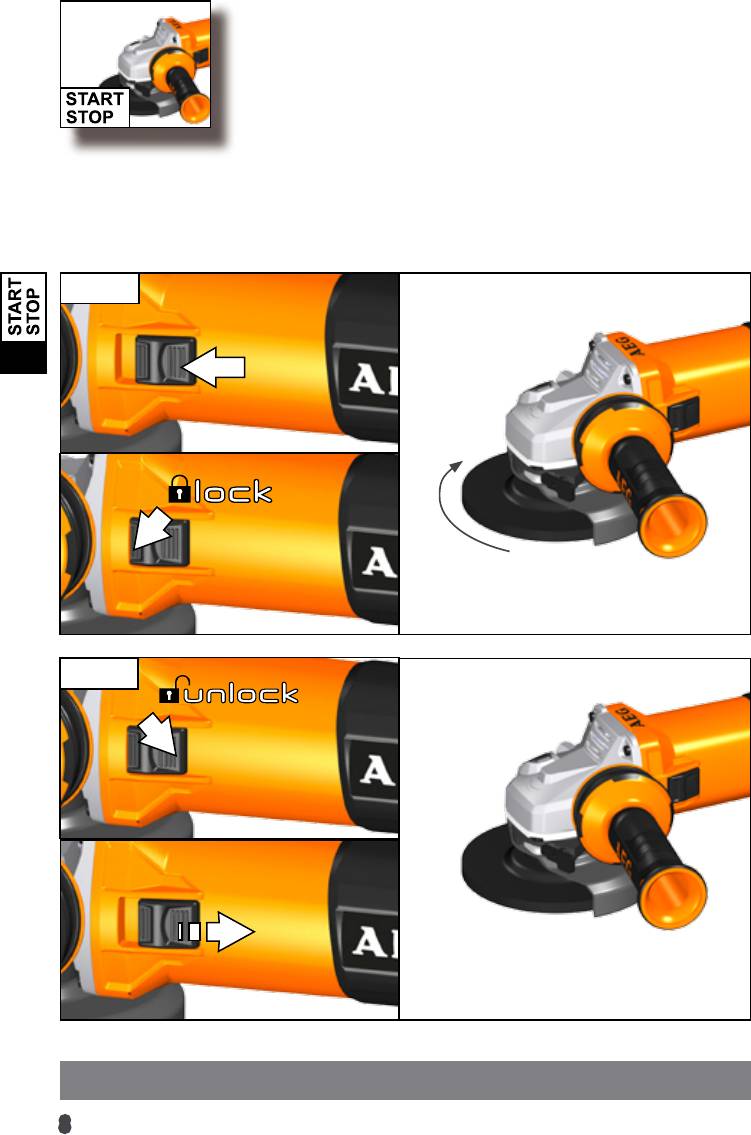

Start

V

Stop

8

Startup protection:

Ochrana proti opätovnému nábehu

When switched on, the machine will not start up after voltage break-

Zapnutá rozbrusovačka sa v prípade výpadku prúdu po jeho opätovnom

down. To continue working, switch the machine o and then on again.

zapnutí sama nerozbehne. K pokračovaniu práce sa rozbrusovačka musí

vypnúť a opäť zapnúť.

Wiederanlaufschutz:

Eingeschaltete Maschine läuft nach Spannungsausfall nicht wieder an.

Zabezpieczenie przed ponownym uruchomieniem

Um weiter zu arbeiten Maschine aus- und wieder einschalten.

Włączone urządzenie nie uruchamia się z powrotem po ustąpienia

V

zaniku napięcia. Aby móc kontynuować pracę, urządzenie należy

Dispositif de protection contre un redemarrage

wyłączyć, a potem z powrotem włączyć.

Après une coupure de tension, la machine enclenchée ne redémarre

pas. Pour continuer à travailler, il convient d‘éteindre la machine et de

Újraindulás elleni védelem

l‘enclencher à nouveau.

A bekapcsolt gép feszültségkimaradás után ismét elindul. A munka

folytatásához a gépet ki és újra be kell kapcsolni.

Protezione contro il riavvio

La macchina accesa non riparte in seguito alla caduta della tensione.

Zaščita pred ponovnim zagonom

Per poter continuare a lavorare bisogna prima spegnere e poi riaccen-

Vklopljen stroj se po izpadu napetosti ponovno ne zažene. Za nadalje-

dere la macchina.

vanje dela stroj izklopite in ponovno vklopite.

Protección contra el rearranque

Zaštita protiv ponovnog pokretanja

La máquina conectada no se vuelve a poner en marcha después de

Uključeni stroj poslilje nestanka napona više ne starta. Da bi se dalje

un fallo de corriente. Para continuar el trabajo, desconectar y volver a

radilo, stroj isključiti i ponovno uključiti.

conectar la máquina.

Aizsardzība pret atkārtotu palaišanu

Protecção de reinício

Pārtrūkstot strāvas padevei, ieslēgtā ierīce no jauna neieslēdzas. Darba

Quando está ligada, após uma falha de energia a máquina não retoma o seu

turpināšanai ierīci izslēgt un ieslēgt no jauna.

funcionamento. Para prosseguir o trabalho, desligar a máquina e voltar a ligá-la.

Apsauga nuo pakartotinio įsijungimo

Herstartbeveiliging

Jei darbo metu dingsta įtampa, ją sutvarkius, mašina neįsijungia

Na spanningsuitval schakelt de machine niet automatisch weer in.

automatiškai. Norint vėl dirbti su mašina, reikia ją išjungti ir vėl įjungti.

Schakel de machine uit en weer in om door te kunnen werken.

Taaskäivituskaitse

Genstartsbeskyttelse

Sisselülitatud masin ei käivitu enam uuesti pärast voolukatkestust. Töö

I tilfælde af spændingsudfald, mens maskinen kører, går den ikke i gang

jätkamiseks lülitage masin välja ja seejärel taas sisse.

igen, når spændingen kommer tilbage. For at genoptage arbejdet skal

maskinen slukkes og tændes igen.

При исчезновении напряжения устройство не работает. Для

Automatisk gjenstartsbeskyttelse

продолжения работы устройство выключите и снова

En påslått maskin begynner ikke automatisk å gå igjen etter strømbrudd.

.

For å kunne fortsette å arbeide må maskinen skues av og så på igjen.

Защита от повторно пускане След спиране на електрозахранването

Återstartsskydd

включената машина не започва да работи отново. За да

En påslagen maskin startar inte själv efter ett strömavbrott. Stäng först

продължите работа изключете и отново включете машината.

av och slå sedan på maskinen igen för att fortsätta att arbeta.

Protecie contra repornirii

Uudelleenkäynnistyssuoja

Maşina conectată nu reporneşte după o întrerupere de curent. Pentru a

Päällekytketty kone ei käynnisty sähkökatkon jälkeen uudestaan. Työn

putea lucra în continuare, maşina trebuie oprită şi apoi repornită.

jatkamiseksi tulee kone sammuttaa ja käynnistää uudelleen.

Προστασια επανεκκινηση

Вклучената машина во случај на снемување струја не се вклучува

Η ενεργοποιημένη μηχανή δεν ξεκινά πάλι από μόνη της μετά από μια

повторно. За да продолжите со работа исклучете ја машината и

πτώση ρεύματος. Για να συνεχίσετε την εργασία, απενεργοποιείτε και

вклучете ја повторно.

ενεργοποιείτε πάλι τη μηχανή.

Tekrar çalitirmada koruma

Увімкнена машина не продовжує роботу після того, як була

Çalıştırılan makine voltaj kaybından sonra yeniden çalışmaz. Makineyi

вставлена акумуляторна батарея.

tekrar çalıştırmak için kapatın ve tekrar açın.

Ochrana proti opětovnému náběhu

Zapnutá rozbrušovačka se v případě výpadku proudu po jeho

opětovném zapnutí sama nerozběhne. K pokračování práce se

rozbrušovačka musí vypnout a opět zapnout.

9

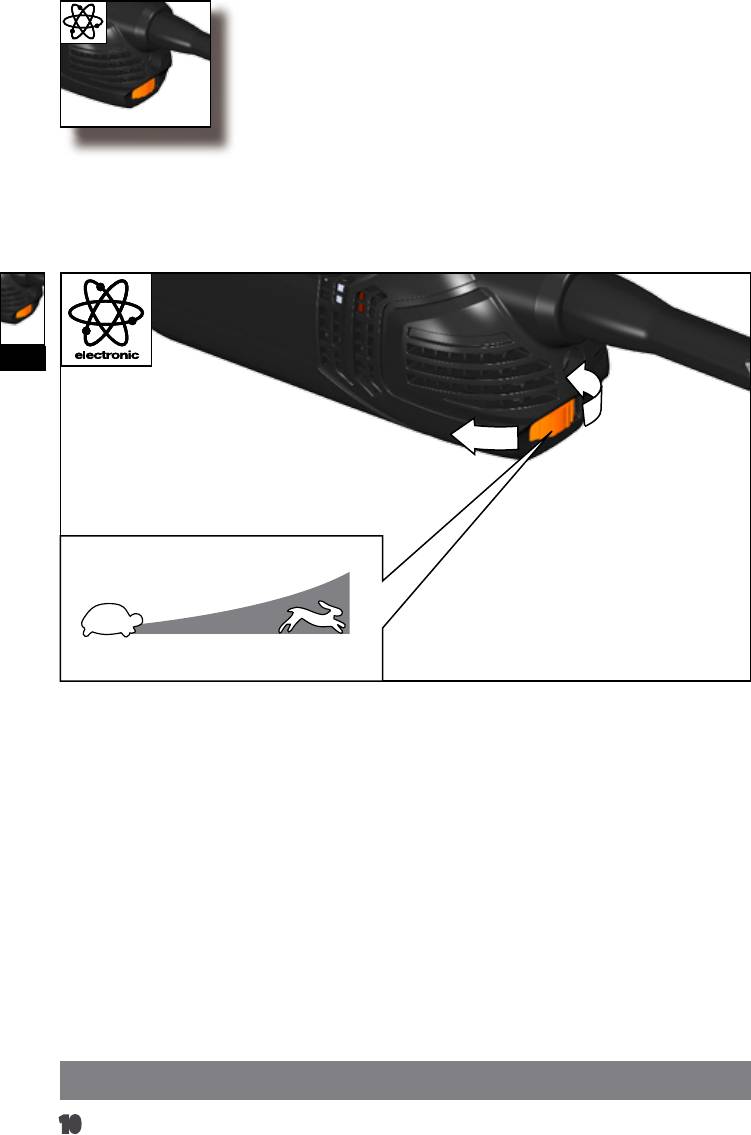

WS ...-... E...

VI

10

TIP

TIP

< 30°

11

TIP

VII

Accessory

Tilbehør

Príslušenstv

Aksessuaarid

Zubehör

Tilbehør

Äîïîëíèòåëü

Accessoires

Tillbehör

Tartozékokat

Accessorio

Lisälaite

Oprema

Accesoriu

Accessorio

Piederumi

Acessório

Aksesuar

Prieda

Toebehoren

Tarvikud

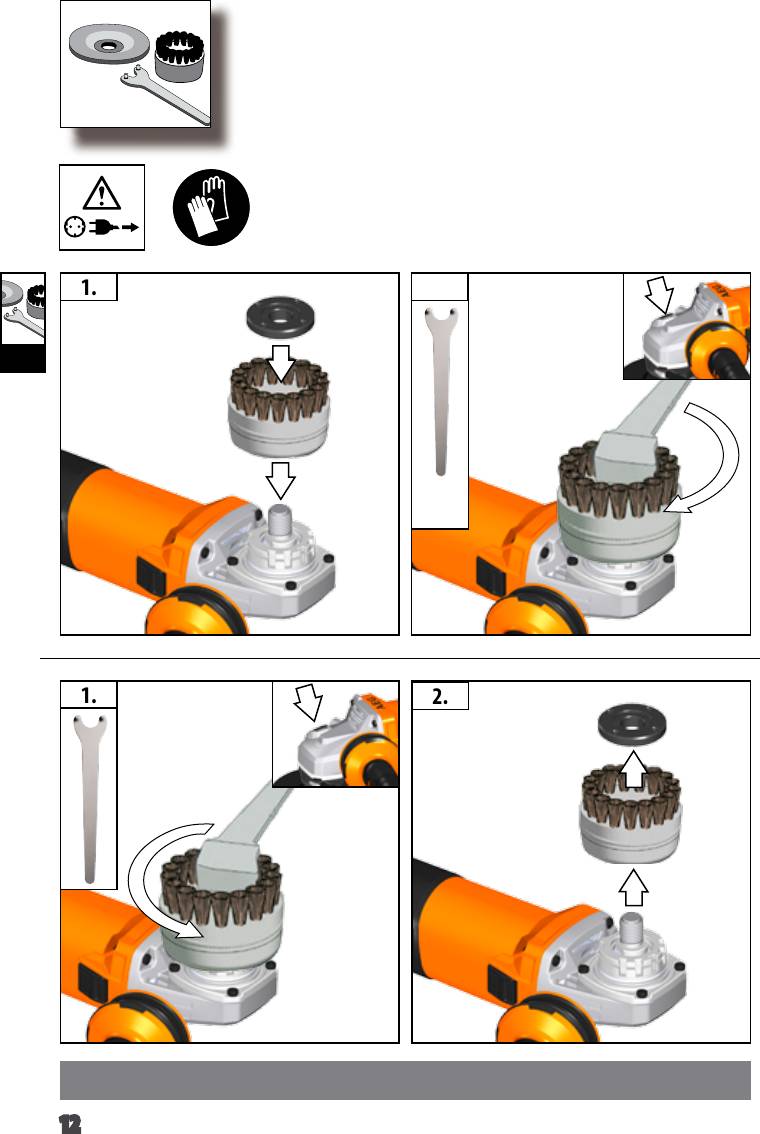

1. 2.

VIII

1.

2.

12

Accessory

Tilbehør

Príslušenstv

Aksessuaarid

Zubehör

Tilbehør

Äîïîëíèòåëü

Accessoires

Tillbehör

Tartozékokat

Accessorio

Lisälaite

Oprema

Accesoriu

Accessorio

Piederumi

Acessório

Aksesuar

Prieda

Toebehoren

Tarvikud

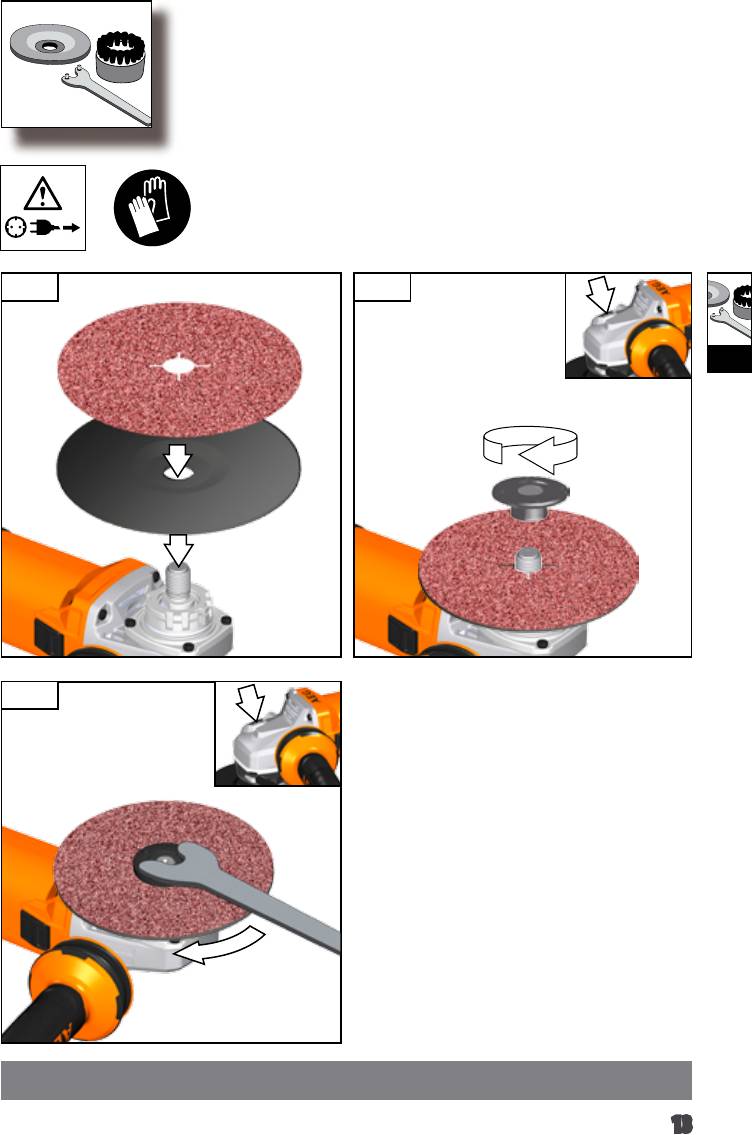

1.

2.

VIII

3.

13

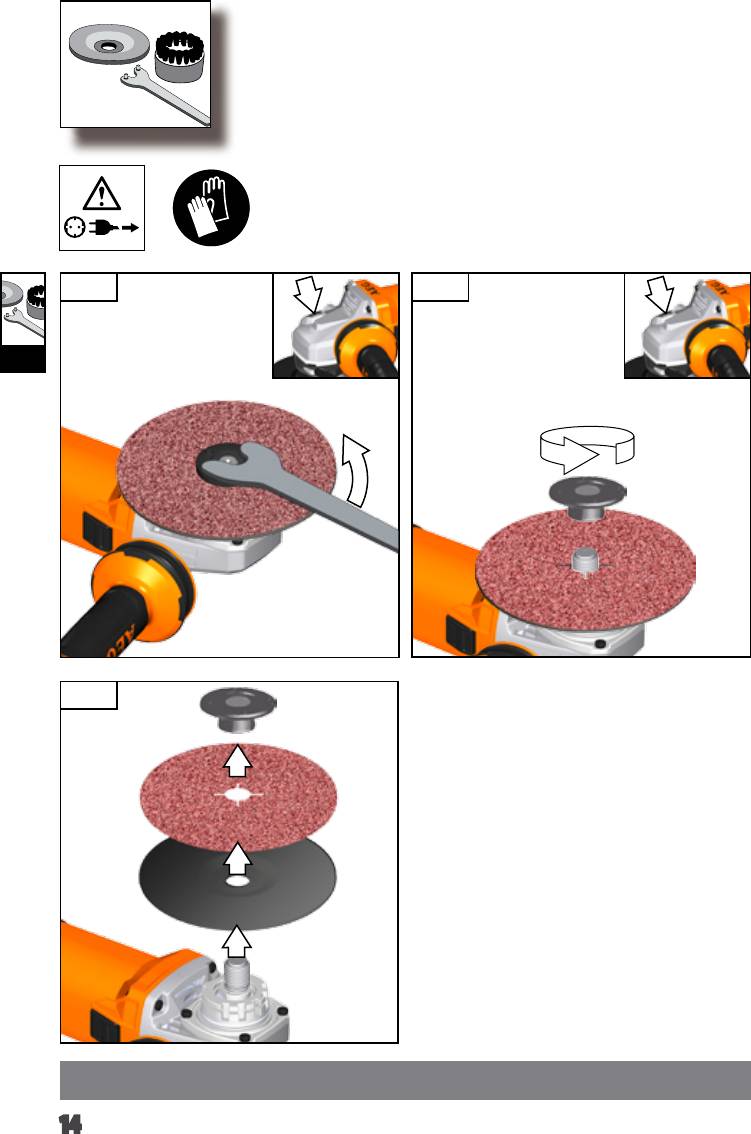

Accessory

Tilbehør

Príslušenstv

Aksessuaarid

Zubehör

Tilbehør

Äîïîëíèòåëü

Accessoires

Tillbehör

Tartozékokat

Accessorio

Lisälaite

Oprema

Accesoriu

Accessorio

Piederumi

Acessório

Aksesuar

Prieda

Toebehoren

Tarvikud

2.1.

VIII

3.

14

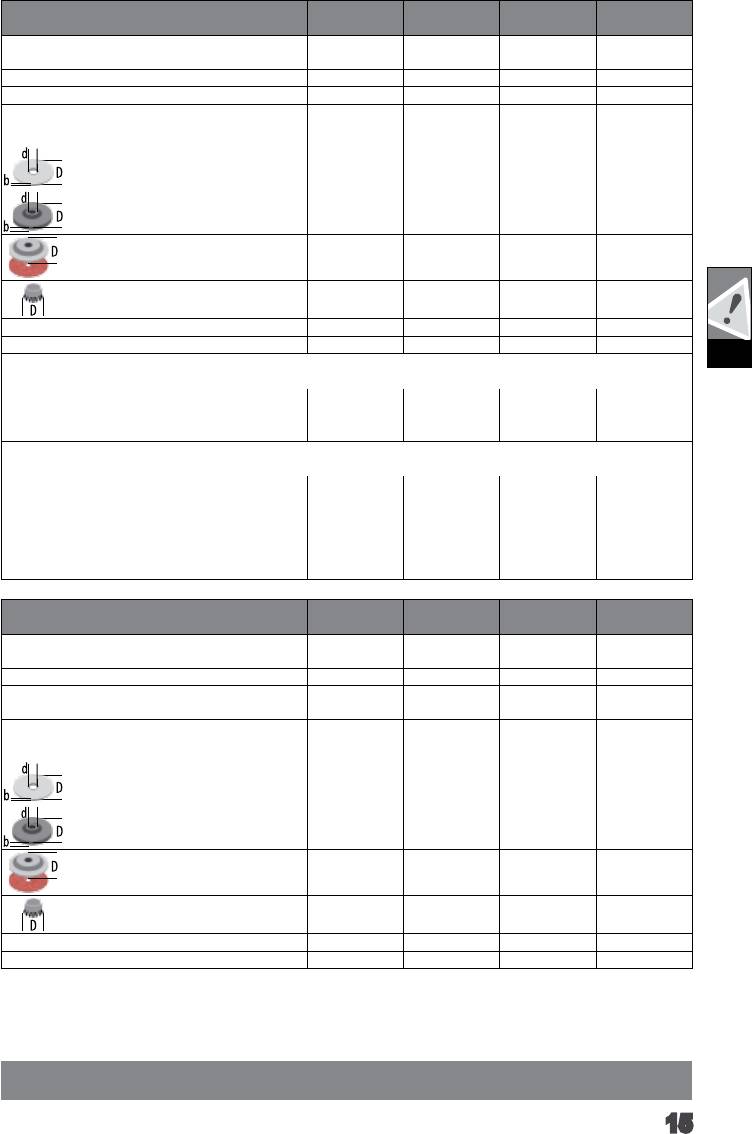

TECHNICAL DATA

WS 10-115 S WS 10-115 SK WS 10-125 S WS 10-125 SK

Angle Grinder

4561 04 01...

4601 57 01...

4561 16 01...

4561 22 01...

Production code

... 000001-999999

... 000001-999999

... 000001-999999

... 000001-999999

Rated input 1000 W 1000 W 1000 W 1000 W

-1

-1

-1

-1

Rated speed 11500 min

11500 min

11500 min

11500 min

D= Grinding disk diameter max.

115 mm

115 mm

125 mm

125 mm

22,2 mm

22,2 mm

22,2 mm

22,2 mm

d= Grinding disk hole diameter

b= Cutting disk thickness min. / max.

1/3 mm 1/3 mm 1/3 mm 1/3 mm

b= Grinding disk thickness max. 6 mm 6 mm 6 mm 6 mm

D= Grinding surface diameter max. 115 mm 115 mm 125 mm 125 mm

D= Wiring brush diameter max. 75 mm 75 mm 75 mm 75 mm

Thread of work spindle M 14 M 14 M 14 M 14

Weight according EPTA-Procedure 01/2003 2,3 kg 2,3 kg 2,3 kg 2,3 kg

GB

Noise information

Measured values determined according to EN 60745. Typically, the A-weighted noise levels of the tool are:

Sound pressure level (Uncertainty K=3dB(A)) 87,1 dB (A) 87,1 dB (A) 87,1 dB (A) 87,1 dB (A)

Sound power level (Uncertainty K=3dB(A)) 98,1 dB (A) 98,1 dB (A) 98,1 dB (A) 98,1 dB (A)

Wear ear protectors!

Vibration information

Vibration total values (triaxial vector sum) determined according to EN 60745

Surface grinding:

2

2

2

2

Vibration emission value a

6,2 m/s

6,2 m/s

6,2 m/s

6,2 m/s

h,SG

2

2

2

2

Uncertainty K=

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

Disk sanding:

2

2

2

2

Vibration emission value a

6,0 m/s

6,0 m/s

6,0 m/s

6,0 m/s

h,DS

2

2

2

2

Uncertainty K=

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

TECHNICAL DATA

WS 12-125 S WS 12-125 SK WS 13-125 SXE WS 13-125 SXEK

Angle Grinder

4561 40 01...

4561 46 01...

4561 58 01...

4561 64 01...

Production code

... 000001-999999

... 000001-999999

... 000001-999999

... 000001-999999

Rated input 1200 W 1200 W 1300 W 1300 W

-1

-1

2800 - 11500

2800 - 11500

Rated speed 11500 min

11500 min

-1

-1

min

min

D= Grinding disk diameter max.

125 mm

125 mm

125 mm

125 mm

22,2 mm

22,2 mm

22,2 mm

22,2 mm

d= Grinding disk hole diameter

b= Cutting disk thickness min. / max.

1/3 mm 1/3 mm 1/3 mm 1/3 mm

b= Grinding disk thickness max. 6 mm 6 mm 6 mm 6 mm

D= Grinding surface diameter max. 125 mm 125 mm 125 mm 125 mm

D= Wiring brush diameter max. 75 mm 75 mm 75 mm 75 mm

Thread of work spindle M 14 M 14 M 14 M 14

Weight according EPTA-Procedure 01/2003 2,4 kg 2,4 kg 2,4 kg 2,4 kg

English

15

TECHNICAL DATA

WS 12-125 S WS 12-125 SK WS 13-125 SXE WS 13-125 SXEK

Angle Grinder

Noise information

Measured values determined according to EN 60745. Typically, the A-weighted noise levels of the tool are:

Sound pressure level (Uncertainty K=3dB(A)) 89,3 dB (A) 89,3 dB (A) 90,1 dB (A) 90,1 dB (A)

Sound power level (Uncertainty K=3dB(A)) 100,3 dB (A) 100,3 dB (A) 101,1 dB (A) 101,1 dB (A)

Wear ear protectors!

Vibration information

Vibration total values (triaxial vector sum) determined according to EN 60745

Surface grinding:

2

2

2

2

Vibration emission value a

5,8 m/s

5,8 m/s

8,0 m/s

8,0 m/s

h,SG

2

2

2

2

Uncertainty K=

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

Disk sanding:

2

2

2

2

Vibration emission value a

5,5 m/s

5,5 m/s

7,5 m/s

7,5 m/s

h,DS

2

2

2

2

Uncertainty K=

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

For other applications, e.g. Abrasive Cutting-O Operations or Wire Brushing other vibration values could occur.

WARNING!

The vibration emission level given in this information sheet has been measured in accordance with a standardised test given in EN 60745

and may be used to compare one tool with another. It may be used for a preliminary assessment of exposure.

GB

The declared vibration emission level represents the main applications of the tool. However if the tool is used for dierent applications,

with dierent accessories or poorly maintained, the vibration emission may dier. This may signicantly increase the exposure level over

the total working period.

An estimation of the level of exposure to vibration should also take into account the times when the tool is switched o or when it is

running but not actually doing the job. This may signicantly reduce the exposure level over the total working period.

Identify additional safety measures to protect the operator from the eects of vibration such as: maintain the tool and the accessories,

keep the hands warm, organisation of work patterns.

WARNING!

Read all safety warnings and all instructions. Failure to

f) Threaded mounting of accessories must match the grin-

follow the warnings and instructions may result in electric shock,

der spindle thread. For accessories mounted by anges, the

re and/or serious injury.

arbour hole of the accessory must t the locating diameter

Save all warnings and instructions for future reference.

of the ange. Accessories that do not match the mounting hard-

ware of the power tool will run out of balance, vibrate excessively

ANGLE GRINDER SAFETY WARNINGS

and may cause loss of control.

Safety Warnings Common for Grinding, Sanding, Wire

g) Do not use a damaged accessory. Before each use inspect

Brushing or Abrasive Cutting-O Operations:

the accessory such as abrasive wheels for chips and cracks,

a) This power tool is intended to function as a grinder,

backing pad for cracks, tear or excess wear, wire brush for

sander, wire brush or cut-o tool. Read all safety warnings,

loose or cracked wires. If power tool or accessory is dropped,

instructions, illustrations and specications provided with

inspect for damage or install an undamaged accessory. After

this power tool. Failure to follow all instructions listed below may

inspecting and installing an accessory, position yourself and

result in electric shock, re and/or serious injury.

bystanders away from the plane of the rotating accessory

and run the power tool at maximum no-load speed for one

b) Operations such as polishing are not recommended

minute. Damaged accessories will normally break apart during this

to be performed with this power tool.Operations for which

test time.

the power tool was not designed may create a hazard and cause

personal injury.

h) Wear personal protective equipment. Depending on

application, use face shield, safety goggles or safety glasses.

c) Do not use accessories which are not specically

As appropriate, wear dust mask, hearing protectors, gloves

designed and recommended by the tool manufacturer. Just

and shop apron capable of stopping small abrasive or

because the accessory can be attached to your power tool, it does

workpiece fragments. The eye protection must be capable of

not assure safe operation.

stopping ying debris generated by various operations. The dust

d) The rated speed of the accessory must be at least equal

mask or respirator must be capable of ltrating particles generated

to the maximum speed marked on the power tool. Accesso-

by your operation. Prolonged exposure to high intensity noise may

ries running faster than their rated speed can break and y apart.

cause hearing loss.

e) The outside diameter and the thickness of your

i) Keep bystanders a safe distance away from work area.

accessory must be within the capacity rating of your power

Anyone entering the work area must wear personal protec-

tool. Incorrectly sized accessories cannot be adequately guarded

tive equipment. Fragments of workpiece or of a broken accessory

or controlled.

may y away and cause injury beyond immediate area of operation.

English

16

j) Hold the power tool by insulated gripping surfaces only,

Safety Warnings Specic for Grinding and Abrasive Cutting-

when performing an operation where the cutting accessory

O Operations:

may contact hidden wiring or its own cord. Cutting accessory

a) Use only wheel types that are recommended for your

contacting a “live” wire may make exposed metal parts of the power

tool “live” and could give the operator an electric shock.

power tool and the specic guard designed for the selected

wheel. Wheels for which the power tool was not designed cannot

k) Position the cord clear of the spinning accessory. If you lose

be adequately guarded and are unsafe.

control, the cord may be cut or snagged and your hand or arm may be

pulled into the spinning wheel.

b) The guard must be securely attached to the power tool

and positioned for maximum safety, so the least amount

l) Never lay the power tool down until the accessory has

of wheel is exposed towards the operator. The guard helps

come to a complete stop. The spinning accessory may grab the

to protect the operator from broken wheel fragments, accidental

surface and pull the power tool out of your control.

contact with wheel and sparks that could ignite clothing.

m) Do not run the power tool while carrying it at your side.

c) Wheels must be used only for recommended applications.

Accidental contact with the spinning accessory could snag your

For example: do not grind with the side of cut-o wheel.

clothing, pulling the accessory into your body.

Abrasive cut-o wheels are intended for peripheral grinding, side

n) Regularly clean the power tool’s air vents. The motor’s fan

forces applied to these wheels may cause them to shatter.

will draw the dust inside the housing and excessive accumulation of

d) Always use undamaged wheel anges that are of correct

powdered metal may cause electrical hazards.

size and shape for your selected wheel. Proper wheel anges

o) Do not operate the power tool near ammable materials.

support the wheel thus reducing the possibility of wheel breakage.

Sparks could ignite these materials.

Flanges for cut-o wheels may be dierent from grinding wheel

p) Do not use accessories that require liquid coolants. Using

anges.

GB

water or other liquid coolants may result in electrocution or shock.

e) Do not use worn down wheels from larger power tools.

Wheel intended for larger power tool is not suitable for the higher

Kickback and Related Warnings

speed of a smaller tool and may burst.

Kickback is a sudden reaction to a pinched or snagged rotating

Additional Safety Warnings Specic for Abrasive Cutting-O

wheel, backing pad, brush or any other accessory. Pinching or snag-

Operations:

ging causes rapid stalling of the rotating accessory which in turn

causes the uncontrolled power tool to be forced in the direction

a) Do not “jam” the cut-o wheel or apply excessive pressure.

opposite of the accessory’s rotation at the point of the binding.

Do not attempt to make an excessive depth of cut. Overstressing

For example, if an abrasive wheel is snagged or pinched by the

the wheel increases the loading and susceptibility to twisting or

workpiece, the edge of the wheel that is entering into the pinch

binding of the wheel in the cut and the possibility of kickback or wheel

point can dig into the surface of the material causing the wheel

breakage.

to climb out or kick out. The wheel may either jump toward or

b) Do not position your body in line with and behind the

away from the operator, depending on direction of the wheel’s

rotating wheel. When the wheel, at the point of operation, is moving

movement at the point of pinching. Abrasive wheels may also break

away from your body, the possible kickback may propel the spinning

under these conditions.

wheel and the power tool directly at you.

Kickback is the result of power tool misuse and/or incorrect opera-

c) When wheel is binding or when interrupting a cut for any

ting procedures or conditions and can be avoided by taking proper

reason, switch o the power tool and hold the power tool

precautions as given below.

motionless until the wheel comes to a complete stop. Never

a) Maintain a rm grip on the power tool and position your

attempt to remove the cut-o wheel from the cut while the

body and arm to allow you to resist kickback forces. Always

wheel is in motion otherwise kickback may occur. Investigate

use auxiliary handle, if provided, for maximum control over

and take corrective action to eliminate the cause of wheel binding.

kickback or torque reaction during start-up. The operator can

d) Do not restart the cutting operation in the workpiece. Let

control torque reactions or kickback forces, if proper precautions

the wheel reach full speed and carefully re-enter the cut. The

are taken.

wheel may bind, walk up or kickback if the power tool is restarted in

b) Never place your hand near the rotating accessory.

the workpiece.

Accessory may kickback over your hand.

e) Support panels or any oversized workpiece to minimize the

c) Do not position your body in the area where power tool

risk of wheel pinching and kickback. Large workpieces tend to sag

will move if kickback occurs. Kickback will propel the tool

under their own weight. Supports must be placed under the workpiece

in direction opposite to the wheel’s movement at the point of

near the line of cut and near the edge of the workpiece on both sides

snagging.

of the wheel.

d) Use special care when working corners, sharp edges etc.

f) Use extra caution when making a “pocket cut” into existing

Avoid bouncing and snagging the accessory. Corners, sharp

walls or other blind areas. The protruding wheel may cut gas or

edges or bouncing have a tendency to snag the rotating accessory

water pipes, electrical wiring or objects that can cause kickback.

and cause loss of control or kickback.

Safety Warnings Specic for Sanding Operations:

e) Do not attach a saw chain woodcarving blade or toothed

saw blade. Such blades create frequent kickback and loss of control.

a) Do not use excessively oversized sanding disc paper.

Follow manufacturers recommendations, when selecting

sanding paper. Larger sanding paper extending beyond the

sanding pad presents a laceration hazard and may cause snagging,

tearing of the disc or kickback.

English

17

Safety Warnings Specic for Wire Brushing Operations:

WORKING INSTRUCTIONS

For accessories intended to be tted with threaded hole wheel,

a) Be aware that wire bristles are thrown by the brush

ensure that the thread in the wheel is long enough to accept the

even during ordinary operation. Do not overstress the wires

spindle length.

by applying excessive load to the brush. The wire bristles can

Always use and store the cutting and grinding disks according to

easily penetrate light clothing and/or skin.

the manufacturer‘s instructions.

b) If the use of a guard is recommended for wire brushing,

Always use the correct guard for cutting and grinding.

do not allow any interference of the wire wheel or brush

with the guard. Wire wheel or brush may expand in diameter due

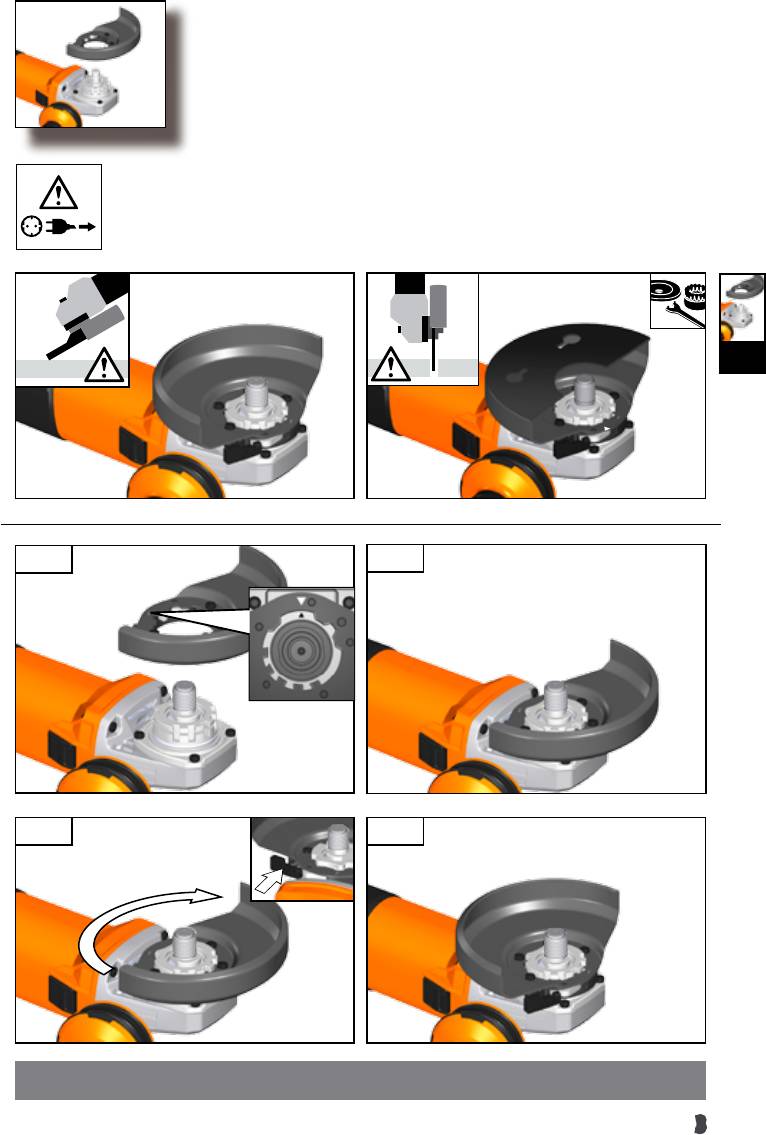

The grinding surface of the centre depressed disks must be moun-

to work load and centrifugal forces.

ted min. 2 mm below the plane of the guard lip.

The adjusting nut must be tightened before starting to work with

Additional Safety and Working Instructions

the machine.

When grinding metal, ying sparks are produced. Take care that

Always use the auxiliary handle.

no persons are endangered. Because of the danger of re, no

The workpiece must be xed if it is not heavy enough to be steady.

combustible materials should be located in the vicinity (spark ight

Never move the workpiece towards the rotating disk by hand.

zone). Do not use dust extraction.

The ange nut must be securely tightened before the machine is

Avoid ying sparks and sanding dust hit your body.

started.

If the tool is not securely tightened with the ange nut, it is pos-

Never reach into the danger area of the machine when it is running.

sible that the tool will lose the required clamping force when it is

Immediately switch o the machine in case of considerable vibra-

decelerated.

tions or if other malfunctions occur. Check the machine in order to

In the event that a power failure occurs whilst the machine is

GB

nd out the cause.

operating, the brake function will be inoperative.

Under extreme conditions (e.g. smooth-grinding metals with

the arbour and vulcanized bre grinding disk), signicant

ELECTRONICS

contamination can build up on the inside of the angle grinder. For

Machines with a lockable switch are supplied with a restart cutout.

safety reasons, in such conditions a ground fault interrupter must

This prevents the machine restarting by itself after a power failure.

be connected in series. If the ground fault interrupter trips the

When resuming work, switch the machine o and then switch it

machine must be sent for service.

back on again.

Chips and splinters must not be removed while the machine is

The device has an overload protection function and will stop if an

running.

overload occurs. Machine shut-o. After the machine has cooled

down the device can be put back into operation.

MAINS CONNECTION

Connect only to single-phase AC system voltage as indicated on

SMOOTH START

the rating plate. It is also possible to connect to sockets without an

Electronic smooth start for save use prevents jerky run-up of the

earthing contact as the design conforms to safety class II.

machine.

Appliances used at many dierent locations including wet room

and open air must be connected via a residual current device (FI,

MAINTENANCE

RCD, PRCD) of 30mA or less.

The ventilation slots of the machine must be kept clear at all times.

Only plug-in when machine is switched o.

If the supply cord of this power tool is damaged, it must be

Do not let any metal parts enter the airing slots - danger of short

replaced by a specially prepared cord available through the service

circuit!

organization.

Inrush currents cause short-time voltage drops. Under unfavoura-

Use only AEG accessories and spare parts. Should components need to

ble power supply conditions, other equipment may be aected. If

be replaced which have not been described, please contact one of our

the system impedance of the power supply is lower than 0,2 Ohm,

AEG service agents (see our list of guarantee/service addresses).

disturbances are unlikely to occur.

If needed, an exploded view of the tool can be ordered. Please state

the Article No. as well as the machine type printed on the label

SPECIFIED CONDITIONS OF USE

and order the drawing at your local service agents or directly at:

The angle grinder is intended for grinding and cutting metal, stone

Techtronic Industries GmbH, Max-Eyth-Straße10, 71364Winnen-

and ceramicmaterials as well as sanding and wire brushing.

den, Germany.

Use the cutting guard from the accessories range for cutting

application.

Please refer to the instructions supplied by the accessory

manufacturer.

The machine is suitable only for working without water.

English

18