AEG ws10-125 451301: инструкция

Раздел: Инструмент, электроинструмент, силовая техника

Тип: Угловая Шлифмашина

Характеристики, спецификации

Инструкция к Угловой Шлифмашиной AEG ws10-125 451301

WS 10-115, WS 10-125,

WS 12-115, WS 12-125, WS 13-125 XE

Original instructions

Instrukcją oryginalną

Originalbetriebsanleitung

Eredeti használati utasítás

Notice originale

Izvirna navodila

Istruzioni originali

Originalne pogonske upute

Manual original

Instrukcijâm oriěinâlvalodâ

Manual original

Originali instrukcija

Oorspronkelijke gebruiksaanwijzing

Algupärane kasutusjuhend

Original brugsanvisning

Оригинальное руководство по

Original bruksanvisning

эксплуатации

Bruksanvisning i original

Оригинално ръководство за

експлоатация

Alkuperäiset ohjeet

Instrucţiuni de folosire originale

Πρωτότυπο οδηγιών χρήσης

Оригинален прирачник за работа

Orijinal işletme talimatı

Оригінал інструкції з експлуатації

Původním návodem k používání

Pôvodný návod na použitie

Technical Data,Safety Instructions, Specied Conditions of Use,

Please read and save

English

14

Mains connection, Maintenance, Symbols

these instructions!

Technische Daten, Sicherheitshinweise, Bestimmungsgemäße Verwendung,

Bitte lesen und

Deutsch

18

Netzanschluss, Wartung, Symbole

aufbewahren!

Caractéristiques techniques, Instructions de sécurité, Utilisation conforme aux

A lire et à conserver

Français

22

prescriptions, Branchement secteur, Entretien, Symboles

soigneusement

Dati tecnici,Norme di sicurezza,Utilizzo conforme, Collegamento alla rete,

Si prega di leggere e

Italiano

26

Manutenzione, Simboli

conservare le istruzioni!

Datos técnicos, Instrucciones de seguridad, Aplicación de acuerdo a la nalidad,

Lea y conserve estas

Español

30

Conexión eléctrica, Mantenimiento, Símbolos

instrucciones por favor!

Características técnicas, Instruções de segurança, Utilização autorizada,

Por favor leia e conserve

Português

34

Ligação à rede, Manutenção, Symbole

em seu poder!

Technische gegevens, Veiligheidsadviezen, Voorgeschreven gebruik van het

Lees en let goed

Nederlands

38

systeem, Netaansluiting,Onderhoud, Symbolen

op deze adviezen!

Tekniske data, Sikkerhedshenvisninger, Tiltænkt formål, Nettilslutning,

Vær venlig at læse

Dansk

42

Vedligeholdelse, Symboler

og Opbevare!

Tekniske data, Spesielle sikkerhetshenvisninger, Formålsmessig bruk,

Vennligst les og oppbevar!

Norsk

46

Nettilkopling, Vedlikehold, Symboler

Tekniska data, Säkerhetsutrustning, Använd maskinen Enligt anvisningarna,

Läs igenom och spara!

Svenska

50

Nätanslutning, Skötsel, Symboler

Tekniset arvot, Turvallisuusohjeet, Tarkoituksenmukainen käyttö,

Lue ja säilytö!

Suomi

54

Verkkoliitäntä, Huolto, Symbolit

Τεχνικά στοιχεία, Ειδικές υποδείξεις ασφάλειας, Χρήση σύμφωνα με το σκοπό

Ελληνικά

58

προορισμού, Μπαταρίες, Χαρακτηριστικά, Συντήρηση, Σύμβολα.

Teknik veriler, Güvenliğiniz için talimatlar, Kullanim, Şebeke bağlantisi,

Lütfen okuyun ve saklayın

Türkçe

63

Bakim, Semboller

Technická data, Speciální bezpečnostní upozornění, Oblast využití,

Po přečtení uschovejte

Česky

67

Připojení na sít, Údržba, Symboly

Technické údaje, Špeciálne bezpčènostné pokyny, Použitie podl’a predpisov,

Prosím prečítať a uschovať!

Slovensky

71

Siet’ová prípojka, Údrzba, Symboly

Dane techniczne, Specjalne zalecenia dotyczące bezpiecze´nstwa,

Należy uważnie przeczytać i

Polski

75

Użytkowanie zgodne z przeznaczeniem, Podłączenie do sieci, Gwarancja, Symbole

zachować do wglądu!

Műszaki adatok, Különleges biztonsági tudnivalók, Rendeltetésszerű használat,

Olvassa el és őrizze meg

Magyar

79

Hálózati csatlakoztatás, Karbantartás, Szimbólumok

Tehnični podatki, Specialni varnostni napotki, Uporaba v skladu z namembnostjo,

Prosimo preberite

Slovensko

83

Omrežni priključek, Vzdrževanje, Simboli

in shranite!

Tehnički podaci, Specijalne sigurnosne upute, Propisna upotreba,

Molimo pročitati i sačuvati

Hrvatski

87

Priključak na mrežu, Održavanje, Simboli

Tehniskie dati, Speciālie drošības noteikumi, Noteikumiem atbilstošs izmantojums,

Pielikums lietošanas pamācībai

Latviski

91

Tīkla pieslēgums, Apkope, Simboli

Techniniai duomenys, Ypatingos saugumo nuorodos, Naudojimas pagal paskirti,

Prašome perskaityti

Lietuviškai

95

Elektros tinklo jungtis, Techninis aptarnavimas, Simboliai

ir neišmesti!

Tehnilised andmed, Spetsiaalsed turvajuhised, Kasutamine vastavalt otstarbele,

Palun lugege läbi ja hoidke alal!

Eesti

99

Võrku ühendamine, Hooldus, Sümbolid

Òåõíè÷åñêèå äàííûå, Ðåêîìåíäàöèè ïî òåõíèêå áåçîïàñíîñòè,

Пожалуйста прочтите и

Pусский

103

Èñïîëüçî- âàíèå, Îáñëóæèâàíèå, Ñèìâîëû

сохраните эту инструкцию.

Òåõíè÷åñêè äàííè, Ñïåöèàëíè óêàçàíèÿ çà áåçîïàñíîñò, Èçïîëçâàíå ïî

Моля прочетете и запазете!

Български

108

ïðåäíàçíà÷åíèå, Ñâúðçâàíå êúì ìðåæàòà, Ïîääðúæêà, Ñèìâîëè

Date tehnice, Instrucţiuni de securitate, Condiţii de utilizare specifcate,

Va rugăm citiţi şi păstraţi

Română

112

Acumulatori, Intreţinere, Simboluri

aceste instrucţiuni

Òåõíè÷êè Ïîäàòîöè, Óïàòñòâî Çà Óïîòðåáà, Ñïåöèôèöèðàíè Óñëîâè

Ве мoлиме прочитаjте го и

Мaкeдohcки

116

Íà Óïîòðåáà, БАТЕРИИ, Îäðæóâàњå, Ñèìáîëè

чувајте го ова упатство!

Технічні характеристики, Вказівки З Техніки Безпеки, Використання за призначенням,

Прочитайте та збережіть

Українська

120

Підключення до мережі, Обслуговування, Символи

цю інструкцію.

127

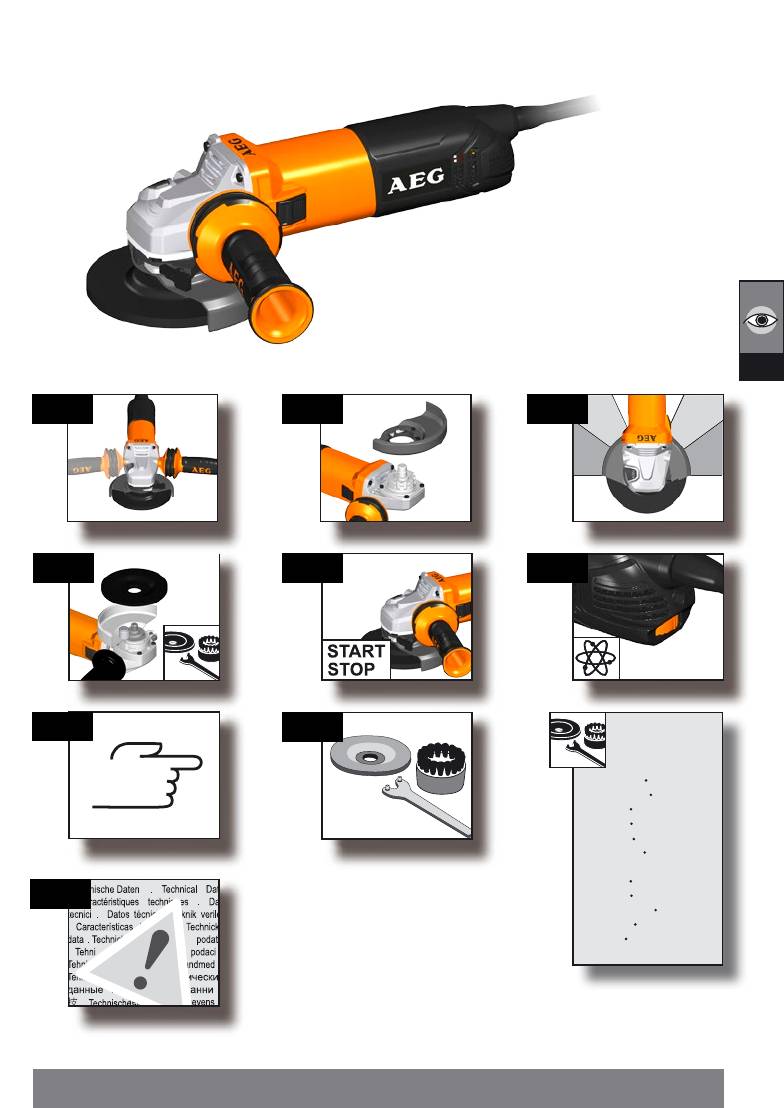

VII

TIP

I II III

IV

V

VI

Accessory

VIII

Zubehör

Accessoires

Accessorio

Accessorio Acessório

Toebehoren

Tilbehør

Tilbehør

Tillbehör

Lisälaite

Aksesuar

Příslušenství

Príslušenstv

Azokat a tartozékokat

Oprema

Piederumi

IX

Priedas

Tarvikud

Äîïîëíèòåëü

Accesoriu

A B

I

2

II

1.

2.

4.3.

2

1

3

60

°

°

60

0°

30

°

°

30

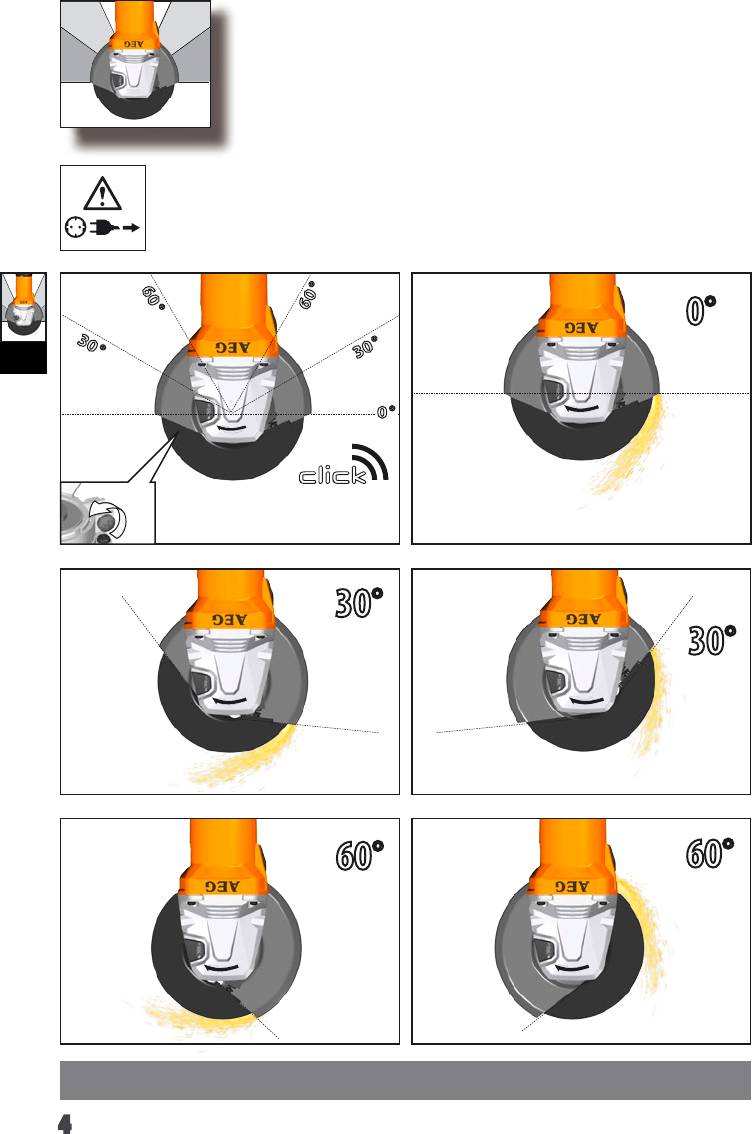

III

0

°

30°

30°

60°

60°

4

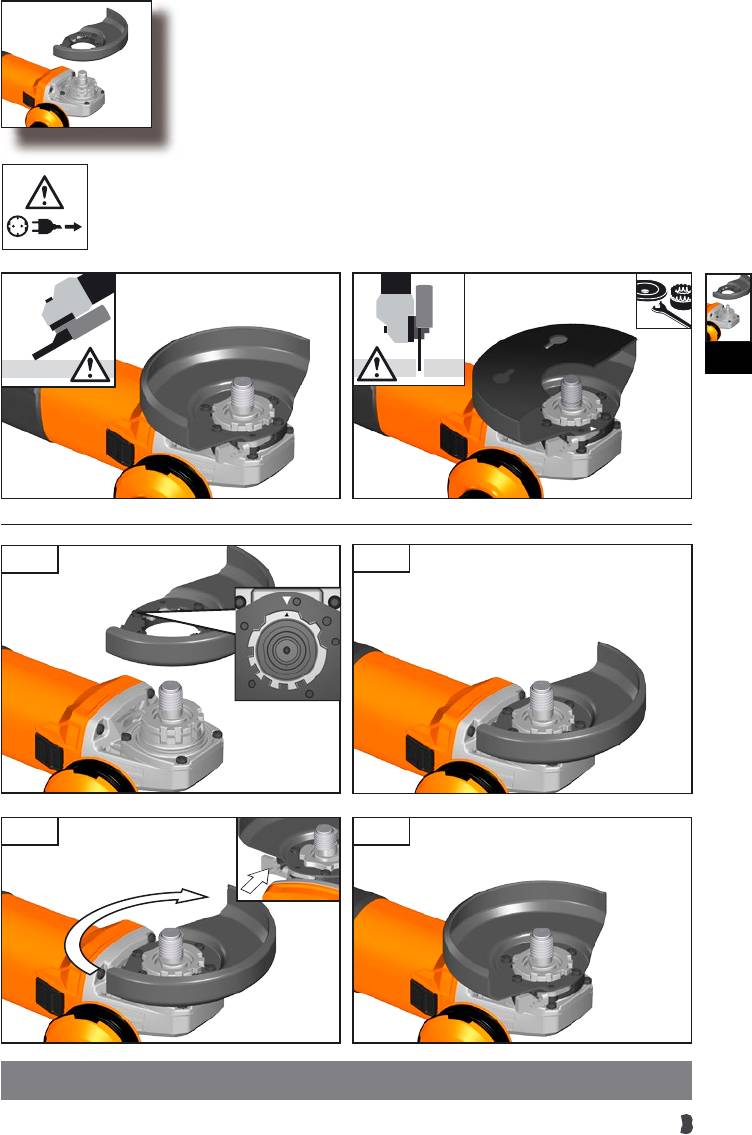

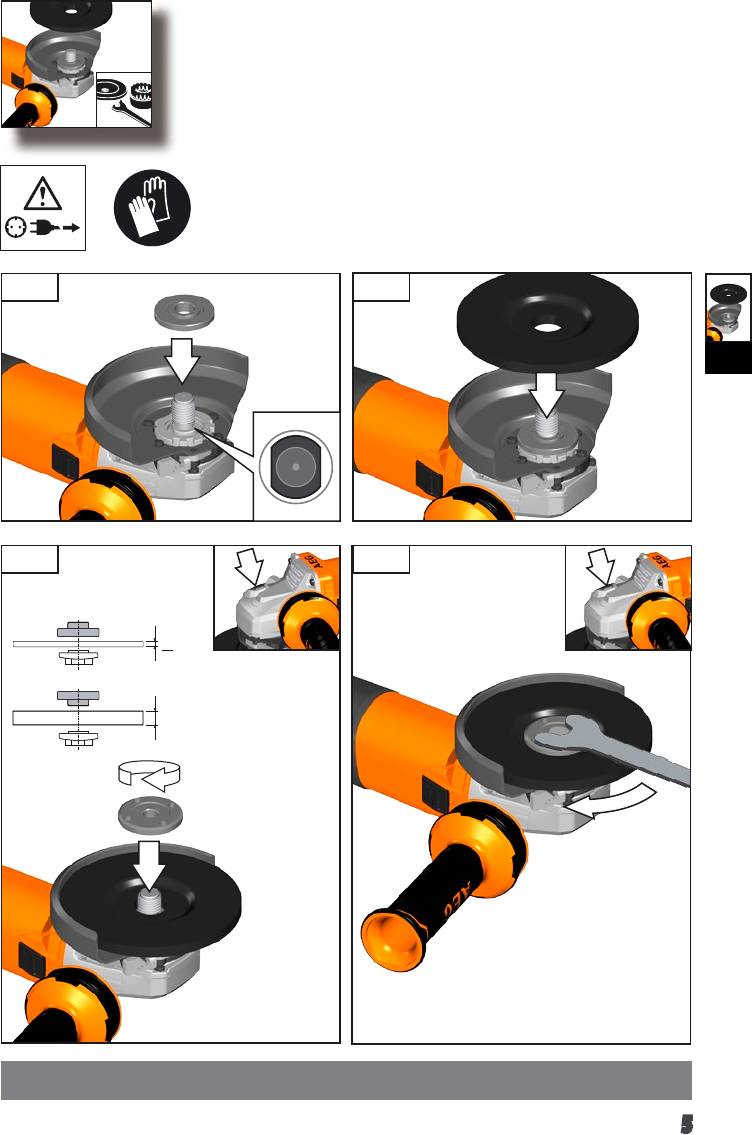

1.

2.

IV

3.

4.

< 6 mm

> 6 mm

5

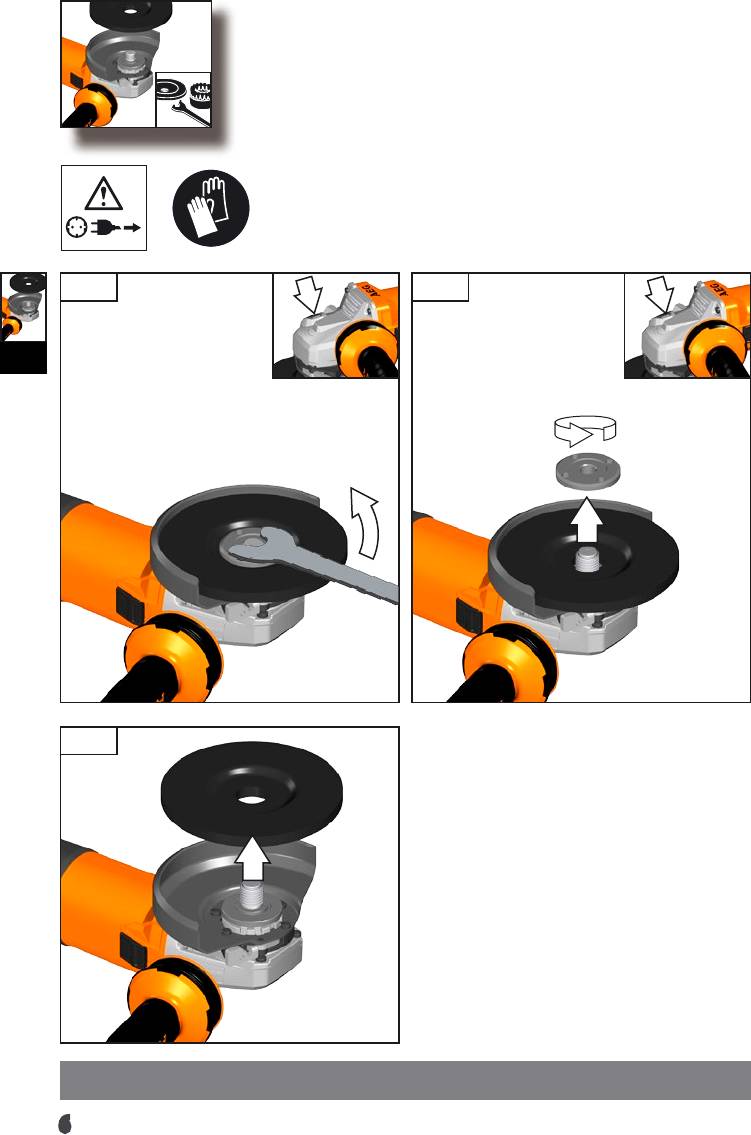

2.1.

IV

3.

6

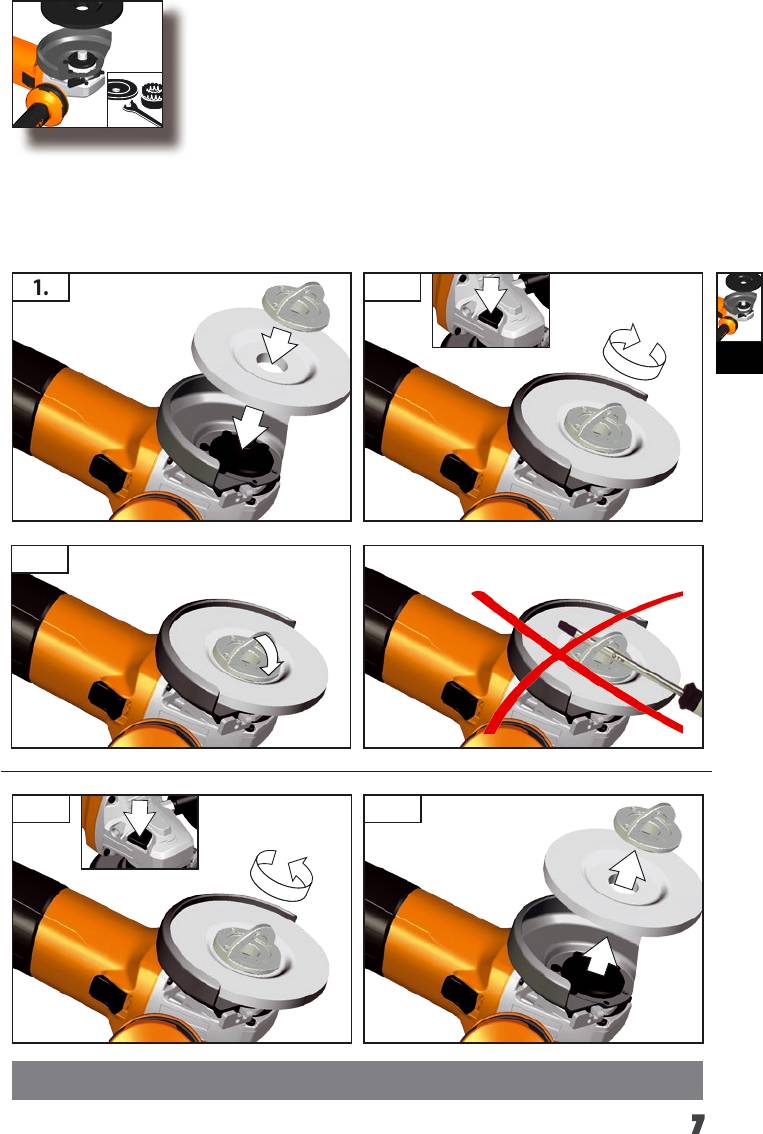

WS ...-... X...

1. 2.

IV

3.

1. 2.

7

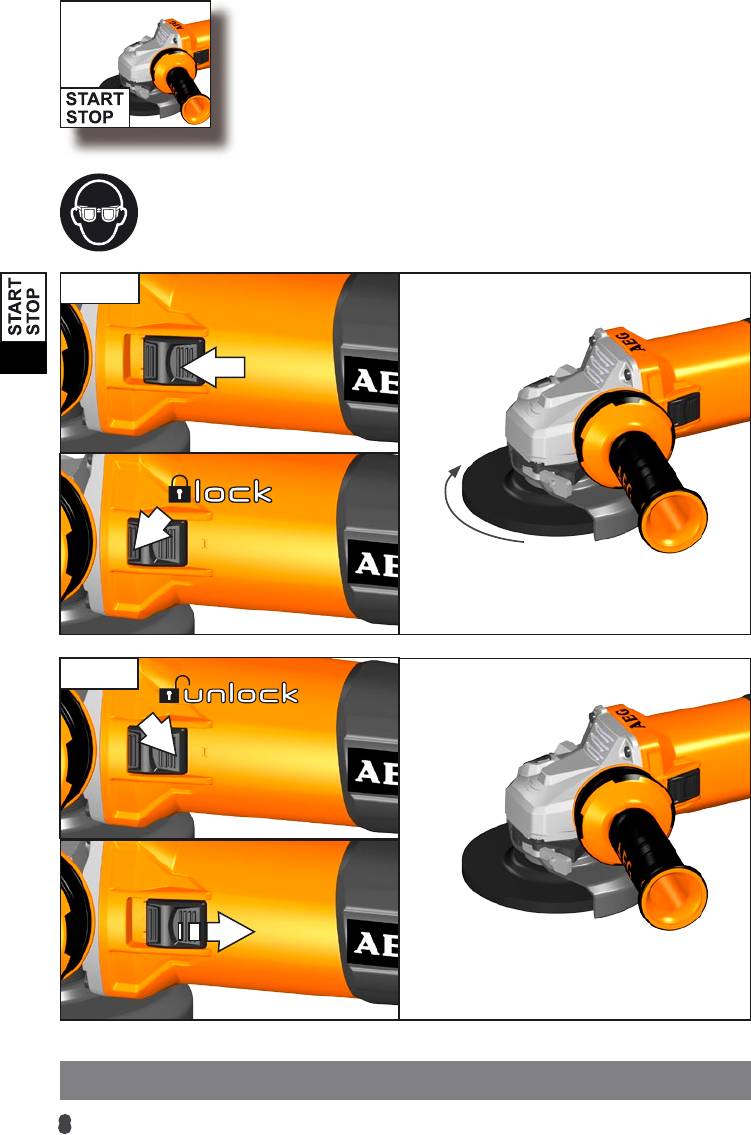

Start

V

Stop

8

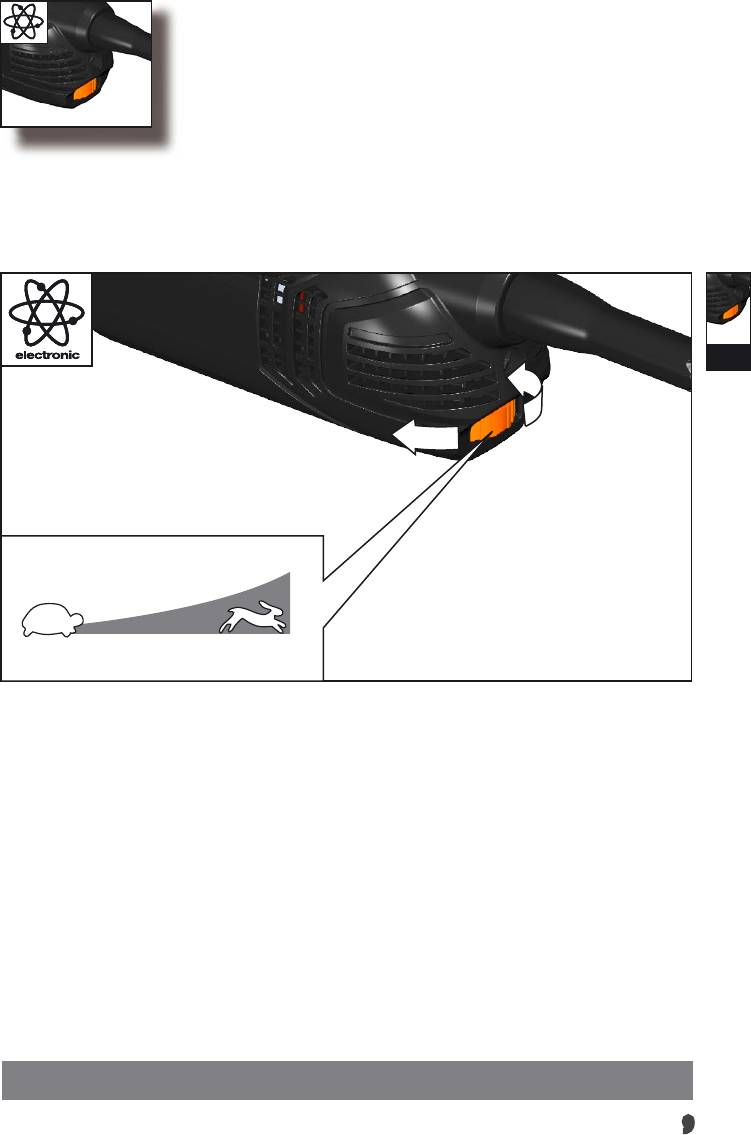

WS ...-... E...

VI

C

A...B...C...D...E

9

TIP

TIP

< 30°

10

TIP

VII

Accessory

Tilbehør

Príslušenstv

Aksessuaarid

Zubehör

Tilbehør

Äîïîëíèòåëü

Accessoires

Tillbehör

Tartozékokat

Accessorio

Lisälaite

Oprema

Accesoriu

Accessorio

Piederumi

Acessório

Aksesuar

Prieda

Toebehoren

Tarvikud

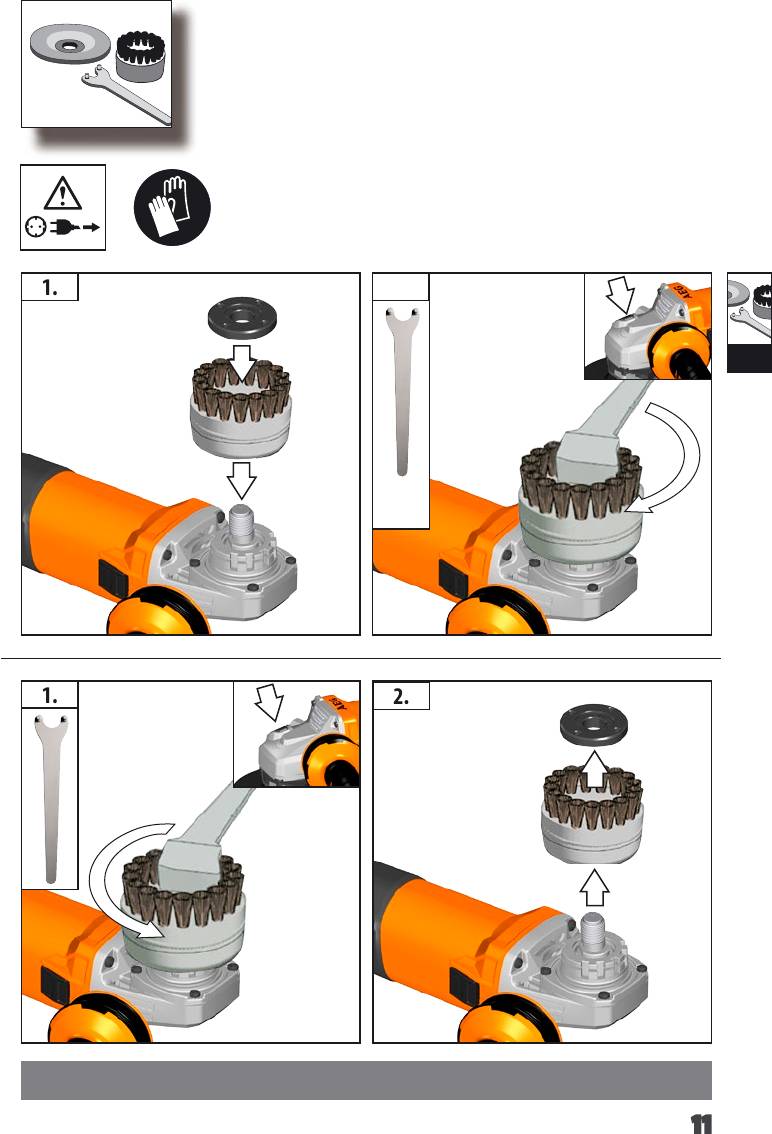

1. 2.

VIII

1.

2.

11

Accessory

Tilbehør

Príslušenstv

Aksessuaarid

Zubehör

Tilbehør

Äîïîëíèòåëü

Accessoires

Tillbehör

Tartozékokat

Accessorio

Lisälaite

Oprema

Accesoriu

Accessorio

Piederumi

Acessório

Aksesuar

Prieda

Toebehoren

Tarvikud

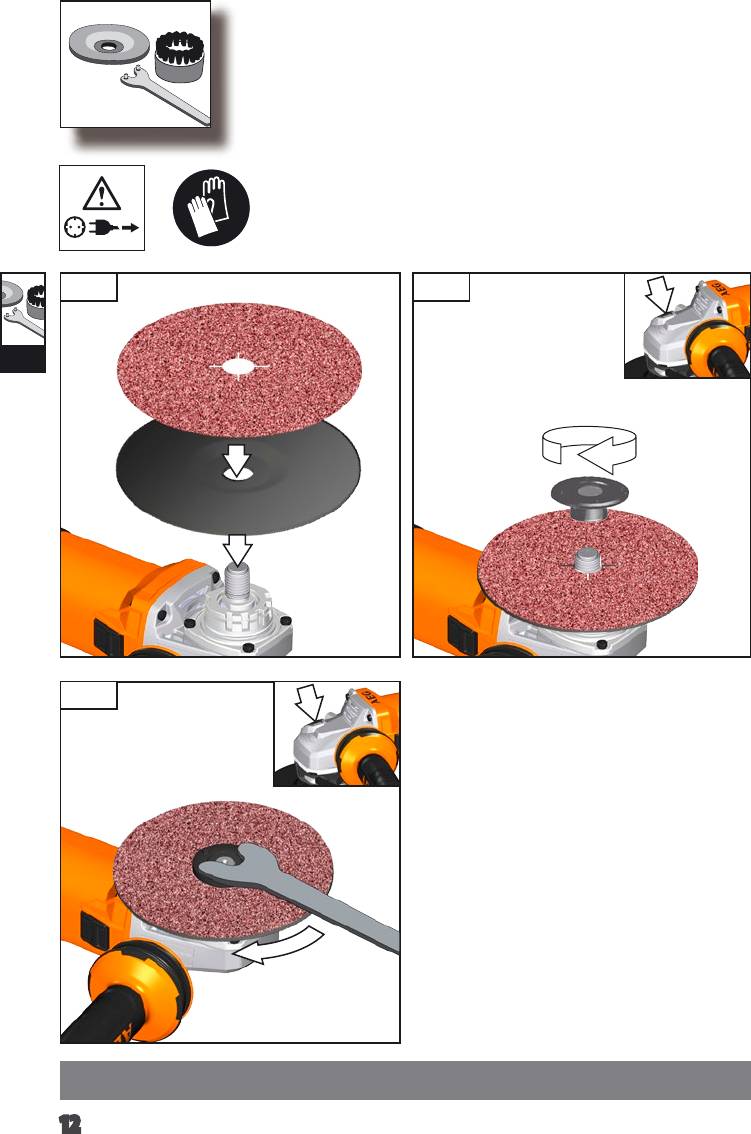

1.

2.

VIII

3.

12

Accessory

Tilbehør

Príslušenstv

Aksessuaarid

Zubehör

Tilbehør

Äîïîëíèòåëü

Accessoires

Tillbehör

Tartozékokat

Accessorio

Lisälaite

Oprema

Accesoriu

Accessorio

Piederumi

Acessório

Aksesuar

Prieda

Toebehoren

Tarvikud

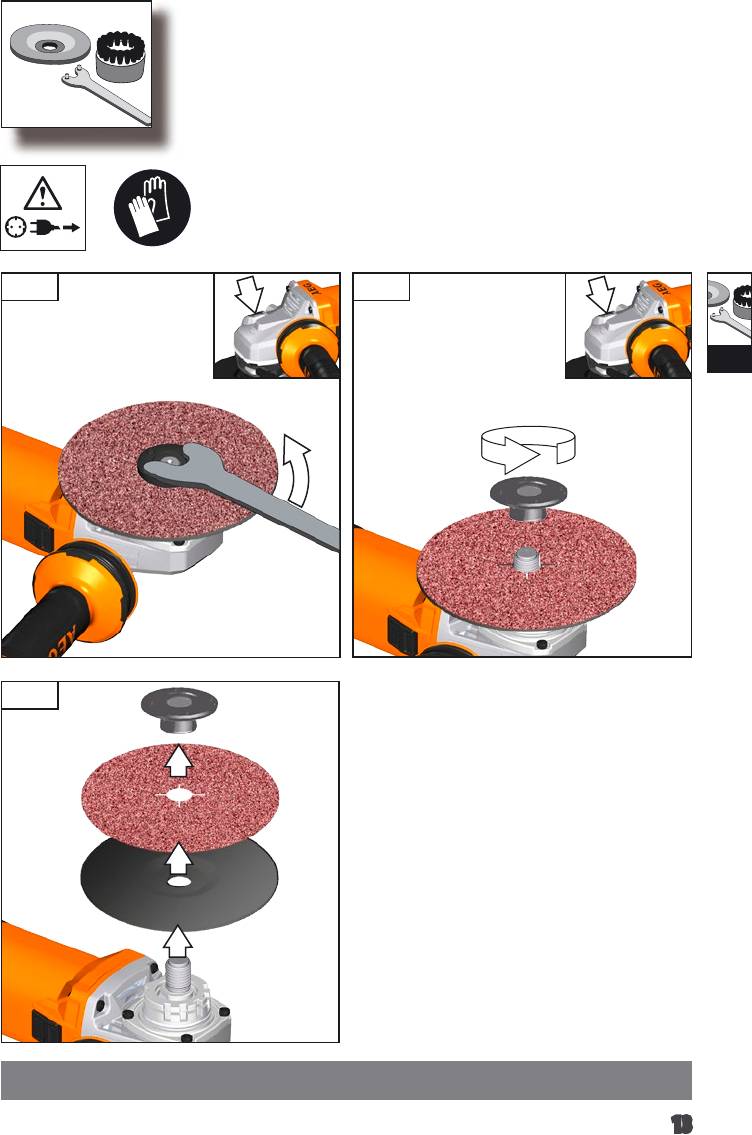

2.1.

VIII

3.

13

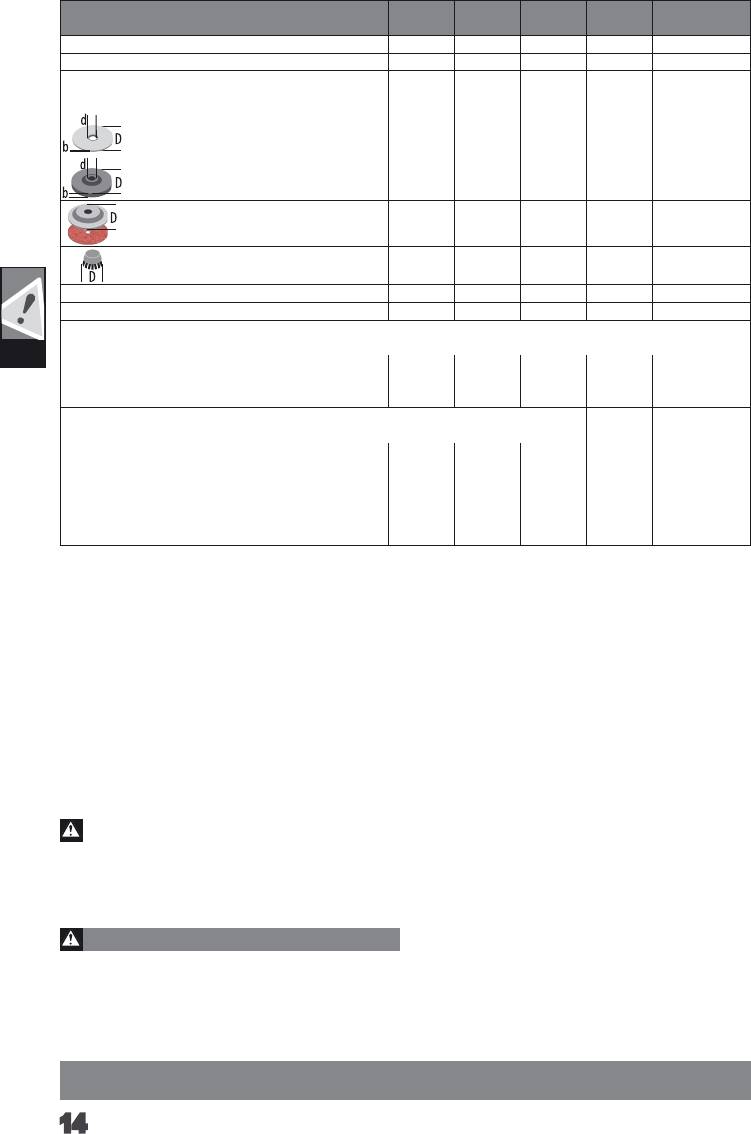

TECHNICAL DATA

WS 10-115 WS 10-125 WS 12-115 WS 12-125 WS 13-125 XE

Angle Grinder

Rated input 1000 W 1000 W 1200 W 1200 W 1300 W

-1

-1

-1

-1

-1

Rated speed 11500 min

11500 min

11500 min

11500 min

2800 - 11500 min

D= Grinding disk diameter max.

115 mm

125 mm

115 mm

125 mm

125 mm

22,2 mm

22,2 mm

22,2 mm

22,2 mm

22,2 mm

d= Grinding disk hole diameter

b= Cutting disk thickness min. / max.

1/3 mm 1/3 mm 1/3 mm 1/3 mm 1/3 mm

b= Grinding disk thickness max. 6 mm 6 mm 6 mm 6 mm 6 mm

D= Grinding surface diameter max. 115 mm 125 mm 115 mm 125 mm 125 mm

D= Wiring brush diameter max. 75 mm 75 mm 75 mm 75 mm 75 mm

Thread of work spindle M 14 M 14 M 14 M 14 M 14

Weight according EPTA-Procedure 01/2003 2,3 kg 2,3 kg 2,4 kg 2,4 kg 2,4 kg

Noise information

Measured values determined according to EN 60745. Typically, the A-weighted noise levels of the tool are:

GB

Sound pressure level (Uncertainty K=3dB(A)) 87,1 dB (A) 87,1 dB (A) 87,1 dB (A) 87,1 dB (A) 90,1 dB (A)

Sound power level (Uncertainty K=3dB(A)) 98,1 dB (A) 98,1 dB (A) 98,1 dB (A) 98,1 dB (A) 101,1 dB (A)

Wear ear protectors!

Vibration information

Vibration total values (triaxial vector sum) determined according to EN 60745

Surface grinding:

2

2

2

2

2

Vibration emission value a

6,2 m/s

6,2 m/s

6,2 m/s

6,2 m/s

8,0 m/s

h,SG

2

2

2

2

2

Uncertainty K=

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

Disk sanding:

2

2

2

2

2

Vibration emission value a

6,0 m/s

6,0 m/s

6,0 m/s

6,0 m/s

7,5 m/s

h,DS

2

2

2

2

2

Uncertainty K=

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

For other applications, e.g. Abrasive Cutting-O Operations or Wire Brushing other vibration values could occur.

WARNING!

The vibration emission level given in this information sheet has been measured in accordance with a standardised test given in EN 60745

and may be used to compare one tool with another. It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main applications of the tool. However if the tool is used for dierent applications,

with dierent accessories or poorly maintained, the vibration emission may dier. This may signicantly increase the exposure level over

the total working period.

An estimation of the level of exposure to vibration should also take into account the times when the tool is switched o or when it is

running but not actually doing the job. This may signicantly reduce the exposure level over the total working period.

Identify additional safety measures to protect the operator from the eects of vibration such as: maintain the tool and the accessories,

keep the hands warm, organisation of work patterns.

this power tool. Failure to follow all instructions listed below may

WARNING!

result in electric shock, re and/or serious injury.

Read all safety warnings and all instructions. Failure to

b) Operations such as polishing are not recommended

follow the warnings and instructions may result in electric shock,

to be performed with this power tool.Operations for which

re and/or serious injury.

the power tool was not designed may create a hazard and cause

Save all warnings and instructions for future reference.

personal injury.

ANGLE GRINDER SAFETY WARNINGS

c) Do not use accessories which are not specically

designed and recommended by the tool manufacturer. Just

Safety Warnings Common for Grinding, Sanding, Wire

because the accessory can be attached to your power tool, it does

Brushing or Abrasive Cutting-O Operations:

not assure safe operation.

a) This power tool is intended to function as a grinder,

d) The rated speed of the accessory must be at least equal

sander, wire brush or cut-o tool. Read all safety warnings,

to the maximum speed marked on the power tool. Accesso-

instructions, illustrations and specications provided with

ries running faster than their rated speed can break and y apart.

English

14

e) The outside diameter and the thickness of your

causes the uncontrolled power tool to be forced in the direction

accessory must be within the capacity rating of your power

opposite of the accessory’s rotation at the point of the binding.

tool. Incorrectly sized accessories cannot be adequately guarded

For example, if an abrasive wheel is snagged or pinched by the

or controlled.

workpiece, the edge of the wheel that is entering into the pinch

f) Threaded mounting of accessories must match the grin-

point can dig into the surface of the material causing the wheel

to climb out or kick out. The wheel may either jump toward or

der spindle thread. For accessories mounted by anges, the

away from the operator, depending on direction of the wheel’s

arbour hole of the accessory must t the locating diameter

movement at the point of pinching. Abrasive wheels may also break

of the ange. Accessories that do not match the mounting hard-

under these conditions.

ware of the power tool will run out of balance, vibrate excessively

and may cause loss of control.

Kickback is the result of power tool misuse and/or incorrect opera-

ting procedures or conditions and can be avoided by taking proper

g) Do not use a damaged accessory. Before each use inspect

precautions as given below.

the accessory such as abrasive wheels for chips and cracks,

backing pad for cracks, tear or excess wear, wire brush for

a) Maintain a rm grip on the power tool and position your

loose or cracked wires. If power tool or accessory is dropped,

body and arm to allow you to resist kickback forces. Always

inspect for damage or install an undamaged accessory. After

use auxiliary handle, if provided, for maximum control over

inspecting and installing an accessory, position yourself and

kickback or torque reaction during start-up. The operator can

control torque reactions or kickback forces, if proper precautions

bystanders away from the plane of the rotating accessory

are taken.

and run the power tool at maximum no-load speed for one

minute. Damaged accessories will normally break apart during this

b) Never place your hand near the rotating accessory.

test time.

Accessory may kickback over your hand.

h) Wear personal protective equipment. Depending on

c) Do not position your body in the area where power tool

GB

application, use face shield, safety goggles or safety glasses.

will move if kickback occurs. Kickback will propel the tool in

As appropriate, wear dust mask, hearing protectors, gloves

direction opposite to the wheel’s movement at the point of snagging.

and shop apron capable of stopping small abrasive or

d) Use special care when working corners, sharp edges etc.

workpiece fragments. The eye protection must be capable of

Avoid bouncing and snagging the accessory. Corners, sharp

stopping ying debris generated by various operations. The dust

edges or bouncing have a tendency to snag the rotating accessory

mask or respirator must be capable of ltrating particles generated

and cause loss of control or kickback.

by your operation. Prolonged exposure to high intensity noise may

e) Do not attach a saw chain woodcarving blade or toothed

cause hearing loss.

saw blade. Such blades create frequent kickback and loss of control.

i) Keep bystanders a safe distance away from work area.

Anyone entering the work area must wear personal protec-

Safety Warnings Specic for Grinding and Abrasive Cutting-

tive equipment. Fragments of workpiece or of a broken accessory

O Operations:

may y away and cause injury beyond immediate area of operation.

a) Use only wheel types that are recommended for your

j) Hold the power tool by insulated gripping surfaces only,

power tool and the specic guard designed for the selected

when performing an operation where the cutting accessory

wheel. Wheels for which the power tool was not designed cannot be

may contact hidden wiring or its own cord. Cutting accessory

adequately guarded and are unsafe.

contacting a „live“ wire may make exposed metal parts of the power

b) The guard must be securely attached to the power tool

tool „live“ and could give the operator an electric shock.

and positioned for maximum safety, so the least amount

k) Position the cord clear of the spinning accessory. If you lose

of wheel is exposed towards the operator. The guard helps

control, the cord may be cut or snagged and your hand or arm may be

to protect the operator from broken wheel fragments, accidental

pulled into the spinning wheel.

contact with wheel and sparks that could ignite clothing.

l) Never lay the power tool down until the accessory has

c) Wheels must be used only for recommended applications.

come to a complete stop. The spinning accessory may grab the

For example: do not grind with the side of cut-o wheel. Abra

-

surface and pull the power tool out of your control.

sive cut-o wheels are intended for peripheral grinding, side forces

m) Do not run the power tool while carrying it at your side.

a

pplied to these wheels may cause them to shatter.

Accidental contact with the spinning accessory could snag your

d) Always use undamaged wheel anges that are of correct

clothing, pulling the accessory into your body.

size and shape for your selected wheel. Proper wheel anges

n) Regularly clean the power tool’s air vents. The motor’s fan

support the wheel thus reducing the possibility of wheel breakage.

will draw the dust inside the housing and excessive accumulation of

Flanges for cut-o wheels may be dierent from grinding wheel

powdered metal may cause electrical hazards.

anges.

o) Do not operate the power tool near ammable materials.

e) Do not use worn down wheels from larger power tools.

Sparks could ignite these materials.

Wheel intended for larger power tool is not suitable for the higher

p) Do not use accessories that require liquid coolants. Using

speed of a smaller tool and may burst.

water or other liquid coolants may result in electrocution or shock.

Additional Safety Warnings Specic for Abrasive Cutting-O

Kickback and Related Warnings

Operations:

Kickback is a sudden reaction to a pinched or snagged rotating

a) Do not “jam” the cut-o wheel or apply excessive pressure.

wheel, backing pad, brush or any other accessory. Pinching or snag-

Do not attempt to make an excessive depth of cut. Overstressing

ging causes rapid stalling of the rotating accessory which in turn

the wheel increases the loading and susceptibility to twisting or

English

15

binding of the wheel in the cut and the possibility of kickback or wheel

MAINS CONNECTION

breakage.

Connect only to single-phase AC system voltage as indicated on

b) Do not position your body in line with and behind the

the rating plate. It is also possible to connect to sockets without an

rotating wheel. When the wheel, at the point of operation, is moving

earthing contact as the design conforms to safety class II.

away from your body, the possible kickback may propel the spinning

Appliances used at many dierent locations including wet room

wheel and the power tool directly at you.

and open air must be connected via a residual current device (FI,

c) When wheel is binding or when interrupting a cut for any

RCD, PRCD) of 30mA or less.

reason, switch o the power tool and hold the power tool

Only plug-in when machine is switched o.

motionless until the wheel comes to a complete stop. Never

Do not let any metal parts enter the airing slots - danger of short

attempt to remove the cut-o wheel from the cut while the

circuit!

wheel is in motion otherwise kickback may occur. Investigate

Inrush currents cause short-time voltage drops. Under unfavoura-

and take corrective action to eliminate the cause of wheel binding.

ble power supply conditions, other equipment may be aected. If

d) Do not restart the cutting operation in the workpiece. Let

the system impedance of the power supply is lower than 0,2 Ohm,

the wheel reach full speed and carefully re-enter the cut. The

disturbances are unlikely to occur.

wheel may bind, walk up or kickback if the power tool is restarted in

the workpiece.

SPECIFIED CONDITIONS OF USE

e) Support panels or any oversized workpiece to minimize the

The angle grinder is intended for grinding and cutting metal, stone

risk of wheel pinching and kickback. Large workpieces tend to sag

and ceramicmaterials as well as sanding and wire brushing.

under their own weight. Supports must be placed under the workpiece

Use the cutting guard from the accessories range for cutting

near the line of cut and near the edge of the workpiece on both sides

application.

GB

of the wheel.

Please refer to the instructions supplied by the accessory

f) Use extra caution when making a “pocket cut” into existing

manufacturer.

walls or other blind areas. The protruding wheel may cut gas or

The machine is suitable only for working without water.

water pipes, electrical wiring or objects that can cause kickback.

WORKING INSTRUCTIONS

Safety Warnings Specic for Sanding Operations:

For accessories intended to be tted with threaded hole wheel,

a) Do not use excessively oversized sanding disc paper.

ensure that the thread in the wheel is long enough to accept the

Follow manufacturers recommendations, when selecting

spindle length.

sanding paper. Larger sanding paper extending beyond the

Always use and store the cutting and grinding disks according to

sanding pad presents a laceration hazard and may cause snagging,

the manufacturer‘s instructions.

tearing of the disc or kickback.

Always use the correct guard for cutting and grinding.

Safety Warnings Specic for Wire Brushing Operations:

The grinding surface of the centre depressed disks must be moun-

ted min. 2 mm below the plane of the guard lip.

a) Be aware that wire bristles are thrown by the brush

The adjusting nut must be tightened before starting to work with

even during ordinary operation. Do not overstress the wires

the machine.

by applying excessive load to the brush. The wire bristles can

Always use the auxiliary handle.

easily penetrate light clothing and/or skin.

The workpiece must be xed if it is not heavy enough to be steady.

b) If the use of a guard is recommended for wire brushing,

Never move the workpiece towards the rotating disk by hand.

do not allow any interference of the wire wheel or brush

The ange nut must be securely tightened before the machine is

with the guard. Wire wheel or brush may expand in diameter due

started.

to work load and centrifugal forces.

If the tool is not securely tightened with the ange nut, it is pos-

Additional Safety and Working Instructions

sible that the tool will lose the required clamping force when it is

decelerated.

When grinding metal, ying sparks are produced. Take care that

In the event that a power failure occurs whilst the machine is

no persons are endangered. Because of the danger of re, no

operating, the brake function will be inoperative.

combustible materials should be located in the vicinity (spark ight

zone). Do not use dust extraction.

ELECTRONICS

Avoid ying sparks and sanding dust hit your body.

WS 13-125 XE: The built-in electronic will keep a constant speed

even under increased load. In case of overload, the rotational speed

Never reach into the danger area of the machine when it is running.

is being reduced until machine stops.

Immediately switch o the machine in case of considerable vibra-

Electronic smooth start for save use prevents jerky run-up of the

tions or if other malfunctions occur. Check the machine in order to

machine.

nd out the cause.

Under extreme conditions (e.g. smooth-grinding metals with

MAINTENANCE

the arbour and vulcanized bre grinding disk), signicant

The ventilation slots of the machine must be kept clear at all times.

contamination can build up on the inside of the angle grinder. For

safety reasons, in such conditions a ground fault interrupter must

If the supply cord of this power tool is damaged, it must be

be connected in series. If the ground fault interrupter trips the

replaced by a specially prepared cord available through the service

machine must be sent for service.

organization.

Chips and splinters must not be removed while the machine is

running.

English

16

Use only AEG accessories and spare parts. Should components need to

be replaced which have not been described, please contact one of our

AEG service agents (see our list of guarantee/service addresses).

If needed, an exploded view of the tool can be ordered. Please state

the Article No. as well as the machine type printed on the label

and order the drawing at your local service agents or directly at:

Techtronic Industries GmbH, Max-Eyth-Straße10, 71364Winnen-

den, Germany.

SYMBOLS

CAUTION! WARNING! DANGER!

Please read the instructions carefully before starting the

machine.

Always wear goggles when using the machine.

Wear gloves!

Always disconnect the plug from the socket before

GB

carrying out any work on the machine.

Do not use force.

Only for cutting work.

Only for grinding.

Accessory - Not included in standard equipment, availa-

ble as an accessory.

Do not dispose of electric tools together with household

waste material. Electric tools and electronic equipment

that have reached the end of their life must be collected

separately and returned to an environmentally compatible

recycling facility. Check with your local authority or retailer

for recycling advice and collection point.

Class II tool. Tool in which protection against electric

shock does not rely on basic insulation only, but in which

additional safety precautions, such as double insulation

or reinforced insulation, are provided. There being

no provision for protective earthing or reliance upon

installation conditions.

UkrSEPRO Conformity Mark

EurAsian Conformity Mark

English

17

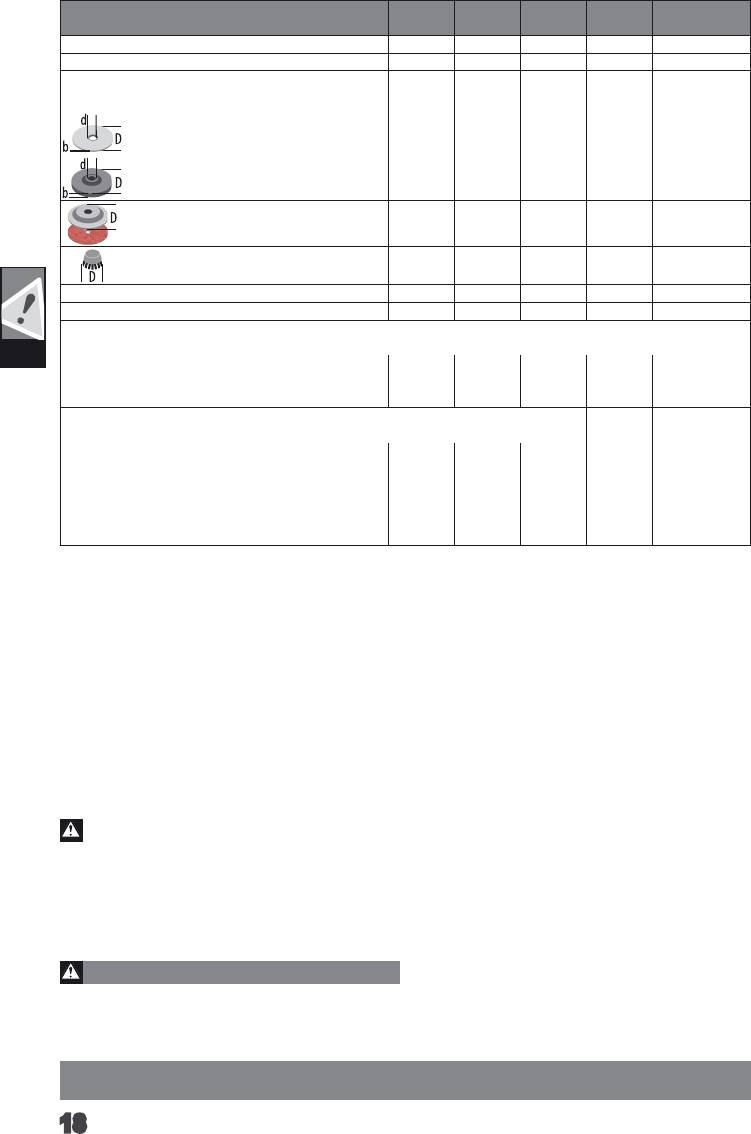

TECHNISCHE DATEN

WS 10-115 WS 10-125 WS 12-115 WS 12-125 WS 13-125 XE

Winkelschleifer

Nennaufnahmeleistung 1000 W 1000 W 1200 W 1200 W 1300 W

-1

-1

-1

-1

-1

Nenndrehzahl 11500 min

11500 min

11500 min

11500 min

2800 - 11500 min

D= Schleifscheibendurchmesser max.

115 mm

125 mm

115 mm

125 mm

125 mm

22,2 mm

22,2 mm

22,2 mm

22,2 mm

22,2 mm

d= Bohrungsdurchmesser

b= Trennscheibendicke min. / max.

1/3 mm 1/3 mm 1/3 mm 1/3 mm 1/3 mm

b= Schleifscheibendicke max. 6 mm 6 mm 6 mm 6 mm 6 mm

D= Schleiächendurchmesser max. 115 mm 125 mm 115 mm 125 mm 125 mm

D= Topfbürstendurchmesser max. 75 mm 75 mm 75 mm 75 mm 75 mm

Spindelgewinde M 14 M 14 M 14 M 14 M 14

Gewicht nach EPTA-Prozedur 01/2003 2,3 kg 2,3 kg 2,4 kg 2,4 kg 2,4 kg

Geräuschinformation

Messwerte ermittelt entsprechend EN 60745. Der A-bewertete Geräuschpegel des Gerätes beträgt typischerweise:

D

Schalldruckpegel (Unsicherheit K=3dB(A)) 87,1 dB (A) 87,1 dB (A) 87,1 dB (A) 87,1 dB (A) 90,1 dB (A)

Schallleistungspegel (Unsicherheit K=3dB(A)) 98,1 dB (A) 98,1 dB (A) 98,1 dB (A) 98,1 dB (A) 101,1 dB (A)

Gehörschutz tragen!

Vibrationsinformationen

Schwingungsgesamtwerte (Vektorsumme dreier Richtungen) ermittelt entsprechend EN 60745.

Oberächenschleifen:

2

2

2

2

2

Schwingungsemissionswert a

6,2 m/s

6,2 m/s

6,2 m/s

6,2 m/s

8,0 m/s

h,SG

2

2

2

2

2

Unsicherheit K=

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

Schleifen mit Schleifblatt:

2

2

2

2

2

Schwingungsemissionswert a

6,0 m/s

6,0 m/s

6,0 m/s

6,0 m/s

7,5 m/s

h,DS

2

2

2

2

2

Unsicherheit K=

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

1,5 m/s

Bei anderen Anwendungen, wie z.B. Trennschleifen oder Schleifen mit der Stahldrahtbürste können sich andere Vibrationswerte ergeben!

WARNUNG!

Der in diesen Anweisungen angegebene Schwingungspegel ist entsprechend einem in EN 60745 genormten Messverfahren gemessen

worden und kann für den Vergleich von Elektrowerkzeugen miteinander verwendet werden. Er eignet sich auch für eine vorläuge

Einschätzung der Schwingungsbelastung.

Der angegebene Schwingungspegel repräsentiert die hauptsächlichen Anwendungen des Elektrowerkzeugs. Wenn allerdings das

Elektrowerkzeug für andere Anwendungen, mit abweichenden Einsatzwerkzeugen oder ungenügender Wartung eingesetzt wird, kann

der Schwingungspegel abweichen. Dies kann die Schwingungsbelastung über den gesamten Arbeitszeitraum deutlich erhöhen.

Für eine genaue Abschätzung der Schwingungsbelastung sollten auch die Zeiten berücksichtigt werden, in denen das Gerät abgeschaltet

ist oder zwar läuft, aber nicht tatsächlich im Einsatz ist. Dies kann die Schwingungsbelastung über den gesamten Arbeitszeitraum

deutlich reduzieren.

Legen Sie zusätzliche Sicherheitsmaßnahmen zum Schutz des Bedieners vor der Wirkung von Schwingungen fest wie zum Beispiel:

Wartung von Elektrowerkzeug und Einsatzwerkzeugen, Warmhalten der Hände, Organisation der Arbeitsabläufe.

a) Dieses Elektrowerkzeug ist zu verwenden als Schleifer,

WARNUNG!

Sandpapierschleifer, Drahtbürste und Trennschleifma-

Lesen Sie alle Sicherheitshinweise und Anweisungen.

schine. Beachten Sie alle Sicherheitshinweise, Anwei-

Versäumnisse bei der Einhaltung der Sicherheitshinweise und

sungen, Darstellungen und Daten, die Sie mit dem Gerät

Anweisungen können elektrischen Schlag, Brand und/oder schwere

erhalten. Wenn Sie die folgenden Anweisungen nicht beachten,

Verletzungen verursachen.

kann es zu elektrischem Schlag, Feuer und/oder schweren Verlet-

Bewahren Sie alle Sicherheitshinweise und Anweisungen

zungen kommen.

für die Zukunft auf.

b) Dieses Elektrowerkzeug ist nicht geeignet zum Polieren.

Verwendungen, für die das Elektrowerkzeug nicht vorgesehen ist,

SICHERHEITSHINWEISE FÜR WINKELSCHLEIFER

können Gefährdungen und Verletzungen verursachen.

Gemeinsame Sicherheitshinweise zum Schleifen,

c) Verwenden Sie kein Zubehör, das vom Hersteller

Sandpapierschleifen, Arbeiten mit Drahtbürsten und

nicht speziell für dieses Elektrowerkzeug vorgesehen

Trennschleifen:

und empfohlen wurde. Nur weil Sie das Zubehör an Ihrem

Deutsch

18