AEG ks 55-2: инструкция

Характеристики, спецификации

Инструкция к Пиле AEG ks 55-2

KS 55-2

Original instructions

Instrukcją oryginalną

Originalbetriebsanleitung

Eredeti használati utasítás

Notice originale

Izvirna navodila

Istruzioni originali

Originalne pogonske upute

Manual original

Instrukcijâm oriěinâlvalodâ

Manual original

Originali instrukcija

Oorspronkelijke gebruiksaanwijzing

Algupärane kasutusjuhend

Original brugsanvisning

Оригинальное руководство по

Original bruksanvisning

эксплуатации

Bruksanvisning i original

Оригинално ръководство за

експлоатация

Alkuperäiset ohjeet

Instrucţiuni de folosire originale

Πρωτότυπο οδηγιών χρήσης

Оригинален прирачник за работа

Orijinal işletme talimatı

Оригінал інструкції з експлуатації

Původním návodem k používání

Pôvodný návod na použitie

Technical Data,Safety Instructions, Specied Conditions of Use,

Please read and save

English

14

EC-Declaration of Conformity, Mains connection, Maintenance, Symbols

these instructions!

Technische Daten, Sicherheitshinweise, Bestimmungsgemäße Verwendung,

Bitte lesen und

Deutsch

17

CE-Konformitätserklärung, Netzanschluss, Wartung, Symbole

aufbewahren!

Caractéristiques techniques, Instructions de sécurité, Utilisation conforme aux

A lire et à conserver

Français

20

prescriptions, Déclaration CE de Conformité, Branchement secteur, Entretien, Symboles

soigneusement

Dati tecnici,Norme di sicurezza,Utilizzo conforme, Dicharazione di Conformità CE,

Si prega di leggere e

Italiano

23

Collegamento alla rete, Manutenzione, Simboli

conservare le istruzioni!

Datos técnicos, Instrucciones de seguridad, Aplicación de acuerdo a la nalidad,

Lea y conserve estas

Español

26

Declaracion de Conformidad CE, Conexión eléctrica, Mantenimiento, Símbolos

instrucciones por favor!

Características técnicas, Instruções de segurança, Utilização autorizada,

Por favor leia e conserve

Português

29

Declaração de Conformidade CE, Ligação à rede, Manutenção, Symbole

em seu poder!

Technische gegevens, Veiligheidsadviezen, Voorgeschreven gebruik van het

Lees en let goed

Nederlands

32

systeem, EC-Konformiteitsverklaring, Netaansluiting,Onderhoud, Symbolen

op deze adviezen!

Tekniske data, Sikkerhedshenvisninger, Tiltænkt formål,

Vær venlig at læse

Dansk

35

CE-Konformitetserklæring, Nettilslutning, Vedligeholdelse, Symboler

og Opbevare!

Tekniske data, Spesielle sikkerhetshenvisninger, Formålsmessig bruk,

Vennligst les og oppbevar!

Norsk

38

CE-Samsvarserklæring, Nettilkopling, Vedlikehold, Symboler

Tekniska data, Säkerhetsutrustning, Använd maskinen Enligt anvisningarna,

Läs igenom och spara!

Svenska

41

CEFörsäkran, Nätanslutning, Skötsel, Symboler

Tekniset arvot, Turvallisuusohjeet, Tarkoituksenmukainen käyttö,

Lue ja säilytö!

Suomi

44

Todistus CE-standardinmukaisuudesta, Verkkoliitäntä, Huolto, Symbolit

Τεχνικά στοιχεία, Ειδικές υποδείξεις ασφάλειας, Χρήση σύμφωνα με το σκοπό

Ελληνικά

47

προορισμού, Δήλωση πιστότητας ΕΚ, Μπαταρίες, Χαρακτηριστικά, Συντήρηση, Σύμβολα.

Teknik veriler, Güvenliğiniz için talimatlar, Kullanim, CE uygunluk beyanice,

Lütfen okuyun ve saklayın

Türkçe

50

Şebeke bağlantisi, Bakim, Semboller

Technická data, Speciální bezpečnostní upozornění, Oblast využití,

Po přečtení uschovejte

Česky

53

Ce-prohlášení o shodě, Připojení na sít, Údržba, Symboly

Technické údaje, Špeciálne bezpčènostné pokyny, Použitie podl’a predpisov,

Prosím prečítať a uschovať!

Slovensky

56

CE-Vyhlásenie konformity, Siet’ová prípojka, Údrzba, Symboly

Dane techniczne, Specjalne zalecenia dotyczące bezpiecze´nstwa, Użytkowanie zgodne z

Należy uważnie przeczytać i

Polski

59

przeznaczeniem, Świadectwo zgodności ce, Podłączenie do sieci, Gwarancja, Symbole

zachować do wglądu!

Műszaki adatok, Különleges biztonsági tudnivalók, Rendeltetésszerű használat,

Olvassa el és őrizze meg

Magyar

62

Ce-azonossági nyilatkozat, Hálózati csatlakoztatás, Karbantartás, Szimbólumok

Tehnični podatki, Specialni varnostni napotki, Uporaba v skladu z namembnostjo,

Prosimo preberite

Slovensko

65

Ce-izjava o konformnosti, Omrežni priključek, Vzdrževanje, Simboli

in shranite!

Tehnički podaci, Specijalne sigurnosne upute, Propisna upotreba,

Molimo pročitati i sačuvati

Hrvatski

68

CE-Izjava konformnosti, Priključak na mrežu, Održavanje, Simboli

Tehniskie dati, Speciālie drošības noteikumi, Noteikumiem atbilstošs izmantojums,

Pielikums lietošanas pamācībai

Latviski

71

Atbilstība CE normām, Tīkla pieslēgums, Apkope, Simboli

Techniniai duomenys, Ypatingos saugumo nuorodos, Naudojimas pagal paskirti,

Prašome perskaityti

Lietuviškai

74

CE Atitikties pareiškimas, Elektros tinklo jungtis, Techninis aptarnavimas, Simboliai

ir neišmesti!

Tehnilised andmed, Spetsiaalsed turvajuhised, Kasutamine vastavalt otstarbele,

Palun lugege läbi ja hoidke alal!

Eesti

77

EÜ Vastavusavaldus, Võrku ühendamine, Hooldus, Sümbolid

Òåõíè÷åñêèå äàííûå, Ðåêîìåíäàöèè ïî òåõíèêå áåçîïàñíîñòè,

Пожалуйста прочтите и

Pусский

80

Èñïîëüçî- âàíèå, Ïîäêëþ÷åíèå ê ýëåêòðîñåòè, Îáñëóæèâàíèå, Ñèìâîëû

сохраните эту инструкцию.

Òåõíè÷åñêè äàííè, Ñïåöèàëíè óêàçàíèÿ çà áåçîïàñíîñò, Èçïîëçâàíå ïî ïðåäíàçíà÷åíèå,

Моля прочетете и запазете!

Български

83

ÑÅ-Äåêëàðàöèÿ çà ñúîòâåòñòâèå, Ñâúðçâàíå êúì ìðåæàòà, Ïîääðúæêà, Ñèìâîëè

Date tehnice, Instrucţiuni de securitate, Condiţii de utilizare specifcate,

Va rugăm citiţi şi păstraţi

Română

86

Declaraţie de conformitate, Acumulatori, Intreţinere, Simboluri

aceste instrucţiuni

Òåõíè÷êè Ïîäàòîöè, Óïàòñòâî Çà Óïîòðåáà, Ñïåöèôèöèðàíè Óñëîâè Íà

Ве мoлиме прочитаjте го и

Мaкeдohcки

89

Óïîòðåáà, Åó-äåêëàðàöè¼à Çà Ñîîáðàçíîñò, БАТЕРИИ, Îäðæóâàњå, Ñèìáîëè

чувајте го ова упатство!

Технічні характеристики, Вказівки З Техніки Безпеки, Використання за призначенням,

Прочитайте та збережіть

Українська

92

Сертифікат Відповідності Вимогам Єс, Підключення до мережі, Обслуговування, Символи

цю інструкцію.

97

Aufnahme

aufschrauben

I

II III

IV

V

VI

x cm

x cm

Accessory

VII

VIII

Zubehör

Accessoires

Accessorio

Accessorio Acessório

Toebehoren

Tilbehør

TIP

Tilbehør

Tillbehör

Lisälaite

Aksesuar

Příslušenství

Príslušenstv

Azokat a tartozékokat

Oprema

Piederumi

Priedas

Tarvikud

Äîïîëíèòåëü

Accesoriu

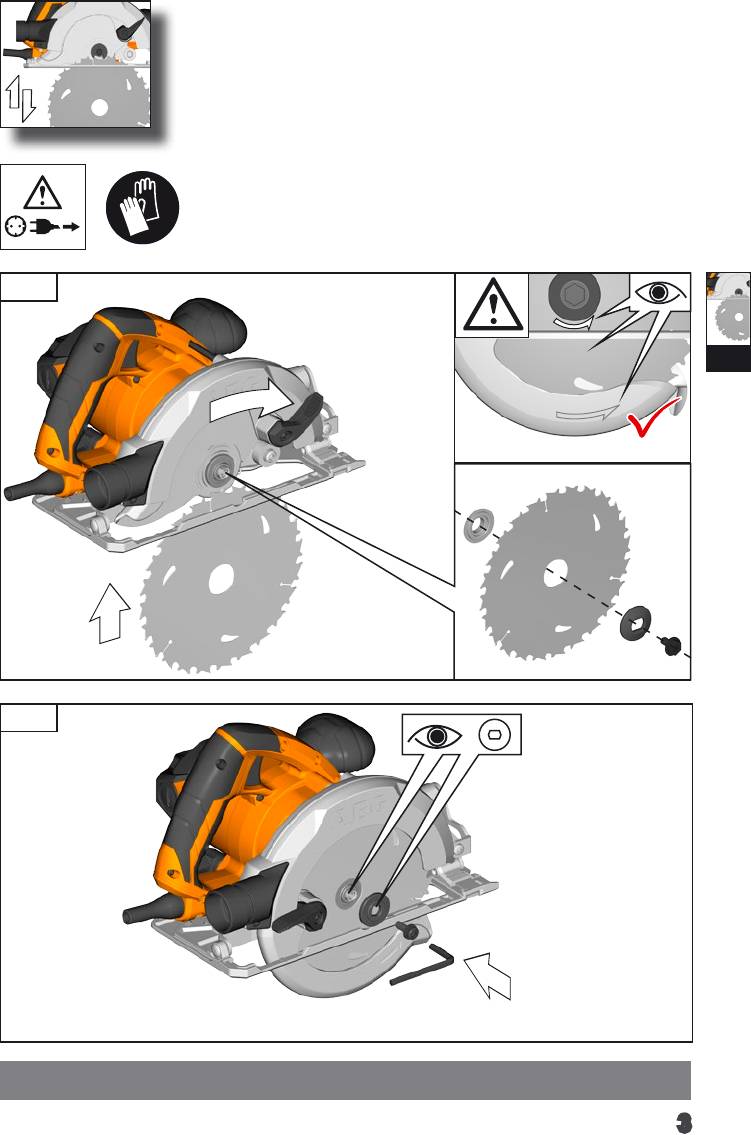

1.

1

I

2

3.2.

4

3

5

2

4.

EN 847-1

I

1

2

5.

3

3

6.

4

I

5

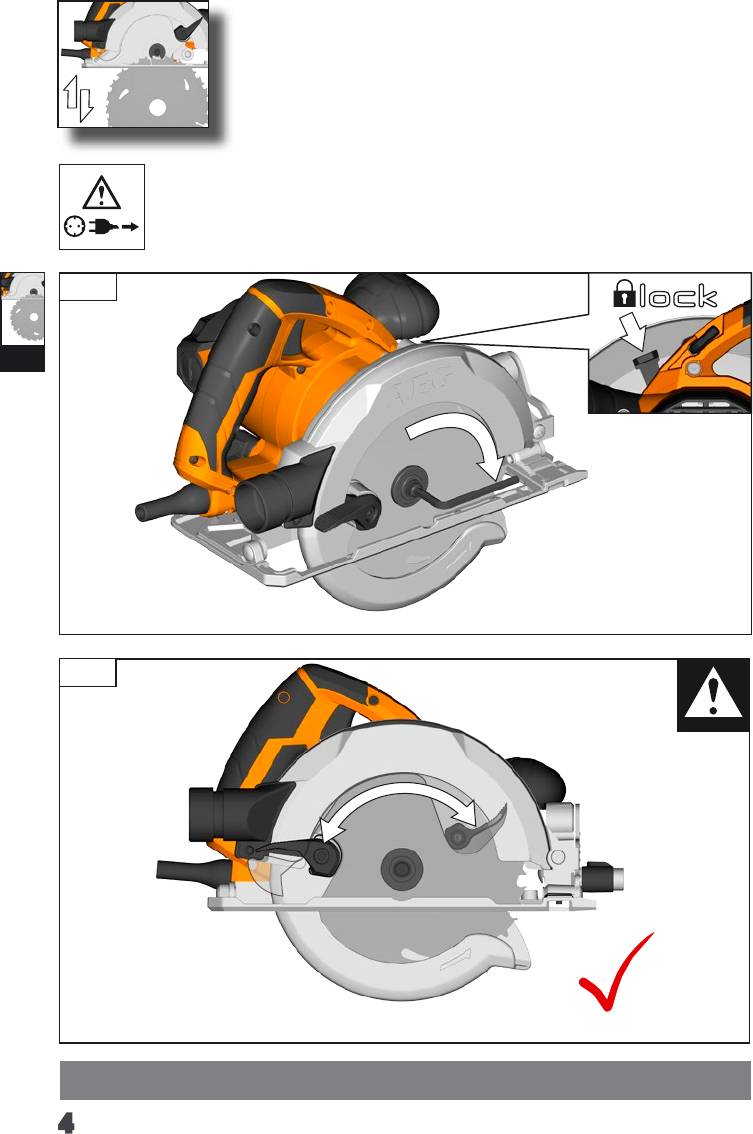

7.

2 x

4

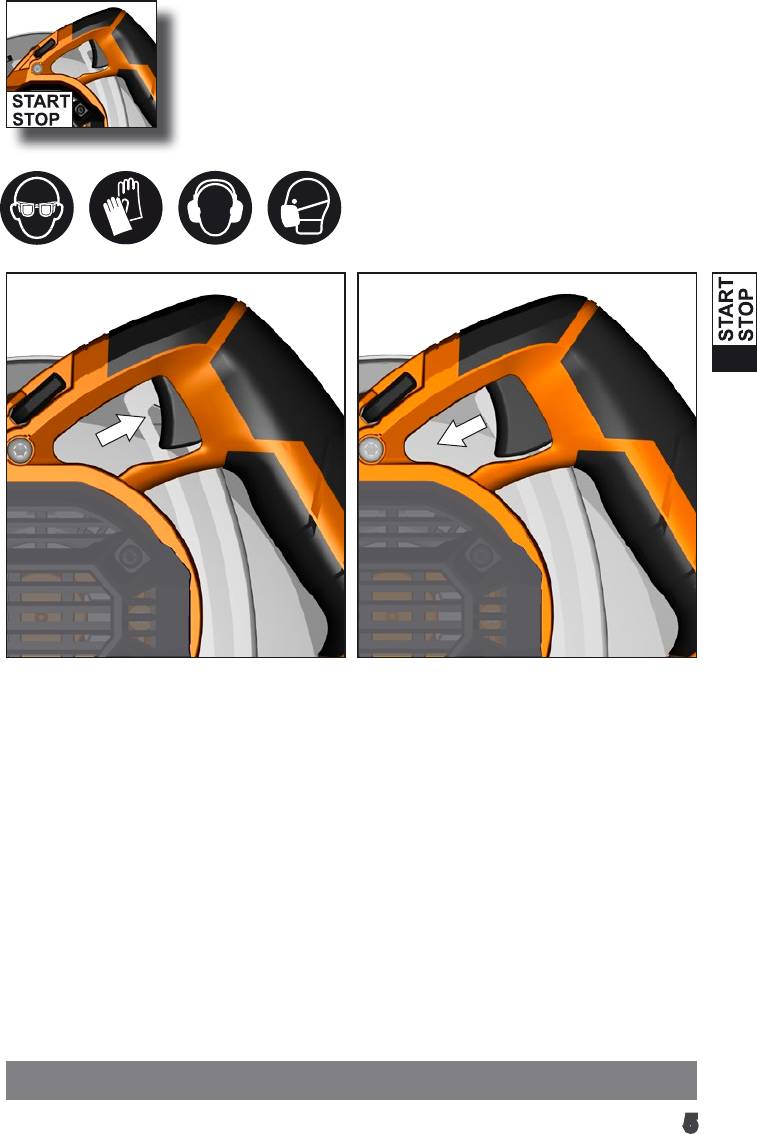

Start

Stop

II

5

1. 2.

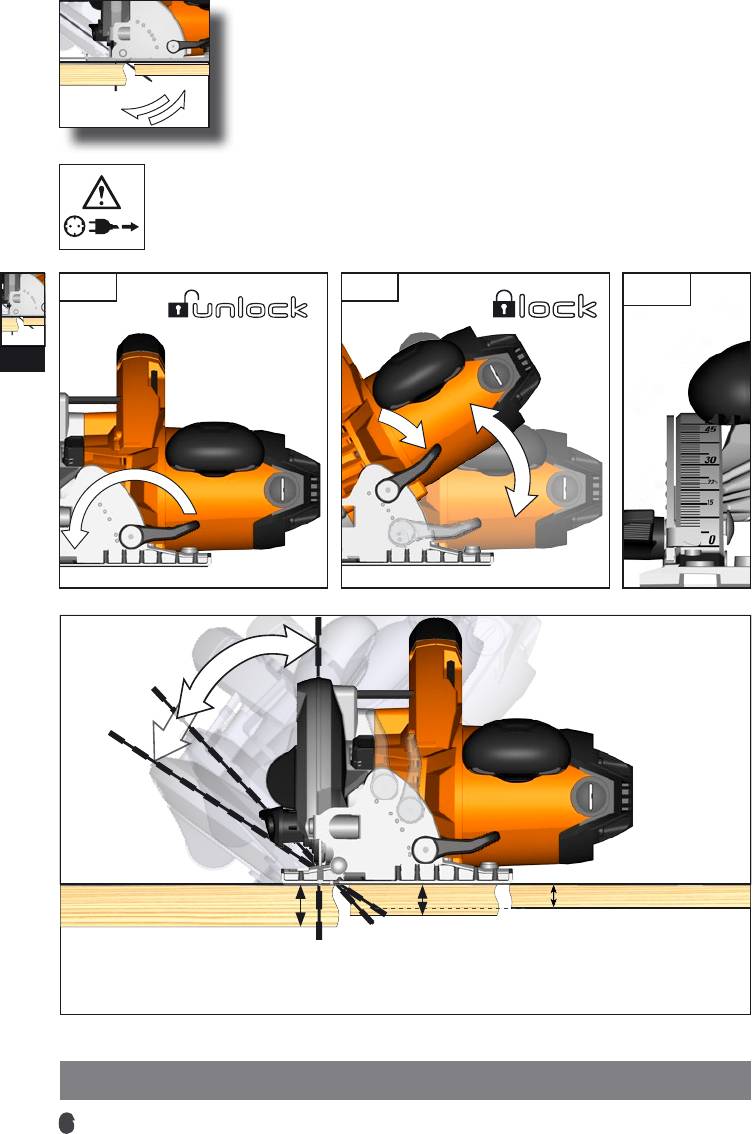

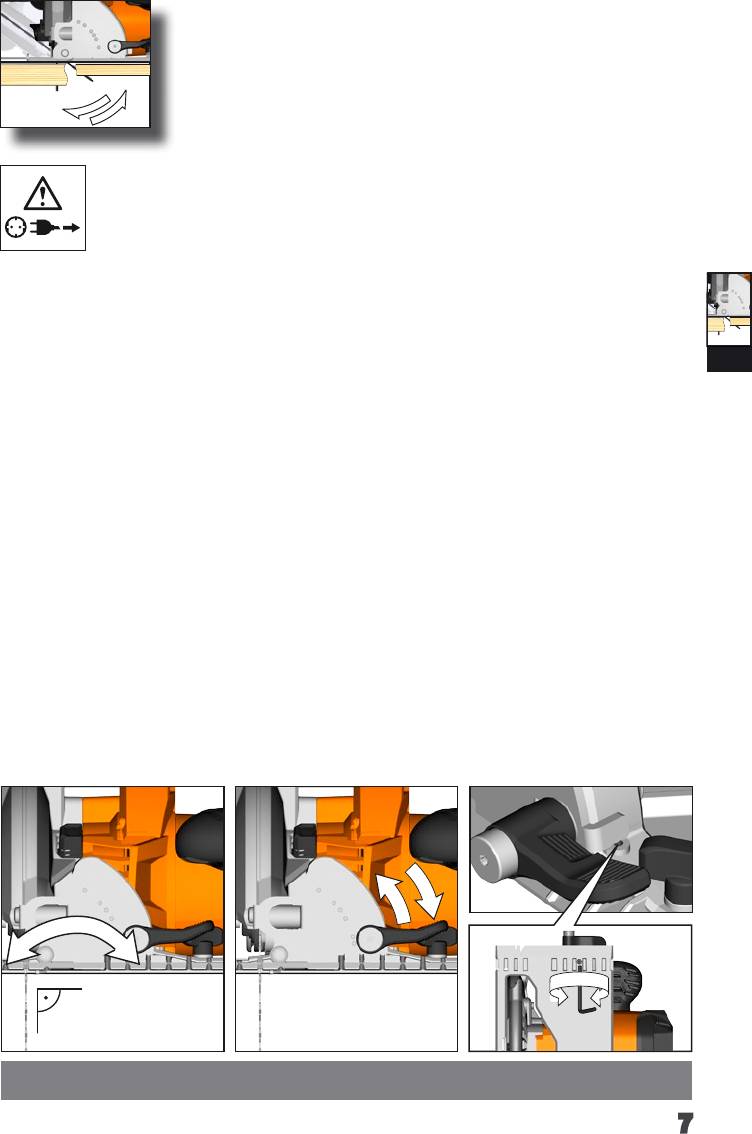

0 – 50°

III

2

3

1

38 mm

41 mm

54 mm

0° .................

45°

....................... 50°

6

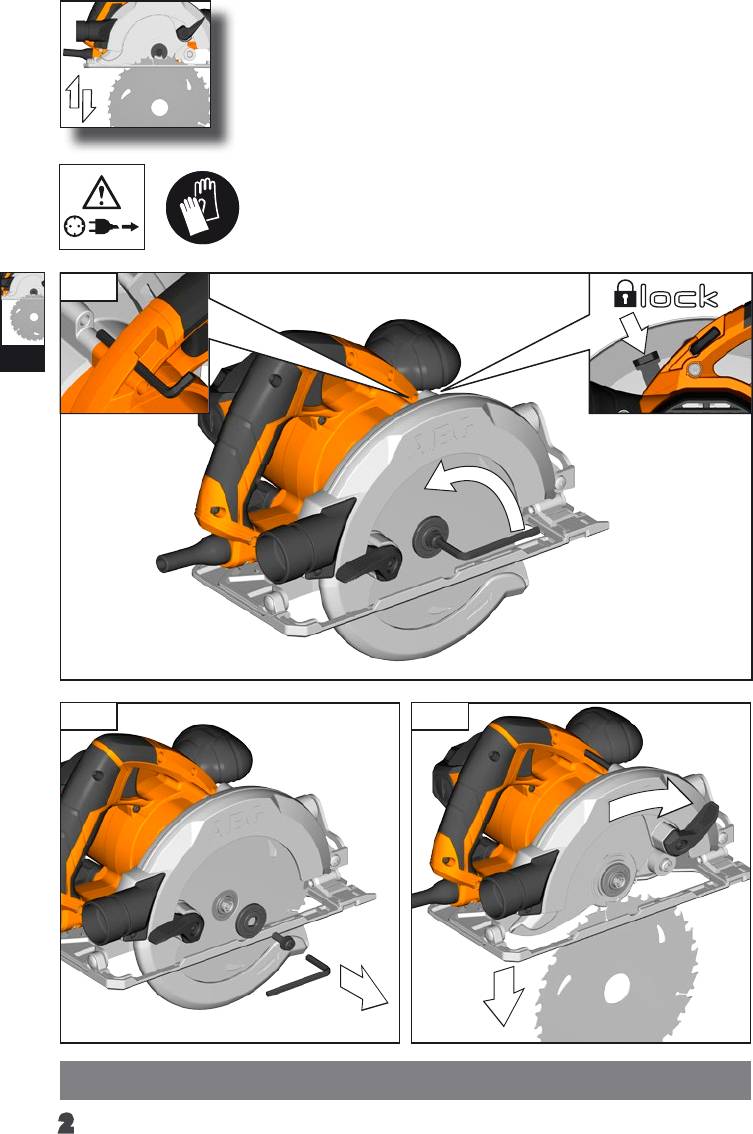

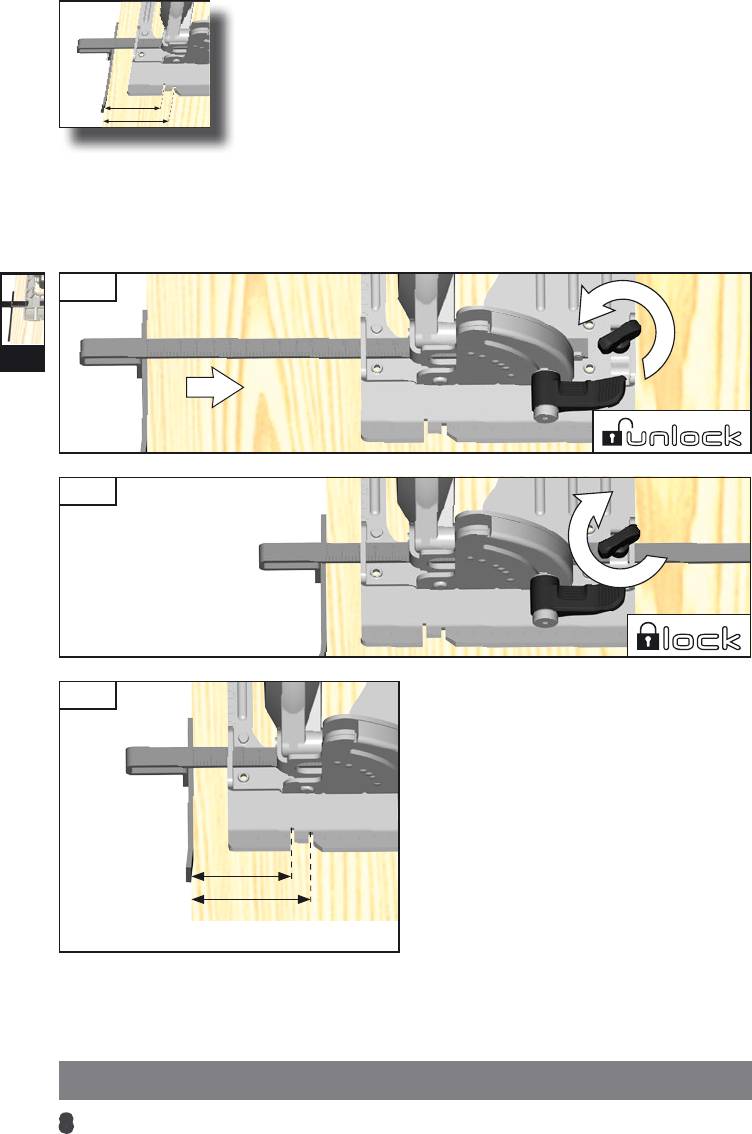

If a correction of the 90° angle of the guide-plate to the saw blade is

Ak je potrebná korektúra 90° uhlu vodiacej platne k pílovému listu, použite

necessary, use the correction screw.

korekčnú skrutku.

Falls eine Korrektur des 90° Winkels der Führungsplatte zum Sägeblatt nötig

Jeżeli konieczne jest skorygowanie kąta ustawienia płytki prowadzącej

ist, diese mit der Korrekturschraube durchführen

90° w stosunku do brzeszczota, należy wykorzystać do tego celu śrubę

regulacyjną.

Si une correction de l’angle à 90° de la plaque de base par rapport à la

lame de scie s’avère nécessaire, il convient alors d’avoir recours à la vis de

Ha az alaplap és a fűrészlap által bezárt 90 fokos szög korrekcióra szorul,

III

correction.

használja az állító csavart.

Nella caso in cui si rendesse necessaria una correzione dell ‘angolo di 90°

Če je potrebna korektura 90° kota vodilne plošče k žaginemu listu, to

della piastra di base rispetto alla lama, questa potrà essere eettuata

opravite s pomočjo korekturnega vijaka.

agendo sulla vite di correzione.

Ako je potrebno korektura kuta vodeće ploče od 90° prema listu pile, ovu

Si es necesario un ajuste o corrección de perpendicularidad (90°) del disco de

izvesti sa vijkom za korekturu.

sierra actuar sobre el tornillo de ajuste.

Gadījumā, ja nepieciešama atbalsta plāksnes 90° leņķa korekcija attiecībā

Caso se torne necessário corrigir a esquadria da base em relação ao disco de

pret zāģa ripu, izmantojiet korekcijas skrūvi.

corte, agir sobre o parafuso de anação.

Jei tarp kreipiamosios ir pjūklo reikalinga 90° laipsnių pataisa, tai atlikite

Indien een korrektie van de 90° hoek van de bodemplaat ten opzichte

pataisos varžtu.

van het zaagblad nodig is kan deze worden gekorrigeerd met de

Juhul kui on vaja parandada juhtplaadi 90° nurka saelehe suhtes, siis tehke

korrektieschroef.

seda korrigeeriva kruviga.

Såfremt det er nødvendigt med en korrektion af bundpladens 90° vinkel i

Для регулировки угла 90 град направляющей шины пильного полотна

forhold til savklingen, gennemføres denne med korrektionsskruen.

служит

Hvis det er nødvendig å foreta en justering av 90°-vinkelen på føringsplaten

регулировочный винт Ако е необходима корекция на ъгъла от 90°

i forhold til

наводещата плоча спрямо режещия диск, направете я с коригиращия

sagbladet, må dette gjøres med justeringsskruen.

винт.

Med ställskruv är det möjligt att justera 90°- vinkeln, bottenplatta till

Dacă este necesară o corecţie în unghi de 90° a plăcii de ghidare faţă de lama

sågklingan.

ferăstraului, utilizaţi şurubul de corecţie.

Mikäli pohjalevyn 90°-kulman oikaisu sahanterään nähden on tarpeen,

Доколку е потребно корегирање на аголот од 90° водечката површина

oikaisu suoritetaan oikaisuruuvista.

кон сечилото на пилата, користет го шрафот за корекција.

Kılavuz levhanın testere bıçağına 90°’lik konumunda bir düzeltme gerekiy-

Якщо необхідна корекція кута 90° напрямної пластини пилкового диску,

orsa, bunu düzeltme vidası ile yapın.

виконати корекцію за допомоги регулювального гвинта

Je-li nutná oprava kolmosti vodicí desky k pilovému kotouči, proveďte to

nastavovacím šroubem.

1

3

2

90°

7

x cm

x cm

1.

1

IV

2

2.

Carry out a test cut

Jāveic izmēģinājuma

3.

griezums!

Probeschnitt durchführen

Atlikite bandomąjį pjūvį!

Effectuer une coupe d‘essai

Teha proovilõige!

Effettuare un taglio di prova

Выполните пробный

Efectuar corte de prueba

проход

Efectuar experiências de

Направете пробно рязане!

corte

Efectuaţi un test de tăiere

Proefsnede maken

0°

45°

Да се направи пробно

Foretages et prøvesnit

сечење

Foreta prøvekutt

Виконати пробне різання

Gör ett provsnitt!

x cm

Πραγματοποιήστε μια

x cm

δοκιμαστική τομή.

Deneme kesmesi yapın

Proveďte zkušební řez.

Vykonať skušobný rez.

Wykonac próbę cięcia

Végezzen teszvágást

Opravite preizkusni rez!

Izvesti probno rezanje

8

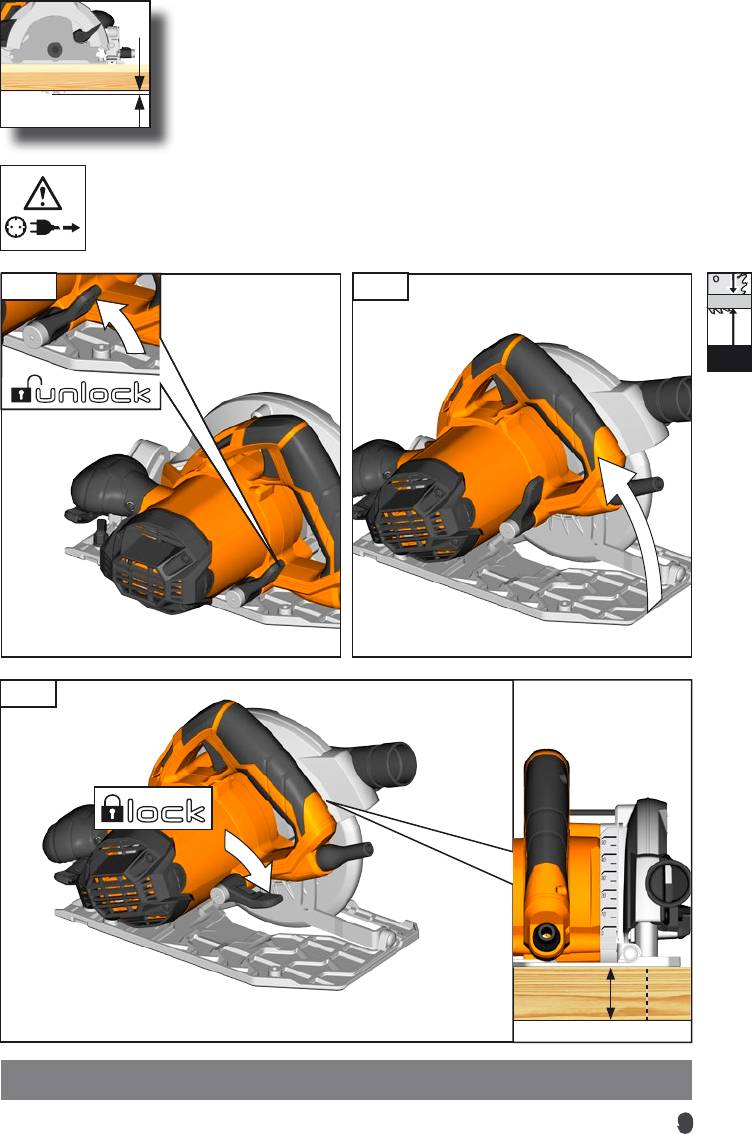

2.1.

V

3.

0 – 54 mm

9

V

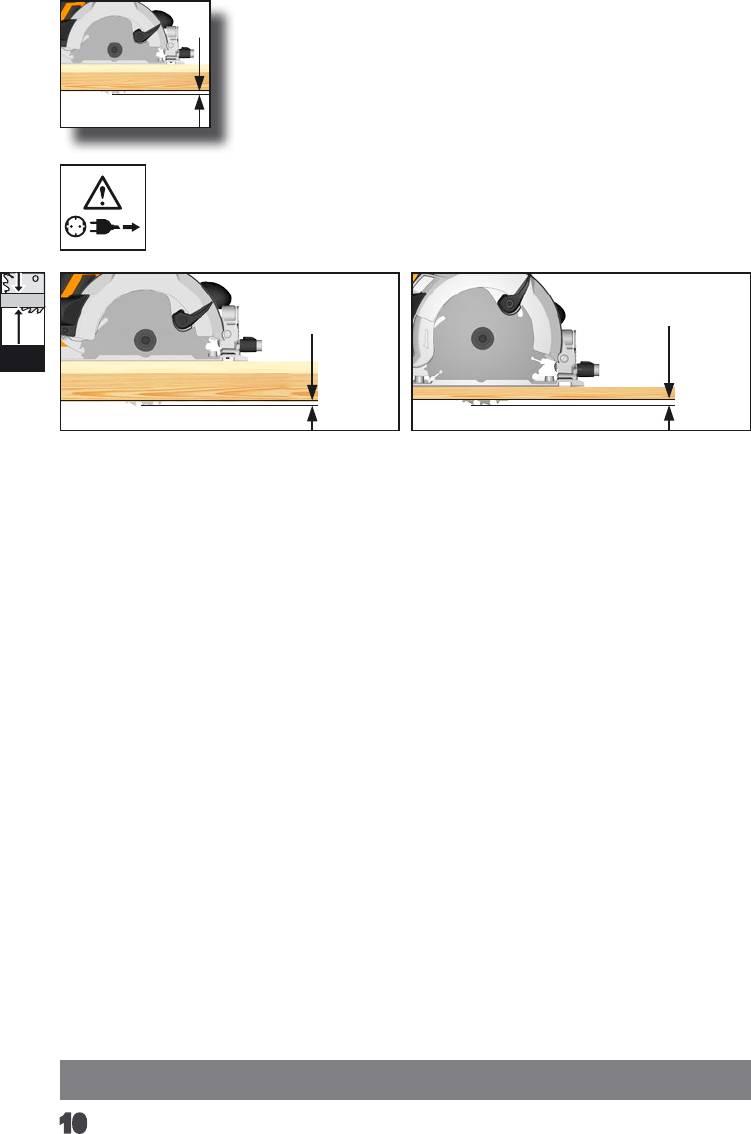

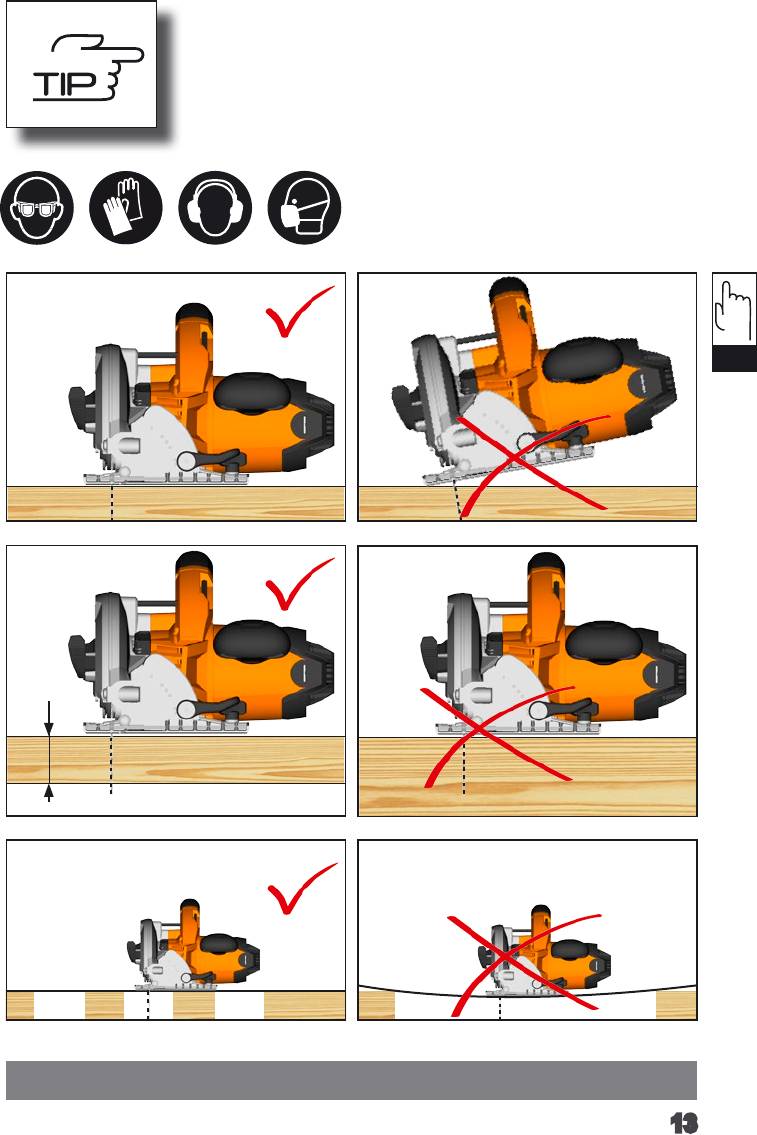

Adjust the cutting depth to the thickness of the workpiece. Less than a full

Głębokość cięcia należy dopasować do grubości obrabianego przedmiotu.

tooth of the blade teeth should be visible below the workpiece.

Powinno być widoczne mniej jak pełna wysokość zębów pod obrabianym

przedmioten.

Passen Sie die Schnitttiefe an die Dicke des Werkstücks an. Es sollte weniger

als eine volle Zahnhöhe unter dem Werkstück sichtbar sein.

A vágási mélységet a munkadarab vastagságának megfelelően kell

megválasztani. A fűrészlapból a munkadarab alatt kevesebb mind egy teljes

Adapter la profondeur de coupe à l’épaisseur de la pièce. Moins d’une dent

fogmagasságnyinak kell kilátszania.

complète devrait apparaître sous la pièce.

Prosimo, da globino reza prilagodite debelini obdelovanca. Znaša naj manj

Adattare la profondità di taglio allo spessore del pezzo in lavorazione. Nella

kot višina zoba, ki je vidna pod obdelovancem.

parte inferiore del pezzo in lavorazione dovrebbe essere visibile meno della

completa altezza del dente.

Prilagodite dubinu rezanja debljini izratka. Ispod izratka treba biti vidljiv

manje od jedan puni zub.

Adaptar la profundidad de corte al grosor de la pieza de trabajo. La hoja de

sierra no deberá sobresalir más de un diente de la pieza de trabajo.

Izvçlieties zâìçðanas dziïumu, kas atbilst zâìçjamâ priekðmeta biezumam.

Zâìçðanas dziïumam jâbût tik lielam, lai zem zâìçjamâ priekðmeta redzamâs

Adaptar a profundidade de corte à espessura da peça a ser trabalhada.

asmens daïas augstums bûtu mazâks par asmens zobu augstumu.

Deveria estar visível por aproximadamente menos do que uma altura de

dente abaixo da peça a ser trabalhada.

Pjovimo gylá tinkamai nustatykite pagal ruoðinio storá. Ruoðinio apaèioje

turi matytis ðiek tiek maþiau, nei per visà pjûklo danties aukðtá, iðlindusi

Pas de zaagdiepte aan de dikte van het werkstuk aan. Er dient minder dan

disko dalis.

een volledige tandhoogte onder het werkstuk zichtbaar te zijn.

Kohandage lõikesügavus tooriku paksusega. Saeketas võib tooriku alt

Tilpas skæredybden efter arbejdsemnets tykkelse. Der må maksimalt være

vähem kui ühe täishamba võrra välja ulatuda.

en hel tandhøjde synlig under emnet.

Устанавливайте глубину реза в соответствии с толщиной детали. Под

Tilpass skjæredybden til tykkelsen på arbeidsstykket. Det skal være mindre

деталью пильное полотно не должно высовываться более чем на один

enn en full tannhøyde synlig under arbeidsstykket.

зуб.

Anpassa sågdjupet till arbetsstyckets tjocklek. Den synliga delen av en tand

Винаги настройвайте дълбочината на рязане съобразно дебелината

under arbetsstycket måste vara mindre än en hel tand.

на стената на обработвания детайл. От обратната страна на детайла

Aseta leikkaussyvyys työkappaleen paksuuden mukaan. Työkappaleen alla

дискът трябва да се подава на разстояние, по-малко от една височина

tulisi terää näkyä korkeintaan täysi hammaskorkeus.

на зъба.

Προσαρμόστε το βάθος κοπής στο πάχος του υπό κατεργασία τεμαχίου. Κάτω

Adaptaţi adâncimea de tăiere la grosimea piesei de lucru. Sub piesa de lucru

το υπό κατεργασία τεμάχιο πρέπει να φαίνεται λιγότερο από ένα ολόκληρο

ar trebui să se vadă mai puţin de înălţimea întreagă a unui dinte.

δόντι του πριονόδισκου.

Прилагодете ја длабочината на засекот во зависност од густината на

Kesme derinliğini iş parçasının kalınlığına göre ayarlayın. İş parçası altında

обработуваното парче. Нешто помалку од цел забец од сечилото треба

tam diş uzunluğunun daha azı görünmelidir.

да биде видлив под работното парче.

Přizpůsobte hloubku řezu tloušťce obrobku. Pod obrobkem by měla být

Глибина різання повинна відповідати товщині заготовки.

viditelná méně než celá výška zubu.

Hrúbku rezu prispôsobte hrúbke obrobka. Pod obrobkom by malo byť vidieť

menej pílového listu ako plnú výšku zuba píly.

10

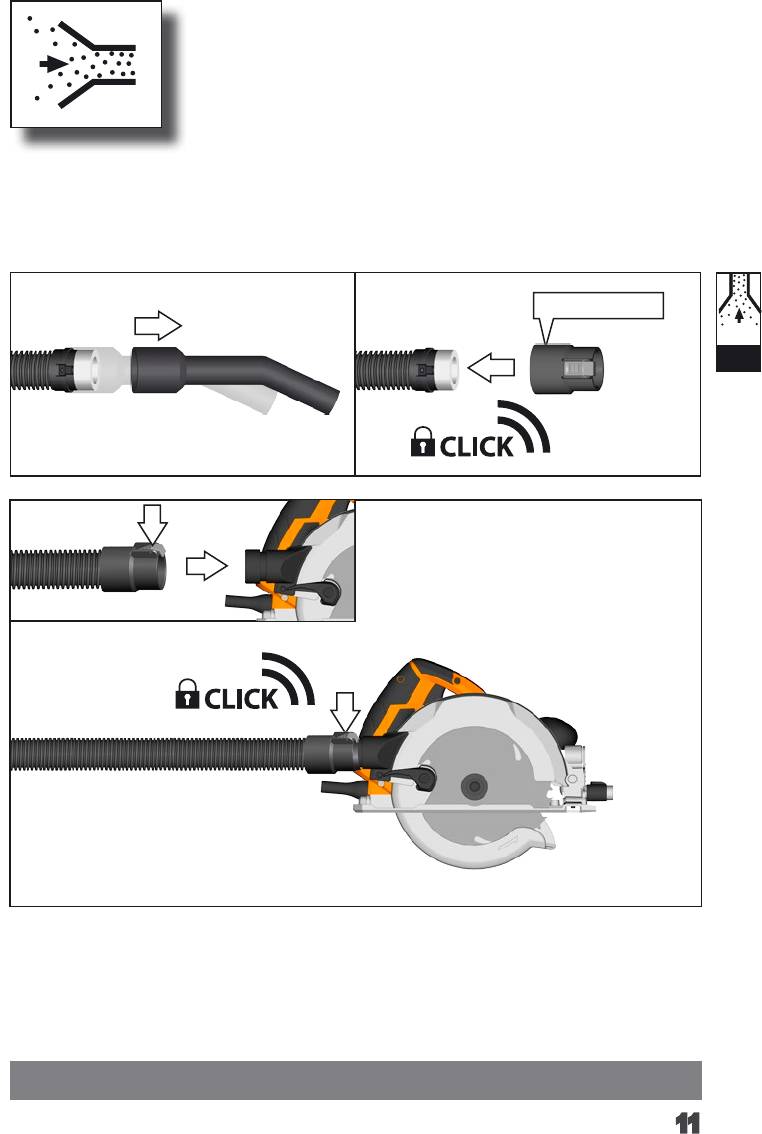

Aufnahme

aufschrauben

No. 4931 4472 95

1

VI

2

1

2

3

11

Aufnahme

aufschrauben

1. Start

TIP

VII

2.

3. Stop

0° 45°

12

Aufnahme

aufschrauben

TIP

VII

max. 54 mm

13

d) Never hold the workpiece in your hands or across

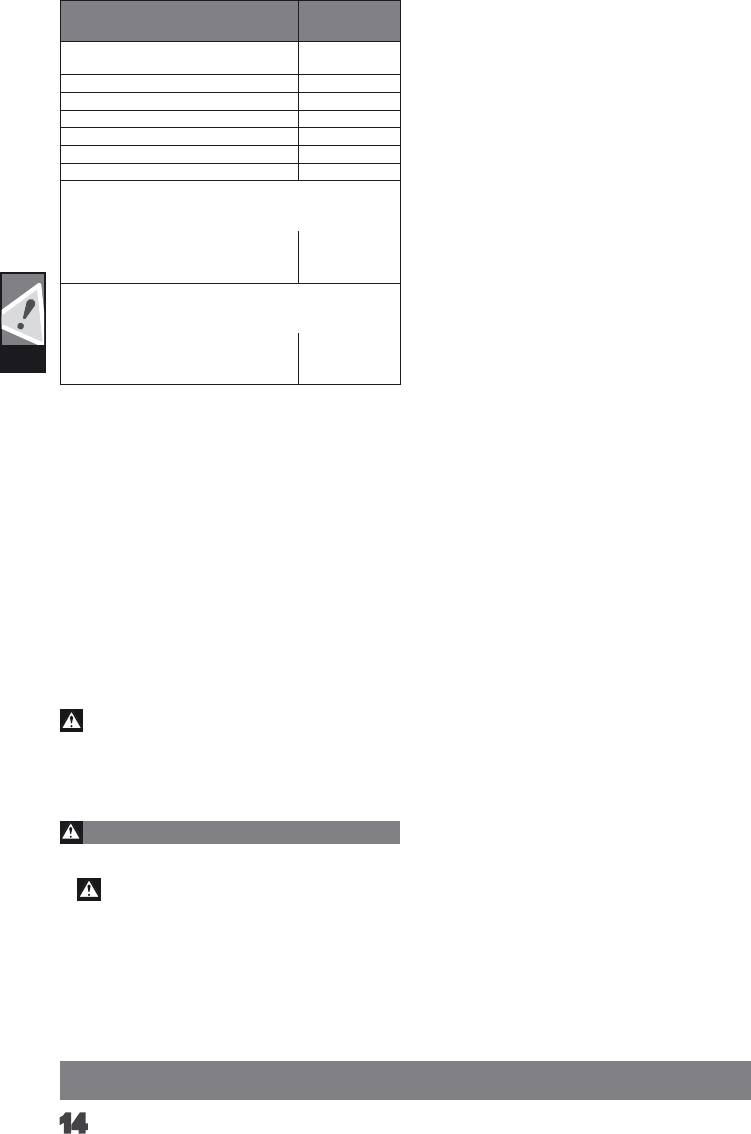

TECHNICAL DATA

your leg while cutting. Secure the workpiece to a stable

Circular saw

KS 55-2

platform. It is important to support the work properly to minimise

Production code 4466 66 02 ...

body exposure, blade binding, or loss of control.

... 000001-999999

Rated input 1200 W

e) Hold the power tool by insulated gripping surfaces,

-1

No-load speed 6100 min

when performing an operation where the cutting tool may

Saw blade dia. x hole dia 165 x 20 mm

contact hidden wiring or its own cord. Contact with a "live"

Saw blade thickness 1,6 mm

wire will also make exposed metal parts of the power tool "live"

Max. Cutting depth at 0° / 45° / 50° 54 / 41 / 38 mm

and could give the operator an electric shock.

Weight according EPTA-Procedure 01/2003 3,3 kg

f) When ripping, always use a rip fence or straight edge

Noise information

guide. This improves the accuracy of cut and reduces the chance

Measured values determined according to EN 60745. Typically, the

of blade binding.

A-weighted noise levels of the tool are:

g) Always use blades with correct size and shape (diamond

Sound pressure level (Uncertainty K=3dB(A)) 92 dB(A)

versus round) of arbour holes. Blades that do not match the

Sound power level (Uncertainty K=3dB(A)) 103 dB(A)

mounting hardware of the saw will run o-centre, causing loss of

Wear ear protectors!

control.

Vibration information

Vibration total values (triaxial vector sum) determined according

h) Never use damaged or incorrect blade washers or bolt.

to EN 60745

The blade washers and bolt were specially designed for your saw,

Sawing of wood

for optimum performance and safety of operation.

2

GB

Vibration emission value a

4,5 m/s

h,W

2

Kickback causes and related warnings

Uncertainty K= 1,5 m/s

– kickback is a sudden reaction to a pinched, jammed or misaligned

WARNING!

saw blade, causing an uncontrolled saw to lift up and out of the

The vibration emission level given in this information sheet has

workpiece toward the operator;

been measured in accordance with a standardised test given in EN

– when the blade is pinched or jammed tightly by the kerf closing

60745 and may be used to compare one tool with another. It may be

down, the blade stalls and the motor reaction drives the unit

used for a preliminary assessment of exposure.

rapidly back toward the operator;

The declared vibration emission level represents the main applica-

– if the blade becomes twisted or misaligned in the cut, the teeth

tions of the tool. However if the tool is used for dierent applica-

at the back edge of the blade can dig into the top surface of the

tions, with dierent accessories or poorly maintained, the vibration

wood causing the blade to climb out of the kerf and jump back

emission may dier. This may signicantly increase the exposure

toward the operator.

level over the total working period.

Kickback is the result of saw misuse and/or incorrect operating

An estimation of the level of exposure to vibration should also

procedures or conditions and can be avoided by taking proper

take into account the times when the tool is switched o or when

precautions as given below.

it is running but not actually doing the job. This may signicantly

a) Maintain a rm grip with both hands on the saw and

reduce the exposure level over the total working period.

position your arms to resist kickback forces. Position your

Identify additional safety measures to protect the operator from

body to either side of the blade, but not in line with the

the eects of vibration such as: maintain the tool and the acces-

blade. Kickback could cause the saw to jump backwards, but kick-

sories, keep the hands warm, organisation of work patterns.

back forces can be controlled by the operator, if proper precautions

are taken.

WARNING!

b) When blade is binding, or when interrupting a cut for

Read all safety warnings, instructions, illustrations and

any reason, release the trigger and hold the saw motionless

specications provided with this device.Failure to follow the

in the material until the blade comes to a complete stop.

warnings and instructions may result in electric shock, re and/or

Never attempt to remove the saw from the work or pull the

serious injury.

Save all warnings and instructions for future reference.

saw backward while the blade is in motion or kickback may

occur.Investigate and take corrective actions to eliminate the cause

CIRCULAR SAW SAFETY WARNINGS

of blade binding.

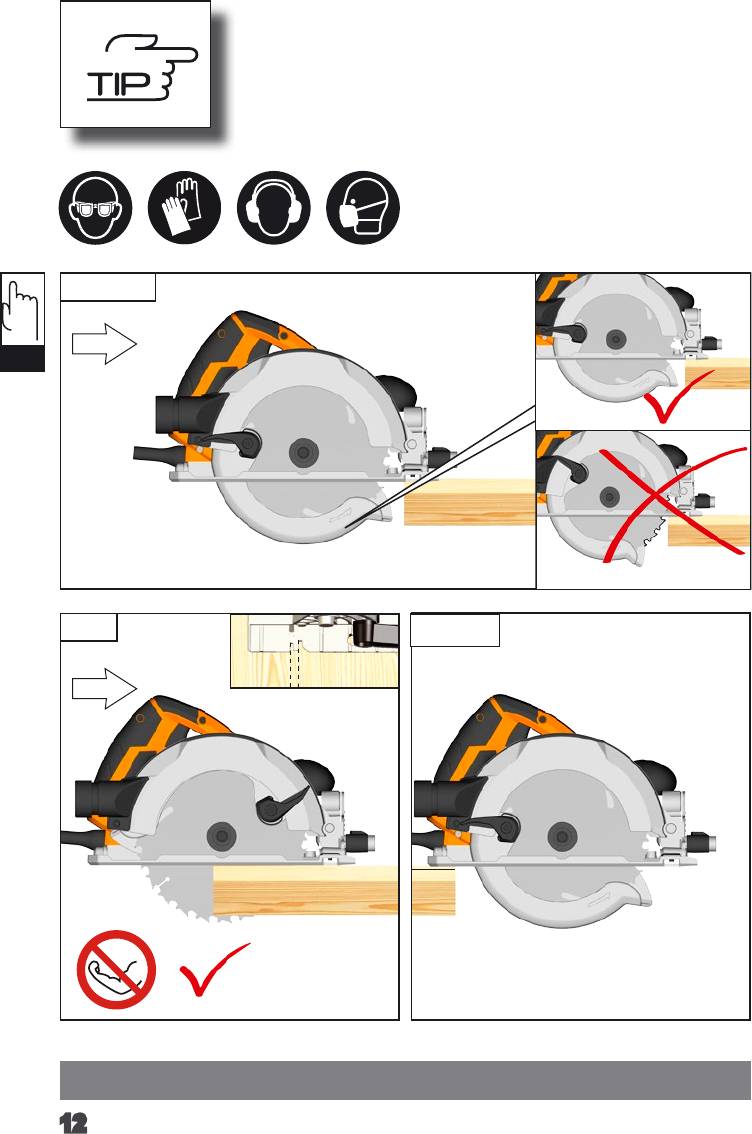

Cutting procedures

c) When restarting a saw in the workpiece, centre the saw

blade in the kerf so that the saw teeth are not engaged into

a)

DANGER: Keep hands away from cutting area and

the material. If a saw blade binds, it may walk up or kickback from

the blade. Keep your second hand on auxiliary handle, or

the workpiece as the saw is restarted.

motor housing. If both hands are holding the saw, they cannot be

d) Support large panels to minimise the risk of blade

cut by the blade.

pinching and kickback.Large panels tend to sag under their own

b) Do not reach underneath the workpiece. The guard cannot

weight. Supports must be placed under the panel on both sides,

protect you from the blade below the workpiece.

near the line of cut and near the edge of the panel.

c) Adjust the cutting depth to the thickness of the work-

e) Do not use dull or damaged blades. Unsharpened or impro-

piece. Less than a full tooth of the blade teeth should be visible

perly set blades produce narrow kerf causing excessive friction,

below the workpiece.

blade binding and kickback.

English

14

f) Blade depth and bevel adjusting locking levers must be

Do not let any metal parts enter the airing slots - danger of short

tight and secure before making the cut. If blade adjustment

circuit!

shifts while cutting, it may cause binding and kickback.

Keep mains lead clear from working range of the machine. Always

lead the cable away behind you.

g) Use extra caution when sawing into existing walls or

other blind areas. The protruding blade may cut objects that can

Before use check machine, cable, safety harness and plug for any

cause kickback.

damages or material fatigue. Repairs should only be carried out by

authorised Service Agents.

Lower guard function

SPECIFIED CONDITIONS OF USE

a) Check the lower guard for proper closing before each

This electronic circular saw can cut lengthways and mitre accura-

use. Do not operate the saw if the lower guard does not

tely in wood.

move freely and close instantly. Never clamp or tie the

lower guard into the open position. If the saw is accidentally

MAINTENANCE

dropped, the lower guard may be bent. Raise the lower guard with

Always disconnect the plug from the socket before carrying out any

the retracting handle and make sure it moves freely and does not

work on the machine.

touch the blade or any other part, in all angles and depths of cut.

Be sure to disconnect the tool from the power supply before

b) Check the operation of the lower guard spring. If the

attaching or removing the saw blade.

guard and the spring are not operating properly, they must

Clean tool and guarding system with dry cloth.

be serviced before use. Lower guard may operate sluggishly due

Certain cleaning agents and solvents are harmful to plastics and

to damaged parts, gummy deposits, or a build-up of debris.

other insulated parts.

c) The lower guard may be retracted manually only for

The ventilation slots of the machine must be kept clear at all times.

GB

special cuts such as "plunge cuts" and "compound cuts".

Remove dust regularly. Remove the sawdust which has accummu-

Raise the lower guard by the retracting handle and as soon

lated inside the saw in order to avoid the risk of re.

as the blade enters the material, the lower guard must be

Keep the apparatus handle clean, dry and free of spilt oil or grease.

released. For all other sawing, the lower guard should operate

Check the function of guards.

automatically. NOTE Alternate wording for "retracting handle" is

Regular maintenance and cleaning provide for a long service life

possible.

and safe handling.

d) Always observe that the lower guard is covering the

If the supply cord of this power tool is damaged, it must be

blade before placing the saw down on bench or oor. An

replaced by a specially prepared cord available through the service

unprotected, coasting blade will cause the saw to walk backwards,

organization.

cutting whatever is in its path. Be aware of the time it takes for the

Use only AEG accessories and spare parts. Should components

blade to stop after switch is released.

need to be replaced which have not been described, please contact

one of our AEG service agents (see our list of guarantee/service

Additional Safety and Working Instructions

addresses).

Wear ear protectors. Exposure to noise can cause hearing loss.

If needed, an exploded view of the tool can be ordered. Please

Use protective equipment. Always wear safety glasses when

state the Article No. as well as the machine type printed on the

working with the machine. The use of protective clothing is recom-

label and order the drawing at your local service agents or directly

mended, such as dust mask, protective gloves, sturdy non-slip

at: Techtronic Industries GmbH, Max-Eyth-Straße10, 71364Win-

footwear, helmet and ear defenders.

nenden, Germany.

The dust produced when using this tool may be harmful to health.

ECDECLARATION OF CONFORMITY

Do not inhale the dust. Use a dust absorption system and wear a

We declare under our sole responsibility that the product described

suitable dust protection mask. Remove deposited dust thoroughly,

under “Technical Data” fullls all the relevant provisions of the

e.g. with a vacuum cleaner.

directives

Do not use saw blades not corresponding to the key data given in

2011/65/EU (RoHS)

these instructions for use.

2006/42/EC

Do not use abrasion disks in this machine!

2014/30/EU

Do not x the on/o switch in the "on" position when using the saw

and the following harmonized standards have been used.

hand-held.

EN 60745-1:2009 + A11:2010

EN 60745-2-5:2010

WORKING INSTRUCTIONS

EN 55014-1:2006 + A1:2009 + A2:2011

Adapt the feed speed to avoid overheating the blade tips.

EN 55014-2:1997 + A1:2001 + A2:2008

EN 61000-3-2:2014

MAINS CONNECTION

EN 61000-3-11:2000

Connect only to single-phase AC system voltage as indicated on

EN 50581:2012

the rating plate. It is also possible to connect to sockets without an

earthing contact as the design conforms to safety class II.

Appliances used at many dierent locations including wet room

Winnenden, 2016-03-25

and open air must be connected via a residual current device (FI,

RCD, PRCD) of 30mA or less.

Only plug-in when machine is switched o.

English

15

Alexander Krug / Managing Director

Authorized to compile the technical le

Techtronic Industries GmbH

Max-Eyth-Straße 10, 71364 Winnenden, Germany

SYMBOLS

CAUTION! WARNING! DANGER!

Please read the instructions carefully before starting the

machine.

Always wear goggles when using the machine.

Wear ear protectors!

GB

Wear a suitable dust protection mask.

Wear gloves!

Always disconnect the plug from the socket before carrying out

any work on the machine.

Do not use force.

Accessory - Not included in standard equipment, available as an

accessory.

Do not dispose of electric tools together with household

waste material. Electric tools and electronic equipment

that have reached the end of their life must be collected

separately and returned to an environmentally compatible

recycling facility.Check with your local authority or retailer

for recycling advice and collection point.

Class II tool. Tool in which protection against electric

shock does not rely on basic insulation only, but in which

additional safety precautions, such as double insulation or

reinforced insulation, are provided. There being no provi-

sion for protective earthing or reliance upon installation

conditions.

European Conformity Mark

UkrSEPRO Conformity Mark

EurAsian Conformity Mark

English

16