Karcher Balayeuse KM 80 W P: Shutdown Maintenance and care

Shutdown Maintenance and care: Karcher Balayeuse KM 80 W P

-

4

In order to sweep the dirt to the side, the

roller brush can be swivelled to the left or

right.

This is also a benefit for removing snow by

means of the snow removal shield upgrade

kit.

Tilt the swivel bracket forwards until the

notch is free.

Swivel to the left or right, depending on

which side you wish to sweep the dirt to.

Tilt swivel bracket backwards and snap

into place.

Release parking brake.

Pull clutch lever for travel drive.

Note:

The driving speed is fixed and

cannot be modified.

Release clutch lever for travel drive.

Device comes to a halt.

Pull the lever for the roller brush drive,

roller brush is turning.

Release the lever for roller brush drive.

Roller brush comes to a halt.

Release clutch lever for roller brush

drive and travel drive.

Gas lever to "OFF" position.

Close the fuel supply.

Turn the rotating knob perpendicular to

the fuel tap.

Activate immobilising brake.

Danger

Risk of injury and damage! Observe the

weight of the appliance when you transport

it.

Switch off engine.

Empty fuel tank.

Secure the machine with tensioning

straps or cables.

When transporting in vehicles, secure

the appliance according to the guide-

lines from slipping and tipping over.

Note:

Do not kink the bowden or sheathed

cables.

Danger

Risk of injury and damage! Note the weight

of the appliance in case of storage.

Park the machine in a safe and dry

place.

Activate immobilising brake.

Follow operating instructions of the en-

gine manufacturer!

If the sweeper is going to be out of service

for a longer time period, observe the follow-

ing points:

Park the sweeper on an even surface.

Switch off engine.

Allow engine to cool down.

Drain the fuel tank and the carburettor.

Change engine oil.

Raise roller brush. In order to do this,

turn the height adjustment all the way to

the top (direction –).

Clean the device.

Park the machine in a safe and dry

place.

Activate immobilising brake.

Note:

For description, see section on Care

and maintenance.

Caution

Switch off the motor and unplug the spark

plug connector prior to performing repair,

maintenance or cleaning tasks.

Please note that only the handling of the

engine that is necessary for operating

the sweeper is explained in these in-

structions.

For all other information on the motor

please refer to the enclosed operating

manual of the manufacturer of the en-

gine!

–

Maintenance work may only be carried

out by approved customer service out-

lets or experts in this field who are famil-

iar with the respective safety

regulations.

–

Mobile appliances used for commercial

purposes are subject to safety inspec-

tions according to VDE 0701.

Caution

Do not clean the appliance with a water

hose or high-pressure water jet (danger of

short circuits or other damage).

Clean the machine with a damp cloth

which has been soaked in mild deter-

gent.

Note:

Do not use aggressive cleaning

agents.

Note:

With a new motor, the oil must be

changed after the first 5 operating hours.

In order to safeguard warranty claims, all

service and maintenance work during the

warranty period must be carried out by the

authorised KÄRCHER specialist in accord-

ance with the maintenance booklet.

Note:

Where maintenance is carried out by

the customer, all service and maintenance

work must be undertaken by a qualified

specialist. If required, a specialised Kärch-

er dealer may be contacted at any time.

Note:

For description, see section on Main-

tenance work.

Daily maintenance:

Check engine oil level.

Check air filter.

Check tyre pressure.

Check the roller brush for wear and

wrapped belts.

Check the height adjustment of the roll-

er brush.

Check for smooth running of the

Bowden cables and the moveable parts

Maintain every 3 months or 25 hours of

operation:

Clean air filter.

Note: If the appliance is frequently used

in a dusty environment, maintain more

frequently.

Maintain every 6 months or 50 hours of

operation:

Perform a motor oil change.

Check spark plug.

Maintain every 2 years or 250 hours of

operation:

Replace the air filter.

Replace the spark plug.

Maintenance after the first month or 5 oper-

ating hours:

Carry out initial inspection.

In order to safeguard warranty claims, all

service and maintenance work during the

warranty period must be carried out by the

authorised KÄRCHER specialist in accord-

ance with the maintenance booklet.

Preparation:

Park the sweeper on an even surface.

Activate immobilising brake.

Danger

Risk of injury!

The engine requires approx. 3-4 seconds

to come to a standstill once it has been

switched off. During this time, stay well

clear of the working area.

–

Allow the machine sufficient time to cool

down before carrying out any mainte-

nance and repair work.

–

Do not touch any hot parts, such as the

drive motor and exhaust system.

Note:

The appliance may only be tilted

backwards if the fuel tank is empty.

Park the sweeper on an even surface.

Connect air pressure testing device to

tyre valve.

Check air pressure and adjust if re-

quired.

For permissible tyre air pressures see

"Technical data".

Angle adjustment roller brush

Driving operations

Roller brush drive

Turn off the appliance

Transport

Storage

Shutdown Maintenance and care

General notes

Cleaning

Cleaning the device

Maintenance intervals

Maintenance by the customer

Maintenance by Customer Service

Maintenance Works

General notes on safety

Check the tyre pressure

12

EN

-

5

Danger

Risk of burns!

Allow engine to cool down.

Wait for at least 5 minutes after switch-

ing off the engine before checking the

engine oil fill level.

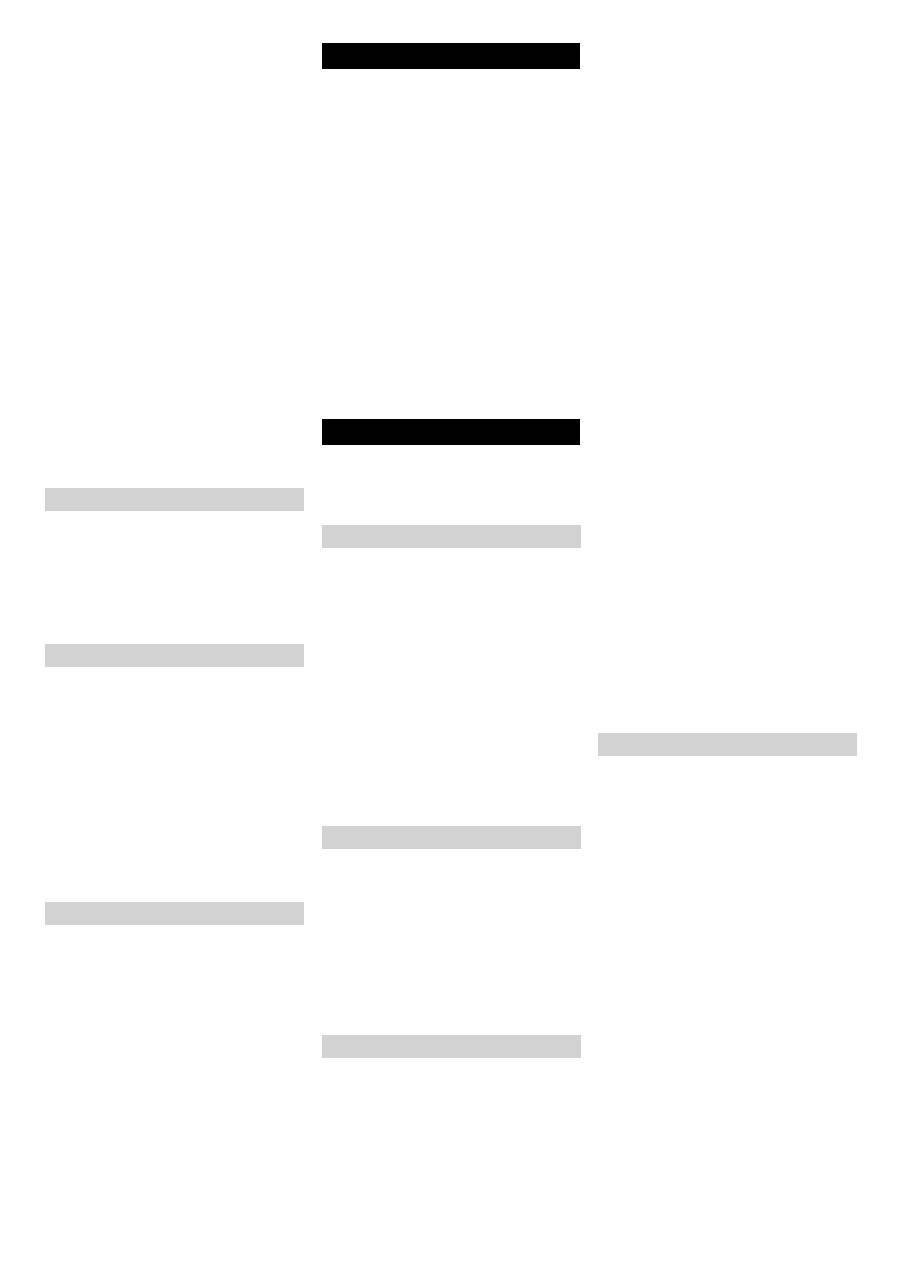

1 Oil dipstick

2 Oil filling nozzle

Unscrew and withdraw oil dipstick.

Wipe off and insert the oil dipstick (do

not turn it in).

Remove the oil dip one more time and

check the oil level.

–

The oil level must lie between “MIN“

and “MAX“ marking.

–

Add motor oil if the oil level is below the

"MIN" marking.

–

Do not fill oil above the "MAX" marking.

Fill motor oil into the oil fill neck.

For oil type refer to Chapter "Technical

specifications".

Wait at least 5 minutes.

If the engine oil level is correct, screw in

the oil dipstick.

Danger

Risk of burns due to hot oil!

Allow engine to cool down.

Open the device hood.

Unscrew and withdraw oil dipstick.

Draw off engine oil via the oil filler neck

using 6.491-538 oil-change pump.

Fill motor oil into the oil fill neck.

For oil type and filling quantity refer to

Chapter "Technical specifications".

Reinsert the oil dipstick.

Wait at least 5 minutes.

Check engine oil level.

Deliver the old oil to the respective col-

lection centres.

1 Latching tabs

2 Filter cover

3 Filter inlay

Press the locking nose in the direction

of the arrow.

Remove the filter cover.

Take out the filter inlay.

Check filter inlay and clean or replace if

required.

Blow out the filter cartridge from the in-

side using compressed air (max. 2 bar)

or knock it on a hard surface. Do not

brush down.

Carefully clean the filter housing and fil-

ter cover by means of a damp cloth and

ensure that no dirt finds its way into the

carburettor.

Close the filter cover.

Danger

Risk of burns!

Allow engine to cool down.

Remove spark-plug connector.

Unscrew and clean spark plug.

Screw in cleaned or new spark plug.

Recommended spark plug: see techni-

cal data

Push on spark-plug connector.

1 Fuel cock closed

2 Hose clip

3 Fuel hose

Close fuel cock.

Turn the rotating knob perpendicular to

the fuel tap.

Press together the fuel hose from the

tank to the fuel tap.

Loosen the hose clamp on the fuel tap.

Remove the fuel hose.

Open fuel filler cap.

Hold the fuel hose over a suitable catch

bin and drain the fuel.

If the tank is empty, reattach the fuel

hose to the stub of the fuel tap and in-

stall the hose clamp.

Note

: If the appliance is not used for a

longer period of time, drain the carbu-

rettor too. In order to do so, start the

motor and let it run until it stops due to

a lack of fuel.

Remove belts or cords from roller

brush.

Replacement is due if a visible deteriora-

tion in sweeping performance caused by

bristle wear despite height adjustment of

the roller brush is evident.

Park the sweeper on an even surface.

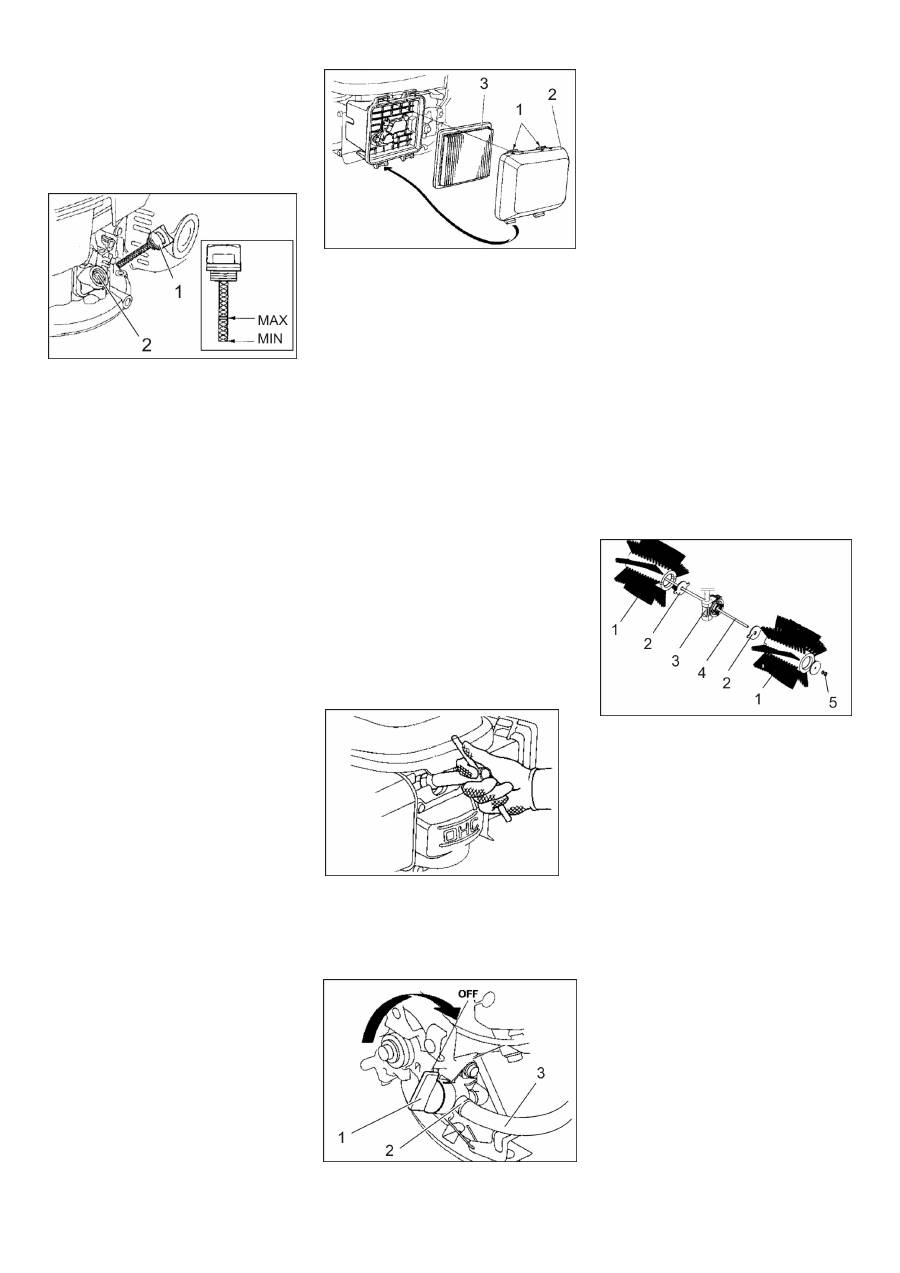

1 Roller brush

2 Dog plate

3 Dog, roller brush drive

4 Threaded rod

5 Nut

Loosen the nut on the threaded rod and

pull out the rod.

Remove the roller brush halves and re-

place it by new ones.

Note

: Ensure that the recesses of the

roller brush halves point towards the

dog.

Insert the threaded rod and secure it by

means of a nut.

Set the roller brush to the proper height,

using the height adjustment.

Check engine oil level and top up, if re-

quired

Change the engine oil

Clean or replace filter cartridge

Clean or replace the spark plug

Empty fuel tank

Checking roller brush

Replacing roller brush

13

EN

Оглавление

- Deutsch

- Sicherheitshinweise

- Bedien- und Funktionsele- mente

- Stilllegung Pflege und Wartung

- Hilfe bei Störungen

- EG-Konformitätserklärung

- English

- Safety instructions

- Operating and Functional El- ements

- Shutdown Maintenance and care

- Troubleshooting

- EC Declaration of Conformity

- Français

- Utilisation conforme

- Eléments de commande et de fonction

- Remisage Entretien et maintenance

- Assistance en cas de panne

- Déclaration de conformité CE

- Italiano

- Norme di sicurezza

- Elementi di comando e di fun- zione

- Fermo dell'impianto Cura e manutenzione

- Guida alla risoluzione dei guasti

- Dichiarazione di conformità CE

- Nederlands

- Veiligheidsinstructies

- Elementen voor de bediening en de functies

- Stillegging Onderhoud

- Hulp bij storingen

- EG-conformiteitsverklaring

- Español

- Indicaciones de seguridad

- Elementos de operación y funcionamiento

- Parada Cuidados y mantenimiento

- Ayuda en caso de avería

- Declaración de conformidad CE

- Português

- Avisos de segurança

- Elementos de comando e de funcionamento

- Desactivação da máquina Conservação e manutenção

- Ajuda em caso de avarias

- Declaração de conformidade CE

- Dansk

- Sikkerhedsanvisninger

- Betjenings- og funktionsele- menter

- Afbrydning/nedlæggelsePleje og vedligeholdelse

- Hjælp ved fejl

- EU-overensstemmelseser- klæring

- Norsk

- Forskriftsmessig bruk

- Betjenings- og funksjonele- menter

- Sette bort Pleie og vedlikehold

- Feilretting

- EU-samsvarserklæring

- Svenska

- Säkerhetsanvisningar

- Manövrerings- och funktions- element

- Nedstängning Skötsel och underhåll

- Åtgärder vid störningar

- Försäkran om EU-överens- stämmelse

- Suomi

- Turvaohjeet

- Ohjaus- ja käyttölaitteet

- Seisonta-aika Hoito ja huolto

- Häiriöapu

- EU-standardinmukaisuusto- distus

- Πίνακας περιεχομένων

- Χρήση σύμφωνα με τους κα - νονισμούς

- Στοιχεία χειρισμού και λει - τουργίας

- Διακοπή της λειτουργίας Φροντίδα και συντήρηση

- Αντιμετώπιση βλαβών

- Δήλωση Συμμόρφωσης των Ε . Κ .

- Türkçe

- Güvenlik uyar ı lar ı

- Kullan ı m ve çal ı ş ma eleman- lar ı

- Durdurma Koruma ve Bak ı m

- Ar ı zalarda yard ı m

- AB uygunluk bildirisi

- Оглавление

- Использование по назначе - нию

- Описание элементов управ - ления и рабочих узлов

- Эксплуатация

- Помощь в случае неполадок

- Заявление о соответствии ЕС

- Magyar

- Rendeltetésszer ű használat

- Kezelési- és funkciós elemek

- Leállítás Ápolás és karbantartás

- Segítség üzemzavar esetén

- EK konformitási nyiltakozat

- eština

- Používání v souladu s ur č e- ním

- Ovládací a funk č ní prvky

- Odstavení Ošet ř ování a údržba

- Pomoc p ř i poruchách

- Prohlášení o shod ě pro ES

- Slovenšina

- Varnostna navodila

- Upravljalni in funkcijski ele- menti

- Mirovanje naprave Nega in vzdrževanje

- Pomo č pri motnjah

- ES-izjava o skladnosti

- Polski

- U ż ytkowanie zgodne z prze- znaczeniem

- Elementy urz ą dzenia

- Wy łą czenie z eksploatacji Czyszczenie i konserwacja

- Usuwanie usterek

- Deklaracja zgodno ś ci UE

- Românete

- Utilizarea corect ă

- Elemente de utilizare ş i func- ţ ionale

- Scoaterea din func ţ iune Îngrijirea ş i între ţ inerea

- Remedierea defec ţ iunilor

- Declara ţ ie de conformitate CE

- Slovenina

- Bezpe č nostné pokyny

- Ovládacie a funk č né prvky

- Odstavenie Starostlivos ť a údržba

- Pomoc pri poruchách

- Vyhlásenie o zhode s norma- mi EÚ

- Hrvatski

- Sigurnosni napuci

- Komandni i funkcijski ele- menti

- Stavljanje ure đ aja van pogo- na Njega i održavanje

- Otklanjanje smetnji

- EZ izjava o uskla đ enosti

- Srpski

- Namensko koriš ć enje

- Komandni i funkcioni elementi

- Stavljanje ure đ aja van pogona Nega i održavanje

- Otklanjanje smetnji

- Izjava o uskla đ enosti sa propisima EZ

- Съдържание

- Употреба по предназначе - ние

- Обслужващи и функцио - нални елементи

- Спиране от експлоатация Грижи и поддръжка

- Помощ при неизправности

- Технически данни

- Eesti

- Ohutusalased märkused

- Enne seadme kasutuselevõt- tu

- Seismapanek Korrashoid ja tehnohooldus

- Abi häirete korral

- EÜ vastavusdeklaratsioon

- Latviešu

- Noteikumiem atbilstoša lieto- šana

- Vad ī bas un funkcijas elemen- ti

- Iekonserv ē šana Kopšana un tehnisk ā apkope

- Pal ī dz ī ba darb ī bas trauc ē jumu gad ī jum ā

- EK Atbilst ī bas deklar ā cija

- Lietuviškai

- Naudojimas pagal paskirt į

- Valdymo ir funkciniai elemen- tai

- Laikinas prietaiso nenaudoji- mas Prieži ū ra ir aptarnavimas

- Pagalba gedim ų atveju

- EB atitikties deklaracija

- Перелік

- Правильне застосування

- Елементи управління і функціональні вузли

- Експлуатація

- Допомога у випадку неполадок

- Заява при відповідність Європейського співтовариства