Karcher WV 50: инструкция

Раздел: Бытовая, кухонная техника, электроника и оборудование

Тип: Насосное оборудование

Инструкция к Насосному оборудованию Karcher WV 50

SHD-R 3000

Betriebsanleitung

5.956-486 A2005937 (06/03)

!

www.karcher.com

Operating Instructions

To be handed to the operator

Read these instructions carefully before starting up the unit

Retain for future reference

Notes about these operating

Cleaning liquids

instructions

Please do not allow them to get into the

environment. Please protect the soil and

Before starting up the interior cleaner for the

dispose of waste oil in an environmentally

first time, please carefully read through

friendly way.

these instructions. In particular, you should

note all the safety information. Store these

Waste water containing mineral oil (i.e.

instructions in a safe place for future use.

petrol, etc.)

Please do not allow this waste water to get

into the ground, bodies of water or the

For whom are these instructions

sewers.

intended

Mineral oil in the high-pressure pump

All users

Mineral oil is used to lubricate the high-

Users are persons who have received

pressure pump. The waste oil resulting from

instruction on how the system functions,

an oil change, any oil and water mixture that

operators and trained specialists.

may occur, and rags that have been soaked

Trained specialists

in oil should be delivered to a proper

Trained specialists are persons who are

collection point for disposal.

professionally qualified to install and

commission this type of system.

Environmental protection

Please dispose of the packaging in an

environmentally friendly way.

The packaging materials are recyclable.

Please do not throw the packaging into the

domestic waste but in the appropriate

recyclable waste collection containers

instead.

Please dispose of old units in an

environmentally friendly way

Old units contain valuable recyclable

materials, which should be reused. You

should never allow oil and similar materials

to get into the environment. Therefore,

please dispose of old units via suitable

collection systems.

i

Important!

Waste oil may only be disposed of by the

operators of special collection points.

Please deposit your waste oil at one of

these locations. Polluting the environment

with waste oil is a criminal offence.

Detergents

KÄRCHER detergents possess demulsifying

properties (ASF). This means that they do

not interfere with the function of an oil se-

parator.

i

Important

These instructions contain descriptions of

different types of system, accessory kits

and other supplementary components.

There are significant differences between

the various parts so that you should not

encounter any problems with identifying all

the parts in your particular type of system.

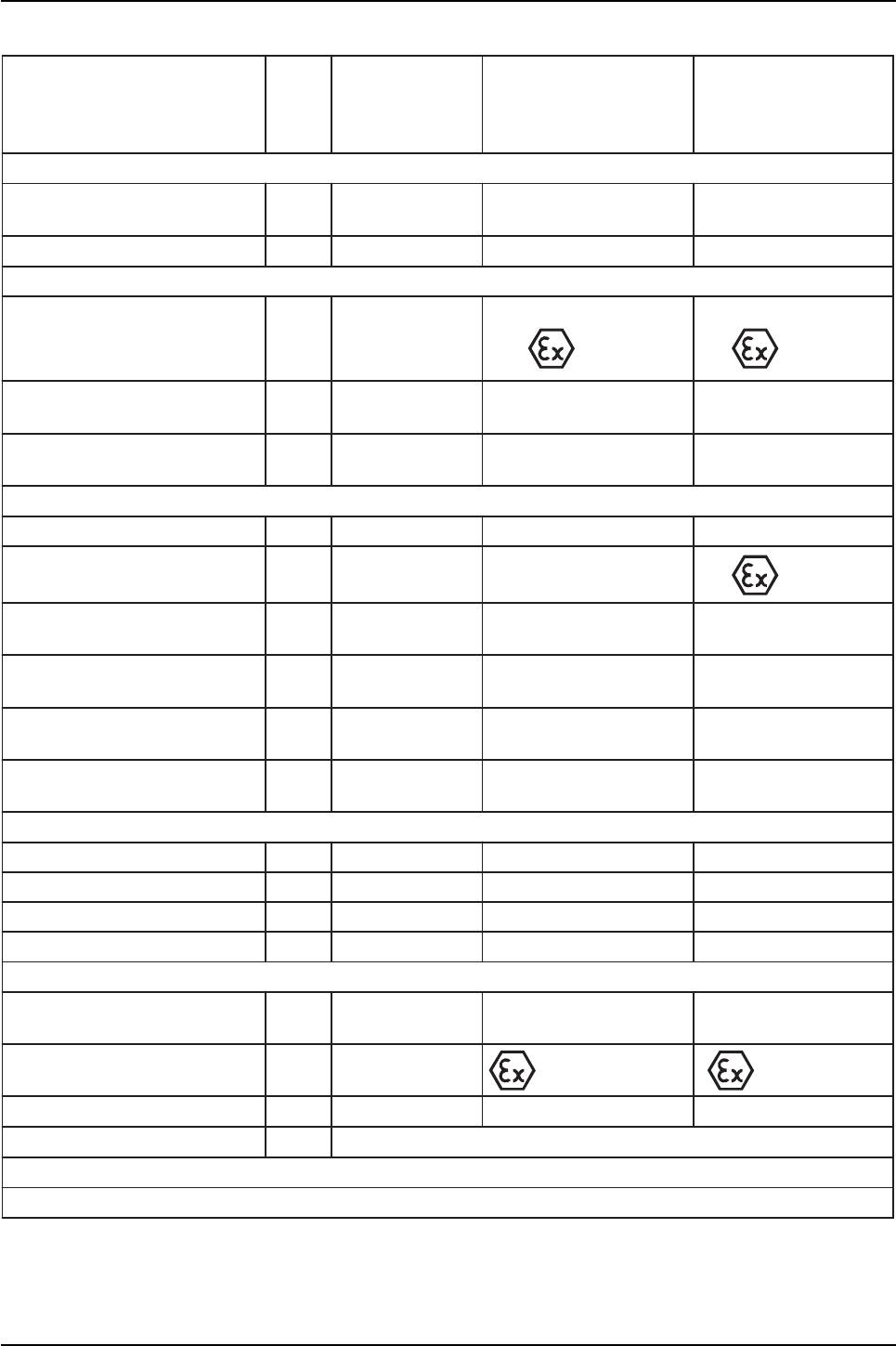

SHD-R 3000

Table of contents

English

A. For your safety

E. Care and maintenance

1. Safety information and instructions

1. General information

2. Noise protection

2. Maintenance schedule

3. Authorized operators

3. Maintenance tasks

4. Personal protective equipment

5. Emergency drill

F. Troubleshooting

6. Safety devices

1. Fault-finding

7. Applicable regulations

8. Using the system for its intended

G. Mounting kits and accessories

purpose

1. Mounting kits (non-hazardous area)

9. Special conditions in hazardous area

2. Mounting kits (hazardous area)

10. Schematic diagram of area

3. Accessories

classification

11. Area classification

H. Warranty

B. Types of system, and operating

I. System installation

information

1. Types of system

J. Declaration of Conformity

2. System start-up

3. System shut-down

K. Test record

C. System functions

D. Technical specifications

5.956-486 A2005937 (06/03)

1

English

SHD-R 3000

1. Safety information

and instructions

The following symbols are used throughout

these Operating Instructions:

5.956-486 A2005937 (06/03)

!

Danger!

Denotes an immediate and present danger.

Failure to observe this notice could lead to

severe injury or death.

Caution!

Denotes a potentially hazardous situation.

Failure to observe this notice could lead to

minor injuries or damage to property.

i

A. For your safety

All persons charged with the installation,

commissioning, operation, maintenance or

service of the machine are required:

to be appropriately qualified,

to read and observe these operating

instructions,

to be aware of and observe associated

regulations.

2. Noise protection

The sound level generated by the system is

80 dB(A).

A noise hazard can occur if the water jet is

directed at resonating components (e.g.

large metal panels). In this case a hearing

protection device must be worn.

Important!

Denotes operating hints and important

3. Authorized operators

information.

The operation of the system is restricted to

persons over the age of 18 who have

Errors in operation or misuse can result in

received proper instruction as to how this

danger to the operator or other persons

system is to be used (For exceptions for

due to:

trainees see BGV D15 Art. 6).

high water pressure,

hot liquids,

4. Personal protective equipment

high voltages,

detergents and solvents,

Explosion hazard.

In order to avoid errors in operation or

potentially dangerous situations, read the

following before starting the system up for

the first time:

all safety information in the enclosed

brochure "Safety information for high-

pressure cleaning units" No. 5.951-949,

these operating instructions,

the legal requirements that are currently

applicable in your country.

!

Danger!

Health hazard due to cleaning fluids.

Wear the prescribed protective equipment

for the cleaning liquid to be used, e.g.

protective clothing/overalls,

protective goggles or face mask,

watertight gloves,

watertight shoes.

A1

SHD-R 3000

A. For your safety

English

5. Emergency drill

Turn mains supply voltage off at system

master switch.

Turn off supply of cleaning liquid.

If a handgun is being used, release any

remaining pressure in the system by

pressing the lever on the handgun.

6. Safety devices

Safety valve

5.956-486 A2005937 (06/03)

A2

!

If acids, alkaline solutions or solvents are to

be used:

Observe the legal requirements that are

currently applicable in your country. In

Germany the regulations of the industrial

employer's liability insurance

associations apply (BGI 504).

Observe instruction leaflets provided by

manufacturers of the detergent

concentrates that are to be used with this

system.

Danger!

Injury hazard due to excessive pressure

within system. Do not adjust safety valve.

The safety valve has been preset and

sealed in the factory. Adjustments should

only be made by a Kärcher Customer

Service engineer.

7. Applicable regulations

Accident prevent regulations

Working with liquid sprayers BGV D15.

If water is used as the cleaning liquid:

Observe local regulations for disposal of

waste water.

Waste water should be directed into the

main drainage system in accordance with

local regulations.

If the water to be used is drawn from the

main supply network:

Install a mains disconnector to EN 1717

(e.g. float tank with float valve),

BetrSichV (industrial safety regulations).

i

Important!

According to the UVV (accident prevention)

Guidelines (BGV D15, Art. 23), high-

pressure sprayers must be checked by an

expert with the initial startup and at least

every 12 months thereafter. Kärcher

Customer Service engineers are qualified to

carry out the prescribed tests on your

system.

The results of the test procedures must be

recorded in writing. A form into which the

test results can be entered is shown in

Chapter K: Test Record.

English

A. For your safety

SHD-R 3000

8. Using the system for its

6. The pump's flow rate must not exceed

50 l/min when used with solvents.

intended purpose

7. The operating temperature of the cleaning

This system is used for pumping a cleaning

liquid, made up of water with cleaning agent,

liquid at high-pressure, for the purpose of:

must not exceed 60 °C.

with the handgun attached – cleaning

8. The operating temperature of the cleaning

containers, boxes, cases and equipment

liquids must not exceed 20 °C where

parts, etc.

solvents, lyes (alkali solutions) and acids

with the interior cleaner attached –

are used.

cleaning enclosed containers, drums,

9. The pump must be inspected after a

barrels, etc.

reasonable operating time to ensure it has a

faultless condition and function (among

other things, bearings for wear, pump for

Cleaning the following is considered to be

leaks, tension in the V-belt). Repair if

contrary to the intended purpose, and is

necessary.

strictly forbidden:

10. The pump may only be operated with

Persons and animals

cleaning liquids against which the materials

The high-pressure jet represents a serious

from which the pump is made have

injury hazard.

adequate resistance.

Loose objects

11. Cleaning liquids, which contain

Such items could be catapulted away by

combustible solvent fractions, must

the high-pressure jet, causing damage to

correspond to the temperature classes IIA

property or injury to persons.

and IIB. Solvents in the temperature class

IIC must not be sprayed.

If water is used as the cleaning liquid, the

12. The pump may only be operated in Zone

system must be protected against freezing

1 during cleaning. Ensure compliance with

temperatures. Damage could be caused if

the conditions applicable within the scope of

water freezes inside the system.

the BetrSichV (industrial safety regulations)

and other national conditions.

13. Hoses must be electrostatically

conductive (resistance R < 1 MΩ).

14. Only use cleaning liquids with a

9. Special Conditions in a

conductivity G > 1000 pS/m.

hazardous area

15. All parts in contact with the media are to

1. The pump may only be used in zones

be connected to the earth connection

which correspond to the type of explosion

system.

protection given on the rating plate.

16. The electric motor used must have a

2. The cleaning liquid must not contain more

prescribed type testing certificate to

than 1% by weight of undissolved solids.

94/9/EC.

3. The interior cleaner must be

electrostatically grounded.

4. The cleaning liquid pump may only be run

if it is filled with liquid.

5. The nominal pressure of the pump must

not exceed 50 bar when used with solvents.

A3

5.956-486 A2005937 (06/03)

SHD-R 3000

A. For your safety

English

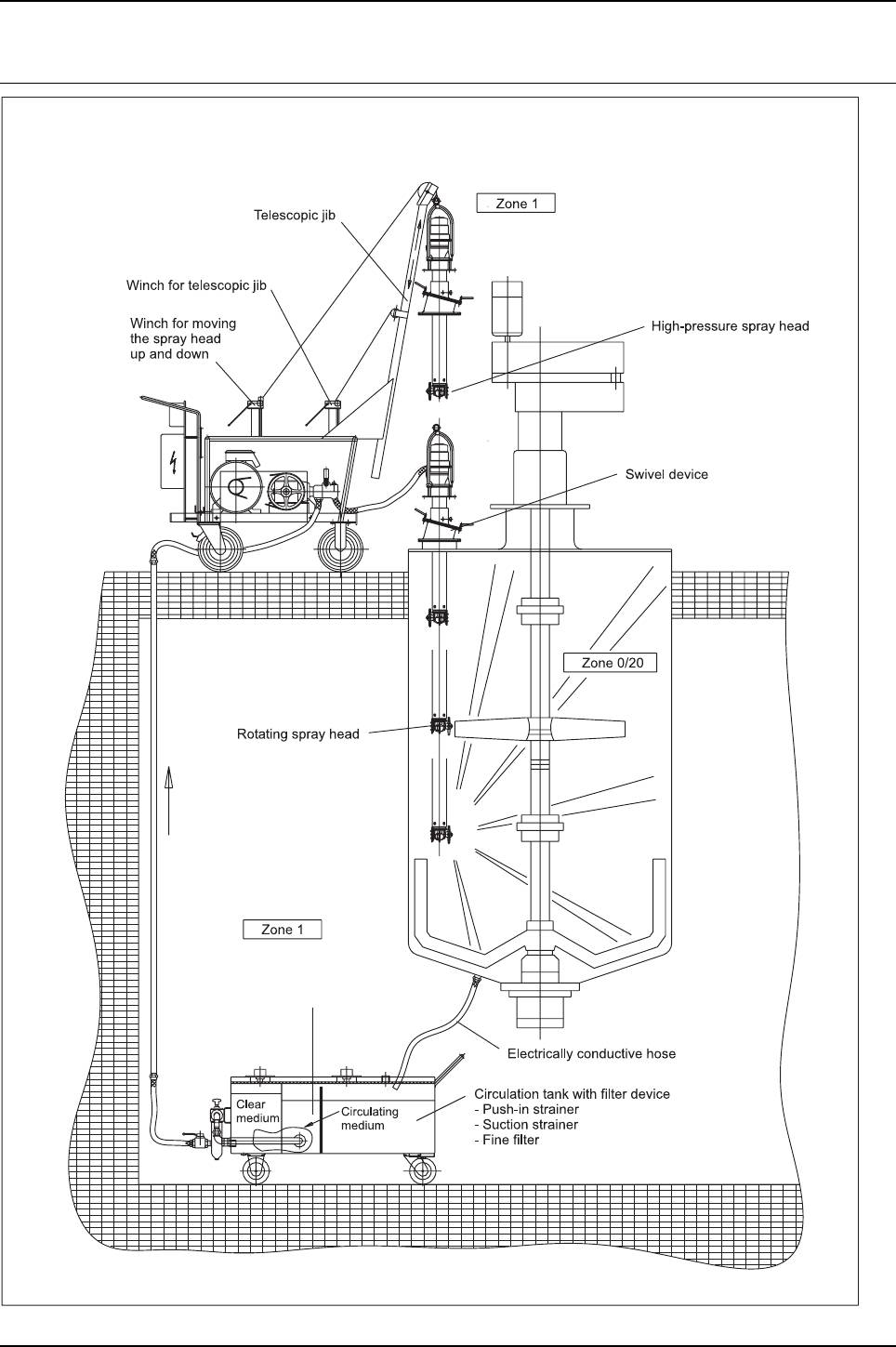

10. Schematic diagram of area classification

5.956-486 A2005937 (06/03)

A4

English

A. For your safety

SHD-R 3000

Zone 21

is an area in which hazardous, potentially

11. Area Classification

explosive atmospheres in the form of a

cloud of combustible dust contained in the

In the BetrSichV and EN 1127-1, hazardous

air can occasionally form during standard

(potentially explosive) areas are classified

operation.

into zones according to the frequency and

duration of the occurrence of hazardous,

Zone 22

potentially explosive atmospheres.

is an area in which hazardous, potentially

It is the responsibility of the owner/

explosive atmospheres in the form of a

operator to define these zones.

cloud of combustible dust contained in the

air do not form during standard operation or

Notes on area classification are given in the

only for a short time.

BetrSichV, EN 1127-1, BGR 104 - Ex-

Guidelines of BG Chemie and in

DIN EN 60 079-10.

Zone 0

is an area in which hazardous, potentially

explosive atmospheres exists constantly,

for long periods of time or frequently as a

mixture of air and combustible gases,

vapours or mists.

Zone 1

is an area in which hazardous, potentially

explosive atmospheres consisting of a

mixture of air and combustible gases,

vapours or mists can occasionally form

during standard operation.

Zone 2

is an area in which hazardous, potentially

explosive atmospheres consisting of a

mixture of air and combustible gases,

vapours or mists do not normally occur

during standard operation or only for a short

time.

Zone 20

is an area in which hazardous, potentially

explosive atmospheres in the form of a

cloud of combustible dust contained in the

air exist constantly, frequently or for long

periods of time.

A5

5.956-486 A2005937 (06/03)

SHD-R 3000

B. Types of system, and operating information

English

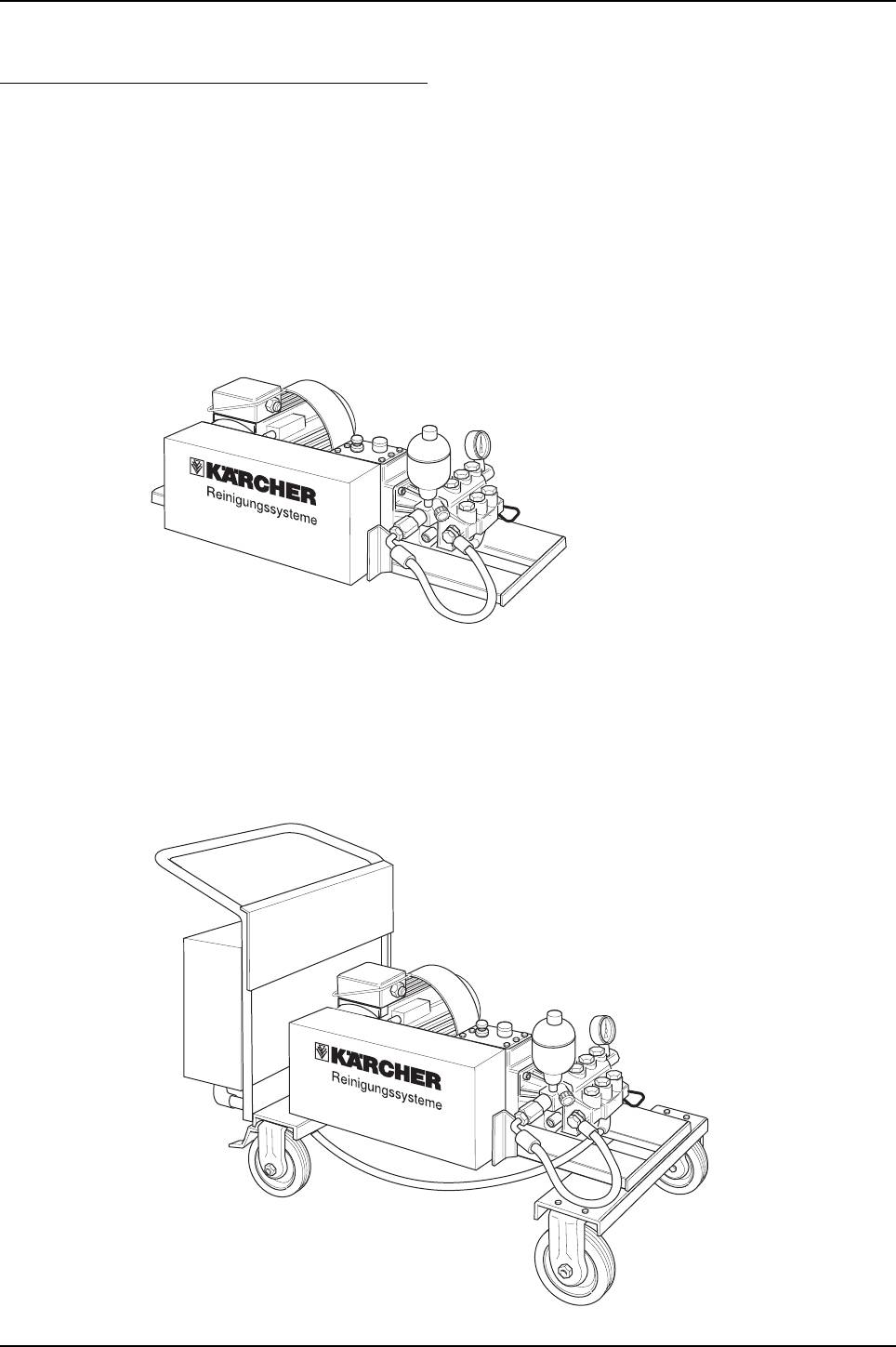

1. Types of system

Static or mobile systems

The static system

is intended to be installed on a base,

has been mounted onto a rigid steel

frame,

is most suitable for use in conjunction

with fixed-installation high-pressure lines.

The mobile system

has been mounted onto a trolley,

can be used in different locations.

5.956-486 A2005937 (06/03)

B1

English

B. Types of system, and operating information

SHD-R 3000

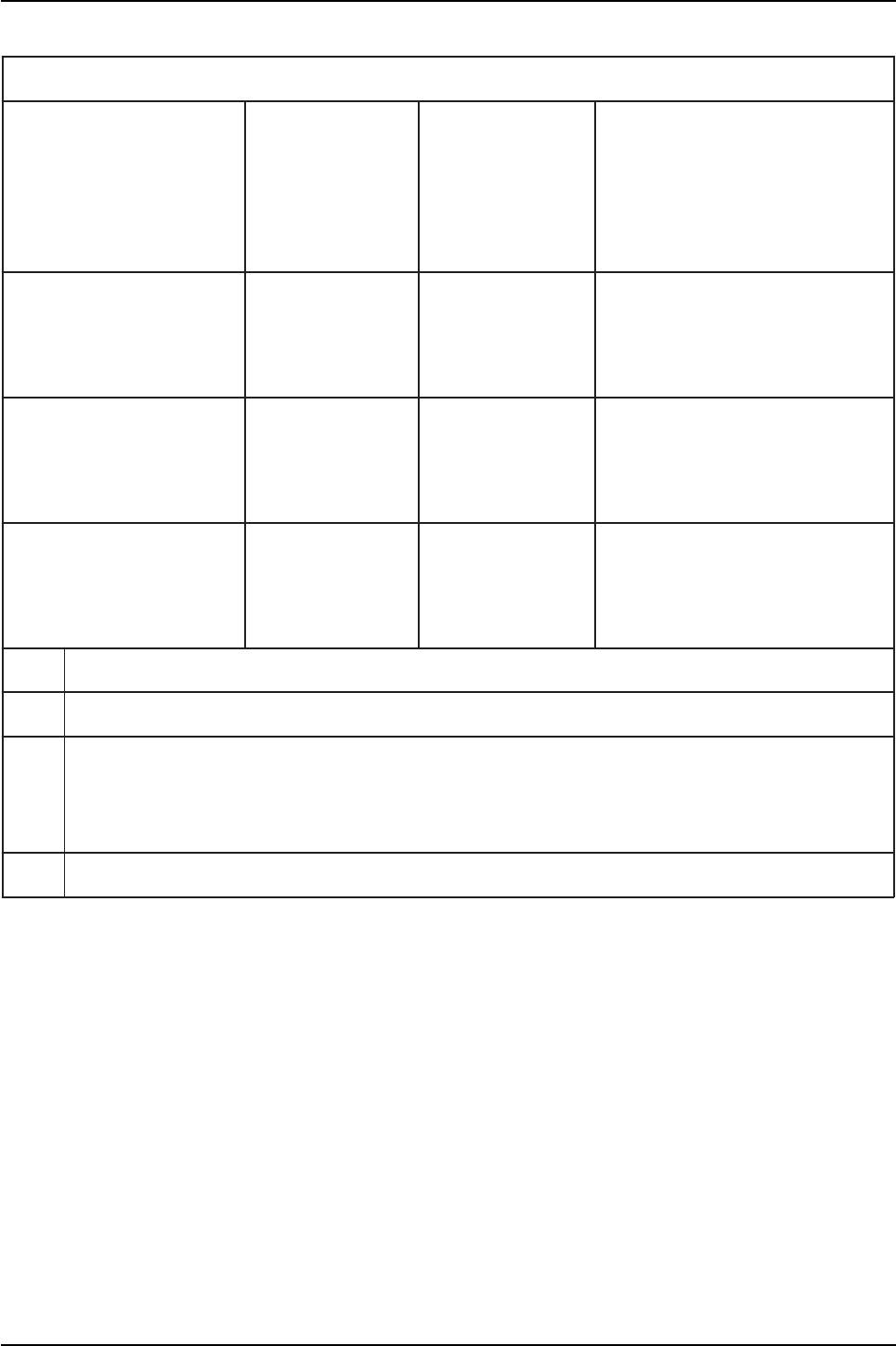

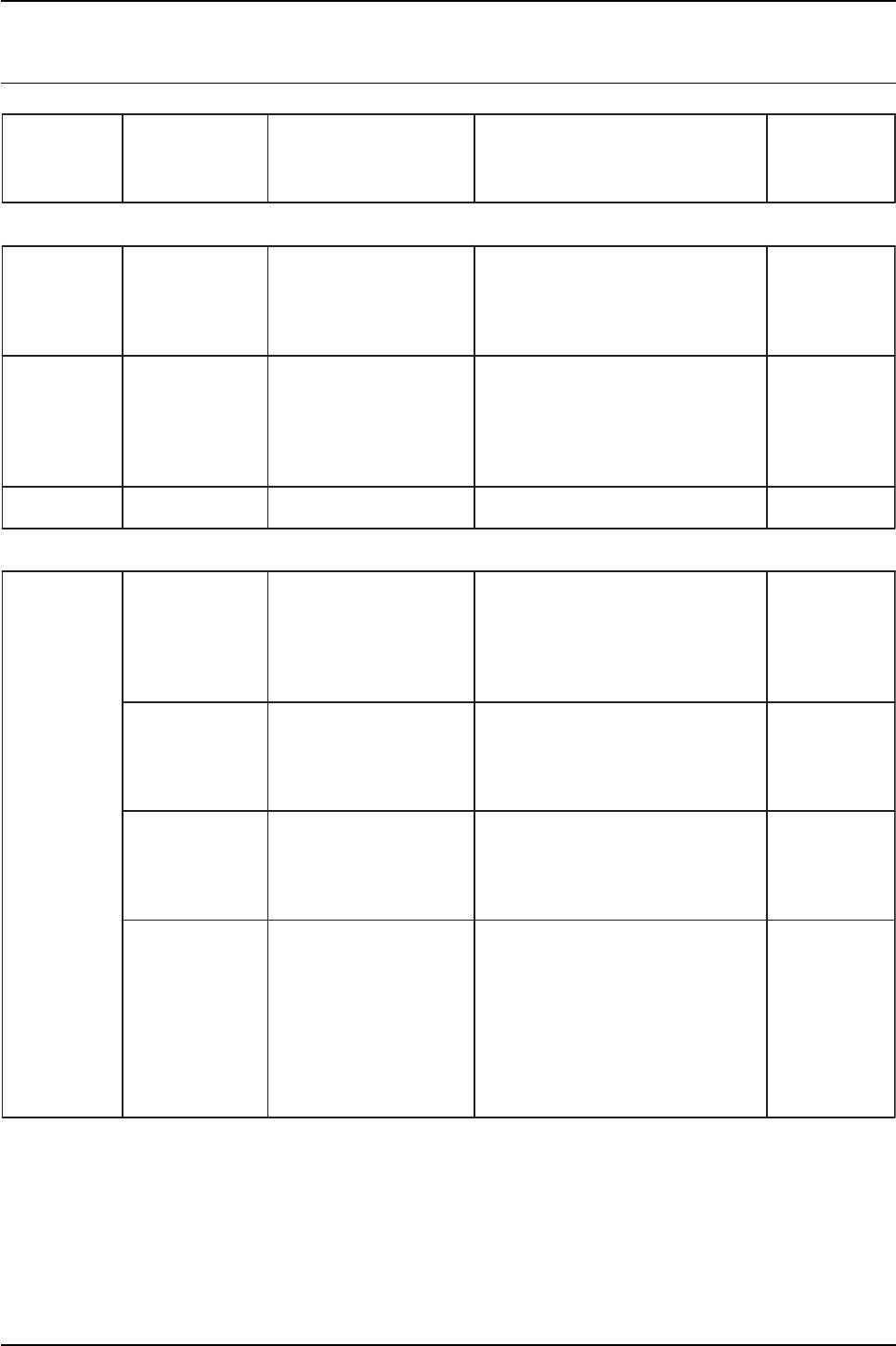

Cleaning liquids

Type of system

Cleaning liquid Working

Comments

(see rating plate)

pressure/

Pressure

setting for

safety valve

[bar]

SHD-R 3000 (F)

-

Water

50/65 Standard version

- VE

-water

*

-

Water with

Kärcher-RM

SHD-R 3000 (F) S

-

Water

85/100 Standard version with

- VE

-water

*

increased working pressure

-

Water with

Kärcher-RM

SHD-R 3000 (F) SVA

-

Water

85/100 Pump parts that come into

- VE

-water

*

contact with the cleaning liquid

are made from stainless steel.

-

Water with

Kärcher-RM

VE Fully demineralised water

* Conditionally resistant, use possible, however Cu and Zn ions in the medium

RM

RM Alkali cleaning agent: e.g. RM31 (max. 0 - 2%)

Acidic cleaning agent: e.g. RM25 (max. 0 - 1%)

Max. temperature + 60˚C

(Higher temperatures available on request - precompression pump required!)

(F) Mobile system

Other cleaning liquids may only be used after being released by Kärcher!

B2

5.956-486 A2005937 (06/03)

SHD-R 3000

B. Types of system, and operating information

English

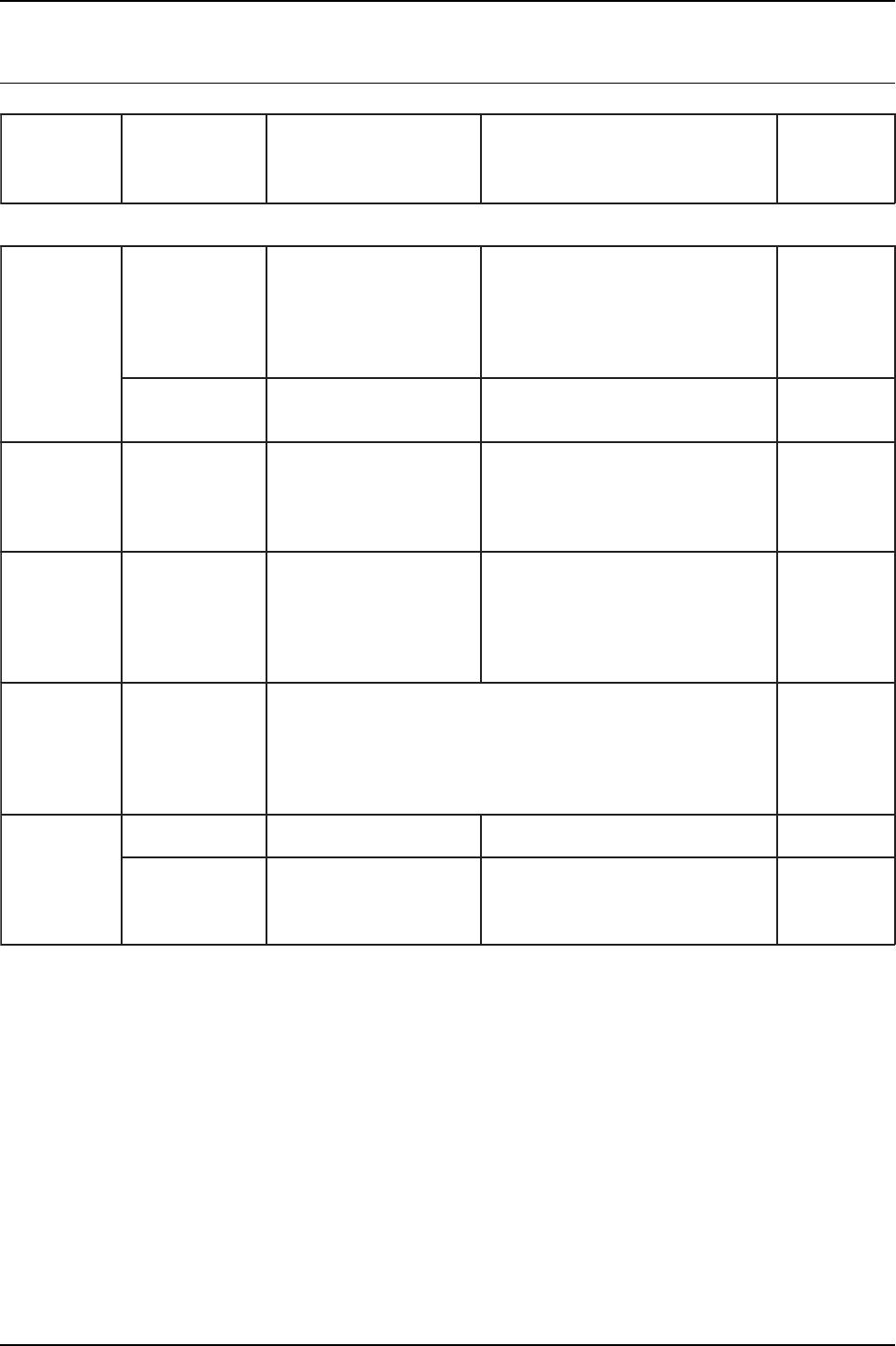

Cleaning liquids

Type of system

Cleaning liquid Working

Comments

(see rating plate)

pressure/

Pressure

setting for

safety valve

[bar]

SHD-R 3000 (F)

SSR

-

Water

85/100 - The pistons are made

- VE

-water

from ceramic materials,

-

Water with

other pump parts that

Kärcher-RM

come into contact with

1)

- Acids

acids are made from

- Alkali

stainless steel.

2)

solutions

- Ex-versions possible.

VE Fully demineralised water

RM

RM Alkali cleaning agent: e.g. RM31 (max. 0 - 2%)

Acidic cleaning agent: e.g. RM25 (max. 0 - 1%)

Max. temperature + 60 ˚C

(Higher temperatures available on request - precompression pump required!)

1)

Caution!

Increased material removal in hydrochloric and sulphuric acid, therefore rinse/neutralise

immediately after use!

Reduced resistance against contaminated acids!

If necessary contact Kärcher!

Acids (max. temperature +

20 ˚C)

Nitric acid max. 10%

Acetic acid max. 10%

Formic acid max. 10%

Phosphoric acid max. 10%

Citric acid max. 10%

Sulphuric acid max. 0.5%

Hydrochloric acid max. 0.5%

2)

Sodium hydroxide solutions max. 10%, without hypochlorite fractions

(max. temperature

+ 20 ˚C)

Potassium hydroxide max. 10%, without hypochlorite fractions (max. temperature + 20 ˚C

5.956-486 A2005937 (06/03)

B3

)

(F) Mobile system

Other cleaning liquids may only be used after being released by Kärcher!

English

B. Types of system, and operating information

SHD-R 3000

Cleaning liquids

Type of system

Cleaning liquid Working

Comments

(see rating plate)

pressure/

Pressure

setting for

safety valve

[bar]

SHD-R 3000 (F) SLA

–

Water

85/100 –

Version with increased

–

VE water*

working pressure.

–

Leaked liquid is collected in

– Water with

a pipe (leakage recycling).

Kärcher-RM

– Alkali

–

Ex-versions possible.

2)

solutions

SHD-R 3000 (F) LM

–

Water

50/65 –

Explosion-proof version.

–

VE water*

–

Leaked liquid is collected in

a pipe (leakage recycling).

– Water with

–

Additional pressure switch as

Kärcher-RM

safety device (optional).

– Alkali

2)

solutions

3)

– Solvents

VE

Fully demineralised water

*

Conditionally resistant, use possible, however Cu and Zn ions in the medium

RM

Acidic cleaning agent: e.g. RM25 (max. 0 - 1%)

Max. temperature + 60

˚C

(Higher temperatures available on request - precompression pump required!)

2)

Sodium hydroxide solutions max. 10%, without hypochlorite fractions

(max. temperature + 20 ˚C)

Potassium hydroxide max. 10%, without hypochlorite fractions (max. temperature + 20 ˚C)

3)

Solvents (max. temperature + 20 ˚C)

1. Hydrocarbons, e.g.: petroleum

2. Aromatic compounds, e.g.: benzene, toluol

3. Ketones, e.g.: MEK (methyl ethyl ketones), acetone

4. Esters, e.g.: butyl acetate, methyl acetate

5. Glycols, e.g.: butyl glycol

6. Mixed solvents, e.g.: butyl acetate 85, isobutyl acetate 85

(85=85% butyl acetate + 15% n-butanol)

7. Regenerates, distillates made from various solvents which have already been used

f

or cleaning purposes or similar.

(F) Mobile system

Other cleaning liquids may only be used after being released by Kärcher!

B4

5.956-486 A2005937 (06/03)

SHD-R 3000

B. Types of system, and operating information

English

2. System start-up

Mobile and static system

Turn on cleaning liquid supply.

Emergency drill

Switch system on at master switch.

Turn mains supply voltage of at system

master switch.

Commence cleaning with high-pressure

jet.

Turn off supply of cleaning liquid.

If a handgun is being used, release any

remaining pressure in the system by

pressing the lever on the handgun.

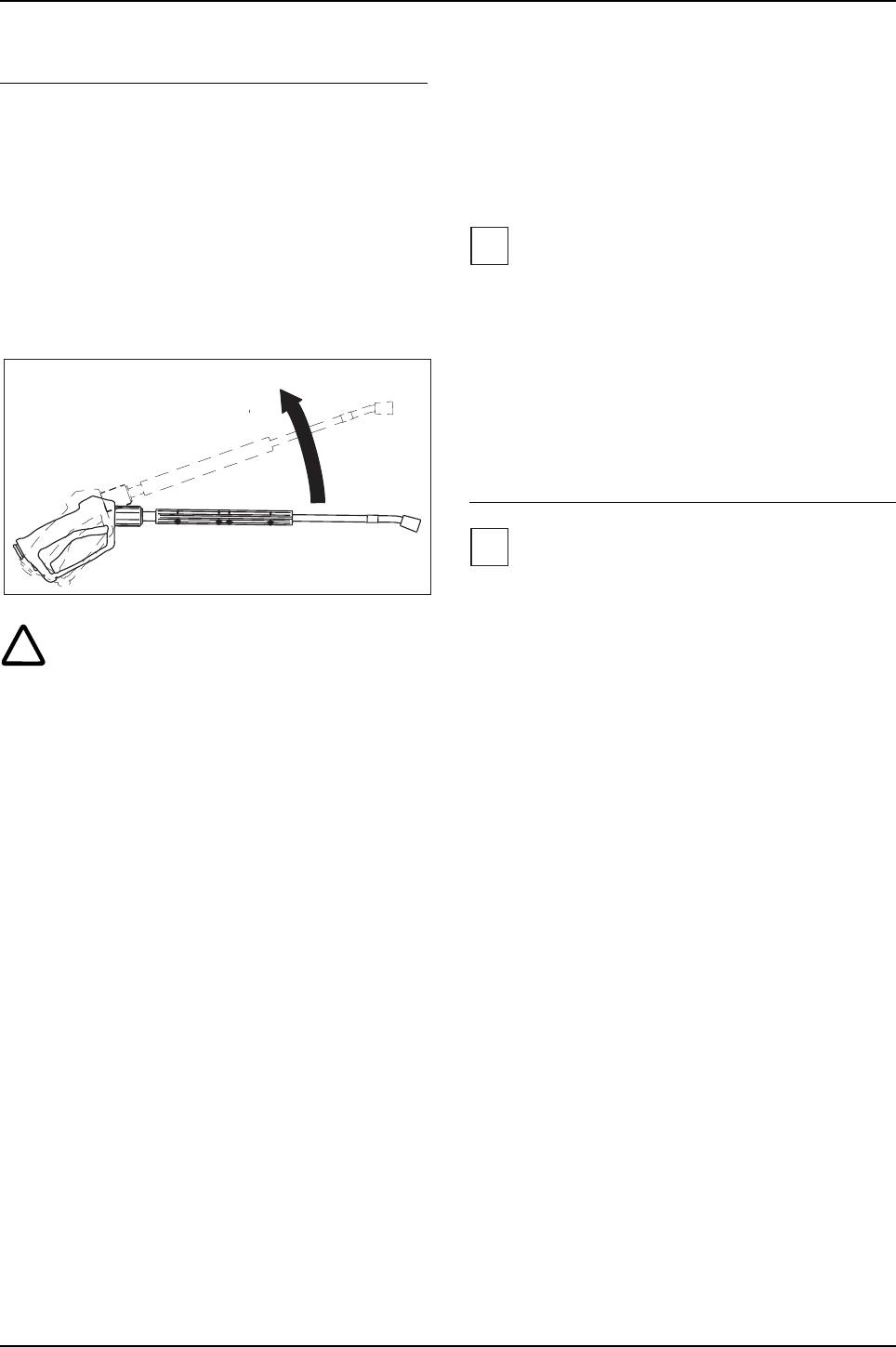

Working with the handgun

5.956-486 A2005937 (06/03)

B5

i

Important !

In types LM, SLA and SSR the stuffing

boxes must be retightened after the initial

startup. The tension should be regulated

one, two, four and 10 hours after initial start-

up. (For the running-in phase of the seals,

see E.3 Maintenance work).

3. System shut-down

i

!

Important!

Before carrying out the shut-down

procedures, flush through without adding

cleaning agents. This prevents a crust

forming on the seals or that they become

stuck fast, either of which would lead to

premature wear.

During the recirculation operation with

solvent, the system must be rinsed through

thoroughly using clean solvent before the

shut-down procedure takes place.

Switch system off at master switch.

Turn off cleaning liquid supply.

If a handgun is being used, release any

remaining pressure in the system by

pressing the lever on the handgun.

!

Danger!

The high-pressure jet produces a recoil

effect.

You could lose your balance.

You could fall over.

Therefore:

Ensure that you have a firm footing.

Keep a tight grip on the handgun.

Do not wedge the handgun fast in the

open position.

If the lever is wedged fast, the recoil effect

causes the high-pressure hose to twist and

turn in various directions, which result in

damage to other equipment or persons.

Starting up the system

Mobile system

Place system on a horizontal, solid

surface.

Lock wheel brakes.

English

C. System functions

SHD-R 3000

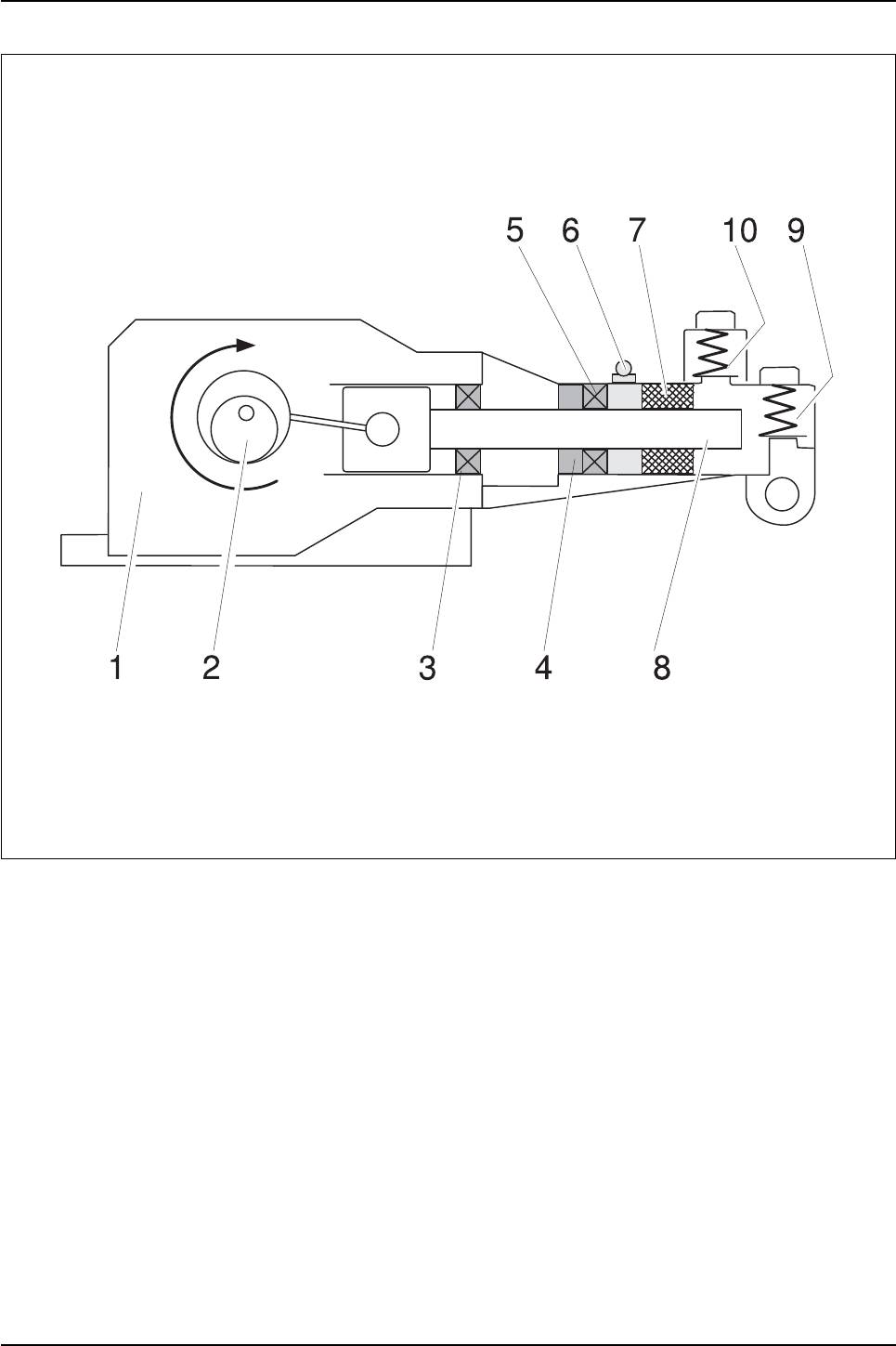

1 Transmission casing

6 Lubrication nipple or leakage pipe

2 Crankshaft with drive

7 Sealing pack (high-pressure)

3 Seal (oil compartment)

8 Piston

4 Gland

9 Suction valve

5 Seal (grease compartment)

10 Pressure valve

C1

5.956-486 A2005937 (06/03)

SHD-R 3000

C. System functions

English

Operational sequence of the high-

Safety valve

pressure pump

Cleaning liquid is taken in by the piston.

Suction valves (9) prevent cleaning liquid

from flowing backwards.

Action of piston pumps cleaning liquid

onwards.

Pressure valves (10) prevent cleaning

liquid from flowing backwards.

Action of piston takes in cleaning liquid

again.

Features of the high-pressure pump

Horizontal construction.

Drive runs in an oil bath.

Oil compartment for drive unit is separa-

ted from pressure chamber for cleaning

liquid.

Pump has three cylinders, each with a

pressure chamber, and one suction

chamber.

Drive for the high-pressure pump

The high-pressure pump is driven by an

electric motor.

V-belts attached to the electric motor

provide the actual drive to the high-

pressure pump.

5.956-486 A2005937 (06/03)

C2

!

Danger!

Injury hazard due to excessive pressure

within system. Do not adjust safety valve.

the safety valve has been pre-set and

sealed in the factory. Adjustments should

only be made by a Kärcher Customer

Service engineer.

The safety valve opens if the pressure

exceeds the prescribed maximum level.

Cleaning liquid is allowed to escape,

thereby avoiding damage to the pump and

high-pressure hoses due to too much

pressure in the system.

Pulsation damper

The pulsation damper compensates for the

variations or peaks in pressure. This

reduces the wear on pump components.

English

D. Technical specifications

SHD-R 3000

Unit SHD-R 3000 (F) SHD-R 3000 (F) S

SHD-R 3000 (F) LM

1)

SHD-R 3000 (F) SSR

1)

SHD-R 3000 (F) SLA

SHD-R 3000 (F) SVA

Electrical connection

Type of current

3~

3~

3~

Frequency Hz

50*

50*

50*

Voltage V 400** 400** 400**

Motor rating with

Class of protection IP55

kW

5.5

11

–

Class of protection IP55 Ex

kW

–

13.5

6.8

Mains fuse

A25 35 25

Direct starting

Mains fuse

A16 35 16

Star-delta starting

Performance data

Pump flow rate

L/h 3000 3000 3000

Working pressure bar 55 85 50

Pressure setting

bar 65 100 65

Safety valve

Max. inlet temperature for

˚C 60 60 60

water with detergents

Max. temperature for solvents,

˚C – 20 20

alkalis, acids

Noise pressure level

dB(A) 80 80 80

(EN 60704-1)

Dimensions and weight

Length approx. mm 1200 1200 1200

Width approx. mm 600 600 600

Height approx. mm 500 500 500

Weight approx. kg 125 165 135

Miscellaneous

Ambient conditions,

˚C +2 ... +40 +2 ... +40 +2 ... +40

temperature

1)

Type of protection –

possible

II 2 G ck T3 II 2 G ck T4

Oil capacity L 3 3 3

Type of oil Oil 40 Special Order no. 6.288-003 (3 x 1 litre pack)

* Available as special version with 60 Hz

** Versions for other voltages available

D1

5.956-486 A2005937 (06/03)

SHD-R 3000

E. Care and maintenance

English

1. General information

It is a fundamental requirement for ensuring

that this system functions safely and reliably

that maintenance is carried out regularly in

accordance with the following schedule.

Use only original spare parts supplied by

the manufacturer or recommended alterna-

tives, for example:

replacement and wearing parts

accessories

fuels, lubricants, etc.

detergents.

5.956-486 A2005937 (06/03)

E1

!

Who is permitted to carry out maintenance

tasks?

Operator

Tasks that are marked “Operator” may

only be carried out by persons who have

been instructed in the safe operation and

maintenance of high-pressure systems.

Customer service

Tasks that are marked “Customer service”

may only be carried out by Kärcher

Customer Service engineers.

Maintenance agreement

In order to ensure that the system functions

reliably, we recommend that you conclude

Danger!

a service agreement. Please contact your

Injury hazard while working on the system.

local authorized Kärcher Customer Service

Before commencing any work:

agent.

Turn mains supply voltage off at system

master switch, and ensure that it cannot

be turned back on again unintentionally.

Turn off supply of cleaning liquid.

If a handgun is being used, release any

remaining pressure in the system by

pressing the lever on the handgun.

English

E. Care and maintenance

SHD-R 3000

2. Maintenance schedule

Frequency Type of pump

Action Procedure By whom?

SHD-R 3000

(F)

1, 2, 4, 10

LM

Regulate tension in

See Maintenance Tasks Operator

hours after

SLA

compression glands

initial start-

SSR

up.

Once

all Check tension

See Maintenance Tasks Operator

only after

of V-belt

first 100

operating

hours

all Oil change See Maintenance Tasks Operator

Weekly

all Check oil level Oil level must be between MIN

Operator

or after

and MAX marks. If level below

every 40

MIN, fill up with oil.

operating

hours

Standard

Check oil condition If oil is milky-white, change oil

Operator

S / SVA

and tighten piston seal (See

SLA

Maintenance Tasks)

SSR

LM Check oil condition If oil has thinned out or is

Operator

discoloured, change oil and

tighten piston seal (See

Maintenance Tasks)

all Check high-pressure

Visual check of high-pressure

Operator

hoses

hoses for signs of damage such

as

– wear due to abrasion

– inner fabric is visible

– creases due to bending

– porous and split rubber

Replace any damaged hoses

E2

5.956-486 A2005937 (06/03)

SHD-R 3000

E. Care and maintenance

English

2. Maintenance schedule

Frequency Type of pump

Action Procedure By whom?

SHD-R 3000

(F)

Monthly

Standard

Check pump for leaks If during operation more than

Operator

or after

S / SVA

5 droplets per minute leak from

every 160

the pump, tighten piston seal

operating

hours

Standard

Lubrication Lubricate with 2 pump strokes of

Operator

S

grease gun per nipple

After

LM Oil change See Maintenance Tasks Operator

every 200

operating

hours

Six-monthly

Standard

Oil change See Maintenance Tasks Operator

or after

S / SVA

every 500

SLA

operating

SSR

hours

After

all – Check and clean valves on pump

Customer

every 1000

– Check piston

service

operating

– Replace set of seals if required

hours

– Oil change

– Check for correct functioning

Annually all Check tension of V-belt See Maintenance Tasks Operator

all Formal test Inspection in accordance with

Specialist

Directive on "Working With

Liquid-spraying Devices"

5.956-486 A2005937 (06/03)

E3

English

E. Care and maintenance

SHD-R 3000

3. Maintenance tasks

Changing the oil

E4

5.956-486 A2005937 (06/03)

!

Danger!

Burns hazard due to hot oil and hot system

components. Allow pump to cool down for

15 minutes before changing oil.

i

Tightening the piston seals

Important!

Waste oil may only be disposed of by the

operators of special collection points.

Please deposit your waste oil at one of

these locations. Polluting the environment

with waste oil is a criminal offence.

Oil type: Oil 40 special

Order no. 6.288-003 (3 x 1 litre pack)

Oil capacity per pump: 3 L

i

Important!

If the piston seal is held too tight by the

gland, it will be subjected to increased wear.

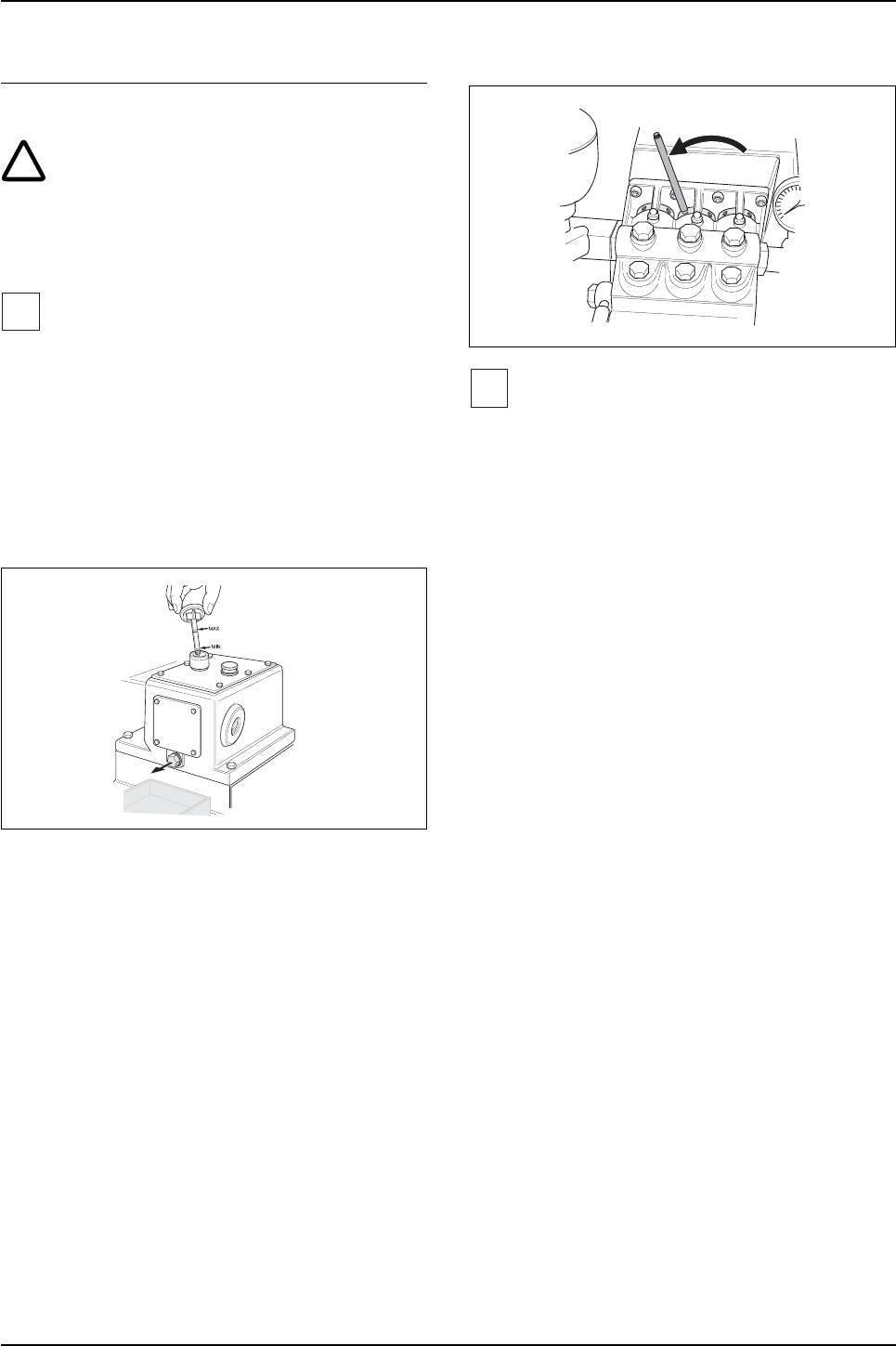

Insert rod into gland and turn in direction

indicated by arrow. This increases the

tension on the piston seal.

Tighten all three piston seals uniformly,

by turning the glands until they are hand-

tight.

Relieving tension on piston seal:

Insert rod into gland and turn in opposite

direction to that indicated by arrow.

This relieves the tension on the piston

seal.

Relieve the tension on all three piston

seals uniformly.

Oil change procedure:

place drip pan under pump to collect

waste oil

remove oil drain plug, and collect waste

oil in drip pan

wash out pump casing with diesel

allow diesel to drain thoroughly

fit new sealing ring (A18 x 22), and refit

oil drain plug

slowly fill up with fresh oil as far as MAX

mark

deliver waste oil to an appropriate

collection point.

- 1

- 2