Karcher WV 50 – страница 2

Инструкция к Насосному оборудованию Karcher WV 50

SHD-R 3000

E. Care and maintenance

English

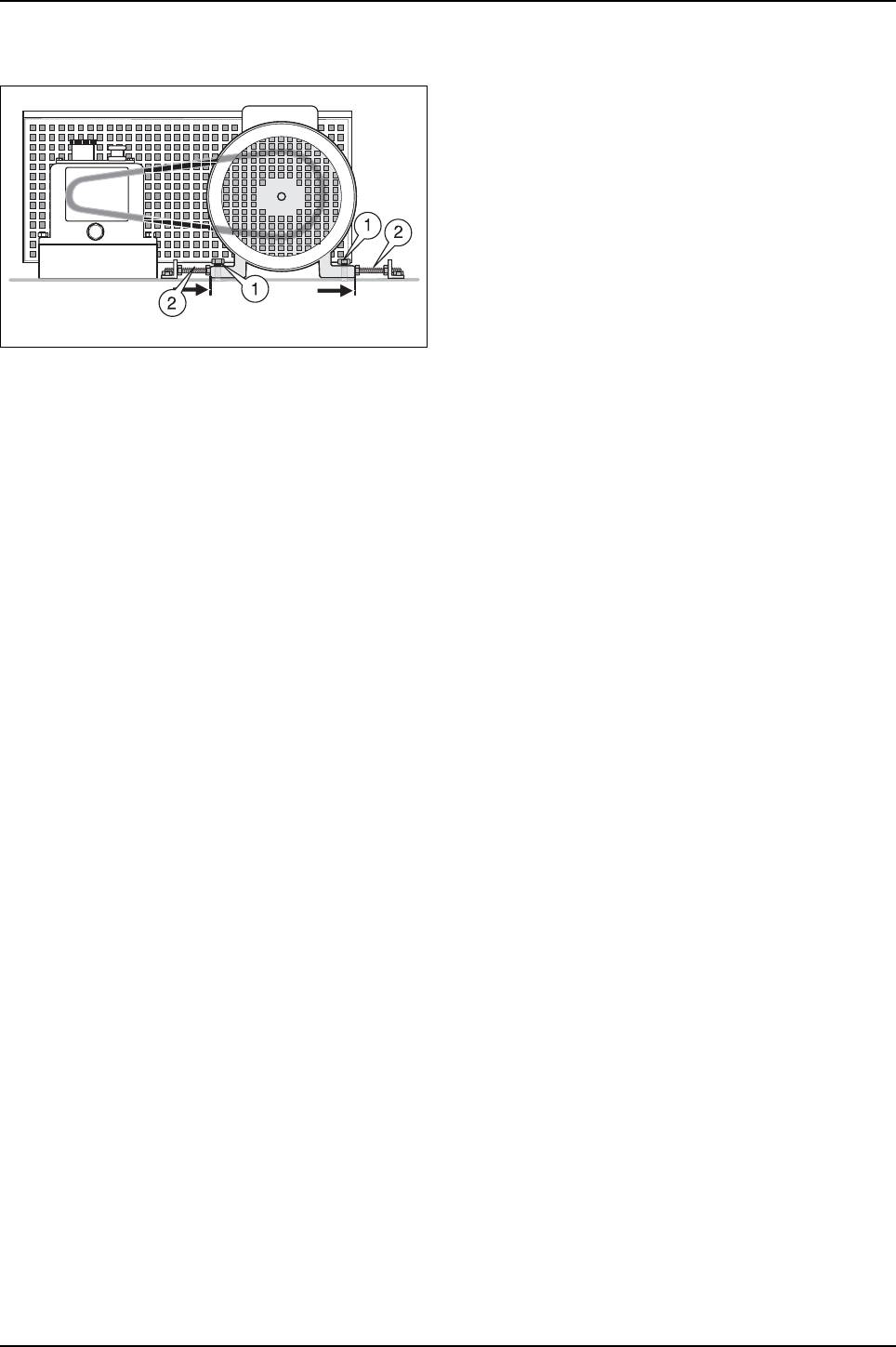

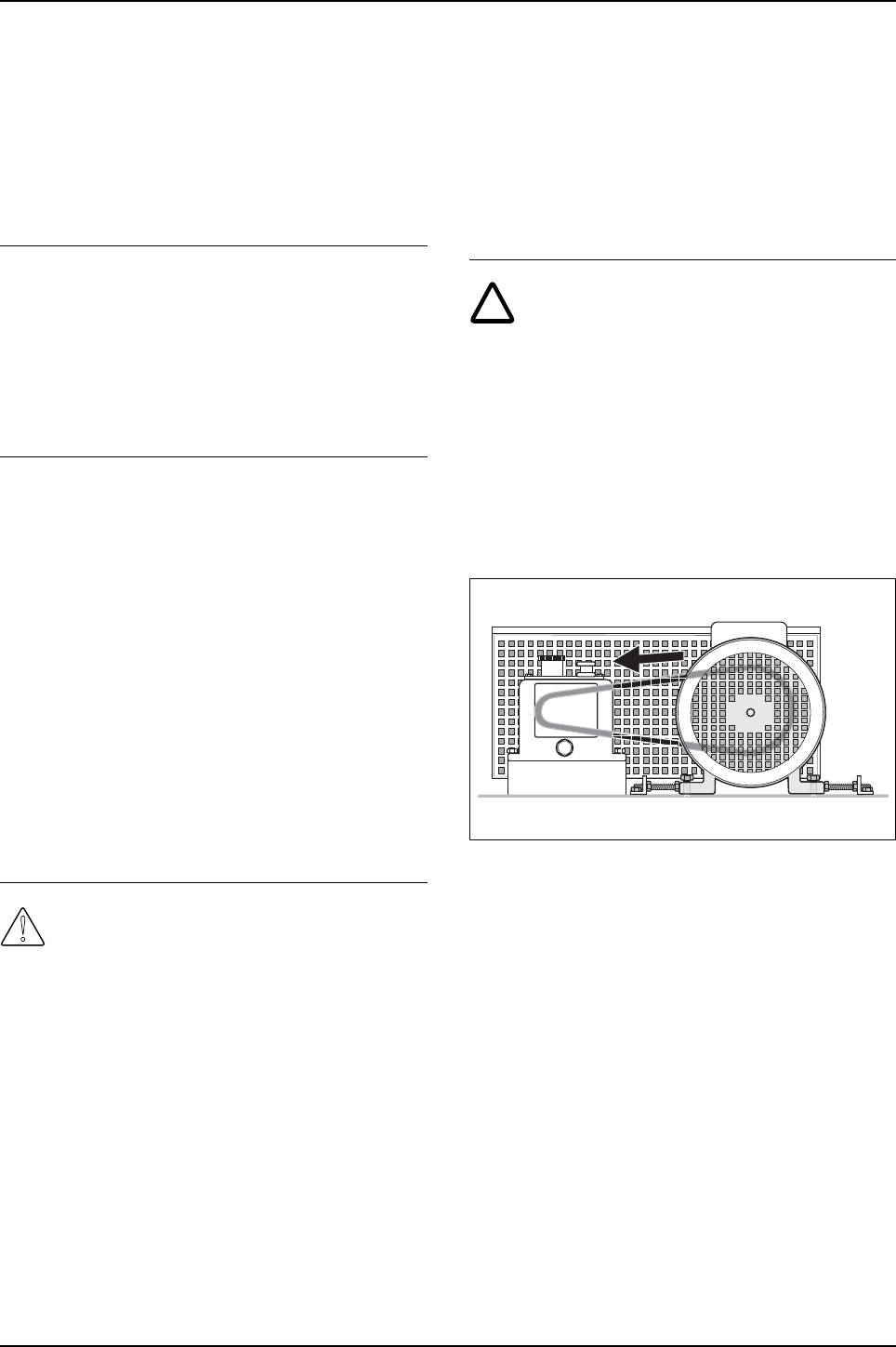

V-belt

Replacing the V-belt:

Switch off system, and ensure that it

cannot be switched back on again uninten-

tionally.

Remove guard over V-belt.

Slacken off mounting bolts (1).

Unscrew bolts (2) fully, and push motor

towards pump.

Replace V-belt.

Tension belt by adjusting bolts (2).

Test tension of V-belt and adjust as follows:

Ensure that V-belt runs in a straight line.

Switch off system, and ensure that it

Tighten mounting bolts (1).

cannot be switched back on again

Refit belt guard.

unintentionally.

Remove guard over V-belt.

Test belt tension.

Press down on belt which should not

move by more than 1 cm. If necessary,

adjust as follows:

Slacken off mounting bolts (1).

Tension V-belt by adjusting bolts (2).

Ensure that V-belt runs in a straight line.

Tighten mounting bolts (1).

Refit belt guard.

5.956-486 A2005937 (06/03)

E5

English

F. Troubleshooting

SHD-R 3000

Who is permitted to repair faults on the

system?

Operator

Tasks that are marked “Operator” may

only be carried out by persons who have

been instructed in the safe operation and

maintenance of high-pressure systems.

Qualified electrician

Persons who have a professional quali-

fication in an electrical engineering

discipline.

Customer Service

Tasks that are marked “Customer Service”

should only be carried out by a Kärcher

Customer Service engineer.

F1

5.956-486 A2005937 (06/03)

!

Danger!

Injury hazard while working on the system.

Before commencing any work:

Turn mains supply voltage off at system

master switch, and ensure that it cannot

be turned back on again unintentionally.

Turn off supply of cleaning liquid.

If a handgun is being used, release any

remaining pressure in the system by

pressing the lever on the handgun.

SHD-R 3000

F. Troubleshooting

English

1. Fault-finding

Problem Component Possible cause Remedy By whom?

System

Control

No voltage supply to

Check mains voltage Electrician

does not

circuitry

system or control

start up

circuitry

Control

Fault on

Check Electrician

circuitry

– motor contactor

– fuses

Control

Bimetal relay has

Wait for motor to cool down, and

Electrician

circuitry

switched off

then re-set relay.

Measure motor current. If

current consumption is too high,

relieve tension on piston seal

(see Maintenance Tasks).

Pressure

Defective or wrongly

Release pressure from system,

Customer

switch

adjusted pressure switch

and check pressure valve.

service

(Accessory

kit)

System

V-belt No tension in V-belt Tighten V-belt (see Maintenance

Operator

does not

Tasks)

build up

pressure

Filter or

Blocked filter or strainer

Remove and clean filter or

Operator

strainer

in supply line

strainer.

(Accessories)

Inlet hose Supply volume too small Test whether the correct amount

Operator

of cleaning liquid is being

supplied to system.

High-pressure

Worn out valves or

Replace defective part. Operator

pump

broken valve spring

High-pressure

Defective piston, seal or

Replace defective part. Customer

pump

valve

service

Detergent

Pump taking in air due

Fill detergent reservoir. Operator

reservoir

to empty detergent

(Accessory

container

kit)

Screech-

V-belt Incorrect V-belt tension Tighten V-belt (see Maintenance

Operator

ing noise

Tasks).

5.956-486 A2005937 (06/03)

F2

English

F. Troubleshooting

SHD-R 3000

1. Fault-finding

Problem Component Possible cause Remedy By whom?

Knocking

V-belt V-belt has snapped Replace V-belt (see Maintenance

Operator

noise

Tasks)

Detergent

Pump is taking in air –

Fill up with cleaning liquid.

Operator

metering on

–

Check hoses to establish

suction side of

whether they are taking in air

pump

(Accessory

kit)

Cleaning

Cleaning liquid is too

Check supply temperature of

Operator

liquid

warm

cleaning liquid

High-pressure

Broken valve spring Replace valve springs Operator

pump

High-pressure

Flange has come loose Tighten flange (see Maintenance

Operator

pump

Tasks)

Pulsation

Defective pulsation

Replace pulsation damper. Customer

damper

damper

service

(Accessory

kit)

Leaking

Pressure

Defective seal Replace seal. Customer

pressure

switch

service

switch

(Accessory

kit)

Leaking

High-pressure

Too much free play in

Tighten piston seal (see

Operator

pump

switch

piston seal

Maintenance Tasks)

System

Pressure

Wrongly adjusted

Re-adjust pressure switch and

Customer

does not

switch/Volume

pressure switch or

volume control valve.

service

switch off

control valve

volume control valve

although

(Accessory

handgun

kit)

is closed

Float tank

Float tank

Wrongly adjusted

Re-adjust closing force and filling

Operator

overflows

(Accessory

closing force or

level, see Chapter G1: Float

kit)

maximum filling level

tank.

Float tank

Defective seal on float

Replace seal. Operator

(Accessory

valve

kit)

F3

5.956-486 A2005937 (06/03)

SHD-R 3000

English

5.956-486 A2005937 (06/03)

!

G. Mounting kits and accessories

Volume control valve

Hazard!

Function

The following mounting and accessory kits

If only a part of the pump delivery volume is

must not be used for operation with solvents

required, the remainder is fed back to the

or in a hazardous (potentially explosive

suction side of the pump via the volume

atmosphere) area.

control valve.

This item is required when the system is

1. Mounting kits

used with handguns.

(non-hazardous area)

Pressure switch

Float tank with float valve

Function

The float valve fitted inside the float tank

controls the level of liquid.

The float tank serves as a service

reservoir for the cleaning liquid.

If water is used as the cleaning agent,

the float tank corresponds to mains

disconnection according to EN 1717.

In the case of the mobile systems, the

float tank is fitted to the trolley.

Settings

Closing force

Extending the length of L increases the

amount of closing force, i.e. even when the

cleaning liquid is fed in at quite high pressure

the float valve is able to shut off the supply.

Technical specification

Capacity up to overflow: 30 litres.

G1

!

Danger!

Danger due to high voltage. The pressure

switch has been pre-set in the factory,

adjustments should only be made by a

Kärcher Customer Service engineer.

Function

The pressure switch

switches the system off if the working

pressure is exceeded.

switches the system back on when the

pressure drops again.

Pulsation damper

Caution!

As the membrane in the pulsation damper is

not suitable for solvents, do not use the

pulsation damper for operation with

solvents.

Function

The pulsation damper evens out variations

or peaks in pressure while the system is in

operation.

i

Important!

Volume control valve, pressure switch and

pulsation damper are usually employed

together as an automatic volume control

system.

English

G. Mounting kits and accessories

SHD-R 3000

Pressure-relief valve

Detergent metering at the pressure

side of the pump

Function

Function

The pressure-relief valve is an integrated

solenoid valve.

Detergents are taken in from an external

reservoir and fed to the output from the

The pressure-relief valve is only active

pump,

during the start-up phase when the

system is configured for star-delta

an injector mixes the detergent with the

starting.

high-pressure jet (double spray lance

required for detergent metering),

When the pressure-relief valve is opened,

the liquid delivered by the pump flows

detergents can also be metered by

back to the suction side. As a result, no

means of a high-pressure metering pump.

pressure is built up, and the load on the

motor is reduced during the start-up

phase.

2. Mounting kits

(hazardous area)

Detergent metering at the suction

Please contact Kärcher about mounting kits

side of the pump

for hazardous (potentially explosive

atmosphere) areas.

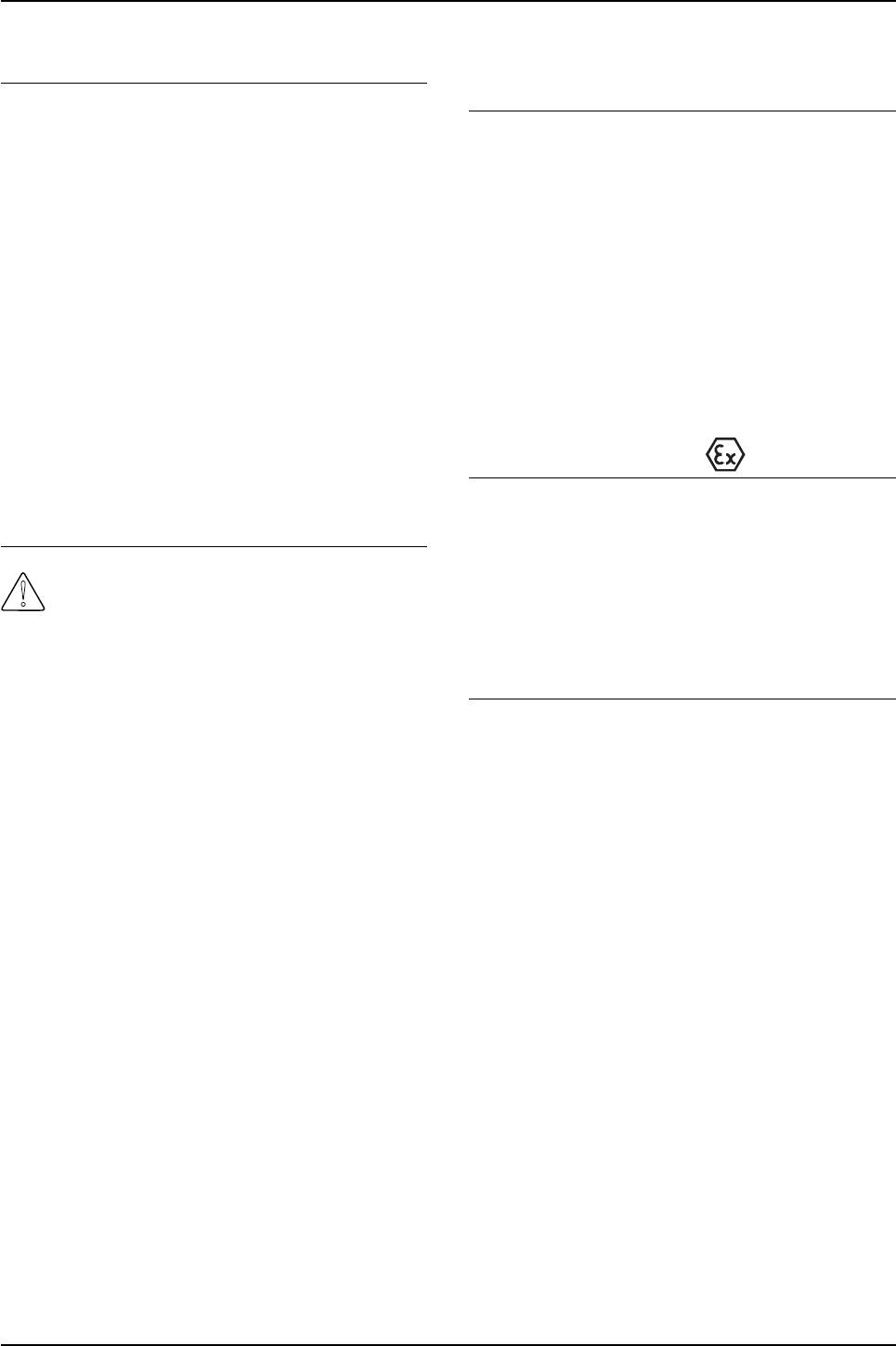

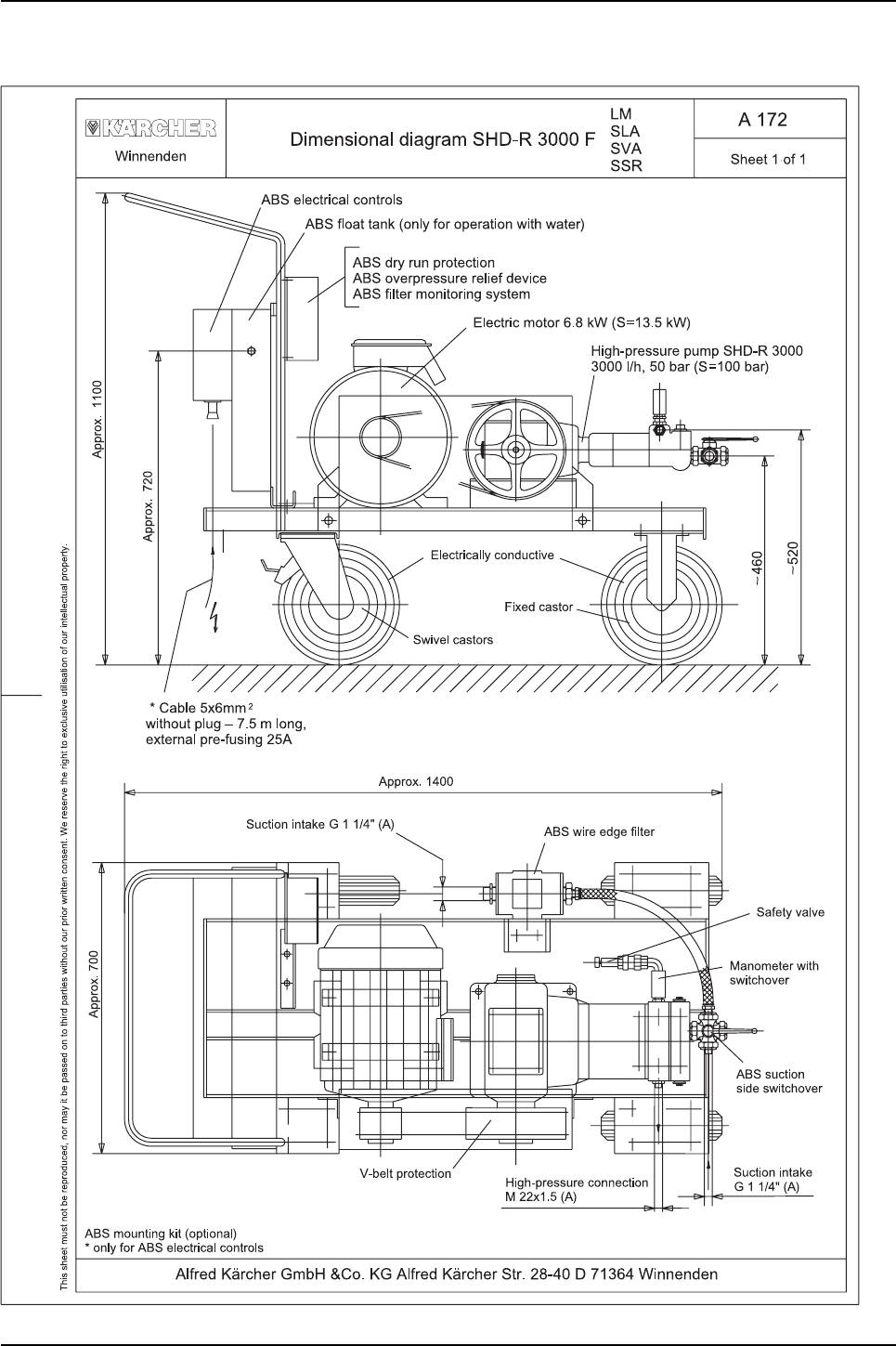

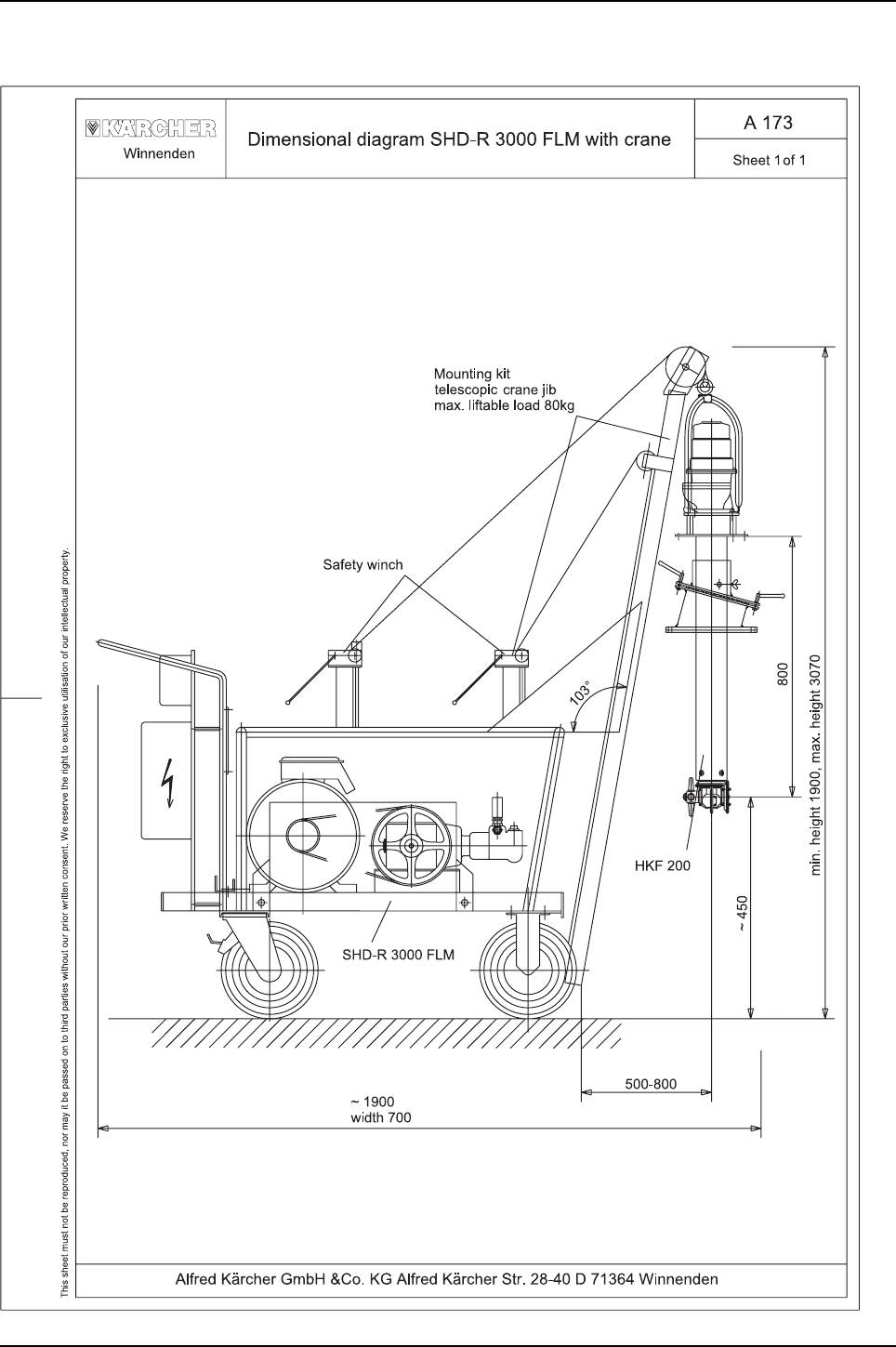

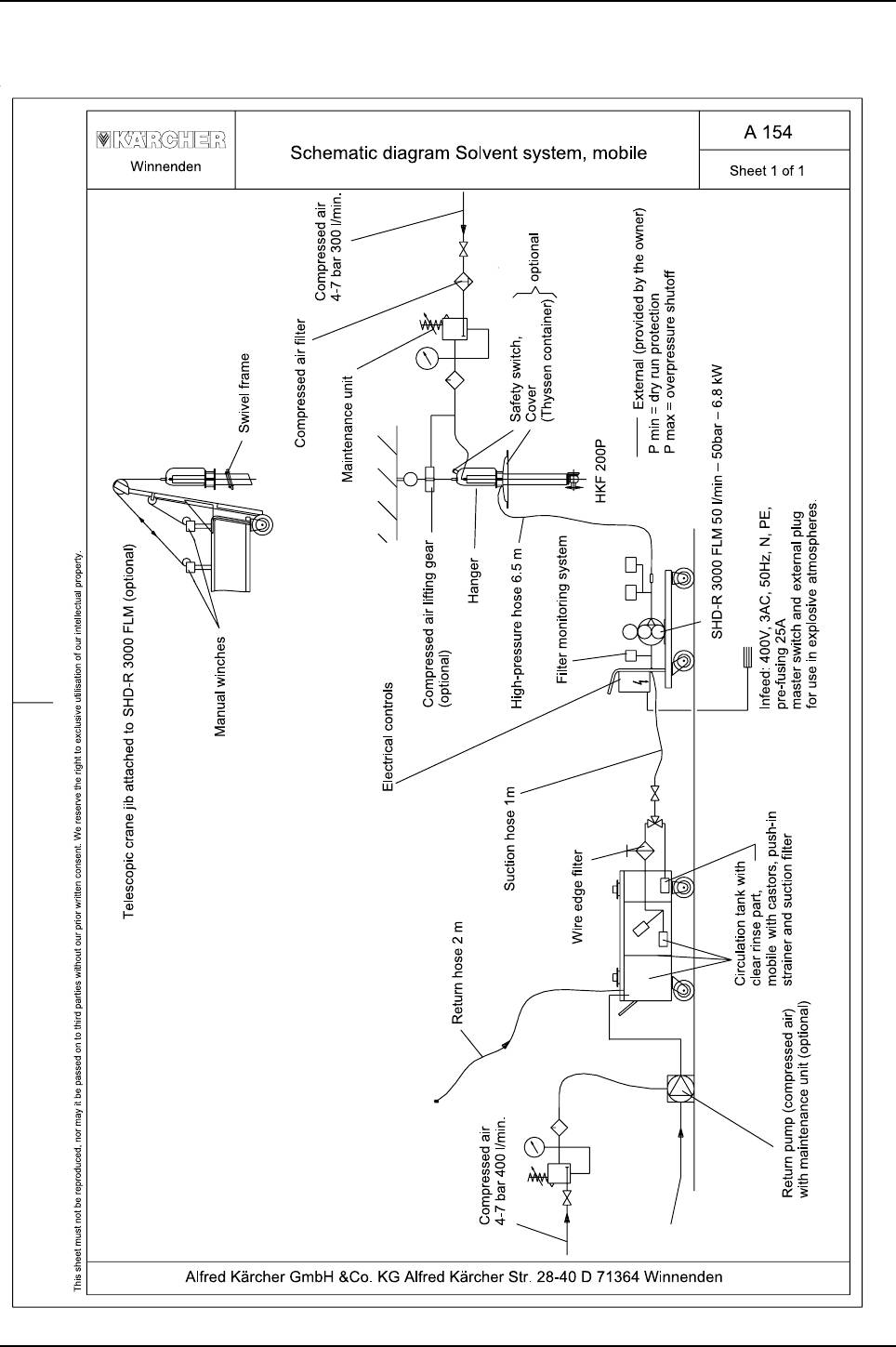

For representations, please refer to figures

Danger!

A 170/1, A 172, A 173, A 161 and A 154.

If the detergent reservoir is empty and the

metering valve is open, the pump takes in

air. This can lead to damage to the pump,

3. Accessories

therefore:

Lubricants:

check detergent reservoir regularly,

Oil for pump: Oil 40 special

do not open metering valve until actual

Order no. 6.288-003 (1 litre pack)

work commences,

Lubricating grease for:SHD-R 3000 (F)

close metering valve as soon as work

SHD-R 3000 (F) S/

has ended.

SHD-R 3000 (F) SVA

(6.288-034)

Function

For normal use:

A diaphragm has been inserted into the

Order no. 6.288-015 (Tin with 1 kg)

pump intake connection,

The following grease is prescribed for food-

detergent is taken in from an external

processing operations:

reservoir,

Order no. 6.288-034 (Tin with 1 kg)

the amount taken in is determined by a

metering valve,

High-pressure hoses, nozzles,

metering is switched on or off by a solenoid

detergents

valve.

Ask your dealer for further details about

these or any other accessories, or contact

Kärcher Plant Engineering.

G2

5.956-486 A2005937 (06/03)

SHD-R 3000

G. Mounting kits and accessories

English

Figure A 170/1

5.956-486 A2005937 (06/03)

G3

English

G. Mounting kits and accessories

SHD-R 3000

Figure A 172

G4

5.956-486 A2005937 (06/03)

SHD-R 3000

G. Mounting kits and accessories

English

Figure A 173

5.956-486 A2005937 (06/03)

G5

English

G. Mounting kits and accessories

SHD-R 3000

Figure A 161

G6

5.956-486 A2005937 (06/03)

SHD-R 3000

G. Mounting kits and accessories

English

Figure A 154

5.956-486 A2005937 (06/03)

G7

English

H. Warranty

SHD-R 3000

The applicable warranty conditions in

different countries are issued by the

respective national distributor of KÄRCHER

products.

In the event of a warranty claim, please

contact your original dealer or the nearest

authorized customer service centre.

H1

5.956-486 A2005937 (06/03)

SHD-R 3000

I. System installation

English

This system should only be installed by

Check the oil level

Kärcher Customer Service engineers,

The level of oil in the reservoir on the high-

pressure pump should be between the MIN

persons who have been specially

and MAX marks. Fill up with oil if the level

authorized by Kärcher.

is below the MIN mark.

Unpacking the system

Electrical connections

Unpack the system and deliver the packag-

ing materials to an appropriate collection

point for recycling.

For static systems

Preparing the installation site

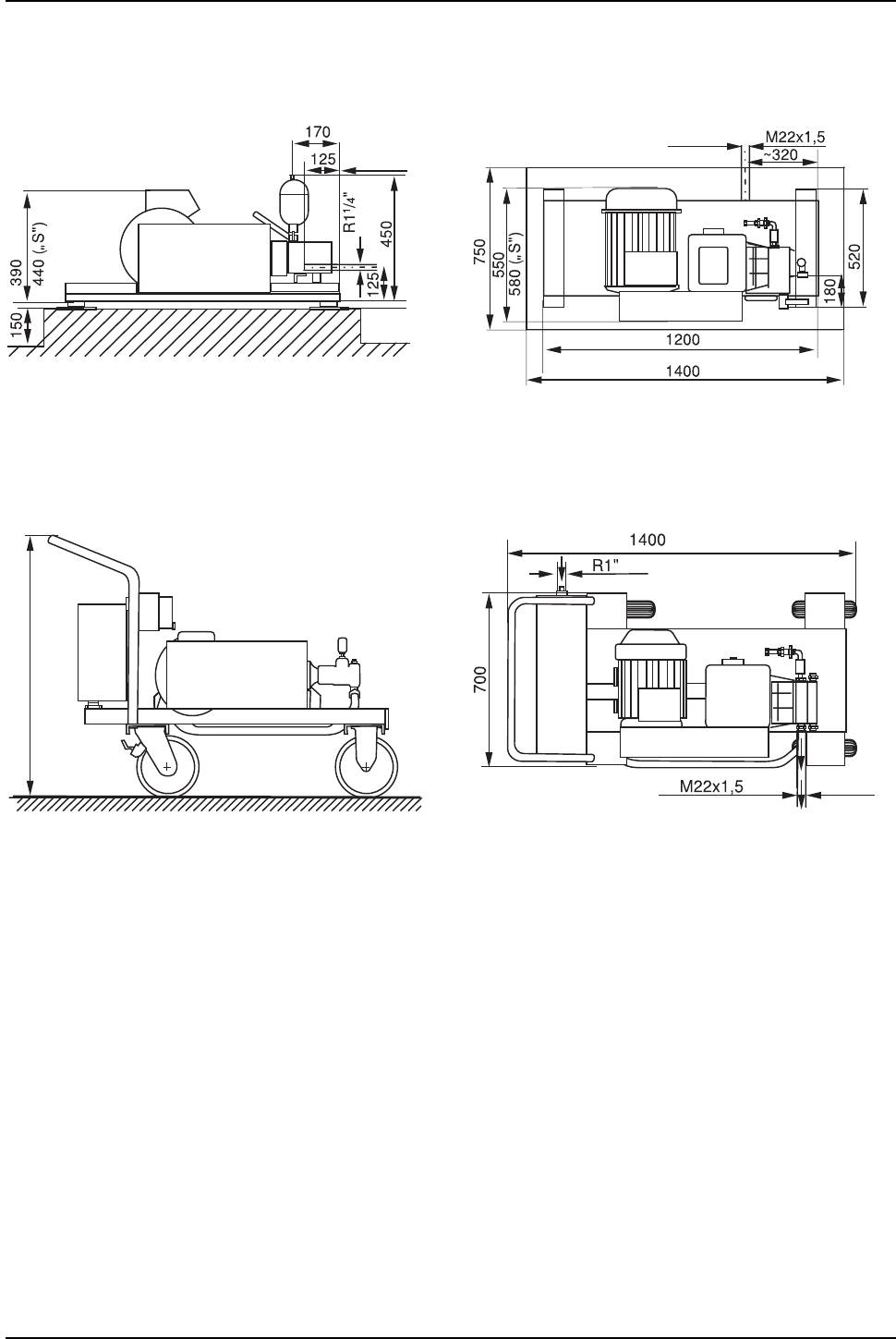

A horizontal, flat area or base of 1400 x

750 mm is required for installing the

system.

Place the system on the designated area

or base and align it exactly.

Install the unit in such a way as to ensure

that it can be easily accessed for

maintenance work.

Secure in position with suitable materials.

For static and mobile systems

Connecting hoses for supply

of cleaning liquid

Caution!

Vibrations generated by the system during

operation could cause damage to the main

water supply network, therefore connect the

system by means of flexible hoses.

Connect the supply hose for cleaning

liquid to the system (Thread R 1 1/4").

Connect the high-pressure hose for the

cleaning liquid output to the system

(Thread M22 x 1.5).

5.956-486 A2005937 (06/03)

I1

!

Danger!

Dangerous voltage. The electrical installation

should only be carried out by a qualified

electrician in accordance with current local

regulations.

Connect the electric motor into the

terminal strip.

Switch on motor briefly, and check

direction of rotation.

Start up the system

Switching off in an emergency

(see Chapter B)

English

I. System installation

SHD-R 3000

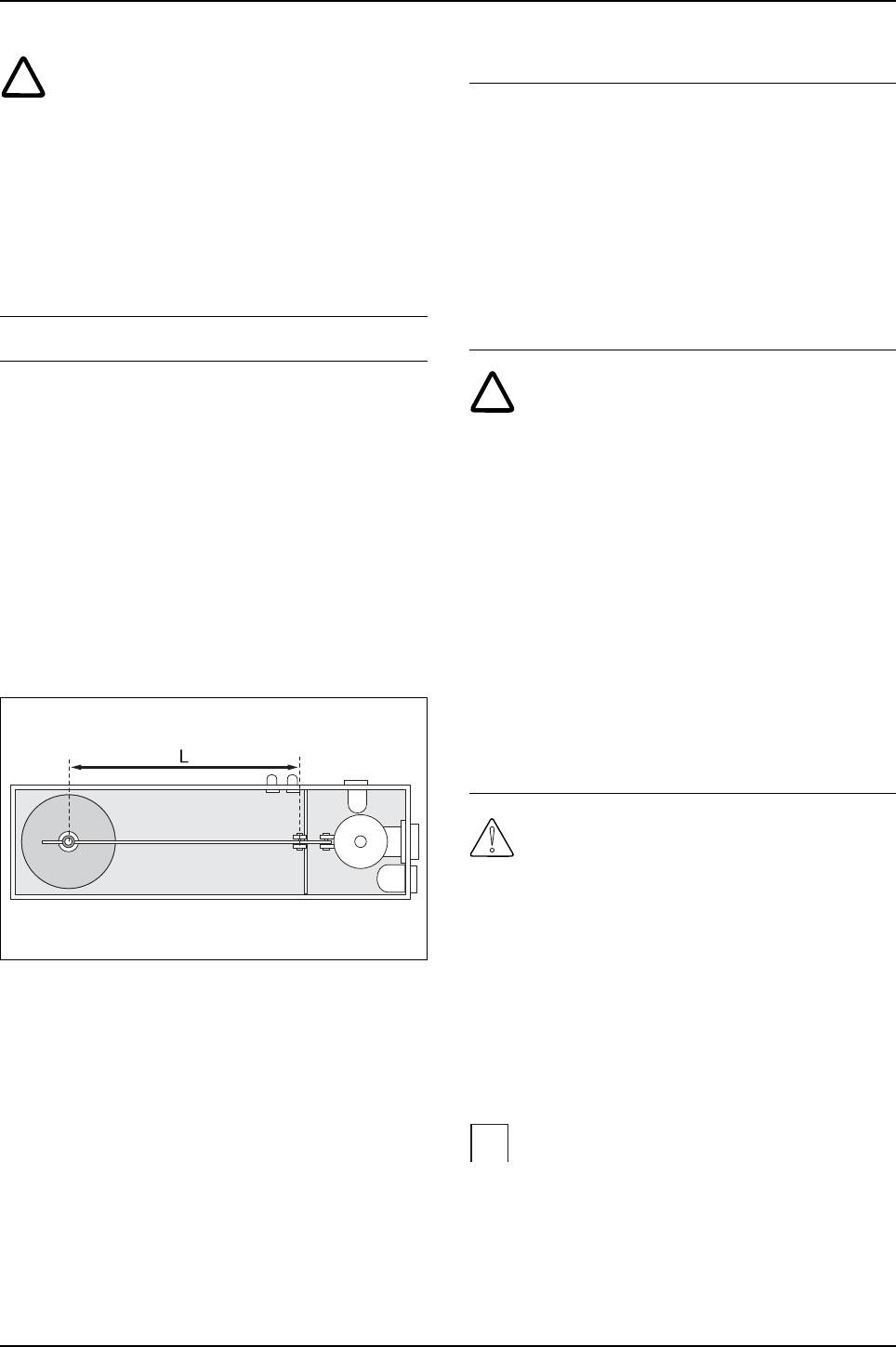

Dimensional diagram:

Static system

Mobile system

approx. 1100

I2

5.956-486 A2005937 (06/03)

SHD-R 3000

J. Declaration of Conformity

English

EC Declaration of Conformity

We herewith declare that the design and

Alfred Kärcher GmbH & Co. KG

type of machine named in the following as

Cleaning Systems

well as the model marketed by us complies

Alfred-Kärcher-Str. 28-40

with the relevant fundamental health and

P.O. Box 160

safety requirements of the EC Directives.

D-71349 Winnenden

This declaration becomes invalid if

Tel.: ++ 49 71 95 14-0

modifications are made to the machine

Fax: ++ 49 71 95 14-22 12

which have not been previously agreed with

us.

5.957-383 (01/02)

Product: High-pressure cleaner

Alfred Kärcher Kommanditgesellschaft.

Type: SHD-R 3000 (F), S, SVA

Registered offices: Winnenden.

Register court: Waiblingen, HRA 169.

Relevant EC Directives:

Personally liable shareholder: Kärcher

EC Machinery Directive (98/37/EC)

Reinigungstechnik GmbH.

Registered office: Winnenden, 2404

EC Low Voltage Directive (73/23/EEC),

Waiblingen register court, HRB

amended by 93/68/EEC

Managing Directors: Dr. Bernhard Graf,

EC Electromagnetic Compatibility

Hartmut Jenner, Georg Metz

Directive (89/336/EEC), amended by

91/263/EEC, 92/31/EEC, 93/68/EEC

Harmonised standards used:

DIN EN 60 335 - 1

DIN EN 60 335 - 2 - 79

DIN EN 55 014 - 1:2000 + A1 : 2001

DIN EN 55 014 - 2 : 1997

DIN EN 61 000 - 3 - 2 : 2000

DIN EN 61 000 - 3 - 3 : 1995 + A1 : 2001

National standards used: –

Internal measures ensure that serial

production units always comply with the

requirements of the current EC Directives

and the standards used.

The undersigned act on behalf of and with

power of attorney issued by the

Management.

S. Reiser H. Jenner

5.956-486 A2005937 (06/03)

J1

English

J. Declaration of Conformity

SHD-R 3000

EC Declaration of Conformity

We herewith declare that the design and

Alfred Kärcher GmbH & Co. KG

type of machine named in the following as

Cleaning Systems

well as the model marketed by us complies

Alfred-Kärcher-Str. 28-40

with the relevant fundamental health and

P.O. Box 160

safety requirements of the EC Directives.

D-71349 Winnenden

This declaration becomes invalid if

Tel.: ++ 49 71 95 14-0

modifications are made to the machine

Fax: ++ 49 71 95 14-22 12

which have not been previously agreed with

us.

5.957-384 (06/03)

Product: High-pressure cleaner

Type: SHD-R 3000 (F), LM, SSR, SLA

Alfred Kärcher Kommanditgesellschaft.

Registered office: Winnenden.

Register court: Waiblingen, HRA 169.

Relevant EC Directives:

Personally liable shareholder:

EC Machinery Directive (98/37/EC)

Kärcher Reinigungstechnik GmbH.

Registered office: Winnenden, 2404

EC ATEX Directive (94/9/EC)

Waiblingen register court, HRB

Managing Directors: Dr. Bernhard Graf,

Hartmut Jenner, Georg Metz

Harmonised standards used:

DIN EN 60 335 - 1

DIN EN 60 335 - 79

DIN EN 13463 - 1 : 2002

prEN 13463 - 5 : 2002

EN 1127 - 1 : 1997

National standards used: –

No. of nominated test institute: 0123

Test report No. 070039582

Type LM designation: Ex II 2 G ck T4

Type SSR, SLA designation: Ex II 2 G ck T3

Internal measures ensure that serial

production units always comply with the

requirements of the current EC Directives

and the standards used.

The undersigned act on behalf of and with

power of attorney issued by the

Management.

S. Reiser H. Jenner

J2

5.956-486 A2005937 (06/03)

SHD-R 3000

K. Test record

English

Type no.: Factory no.: Commissioned on:

Tests carried out on:

..............................................................................................................

Results

.......................................

Signature

Tests carried out on:

..............................................................................................................

Results

.......................................

Signature

Tests carried out on:

..............................................................................................................

Results

.......................................

Signature

Tests carried out on:

..............................................................................................................

Results

.......................................

Signature

5.956-486 A2005937 (06/03)

K1

- 1

- 2