AEG EWH 150 Trend: INSTALLATION

INSTALLATION: AEG EWH 150 Trend

Operation - Installation

6. Troubleshooting

Problem

INSTALLATION

The water does not

There is no power. Check the fuses/

heat up and the ON/

MCBs in your fuse

OFF indicator does

box.

not illuminate.

The water does not

The temperature is set

Select a higher tem-

7.

heat up sufficiently

too low.

perature.

and the ON/OFF indi-

commissioning, maintenance and repair of the appliance.

cator illuminates.

The appliance heats,

Wait until the ON/OFF

7.1

for example, after

indicator goes out.

large amounts of

We guarantee trouble-free function and operational relia-

DHW have been

bility only if original accessories and spare parts intended

drawn.

for the appliance are used.

The flow rate is low.

The aerator in the

Clean and/or descale

tap or shower head is

the aerator or shower

7.2

scaled up or contam-

head.

inated.

Note

-

-

tractor. To facilitate and speed up your enquiry, please

provide the numbers from the type plate (000000 and

0000-000000):

8.

8.1

E-NO.: 000000

F-NO.: 0000-000000

The following are delivered with the appliance:

Safety valve

The safety valve supplied must not be used in

Belgium. For use here please use standard safety

valves (see also pricelist).

Temperature indicator

D0000037149

8.2 Accessories

Pressure-tested taps are available as accessories.

9.

9.1

The appliance is designed to be permanently wall-mount-

ed to a solid surface. Ensure the wall offers adequate load

bearing capacity.

There should be a suitable drain near the appliance to

drain off the expansion water.

Always install the appliance vertically in a room free from

the risk of frost and near the draw-off point.

the appliance to the wall must remain accessible.

16

Installation - for contractors

9.2

10.1.2

Note

Note

-

from the front.

The mounting bracket attached to the appliance has hook-

in slots, which in most cases enables installation on the

Note

bolts that are already in place from previous appliances.

» Otherwise, transfer the dimensions for the holes to

Dimensions and connections").

The maximum permissible pressure must not be exceed-

» Drill the holes and secure the wall mounting bracket

with screws and rawl plugs.

» Install a type-tested safety valve in the cold water

accordance with the wall construction/condition.

supply line. Please note that, depending on the static

pressure, you may also need a pressure reducing

» Hook the appliance with wall mounting brackets on to

valve.

the screws or bolts. Observe the weight of the appli-

» Size the drain so that water can drain off unimpeded

table") and, if necessary, ask another person to help.

when the safety valve is fully opened.

» Align the appliance horizontally.

» Fit the discharge pipe of the safety valve with a con-

stant downward slope and in a room free from the

risk of frost.

10.

» The safety valve discharge aperture must remain

open to the atmosphere.

10.1

10.2

!

WARNING Electrocution

Operate the appliance only with pressure-tested taps.

10.1.1

WARNING Electrocution

!

-

-

WARNING Electrocution

Galvanised steel, stainless steel, copper and plastic are

approved materials.

DHW line

!

Stainless steel, copper and plastic pipework are approved

materials.

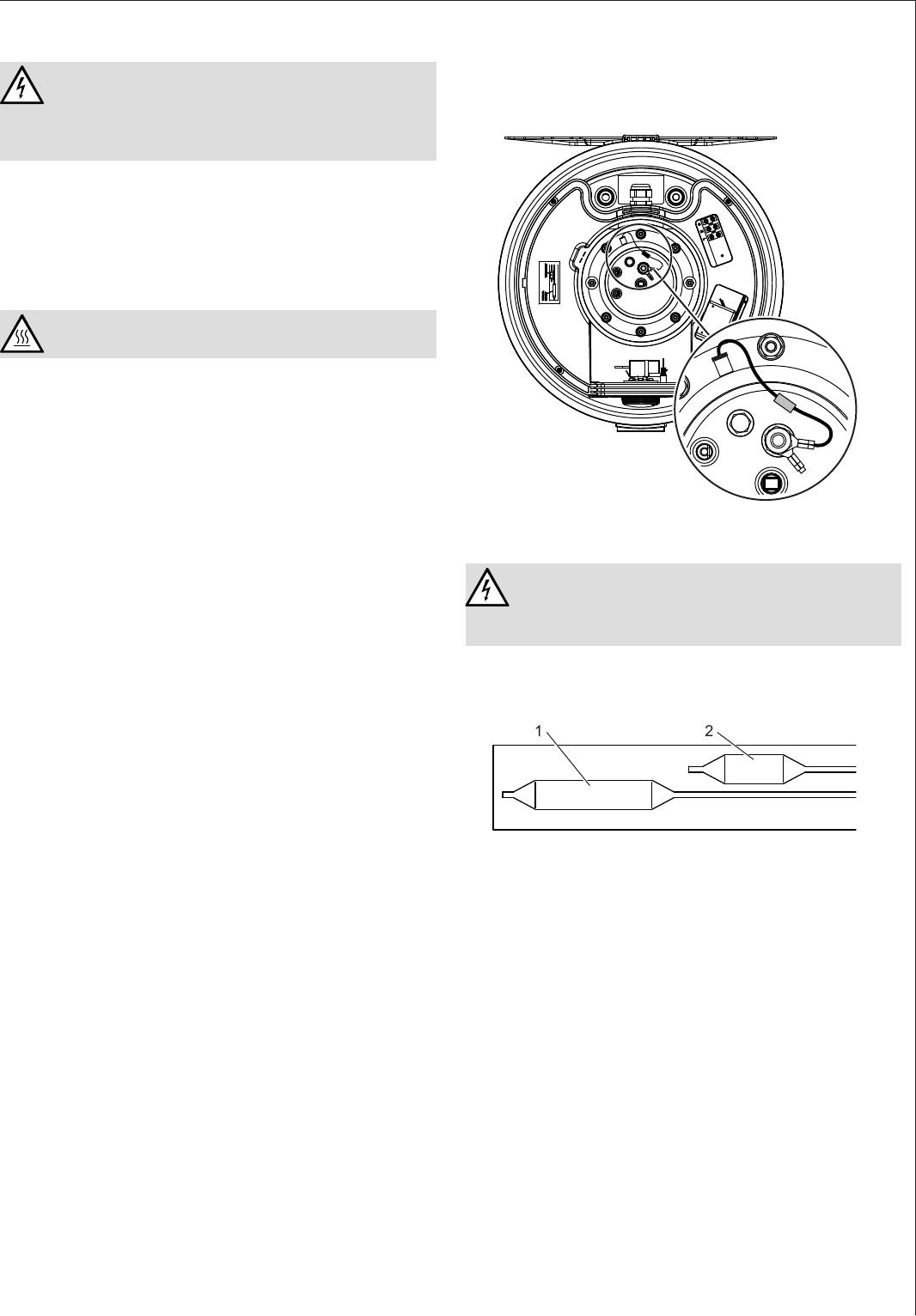

DANGER Electrocution

-

wire ferrules and without plug, ready to connect.

»

from the appliance. Use a suitable installation cable.

» When routing the new power cable, ensure that it is

waterproof as it passes through the existing cable

grommet, and is correctly routed and connected in-

side the appliance.

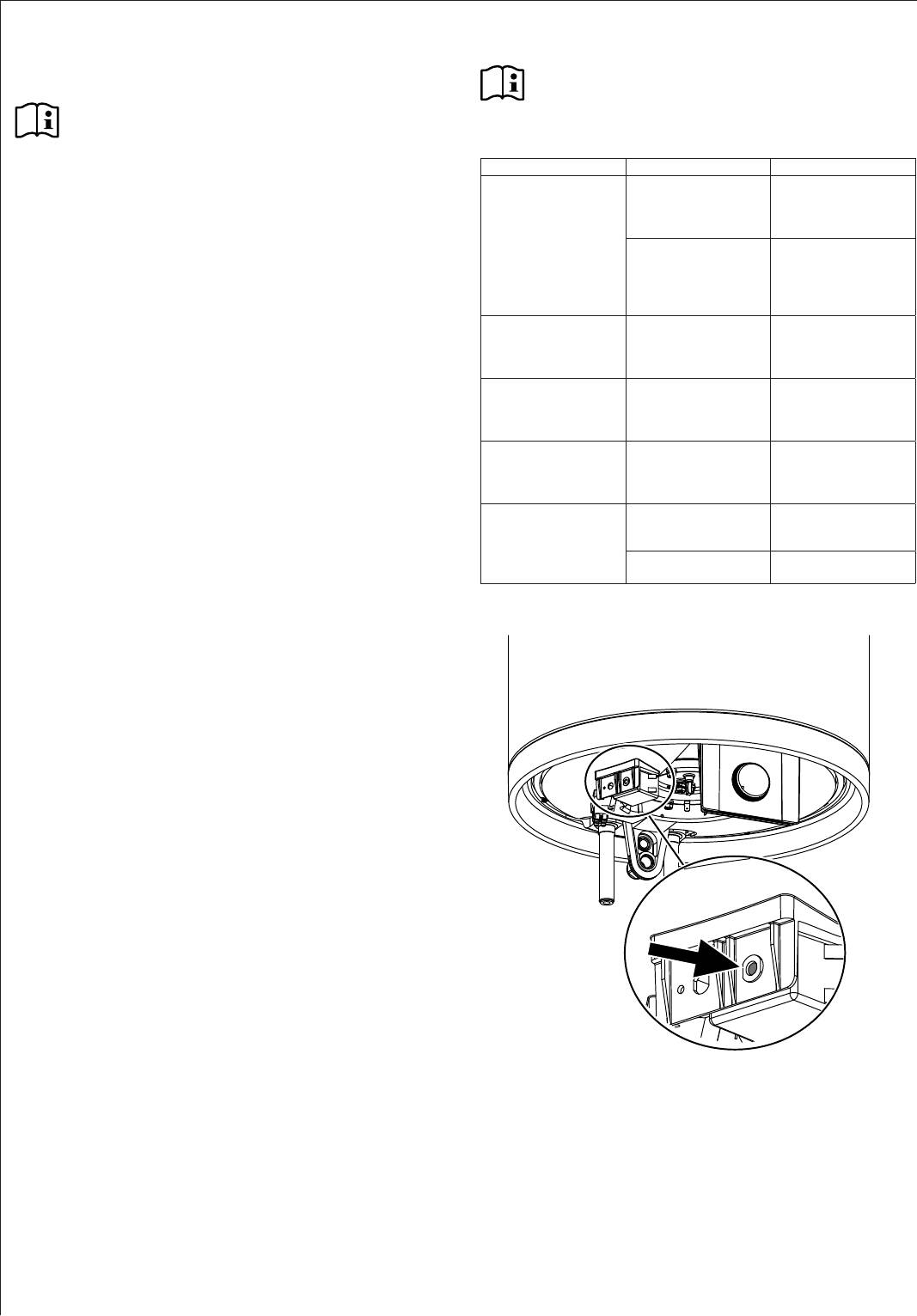

10.3

» Press the temperature indicator into the opening until

it clicks into place.

17

Installation - for contractors

11. Commissioning

13. Troubleshooting

Note

11.1 Commissioning

-

Note

-

nection.

The water does not

The high limit safety

Remedy the cause of

» -

heat up and the ON/

cut-out has responded

the fault. Replace the

necting the appliance, so that no foreign matter gets

OFF indicator does

because the controller

controller.

not illuminate.

is faulty.

into the water heater or safety valve.

The high limit safety

Press the reset button

» Open the shut-off valve in the cold water feed line.

cut-out has responded

(see diagram).

»

because the temper-

up and the pipework is free of air.

ature has fallen below

-15 °C.

» For this, observe the maximum

The water does not

The heating element

Replace the heating

heat up and the ON/

is faulty.

element.

OFF indicator illumi-

»

nates.

valve of the safety valve.

The water does not

The temperature con-

Replace the tempera-

heat up sufficiently

troller is faulty.

ture controller.

» Turn the temperature selector to maximum.

and the ON/OFF indi-

» Switch the mains power ON.

cator illuminates.

The heat-up time is

The heating element

Descale the heating

» Check the function of the appliance. Ensure that the

very long and the ON/

is scaled up.

element.

thermostat switches off.

OFF indicator illumi-

» Check that the safety valve is working correctly.

nates.

The safety valve

The valve seat is con-

Clean the valve seat.

11.1.1

drips when heating is

taminated.

switched off.

» Explain the function of the appliance and safe-

Water pressure is too

Install a pressure re-

ty valve to users and familiarise them with their

high.

ducing valve.

operation.

» Make users aware of potential dangers, especially

the risk of scalding.

» Hand over these instructions.

11.2 Recommissioning

See chapter "Commissioning".

12.

» Disconnect the appliance from the mains at the

MCB/fuse in the fuse box.

» Drain the appliance. See chapter "Maintenance /

Draining the appliance".

D0000037143

18

Installation - for contractors

14.5

14.

Ensure that while carrying out maintenance work the an-

WARNING Electrocution

ti-corrosion protection (560 Ω) is not damaged or removed.

Reinsert the anti-corrosion protection correctly after re-

placement.

If you need to drain the appliance, observe chapter

"Draining the appliance".

14.1

» Test the safety valve regularly.

14.2

WARNING Burns

If is necessary to drain the cylinder for maintenance or

to protect the whole installation from frost, proceed as

follows:

» Close the shut-off valve in the cold water feed line.

» Open the DHW valves of all draw-off points until the

appliance is fully drained.

» Drain any residual water from the safety valve.

D0000037141

14.3

14.6

»

DANGER Electrocution

and replace if necessary.

» Next, decide the time intervals at which further

-

checks should be carried out.

14.4

14.7

» Remove loose scale deposits from the water heater.

limiter

» If necessary, descale the inner cylinder with com-

mercially available descaling agents.

21

»

treat the cylinder surface and protective anode with

descaling agents.

D0000037142

1 Controller sensor

2 Limiter sensor

» Insert the controller sensor and the limiter sensor

into the sensor well as far as they will go.

19

Installation - for contractors

15.

15.1

c06

c01

h46

i13

b01

20

a10

100

a40 a30

61

23

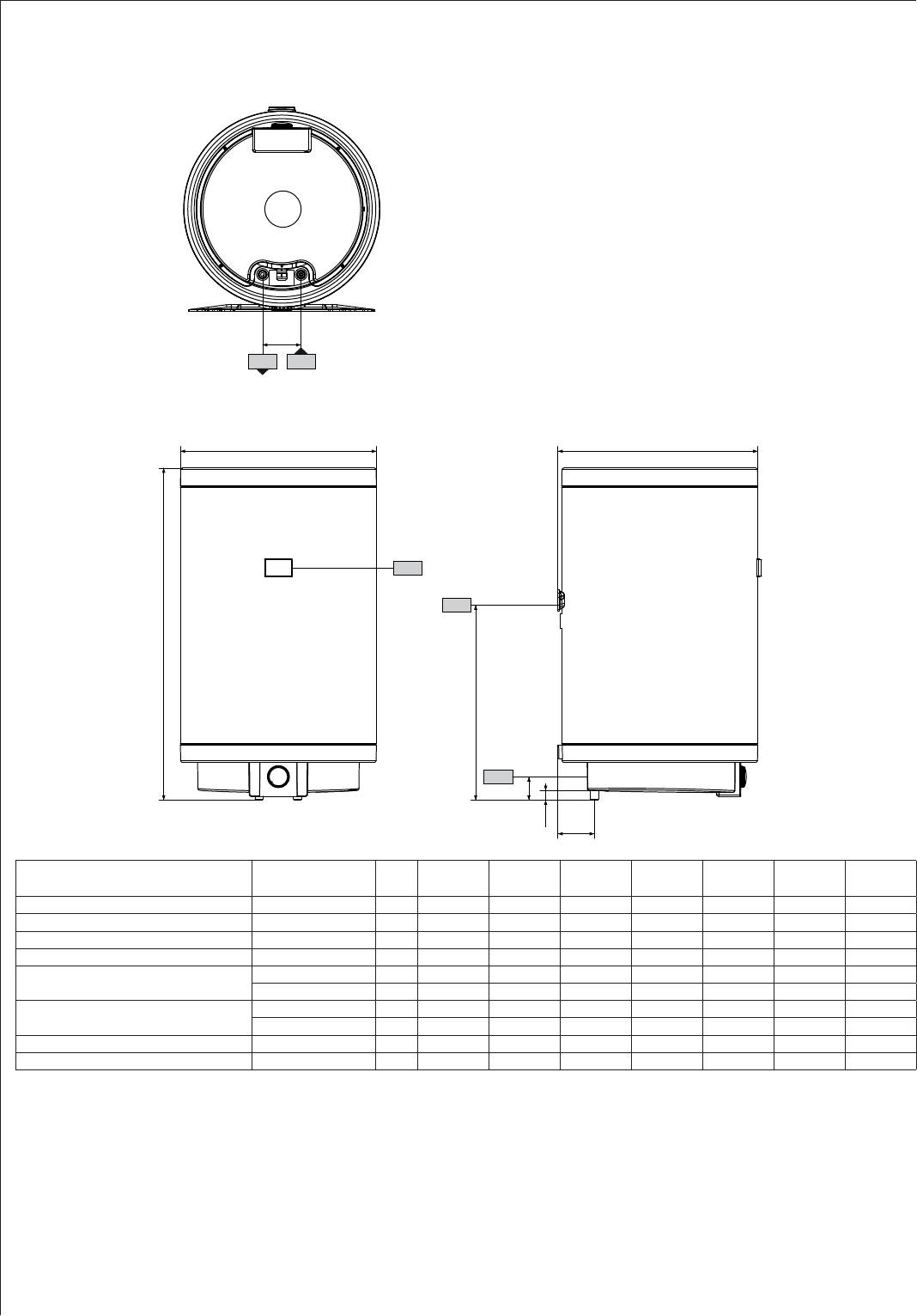

D0000037133

EWH 30

EWH 50

EWH 80

EWH 100

EWH 120

EWH 150

EWH 200

a10 Appliance Height mm 642 897 871 1025 1178 1410 1715

a30 Appliance Depth mm 410 410 520 520 520 520 520

a40 Appliance Diameter mm 405 405 510 510 510 510 510

b01 Entry electrical cables Threaded fitting PG 16 PG 16 PG 16 PG 16 PG 16 PG 16 PG 16

c01 Cold water inlet Male thread G 1/2 A G 1/2 A G 1/2 A G 1/2 A G 1/2 A G 1/2 A G 1/2 A

Rear clearance mm 85.5 85.5 95 95 95 95 95

c06 DHW outlet Male thread G 1/2 A G 1/2 A G 1/2 A G 1/2 A G 1/2 A G 1/2 A G 1/2 A

Rear clearance mm 85.5 85.5 95 95 95 95 95

h46 Temperature indicator

i13 Wall mounting bracket Height mm 530 590 585 735 890 1125 1425

Installation - for contractors

15.3

30 - 50 l

The heat-up time depends on the cylinder capacity, cold

water inlet temperature and heating output.

Graph assumes 15 °C cold water inlet temperature:

184

6

265

300

5

360

80_02_07_0005

4

80 - 200 l

3

2

265

300

1

350

360

0

415

35 45 55 65 75

450

80_02_07_0006

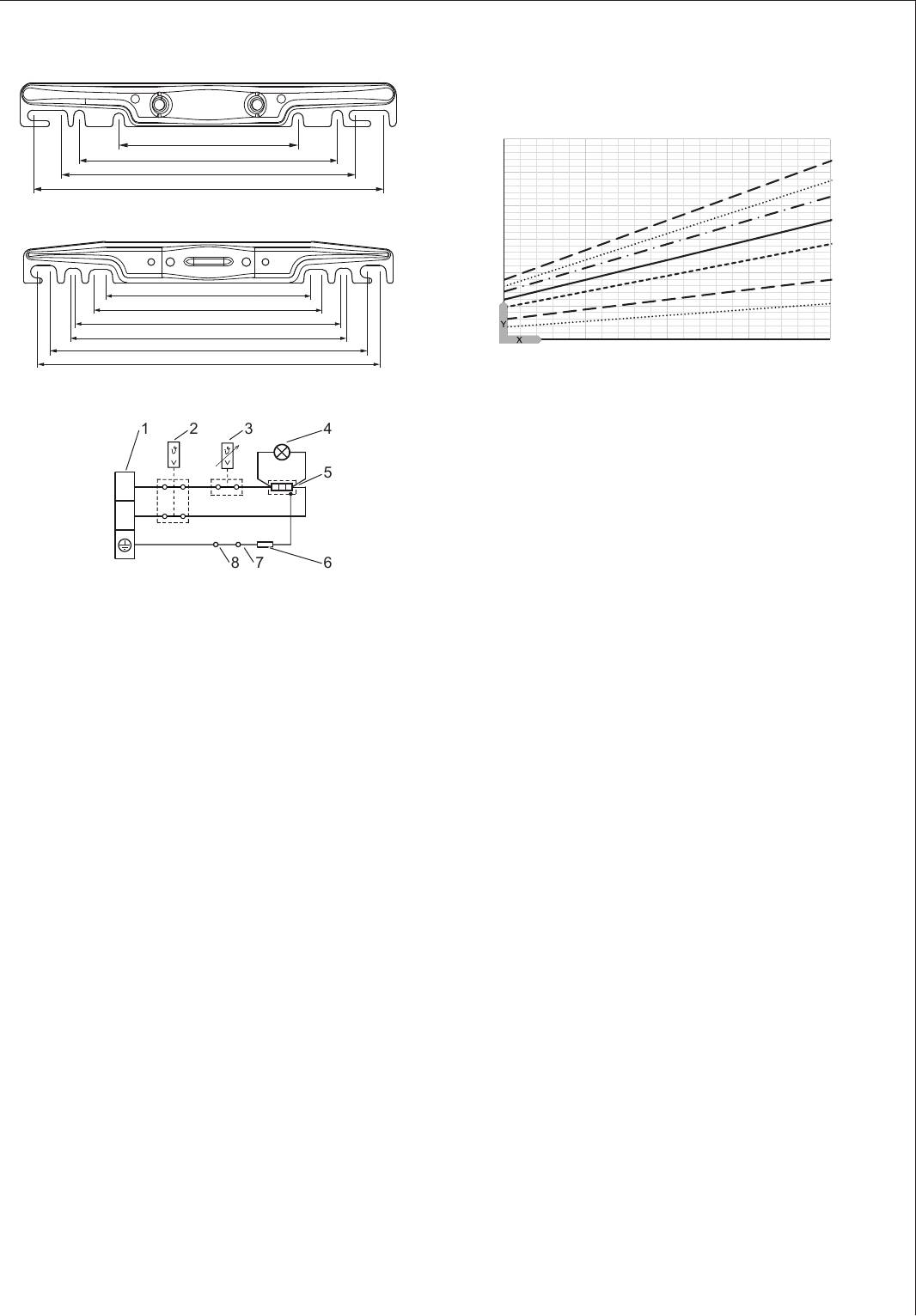

15.2

21 3 4

5

L

N

678

D0000037038

1 Terminal

2 High limit safety cut-out

3 Temperature controller

4 ON/OFF indicator

5 Heating element

6 Electrical resistance 560 ohm

7 Anode

8 Cylinder

21

1

2

3

4

5

6

7

D0000037214

X Temperature setting [°C]

Y Heat-up time [h]

1 150 l

2 200 l

3 120 l

4 100 l

5 80 l

6 50 l

7 30 l

15.4

In the event of a fault, temperatures of up to 95 °C at

0.6 MPa can occur.

WARRANTY

ENVIRONMENT AND RECYCLING

Installation - Warranty - Environment and recycling

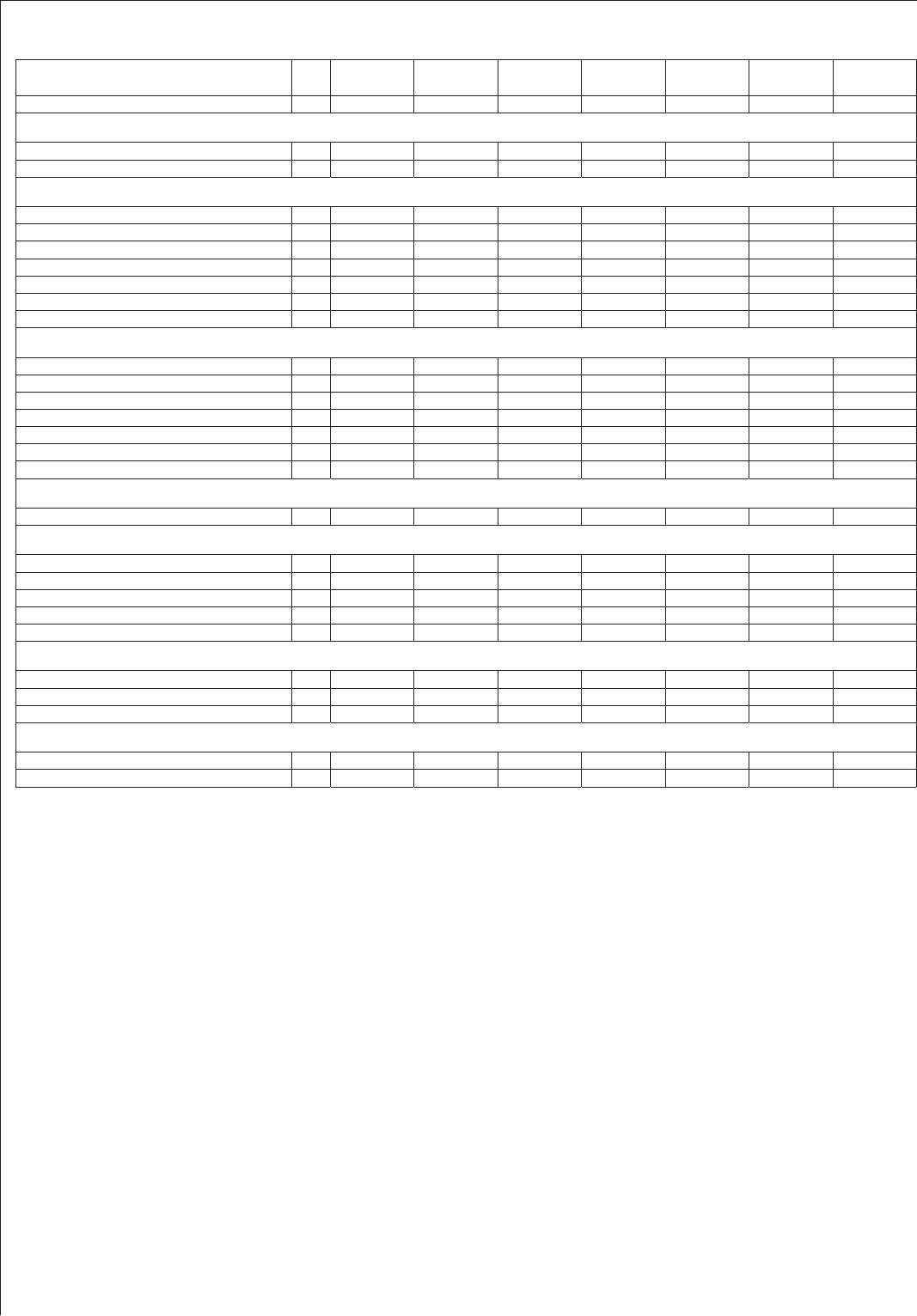

15.5

EWH 30

EWH 50

EWH 80

EWH 100

EWH 120

EWH 150

EWH 200

232087 232088 232089 232090 232091 232092 232093

Nominal capacity l 30 50 80 100 120 150 200

Amount of mixed water 40 °C (15 °C/65 °C) l 52 99 142 186 224 288 376

Connected load ~ 230 V kW 2 2 2 2 2 2 3

Rated voltage V 220-240 220-240 220-240 220-240 220-240 220-240 220-240

Phases 1/N/PE 1/N/PE 1/N/PE 1/N/PE 1/N/PE 1/N/PE 1/N/PE

Frequency Hz 50/60 50/60 50/60 50/60 50/60 50/60 50/60

Single circuit operating mode X X X X X X X

Heat-up time 2.0 kW (15 °C/60 °C) h 0.80 1.33 2.13 2.66 3.20 4.00

Heat-up time 3.0 kW (15 °C/60 °C) h 3.55

Temperature setting range °C 7-75 7-75 7-75 7-75 7-75 7-75 7-75

Max. permissible pressure MPa 0.6 0.6 0.6 0.6 0.6 0.6 0.6

Test pressure MPa 0.2 0.2 0.2 0.2 0.2 0.2 0.2

Max. permissible temperature °C 95 95 95 95 95 95 95

Max. flow rate l/min 23.5 23.5 23.5 23.5 23.5 23.5 23.5

Min. water inlet pressure MPa 0.1 0.1 0.1 0.1 0.1 0.1 0.1

Max. water inlet pressure MPa 0.6 0.6 0.6 0.6 0.6 0.6 0.6

Standby energy consumption/24 h at 65 °C kWh 0.53 0.72 0.79 0.98 1.14 1.33 1.61

Versions

Colour White White White White White White White

IP rating IP25 IP25 IP25 IP25 IP25 IP25 IP25

Sealed unvented type X X X X X X X

Power cable X X X X X X X

Power cable length approx. mm 1000 1000 1000 1000 1000 1000 1000

Dimensions

Height mm 642 897 871 1025 1178 1410 1715

Depth mm 410 410 520 520 520 520 520

Diameter mm 405 405 510 510 510 510 510

Weights

Weight, empty kg 16.4 21.4 28.2 33.6 39.1 46.2 56.3

Weight, full kg 46.4 71.4 108.2 133.6 159.1 196.2 256.3

Warranty

The warranty conditions of our German companies do not

apply to appliances acquired outside of Germany. In countries

where our subsidiaries sell our products, it is increasingly the

case that warranties can only be issued by those subsidiaries.

Such warranties are only granted if the subsidiary has issued

its own terms of warranty. No other warranty will be granted.

We shall not provide any warranty for appliances acquired in

countries where we have no subsidiary to sell our products.

This will not aect warranties issued by any importers.

Environment and recycling

We would ask you to help protect the environment. After use,

dispose of the various materials in accordance with national

regulations.

22