Karcher Balayeuse KM 85-50 W Bat Pack Classic: Shutdown Maintenance and care

Shutdown Maintenance and care: Karcher Balayeuse KM 85-50 W Bat Pack Classic

-

7

Danger

Risk of injury and damage! Observe the

weight of the appliance when you transport

it.

Lock parking brake.

Disconnect batteries.

Secure the wheels of the machine with

wheel chocks.

Secure the machine with tensioning

straps or cables.

When transporting in vehicles, secure

the appliance according to the guide-

lines from slipping and tipping over.

KM 85/50 W Bp Adv

KM 85/50 W Bp Pack Adv

Turn the push handle lock clockwise;

lock is locked.

1 Fastening area above the pushing han-

dle

2 Fastening area under the device hood

Note:

Observe markings for fixing points on

base frame (chain symbols).

Danger

Risk of injury and damage! Note the weight

of the appliance in case of storage.

If the sweeper is going to be out of service

for a longer time period, observe the follow-

ing points:

Park the sweeper on an even surface.

Turn the main switch using "0" position

and pull it out.

Lock parking brake.

Lock the sweeper to ensure that it does

not roll off.

KM 85/50 W Bp Adv

KM 85/50 W Bp Pack Adv

Turn the push handle lock clockwise;

lock is locked.

(only Adv model)

Raise roller brush.

The side-brushes lift up.

Clean the inside and outside of the

sweeper.

Park the machine in a safe and dry

place.

Disconnect batteries.

Charge battery and recharge it approx.

every 2 months.

–

Maintenance work may only be carried

out by approved customer service out-

lets or experts in this field who are famil-

iar with the respective safety

regulations.

–

Mobile appliances used for commercial

purposes are subject to safety inspec-

tions according to VDE 0701.

Caution

Risk of damage! Do not clean the appliance

with a water hose or high-pressure water

jet (danger of short circuits or other dam-

age).

Danger

Risk of injury! Wear dust mask and protec-

tive goggles.

Open the device hood.

Clean machine with a cloth.

Blow through machine with com-

pressed air.

Close cover.

Clean the machine with a damp cloth

which has been soaked in mild deter-

gent.

Note:

Do not use aggressive cleaning

agents.

KM 85/50 W Bp Adv

KM 85/50 W Bp Pack Adv

Note:

The elapsed-time counter shows the

timing of the maintenance intervals.

Daily maintenance:

Check the sweeping roller and the side

brush for wear and wrapped belts.

Check function of all operator control el-

ements.

Check functioning of all indicator lamps.

Weekly maintenance:

Check tension, wear and tear and func-

tioning of the drive belts and drive

chain.

Check for smooth running of the

Bowden cables and the moveable parts

Check sealing strips at the dust filter.

Check functioning of the filter cleaning

system.

Check the sealing strips in the sweep-

ing area for position and wear.

Check the sweeping track of the sweep-

ing roller.

Check the function of the sweeping roll-

er and the side brushes.

Clean the dust filter.

Note:

For description, see section on Main-

tenance work.

Note:

Where maintenance is carried out by

the customer, all service and maintenance

work must be undertaken by a qualified

specialist. If required, a specialised Kärch-

er dealer may be contacted at any time.

Maintenance to be carried out after 5 oper-

ating hours:

Carry out initial inspection.

Maintenance to be carried out every 50 op-

erating hours

Maintenance to be carried out every 100

operating hours

Maintenance to be carried out every 500

operating hours

Note:

In order to safeguard warranty

claims, all service and maintenance work

during the warranty period must be carried

out by the authorised Kärcher Customer

Service in accordance with the mainte-

nance booklet.

Preparation:

Park the sweeper on an even surface.

Turn the main switch using "0" position

and pull it out.

Lock parking brake.

KM 85/50 W Bp Adv

KM 85/50 W Bp Pack Adv

Turn the push handle lock clockwise;

lock is locked.

Danger

Risk of injury!

The engine requires approx. 3-4 seconds

to come to a standstill once it has been

switched off. During this time, stay well

clear of the working area.

Pull out the battery plug or clamp the

battery while working on the electrical

unit.

First switch off the appliance, remove

the key from the main switch and re-

move the battery plug or disconnect the

battery before performing any cleaning

or maintenance tasks on the appliance,

replacing parts or switching over to an-

other function.

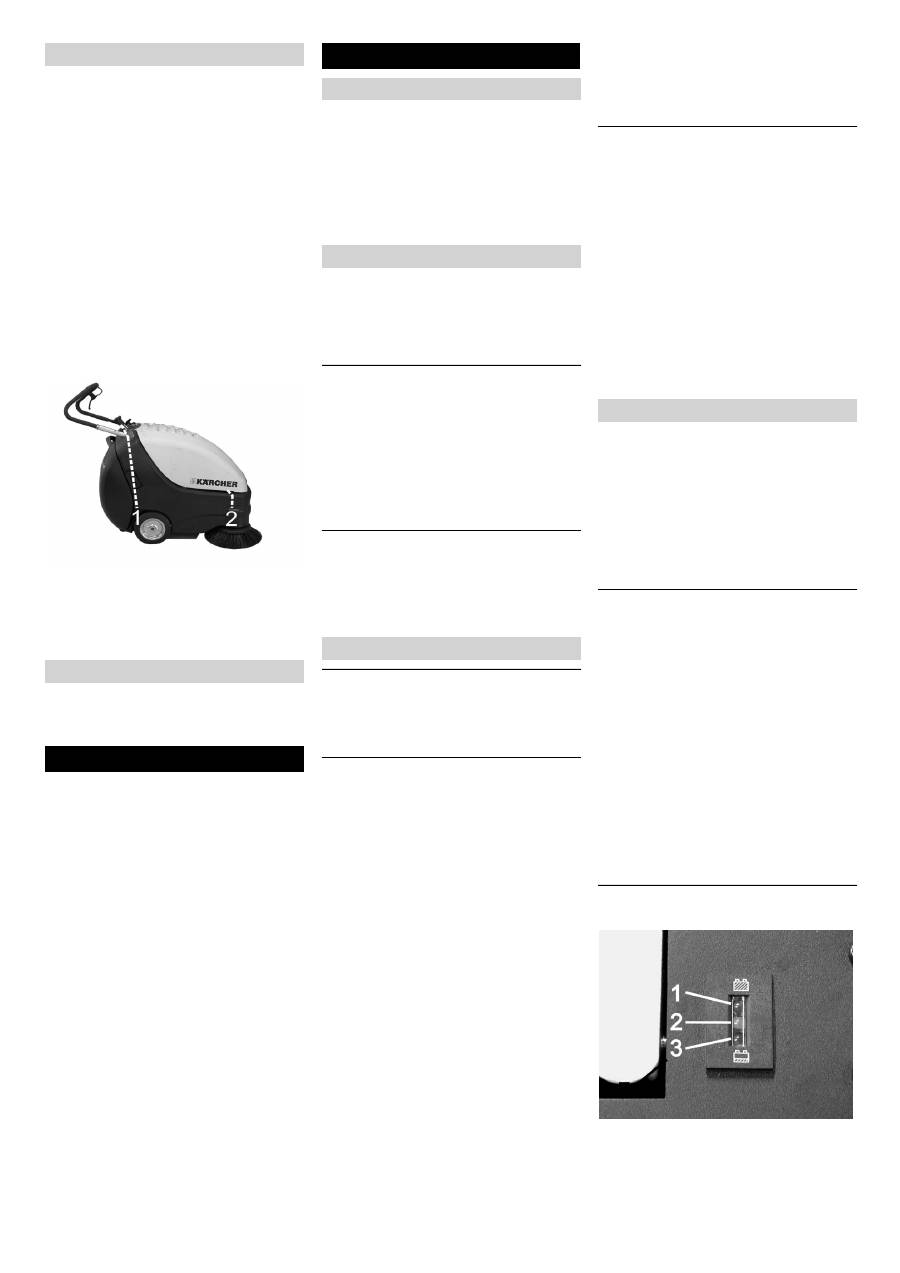

Turn the main switch to position “1”.

1 Green: Batteries are charged

2 Yellow: Operating time left: approxi-

mately 5 to 10 minutes

3 Red: Appliance switches off - batteries

are charged

Transport

Storage

Shutdown Maintenance and care

General notes

Cleaning

Cleaning the inside of the machine

External cleaning of the appliance

Maintenance intervals

Operating hour counter

Maintenance by the customer

Maintenance by Customer Service

Maintenance Works

General notes on safety

Check charging status of batteries

21 EN

-

8

Lock parking brake.

Remove the waste container.

Remove belts or cords from roller

brush.

Replacement is due if a visible deteriora-

tion in sweeping performance caused by

bristle wear is evident.

KM 85/50 W Bp Adv

KM 85/50 W Bp Pack Adv

Turn the push handle lock counter-

clockwise; lock is unlocked.

Remove the waste container.

Push appliance to the back onto the

push handle.

Unscrew left and right locking screws.

Remove the sweeping roll downwards.

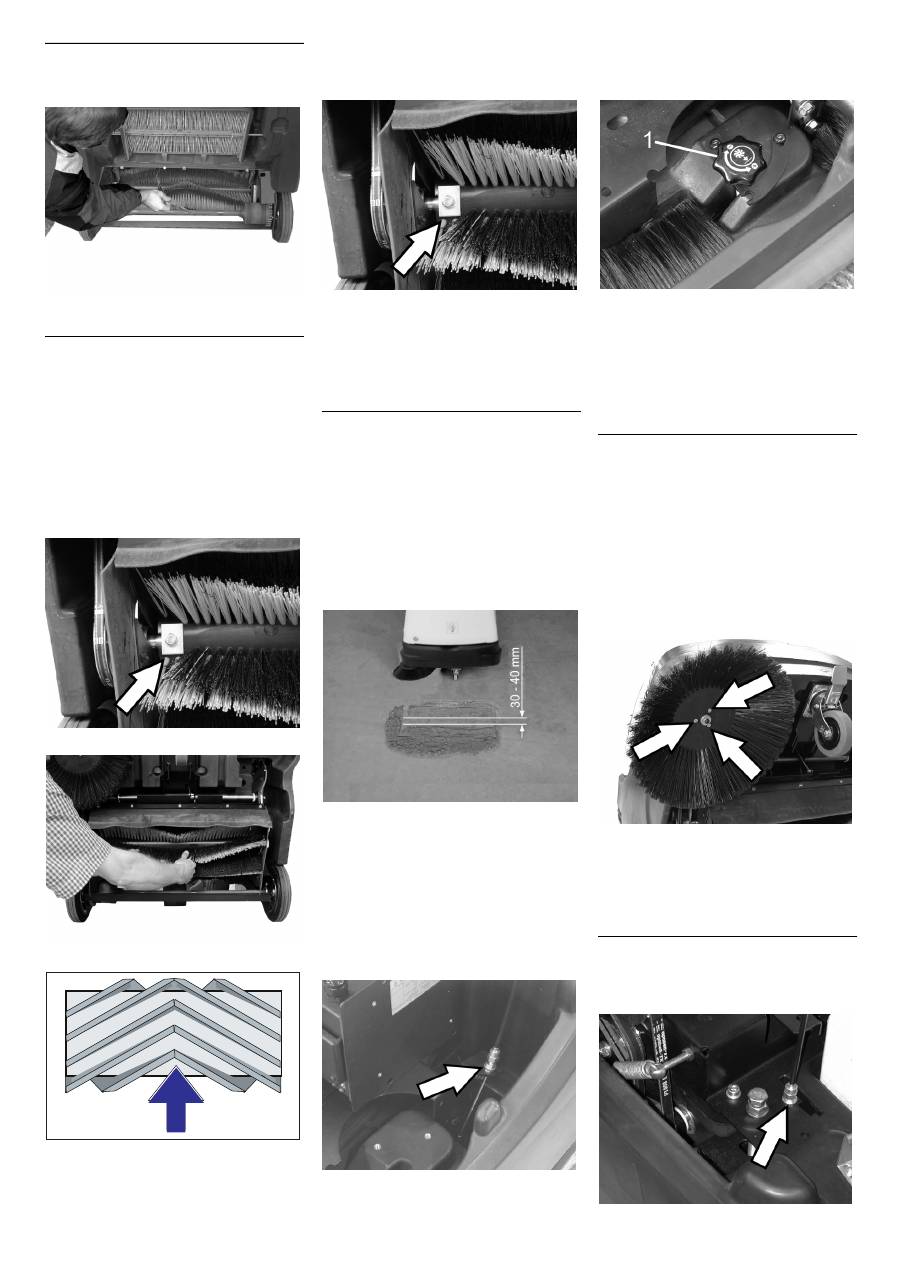

Installation position of roller brush in direc-

tion of travel

Insert new sweep roller and fasten it.

Note:

When installing the new roller brush,

ensure correct positioning of the bristle as-

sembly.

Make sure that the right angled clamping

plates are in proper position. They should

overlap the sweeping cylinder from above

and below.

Note:

Once the new roller brush has been

installed, the sweeping track must readjust-

ed.

Raise the sweeper from the front and

drive it on to a smooth, even surface

covered with a visible layer of dust or

chalk.

Lock parking brake.

Let the sweeping roller rotate for ap-

prox. 15-30 seconds.

Raise the sweeper at the front and drive

it towards the side.

The sweeping track should have an even

rectangular shape which is between 30 and

40 mm wide.

Adjusting the sweeping track:

KM 85/50 W Bp Adv

KM 85/50 W Bp Pack Adv

Note:

If the sweeping track is too small and

the Bowden cable is tensioned when the

roller brush is lowered, the Bowden cable

must be adjusted.

Adjust sweeping track on Bowden cable.

Check sweeping mirror.

Adjusting the sweeping track:

KM 85/50 W Bp

KM 85/50 W Bp Pack

1 Rotary knob

Turn the rotary knob:

–

In clock-wise direction: Sweeping track

becomes smaller

–

Anti-clockwise direction: Sweeping

track becomes bigger

Check sweeping mirror.

Replacement is due if a visible deteriora-

tion in sweeping performance caused by

bristle wear is evident.

KM 85/50 W Bp Adv

KM 85/50 W Bp Pack Adv

Turn the push handle lock counter-

clockwise; lock is unlocked.

Remove the waste container.

Push appliance to the back onto the

push handle.

Unscrew 3 screws from the underside

of the side brush.

Remove the wiper blade.

Clip new side brushes on to driver and

screw on.

Tilt the appliance forward.

Adjustment is necessary if a visible deterio-

ration in sweeping performance caused by

side-brush is evident.

Checking roller brush

Replacing roller brush

Check and adjust roller brush sweeping

track

Replacing side brush

Adjust side-brush lowering

22 EN

-

9

Loosen counter-nut.

Adjust the adjustment screw.

Tighten the counter-nut.

–

Adjustment is necessary if the bulk

waste flap cannot be raised wide

enough.

–

The Bowden cable needs to be re-

leased a little if the sweeper results be-

come poorer, for e.g. due to the wearing

of the front lip.

Loosen counter-nut.

Adjust the adjustment screw.

Tighten the counter-nut.

If the sweeping results degrade due to the

wear of the sealing strips, the sealing strips

must be readjusted or replaced.

KM 85/50 W Bp Adv

KM 85/50 W Bp Pack Adv

Turn the push handle lock counter-

clockwise; lock is unlocked.

Remove the waste container.

Push appliance to the back onto the

push handle.

Front sealing strip

Loosen the fastening screws of the

sealing strip.

Readjust the sealing strips pushing

them downward into the slot.

Tighten the fastening screws of the

sealing strip.

Prepare the appliance and move it a

small distance forwards.

Set the distance between the sealing

strip and the floor so that the bottom

edge trails behind at a distance of be-

tween 10 and 15 mm.

Note:

If the setting range is not sufficient,

the sealing strip is worn off and should be

replaced.

Rear sealing strip

Remove the waste container.

Loosen the fastening screws of the

sealing strip.

Replace the sealing strip.

Tighten the fastening of the sealing

strip.

Side sealing strips

Loosen the fastening screws of the

sealing strip.

Replace the sealing strip.

Screw on new sealing strip without fully

tightening it.

To set the floor clearance, insert a

sheet with a thickness of between 1 and

2 mm under the sealing strip.

Adjust sealing strip.

Tighten the fastening of the sealing

strip.

몇

Warning

Empty waste container before replacing

dust filter. Wear a dust mask when working

around the dust filter. Observe safety regu-

lations on the handling of fine particulate

material.

Lock parking brake.

Remove the waste container.

Remove the securing splint of the vibra-

tor bar.

Pull out the bar.

Loosen screws.

Remove the tin frame.

Replace the dust filter.

Note:

Make sure when installing the new

filter that the fins are not damaged.

Adjust the raising of the bulk waste flap

Adjusting and replacing sealing strips

Replacing dust filter

23 EN

Оглавление

- Inhaltsverzeichnis

- Funktion Bestimmungsgemäße Verwendung

- Bedien- und Funktionselemente 12 3 456 879 10 1213 11 141516 17

- Vor Inbetriebnahme

- Inbetriebnahme

- Betrieb

- Stilllegung Pflege und Wartung

- Zubehör

- Hilfe bei Störungen

- Technische Daten

- Contents

- Function Proper use

- Operating and Functional Elements 12 3 456 879 10 1213 11 141516 17

- Before Startup

- Start up

- Operation

- Shutdown Maintenance and care

- Accessories

- Troubleshooting

- Technical specifications

- Table des matières

- Fonction Utilisation conforme

- Eléments de commande et de fonction 12 3 456 879 10 1213 11 141516 17

- Avant la mise en service

- Mise en service

- Fonctionnement

- Remisage Entretien et maintenance

- Accessoires

- Assistance en cas de panne

- Caractéristiques techniques

- Indice

- Funzione Uso conforme a destinazione

- Elementi di comando e di funzione 12 3 456 879 10 1213 11 141516 17

- Prima della messa in funzione

- Messa in funzione

- Funzionamento

- Fermo dell'impianto Cura e manutenzione

- Accessori

- Guida alla risoluzione dei guasti

- Dati tecnici

- Inhoudsopgave

- Functie Reglementair gebruik

- Elementen voor de bediening en de functies 12 3 456 879 10 1213 11 141516 17

- Voor de inbedrijfstelling

- Inbedrijfstelling

- Werking

- Stillegging Onderhoud

- Toebehoren

- Hulp bij storingen

- Technische gegevens

- Índice de contenidos

- Función Uso previsto

- Elementos de operación y funcionamiento 12 3 456 879 10 1213 11 141516 17

- Antes de la puesta en marcha

- Puesta en marcha

- Funcionamiento

- Parada Cuidados y mantenimiento

- Accesorios

- Ayuda en caso de avería

- Datos técnicos

- Índice

- Funcionamento Utilização conforme o fim a que se destina a máquina

- Elementos de comando e de funcionamento 12 3 456 879 10 1213 11 141516 17

- Antes de colocar em funcionamento

- Colocação em funcionamento

- Funcionamento

- Desactivação da máquina Conservação e manutenção

- Acessórios

- Ajuda em caso de avarias

- Dados técnicos

- Indholdsfortegnelse

- Funktion Bestemmelsesmæssig‚ anvendelse

- Betjenings- og funktionselementer 12 3 456 879 10 1213 11 141516 17

- Inden ibrugtagning

- Ibrugtagning

- Drift

- Afbrydning/nedlæggelse Pleje og vedligeholdelse

- Tilbehør

- Hjælp ved fejl

- Tekniske data

- Innholdsfortegnelse

- Funksjon Forskriftsmessig bruk

- Betjenings- og funksjonelementer 12 3 456 879 10 1213 11 141516 17

- Før den tas i bruk

- Ta i bruk

- Sette bort Pleie og vedlikehold

- Tilbehør

- Feilretting

- Tekniske data

- Innehållsförteckning

- Funktion Ändamålsenlig användning

- Manövrerings- och funktionselement 12 3 456 879 10 1213 11 141516 17

- Före ibruktagande

- Idrifttagning

- Nedstängning Skötsel och underhåll

- Tillbehör

- Åtgärder vid störningar

- Tekniska data

- Sisällysluettelo

- Toiminta Käyttötarkoitus

- Ohjaus- ja käyttölaitteet 12 3 456 879 10 1213 11 141516 17

- Ennen käyttöönottoa

- Käyttöönotto

- Seisonta-aika Hoito ja huolto

- Tarvikkeet

- Häiriöapu

- Tekniset tiedot

- Πίνακας περιεχομένων

- Λειτουργία Χρήση σύμφωνα με τους κανονισμούς

- Στοιχεία χειρισμού και λειτουργίας 12 3 456 879 10 1213 11 141516 17

- Πριν τη θέση σε λειτουργία

- Έναρξη λειτουργίας

- Λειτουργία

- Διακοπή της λειτουργίας Φροντίδα και συντήρηση

- Εξαρτήματα

- Αντιμετώπιση βλαβών

- Τεχνικά χαρακτηριστικά

- İ çindekiler

- Fonksiyon Kurallara uygun kullan ı m

- Kullan ı m ve çal ı ş ma elemanlar ı 12 3 456 879 10 1213 11 141516 17

- Cihaz ı çal ı ş t ı rmaya ba ş lama- dan önce

- İş letime alma

- Durdurma Koruma ve Bak ı m

- Aksesuar

- Ar ı zalarda yard ı m

- Teknik Bilgiler

- Оглавление

- Назначение Использование по назначению

- Описание элементов управления и рабочих узлов 12 3 456 879 10 1213 11 141516 17

- Перед началом работы

- Начало работы

- Вывод из эксплуатации Уход и техническое обслуживание

- Принадлежности

- Помощь в случае неполадок

- Технические данные

- Tartalomjegyzék

- Funkció Rendeltetésszer ű használat

- Kezelési- és funkciós elemek 12 3 456 879 10 1213 11 141516 17

- Üzembevétel el ő tt

- Üzembevétel

- Üzem

- Leállítás Ápolás és karbantartás

- Tartozékok

- Segítség üzemzavar esetén

- M ű szaki adatok

- Obsah

- Funkce Používání v souladu s ur č ením

- Ovládací a funk č ní prvky 12 3 456 879 10 1213 11 141516 17

- P ř ed uvedením do provozu

- Uvedení do provozu

- Provoz

- Odstavení Ošet ř ování a údržba

- P ř íslušenství

- Pomoc p ř i poruchách

- Technické údaje

- Vsebinsko kazalo

- Delovanje Namenska uporaba

- Upravljalni in funkcijski elementi 12 3 456 879 10 1213 11 141516 17

- Pred zagonom

- Zagon

- Obratovanje

- Mirovanje naprave Nega in vzdrževanje

- Pribor

- Pomo č pri motnjah

- Tehni č ni podatki

- Spis tre ś ci

- Funkcja U ż ytkowanie zgodne z przeznaczeniem

- Elementy urz ą dzenia 12 3 456 879 10 1213 11 141516 17

- Przed pierwszym uruchomieniem

- Uruchamianie

- Wy łą czenie z eksploatacji Czyszczenie i konserwacja

- Akcesoria

- Usuwanie usterek

- Dane techniczne

- Cuprins

- Func ţ ionarea Utilizarea corect ă

- Elemente de utilizare ş i func ţ ionale 12 3 456 879 10 1213 11 141516 17

- Înainte de punerea în func ţ iune

- Punerea în func ţ iune

- Func ţ ionarea

- Scoaterea din func ţ iune Îngrijirea ş i între ţ inerea

- Accesorii

- Remedierea defec ţ iunilor

- Date tehnice

- Obsah

- Funkcia Používanie výrobku v súlade s jeho ur č ením

- Ovládacie a funk č né prvky 12 3 456 879 10 1213 11 141516 17

- Pred uvedením do prevádzky

- Uvedenie do prevádzky

- Prevádzka

- Odstavenie Starostlivos ť a údržba

- Príslušenstvo

- Pomoc pri poruchách

- Technické údaje

- Pregled sadržaja

- Funkcija Namjensko korištenje

- Komandni i funkcijski elementi 12 3 456 879 10 1213 11 141516 17

- Prije prve uporabe

- Stavljanje u pogon

- U radu

- Stavljanje ure đ aja van pogona Njega i održavanje

- Pribor

- Otklanjanje smetnji

- Tehni č ki podaci

- Pregled sadržaja

- Funkcija Namensko koriš ć enje

- Komandni i funkcioni elementi 12 3 456 879 10 1213 11 141516 17

- Pre upotrebe

- Stavljanje u pogon

- Rad

- Stavljanje ure đ aja van pogona Nega i održavanje

- Pribor

- Otklanjanje smetnji

- Tehni č ki podaci

- Съдържание

- Функция Употреба по предназначение

- Обслужващи и функционални елементи 12 3 456 879 10 1213 11 141516 17

- Преди пускане в експлоата - ция

- Пускане в експлоатация

- Спиране от експлоатация Грижи и поддръжка

- Принадлежности

- Помощ при неизправности

- Технически данни

- Sisukord

- Funktsioon Sihipärane kasutamine

- Teenindus- ja funktsioonielemendid 12 3 456 879 10 1213 11 141516 17

- Enne seadme kasutuselevõt- tu

- Kasutuselevõtt

- Käitamine

- Seismapanek Korrashoid ja tehnohooldus

- Tarvikud

- Abi häirete korral

- Tehnilised andmed

- Satura r ā d ī t ā js

- Darb ī ba Noteikumiem atbilstoša lietošana

- Vad ī bas un funkcijas elementi 12 3 456 879 10 1213 11 141516 17

- Pirms ekspluat ā cijas uzs ā kšanas

- Ekspluat ā cijas uzs ā kšana

- Ier ī ces darb ī ba

- Iekonserv ē šana Kopšana un tehnisk ā apkope

- Piederumi

- Pal ī dz ī ba darb ī bas trauc ē jumu gad ī jum ā

- Tehniskie dati

- Turinys

- Veikimas Naudojimas pagal paskirt į

- Valdymo ir funkciniai elementai 12 3 456 879 10 1213 11 141516 17

- Prieš pradedant naudoti

- Naudojimo pradžia

- Naudojimas

- Laikinas prietaiso nenaudojimas Prieži ū ra ir aptarnavimas

- Dalys

- Pagalba gedim ų atveju

- Techniniai duomenys

- Перелік

- Призначення Правильне застосування

- Елементи управління і функціональні вузли 12 3 456 879 10 1213 11 141516 17

- Перед початком роботи

- Введення в експлуатацію

- Експлуатація

- Зберігання Догляд та технічне обслуговування

- Аксесуари

- Допомога у випадку неполадок

- Технічні характеристики