Karcher ICC 2 D ADV STAGE IIIa: Before Startup

Before Startup: Karcher ICC 2 D ADV STAGE IIIa

-

6

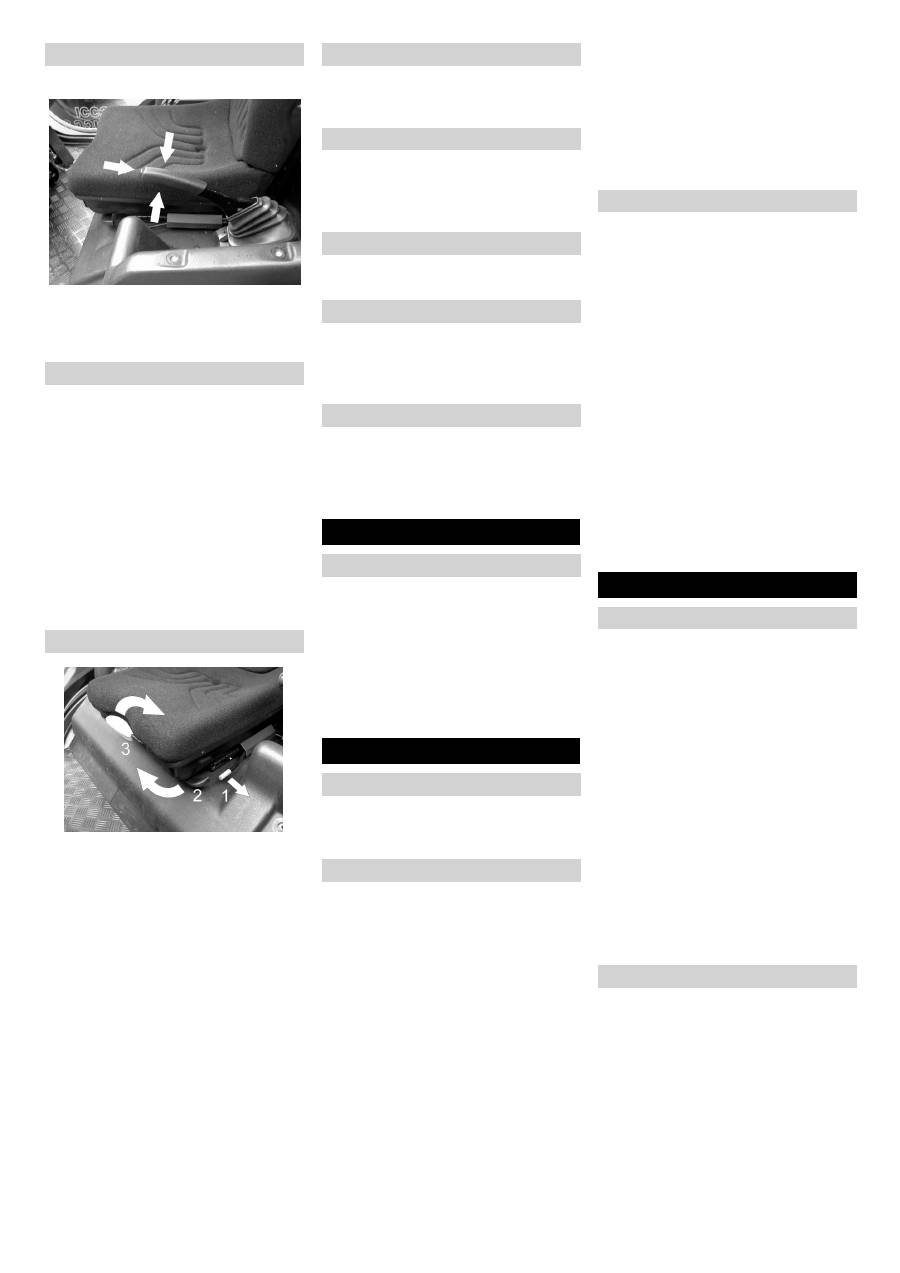

Pull up the handle.

Press the locking button and release

the handle.

Pull upwards the lever located under

the seat.

Slide seat, release lever and lock in

place.

Check that the seat is properly locked in

position by attempting to move it back-

wards and forwards.

Turn the hand-wheel at the rear of the

seat.

–

In clock-wise direction: Spring harder

–

Anti-clockwise direction: Spring softer

Press the lever (1).

Slide seat, release lever and lock in

place.

Check that the seat is properly locked in

position by attempting to move it back-

wards and forwards.

Tilt the lever (2) until the scales show

your body weight.

–

Set the body weight between 50-130

kg.

–

If you tilt until the end, the setting is

done for 50 kg.

Tilt the handle (3).

Adjust the seat.

Insert the consumer load at 12V-con-

nection.

(see switch strip)

Switch on/off the blower.

(see switch strip)

–

for heating: level 2

–

for air-conditioner: level 3

Turn on/off the air-conditioner.

(see switch strip)

Activate the slide.

(see switch strip)

–

Slide is pushed in = fresh air

–

Slide is pulled out = air circulation

Activate the slide.

(see switch strip)

–

Slide is pushed in = cold

–

Slide is pulled out = warm

Note

The appliance is fitted with tension belts for

safe transport.

To unload the machine, proceed as follows:

Remove tension belts.

Release parking brake.

Drive down the appliance from the

transport vehicle.

Park the sweeper on an even surface.

Remove ignition key.

Lock parking brake.

Danger

Risk of explosion!

–

Only use the fuels specified in the Op-

erations Manual.

–

Do not refuel the machine in enclosed

spaces.

–

Smoking and naked flames are strictly

prohibited.

–

Ensure that no fuel reaches the hot

open surfaces.

Switch off engine.

Open fuel filler cap.

Fill in diesel.

Fill in the tank up to a level 1 cm below

the lower edge of the filling nozzle be-

cause the fuel expands on heating.

Wipe off any spilt fuel and close fuel fill-

er cap.

–

Estimate the fuel requirement in order

to avoid overflows.

–

Insert the fuelling gun as deep as possi-

ble into the fuel nozzle. Do not add any

more fuel once the fuelling gun stops

according to the settings.

Check engine oil level. *

Check water cooler and maintain it. *

Check tyre pressure. *

Check fill level of fuel tank. *

Adjust driver's seat.

Check suction channel. *

Check setting of suction opening. *

Check lights and ensure that they are

functioning properly. *

Check signaling and warning systems

for proper functioning. *

Fill the water reservoir. *

Check side brush. *

Empty waste container.

* For description, see section on Care and

maintenance.

몇

Warning

Rectify any defect you may find immediate-

ly or bring the vehicle to a halt.

Sit on the driver's seat.

Do NOT press the accelerator pedal.

Lock parking brake.

Switch off the working hydraulic.

Set the drive direction indicator to posi-

tion (0) (neutral).

Turn the ignition key to position "I".

Pre-heat lamp glows.

When the pre-heating lamp goes off,

turn the ignition key to position "II".

If the machine starts, release the igni-

tion key.

Note

Never operate the starter motor for longer

than 10 seconds. Wait at least 10 seconds

before operating the starter motor again.

Press the brake pedal.

Set the drive direction indicator to posi-

tion (1) (drive forwardl).

Release parking brake.

Press accelerator pedal down slowly.

Danger

Risk of injury! While reversing, ensure that

there is nobody in the way, ask them to

move if somebody is around.

Press the brake pedal.

Parking brake

Lock parking brake

Release parking brake

Adjusting driver's seat

Adjusting the seat position

Adjusting the seat springs

Comfortable seat (accessory)

Adjusting the seat position

Adjusting the seat springs

Adjust seat position

12V connection

Blower

Air-conditioner (accessory)

Fresh air circulation

Heating

Before Startup

Unloading

Start up

General notes

Refuelling

Fuelling using a can

Fuelling using the fuelling gun

Inspection and maintenance work

Operation

Starting the machine

Pre-heat

Start the engine

Drive the machine

Drive forward

Reverse drive

28 EN

-

7

Set the drive direction indicator to posi-

tion (2) (reverse drive).

Release parking brake.

Press accelerator pedal down slowly.

Note

Driving method

–

A warning tone is sounded while revers-

ing.

–

The accelerator pedal can be used to

vary the driving speed infinitely.

–

Avoid pressing the pedal suddenly as

this may damage the hydraulic system.

–

In the event of power loss on inclined

surfaces, slightly reduce the pressure

on the accelerator pedal.

–

Change the driving direction only after

the vehicle has come to a halt.

Release the accelerator pedal, the ma-

chine brakes automatically and stops.

Note

The braking effect can be supported by

pressing the foot-brake.

몇

Warning

Raise the side-brushes and the suction

opening before overtaking hurdles.

Hurdles up to 150 mm in height:

Bypass the hurdle slowly and carefully

at an angle of 45°.

Hurdles more than 150 mm in height:

Only drive over these obstacles using a

suitable ramp.

몇

Warning

Risk of damage! Ensure that the vehicle

does not get stuck up.

Danger

Risk of injury! If the bulk waste flap is open,

stones or gravel may be flung forwards by

the roller brush. Make sure that this does

not endanger persons, animals or objects.

몇

Warning

Do not sweep up packing strips, wire or

similar objects as this may choke up the

suction canal.

몇

Warning

To avoid damaging the floor, do not contin-

ue to operate the sweeping machine in the

same position.

Note

To achieve an optimum cleaning result, the

driving speed should be adjusted to take

specific situations into account.

Note

During operation, the waste container

should be emptied at regular intervals.

Set the idle running for the motor rpm

setting to 1600-1800 1/min.

(see console ).

Note

The motor rpm can be called via the multi-

functional display.

Turn on the working hydraulics (1st lev-

el).

(see operating panel).

Switch on the suction turbine and the

side-brushes (2nd step).

Note

Only driving is possible if the working hy-

draulics is switched off.

Set the side-brush speed on the speed

regulator.

(see operating panel).

–

In clock-wise direction: Side-brush

speed increases

–

Anti-clockwise direction: Side-brush

speed decreases

Press spray water button.

(see console ).

Spray water for side-brushes and suction

opening gets activated.

Note

The function of the spray-water pump is

displayed on a yellow indicator lamp, see

multi-functional display.

If the tank is empty, the yellow indicator

lamp goes off.

Switch-off spray water.

Fill the water reservoir.

Adjust the water flow to the side-brush-

es using the regulation valve.

–

In clock-wise direction: Water flow in-

creases

–

Anti-clockwise direction: Water flow de-

creases

Note

There is an accessory with 2 regulation

valves for separately controlling the water

flow to both the sides.

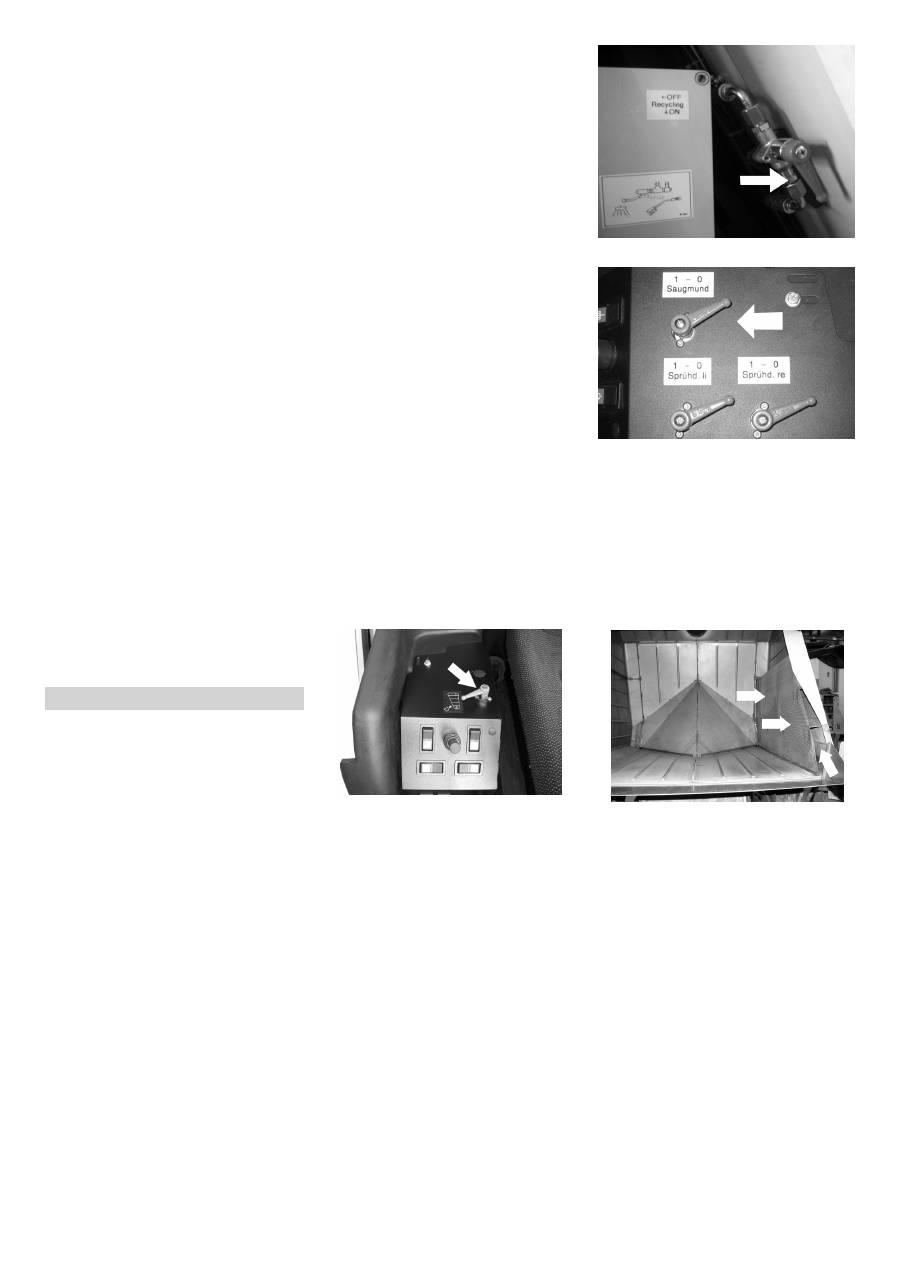

The applicance is fitted with a water circu-

lation system for increasing the duration of

usage (fresh water reservoir). In the water

circulation system, the water from the

waste container is guided to the suction

opening and thus circulated. Further, it is

also possible to add fresh water.

Fill the waste container with water up to

the end of the front slant. To suck in

leaves, fill lesser quantity of water in the

waste container.

Set the lever for recycling to ON.

Regulate additional supply of fresh wa-

ter to the suction opening using the le-

ver for suction opening.

Switch on the suction turbine; start

cleaning work.

After finishing operations, switch off the

suction turbine approx. 30 seconds af-

ter the suction opening has got raised.

This will prevent water from leaking

when the appliance has been switched

off.

Every time you empty the waste con-

tainer, rinse the sieve in the waste con-

tainer using the water hose and clean

the space behind the sieve.

Set the lever for recycling to OFF while

operating without water circulation.

When the appliance is switched off,

make sure the lever for recycling is set

to OFF because otherwise the hoses

leading to the suction opening will get

blocked.

The sieve and the space behind the

sieve must be cleaned every time you

empty the waste container even if you

are operating the appliance without wa-

ter circulation.

4-brush system:

Press the toggle switch downward. The

side-brushes will be lowered.

(see console ).

Brakes

Driving over obstacles

Sweeping mode

Setting the motor rpm

Switching on the working hydraulics

Adjusting the side-brush speed

Turn on/off the spray water

Regulate the water flow to the side-

brushes.

Water circulation system

Operating without water circulation sys-

tem

Raise/lower side-brushes

29 EN

-

8

Press the toggle switch upward. Side

brushes lift up.

2-brush system:

Press the toggle switch downward. The

side-brushes will be lowered.

(see console ).

Press the toggle switch upward. Side

brushes lift up.

–

The hydraulic side-brush relief reduces

the contact pressure of the brush on the

track.

–

The floor is protected against friction

and wear if the brushes are relieved

and this also increases the life of the

brushes.

–

The relief can be adjusted in infinitely

variable steps depending on the track

surface and the dirt that appears.

Raise/lower side-brushes:

Press the toggle switch downward. The

side-brushes are lowered; the relief is

deactivated.

(see console ).

Toggle switch in central position. The

side-brushes are lowered; the relief is

activated.

Press the toggle switch upward. Side

brushes lift up.

Setting the hydraulic side-brush relief:

Setting the relief of the brushes at the

speed regulator.

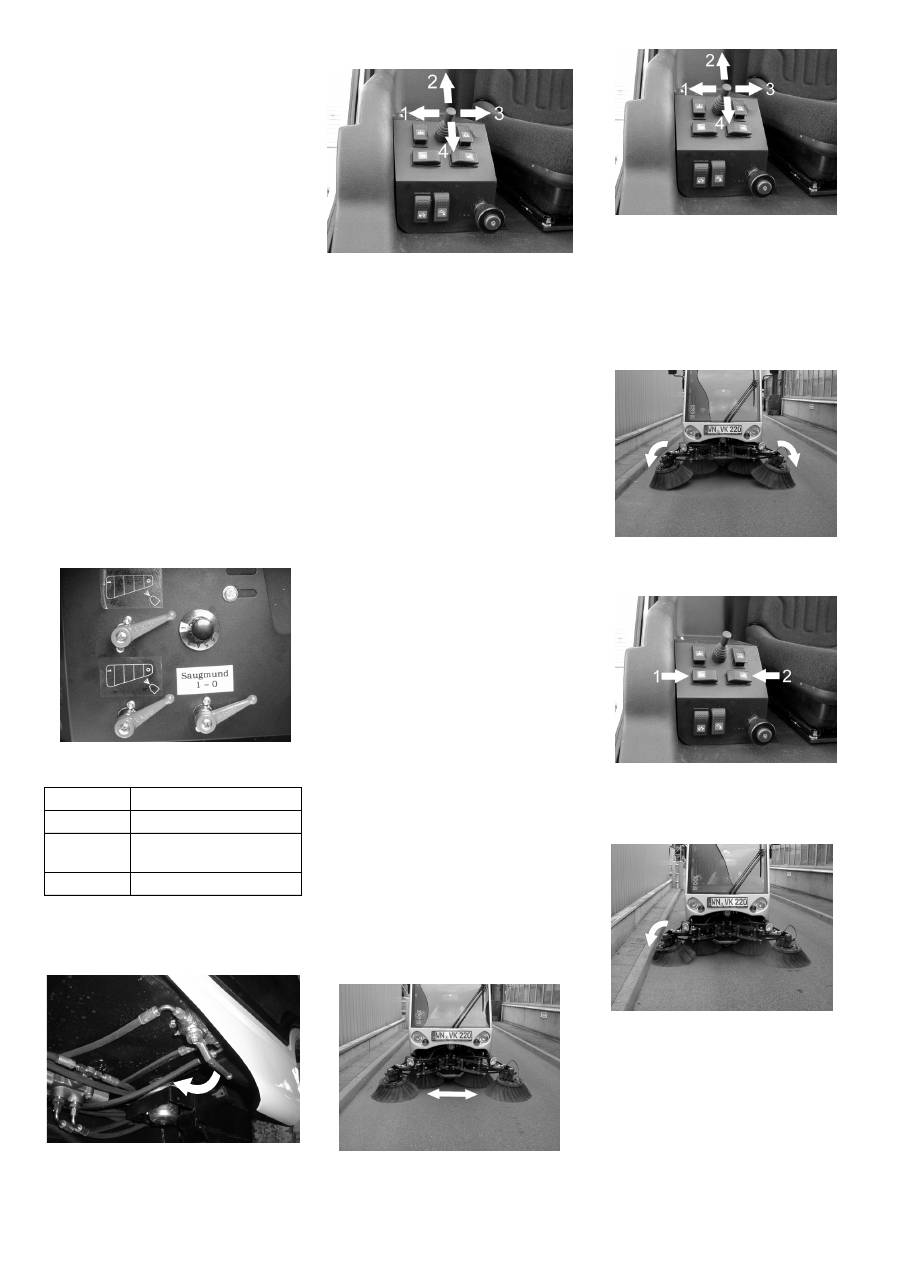

The side-brushes can individually be

stopped in a raised position.

Close the ball tap when the side-brush-

es are lifted up.

Move joystick to position (2). Side-

brushes are driven out.

Move joystick to position (4). Side-

brushes are drawn in.

Note

Only 2-brush system: The side-brushes

can only be driven out when they are rotat-

ing.

Note

To sweep in larger objects such as bever-

age cans or larger quantities of leaves, it is

necessary to briefly raise the bulk waste

flap.

Raising bulk waste flap:

Press the pedal for the bulk waste flap

forwards and keep pressed down.

To lower it, take foot off pedal.

Note

An optimum cleaning result can only be

achieved if the bulk waste flap has been

lowered completely.

To avoid deposits in the suction channel

and durst formation, the water supply to the

brush nozzles must be on.

Switch on the spray water.

(see console ).

Switch off the water supply to the brush

nozzles if there is practically no dust forma-

tion.

Switch-off spray water.

(see console ).

Note

To achieve an optimum cleaning result, the

driving speed or rahter the sweeping width

should be adjusted to take specific situa-

tions into account.

The front side-brushes can be driven in or

out depending on how dirty the plane sur-

face is.

Drive out the side-brushes (2).

Drive in the side-brushes (4).

Note

The sweeping width should be adjusted ac-

cording to how dirty the plane surface is so

that the waste can be sucked in completely.

The inclination of the front side-brushes

can be adjusted according to the geometry

of the driving path.

Tilt the right side-brushes (1).

Tilt the left side-brushes (2).

Tilt the right side-brushes if required.

Hydraulic side-brush relief (attachment)

Position

Relief on the brushes

1

minimum

5-8

medium (recommended

setting)

11

maximum

Stop side-brush lift up (only 2-brush

system)

Move in/out the side-brush

Sweeping in larger objects

Sweeping dry floors

Sweeping damp or wet floors

Sweeping plane surfaces

Inclination of the front side-brushes (on-

ly 4-brush system)

Sweeping along the limitations of the

driving path (only 4-brush system)

30 EN

-

9

To sweep in edge area on right-hand side:

Drive in the left side-brush and drive out

the right side-brush (1).

To sweep in edge area on left-hand side:

Drive in the right side-brush and drive

out the left side-brush (3).

–

The left side-brushes can be locked to

sweep narrow passages or foot-paths.

–

The right side-brushes can still be

moved using the joystick in position (1)

and (3).

–

If you move the joystick to position (2)

and (4), both the side-brushes in or out.

–

At narrow bends, turn in the external

brushes.

Danger

Risk of injury! While reversing, ensure that

there is nobody in the way, ask them to

move if somebody is around.

Danger

Danger of tipping. Place the machine on an

even surface during emptying.

Danger

Danger of tipping. Maintain the required

safety distance while emptying on dumps

or ramps.

Danger

Risk of injury! Switch off the suction turbine

before emptying the waste container.

Danger

Risk of injury! When emptying the waste

container, care should be taken to ensure

that no persons or animals are within its

swivelling range.

Danger

Danger of crushing. Never reach into the

rod assembly for the drainage mechanism.

Note

Always raise the waste container complete-

ly until its end position.

Switch off the spray water for side-

brushes and suction opening.

Stop the machine.

Lock parking brake.

Set the drive direction indicator to posi-

tion (0) (neutral).

Drive in the side-brushes.

The side-brushes lift up.

Switch off the suction turbine and the

side-brushes (2nd step).

Open the side-flaps.

Drain off water on both sides.

Raise waste container (1).

Empty waste container.

Lower waste container (2).

Note

There is a warning sound signal when the

waste container is lowered.

Lock parking brake.

Open the side-flaps.

Drain off water on both sides.

Remove the operating lever for the

pump.

Insert the operating lever on the pump

lever.

몇

Warning

Manually lift the lid of the waste container

before starting the pumping operations.

This will help in avoiding damage to the

rear panel.

Raise the waste container through

pumping.

Switch off the spray water for side-

brushes and suction opening.

Stop the machine.

Lock parking brake.

Set the drive direction indicator to posi-

tion (0) (neutral).

Drive in the side-brushes.

The side-brushes lift up.

Switch off the suction turbine and the

side-brushes (2nd step).

Turn off the working hydraulics (1st lev-

el).

Set the dry run speed.

Turn ignition key to "0" and remove it.

Open the screw cap.

Hang in the special tool (accessory)

and turn in anti-clockwise direction.

Loosen the fasteners of the suction

hose.

Connect the hose to the nozzle.

Loosen the fasteners of the suction

nozzle

Sweeping at narrow places

Emptying waste container

Emptying the waste container man-

ually

Turn off the appliance

Leaf suction (accessory)

31 EN

Оглавление

- Inhaltsverzeichnis

- Funktion Bestimmungsgemäße Ver- wendung

- Bedien- und Funktionselemente

- Bedienung

- Vor Inbetriebnahme

- Stilllegung Pflege und Wartung

- Zubehör

- Hilfe bei Störungen

- Technische Daten

- EG-Konformitätserklärung

- Contents

- Function Proper use

- Operating and Functional Elements

- Operation

- Before Startup

- Shutdown Maintenance and care

- Accessories

- Troubleshooting

- Technical specifications

- EC Declaration of Conformity

- Table des matières

- Fonction Utilisation conforme

- Eléments de commande et de fonction

- Utilisation

- Avant la mise en service

- Remisage Entretien et maintenance

- Accessoires

- Assistance en cas de panne

- Caractéristiques techniques

- Déclaration de conformité CE

- Indice

- Funzione Uso conforme a destinazione

- Elementi di comando e di funzione

- Uso

- Prima della messa in funzione

- Fermo dell'impianto Cura e manutenzione

- Accessori

- Guida alla risoluzione dei guasti

- Dati tecnici

- Dichiarazione di conformità CE

- Inhoudsopgave

- Functie Reglementair gebruik

- Elementen voor de bediening en de functies

- Bediening

- Voor de inbedrijfstelling

- Stillegging Onderhoud

- Toebehoren

- Hulp bij storingen

- Technische gegevens

- EG-conformiteitsverklaring

- Índice de contenidos

- Función Uso previsto

- Elementos de operación y funcionamiento

- Manejo

- Antes de la puesta en marcha

- Parada

- Cuidados y mantenimiento

- Accesorios

- Ayuda en caso de avería

- Datos técnicos

- Declaración de conformidad CE

- Índice

- Funcionamento Utilização conforme o fim a que se destina a máquina

- Elementos de comando e de funcionamento

- Manuseamento

- Antes de colocar em funcio- namento

- Desactivação da máquina Conservação e manutenção

- Acessórios

- Ajuda em caso de avarias

- Dados técnicos

- Declaração de conformidade CE

- Indholdsfortegnelse

- Funktion Bestemmelsesmæssig‚ anvendelse

- Betjenings- og funktionselementer

- Betjening

- Inden ibrugtagning

- Afbrydning/nedlæggelse Pleje og vedligeholdelse

- Tilbehør

- Hjælp ved fejl

- Tekniske data

- EU-overensstemmelseser- klæring

- Innholdsfortegnelse

- Funksjon Forskriftsmessig bruk

- Betjenings- og funksjonelementer

- Betjening

- Før den tas i bruk

- Sette bort Pleie og vedlikehold

- Tilbehør

- Feilretting

- Tekniske data

- EU-samsvarserklæring

- Innehållsförteckning

- Funktion Ändamålsenlig användning

- Manövrerings- och funktionselement

- Handhavande

- Före ibruktagande

- Nedstängning Skötsel och underhåll

- Tillbehör

- Åtgärder vid störningar

- Tekniska data

- Försäkran om EU-överens- stämmelse

- Sisällysluettelo

- Toiminta Käyttötarkoitus

- Ohjaus- ja käyttölaitteet

- Käyttö

- Ennen käyttöönottoa

- Seisonta-aika Hoito ja huolto

- Tarvikkeet

- Häiriöapu

- Tekniset tiedot

- EU-standardinmukaisuusto- distus

- Πίνακας περιεχομένων

- Λειτουργία Χρήση σύμφωνα με τους κα - νονισμούς

- Στοιχεία χειρισμού και λειτουργίας

- Χειρισμός

- Πριν τη θέση σε λειτουργία

- Διακοπή της λειτουργίας Φροντίδα και συντήρηση

- Εξαρτήματα

- Αντιμετώπιση βλαβών

- Τεχνικά χαρακτηριστικά

- Δήλωση Συμμόρφωσης των Ε . Κ .

- İ çindekiler

- Fonksiyon Kurallara uygun kullan ı m

- Kullan ı m ve çal ı ş ma elemanlar ı

- Kullan ı m ı

- Cihaz ı çal ı ş t ı rmaya ba ş lama- dan önce

- Durdurma Koruma ve Bak ı m

- Aksesuar

- Ar ı zalarda yard ı m

- Teknik Bilgiler

- AB uygunluk bildirisi

- Оглавление

- Назначение Использование по назначе - нию

- Описание элементов управления и рабочих узлов

- Управление

- Перед началом работы

- Эксплуатация

- Вывод из эксплуатации Уход и техническое обслу - живание

- Принадлежности

- Помощь в случае неполадок

- Технические данные

- Заявление о соответствии ЕС

- Spis tre ś ci

- Funkcja U ż ytkowanie zgodne z prze- znaczeniem

- Elementy urz ą dzenia

- Obs ł uga

- Przed pierwszym uruchomie- niem

- Wy łą czenie z eksploatacji

- Czyszczenie i konserwacja

- Akcesoria

- Usuwanie usterek

- Dane techniczne

- Deklaracja zgodno ś ci UE