Karcher BD 80/120 W Bp: Faults

Faults: Karcher BD 80/120 W Bp

-

7

1 Sieve with floater ball

2 Pipe

Î

Clean the sieve from the outside and

rinse it.

Î

Check the mobility of the floater ball.

If it is too dirty:

Î

Hold the pipe firmly and pull out the

sieve from the pipe.

Î

Clean sieve and ball.

Î

Hold the pipe firmly and reinsert the

sieve.

Î

Lift the cleaning head.

Î

Turn key to "0" and remove it.

Î

Open the lock of spray-guard.

Î

Move both the spray-guard halves to-

wards the sides.

Î

Turn the unlocking lever of the sliding

brush in an anti-clockwise direction -

the brushes will fall downward and can

be pulled outward at the bottom of the

device.

Î

Hold the new brush under the cleaning

head.

Î

Turn the unlocking lever of the sliding

brush in clockwise direction and press

the brush upward.

Î

Release the unlocking lever and check

that the brush is sitting properly.

Î

Repeat process on the opposite side.

Î

Replace the spray-guard.

Î

Lubricate the greasing nipple with a

grease press.

Danger

Risk of injury! Before carrying out any tasks

on the machine, set the main key to "0" and

remove it. Pull out the battery plug.

Î

Drain and dispose of the dirt water and

the residual fresh water.

In case of faults that cannot be remedied

using the table below please contact the

customer service.

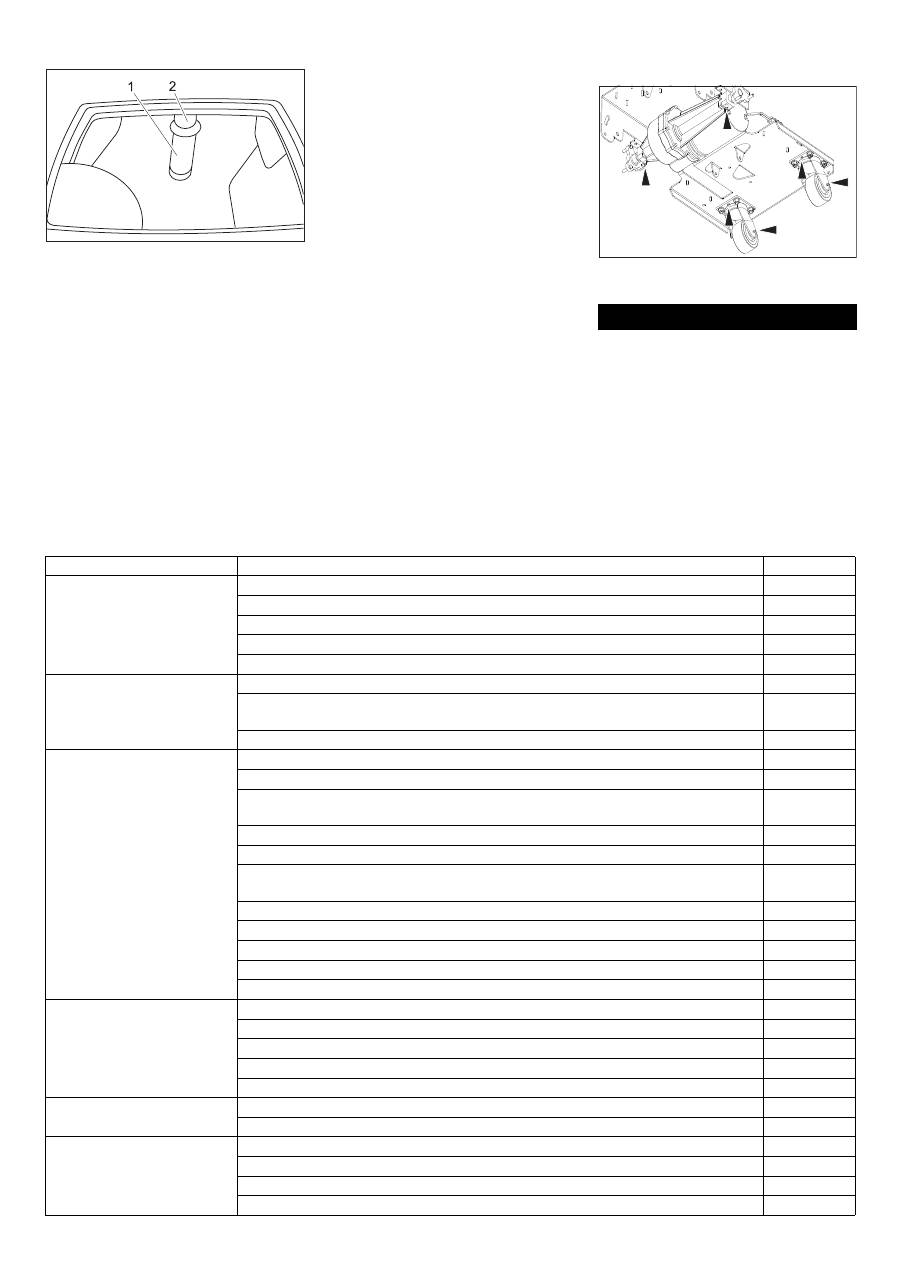

Cleaning the floater

Replacing the Disk Brushes

Lubricating the drive axle and the steer-

ing rollers

Faults

Fault

Remedy

By whom

Appliance cannot be started

Insert the battery plug on the device.

Operator

Release emergency-stop button by turning.

Operator

If battery is low, charge the battery.

Operator

Check battery cable for correct sitting.

Operator

Check battery cable for corrosion; clean, if required.

Operator

Device does not drive or drives

only slowly

Reset fuse of traction drive

Operator

Drive wheels are not gripping due to high brush contact pressure; reduce the brush con-

tact pressure.

Operator

Control system overheated; switch off device and let it cool down.

Operator

Insufficient vacuum perform-

ance

Empty the dirt water reservoir.

Operator

Check the setting of the vacuum bar.

Operator

Clean the seals between dirt water reservoir and cover and check for tightness, replace

if required.

Operator

Clean the vacuum lips on the vacuum bar, turn or replace if required

Operator

Check suction hose for blockages; clean if required.

Operator

Check connection between suction hose and vacuum bar and suction hose and the de-

vice.

Operator

Check the suction hose for tightness; replace if required.

Operator

Check if the cover on the dirt water discharge hose is closed

Operator

Check the setting of the vacuum bar.

Operator

Clean the floater in the dirt water tank.

Operator

Reset fuse of suction turbine.

Operator

Insufficient cleaning result

Set/ adjust contact pressure.

Operator

Check the brushes for wear, replace if required.

Operator

Check brushes for wear and tear, clean.

Operator

Check whether the detergent and brushes are suitable for the cleaning task.

Operator

If battery is low, charge the battery.

Operator

Brushes do not turn

Reset fuse of brush drive.

Operator

Check the brushes for blockage due to foreign particles, remove them if found.

Operator

No or very little detergent solu-

tion gets added

Check level of detergent solution in the fresh water tank; refill, if required.

Operator

Increase detergent dosing.

Operator

Ventilation opening in the lid of the fresh water tank is blocked; clean the opening.

Operator

Check fresh water filter; clean if required.

Operator

18 EN

Оглавление

- Inhaltsverzeichnis

- Bedien- und Funktionselemente

- Vor Inbetriebnahme

- Betrieb

- Anhalten und abstellen

- Störungen

- Zubehör

- CE-Erklärung

- Contents

- Operating and Functional Elements

- Before Commissioning

- Operation

- Shutting Down the Appliance

- Faults

- Accessories

- CE declaration

- Table des matières

- Eléments de commande

- Avant la mise en service

- Fonctionnement

- Arrêt et mise hors marche de l'appareil

- Protection antigel Transport Entreposage Entretien et maintenance

- Pannes

- Accessoires

- Données techniques

- Indice

- Elementi di comando e di funzione

- Prima della messa in funzione

- Funzionamento

- Arresto e spegnimento

- Trasporto Supporto Cura e manutenzione

- Guasti

- Accessori

- Dati tecnici

- Inhoudsopgave

- Bediening- en werkingsonderdelen

- Voor ingebruikneming

- Gebruik

- Stoppen en stilleggen

- Storingen

- Accessoires

- CE-verklaring

- Índice de contenidos

- Elementos de operación y funcionamiento

- Antes de la puesta en marcha

- Funcionamiento

- Detención y apagado

- Almacenamiento Conservación y mantenimiento

- Averías

- Accesorios

- Datos técnicos

- Índice

- Elementos de comando e de funcionamento

- Antes de colocar em funcio- namento

- Funcionamento

- Parar e desligar

- Transporte Armazenamento Conservação e manutenção

- Avarias

- Acessórios

- Dados técnicos

- Indholdsfortegnelse

- Betjenings- og funktionselementer

- Inden idrifttagning

- Drift

- Standse og stille til siden

- Fejl

- Tekniske data

- Innholdsfortegnelse

- Betjenings- og funksjonsorganer

- Før igangsetting

- Drift

- Stansing og parkering

- Funksjonsfeil

- Tilbehør

- Innehållsförteckning

- Manövrerings- och funktionselement

- Före idrifttagandet

- Drift

- Stoppa och parkera

- Störningar

- Tekniska data

- Sisällysluettelo

- Ohjaus- ja toimintaelementit

- Ennen käyttöönottoa

- Käyttö

- Pysähdys ja pysäköinti

- Häiriöt

- Tekniset tiedot

- Πίνακας περιεχομένων

- Στοιχεία χειρισμού και λειτουργίας

- Πριν την ενεργοποίηση

- Λειτουργία

- Αντιπαγετική προστασία Μεταφορά Αποθήκευση Φροντίδα και συντήρηση

- Βλάβες

- Εξαρτήματα

- Τεχνικά χαρακτηριστικά

- İ çindekiler

- Kullan ı m ve çal ı ş ma elemanlar ı

- Cihaz ı çal ı ş t ı rmaya ba ş lamadan önce

- Çal ı ş t ı rma

- Durma ve durdurma

- Ar ı zalar

- Aksesuar

- CE Beyan ı

- Оглавление

- Описание элементов управления и рабочих узлов

- Перед началом работы

- Эксплуатация прибора

- Защита от замерзания Транспортировка Хранение Уход и техническое обслуживание

- Неполадки

- Технические данные

- Заявление о соответствии требованиям СЕ

- Tartalomjegyzék

- Kezelési- és funkciós elemek

- Üzembevétel el ő tt

- Üzem

- Megállás és leállítás

- Ápolás és karbantartás

- Üzemzavarok

- Tartozékok

- CE-Nyilatkozat

- Obsah

- Ovládací a funk č ní prvky

- Pokyny p ř ed uvedením p ř ístroje do provozu

- Provoz

- Zastavení a vypnutí p ř ístroje

- Poruchy

- P ř íslušenství

- ES prohlášení o shod ě

- Vsebinsko kazalo

- Upravljalni in funkcijski elementi

- Pred zagonom

- Obratovanje

- Zaustavljanje in odlaganje

- Motnje

- Tehni č ni podatki

- Spis tre ś ci

- Elementy obs ł ugi urz ą dzenia

- Przed uruchomieniem

- Dzia ł anie

- Zatrzymywanie i odstawianie

- Ochrona przeciwmrozowa Transport Przechowywanie Czyszczenie i konserwacja

- Zak ł ócenia

- Akcesoria

- Dane techniczne

- Cuprins

- Elemente de utilizare ş i func ţ ionale

- Înainte de punerea în func ţ iune

- Func ţ ionarea

- Oprirea ş i depozitarea

- Depozitarea Îngrijirea ş i între ţ inerea

- Defec ţ iuni

- Accesorii

- Date tehnice

- Declara ţ ia CE

- Obsah

- Ovládacie a funk č né prvky

- Pred uvedením do prevádzky

- Prevádzka

- Zastavenie a odstavenie

- Poruchy

- Príslušenstvo

- Vyhlásenie CE

- Pregled sadržaja

- Komandni i funkcijski elementi

- Prije prve uporabe

- U radu

- Zaustavljanje i odlaganje

- Smetnje

- Pribor

- CE-izjava

- Pregled sadržaja

- Komandni i funkcioni elementi

- Pre upotrebe

- Rad

- Zaustavljanje i odlaganje

- Smetnje

- Pribor

- CE-izjava

- Съдържание

- Обслужващи и функционални елементи

- Преди пускане в експлоатация

- Експлоатация

- Защита от замръзване T рансп o рт Съхранение Грижи и поддръжка

- Повреди

- Принадлежности

- Технически данни

- Sisukord

- Teenindus- ja funktsioonielemendid

- Enne seadme kasutuselevõttu

- Käitamine

- Peatumine ja seiskamine

- Rikked

- Tehnilised andmed

- Satura r ā d ī t ā js

- Vad ī bas sist ē mas un funkciju elementi

- Pirms ekspluat ā cijas s ā kuma

- Ekspluat ā cija

- Aptur ē šana un izsl ē gšana

- Kopšana un tehnisk ā apkope

- Trauc ē jumi

- Piederumi

- Tehniskie parametri

- Turinys

- Aptarnavimo ir funkciniai elementai

- Prieš pradedant naudoti

- Naudojimas

- Sustojimas ir palikimas stov ė ti

- Technin ė prieži ū ra ir aptarnavimas

- Gedimai

- Priedai

- Techniniai duomenys

- Перелік

- Елементи управління і функціональні вузли

- Перед введенням в експлуатацію

- Експлуатація

- Захист від замерзання Транспортування Зберігання Догляд та технічне обслуговування

- Неполадки

- Аксесуари

- Технічні дані