Karcher HD 9-18-4 ST: Transport Storing the device Maintenance and care

Transport Storing the device Maintenance and care: Karcher HD 9-18-4 ST

-

5

Note:

The appliance is equipped with a pressure

switch. The motor starts up only when the

lever of the pistol is pulled

Open the water supply.

Plug in the mains plug.

(Only with appliance versions with pow-

er cable and mains plug).

Set the appliance switch to "I".

The indicator lamp glows green.

Unlock the trigger gun and pull the lever

of the gun.

Set working pressure and water quanti-

ty by turning (rungless) at the pressure

and quantity regulation (option) (+/-).

Close the hand spray gun.

Turn the casing of the nozzle till the de-

sired symbol matches the marking.

몇

CAUTION

Unsuitable detergents can cause damage

to the appliance and to the object to be

cleaned. Use only those detergents that

have been approved by Kärcher. Observe

the dosage and other instructions provided

with these detergents. For considerate

treatment of the environment use detergent

economically.

Follow the safety instructions for using de-

tergents.

Kärcher detergents ensure smooth func-

tioning. Please consult us or ask for our cat-

alogue or our detergent information sheets.

Place the detergent can under the de-

vice.

Hang in the detergent hose into the de-

tergent can.

Set nozzle to "CHEM".

Set dosing value for detergent to the

desired concentration.

Spray the detergent sparingly on the

dry surface and allow it to react, but not

to dry.

Spray off loosened dirt with the high-

pressure ray.

After operations, dip the filter in clear

water. Turn the dosing valve to the

highest detergent concentration. Start

the appliance and rinse for one minute.

Release the lever of the trigger gun; the

device will switch off.

Release again the lever of the trigger

gun; the device will switch on again.

The operational readiness period starts

when the hand-spray gun is closed. The

device can no longer be started by tighten-

ing the lever of the hand-spray gun if this

operational readiness period (5 to 0.120

minutes) expires.

The indicator lamp blinks green.

To restart, turn the device switch briefly

to "0" and then again to "I".

Note:

Customer service can set the operational

readiness period.

Set the appliance switch to "0".

Wait for a while.

Set the appliance switch to "I".

or

Use the respective button on the re-

mote control (option).

Set the appliance switch to "0".

Disconnect the mains plug from the

socket.

(Only with appliance versions with pow-

er cable and mains plug).

Shut off water supply.

Activate trigger gun until device is pres-

sure-less.

Press the safety lever of the trigger gun

to secure the lever of the pistol against

being released accidentally.

ATTENTION

Frost will destroy the not completely water

drained device.

The machine should be stored in frost-free

rooms. In case there is frosting risk, for e.g.

if the machine is installed in open areas,

then the machine must first be emptied and

flushed using an anti-freezing agent.

Remove the water inlet hose on the ap-

pliance.

Unscrew the high pressure hose from

the appliance.

Let the appliance run till the pump and

pipes are empty (max. 1 minute).

In case of longer operational breaks:

Fill in normal anti-frost agents in the

swimmer tank right until the top.

Place the collection trough unter the

high pressure exit.

Turn on the equipment and let it run un-

til the equipment is completely rinsed.

Turn the emergency-stop switch to "0".

Shut off water supply.

Activate trigger gun until device is pres-

sure-less.

Unscrew the fastening screw of the ap-

pliance cover.

Slightly lift up the appliance cover and

remove it toward the front.

몇

CAUTION

Risk of injury and damage! Observe the

weight of the appliance when you transport

it.

When transporting in vehicles, secure

the appliance according to the guide-

lines from slipping and tipping over.

몇

CAUTION

Risk of injury and damage! Note the weight

of the appliance in case of storage.

DANGER

Risk of injury! Switch off the power switch

with all maintenance and repair work.

Pull the mains plug and secure it against

being plugged in again

DANGER

Risk of injury on account of the emanating

water jet that could be hot!

During all tasks:

–

Close locking tap of fresh water.

–

Let the hot parts of the plant cool down.

–

Depressurise the plant by opening all

hand-spray guns.

The bases of a safe operating of the equip-

ment is thr regularly maintenance accord-

ing to the following maintenance plan.

Use exclusively original parts of the manu-

facturer or those parts recommended by

him like

– replacement and wear parts

– Accessory parts

– Fuel

– Detergent

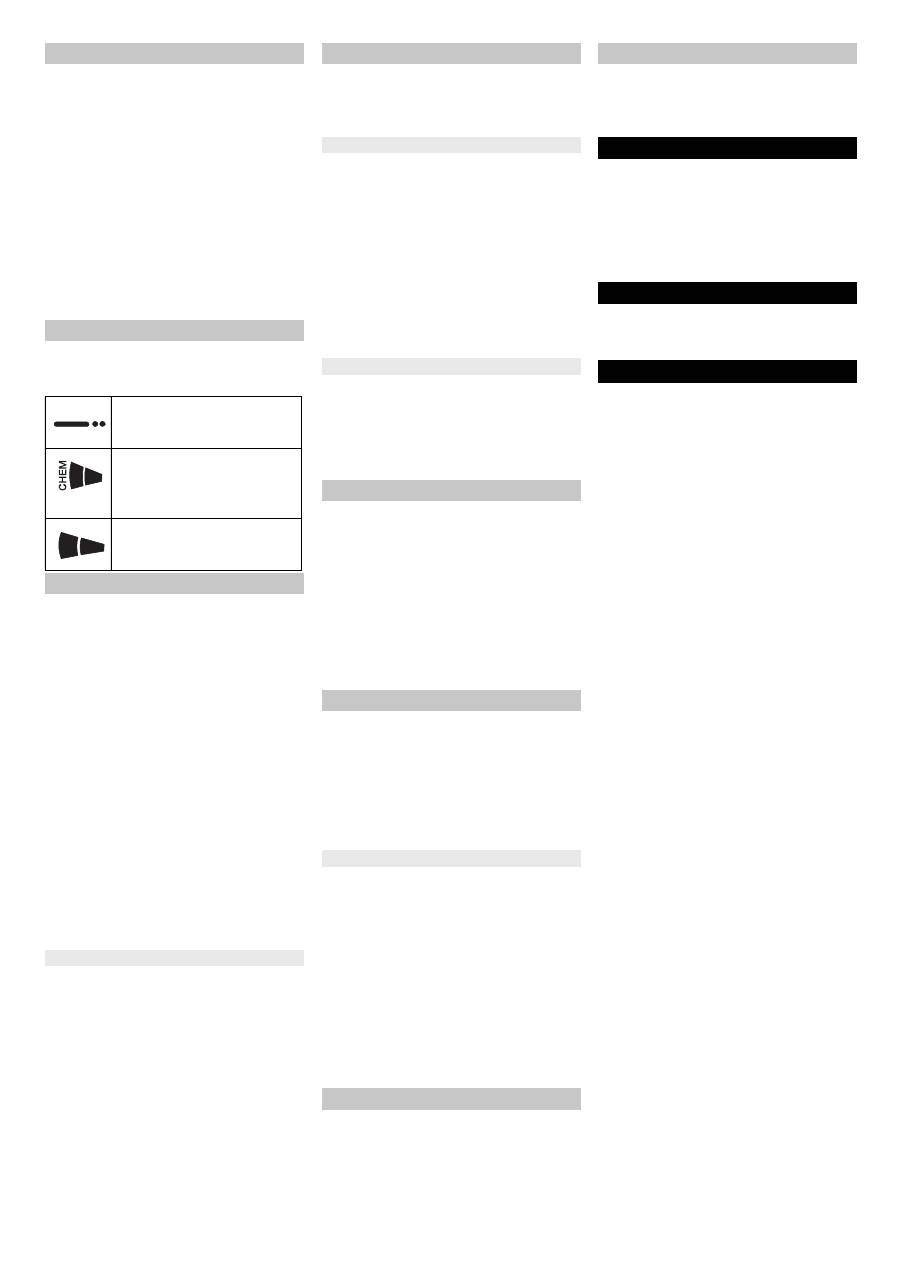

High pressure operation

Select spray type

High pressure circular spray

(0°) for specially stubborn dirt

Flat low pressure spray

(CHEM) for operating using de-

tergents or cleaning at low

pressure.

High pressure flat spray (25°)

for large dirt areas

Operation with detergent

Recommended cleaning method

Interrupting operation

Operational readiness period

Restart the operation readiness time

Turn off the appliance

Frost protection

Emptying the appliance

Switch-off in case of emergency

Remove the appliance cover

Transport Storing the device Maintenance and care

22

EN

-

6

You can sign with your dealer a contract for

regular safety inspection or even sign a

maintenance contract. Please take advice

on this matter.

Safety inspection/ maintenance

contract

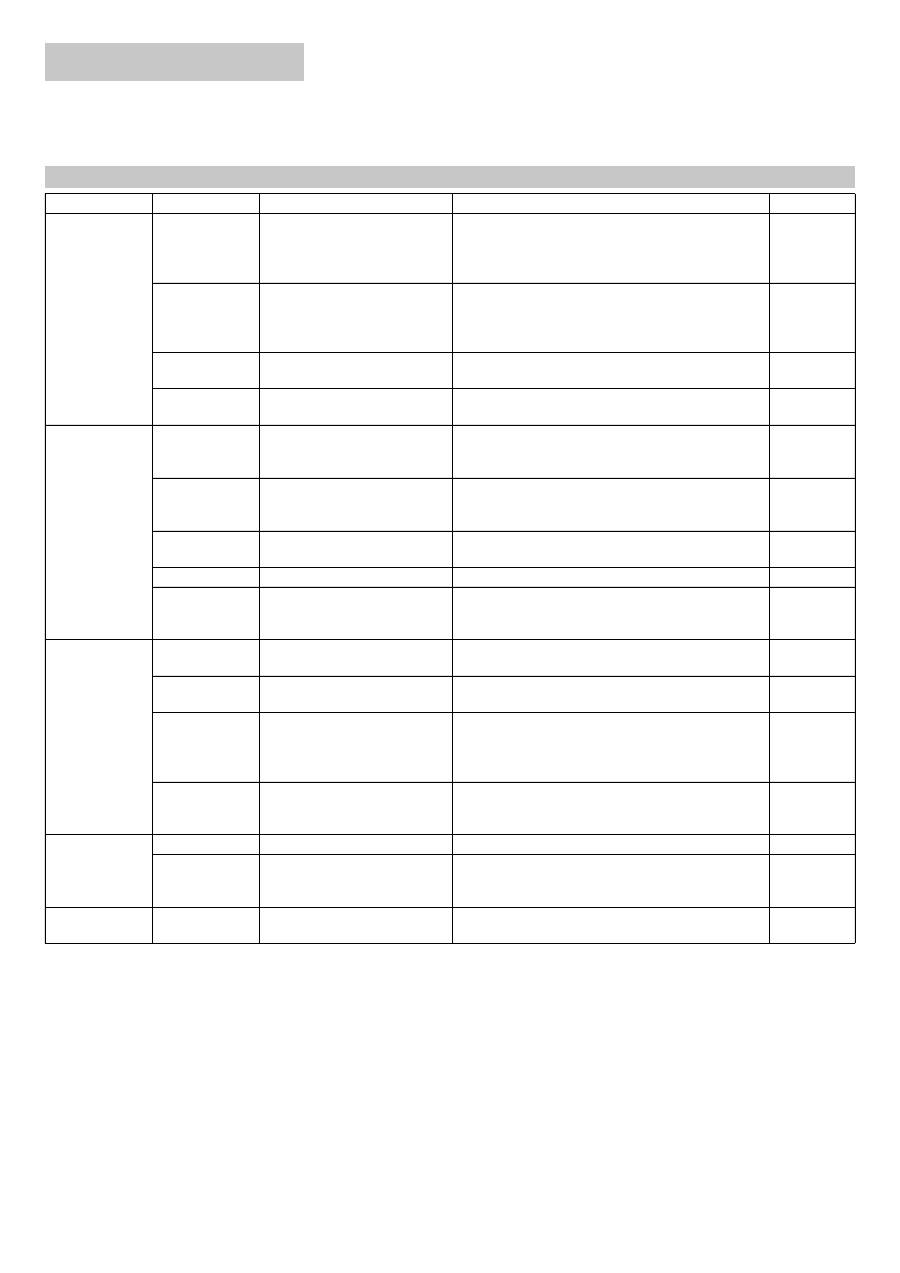

Maintenance schedule

Time

Activity

Assembly affected

Performance

of whom

daily

Check hand-

spray gun

Hand spray gun

Check whether the hand-spray gun closes tightly

without any leaks. Check the protection mechanism

against accidental switching. Replace defective

hand-spray guns.

Operator

opinion

Power cord

(Only with appliance versions

with power cable and mains

plug).

Check the mains cable regularly for damage such as

aging or formation of cracks. If you find a damage,

then the cable must be replaced before using it any

further.

Operator/

Customer

Service

Test fill level

Detergent tank, Installation wa-

ter softener (optional)

Check filling level, refill if necessary.

Operator

Check high pres-

sure hoses

Outlets, hoses towards working

machine

Check hoses to see if there are damages. Replace

defect hoses immediately. Danger of accident!

Operator

weekly or after

40 operating

hours

Check the unit for

leaks

Entire plant

Check pumps and pipes for leaks. Inform Customer

Service if there is oil loss or if there is a leakage of

more than 10 drops of water per minute.

Operator/

Customer

Service

Check oil level

Oil tank at the pump

If the oil is milky, it needs to be replaced. It is recom-

mended likewise in this case that the pump's oil seal

be changed (Customer Service).

Operator/

Customer

Service

Check oil level

Oil tank at the pump

Check oil level of the pump. Refill oil if required (Or-

der no. 6.288-016)

Operator

Clean filter

Filter at the detergent suck hose Clean filter at the detergent suck hose.

Operator

Test vibration

dampener

Vibration dampener

If the vibration of the pump increases it indicates that

the pressure tank is defective. Replace the vibration

dampener.

Customer

Service

monthly or after

200 operating

hours

Cleaning the

sieve

Sieve in water inlet

Check, dismantle sieve and clean it.

Operator

Test swimmer

valve

Float tank

When the swimmer valve is closed no water can es-

cape the overflow.

Operator

Test automatic

start

Pressure switch

Pump is at a standstill, because no water removal

has taken place. Turn on the hand spray gun. If the

pressure in the high pressure network falls below 3

MPa, the pump must be turned on.

Operator

Tighten hose

clips

All hose clips

Tighten the hose clips using a torque wrench. Tight-

ening torque up to a diameter of 28 mm = 2Nm, from

29 mm = 6 Nm.

Operator

annually or after

1000 operating

hours

Oil change

High-pressure pump

Drain off oil. Refill oil. Check oil level in the oil tank. Operator

Check unit for

calcium deposits.

entire water system

Improper functioning of valves or pumps can be an

indication of calcium deposits. If necessary decalcify.

Operator

trained in de-

calcification

annual

Safety check

Entire plant

Safety check according to the guidelines for fluid

spraying equipment.

Technical ex-

pert

23

EN

Оглавление

- Inhaltsverzeichnis

- Bestimmungsgemäße Verwendung

- Funktion

- Geräteelemente

- Transport Lagerung des Gerätes Pflege und Wartung

- Hilfe bei Störungen

- Technische Daten

- Zubehör

- Anlageninstallation

- EG-Konformitätserklärung

- Kundendienst

- Contents

- Proper use

- Function

- Device elements

- Transport Storing the device Maintenance and care

- Troubleshooting

- Technical specifications

- Accessories

- Installing the plant

- EC Declaration of Conformity

- Customer Service

- Πίνακας περιεχομένων

- Χρήση σύμφωνα με τους κανονισμούς

- Λειτουργία

- Στοιχεία συσκευής

- Μεταφορά Αποθήκευση της συσκευής Φροντίδα και συντήρηση

- Αντιμετώπιση βλαβών

- Τεχνικά χαρακτηριστικά

- Εξαρτήματα

- Εγκατάσταση μονάδας

- Δήλωση Συμμόρφωσης των Ε . Κ .

- Υπηρεσία εξυπηρέτησης πελατών

- İ çindekiler

- Kurallara uygun kullan ı m

- Fonksiyon

- Cihaz elemanlar ı

- Ta ş ı ma Cihaz ı n depolanmas ı Koruma ve Bak ı m

- Ar ı zalarda yard ı m

- Teknik Bilgiler

- Aksesuar

- Sistem tesisat ı

- AB uygunluk bildirisi

- Mü ş teri hizmeti

- Оглавление

- Использование по назначению

- Назначение

- Элементы прибора

- Транспортировка Хранение прибора

- Уход и техническое обслуживание

- Помощь в случае неполадок

- Технические данные

- Принадлежности

- Инсталляция оборудования

- Заявление о соответствии ЕС

- Сервисная служба

- Spis tre ś ci

- U ż ytkowanie zgodne z przeznaczeniem

- Funkcja

- Elementy urz ą dzenia

- Transport Przechowywanie urz ą dzenia Czyszczenie i konserwacja

- Usuwanie usterek

- Dane techniczne

- Akcesoria

- Instalacja urz ą dzenia

- Deklaracja zgodno ś ci UE

- Serwis firmy

- Sisukord

- Sihipärane kasutamine

- Funktsioon

- Seadme elemendid

- Transport Seadme ladustamine Korrashoid ja tehnohooldus

- Abi häirete korral

- Tehnilised andmed

- Tarvikud

- Seadme installeerimine

- EÜ vastavusdeklaratsioon

- Klienditeenindus

- Satura r ā d ī t ā js

- Noteikumiem atbilstoša lietošana

- Darb ī ba

- Apar ā ta elementi

- Transport ē šana Apar ā ta uzglab ā šana Kopšana un tehnisk ā apkope

- Pal ī dz ī ba darb ī bas trauc ē jumu gad ī jum ā

- Tehniskie dati

- Piederumi

- Iek ā rtas instal ā cija

- EK Atbilst ī bas deklar ā cija

- Klientu apkalpošanas dienests

- Turinys

- Naudojimas pagal paskirt į

- Veikimas

- Prietaiso dalys

- Transportavimas Į renginio laikymas Prieži ū ra ir aptarnavimas

- Pagalba gedim ų atveju

- Techniniai duomenys

- Dalys

- Prietaiso į rengimas

- EB atitikties deklaracija

- Klient ų aptarnavimo tarnyba

- Зміст

- Правильне застосування

- Призначення

- Елементи приладу

- Транспортування Зберігання пристрою Догляд та технічне обслуговування

- Допомога у випадку неполадок

- Технічні характеристики

- Аксесуари

- Монтаж обладнання

- Заява при відповідність Європейського співтовариства

- Служба підтримки користувачів