Karcher Autolaveuse B 90 R Confort Bp Pack: Operation

Operation: Karcher Autolaveuse B 90 R Confort Bp Pack

-

3

Place the boards on the edge of the pal-

let. Place the boards in such a way that

they lie in front of the four wheels of the

machine. Fasten the boards with

screws.

Slide the four support beams included

in the packaging under the ramp.

Remove the wooden bars in front of the

wheels.

Figure 5, see cover page

Pull the brake lever and push the appli-

ance down the ramp with the level

pulled.

or

Release emergency-stop button by

turning.

Set main switch to "1".

Press the drive direction switch and

slowly move the machine down from

the ramp.

Set main switch back to "0".

The procedure for changing the cleaning

head is described in the chapter "Mainte-

nance Tasks".

Note

On some models, the cleaning head is al-

ready installed.

The installation of the brushes is described

in the chapter "Maintenance Tasks".

Figure 6, see cover page

Insert the vacuum bar into the vacuum

bar suspension in such a manner that

the profiled sheet is positioned above

the suspension.

Tighten the wing nuts.

Insert the suction hose.

Danger

Risk of injuries. Never use the unit without

protective roof in areas where the opera-

tors can be hit by dropping objects.

Note

Press emergency-stop switch to immedi-

ately switch off all functions of the machine.

Danger

Danger of accident. The immobilizing brake

must always be checked first on an even

surface before starting the machine.

Take the seating position.

Release emergency-stop button by

turning.

Set main switch to “1”.

Select a direction of travel.

Gently depress drive pedal.

The brake must get released and you

must be able to hear it (the control lamp

for immobilizing brake on the console

switches off). The machine must roll

slightly on a plane surface. When the

pedal is released, the brake falls in in an

audible manner. Switch off the ma-

chine and call the aftersales service if

the above-mentioned events do not oc-

cur.

Danger

Danger of accident. If the machine does not

brake, then proceed as follows:

If the device does not come to a halt on

a ramp with a gradient of 2% when you

release the drive pedal, then the emer-

gency-stop button may be pressed for

safety reasons only if the mechanical

functioning of the immobilizing brake

has been checked properly before com-

missioning the device.

Switch off the machine only after it

comes to a complete halt (on an even

surface) and call up the aftersales serv-

ice!

Further, follow all warning instructions

for braking.

Danger

Danger of tipping if gradient is too high.

The gradient in the direction of travel

should not exceed 10%.

Danger of tipping when driving round

bends at high speed.

Danger of slipping on wet floors.

Drive slowly when cornering.

Danger of tipping on unstable ground.

Only use the machine on sound surfac-

es.

Danger of tipping with excessive sideways

tilt.

The gradient perpendicular to the direc-

tion of travel should not exceed 10%.

Release emergency-stop button by

turning.

Sit on the seat and set main switch to

"1".

Set the drive direction using the drive

direction button at the operator console.

Determine the driving speed by press-

ing the drive pedal.

Stop the machine: Release the drive

pedal.

Note

The drive direction can also be changed

during the drive. Thus, very blunt edges

can be polished by moving forward and

backward a few times.

When switching on the display, the follow-

ing messages will appear in sequence:

–

„ < SELFTEST >“: The control conducts

a self-test.

–

„Water E-----F“ (model Adv): Water lev-

el in the fresh water tank (lasts for 6

seconds).

„OpHrs xxxxxhxxm+“ (Classic model):

Operating hours (lasts for 6 seconds)

–

"Battery: E-----F“: Charging status of

battery.

In case of overloading, the drive motor au-

tomatically switches off after a certain peri-

od. A fault message is displayed on the

console. The concerned unit gets switched

off if the controls get overheated.

Allow machine to cool down at least for

15 minutes.

Turn the main switch to "0" and turn it

back to "1".

몇

Warning

Risk of damage. Only use the recommend-

ed detergents. With respect to different de-

tergents the operator bears the increased

risk regarding the operational safety and

danger of accident.

Only use detergents that are free from sol-

vents, hydrochloric acid and hydrofluoric

acid.

Follow the safety instructions for using de-

tergents.

Note

Do not use highly foaming detergents.

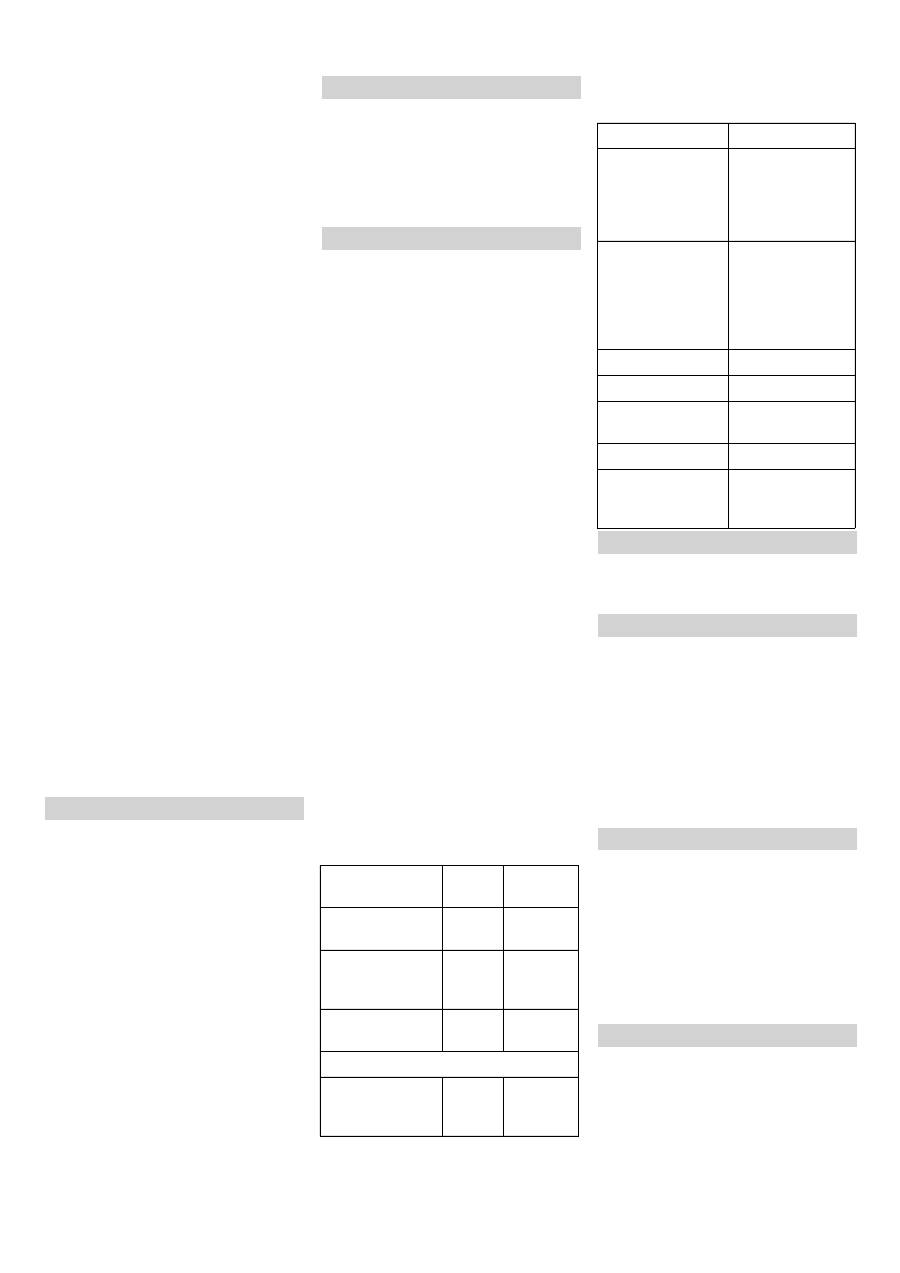

Recommended detergents:

Open the cover of the fresh water reser-

voir.

Fill fresh water (max. 60 °C) until 15 mm

below the upper edge of the tank.

Pour in detergent.

Note

If detergent is added to the cleaning deter-

gent tank first, followed by water, there

could be a lot of foam.

Close the cover of the fresh water res-

ervoir.

Note

Fill up the fresh water tank completely be-

fore starting up the machine to ventilate the

water supply system.

Install cleaning head

Installing the Brushes

Installing the Vacuum Bar

Operation

Check immobilizing brake

Driving

Driving

Display

Overload

Filling in detergents

Detergent

Application

Detergent

Routine cleaning of all wa-

ter resistant floors

RM 746

RM 780

Routine cleaning of glossy

surfaces (e.g. granite)

RM 755 es

Routine cleaning and ba-

sic cleaning of industrial

floors

RM 69 ASF

Routine cleaning and ba-

sic cleaning of fine stone-

ware tiles

RM 753

Routine cleaning of tiles in

sanitary areas

RM 751

Cleaning and disinfection

in sanitary areas

RM 732

Removal of coating from

all alkali-resistant floors

(e.g. PVC)

RM 752

Removal of coating from li-

noleum floors

RM 754

Fresh water

17 EN

-

4

Connect the water hose to the connec-

tion neck on the filling system.

Open the water supply.

Once the maximum fill level is reached,

the built-in floater valve will stop the wa-

ter inflow.

Shut off water supply.

Remove the water hose.

Detergent is added to the fresh water on

the way to the cleaning head with the help

of a dosaging device.

Place the detergent bottle into the de-

vice.

Close the bottle lid.

Insert the suction hose of the dosaging

equipment into the bottle.

Note

The metering device can be used to add

3% of detergent at maximum. In case of a

higher dose the detergent must be poured

into the fresh water tank.

Caution

Danger of plug-up by dried detergent when

the detergent is added to a fresh water tank

made by Dose. The flow meter of the dos-

ing equipment can stick on account of dry-

ing detergent and hamper the functioning

of the dosing equipment. Always rinse at

the end the fresh water tank and the appli-

ance with clear water. To rinse, open the

regulating knob fully, set the detergent me-

tering setting to 0% and set the cleaning

program with water at the programme se-

lection switch.

Note

The appliance is equipped with a fresh wa-

ter level display. If the fresh water tank is

empty, then the function of adding deter-

gent gets deactivated. The cleaning head

continues to work without the addition of

any liquid.

Figure 7, see cover page

1

Driving

Driving to the Place of Use.

2 Scrubbing suction

Wet clean the floor and vacuum up dirt

water.

3 Wet scrubbing

Wet clean the floor and allow the deter-

gent to react.

4 Vacuuming

Suck in the dirt fleet.

5 Polishing

Polishing the floor without the applica-

tion of liquid.

6 Scrub the floor without applying water

(vacuum polishing)

Polish the floor without applying any flu-

id and suck in the polishing dust.

Note

Depending on the programme, the vacuum

bar and the cleaning head must be lowered

using the respective controls in order to ex-

ecute the selected programme.

Use the Info button to select the menu

items and do the settings.

–

Turning the button to the right/left

scrolls through the menus forward/

backward.

–

The selected setting gets accepted by

pressing the button.

You can make the settings for the different

cleaning programs in the operator menu.

Different parameters can be set based on

the cleaning program. The settings are

done using the Info button.

Release emergency-stop button by

turning.

Sit on the seat and set main switch to

"1".

The display shows the battery charging

status and the fresh water level.

Select cleaning program.

Call the operator menu by turning the

info button.

Select the desired parameter by turning

the Info button.

Press Info button - the set value blinks.

Reset the parameter by turning the info

button.

Accept modified setting by pressing the

Info button or wait till the set value is ac-

cepted automatically.

Note

If the selected parameter does not change

within 10 seconds, then the display goes

back to displaying the battery charging sta-

tus and the fresh water level.

The same cleaning parameter can have in-

dividual settings for each cleaning pro-

gram.

All settings are saved even in the power-

less state of the machine.

Turn the info button until "Information-

menu" is displayed.

Retrieve the info menu by pressing the

info button.

The following information can be displayed

by turning the info button:

Set the water quantity at the regulation

knob according to the dirt level and the

type of flooring.

Press down the rear surface of the ped-

al to raise/lower the cleaning head, re-

lease and let the pedal move upwards.

The brush drive will start as soon as the

cleaning head is lowered.

Press down the front surface of the ped-

al to raise/lower the cleaning head and

lock it.

Pull the lever up to raise/lower the vac-

uum bar, press toward the outside and

lower.

The suction process will start as soon

as the level is moved down.

Pull the lever to raise and lower the vac-

uum bar up and lock.

To improve the vacuuming result on tiled

floors the vacuum bar can be turned to an

oblique position of up to 5°.

Figure 8, see cover page

Release the wing nuts.

Turn the vacuum bar.

Tighten the wing nuts.

Filling system (optional)

Metering system (only Dose model)

Cleaning Programs

Info button (only Adv. model)

Settings (only Adv. model)

Operator menu

Adjustable parameters

Adjustable pa-

rameters

min:ste

p:max

Remark

Cleanspeed (max.

cleaning speed)

1:1:6

1=1km/h,

6=6km/h

FACT (brush

speed)

–

Power

Whisper

Fine

Vacuum (suction

performance)

–

Low

High

Only with Dose model

Chemical/Agent

(detergent meter-

ing)

0,5%:0,

5%:3%

–

Info menu

Display

Significance

Ophrs xxxxxhxxm+

Operating hour

counter

When the counter

is running, "+" will

be displayed

Water E-----F

Water level in fresh

water tank

"C" blinks while the

metering pump is

operating (only

Dose model)

Speed: xkm/h

Current speed

Alfred/Kärcher

Manufacturer

B90R Dxx

Appliance descrip-

tion

Prog.Vers. x.x

Softwareversion

Exit Inform.menu

Exit the info menu

by pressing the

info button.

Setting the water quantity

Raise/lower the cleaning head

Lower

Raise

Raise/lower the vacuum bar

Lower

Raise

Setting the Vacuum Bar

Oblique position

18 EN

Оглавление

- Deutsch

- Vor Inbetriebnahme

- Betrieb

- Transport

- Hilfe bei Störungen

- Technische Daten

- Zubehör und Ersatzteile Garantie EG-Konformitätserklärung

- English

- Before Startup

- Operation

- Transport

- Troubleshooting

- Technical specifications

- Accessories and Spare Parts Warranty EC Declaration of Conformity

- Français

- Avant la mise en service

- Fonctionnement

- Transport

- Assistance en cas de panne

- Caractéristiques techniques

- Accessoires et pièces de re- change Garantie Déclaration de conformité CE

- Italiano

- Prima della messa in funzio- ne

- Funzionamento

- Trasporto

- Guida alla risoluzione dei guasti

- Dati tecnici

- Accessori e ricambi Garanzia Dichiarazione di conformità CE

- Nederlands

- Voor de inbedrijfstelling

- Werking

- Transport

- Hulp bij storingen

- Technische gegevens

- Toebehoren en reserveonder- delen Garantie EG-conformiteitsverklaring

- Español

- Antes de la puesta en marcha

- Funcionamiento

- Transporte

- Ayuda en caso de avería

- Datos técnicos

- Accesorios y piezas de re- puesto Garantía Declaración de conformidad CE

- Português

- Antes de colocar em funcio- namento

- Funcionamento

- Transporte

- Conservação e manutenção

- Ajuda em caso de avarias

- Dados técnicos

- Acessórios e peças sobres- salentesGarantia Declaração de conformidade CE

- Dansk

- Inden ibrugtagning

- Drift

- Transport

- Hjælp ved fejl

- Tekniske data

- Tilbehør og reservedele Garanti EU-overensstemmelseser- klæring

- Norsk

- Før den tas i bruk

- Drift

- Transport

- Feilretting

- Tekniske data

- Tilbehør og reservedeler Garanti EU-samsvarserklæring

- Svenska

- Före ibruktagande

- Drift

- Transport

- Åtgärder vid störningar

- Tekniska data

- Tillbehör och reservdelar Garanti Försäkran om EU-överens- stämmelse

- Suomi

- Ennen käyttöönottoa

- Käyttö

- Kuljetus

- Häiriöapu

- Tekniset tiedot

- Varusteet ja varaosat Takuu EU-standardinmukaisuusto- distus

- Πίνακας περιεχομένων

- Πριν τη θέση σε λειτουργία

- Λειτουργία

- Μεταφορά

- Αντιμετώπιση βλαβών

- Τεχνικά χαρακτηριστικά

- Εξαρτήματα και ανταλλακτικά Εγγύηση Δήλωση Συμμόρφωσης των Ε . Κ .

- Türkçe

- Cihaz ı çal ı ş t ı rmaya ba ş lama- dan önce

- Çal ı ş t ı rma

- Ta ş ı ma

- Ar ı zalarda yard ı m

- Teknik Bilgiler

- Aksesuarlar ve yedek parça- lar Garanti AB uygunluk bildirisi

- Оглавление

- Перед началом работы

- Эксплуатация

- Транспортировка

- Помощь в случае непола - док

- Технические данные

- Принадлежности и запас - ные детали Гарантия Заявление о соответствии ЕС

- Magyar

- Üzembevétel el ő tt

- Üzem

- Szállítás

- Segítség üzemzavar esetén

- M ű szaki adatok

- Tartozékok és alkatrészek Garancia EK konformitási nyiltakozat

- eština

- P ř ed uvedením do provozu

- Provoz

- P ř eprava

- Pomoc p ř i poruchách

- Technické údaje

- P ř íslušenství a náhradní díly Záruka Prohlášení o shod ě pro ES

- Slovenšina

- Pred zagonom

- Obratovanje

- Transport

- Pomo č pri motnjah

- Tehni č ni podatki

- Pribor in nadomestni deli Garancija ES-izjava o skladnosti

- Polski

- Przed pierwszym uruchomie- niem

- Dzia ł anie

- Transport

- Czyszczenie i konserwacja

- Usuwanie usterek

- Dane techniczne

- Wyposa ż enie dodatkowe i cz ęś ci zamienne Gwarancja Deklaracja zgodno ś ci UE

- Românete

- Înainte de punerea în func ţ iu- ne

- Func ţ ionarea

- Transportul

- Remedierea defec ţ iunilor

- Date tehnice

- Accesorii ş i piese de schimb Garan ţ ie Declara ţ ie de conformitate CE

- Slovenina

- Pred uvedením do prevádzky

- Prevádzka

- Preprava

- Pomoc pri poruchách

- Technické údaje

- Príslušenstvo a náhradné die- ly Záruka Vyhlásenie o zhode s norma- mi EÚ

- Hrvatski

- Prije prve uporabe

- U radu

- Transport

- Otklanjanje smetnji

- Tehni č ki podaci

- Pribor i pri č uvni dijelovi Jamstvo EZ izjava o uskla đ enosti

- Srpski

- Pre upotrebe

- Rad

- Transport

- Otklanjanje smetnji

- Tehni č ki podaci

- Pribor i rezervni delovi Garancija Izjava o uskla đ enosti sa propisima EZ

- Съдържание

- Преди пускане в експлоата - ция

- Експлоатация

- Транспорт

- Помощ при неизправности

- Технически данни

- Принадлежности и резерв - ни части Гаранция Декларация за съответ - ствие на ЕО

- Eesti

- Enne seadme kasutuselevõttu

- Käitamine

- Transport

- Abi häirete korral

- Tehnilised andmed

- Lisavarustus ja varuosad Garantii EÜ vastavusdeklaratsioon

- Latviešu

- Pirms ekspluat ā cijas uzs ā k- šanas

- Darb ī ba

- Apar ā ta p ā rvietošana

- Pal ī dz ī ba darb ī bas trauc ē ju- mu gad ī jum ā

- Tehniskie dati

- Piederumi un rezerves da ļ as Garantija EK Atbilst ī bas deklar ā cija

- Lietuviškai

- Prieš pradedant naudoti

- Naudojimas

- Transportavimas

- Pagalba gedim ų atveju

- Techniniai duomenys

- Priedai ir atsargin ė s dalys Garantija EB atitikties deklaracija

- Зміст

- Перед початком роботи

- Експлуатація

- Транспортування

- Допомога у випадку неполадок

- Технічні характеристики

- Приладдя й запасні деталі Гарантія Заява при відповідність Європейського співтовариства