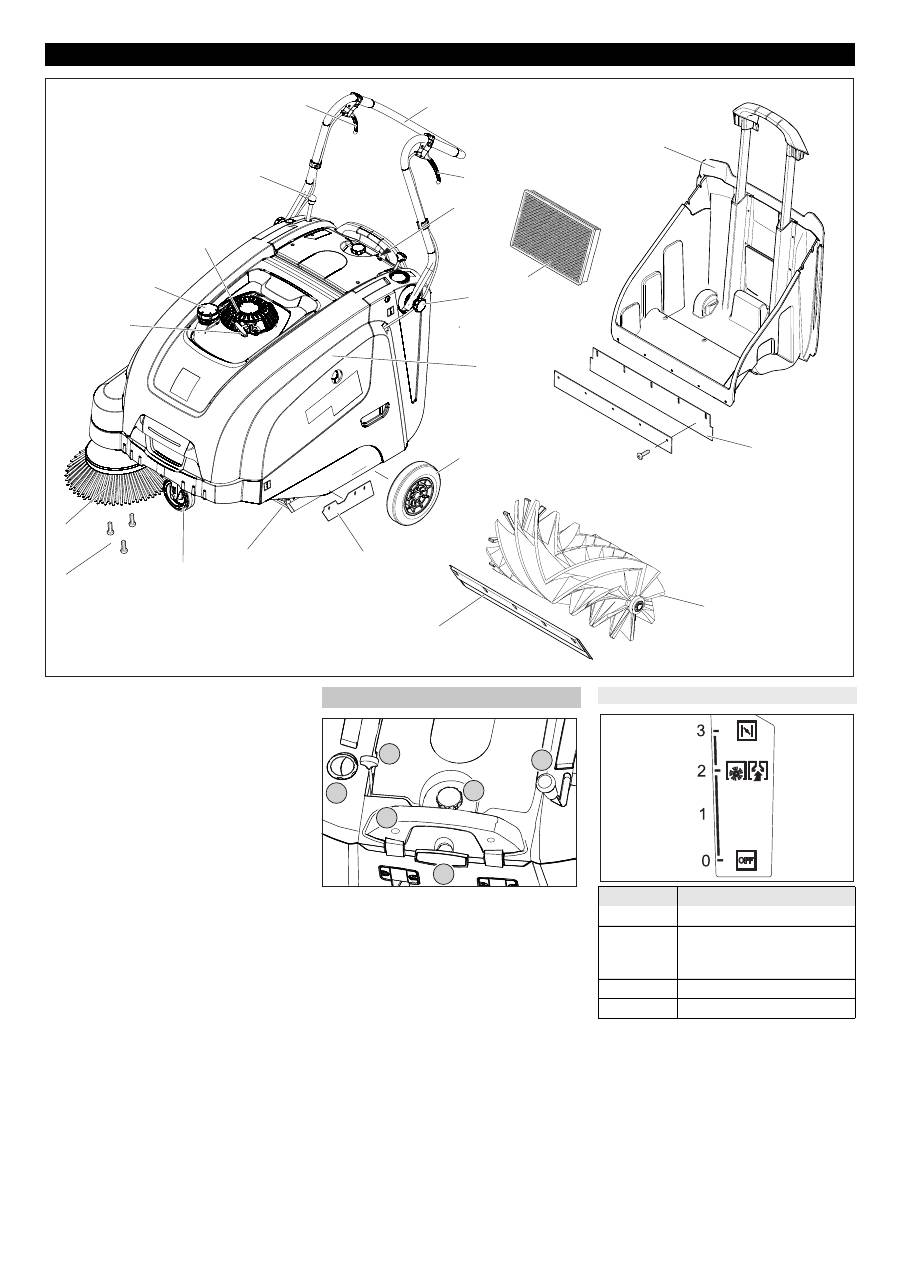

Karcher Balayeuse KM 75-40 W G: 6 5 4 3 2 1

6 5 4 3 2 1: Karcher Balayeuse KM 75-40 W G

-

3

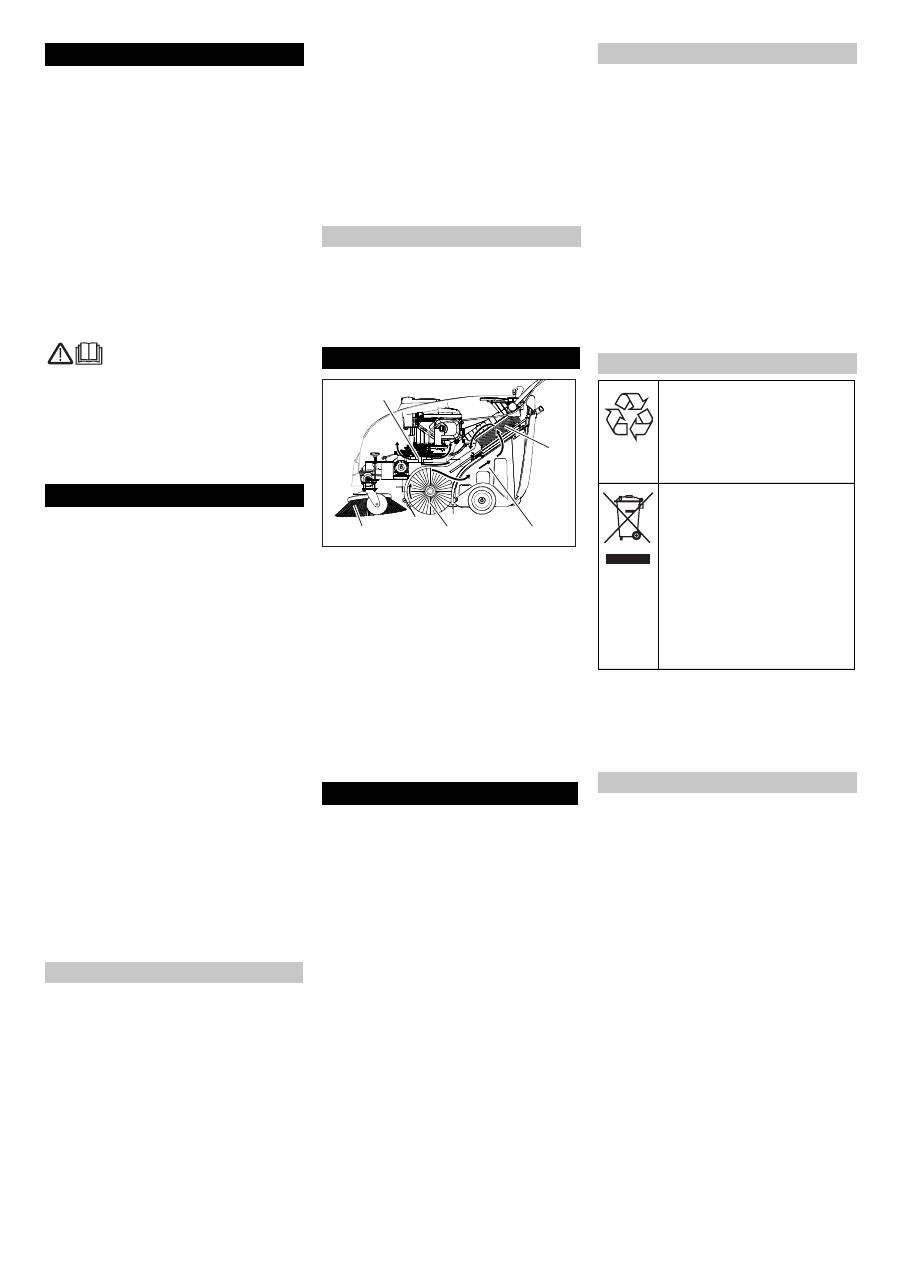

1 Starter rope

2 Tank lid

3 Petrol engine

4 Lever for lowering and raising the side-

brush

5 Lever to raise and lower the bulk waste

flap

6 Push handle

7 Lever for forward drive

8 Operating field

9 Fastening screw for slider

10 Dust filter

11 Waste container

12 Cover

13 Drive wheels

14 Rear sealing strip (at the waste contain-

er)

15 Roller brush

16 Front sealing strip

17 Side sealing strip

18 Bulk waste flap

19 Steering roller with fixed position brake

20 Fastener of the side brush

21 Side brushes

1 Multifunctional lever

2 Lever for lowering and raising the side-

brush

3 Locking screw of the dust filter cover

4 Locking bow of the waste container

5 Filter cleaning for dust filter

6 Wet/dry flap

Operating and Functional Elements

1

2

3

4

5

6

7

8

9

10

12

13

17

18

11

14

15

16

19

20

21

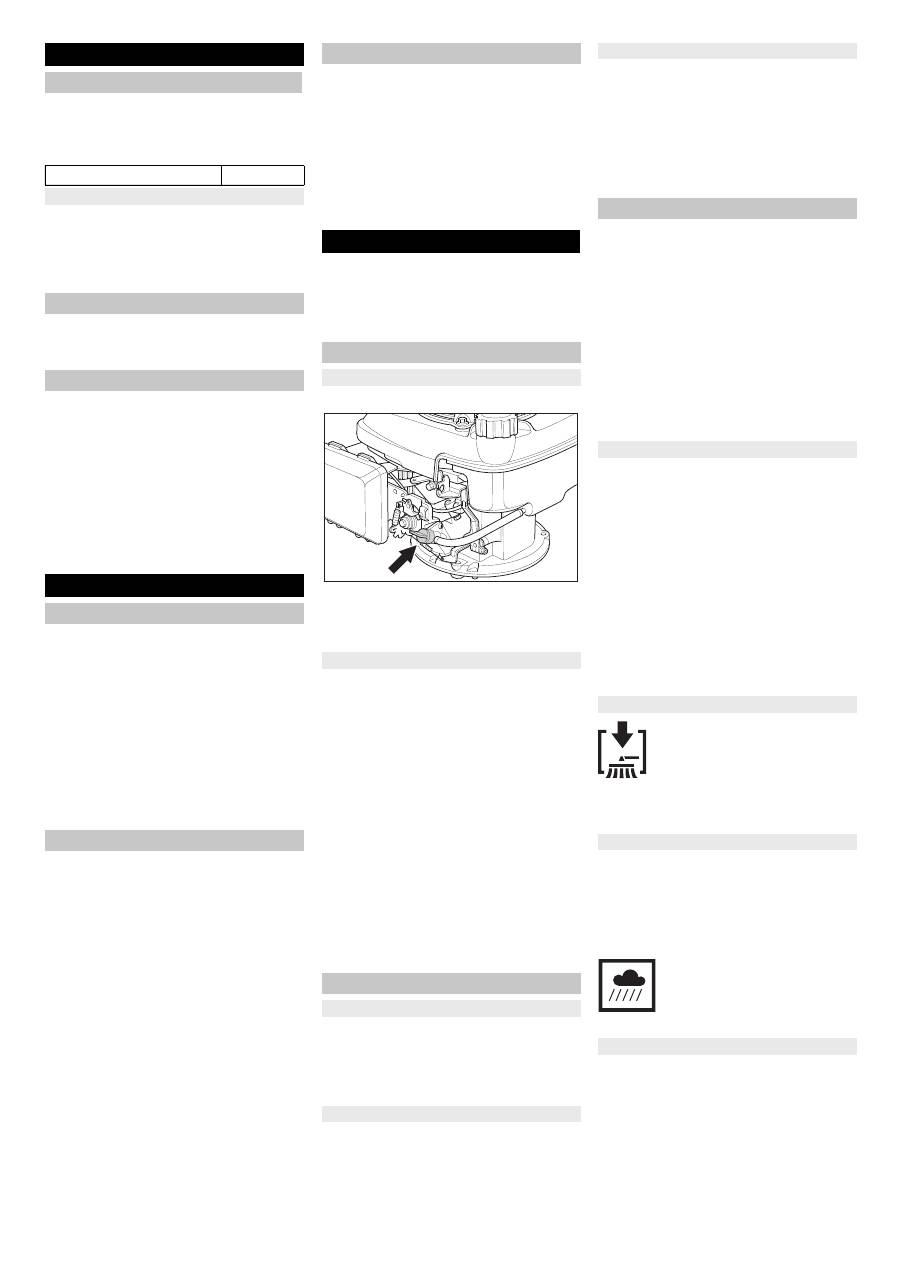

Operating field

6 5 4 3 2 1

Multifunctional lever

Position

Function

0/OFF

Motor off

1

Motor on/multifunctional le-

ver (speed steplessly adjust-

able)

2

Operating speed

3

Choke (cold start)

15

EN

-

4

Danger

Risk of injury, risk of damage!

Observe the weight of the appliance when

you load it!

Remove the cardboard.

Remove the wooden blocks that secure

the wheels and raise the device from

the pallette by hand.

Release parking brake.

Loosen the screws.

Align the pushing handle.

Tighten the screws.

Notice

–

The appliance may only be tilted back-

wards if the fuel tank is empty.

–

Close the fuel tap, remove the waste

container and move the pushing handle

to the front prior to tilting the appliance.

Do not rest the appliance on the push-

ing handle.

Clip side brush on to driver and screw

on.

Danger

Risk of injury! Switch off the appliance prior

to removing the waste container.

Notice

Only operate while the appliance hood is

closed. The appliance is equipped with a

hood contact switch to protect the operator.

The motor starts up only when the appli-

ance hood is closed.

Park the sweeper on an even surface.

Switch off engine.

Lock parking brake.

Danger

Risk of explosion!

–

Only use the fuels specified in the Op-

erations Manual.

–

Do not refuel the machine in enclosed

spaces.

–

Smoking and naked flames are strictly

prohibited.

–

Ensure that no fuel reaches the hot

open surfaces.

Switch off engine.

Open fuel filler cap.

Use "regular unleaded petrol".

Fill tank to max. 1 cm below the lower

edge of the filler nozzle.

Wipe off any spilt fuel and close fuel fill-

er cap.

Note

The machine can be operated for a maxi-

mum of 2.0 hours on a full tank.

Carry out the daily maintenance tasks (see

section "Maintenance and Care").

Check engine oil level.

Check and ensure proper fitting of the

spark plug.

Check side brush.

Check roller brush.

Shake off dust filter.

Empty waste container.

Danger

Ensure that there is adequate ventilation or

provision for diverting the exhaust gas

while operating the appliance in closed

rooms (risk of poisoning).

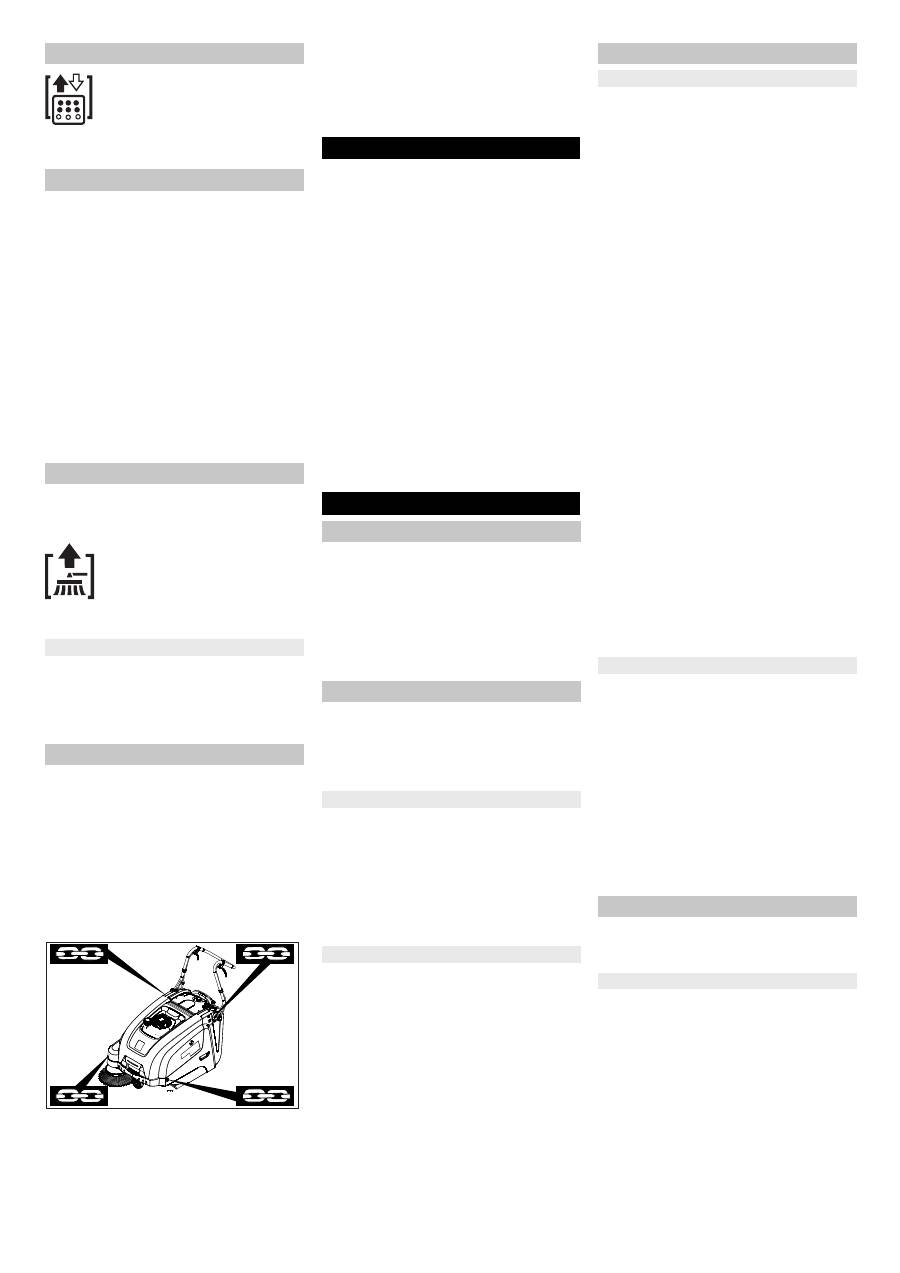

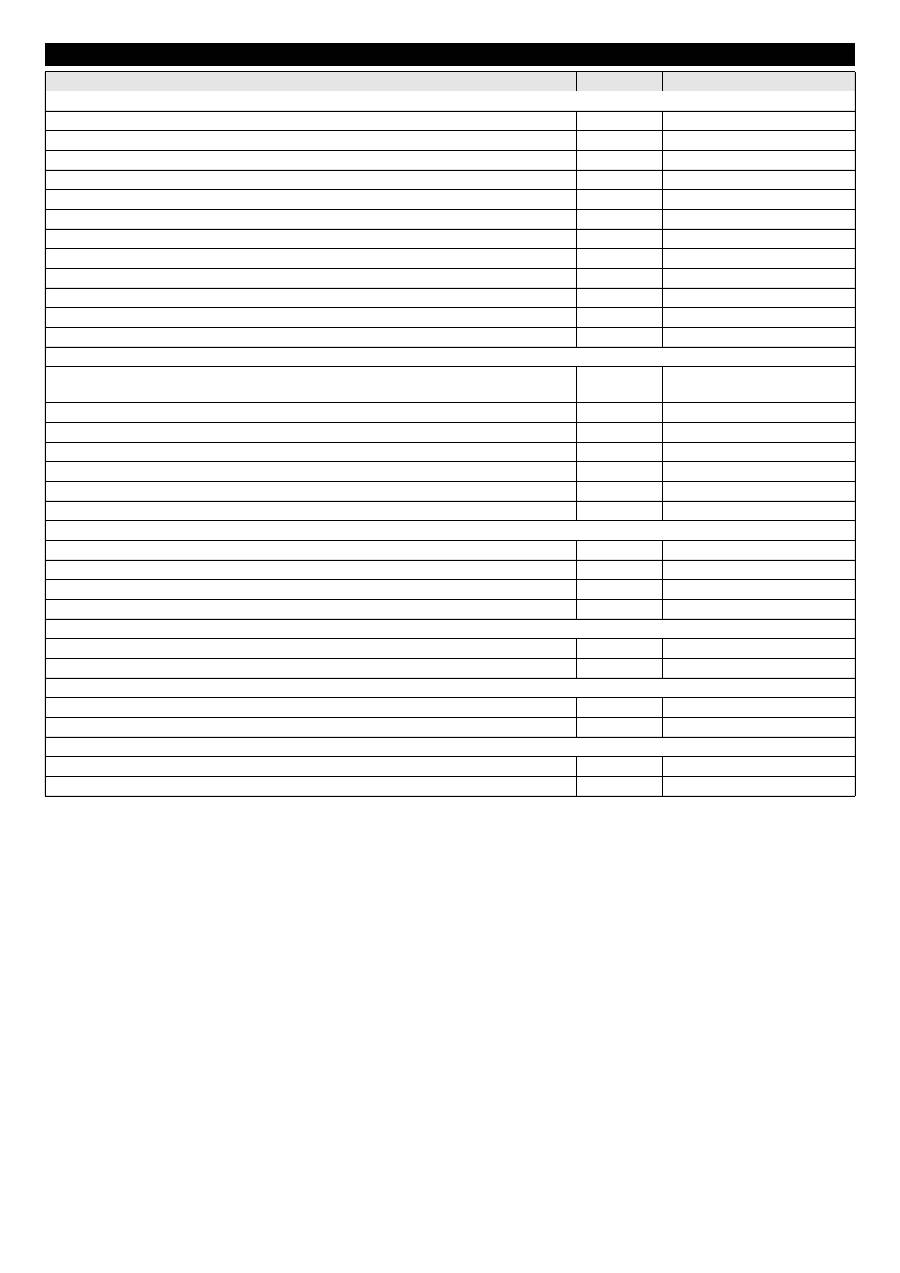

Open the device hood.

Open the fuel supply.

Turn the rotating knob parallel to the

hose of the fuel tap.

Close cover.

Release parking brake.

Slide the multifunctional lever into the

center position "Operation speed"; if the

weather is cold or wet, move it to the

"Choke“ position.

Pull the starter rope slowly until a resist-

ance can be felt.

Pull starter rope swiftly.

Once the motor runs, release the starter

rope. Move the multifunctional lever

from the "Choke" into the "Operating

speed" position.

Note

The appliance works best while in the

operating position.

Note

The sweep roller and the side-brushes start

rotating.

Pull the lever for forward drive.

Note

The drive speed for forward drive can be

adjusted steplessly depending on the posi-

tion of the lever.

Release the lever for forward drive. De-

vice comes to a halt.

Driving over fixed obstacles which are 30

mm high or less:

Raise bulk waste flap.

Drive forwards slowly and carefully.

Driving over fixed obstacles which are

more than 30 mm high:

Only drive over these obstacles using a

suitable ramp.

Danger

Risk of injury! If the bulk waste flap is open,

stones or gravel may be flung forwards by

the roller brush. Make sure that this does

not endanger persons, animals or objects.

몇

Warning

Do not sweep up packing strips, wire or

similar objects as this may damage the

sweeping mechanism.

Note

To achieve an optimum cleaning result, the

driving speed should be adjusted to take

specific situations into account.

Note

To sweep up larger items up to a height of

50 mm, e.g. cigarette packs, the bulk waste

flap must be raised briefly.

Raising bulk waste flap:

Pull the lever for raising the bulk waste

flap.

Lowering the bulk waste flap:

Release the lever for raising the bulk

waste flap.

Note

An optimum cleaning result can only be

achieved if the bulk waste flap has been

lowered completely.

Move the lever to lower the side brush

to the front. The side brush will be low-

ered.

Note

Empty the waste container at regular inter-

vals during the sweeping operation.

Note

During operation, the dust filter should be

shaken off and cleaned at regular intervals.

Close wet/dry flap

Open wet/dry flap.

Note

This protects the filter from moisture.

Before Startup

Unloading tips

Net weight (transport weight) 84 kg

Unloading

Installing the pushing handle

Install side brush

Start up

General notes

Refuelling

Inspection and maintenance work

Operation

Starting the machine

Open fuel cock

Start the engine

Drive the machine

Drive forward

Dry run

Driving over obstacles

Sweeping mode

Sweeping with bulk waste flap raised

Sweeping with side brushes

Sweeping dry floors

Sweeping damp or wet floors

16

EN

-

5

Pull the handle of the filter clean-off out

several times and reinsert it.

Danger

Risk of injury! Switch off the appliance prior

to removing the waste container.

Note

–

Make sure the seal strip is not damaged

while emptying the waste container.

–

The max. load of the waste container is

40 kg.

Shake off dust filter.

Pull lock bow of the waste container up-

ward.

Pull out the waste container.

Empty waste container.

Push in the waste container.

Push lock bow of the waste container

downward.

Switch off engine.

Push the multifunctional lever into

"OFF" position.

The side-brushes lift up.

Lock parking brake.

Open the device hood.

Close the fuel supply.

Turn the rotating knob perpendicular to

the fuel tap.

Close cover.

몇

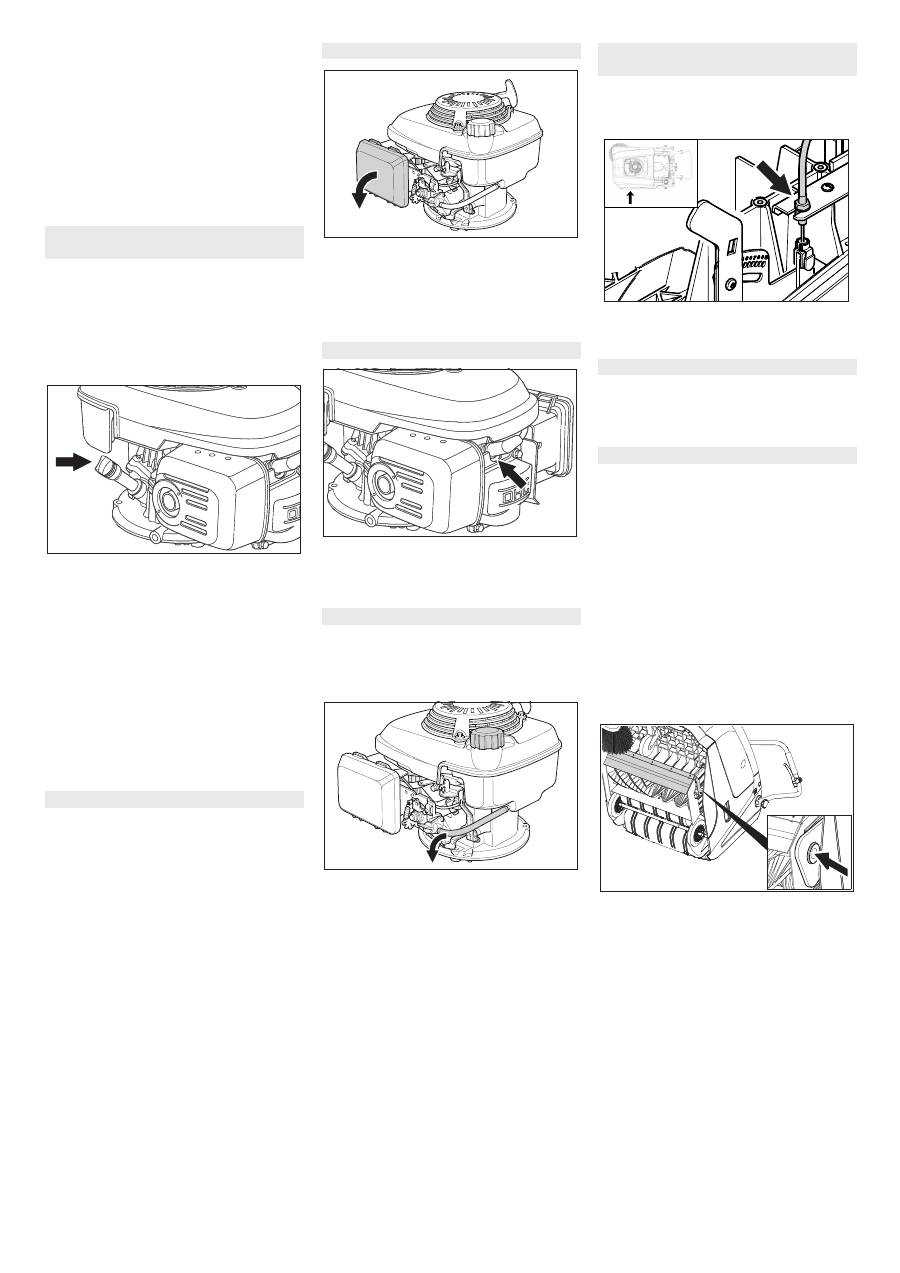

Warning

The appliance must be secured against

slippage during transport.

Switch off engine.

Lock parking brake.

Empty fuel tank.

Secure the wheels of the machine with

wheel chocks.

Secure the machine with tensioning

straps or cables.

1 Fastening area above the pushing han-

dle

2 Fastening area under the device hood

Note

–

Observe markings for fixing points on

base frame (chain symbols).

–

Do not kink the bowden or sheathed ca-

bles.

Follow operating instructions of the en-

gine manufacturer!

If the sweeper is going to be out of service

for a longer time period, observe the follow-

ing points:

Park the sweeper on an even surface.

Switch off engine.

Lock parking brake.

Lock the sweeper to ensure that it does

not roll off.

Empty fuel tank.

Change engine oil.

Raise roller brush. Thus, engage both

adjustment levers in the top boring.

The side-brushes lift up.

Clean the inside and outside of the

sweeper.

Park the machine in a safe and dry

place.

– Maintenance work may only be carried

out by approved customer service out-

lets or experts in this field who are famil-

iar with the respective safety regula-

tions.

– Mobile appliances used for commercial

purposes are subject to safety inspec-

tions according to VDE 0701.

몇

Warning

Risk of damage! Do not clean the appliance

with a water hose or high-pressure water

jet (danger of short circuits or other dam-

age).

Danger

Risk of injury! Wear dust mask and protec-

tive goggles.

Open the device hood.

Clean machine with a cloth.

Blow through machine with com-

pressed air.

Close cover.

Clean the machine with a damp cloth

which has been soaked in mild deter-

gent.

Note

Do not use aggressive and abrasive clean-

ing agents.

Note

With a new motor, the oil must be changed

after the first 5 operating hours.

Daily maintenance:

Check engine oil level.

Check the sweeping roller and the side

brush for wear and wrapped belts.

Check function of all operator control el-

ements.

Weekly maintenance:

Check tension, wear and tear and func-

tioning of the drive belts.

Check for smooth running of the

Bowden cables and the moveable parts

Check the sealing strips in the sweep-

ing area for position and wear.

Check the sweeping track of the sweep-

ing roller.

Clean the dust filter.

Check air filter.

Maintenance to be carried out every 50

operating hours:

Perform a motor oil change.

Check spark plug.

Check function of hood contact switch.

Note

For description, see section on Care and

maintenance.

Note

Where maintenance is carried out by the

customer, all service and maintenance

work must be undertaken by a qualified

specialist. If required, a specialised Archer

dealer may be contacted at any time.

Maintenance to be carried out after 5 op-

erating hours:

Carry out initial inspection.

Maintenance to be carried out every 100

operating hours

Maintenance to be carried out every 300

operating hours

Note

In order to safeguard warranty claims, all

service and maintenance work during the

warranty period must be carried out by the

authorised KÄRCHER specialist in accord-

ance with the maintenance booklet.

Preparation:

Park the sweeper on an even surface.

Lock parking brake.

Danger

Risk of injury!

The engine requires approx. 3-4 seconds

to come to a standstill once it has been

switched off. During this time, stay well

clear of the working area.

– Allow the machine sufficient time to cool

down before carrying out any mainte-

nance and repair work.

– Do not touch any hot parts, such as the

drive motor and exhaust system.

Cleaning the dust filter

Emptying waste container

Turn off the appliance

Close fuel cock

Transport

Shutdown Maintenance and care

General notes

Cleaning

Cleaning the inside of the machine

External cleaning of the appliance

Maintenance intervals

Maintenance by the customer

Maintenance by Customer Service

Maintenance Works

General notes on safety

17

EN

-

6

Note

–

The appliance may only be tilted back-

wards if the fuel tank is empty.

–

Close the fuel tap, remove the waste

container and move the pushing handle

to the front prior to tilting the appliance.

Do not rest the appliance on the push-

ing handle.

Switch off the appliance prior to clean-

ing and performing any maintenance

tasks or replacing parts.

Danger

Risk of burns!

Allow engine to cool down.

Wait for at least 5 minutes after switch-

ing off the engine before checking the

engine oil fill level.

Open the device hood.

Unscrew and withdraw oil dipstick.

Wipe off oil dipstick and screw it in.

Unscrew and withdraw oil dipstick.

Read the value of the oil level.

– The oil level must lie between “MIN“

and “MAX“ marking.

– Add motor oil if the oil level is below the

"MIN" marking.

– Do not fill oil above the "MAX" marking.

Fill motor oil into the oil fill neck.

Oil grade: see Technical Data

Reinsert the oil dipstick.

Wait at least 5 minutes.

Check engine oil level.

Danger

Risk of burns due to hot oil!

Allow engine to cool down.

Open the device hood.

Unscrew and withdraw oil dipstick.

Draw off engine oil via the oil filler neck

using 6.491-538 oil-change pump.

Fill motor oil into the oil fill neck.

Oil grade: see Technical Data

Reinsert the oil dipstick.

Wait at least 5 minutes.

Check engine oil level.

Remove covering lid.

Take out the filter inlay.

Insert a new filter insert.

The filter lamella must point into the di-

rection of the locking cap.

Attach the locking cap.

Remove spark-plug connector.

Unscrew and clean spark plug.

Screw in cleaned or new spark plug.

Push on spark-plug connector.

Open the device hood.

Close the fuel supply.

Turn the rotating knob perpendicular to

the fuel tap.

Press together the fuel hose from the

tank to the fuel tap.

Loosen the hose clamp on the fuel tap.

Remove the fuel hose.

Open fuel filler cap.

Hold the fuel hose over a suitable catch

bin and drain the fuel.

If the tank is empty, reattach the fuel

hose to the stub of the fuel tap and in-

stall the hose clamp.

This must be adjusted if the drive perfor-

mance of the appliance becomes insuffi-

cient when driving uphill.

Loosen counter-nut.

Adjust the adjustment screw.

Tighten the counter-nut.

Lock parking brake.

Remove the waste container.

Remove belts or cords from roller

brush.

Replacement is due if a visible deteriora-

tion in sweeping performance caused by

bristle wear is evident.

Note

–

The appliance may only be tilted back-

wards if the fuel tank is empty.

–

Close the fuel tap, remove the waste

container and move the pushing handle

to the front prior to tilting the appliance.

Do not rest the appliance on the push-

ing handle.

Lock parking brake.

Close fuel cock.

Remove the waste container.

Tilt the appliance rearward.

Lift the waste flap, press in the bearing

cap and swivel the roller brush toward

the front.

Pull out roller brush.

Attach the new roller brush to the drive

pin (left).

Engage the bearing cup into the boring

of the roller brush swinging arm on the

opposite side.

몇

Warning

Risk of damage! Make sure that no bristles

are jammed into the boring of the roller

brush swinging arm.

Note

Once the new roller brush has been in-

stalled, the sweeping track must readjust-

ed.

Check engine oil level and top up, if

required

Change the engine oil

Change the air filter

Clean or replace the spark plug

Empty fuel tank

Adjust the Bowden cable of the

acceleration drive

Checking roller brush

Replacing roller brush

18

EN

-

7

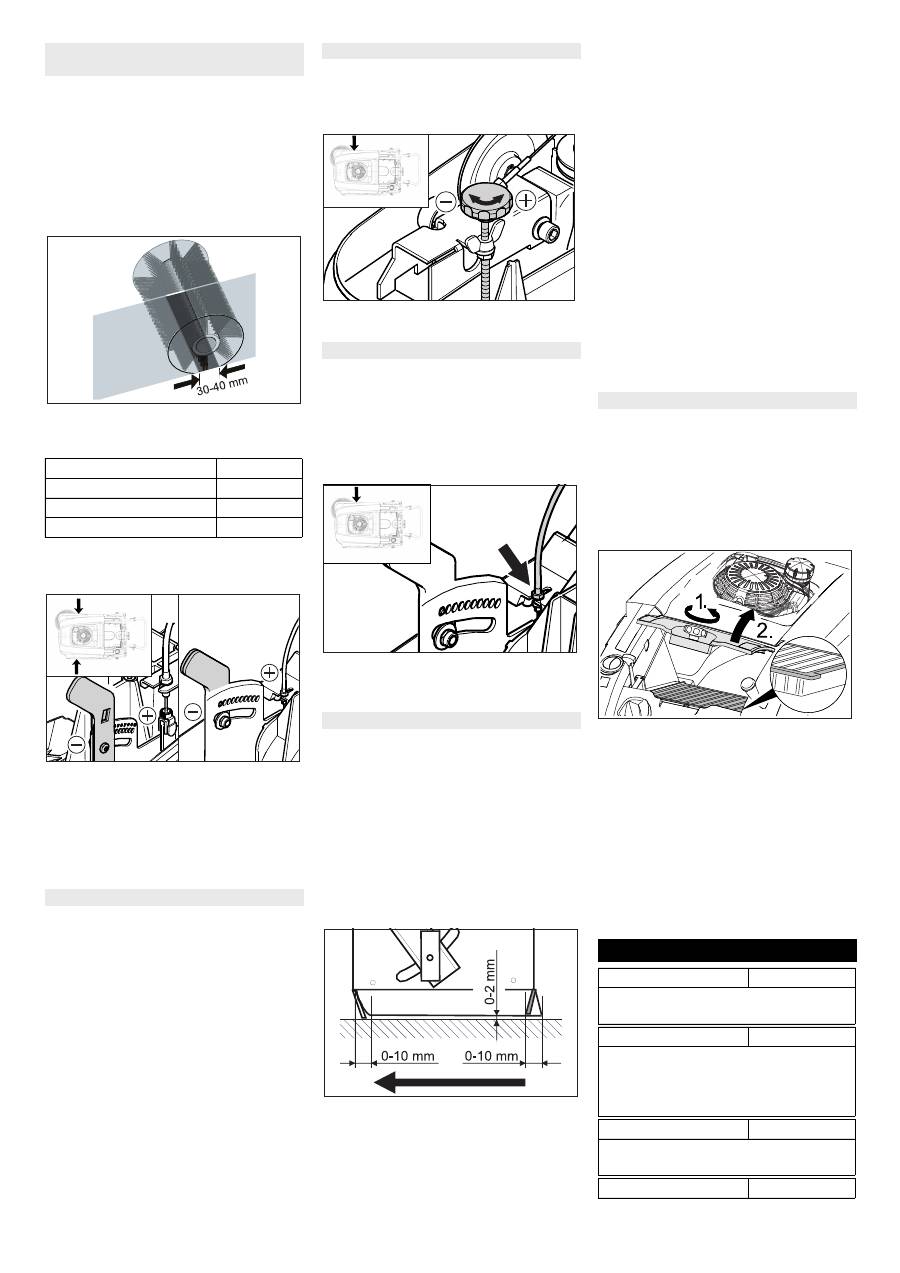

Raise the sweeper from the front and

drive it on to a smooth, even surface

covered with a visible layer of dust or

chalk.

Lock parking brake.

Let the sweeping roller rotate for ap-

prox. 15-30 seconds.

Raise the sweeper at the front and drive

it towards the side.

The sweeping track should have an even

rectangular shape which is between 30 and

40 mm wide.

Adjust sweeping track:

Adjust the left and right adjustment le-

vers and engage into the same boring.

– Engage adjustment lever into the lower

boring (+): Sweeping track becomes

bigger

– Engage the adjustment lever into the

upper boring (-): Sweeping track be-

comes smaller

Check sweeping mirror.

Replacement is due if a visible deteriora-

tion in sweeping performance caused by

bristle wear is evident.

Note

–

The appliance may only be tilted back-

wards if the fuel tank is empty.

–

Close the fuel tap, remove the waste

container and move the pushing handle

to the front prior to tilting the appliance.

Do not rest the appliance on the push-

ing handle.

Unscrew 3 screws from the underside

of the side brush.

Remove the wiper blade.

Clip new side brushes on to driver and

screw on.

Adjustment is necessary if a visible deterio-

ration in sweeping performance caused by

side-brush is evident.

Release the wing nut.

Adjust the adjustment screw.

Tighten the wing nut.

– Adjustment is necessary if the bulk

waste flap cannot be raised wide

enough.

– The Bowden cable needs to be re-

leased a little if the sweeper results be-

come poorer, for e.g. due to the wearing

of the front lip.

Loosen counter-nut.

Adjust the adjustment screw.

Tighten the counter-nut.

Note

–

The appliance may only be tilted back-

wards if the fuel tank is empty.

–

Close the fuel tap, remove the waste

container and move the pushing handle

to the front prior to tilting the appliance.

Do not rest the appliance on the push-

ing handle.

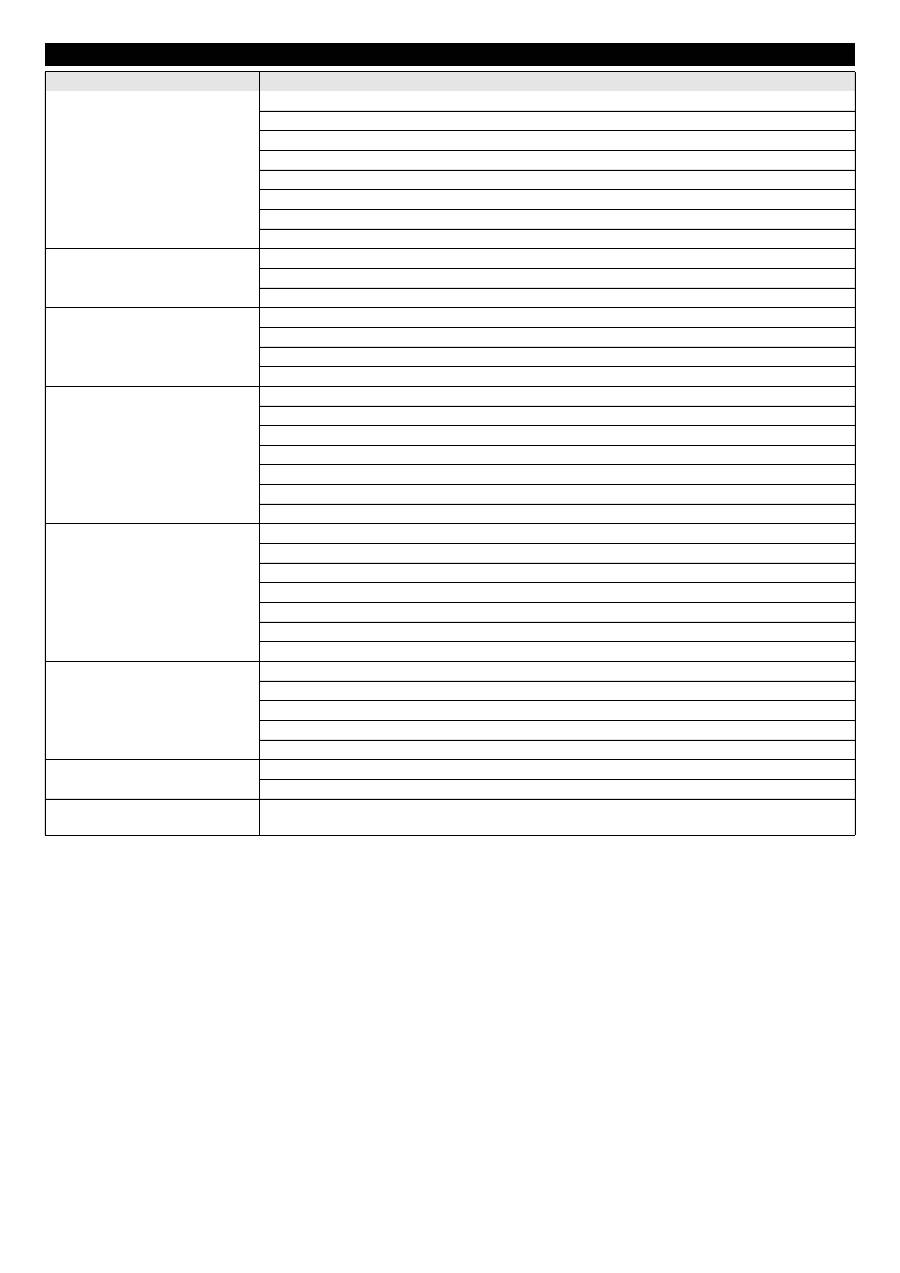

Front sealing strip

Loosen the fastening screws of the

sealing strip.

Adjust or replace sealing strip.

Set the distance between the sealing

strip and the floor so that the bottom

edge trails behind at a distance of be-

tween 0-10 mm.

Adjust sealing strip.

Tighten the fastening of the sealing

strip.

Rear sealing strip

Remove the waste container.

Loosen the fastening screws of the

sealing strip.

Adjust or replace sealing strip.

Set the distance between the sealing

strip and the floor so that the bottom

edge trails behind at a distance of be-

tween 0-10 mm.

Tighten the fastening of the sealing

strip.

Side sealing strips

Loosen the fastening screws of the

sealing strip.

Adjust or replace sealing strip.

To set the floor clearance, insert a

sheet with a thickness of max. 2 mm un-

der the sealing strip.

Adjust sealing strip.

Tighten the fastening of the sealing

strip.

Danger

Empty waste container before replacing

dust filter. Wear a dust mask when working

around the dust filter. Observe safety regu-

lations on the handling of fine particulate

material.

Lock parking brake.

Shake off dust filter.

Open the locking screw of the dust filter

cover in an anticlockwise direction.

Lift the dust filter cover.

Replace dust filter Make sure the dust

filter is inserted correctly (see figure).

Screw in the locking screw all the way.

몇

Warning

If the locking screw is not tightened all the

way, there may be damages.

Note

Make sure when installing the new filter

that the fins are not damaged.

Check and adjust roller brush sweeping

track

Setting range

(-) 1...10 (+)

Minimum sweeping track

1

Maximum sweeping track

10

New roller brush

1...3

Replacing side brush

R

L

R L

Adjust side-brush lowering

Adjust the raising of the bulk waste flap

Adjusting and replacing sealing strips

Replacing dust filter

Accessories

Hard side-brushes

6.905-625.0

For removing stubborn dirt in the external

area; resistant to moisture.

Roller-brush, soft

6.906-886.0

With natural bristles especially for fine dust

sweeping on smooth indoor floors. Not re-

sistant to wetness; not for abrasive surfac-

es.

Roller-brush, hard

6.906-885.0

For removing stubborn dirt in the external

area; resistant to moisture.

Roller brush, antistatic 6.906-950.0

19

EN

-

8

Troubleshooting

Fault

Remedy

Appliance cannot be started

Close appliance hood

Check the hood contact switches

Refuel

Open fuel cock

Check and clean spark plug, replace if necessary.

Check setting of multifunctional lever

Check bowden cable to the motor

Inform Kärcher Customer Service.

Engine is running but machine is

not moving

Adjust the Bowden cable of the acceleration drive

Checking the V-Belt

Inform Kärcher Customer Service.

Device comes to halt while climbing

a slope

Drive over a path with lesser slope

Adjust the Bowden cable of the acceleration drive

Checking the V-Belt

Inform Kärcher Customer Service.

Machine is not sweeping properly Check roller brush and side brushes for wear, replace if necessary.

Check function of bulk waste flap

Release the Bowden cable of the bulk waste flap (adjustment screw)

Check belts for tension and functioning; replace, if required

Adjust roller mirror

Replacing roller brush

Inform Kärcher Customer Service.

Dust gathers in the machine

Check function of bulk waste flap

Release the Bowden cable of the bulk waste flap (adjustment screw)

Check dust filter, clean or replace

Empty waste container

Replace sealing profile at the waste container

Check the seal on the dust filter

Check sealing strips for wear, adjust or replace as required

Poor cleaning performance at edges Adjust side-brush lowering

Replace side brush

Lower the side brushes

Check the drive belt of the side brush

Inform Kärcher Customer Service.

Side-brush raising does not func-

tion

Check Bowden cable of the side-brush raising

Inform Kärcher Customer Service.

The new roller brush brushes

against the waste container

Correct the setting of the sweep track; for this, engage both adjustment levers into the upper boring

(1...3)

20

EN

-

9

Technical specifications

KM 75/40 W G

Machine data

Length x width x height (pushing handle unfolded)

mm

1430 x 750 x 1190

Length x width x height (pushing handle folded in)

mm

1160 x 750 x 930

Unladen weight

kg

84

Driving and sweeping speed

km/h

4,5

Climbing capability (max.)

%

15

Roller brush diameter

mm

265

Side brush diameter

mm

410

Surface area, max.

m

2

/h

3400

Working width without side brushes

mm

550

Working width with side-brush

mm

750

Volume of waste container

l

40

Protection type, drip-proof

--

IPX 3

Engine

Type

--

Honda, 1 cyl., four-stroke

GCV 160

Cylinder capacity

cm

3

160

Operating speed

1/min

2600 ±50

Max. power

kW/PS

3,3/4,5

Capacity of fuel tank, normal petrol (unleaded)

l

0,9

Motor oil (SF, SG)

l

0,50 (SAE 10W30)

Spark plug, NGK

--

BPR 6 ES

Filter and vacuum system

Filter surface area, fine dust filter

m

2

1,8

Category of use – filter for non-hazardous dust

--

L

Nominal vacuum, suction system

mbar

5

Nominal volume flow, suction system

l/s

45

Working conditions

Temperature

°C

-5 and +40

Air humidity, non-condensing

%

0 - 90

Noise emission

Sound pressure level (EN 60704-1)

dB(A)

75

Guaranteed sound power level (2000/14/EC)

dB(A)

92

Machine vibrations

Vibration total value (ISO 5349)

Upper limbs

m/s

2

1,21

21

EN

-

10

We hereby declare that the machine de-

scribed below complies with the relevant

basic safety and health requirements of the

EU Directives, both in its basic design and

construction as well as in the version put

into circulation by us. This declaration shall

cease to be valid if the machine is modified

without our prior approval.

The undersigned act on behalf and under

the power of attorney of the company man-

agement.

Authorised Documentation Representative

S. Reiser

Alfred Kärcher GmbH Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Phone: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2011/08/01

EC Declaration of Conformity

Product:

Vacuum sweeper

Type:

1.049-xxx

Relevant EU Directives

2006/42/EC (+2009/127/EC)

2004/108/EC

2000/14/EC

Applied harmonized standards

EN 55012: 2007 + A1: 2009

EN 55014–2: 1997+A1: 2001+A2: 2008

EN 60335–1

EN 60335–2–72

Applied national standards

--

Applied conformity evaluation method

2000/14/EC: Appendix V

Sound power level dB(A)

KM 75/40 W G

Measured:

89

Guaranteed: 92

CEO

Head of Approbation

22

EN

-

1

Lire ce manuel d'utilisation origi-

nal avant la première utilisation

de votre appareil, le respecter et le conser-

ver pour une utilisation ultérieure ou pour le

futur propriétaire.

Avant la première mise en service, vous

devez impérativement avoir lu les

consignes de sécurité N° 5.956-250 !

L'utilisation de l'appareil doit être faite en

conformité avec les consignes figurant

dans les instructions de service.

Il est nécessaire de contrôler l'état et la

sécurité du fonctionnement de l'appa-

reil et de ses équipements avant toute

utilisation. Ne pas utiliser l'appareil si

son état n'est pas irréprochable.

– Cette balayeuse est conçue pour le ba-

layage de surfaces encrassées en inté-

rieur et en extérieur.

– L'appareil n'est pas destiné au net-

toyage de voies publiques.

– Cet appareil n'est pas conçu pour aspi-

rer des poussières nocives.

– Aucune transformation ne doit être ef-

fectuée sur la machine.

– Cet appareil convient uniquement pour

les revêtements de sol mentionnés

dans le mode d'emploi.

– Il doit exclusivement être utilisé sur des

surfaces autorisées par l'entrepreneur

ou son représentant.

– En règle générale, il convient : d'éloi-

gner les matériaux facilement inflam-

mables de la machine (risque d'explo-

sion ou d'incendie).

– Ne jamais aspirer ni balayer de liquides

explosifs, de gaz inflammables, ni

d'acides ou de solvants non dilués ! Il

s'agit notamment de substances telles

que l'essence, les diluants pour pein-

tures, ou le fuel, qui, en tourbillonnant

avec l'air aspiré, risqueraient de pro-

duire des vapeurs ou des mélanges, ou

de substances telles que l'acétone, les

acides ou les solvants non dilués, qui

pourraient altérer les matériaux consti-

tutifs de l'appareil.

– Ne jamais balayer/aspirer de pous-

sières réactives de métal (par ex. alumi-

nium, magnésium, zinc) ; elles forment

des gaz explosifs en combinaison avec

des détergents alcalins et acides.

– N’aspirer ou ne balayer aucun objet en

flamme ou incandescent.

– Il est interdit de séjourner dans la zone

à risque. Il est interdit d’exploiter l’appa-

reil dans des pièces présentant des

risques d’explosion.

– Asphalte

– Sol industriel

– Chape coulée

– Béton

– Pavé

La balayeuse fonctionne selon le principe

du balayage par soulèvement et projection.

– Le balai latéral (1) nettoie les angles et

les bordures de la surface à balayer et

achemine les déchets dans la zone

d'action de la brosse rotative.

– La brosse rotative (2) rejette directe-

ment les déchets dans le bac à pous-

sières (3).

– La poussière qui se soulève dans le ré-

servoir est recueillie par le filtre à pous-

sières (4) et l'air filtré est aspiré par l'as-

pirateur (5).

Contacter le revendeur en cas de constata-

tion d'une avarie de transport lors du débal-

lage de l'appareil.

– Lire et respecter les instructions de ser-

vice et les consignes de sécurité des

dispositifs de travail placés sur l'appa-

reil.

– Afin d'assurer un fonctionnement sans

danger, observez les avertissements et

consignes placés sur l'appareil.

– Outre les instructions figurant dans le

mode d'emploi, il est important de

prendre en considération les consignes

générales de sécurité et de prévention

contre les accidents imposées par la loi.

Danger

Afin d'éviter tout danger, seul le service

après-vente agréé est habilité à effectuer

des réparations ou à monter des pièces de

rechanger sur l'appareil.

– Utiliser uniquement des accessoires et

des pièces de rechange autorisés par le

fabricant. Des accessoires et des

pièces de rechange d’origine garan-

tissent un fonctionnement sûr et parfait

de l’appareil.

– Une sélection des pièces de rechange

utilisées le plus se trouve à la fin du

mode d'emploi.

– Vous trouverez plus d'informations sur

les pièces de rechange dans le menu

Service du site www.kaercher.com.

Instructions relatives aux ingrédients

(REACH)

Les informations actuelles relatives aux in-

grédients se trouvent sous :

www.kaercher.com/REACH

Dans chaque pays, les conditions de ga-

rantie en vigueur sont celles publiées par

notre société de distribution responsable.

Les éventuelles pannes sur les acces-

soires sont réparées gratuitement dans le

délai de validité de la garantie, dans la me-

sure où celles-ci relèvent d'un défaut maté-

riel ou d'un vice de fabrication. En cas de

recours en garantie, adressez-vous à votre

revendeur ou au service après-vente agréé

le plus proche munis de votre preuve

d'achat.

Contenu

Utilisation conforme . . . . . . . . . FR

1

Fonction. . . . . . . . . . . . . . . . . . FR

1

Consignes générales. . . . . . . . FR

1

Consignes de sécurité . . . . . . . FR

2

Eléments de commande et de

fonction . . . . . . . . . . . . . . . . . . FR

3

Avant la mise en service . . . . . FR

4

Mise en service . . . . . . . . . . . . FR

4

Fonctionnement. . . . . . . . . . . . FR

4

Remisage . . . . . . . . . . . . . . . . FR

5

Entretien et maintenance. . . . . FR

5

Accessoires . . . . . . . . . . . . . . . FR

8

Assistance en cas de panne . . FR

9

Caractéristiques techniques . . FR

10

Déclaration de conformité CE . FR

11

Utilisation conforme

Mauvaise utilisation prévisible

Revêtements appropriés

Fonction Consignes générales 5 4 1 2 3

Accessoires et pièces de rechange

Protection de l’environnement

Les matériaux constitutifs de

l’emballage sont recyclables. Ne

pas jeter les emballages dans

les ordures ménagères, mais les

remettre à un système de recy-

clage.

Les appareils usés contiennent

des matériaux précieux recy-

clables lesquels doivent être ap-

portés à un système de recy-

clage. Il est interdit de jeter les

batteries, l'huile et les subs-

tances similaires dans l'environ-

nement. Pour cette raison, utili-

ser des systèmes de collecte

adéquats afin d'éliminer les ap-

pareils hors d'usage.

Garantie

23

FR

-

2

– Utiliser uniquement des accessoires et

des pièces de rechange autorisés par le

fabricant. Des accessoires et des

pièces de rechange d’origine garan-

tissent un fonctionnement sûr et parfait

de l’appareil.

– Une sélection des pièces de rechange

utilisées le plus se trouve à la fin du

mode d'emploi.

– Vous trouverez plus d'informations sur

les pièces de rechange dans le menu

Service du site www.kaercher.com.

Danger

Signale la présence d'un danger imminent

entraînant de graves blessures corporelles

et pouvant avoir une issue mortelle.

몇

Avertissement

Signale la présence d'une situation éven-

tuellement dangereuse pouvant entraîner

de graves blessures corporelles et même

avoir une issue mortelle.

Attention

Remarque relative à une situation éven-

tuellement dangereuse pouvant entraîner

des blessures légères ou des dommages

matériels.

Contacter le revendeur en cas de constata-

tion d'une avarie de transport lors du débal-

lage de l'appareil.

– Afin d'assurer un fonctionnement sans

danger, observez les avertissements et

consignes placés sur l'appareil.

– Outre les instructions figurant dans le

mode d'emploi, il est important de

prendre en considération les consignes

générales de sécurité et de prévention

contre les accidents imposées par la loi.

Danger

Risque de blessure !

Risque de basculement en cas de pente

trop forte.

–

Dans le sens de la marche, ne pas

monter des pentes supérieures à 15%.

Risque de basculement en cas de sol ins-

table.

–

N'utilisez la machine que sur des sols

stabilisés.

Risque de basculement en cas de pente la-

térale trop importante.

–

N'empruntez aucune pente supérieure

à 15% dans le sens perpendiculaire au

sens de la marche.

– Doivent être respectées les mesures de

règlement, les règles et les décrets qui

sont valables pour les automobiles.

– L’utilisateur doit utiliser l’appareil de fa-

çon conforme. Dans la circulation, il doit

prendre en considération les données

locales et lors du maniement de l’appa-

reil, il doit prendre garde aux tierces

personnes, et en particulier aux en-

fants.

– L'appareil doit uniquement être utilisée

par des spécialistes qui sont instruits

dans la manoeuvre ou par des per-

sonnes qui peuvent justifiée leur apti-

tude d'utilisation et qui sont explicite-

ment mandatées pour l'utilisation.

– Ne jamais laisser des enfants ou des

adolescents utiliser l'appareil.

L'appareil ne doit pas rester sans sur-

veillance pendant tout le temps où le

moteur fonctionne. L'opérateur ne peut

quitter l'appareil que lorsque le moteur

est arrêté, l'appareil assuré contre des

mouvements involontaires et le frein de

stationnement actionné.

Danger

Risque de blessure !

–

Le quatrième trou ne peut être fermé.

–

Ne pas se pencher au-dessus ou tou-

cher le quatrième trou (danger de brû-

lure).

–

Ne pas toucher le moteur de traction

(danger de brûlure).

–

Pour une utilisation de l'appareil dans

des locaux fermés, il doit être garanti

une ventilation suffisante et une éva-

cuation des gazes résiduels (danger

d'intoxication).

–

Les gaz résiduels sont toxiques et no-

cifs, ils ne peuvent être respirés.

–

Le moteur continue à tourner 3 ou 4 se-

condes après l'arrêt. Ne pas s'appro-

cher de la zone de travail pendant ce

laps de temps.

–

La machine ne doit être basculée en ar-

rière qu'avec un réservoir à carburant

vide.

Au transport, le moteur de l'appareil doit

être arrêté et l'appareil doit être bien fixé.

Cf. chapitre « Transport ».

Danger

Si le capot de la machine est ouvert alors

que le moteur tourne, le moteur doit être

coupé. Si le moteur ne s'éteint pas, le

contacteur capot est défectueux. Informer

le service après-vente.

Pièces de rechange

Symboles utilisés dans le mode

d'emploi

Symboles sur l'appareil

Risque de brûlure provoqué

par les pièces chaudes de

l'installation!

Ne pas balayer d'objets en

feu ou brûlants, comme

par.ex. des cigarettes, des

allumettes ou autre.

Risque d'écrasement et de

coupure à la courroie, au

balai latéral, au réservoir, à

l'étrier de poussée.

Risque de blessure par les

pièces en rotation. Ouvrir le

capot seulement lorsque le

moteur est à l'arrêt.

Consignes de sécurité

Consignes générales

Consignes de sécurité relatives au

mode de déplacement

Consignes de sécurité relatives au

moteur à combustion

Consignes de sécurité relatives au

transport de l'appareil

Ouvrir/fermer le capot de l'appareil

24

FR