Karcher HD 7-16-4 ST: Troubleshooting

Troubleshooting: Karcher HD 7-16-4 ST

-

7

In order to guarantee a reliable operation

og the equipment, we success, you signed

a maintenance agreement. Please refer to

you local Kärcher service department.

Who may perform maintenance?

Operator

Work designated with the sign “Opera-

tor” may only be carried out by persons

who have been instructed in the safe

operation and maintenance on the high

pressure plant.

Electricians

Only persons with a professional train-

ing in the electro-technical area.

Customer Service

Work designated with the sign “Cus-

tomer Service” may only be done by the

fitters of Kärcher Customer Service.

WARNING

Risk of burns due to hot oil or hot parts of

the plant. Allow the pump to cool down for

minutes before oil change.

Note:

Used oil must only be disposed of by the

designated collection points. Please turn in

used oil there. Polluting the environment

with used oil is prosecutable.

For oil type refer to technical specifica-

tions.

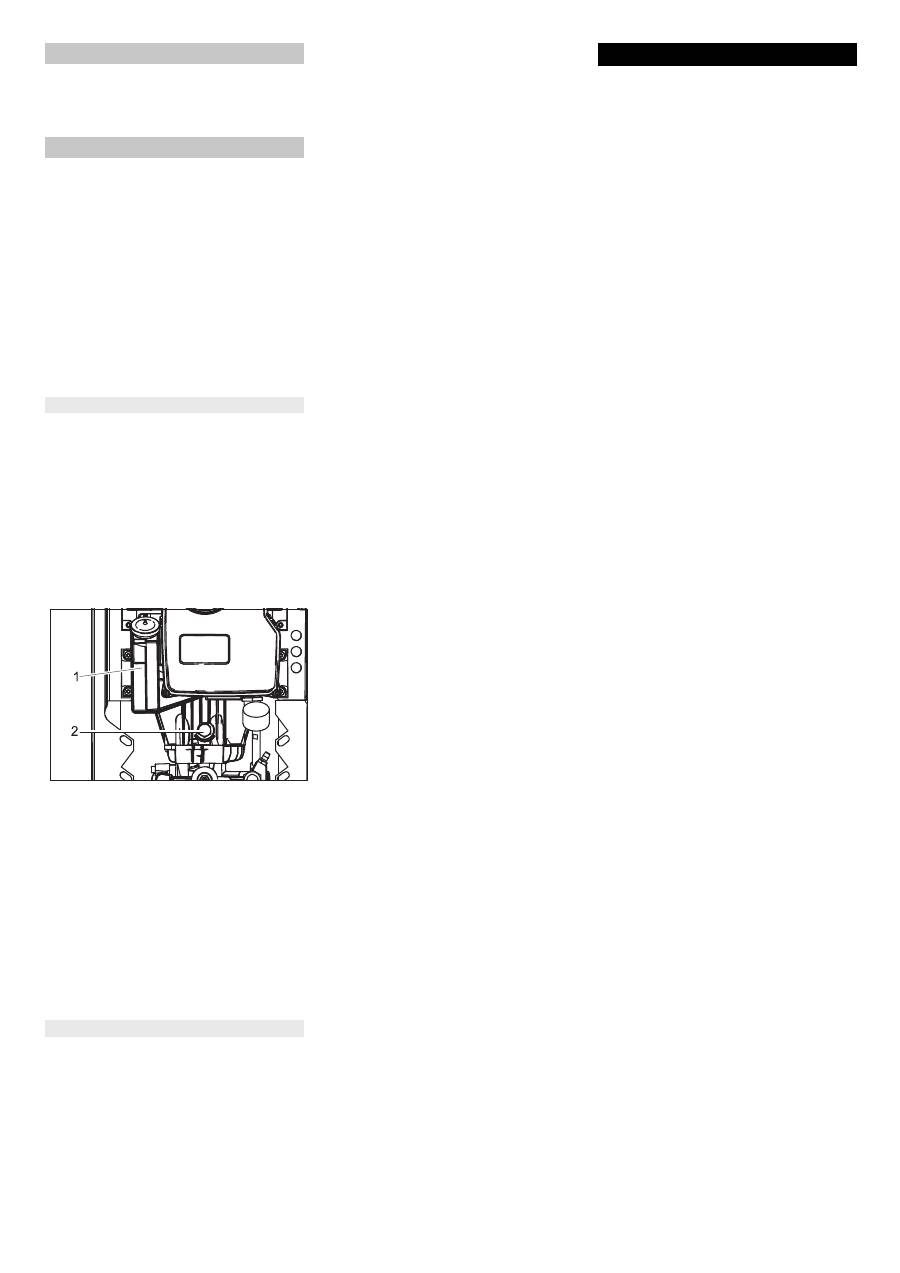

1 Oil tank

2 Oil drain screw

Place the collection trough under the oil

drain screw.

Remove the lid of the oil container.

Unscrew the oil drain screw and collect

oil.

Fix in the oil drain screw and tighten it.

Slowly fill in new oil until the "MAX"

marking on the oil container.

Attach the lid of the oil container.

Dispose of old oil ecologically or turn it

in at a collection point.

Calcium deposits can lead to:

– higher pipe resistances

– even to failure of the components with

heavy calcium deposits

DANGER

–

Risk of explosion due to combustible

gases! Smoking strictly prohibited dur-

ing decalcification. Ensure proper ven-

tilation.

–

Risk of chemical burns on account of

acid! Wear protective glasses and pro-

tective gloves.

Note:

– Follow the specifications of the accident

prevention regulation BGV A1.

– Follow instructions for use on the lable

of the decalcifying agent.

According to statutory requirements, only

tested and approved boiler decrusting

agents may be used.

– RM 100 (Order No. 6.287-008) dis-

solves chalk and simple compounds of

chalk and detergents residues.

– RM 101 (Order No. 6.287-013) dis-

solves the deposits that cannot be dis-

solved using RM 100.

Note:

As an anti-corrosion measure and for neu-

tralising the acid residue, we recommend

that you finally pump an alkaline solution

through the machine (for e.g. RM 81) via

the detergent tank.

First decalcify the swimmer tank.

Shut off water supply.

Remove the lid of the swimming tank.

Remove the hose from the suction site

of the pump for the swimming tank on

the pump site.

Seal the free end of the hose.

Fill in 7 percent decalcification solution.

Remove resin completely from the tank

after decalcification.

Decalcify the high pressure installation:

Remove the high pressure hose from

the network supply and hang it in the

swimmer tank.

Run the calcium dissolving acid mixture

prepared in the tank through the instal-

lation's cycle, allow it to take effect,

rinse.

DANGER

Risk of electric shock.

Risk of injury! Switch off the power switch

with all maintenance and repair work.

Pull the mains plug and secure it against

being plugged in again

DANGER

Risk of injury on account of the emanating

water jet that could be hot!

DANGER

Risk of accident while working on the unit!

During all tasks:

–

Close locking tap of fresh water.

–

Let the hot parts of the plant cool down.

–

Depressurise the plant by opening all

hand-spray guns.

Who may remedy faults?

Operator

Work designated with the sign “Opera-

tor” may only be carried out by persons

who have been instructed in the safe

operation and maintenance on the high

pressure plant.

Electricians

Only persons with a professional train-

ing in the electro-technical area.

Customer Service

Work designated with the sign “Cus-

tomer Service” may only be done by the

fitters of Kärcher Customer Service.

Maintenance contract

Maintenance Works

Oil change

Descaling

Troubleshooting

24

EN

-

8

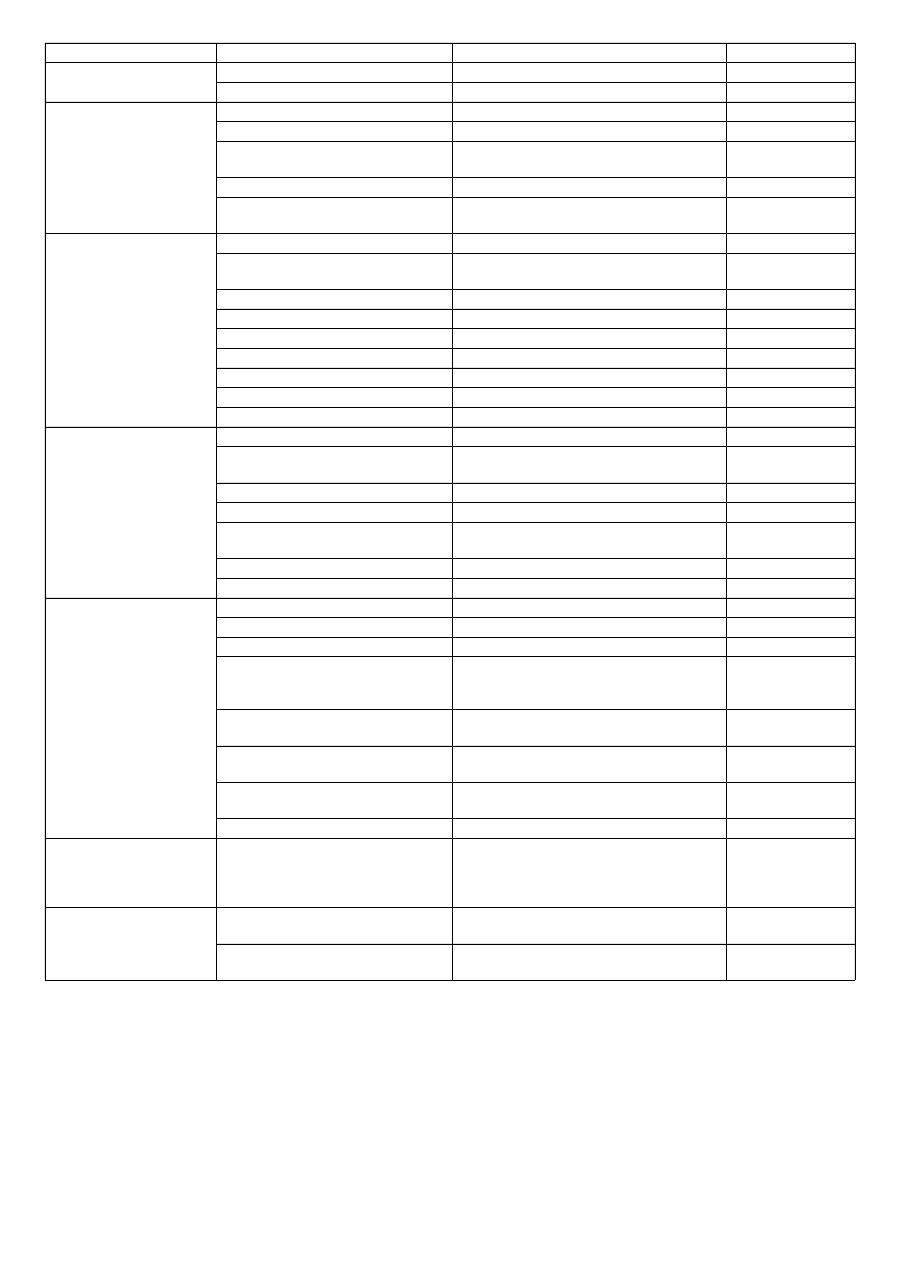

Fault

Possible cause

Remedy

of whom

Water stream is uneven.

Nozzle is blocked.

Clean the nozzle.

Operator

Amount of water supply is too low.

Check water supply.

Operator

Inadequate or no flow of de-

tergent

Dosage adjusted too low.

Increase dose.

Operator

Nozzle is set to "High pressure".

Set nozzle to "CHEM".

Operator

Suction filter in the detergent tank is

dirty.

Clean the suction filter.

Operator

Detergent suck hose leaking.

Replace suck hose.

Customer Service

Manual detergent dispensing valve oc-

cluded, defective.

Check; clean, replace, if required.

Customer Service

Pressure does not build up

in the pump

Nozzle is set to "CHEM"

Set nozzle to "High pressure".

Operator

Air in the high pressure pump

Ventilate the appliance (see "System start-

up")

Operator

Suction site pipe leaking.

Check screw fittings and hoses.

Operator

Not enough water

Ensure adequate water supply.

Operator

Sieve in the water inlet is dirty

Clean sieve.

Operator

High pressure hose leaking.

Replace high pressure hose.

Customer Service

Piping leaking.

Repair piping system.

Customer Service

Flow regulator defective.

Test flow regulator, repair.

Customer Service

The valve in the pump is defective.

Replace valve.

Customer Service

High pressure pump is

knocking; manometer (op-

tion) is swaying wildly

Vibration dampener is defective.

Replace vibration dampener.

Operator

Water pump does not suck in adequate

air.

Check suction system and remove leaks.

Operator

Detergent container is empty

Refill detergent tank.

Operator

Water flow temperature too hot.

Lower water temperature.

Operator

Water flow blocked.

Clean sieve in the water inlet, check the water

flow.

Operator

Valve plate or valve spring is defective. Replace parts

Customer Service

Advance pump calcified or defective. Check advance pump.

Operator

The installation does not

start when switched on or

when pressing the remote

control (optional).

Appliance switch is switched off

Turn it on.

Operator

On-board electricity supply interrupted. Turn it on.

Operator

Pressure switch is defective

Replace pressure switch.

Customer Service

Motor protection switch was trigged by

overflow or loss of a phase of the elec-

tricity supply.

Check the voltage of the three phases.

Electrician/ Custom-

er Service

Motor protection switch is set incorrect-

ly.

Adjust according to circuit diagram.

Electrician/ Custom-

er Service

Motor protection switch for controls and

advance pressure pump triggered.

Check motor protection switch.

Electrician/ Custom-

er Service

Control safety transformer defective.

Examine the cause, replace the control safety

device.

Electrician/ Custom-

er Service

Circuit board defective.

Check circuit board, replace if required.

Customer Service

Pump starts during the

stand-by period and not

when the hand spray gun is

opened.

Pressure switch or pressure switch ca-

ble defective.

Replace the pressure switch or cable.

Customer Service

Installation does not switch

off.

Pump is drawing in air over the empty

detergent tank.

Refill the detergent tank, ventilate suction

line.

Operator

Pressure switch is defective.

Replace pressure switch.

Electrician/ Custom-

er Service

25

EN

Оглавление

- Inhaltsverzeichnis

- Bestimmungsgemäße Verwendung

- Funktion

- Geräteelemente

- Transport Lagerung des Gerätes Pflege und Wartung

- Hilfe bei Störungen

- Technische Daten

- Zubehör

- Anlageninstallation

- EG-Konformitätserklärung

- Kundendienst

- Contents

- Proper use

- Function

- Device elements

- Transport Storing the device Maintenance and care

- Troubleshooting

- Technical specifications

- Accessories

- Installing the plant

- EC Declaration of Conformity

- Customer Service

- Πίνακας περιεχομένων

- Χρήση σύμφωνα με τους κανονισμούς

- Λειτουργία

- Στοιχεία συσκευής

- Μεταφορά Αποθήκευση της συσκευής Φροντίδα και συντήρηση

- Αντιμετώπιση βλαβών

- Τεχνικά χαρακτηριστικά

- Εξαρτήματα

- Εγκατάσταση μονάδας

- Δήλωση Συμμόρφωσης των Ε . Κ .

- Υπηρεσία εξυπηρέτησης πελατών

- İ çindekiler

- Kurallara uygun kullan ı m

- Fonksiyon

- Cihaz elemanlar ı

- Ta ş ı ma Cihaz ı n depolanmas ı Koruma ve Bak ı m

- Ar ı zalarda yard ı m

- Teknik Bilgiler

- Aksesuar

- Sistem tesisat ı

- AB uygunluk bildirisi

- Mü ş teri hizmeti

- Оглавление

- Использование по назначению

- Назначение

- Элементы прибора

- Транспортировка Хранение прибора

- Уход и техническое обслуживание

- Помощь в случае неполадок

- Технические данные

- Принадлежности

- Инсталляция оборудования

- Заявление о соответствии ЕС

- Сервисная служба

- Spis tre ś ci

- U ż ytkowanie zgodne z przeznaczeniem

- Funkcja

- Elementy urz ą dzenia

- Transport Przechowywanie urz ą dzenia Czyszczenie i konserwacja

- Usuwanie usterek

- Dane techniczne

- Akcesoria

- Instalacja urz ą dzenia

- Deklaracja zgodno ś ci UE

- Serwis firmy

- Sisukord

- Sihipärane kasutamine

- Funktsioon

- Seadme elemendid

- Transport Seadme ladustamine Korrashoid ja tehnohooldus

- Abi häirete korral

- Tehnilised andmed

- Tarvikud

- Seadme installeerimine

- EÜ vastavusdeklaratsioon

- Klienditeenindus

- Satura r ā d ī t ā js

- Noteikumiem atbilstoša lietošana

- Darb ī ba

- Apar ā ta elementi

- Transport ē šana Apar ā ta uzglab ā šana Kopšana un tehnisk ā apkope

- Pal ī dz ī ba darb ī bas trauc ē jumu gad ī jum ā

- Tehniskie dati

- Piederumi

- Iek ā rtas instal ā cija

- EK Atbilst ī bas deklar ā cija

- Klientu apkalpošanas dienests

- Turinys

- Naudojimas pagal paskirt į

- Veikimas

- Prietaiso dalys

- Transportavimas Į renginio laikymas Prieži ū ra ir aptarnavimas

- Pagalba gedim ų atveju

- Techniniai duomenys

- Dalys

- Prietaiso į rengimas

- EB atitikties deklaracija

- Klient ų aptarnavimo tarnyba

- Зміст

- Правильне застосування

- Призначення

- Елементи приладу

- Транспортування Зберігання пристрою Догляд та технічне обслуговування

- Допомога у випадку неполадок

- Технічні характеристики

- Аксесуари

- Монтаж обладнання

- Заява при відповідність Європейського співтовариства

- Служба підтримки користувачів