LG PQNFB17B0: инструкция

Раздел: Аксессуары для аудио

Тип:

Инструкция к LG PQNFB17B0

ENGLISH ITALIANO

ESPAÑOL

FRANÇAIS

DEUTSCH CHINESE

РУССКИЙ ЯЗЫК

INSTALLATION/OWNER MANUAL

AIR CONDITIONER

Please read this manual carefully before operating

your set and retain it for future reference.

TYPE : BNU-BAC(BACnet Gateway)

P/NO : MFL37115823

www.lg.com

BNU-BAC(BACnet Gateway)

TABLE OF CONTENTS

Safety Precautions .....................................................................................................3-6

Main Features & Specification ................................................................................7-10

Denomination for each component............................................................................11

How to install

- System Diagram ...............................................................................................12-13

- Installation Order....................................................................................................14

- Hardware Installation ........................................................................................15-21

- Software Installation .........................................................................................22-27

LG's BACnet Gateway Agreement .............................................................................28

Test Operation Procedure......................................................................................29-48

Function Specifications BACnet Gateway

- Summary................................................................................................................49

- Configuration of Connection ..................................................................................49

- Monitoring and Controlling Items of A/C ................................................................50

- Monitoring and Controlling point of indoor and ventilator.......................................51

BACnet Protocol Implementation Conformance Statement(PICS)

- BACnet Protocol Implementation Conformance Statement..............................52-53

Objects (BACnet/IP)

- Supported Object Type ..........................................................................................54

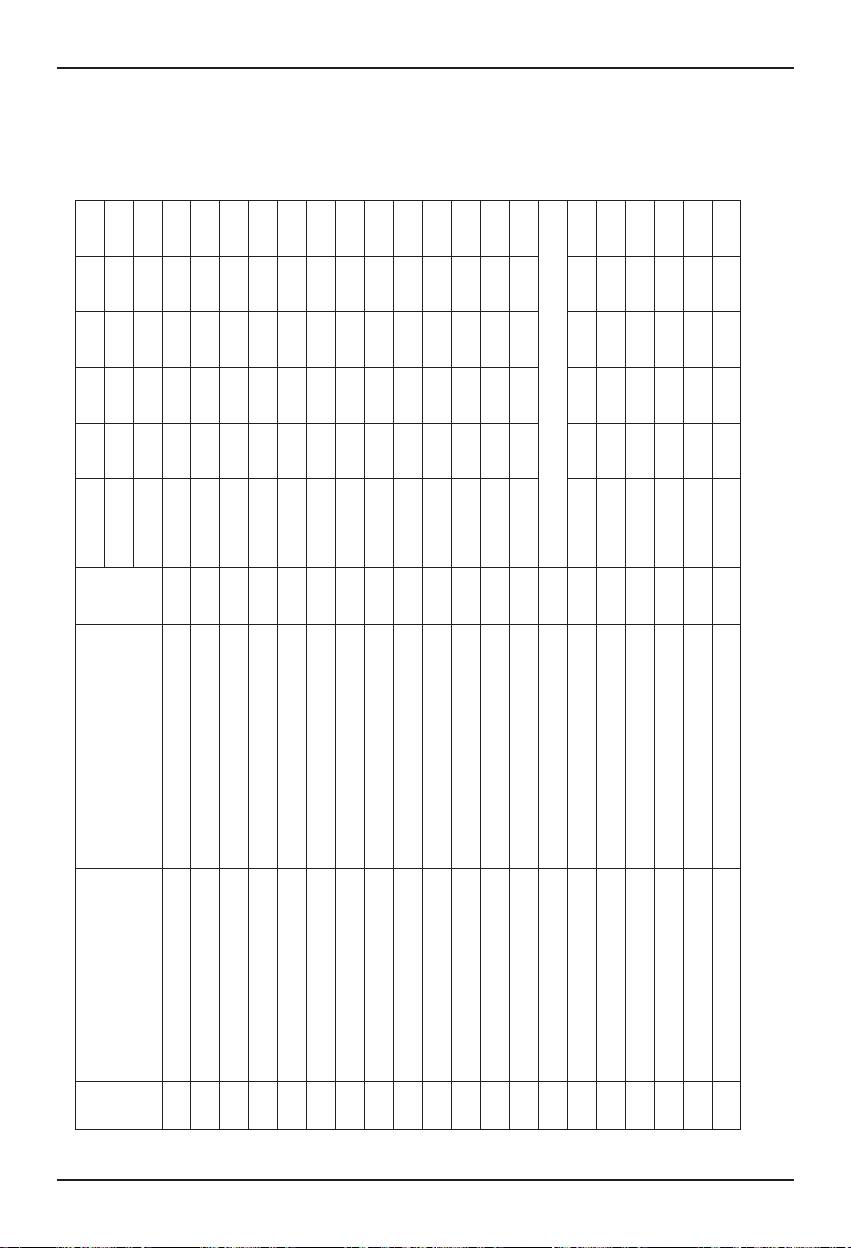

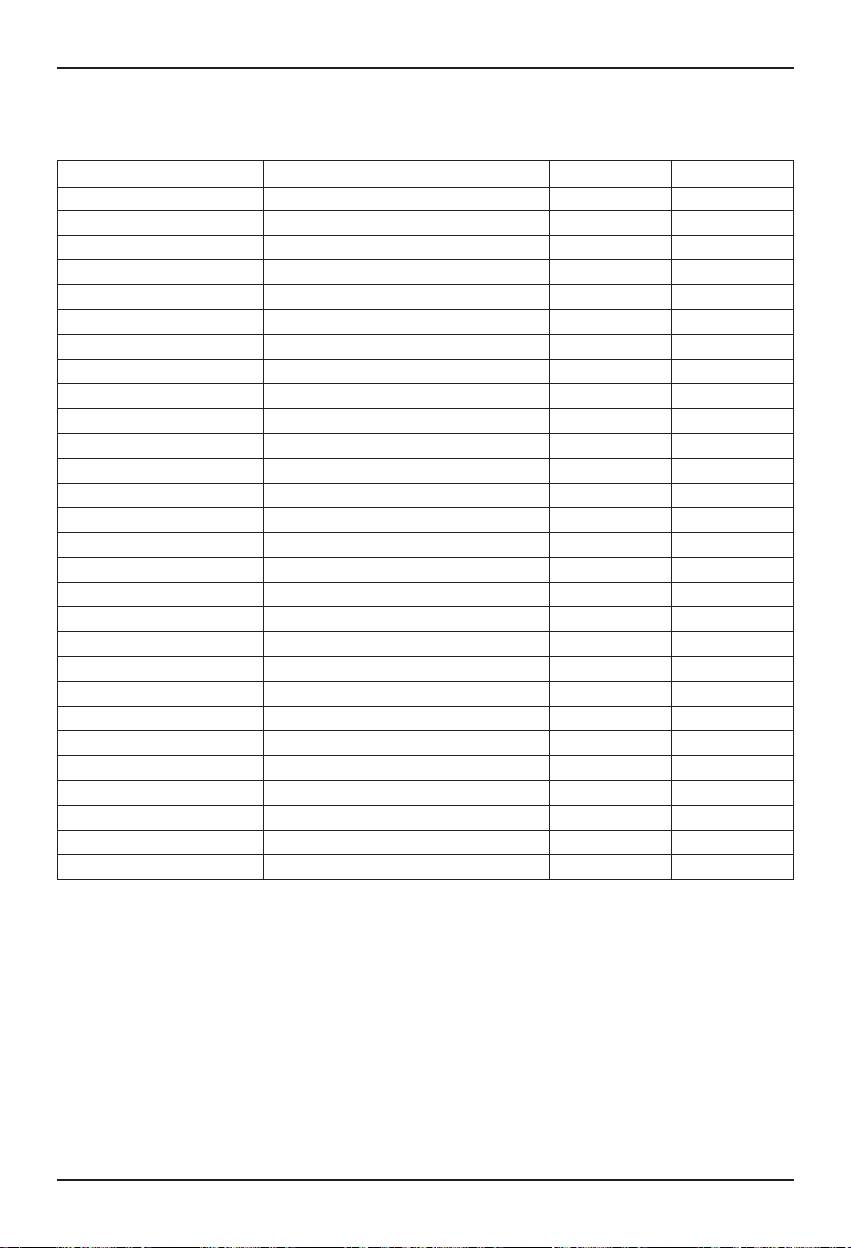

- BACnet Point List : Indoor Unit ........................................................................55~56

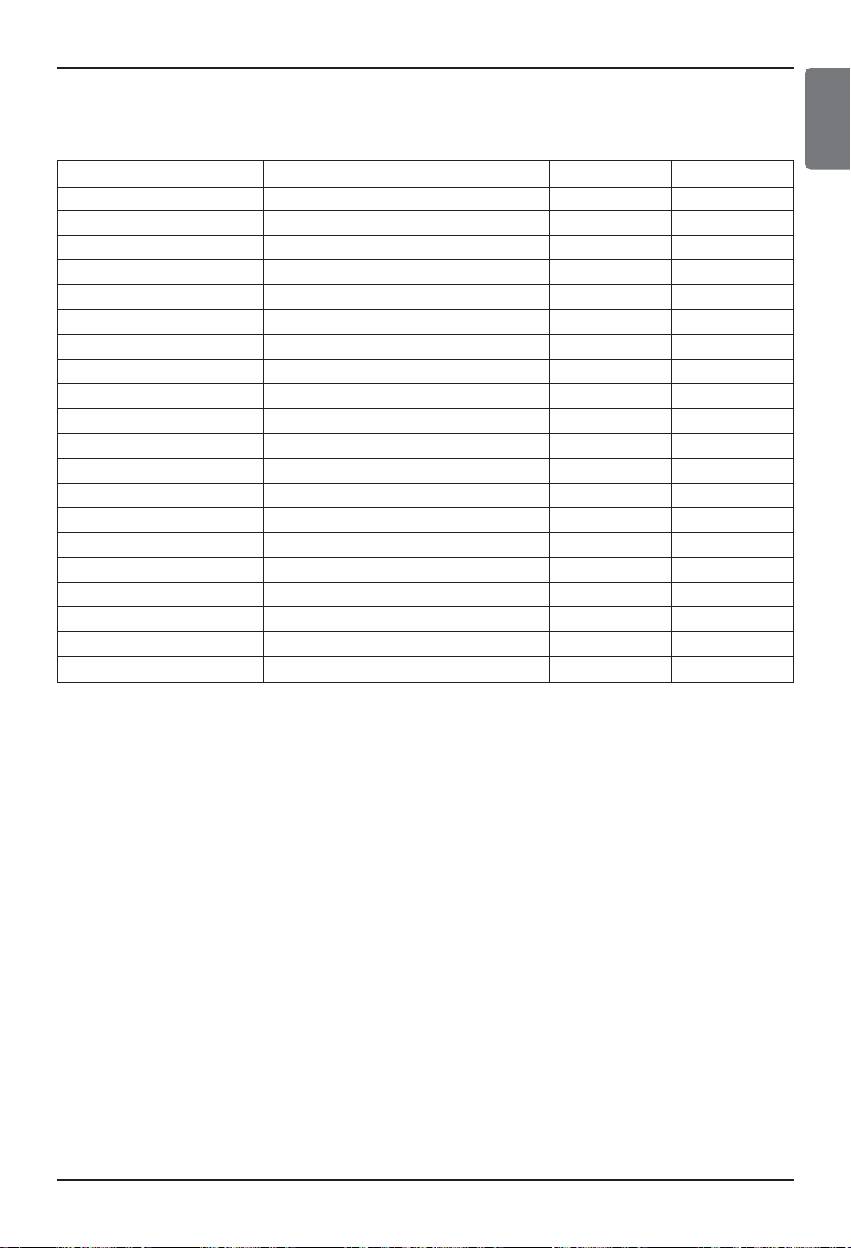

- BACnet Point List : Ventilation .........................................................................57~58

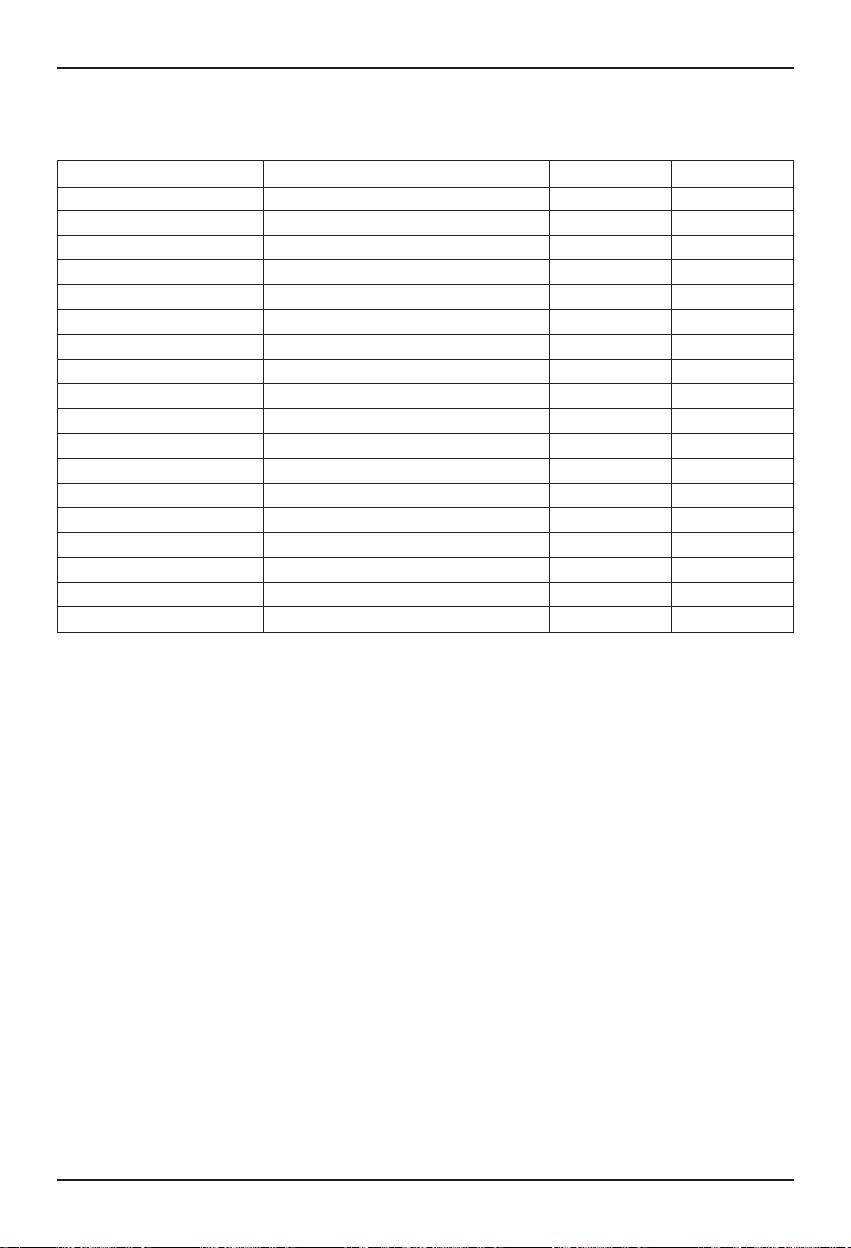

- BACnet Point List : AHU ..................................................................................59~62

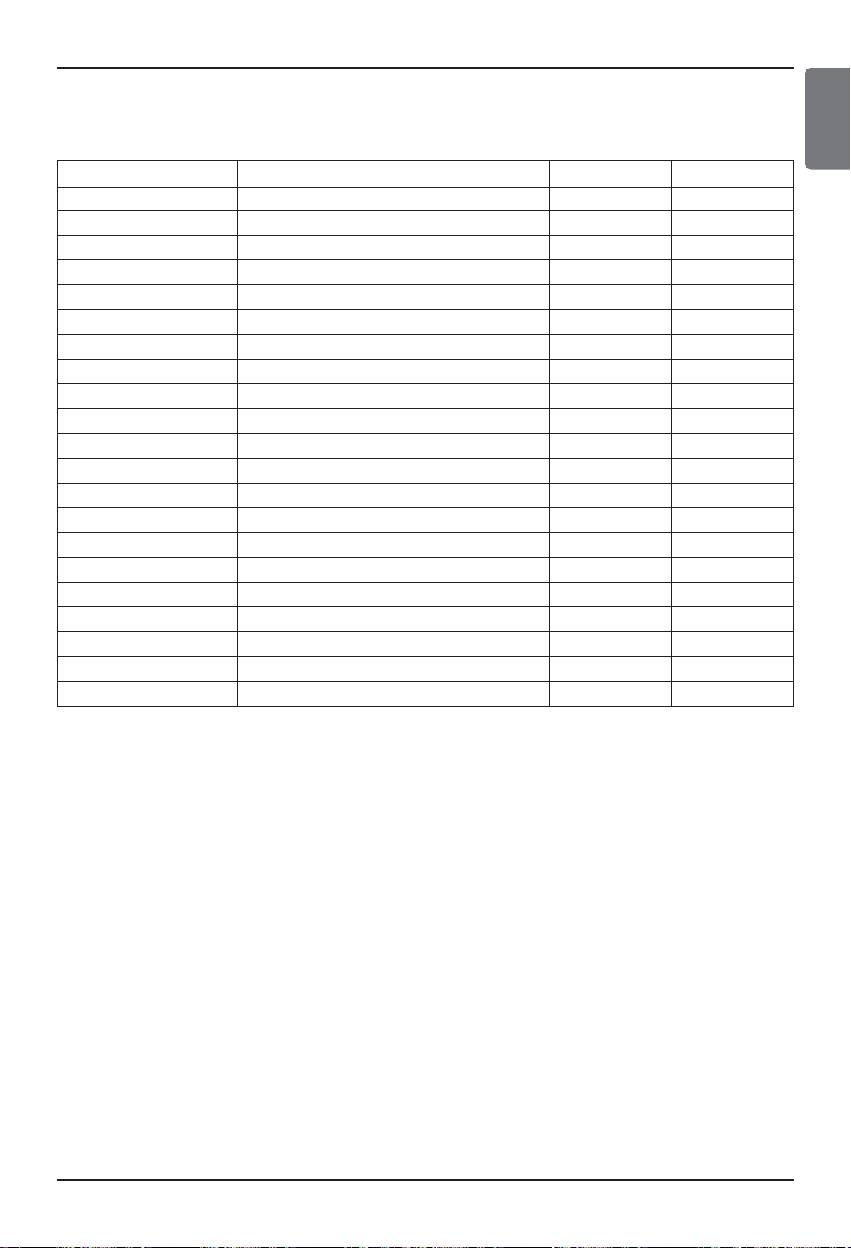

- Example of Point Table ..........................................................................................63

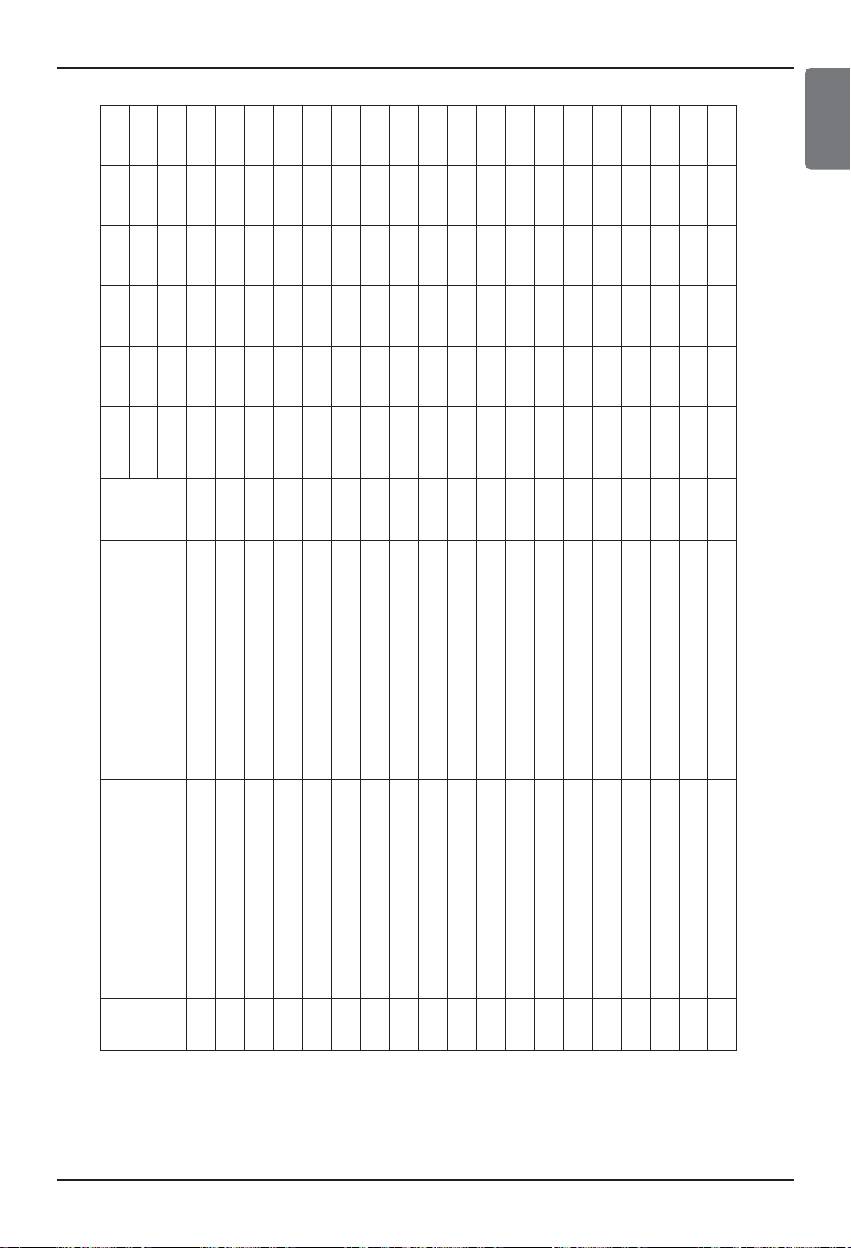

Objects (Modbus-TCP)

- Supported Function Code ......................................................................................64

- Modbus Point List : Indoor Unit........................................................................65~66

- Modbus Point List : Vent ..................................................................................67~68

- Modbus Point List : AHU..................................................................................69~72

- Example of Point Table ....................................................................................73~74

Detailed Explanation of Object.............................................................................75~83

Initialization at the Start Up ........................................................................................84

Report Function

- Event Notification ...................................................................................................84

- COV(Change Of Value) Notification.......................................................................85

Trouble Shooting ...................................................................................................86~90

How to differentiate between Direct Cable & Cross Cable ......................................91

Guide for the open source software ..........................................................................92

Appendix1. BACnet Interoperability Building Blocks Supported(BIBBs)........93~97

Appendix2. Object Property table......................................................................98~106

Appendix3. BACnet Gateway Error Response table ..............................................107

Note : After the LC BACnet Gateway agreement part, please scrutinize with Companies specialized in BMS.

2 BACnet Gateway

Safety Precautions

■ Operation

Do not operate or stop

Ask for Product

Use standard parts.

the unit by inserting or

equipment at the service

pulling out the power

center or establishment

plug.

certainly at the specialty

store.

• Use of non standard parts

• It will cause electric shock

• It can cause an accident,

can cause electric shock,

or fire due to heat

electric shock, explosion

explosion, injury,

generation.

or injury.

breakdown.

Installation/Owner Manual 3

LG-NET 1

TX

RX

1

2

DI

LG-NET 2

TX

RX

3

LG-NET 3

TX

4

5

LG-NET 4

RX

TX

6

RX

7

8

9

10

Ext 1

TX

RX

11

Ext 2

TX

12

RX

13

14

15

16

Ethernet 1

ACT

17

18

MENU/

LNK

19

SELECT

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

LG-NET 1

TX

RX

1

2

DI

LG-NET 2

TX

3

LG-NET 3

RX

TX

4

RX

5

TX

6

LG-NET 4

RX

7

8

9

Ext 1

TX

10

11

Ext 2

RX

TX

12

RX

13

14

15

16

Ethernet 1

ACT

17

18

MENU/

LNK

19

SELECT

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions

must be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

WARNING

CAUTION

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage.

Be sure not to do.

Be sure to follow the instruction.

WARNING

ENGLISH

Standard Parts

If water enters the product, turn the power

Keep the product away from the places

switch of the main body of appliance off.

which can have moisture.

• After taking the power-plug out from the

• Water may enter the unit and degrade the

socket, contact the service center.

insulation. It may cause an electric shock.

LG-NET 1

TX

RX

1

2

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

5

TX

6

RX

7

8

9

10

Ext 1

TX

11

12

Ext 2

RX

TX

RX

13

14

15

16

Ethernet 1

ACT

17

18

MENU/

LNK

19

SELECT

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

1

DI

LG-NET 1

TX

2

RX

3

TX

4

LG-NET 2

5

LG-NET 3

LG-NET 4

RX

TX

6

RX

7

TX

8

RX

9

10

11

12

Ext 1

13

14

Ext 2

TX

RX

TX

15

16

17

18

MENU/

Ethernet 1

Ethernet 2

ACT

RX

19

20

SELECT

LNK

ACT

LNK

Console

TX

RX

1

2

3

4

DO

Run

Power

While re-installing the

Do not use the power cord

Do not disjoint randomly

established product, notify

near Flammable gas or

or repair and remodel the

the service center or

combustibles, such as

product.

establishment specialty

gasoline, benzene, thinner,

store.

etc.

• It can cause an accident,

• It may cause an explosion

• It may cause fire and

electric shock, explosion,

or fire

electric shock

injury.shock.

■ During usage

LG-NET 1

TX

RX

1

2

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

5

TX

6

RX

7

8

9

10

Ext 1

TX

11

12

Ext 2

RX

TX

RX

13

14

15

16

Ethernet 1

ACT

17

18

MENU/

LNK

19

SELECT

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

LG-NET 1

TX

RX

1

TX

2

DI

LG-NET 2

3

LG-NET 3

RX

TX

4

LG-NET 4

RX

5

TX

6

RX

7

8

9

TX

10

Ext 1

11

Ext 2

RX

TX

12

RX

13

14

15

16

Ethernet 1

ACT

17

18

MENU/

LNK

19

SELECT

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

Thinner

Wax

LG-NET 1

TX

RX

1

2

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

5

TX

6

RX

7

8

9

10

Ext 1

TX

11

12

Ext 2

RX

TX

RX

13

14

15

16

Ethernet 1

ACT

17

18

MENU/

LNK

19

SELECT

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

Do not change or extend the

Do not use concert with in

Unplug the unit if strange

conductor at random.

the octopus-like legs way.

sounds, smell, or smoke

comes from it.

• It can cause fire and

• It can cause fire and

• It may cause fire and

electric shock.

electric shock

electric shock accident.

LG-NET 1

TX

RX

1

2

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

5

TX

6

RX

7

8

9

10

Ext 1

TX

11

12

Ext 2

RX

TX

RX

13

14

15

16

Ethernet 1

ACT

17

18

SELECT

MENU/

LNK

19

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

Safety Precautions

4 BACnet Gateway

Do not put firearms near

Do not put an electric heater

Do not spill water inside

product.

or conductor near to the

product.

product.

• It can cause fire.

• It can cause fire and

• It can cause electric

electric shock.

shock and breakdown.

2

3

1

D

I

6

4

7

5

8

LG

L

-N

E

T 1

9

T

X

10

R

X

11

1

2

LG

L

G

G

-N

-

N

-N

E

E

T

2

T

3

R

X

TX

1

1

13

4

5

E

T

4

T

TX

X

R

X

X

18

1

6

R

1

1

7

E

xt 1

T

X

20

9

M

E

E

S

xt 2

R

X

E

L

N

U

TX

E

C

/

T

R

X

E

th

e

r

net

1

A

E

C

the

T

r

net

2

L

A

C

LN

T

K

N

K

2

1

C

ons

o

le

4

3

D

O

T

R

X

X

R

Po

u

n

w

e

r

LG-NET 1

TX

RX

1

2

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

5

TX

6

RX

7

8

9

10

Ext 1

TX

11

12

Ext 2

RX

TX

RX

13

14

15

16

Ethernet 1

ACT

17

18

MENU/

LNK

19

SELECT

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

LG-NET 1

TX

RX

1

2

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

5

TX

6

RX

7

8

9

10

Ext 1

TX

11

12

Ext 2

RX

TX

RX

13

14

15

16

Ethernet 1

ACT

17

18

SELECT

MENU/

LNK

19

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

Do not place heavy goods

Hold the plug by the head of

Do not place heavy goods

on wire.

the power plug when taking

on product.

it out.

• It can cause fire and

• It may cause electric

• It can cause product

electric shock.

shock and damage.

breakdown.

LG-NET 1

TX

RX

1

2

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

5

TX

6

RX

7

8

9

10

Ext 1

TX

11

12

Ext 2

RX

TX

RX

13

14

15

16

Ethernet 1

ACT

17

18

MENU/

LNK

19

SELECT

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

LG-NET 1

TX

RX

2

1

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

TX

6

5

RX

8

7

10

9

Ext 1

TX

12

11

Ext 2

RX

TX

RX

14

13

16

15

Ethernet 1

ACT

18

17

MENU/

LNK

SELECT

Ethernet 2

ACT

20

19

LNK

Console

TX

RX

2

1

3

DO

Run

4

Power

That increase in case of

Protect the product from

Do not apply shock to

product was been flood

handling by a children.

product.

certainly in the service

center or establishment

specialty store commit .

• I am responsible for fire

• It can cause accident and

• I am responsible for

and electric shock.

product breakdown.

breakdown in case of

shock to product.

LG-NET 1

TX

RX

2

1

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

5

TX

6

RX

7

8

9

10

Ext 1

TX

11

12

Ext 2

RX

TX

RX

13

14

15

16

Ethernet 1

ACT

17

18

MENU/

LNK

19

SELECT

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

LG-NET 1

TX

RX

2

1

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

TX

6

5

RX

8

7

10

9

Ext 1

TX

12

11

Ext 2

RX

TX

RX

14

13

16

15

Ethernet 1

ACT

18

17

MENU/

LNK

SELECT

Ethernet 2

ACT

20

19

LNK

Console

TX

RX

2

1

3

DO

Run

4

Power

LG-NET 1

TX

RX

1

2

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

5

TX

6

RX

7

8

9

10

Ext 1

TX

11

12

Ext 2

RX

TX

RX

13

14

15

16

Ethernet 1

ACT

17

18

MENU/

LNK

19

SELECT

Ethernet 2

ACT

20

LNK

Console

TX

RX

1

2

3

DO

Run

4

Power

Safety Precautions

ENGLISH

Installation/Owner Manual 5

■ During usage

CAUTION

Clean by soft hands using a

Use touch screen with a pen

Do not place any live part on

cleaning material like a soft

that product offers.

the surface having water.

cloth.

• It can result in fire and

• Otherwise, there can be

• It can cause product

product transformation.

breakdown and damage

breakdown.

to the product.

LG-NET 1

TX

RX

2

1

DI

LG-NET 2

TX

RX

TX

4

3

LG-NET 3

RX

TX

6

5

LG-NET 4

RX

8

7

TX

10

9

Ext 1

RX

12

11

Ext 2

TX

RX

14

13

16

15

Ethernet 1

ACT

18

17

SELECT

MENU/

LNK

20

19

Ethernet 2

ACT

LNK

Console

TX

RX

2

1

3

DO

Run

4

Power

T

hinner

Wax

LG-NET 1

TX

RX

2

1

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

TX

6

5

RX

8

7

10

9

Ext 1

TX

12

11

Ext 2

RX

TX

RX

14

13

16

15

Ethernet 1

ACT

18

17

SELECT

MENU/

LNK

19

Ethernet 2

ACT

20

LNK

Console

TX

RX

2

1

3

DO

Run

4

Power

LG-NET 1

TX

RX

2

1

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

6

5

TX

7

RX

8

10

9

Ext 1

TX

12

11

Ext 2

RX

TX

RX

14

13

16

15

17

MENU/

Ethernet 1

ACT

LNK

18

SELECT

ACT

20

19

Ethernet 2

LNK

Console

TX

RX

2

1

3

DO

Run

4

Power

Use recommended Adapter.

Avoid contact to the metallic

Hold the plug by the head of

goods such as necklace,

the power plug when taking

coin, key, a watch which

it out.

may touch the battery even

for a short-time.

• It may cause product

• It may cause electric

• Otherwise it can result in

breakdown and injury.

shock and damage.

product breakdown

LG-NET 1

TX

RX

2

1

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

TX

6

5

RX

8

7

10

9

Ext 1

TX

12

11

Ext 2

RX

TX

RX

14

13

16

15

Ethernet 1

ACT

18

17

MENU/

LNK

SELECT

Ethernet 2

ACT

20

19

LNK

Console

TX

RX

2

1

3

DO

Run

4

Power

LG-NET 1

TX

RX

2

1

DI

LG-NET 2

TX

LG-NET 3

RX

3

TX

4

LG-NET 4

RX

TX

6

5

RX

8

7

10

9

Ext 1

TX

12

11

Ext 2

RX

TX

RX

14

13

16

15

Ethernet 1

ACT

18

17

MENU/

LNK

SELECT

Ethernet 2

ACT

20

19

LNK

Console

TX

RX

2

1

3

DO

Run

4

Power

Safety Precautions

6 BACnet Gateway

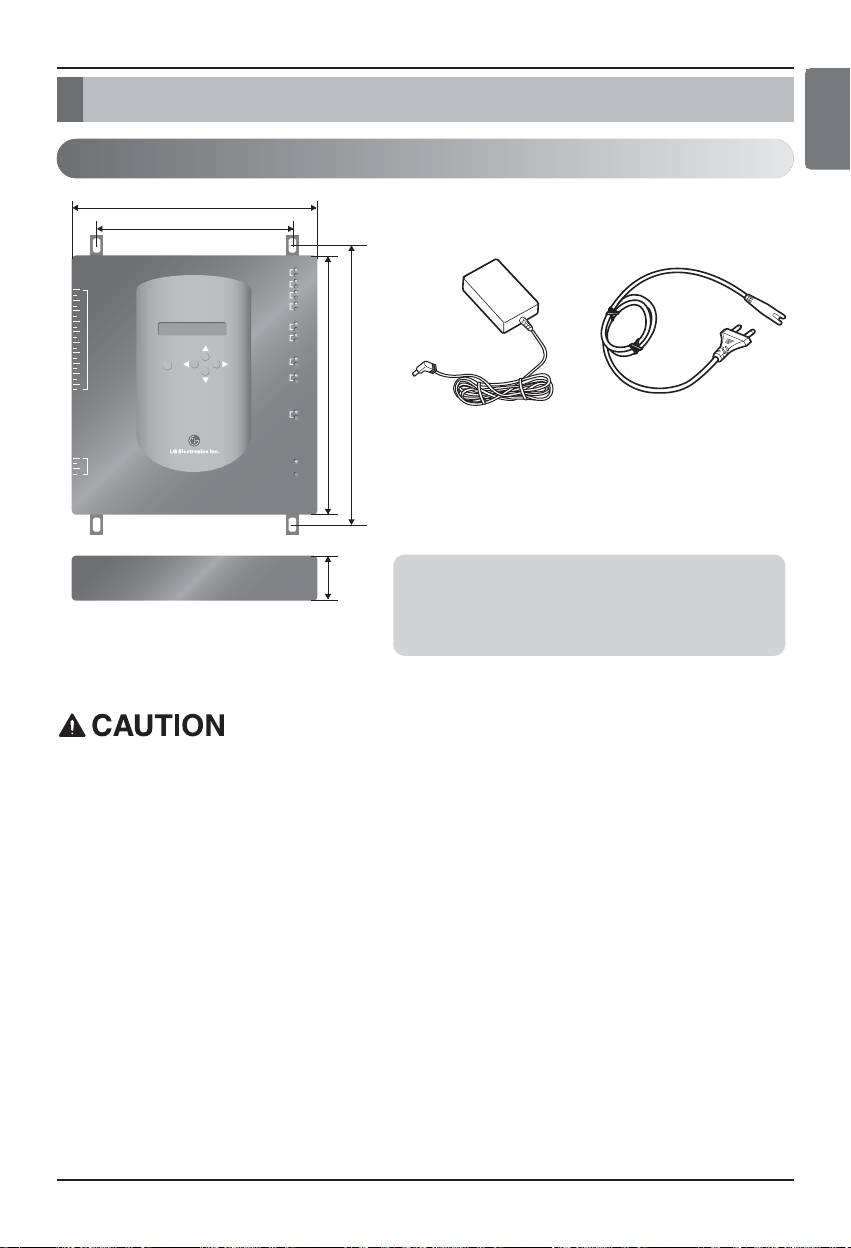

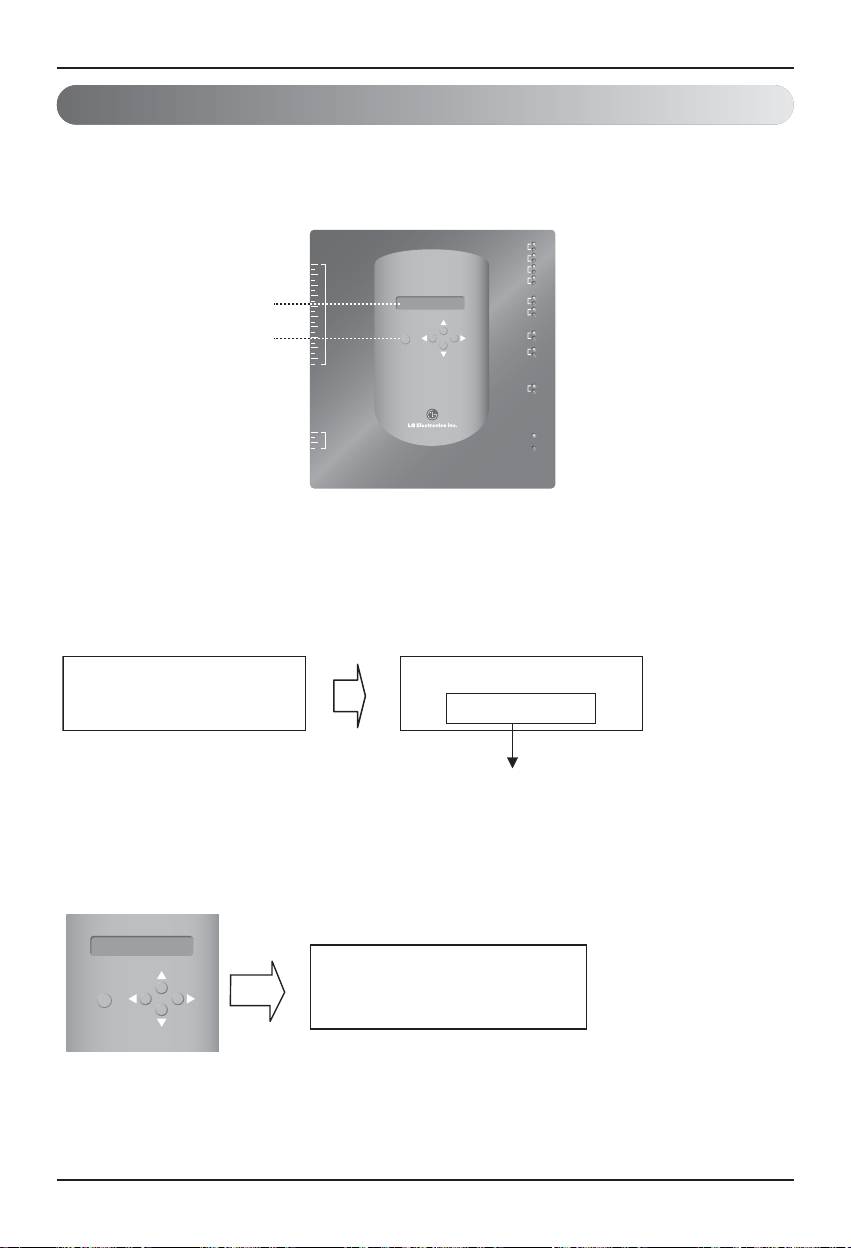

Main features & Specification

273mm

180mm

LG-NET 1

TX

RX

LG-NET 2

TX

1

RX

2

DI

LG-NET 3

TX

3

RX

4

LG-NET 4

TX

5

RX

6

7

8

Ext 1

TX

9

RX

10

Ext 2

TX

11

RX

12

13

14

Ethernet 1

ACT

15

LNK

250mm

273mm

16

17

MENU/

18

SELECT

Ethernet 2

ACT

LNK

19

20

Console

TX

RX

DC adaptor for power supply

Power Cord

1

2

DO

Run

3

Input : 100~240V

250V AC, 3A

4

Power

AC 50/60Hz 1.5A

International

Output : DC 12V

Standard

3.33A, 40W MAX

IEC320 C14 Type

57mm

Notice :

In Australia, purchase the power code

BACnet Gateway dimension

from local area.

The power code is not included in the package.

Main features & Specification

ENGLISH

Components

We are not liable for the problem caused by using the adaptor not supplied by us, so do

not use the product not supplied by us. For more information about the applicable product,

contact with the LG system air conditioner supporting division.

Installation/Owner Manual 7

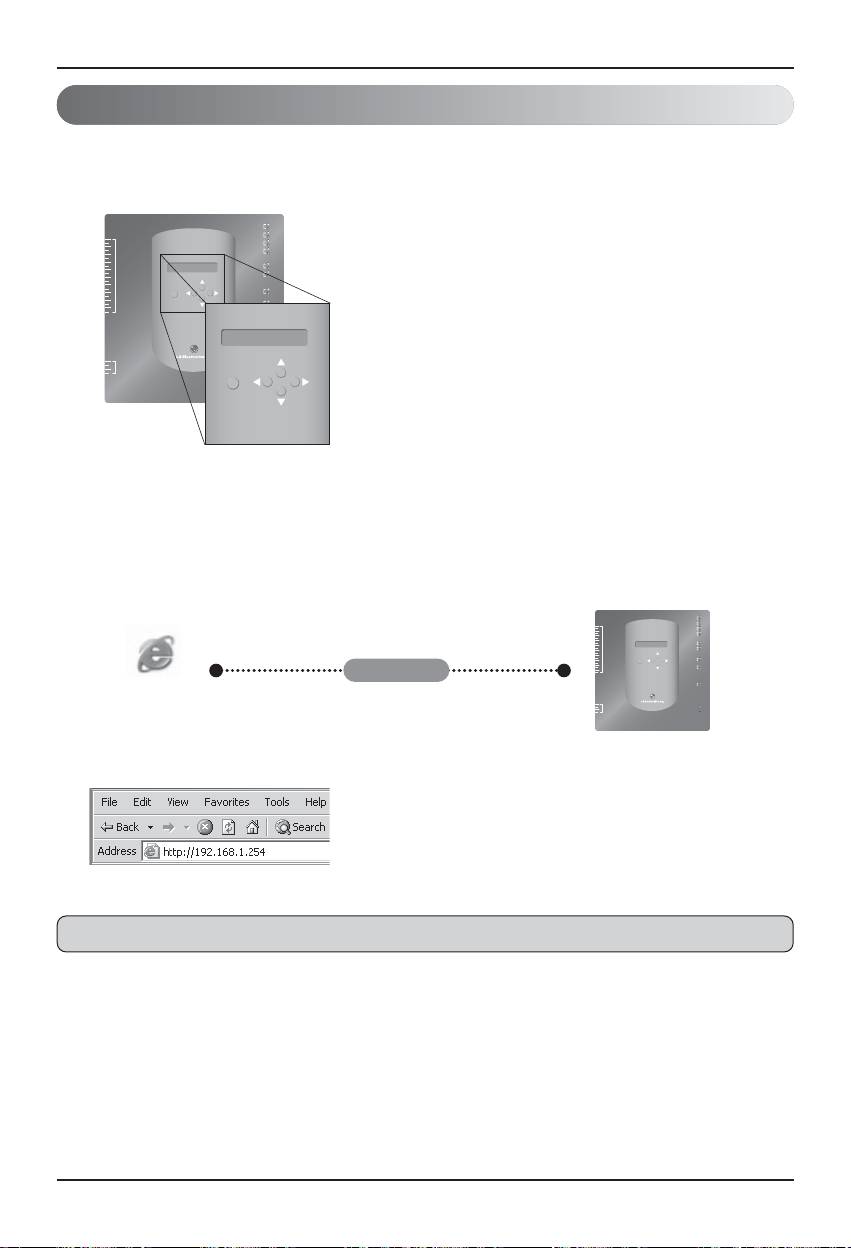

Main features

(1) Environment setup by using the BACnet Gateway button : Network

environment setup

(2) Web server built-in features

Enter the IP address of the BACnet Gateway at the address window by using the Internet

Explorer without installing a separate PC program to access the BACnet Gateway Web Server for

controlling and monitoring the indoor unit/ventilator.

• Controlling 256 air conditioner indoor units and

ventilators at maximum

• Monitoring the error and the operating status

Note: For more information about the detailed features, see the operation section.

LG-NET 1

TX

RX

LG-NET 2

TX

1

RX

2

DI

3

LG-NET 3

TX

RX

4

LG-NET 4

TX

5

RX

6

7

8

TX

9

Ext 1

RX

10

11

Ext 2

TX

RX

12

13

14

15

Ethernet 1

ACT

16

LNK

17

SELECT

MENU/

18

Ethernet 2

ACT

19

LNK

20

Console

TX

RX

1

2

DO

Run

3

4

Power

MENU/

SELECT

LG-NET 1

TX

RX

2

1

LG-NET 2

TX

DI

RX

3

LG-NET 3

TX

4

RX

5

LG-NET 4

TX

6

RX

8

7

9

Ext 1

TX

10

RX

11

Ext 2

TX

12

RX

14

13

ACT

16

15

Ethernet 1

LNK

18

17

MENU/

SELECT

Ethernet 2

ACT

LNK

20

19

Internet

Console

TX

RX

Internet

Explorer

2

1

3

DO

Run

4

Power

Main features & Specification

8 BACnet Gateway

Main features & Specification

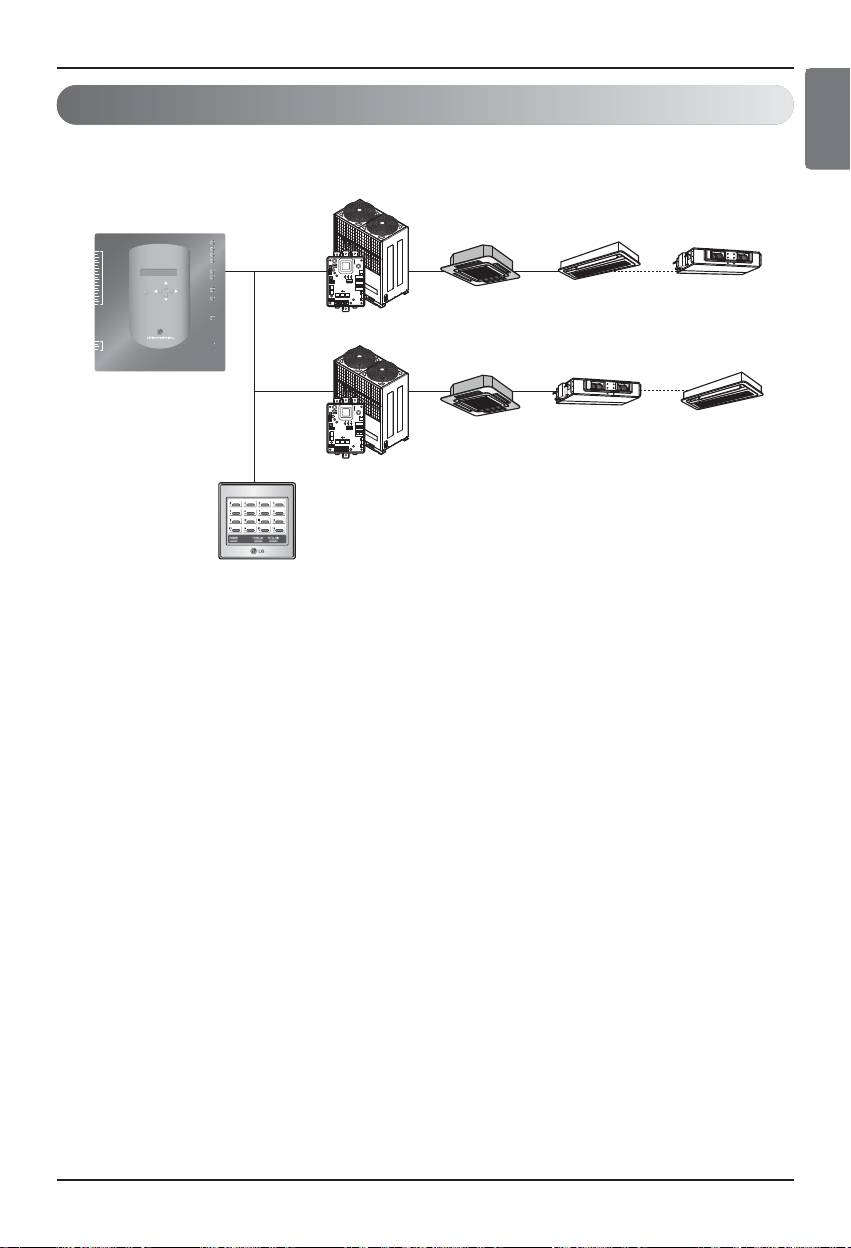

(3) Possible to use together with the simple central controller

It is possible to use the BACnet Gateway by connecting the 16-room simple central controller to

the PI485.

(4) Interlocking Fire feature

The fire is controlled via the extended DI port (DI Port 4). When a fire breaks out, all indoor units

and ventilators on the LG-net are turned off.

Multi V

LG-NET 1

TX

RX

LG-NET 2

TX

2

1

DI

RX

TX

RX

4

3

LG-NET 3

LG-NET 4

RX

6

5

TX

8

7

TX

10

9

Ext 1

RX

Ext 2

TX

12

11

RX

ON

L1 2 3 4

KSDO4H

14

13

16

15

Ethernet 1

ACT

LNK

PI485

18

17

MENU/

19

SELECT

Ethernet 2

ACT

LNK

.......................

20

(0.0) (0.1)

(0.F)

Console

TX

RX

Central control

address

2

1

DO

Run

4

3

Power

........

Multi V

BACnet Gateway

ON

L1 2 3 4

KSDO4H

PI485

(F.0) (F.1)

.......................

(F.F)

Central control

address

Simple central controller

Main features & Specification

ENGLISH

Installation/Owner Manual 9

Main features & Specification

Specification (hardware)

1. CPU: PXA256-400MHz Xscale

2. RAM: 128MB (32 x 4) SDRAM

3. ROM: 512KB NOR Flash – Boot image

128MB (64 x 2) NAND Flash – Program image, database, etc.

4. RS-232 Console : For updating (developing) the program

5. Communication port

• RS-485 port : PI485 communication port 4EA (connecting the air conditioner and the ventilator),

RS-485 port 2EA for connecting the outdoor unit (reserved)

• RS-232 communication port : Port 1EA for upgrading the program

• LAN port : 1EA for the Internet connection (Ethernet 10Base-T Ethernet)

1EA for reserved

6. External input port: 20EA (Pulse countable, DC 12V) extended to the external

External output port : Digital output x 4EA (Relay output, 5V) – DO2~4 : reserved

7. LED: 20EA (RS-485 communication status display / Ethernet communication status display /

RS-232 communication status display / Power & operation status display)

8. LCD : 16 x 2 character

IP address setup and Network environment & information display

Note: This product conforms to the GPL (General Public License) for using the Embedded Linux.

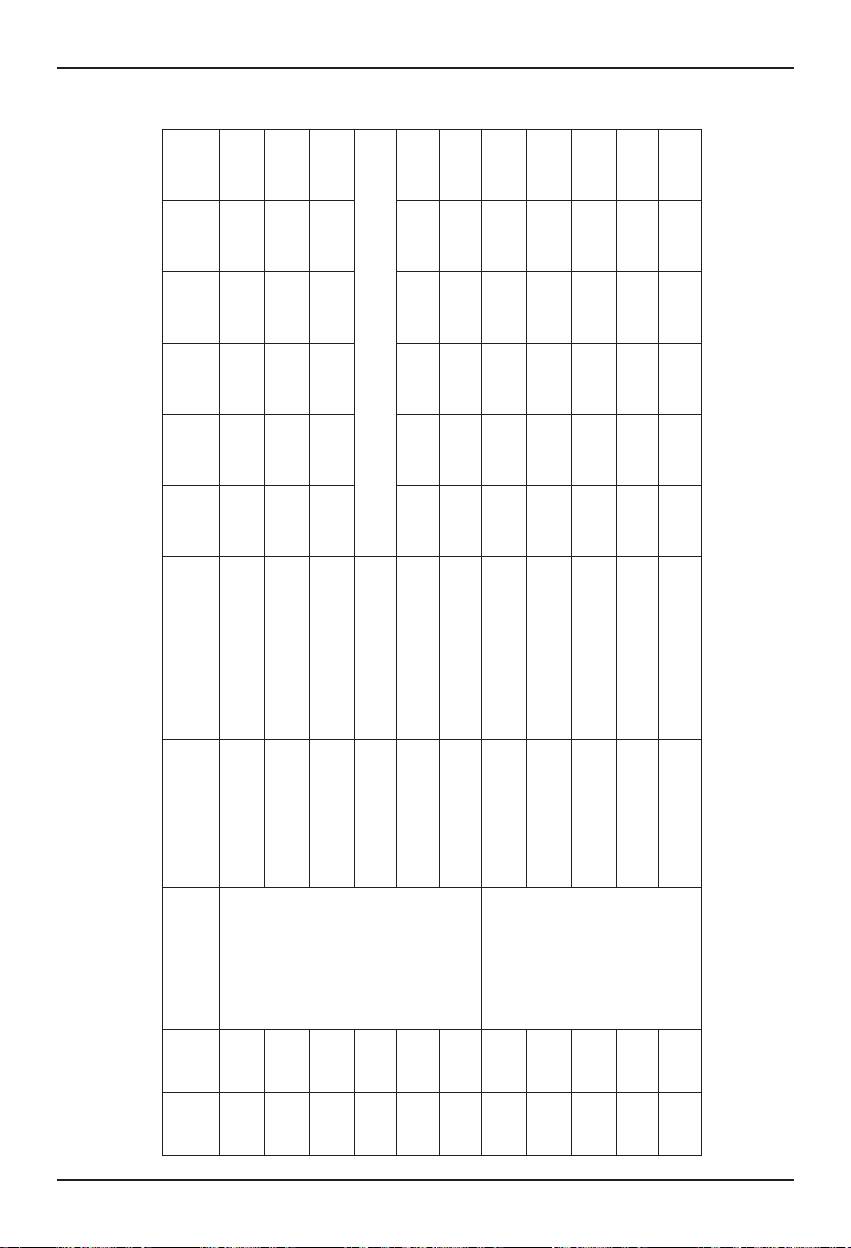

10 BACnet Gateway

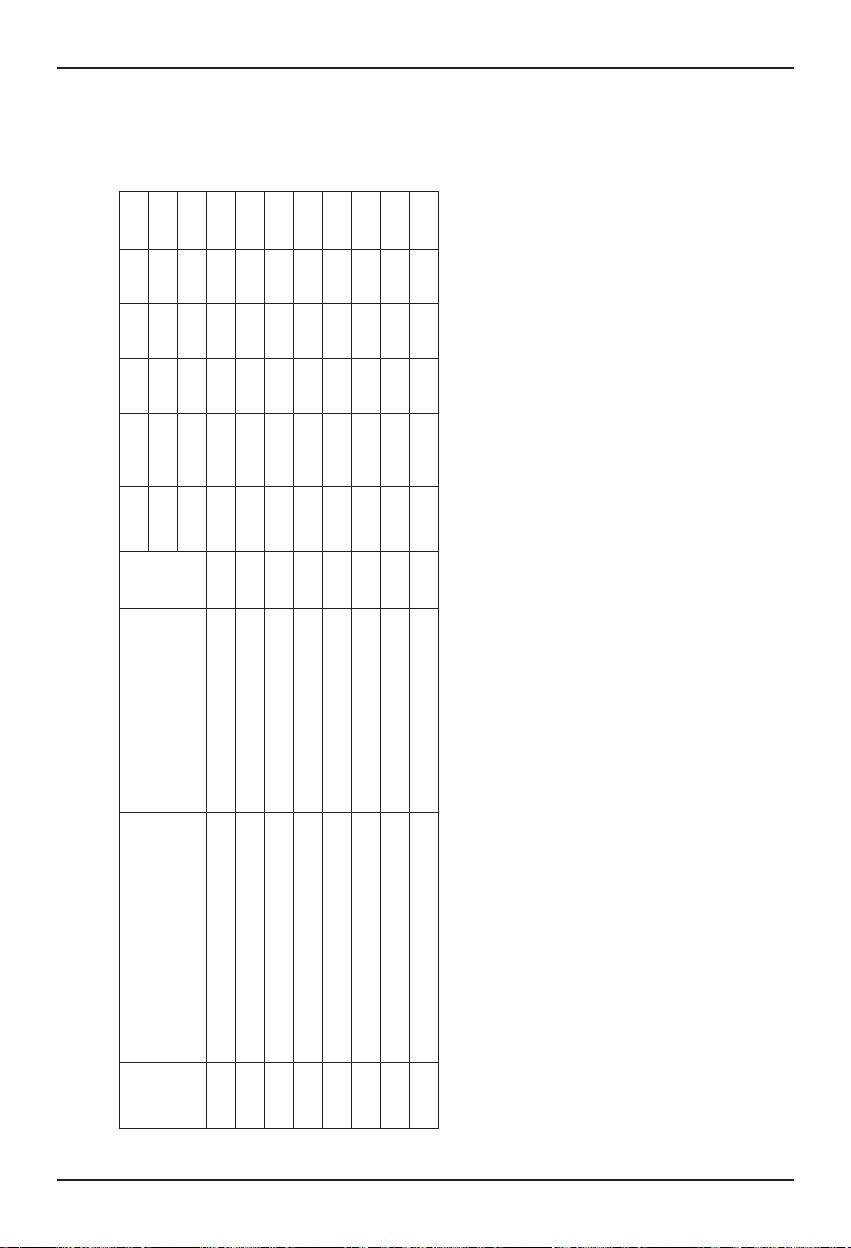

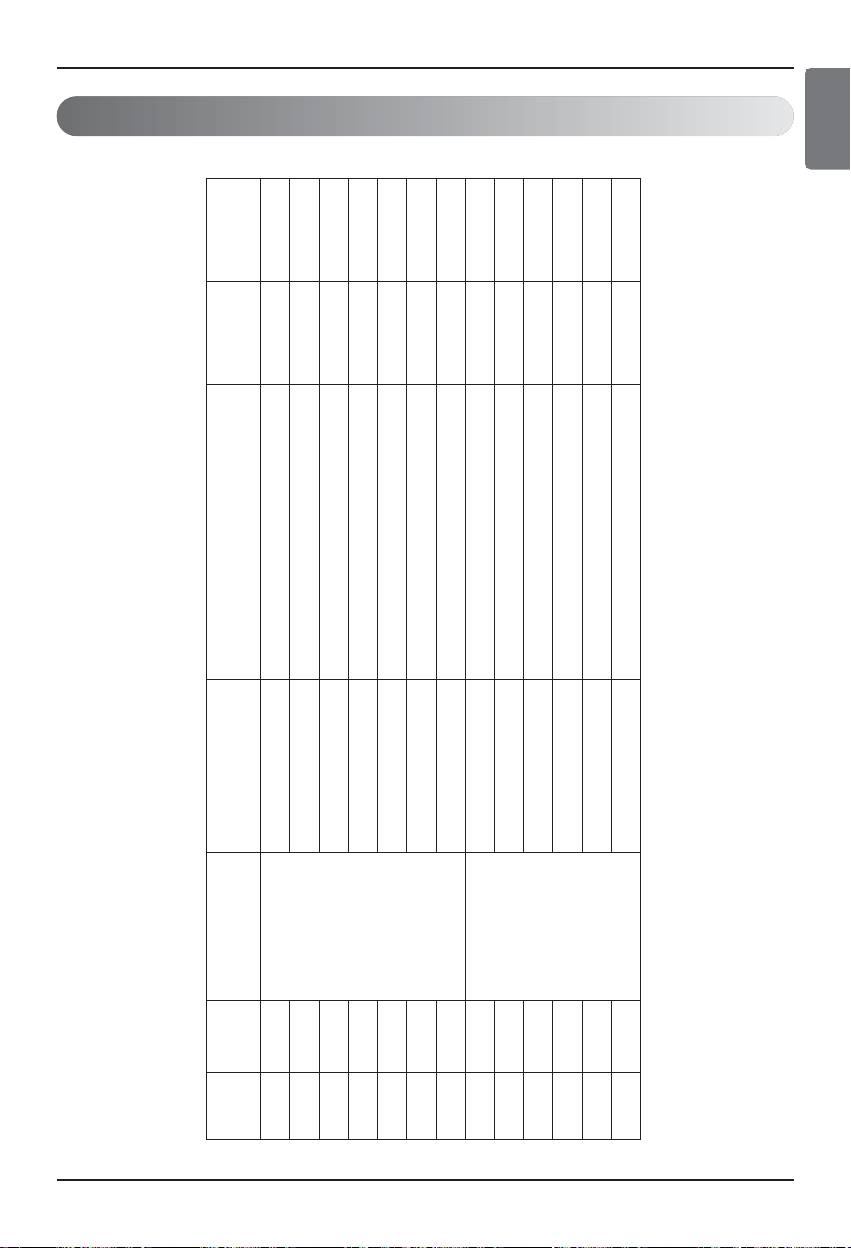

Denomination for each component

Note: It is possible to freely start or stop the indoor unit for corresponding to High or Low signal of

each external input signal.

1

LG-NET 1

TX

RX

LG-NET 2

TX

2

1

RX

2

DI

LG-NET 3

TX

RX

9

3

4

LG-NET 4

TX

5

RX

6

7

8

Ext 1

TX

9

RX

10

Ext 2

TX

11

RX

3

12

13

14

Ethernet 1

ACT

15

LNK

16

17

MENU/

SELECT

Ethernet 2

ACT

18

4

LNK

19

20

Console

TX

RX

5

1

2

DO

Run

10

3

6

4

Power

7

8

Front Right sideLeft side

1. Button & LCD for setting the network environment and displaying the display

2. RS-485 communication port (4EA) for connecting the Air conditioner/Ventilator PI485

3. RS-485 communication terminal (reserved) for the external extension

5. RS-232 port : for updating the program

6. Reset switch : Software reset switch

7. Power On/Off switch

8. DC12V adaptor connection terminal

9. Terminals (20 ports) for connecting the external input signal - DC 0~24V input terminal

10. Terminals(4 port) for connecting the external ouput signal : port # 1 ➝ fire interlocking ,

others ➝ reserved

Main features & Specification

ENGLISH

Installation/Owner Manual 11

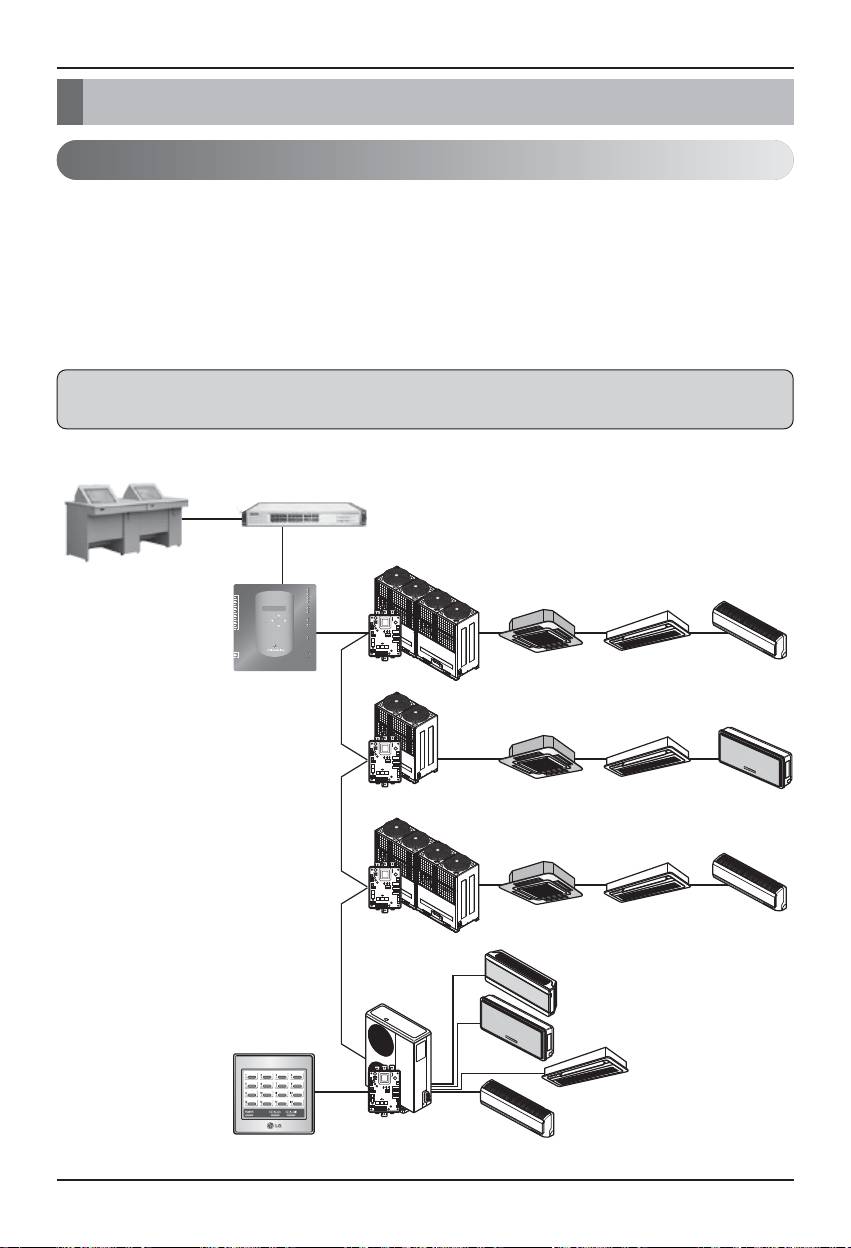

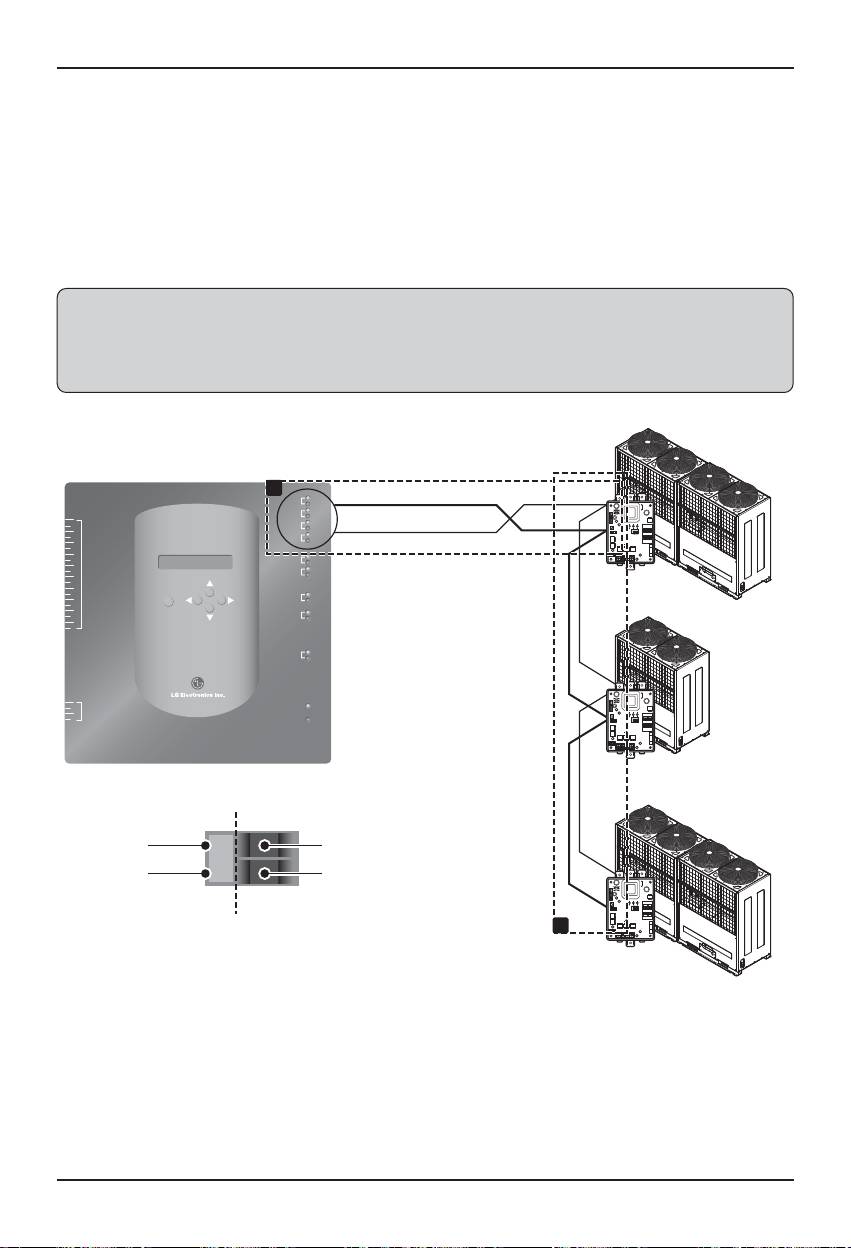

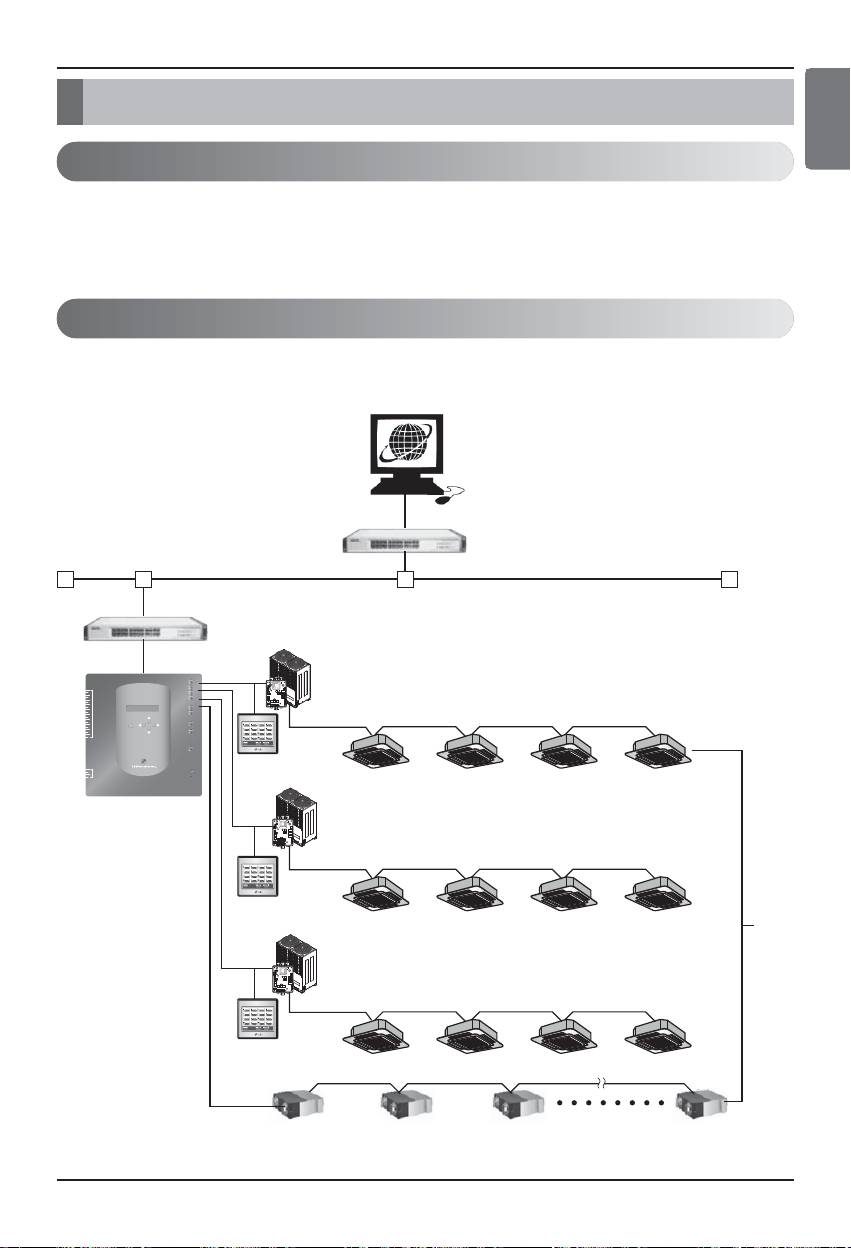

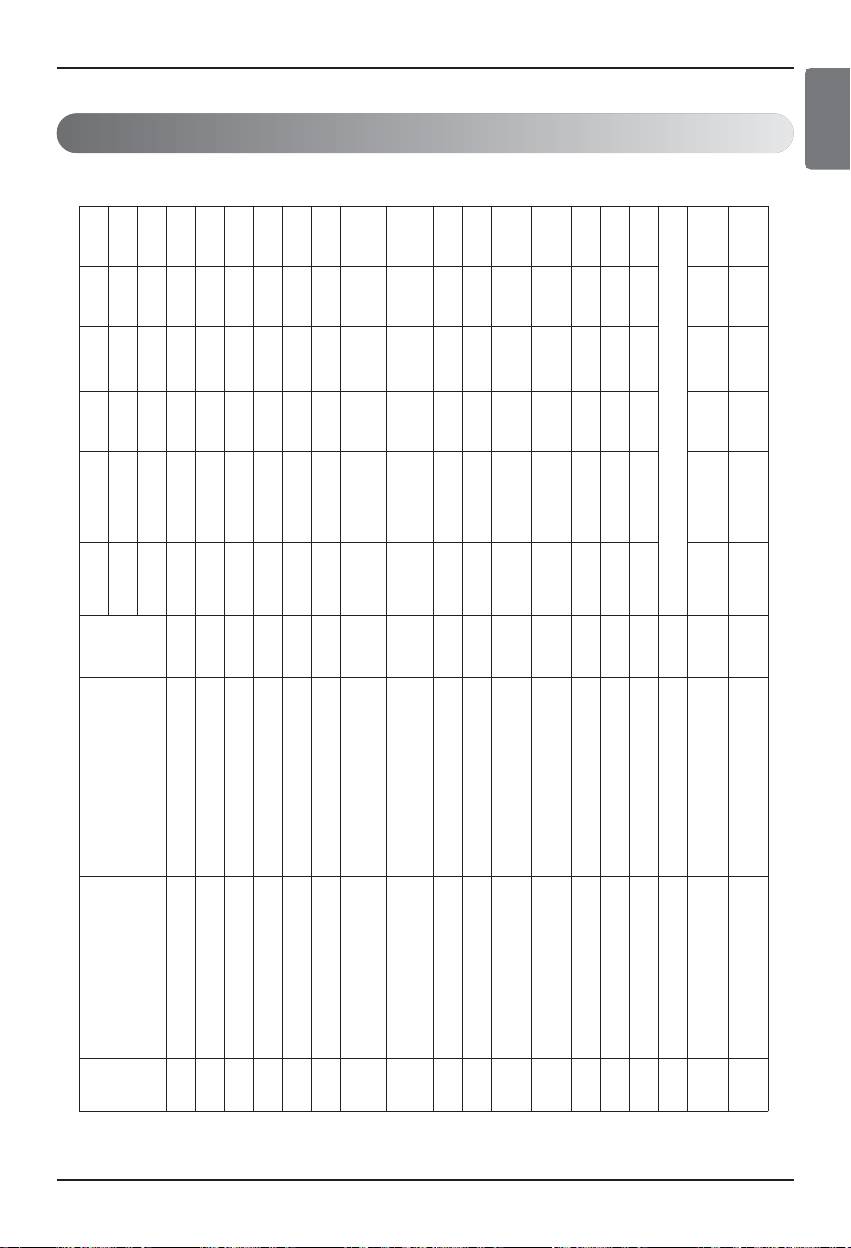

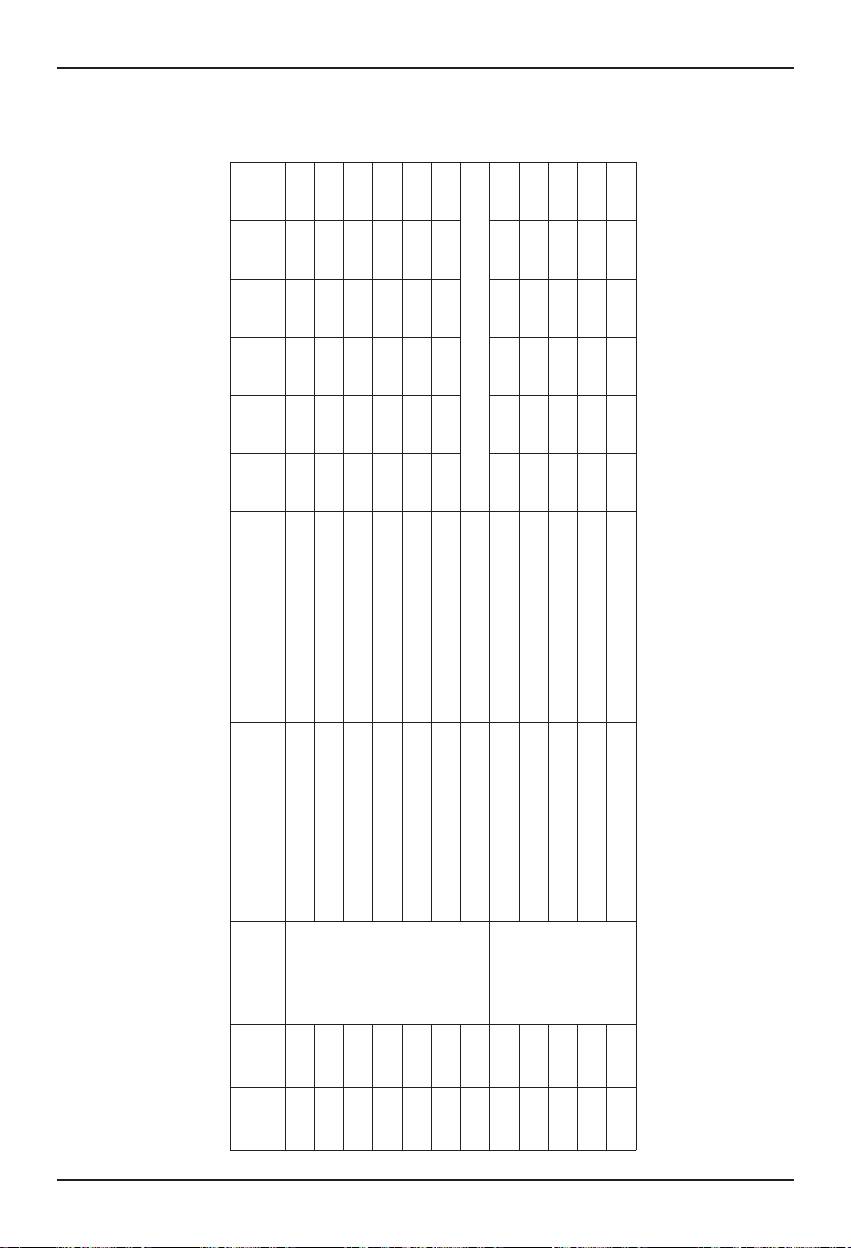

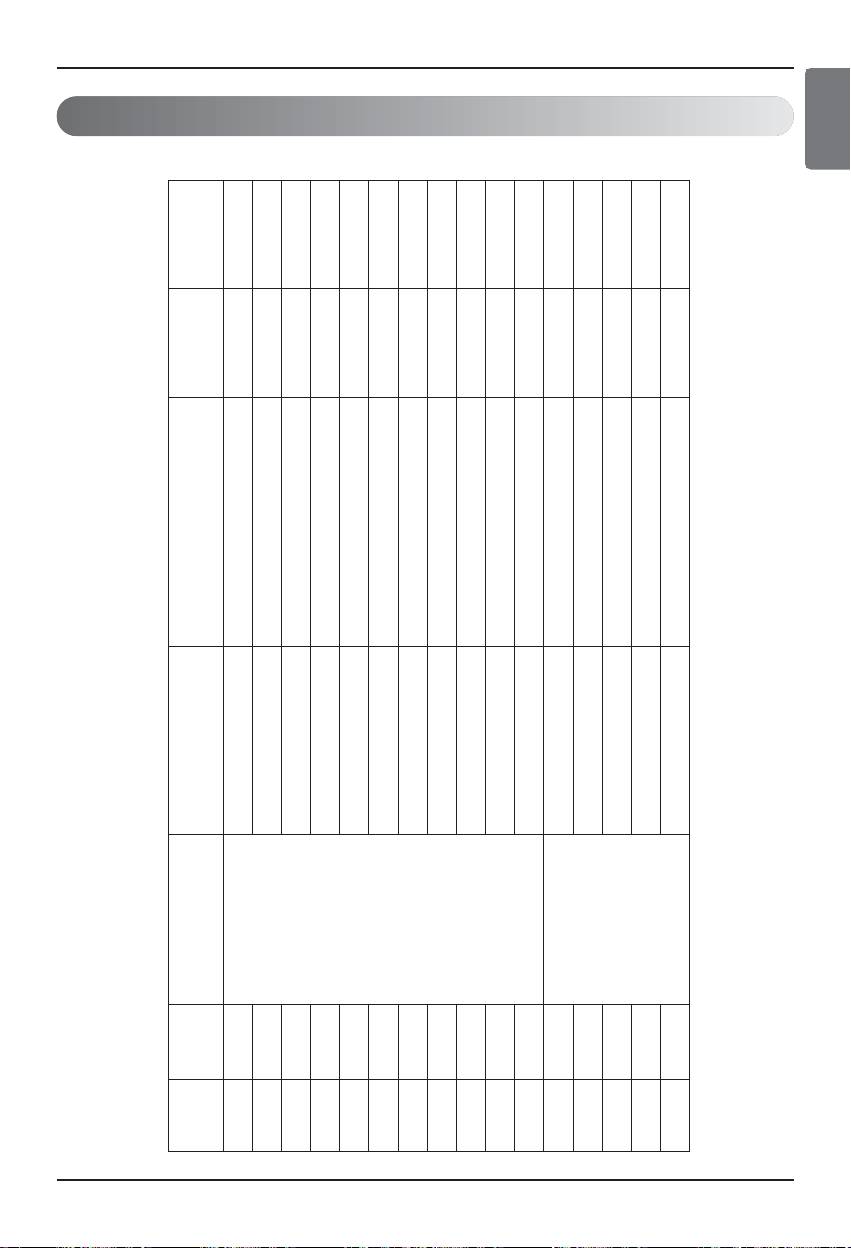

How to install

System diagram

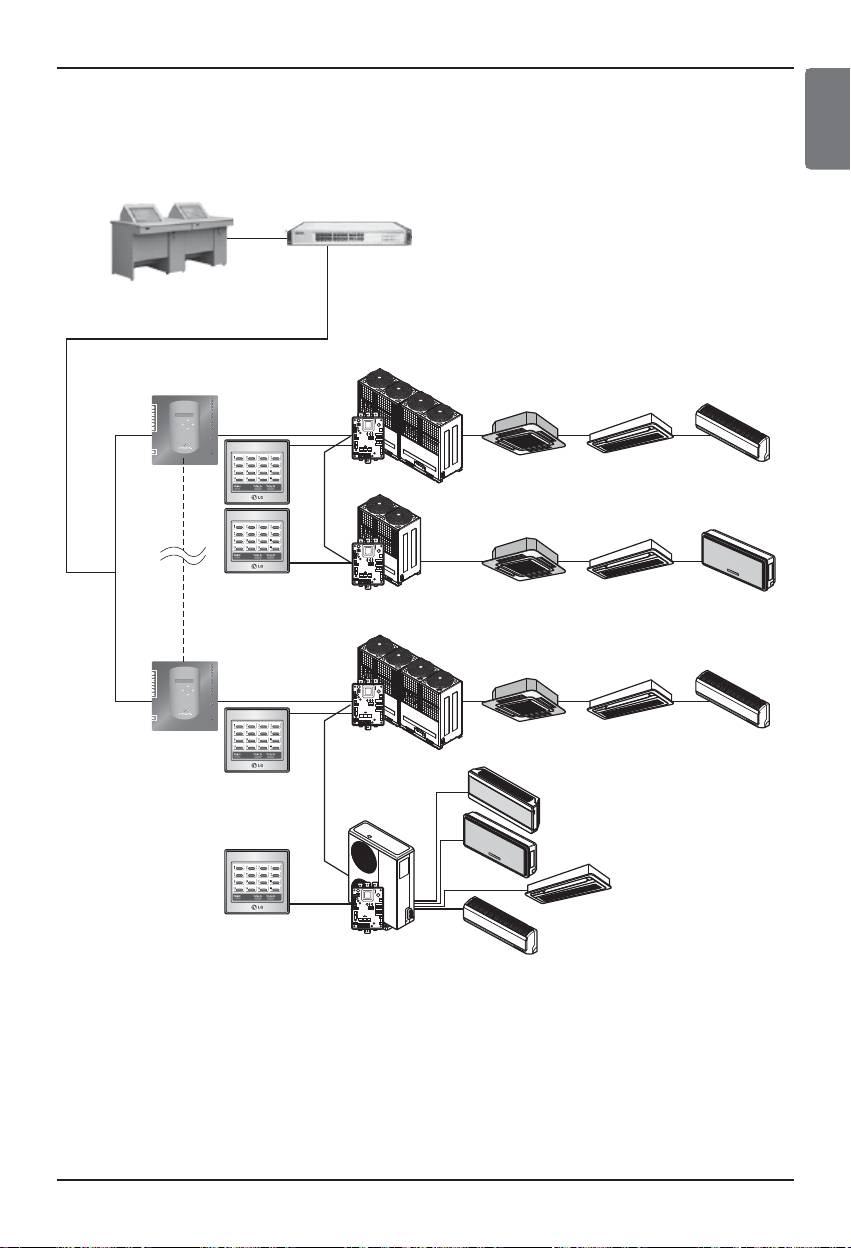

Installation specification

• 256 indoor units at maximum / 1 BACnet Gateway

• Total 256 units(Indoor unit/Vent/DXHRV/AHU) at maximum / 1 BACnet Gateway

• RS-485 ports 4 / 1 BACnet Gateway

• 64 PI485 units at maximum / 1 RS-485 port

• 256 indoor units at maximum / 1 RS-485 port. We recommend to connect them divided into 4 ports

for improving the communication performance.

Note: However, when it should be necessary to change the above specification, contact to the LG

System Air Conditioner supporting division.

(1) When connecting the BMS by using one BACnet Gateway

Hub

LAN

(direct cable)

BMS

Multi V

LG-NET 1

TX

RX

........

(Building

1

2

3

DI

LG-NET 2

TX

LG-NET 3

RX

TX

RX

00 01

0F

4

5

LG-NET 4

TX

6

RX

7

8

9

10

Ext 1

TX

RX

Management

11

12

Ext 2

TX

RX

13

14

15

16

Ethernet 1

ACT

17

MENU/

LNK

18

19

SELECT

Ethernet 2

ACT

System)

20

LNK

Console

TX

ON

RX

L1 2 3 4

KSDO4H

1

2

3

DO

Run

4

Power

PI485

BACnet Gateway

Multi V

........

10 11 1F

ON

L1 2 3 4

KSDO4H

PI485

Multi V

........

20

21 2F

ON

L1 2 3 4

KSDO4H

PI485

........

F0

Multi

F1

F2

ON

L1 2 3 4

KSDO4H

F3

PI485

Simple central controller

(possible to connect if necessary)

How to install

12 BACnet Gateway

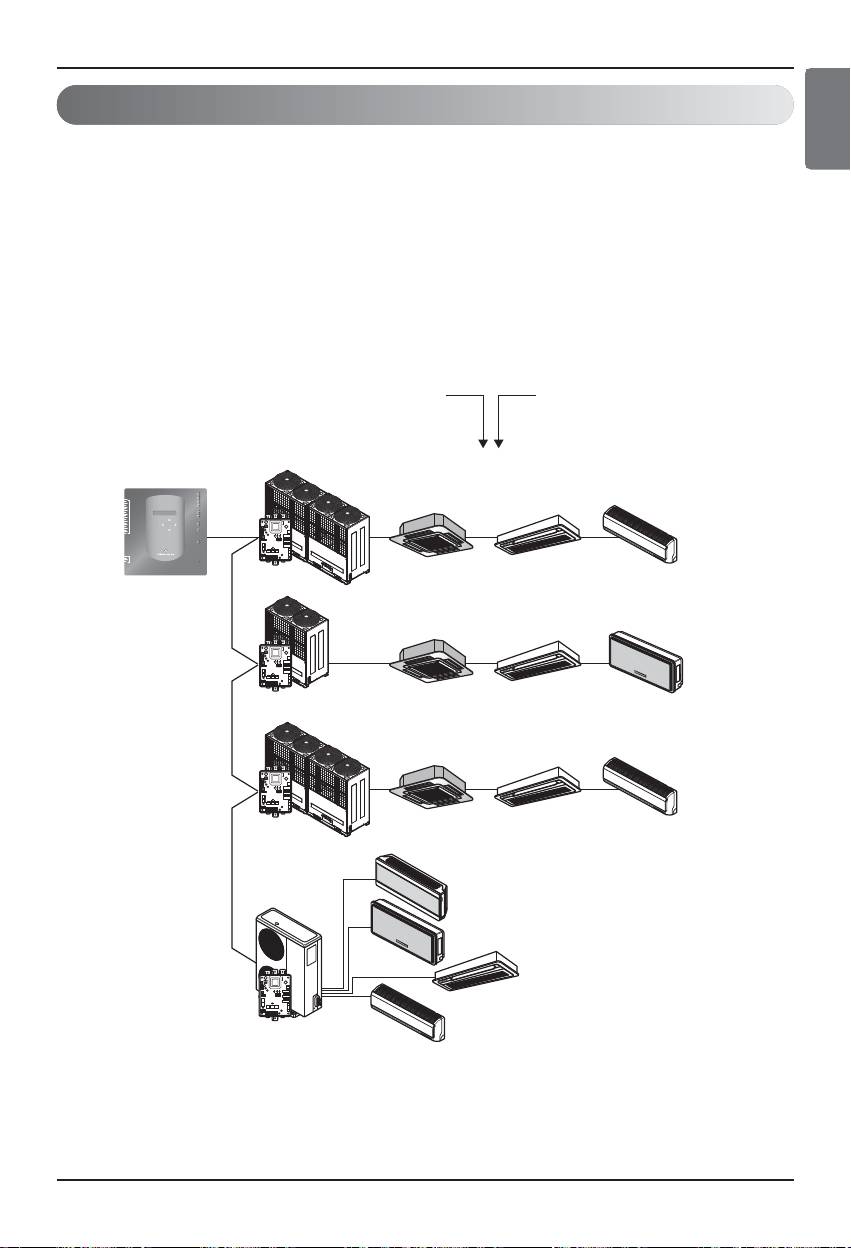

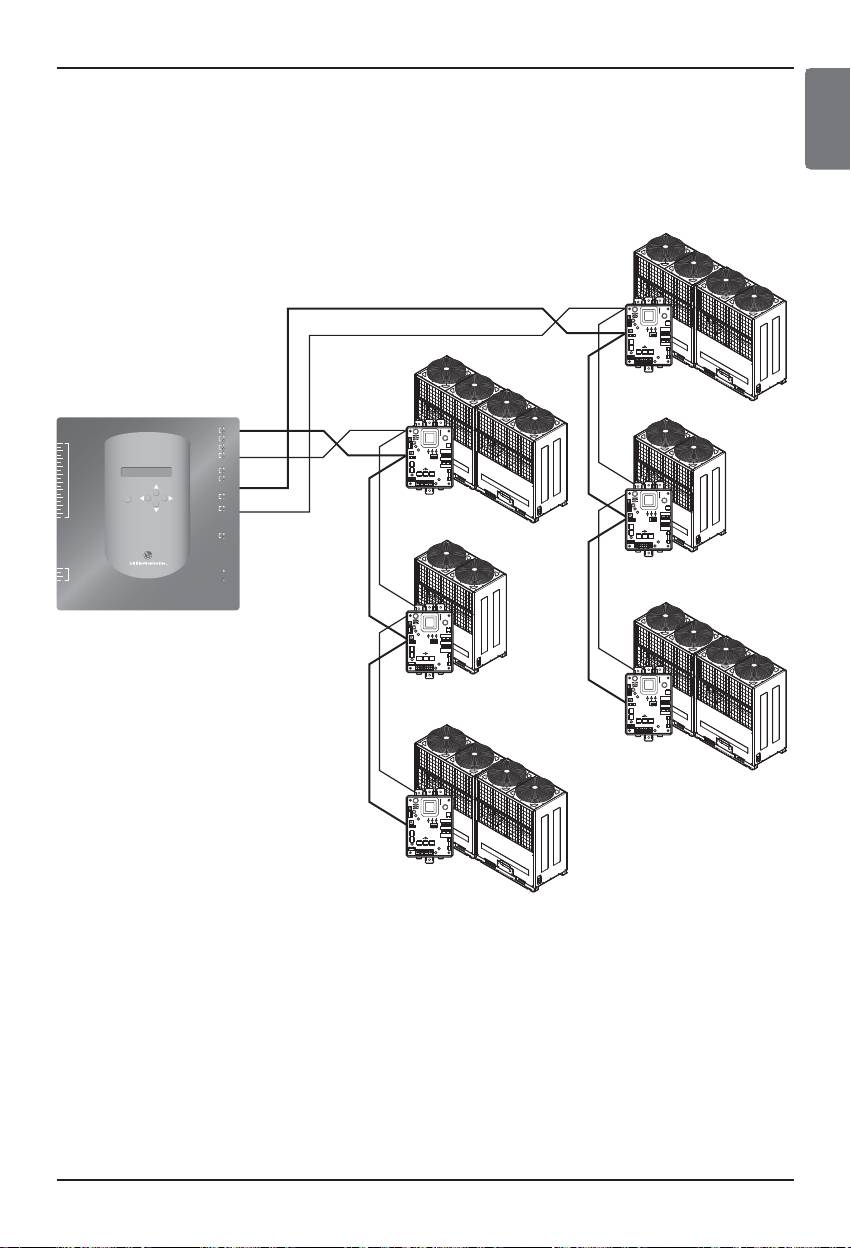

(2) When connecting the BMS by using more than one BACnet

Gateway (possible to connect 16 units at maximum)

Hub

LAN

(direct cable)

BMS(Building Management System)

BACnet Gateway

Multi V

TX

00 01

. . .

LG-NET 1

RX

0F

1

2

LG-NET 2

TX

3

RX

4

DI

LG-NET 3

TX

5

LG-NET 4

RX

6

TX

7

RX

8

9

10

Ext 1

TX

11

RX

12

Ext 2

TX

13

RX

14

15

16

Ethernet 1

ACT

17

18

19

20

SELECT

MENU/

Ethernet 2

LNK

ACT

LNK

Console

TX

RX

ON

L1 2 3 4

KSDO4H

1

2

3

4

DO

Power

Run

PI485

Multi V

. . .

10 11 1F

ON

L1 2 3 4

KSDO4H

Simple central

controller

PI485

(possible to connect

if necessary)

Multi V

. . .

LG-NET 1

TX

LG-NET 2

RX

00

01 2F

1

2

3

DI

LG-NET 3

TX

RX

4

TX

5

RX

6

LG-NET 4

TX

7

RX

8

9

10

Ext 1

TX

11

RX

12

Ext 2

TX

13

RX

14

15

16

ACT

17

Ethernet 1

LNK

18

19

MENU/

ACT

20

SELECT

Ethernet 2

LNK

Console

TX

RX

ON

L1 2 3 4

KSDO4H

1

2

3

4

DO

Power

Run

BACnet Gateway

PI485

. . .

F0

Multi

F1

F2

ON

L1 2 3 4

KSDO4H

Simple central

F3

controller

PI485

(possible to connect

if necessary)

How to install

ENGLISH

Installation/Owner Manual 13

How to install

Installation Order

(1) Installing the hardware

■ Setting the indoor unit

Set the unique address for all indoor units connected to the BACnet Gateway.

Two hexadecimal digits 00~FF can be set to the address. The address can be set by the wired or

wireless remote controller.

■ Installing the PI485

Install one PI485 for each outdoor unit and install the Dip switch correctly. Check the red LED

blinking as many as the number of the indoor units.

■ Connecting the PI485-BACnet Gateway

Connect the PI485 A and B terminals of each outdoor unit to the RS-485 port of the BACnet

Gateway.

■ Connecting the BACnet Gateway to the Internet

Connect the BACnet Gateway to the hub (Internet) or the PC via the LAN cable. And then, apply

the power to the BACnet Gateway.

(2) Installing the software

■ How to set the BACnet Gateway

Set the BACnet Gateway by using the button and the LCD display.

■ Network environment setup of the BACnet Gateway

After getting the IP address of the BACnet Gateway assigned by the network administrator, set the

network environment such as IP address of BACnet Gateway by using the button of the BACnet

Gateway.

(3) Checking the installation

After installing the BACnet Gateway, it is possible to check the product communication status by

using the Web controlling/monitoring feature.

14 BACnet Gateway

Hardware Installation

(1) Setting the indoor unit address

• By considering the entire installation configuration connecting to one BACnet Gateway, set the

unique address for each indoor unit. (We recommend to reflect it to the installation drawing.)

• Two hexadecimal digits 00~FF can be set to the address of the indoor unit.

• For the Multi V product, in order to identify the system component, we recommend to set the outdoor

unit number to the first digit of the address and the indoor unit number to the second digit.

• The ventilating product can be also installed and controlled by the BACnet Gateway.

(However, the address of the ventilation product cannot be set to overlap the address of the air

conditioner.)

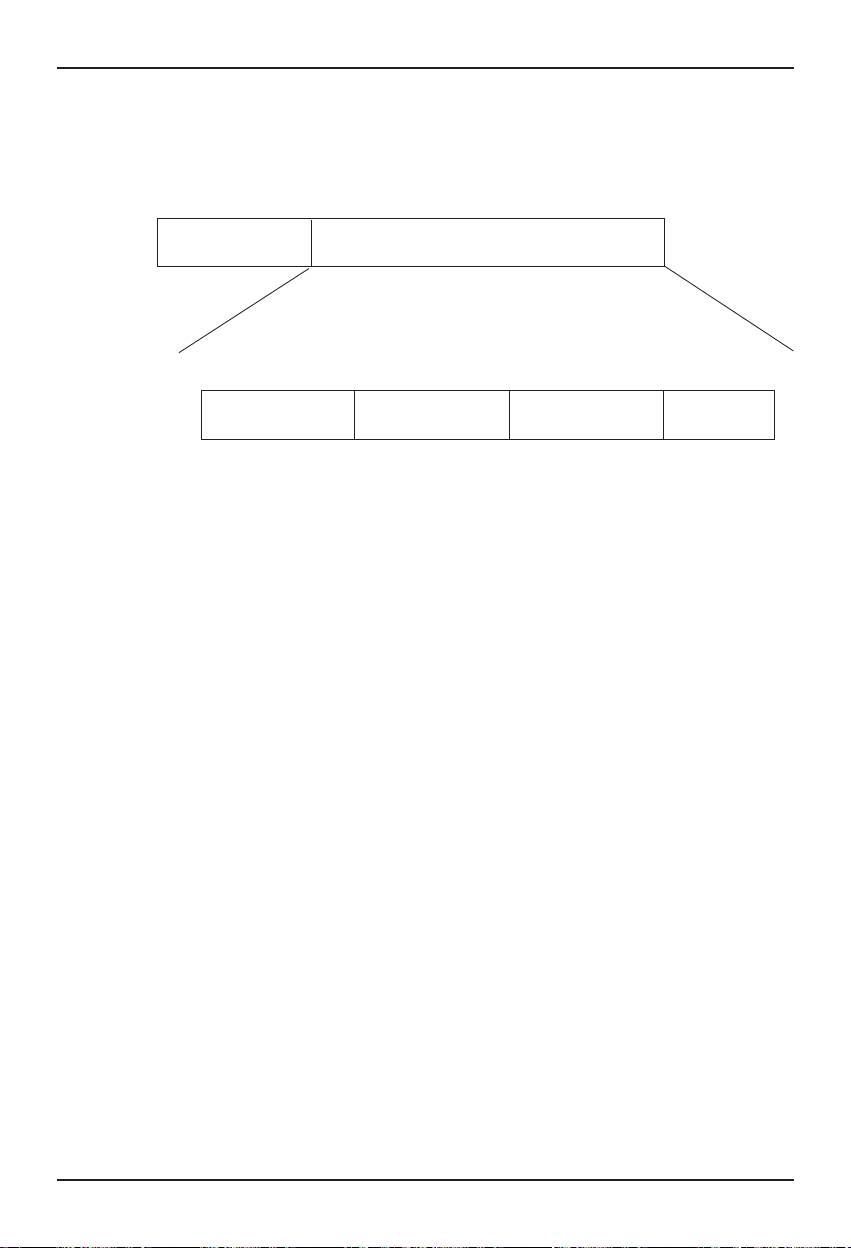

Indoor unit numberOutdoor unit number

00

Multi V

LG-NET 1

TX

RX

. . .

1

2

3

DI

LG-NET 2

TX

RX

TX

00

01

0F

4

LG-NET 3

5

LG-NET 4

RX

TX

6

RX

7

8

9

TX

10

Ext 1

RX

11

Ext 2

TX

12

RX

13

14

15

16

Ethernet 1

ACT

17

18

MENU/

LNK

19

SELECT

Ethernet 2

ACT

20

LNK

Console

TX

ON

RX

L1 2 3 4

KSDO4H

1

2

3

DO

Run

4

Power

PI485

BACnet Gateway

Multi V

. . .

10 11 1F

ON

L1 2 3 4

KSDO4H

PI485

Multi V

. . .

20

21 2F

ON

L1 2 3 4

KSDO4H

PI485

. . .

F0

Multi

F1

F2

ON

L1 2 3 4

KSDO4H

F3

PI485

How to install

ENGLISH

Installation/Owner Manual 15

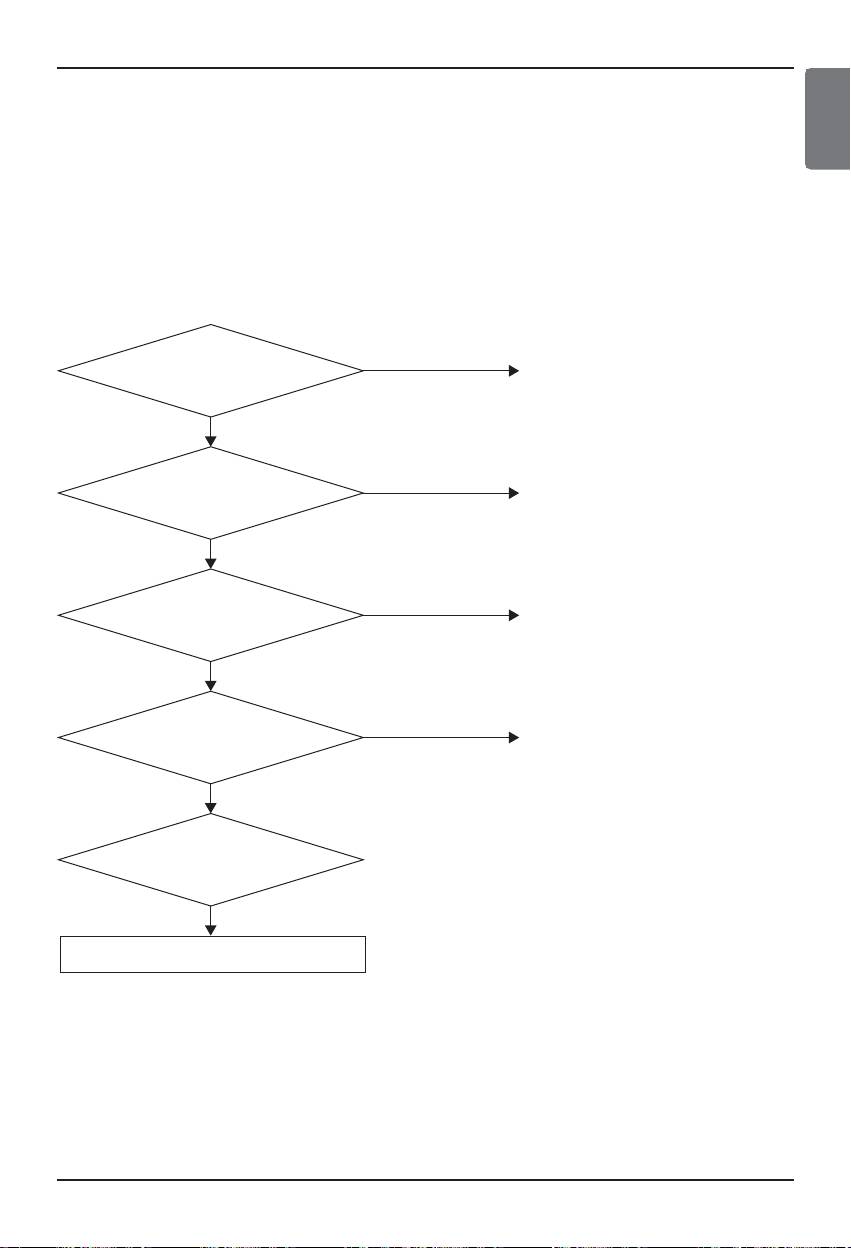

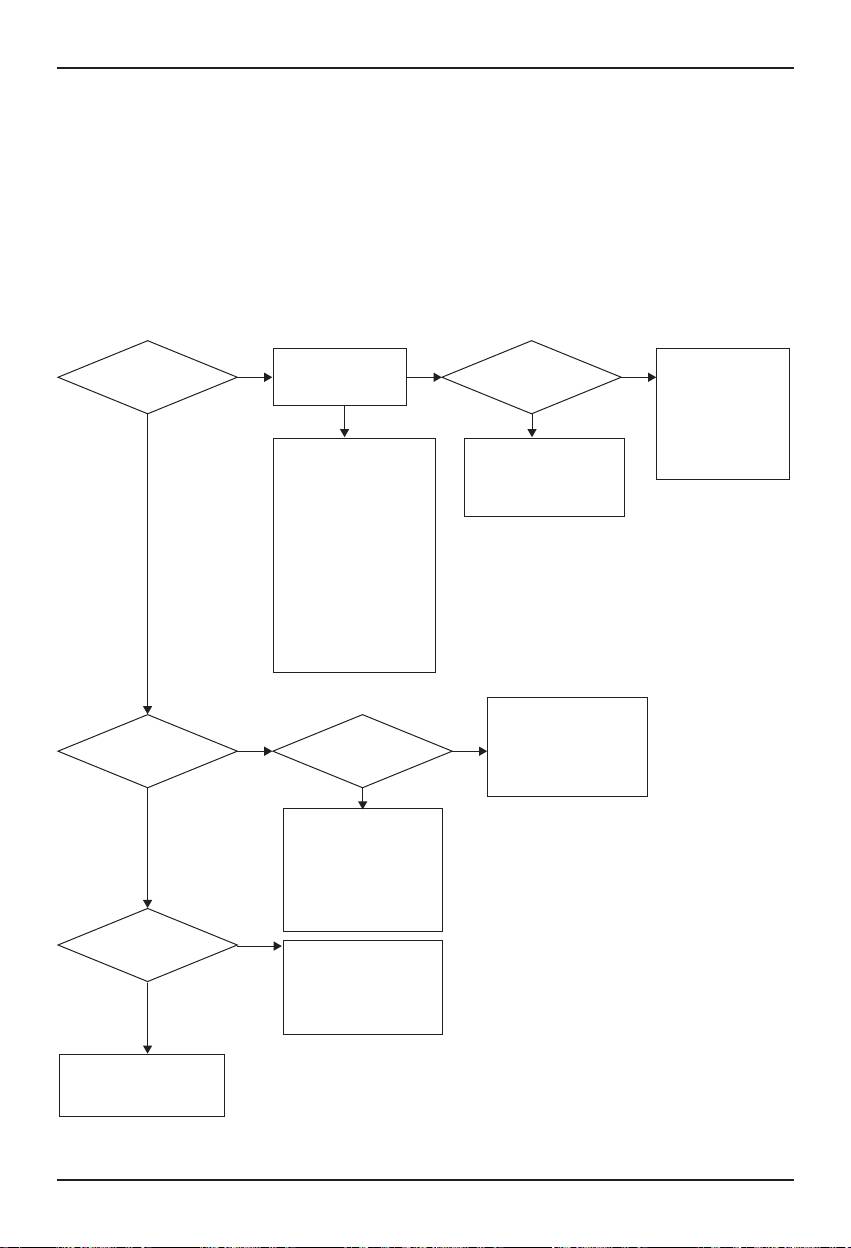

(2) Installation PI485

Select Air

Select Network Type

Conditioer Type

Select Advanced Control Type

ON

KSDO4H

L1 2 3 4

ON

ON

ON

ON

ON

How to install

* LGAP : LG Air conditioner Protocol

Multi V & Multi(LGAP applied) products Configuration Methods

➔ 1 ON, All others OFF: Multi V products(Except CRUN products) or

Multi(Non-Inverter) Product applied Common PCB(Refer to NOTE) or

Multi(Inverter) Product + Central Controller(All types) - Without LGAP

➔ 1 and 4 ON, All others OFF: Multi V products(Except CRUN prod-

ucts) or Multi(Non-Inverter) Product applied Common PCB or

Multi(Inverter) Product + Central Controller(All types) - Using LGAP

➔ 2 ON, All others OFF: Multi(Non-Inverter) Product

+ Centroller(All types) - Without LGAP

➔ 2 and 4 ON, All others OFF: Multi Non-Inverter Product

+ Central Controller(All Types) - Using LGAP

➔ 1,2,3,4 ON : Multi V CRUN Product

+ Central Controller(All types) - Using LGAP

* Please refer the corresponding Central Controller installation manual if you want to know whether

your Central Controller is compatible with LGAP or not.

CAUTION:

The wrong setting of air-conditioner switch could cause malfunctioning.

Switch setting must be done carefully.

Push the Reset button after changing the Dip switch.

NOTE: Multi(Non-Inverter) Product applied Common PCB

PCB P/NO. : 6871A20917*

P/NO. : 6871A20918*

P/NO. : 6871A20910*

16 BACnet Gateway

ON

ON

ON

How to install

ENGLISH

- To use the advanced lock function (Run Mode lock, Fan Speed lock,

Temperature Lock, and Temperature Range lock; adjustable only within certain boundary)

by central controller, Set up the fifth dip switch according to the type of outdoor product.

- In case of advanced lock function, it can use only the central controller applied to LGAP.

➔ 1, 4 and 5 ON, All others OFF :

MultiV Products (Except CRUN products) or MPS Inverter Product

+ Central Controller (All types) - Using LGAP

➔ 2, 4 and 5 ON, All others OFF :

Multi Standard Product + Central Controller (All types) - Using LGAP

➔ 1, 2, 3, 4and 5 ON, All others OFF :

MultiV CRUN Product + Central Controller (All types) - Using LGAP

NOTE : The advanced lock setting

Some products do not support advanced lock function.

In this case, The fifth dip switch on PI485 must be on.

In case of product applied to advanced function, it can process the advanced lock function without fifth dip

switch ON.

If all units support advanced lock function,

It is recommended that the fifth dip switch be off, so that advanced lock function is processed faster.

CAUTION:

The wrong setting of air-conditioner switch could cause malfunctioning.

Switch setting must be done carefully.

After setting the dip switch, PI485 must be reset

Installation/Owner Manual 17

How to install

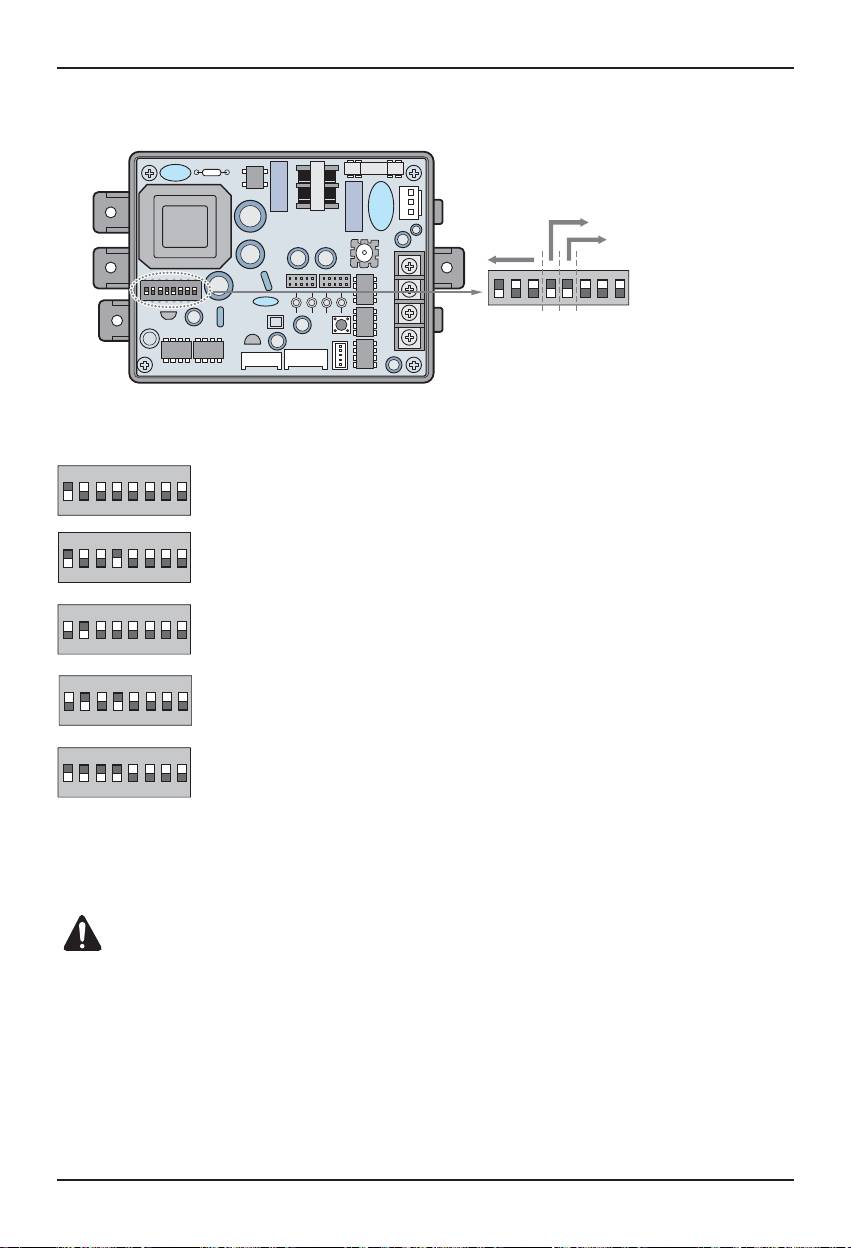

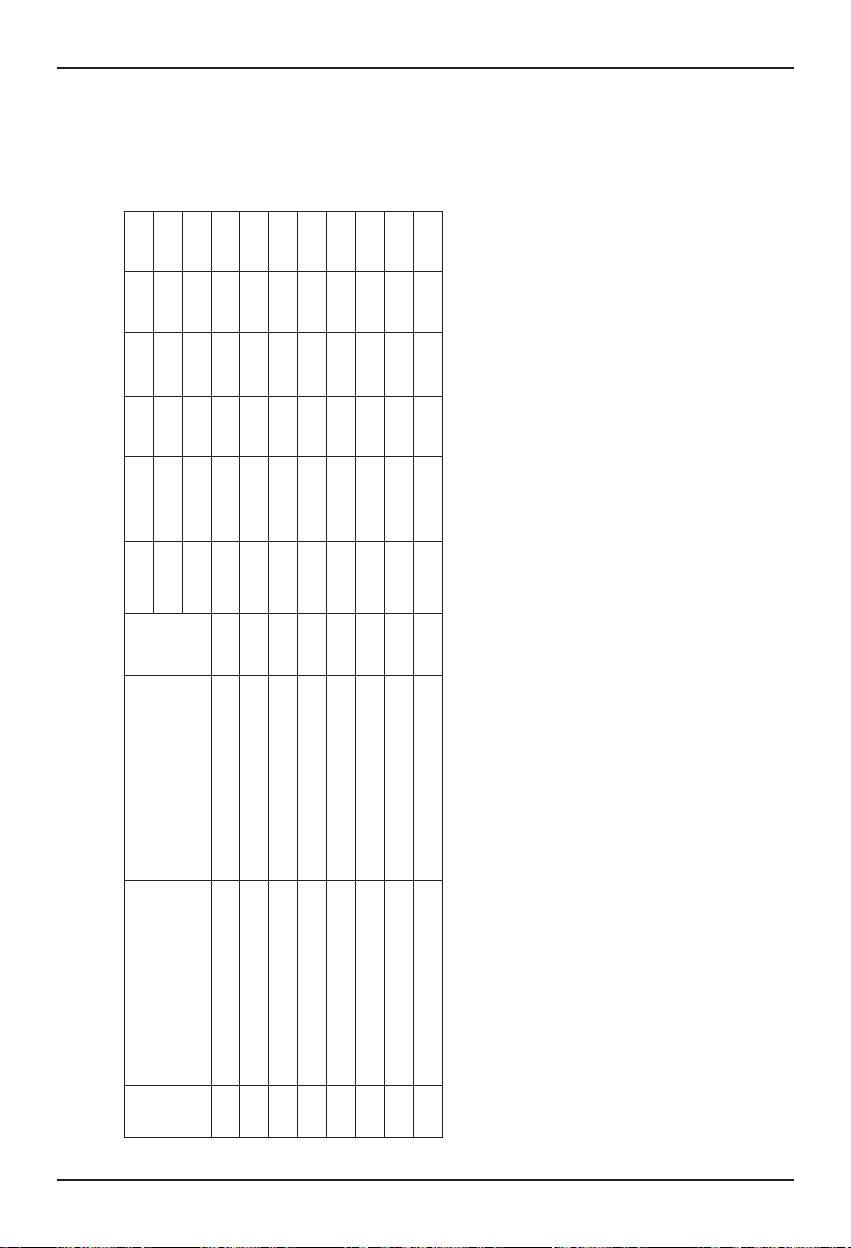

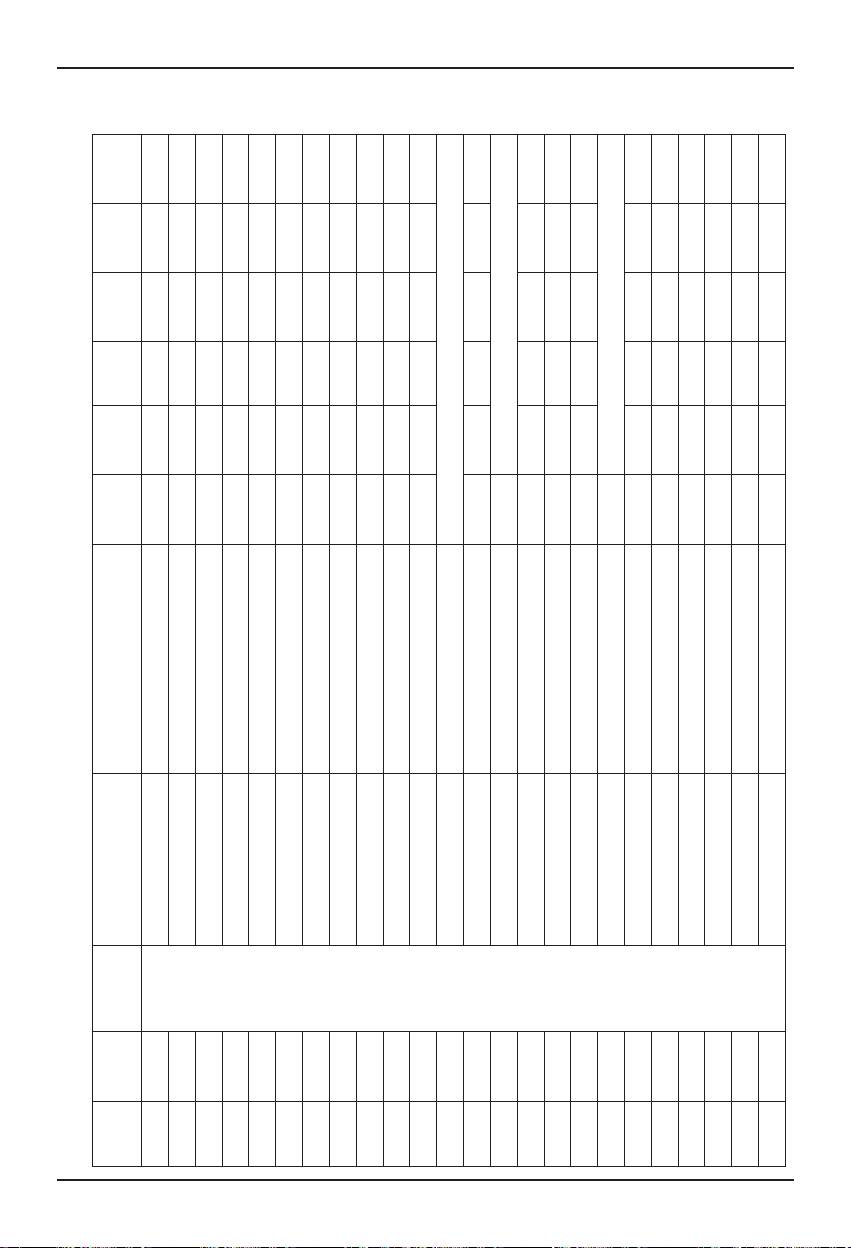

(3) Connecting PI485 – BACnet Gateway

1. When connecting two or more PI485s to one BACnet Gateway, connect each BUS-A/BUS-B of

other PI485s to be connected to BUS-A/BUS-B of the PI485.

2. Connect the BUS-A of the PI485 to the TX of the BACnet Gateway and the BUS-B to the RX.

• Connect LG-NET 1~4 to any of the BACnet Gateway. (Connect the LG-NET to the RS-485 port)

• 64 outdoor units at maximum can be connected to each 485 port of the BACnet Gateway and the

number of indoor units to be connected to the BACnet Gateway is 256 at maximum.

Note: Disconnect the connector from the 485 port of the BACnet Gateway, connect the BUS-A to

the TX and the BUS-B to the RX by using the (-) driver, and then connect the connector to the

485 port of the BACnet Gateway. Because the 485 communication line has a polarity, connect

the line correctly.

18 BACnet Gateway

Multi V

1

LG-NET 1

TX

TX

RX

LG-NET 2

TX

1

RX

2

DI

LG-NET 3

TX

RX

3

RX

ON

TX

L1 2 3 4

KSDO4H

4

LG-NET 4

5

RX

6

7

8

Ext 1

TX

9

RX

2

10

Ext 2

TX

RX

Shield line of 0.75 mm

11

’

12

13

14

ACT

(RS-485 communication line)

PI485

15

Ethernet 1

LNK

16

17

MENU/

18

SELECT

Ethernet 2

ACT

LNK

19

20

Multi V

Console

TX

RX

1

2

DO

Run

3

4

Power

ON

L1 2 3 4

KSDO4H

BACnet Gateway side PI485 side

Multi V

BUS-ATX

RX

BUS-B

ON

L1 2 3 4

KSDO4H

2

PI485

PI485

PI485

PI485

PI485

PI485

How to install

• If there are many outdoor units, distribute the lines to LG-NET 1~4 to improve the control speed.

[Example for distributing the lines to LG-NET 1 and LG-NET 2]

Installation/Owner Manual 19

Multi V

ON

L1 2 3 4

KSDO4H

Multi V

PI485

TX

Multi V

RX

BUS-A

ON

L1 2 3 4

KSDO4H

TX

RX

PI485

ON

L1 2 3 4

KSDO4H

Multi V

PI485

Multi V

ON

L1 2 3 4

KSDO4H

PI485

ON

L1 2 3 4

KSDO4H

Multi V

PI485

ON

L1 2 3 4

KSDO4H

PI485

BUS-A

BUS-A

BUS-B

BUS-A

BUS-A

BUS-B

BUS-A

LG-NET 1

TX

RX

LG-NET 2

TX

1

RX

2

DI

LG-NET 3

TX

3

RX

4

5

LG-NET 4

TX

RX

6

7

8

9

Ext 1

TX

RX

10

Ext 2

TX

11

RX

12

13

14

15

Ethernet 1

ACT

16

LNK

17

MENU/

18

SELECT

Ethernet 2

ACT

19

LNK

20

Console

TX

RX

1

2

DO

Run

3

4

Power

ENGLISH

How to install

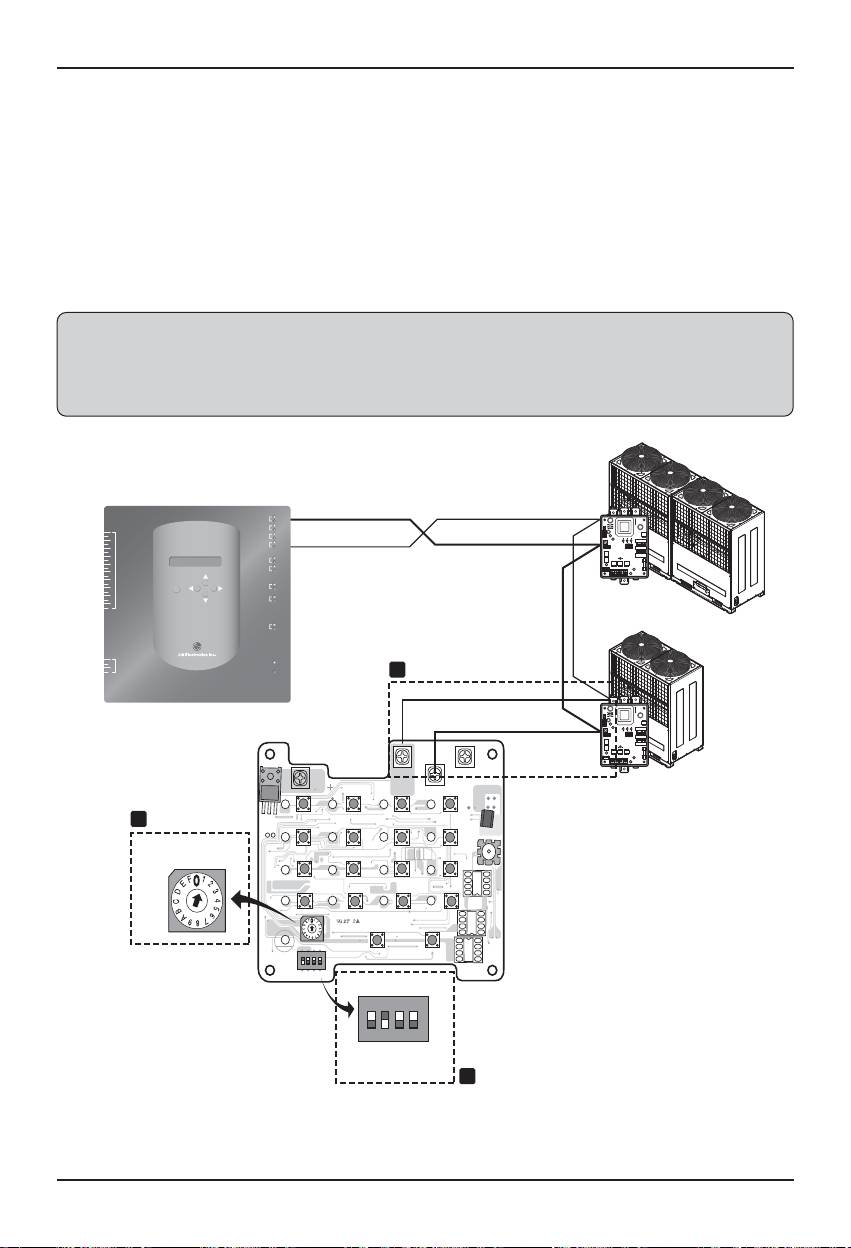

• When using the simple central controller with the BACnet Gateway

1. Connect the BUS-A and the BUS-B of the PI485 to C and D of the simple central controller.

2. Set the rotary switch of the simple central controller to match with the group number of the indoor

unit to control.

3. Set the dip switch number 1 of the simple central controller to Off as slave and set the dip switch

number 2 to On as LGAP use mode.

Note: Check the LGAP label at the right side of the case of the simple central controller.

Only the product with the label can be connected to the BACnet Gateway at the same time.

Connect the VCC and the GND of the simple central controller from the P1485 or separately to

the adaptor. (See the manual for the simple central controller.)

Multi V

BUS-B

TX

TX

LG-NET 1

RX

LG-NET 2

TX

1

RX

2

DI

LG-NET 3

TX

3

RX

BUS-A

4

LG-NET 4

TX

RX

RX

ON

KSDO4H

5

L1 2 3 4

6

7

8

Ext 1

TX

9

RX

10

Ext 2

TX

11

RX

2

12

13

Shield line of 0.75 mm

14

15

Ethernet 1

ACT

16

LNK

’

17

MENU/

18

SELECT

Ethernet 2

ACT

19

LNK

(RS-485 communication line)

20

PI485

Console

TX

RX

1

Multi V

2

DO

Run

3

4

Power

1

ON

L1 2 3 4

KSDO4H

CN-POWER

GND

CN-COM B

CN-POWER

CN-COM A

S1

S2

L

S4

PI485

LED2

LED3

LED4

2

IC1P

S5

+

+

S6

+

+

S3

+

LED5

LED7

LED8

TX1

Rotary switch

S9

S10

S11

S12

+

+

+

Simple central controller

LED9

LED10

LED11

LED12

+

+

S14

+

S15

+

S16

LED13

LED14

LED15

LED16

PWB:6870A10001A

ASM:6711A20005E

+

S15

S18

LED17

ON

KSDO4H

L1 2 3 4

Ex)When controlling

S19

the indoor Unit 10~1F,

ON

KSDO4H

setting the switch to 1.

L1 2 3 4

DIP switch

3

20 BACnet Gateway

How to install

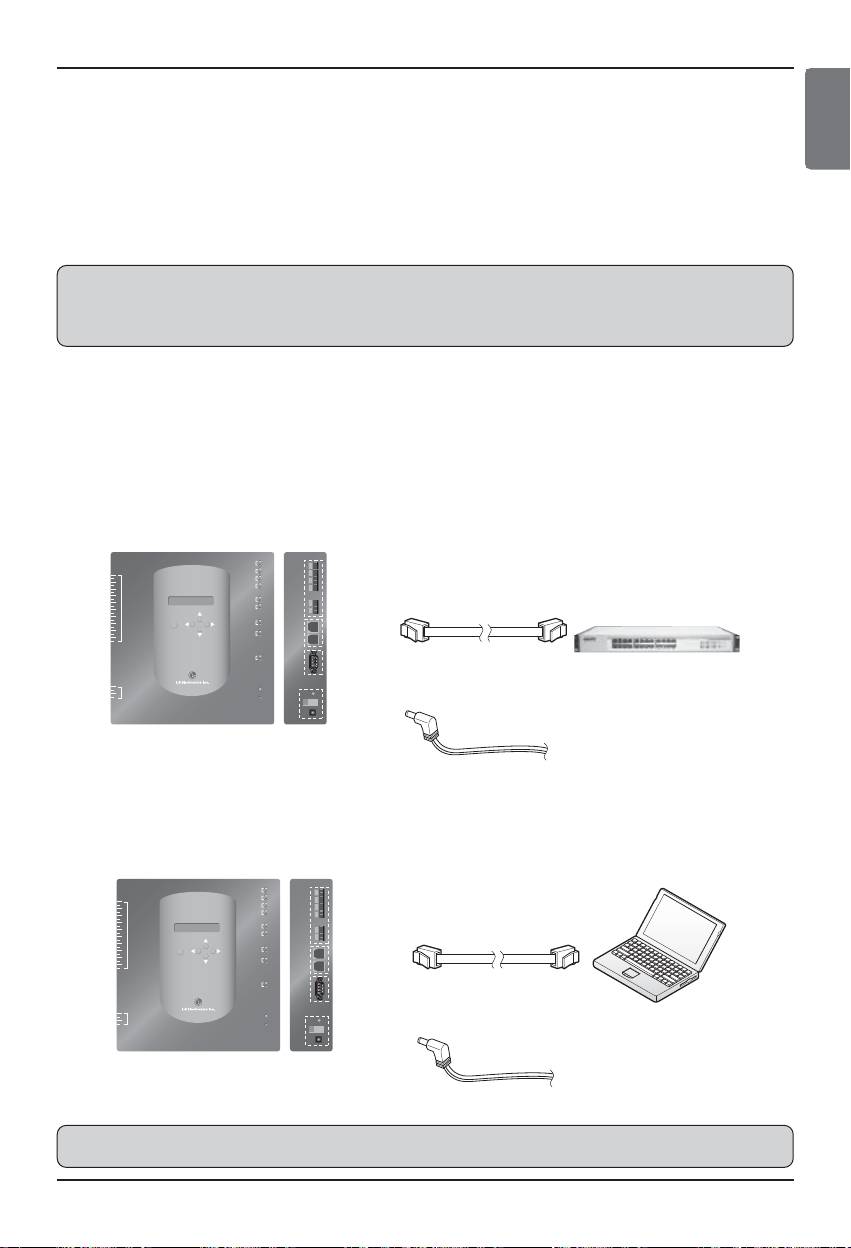

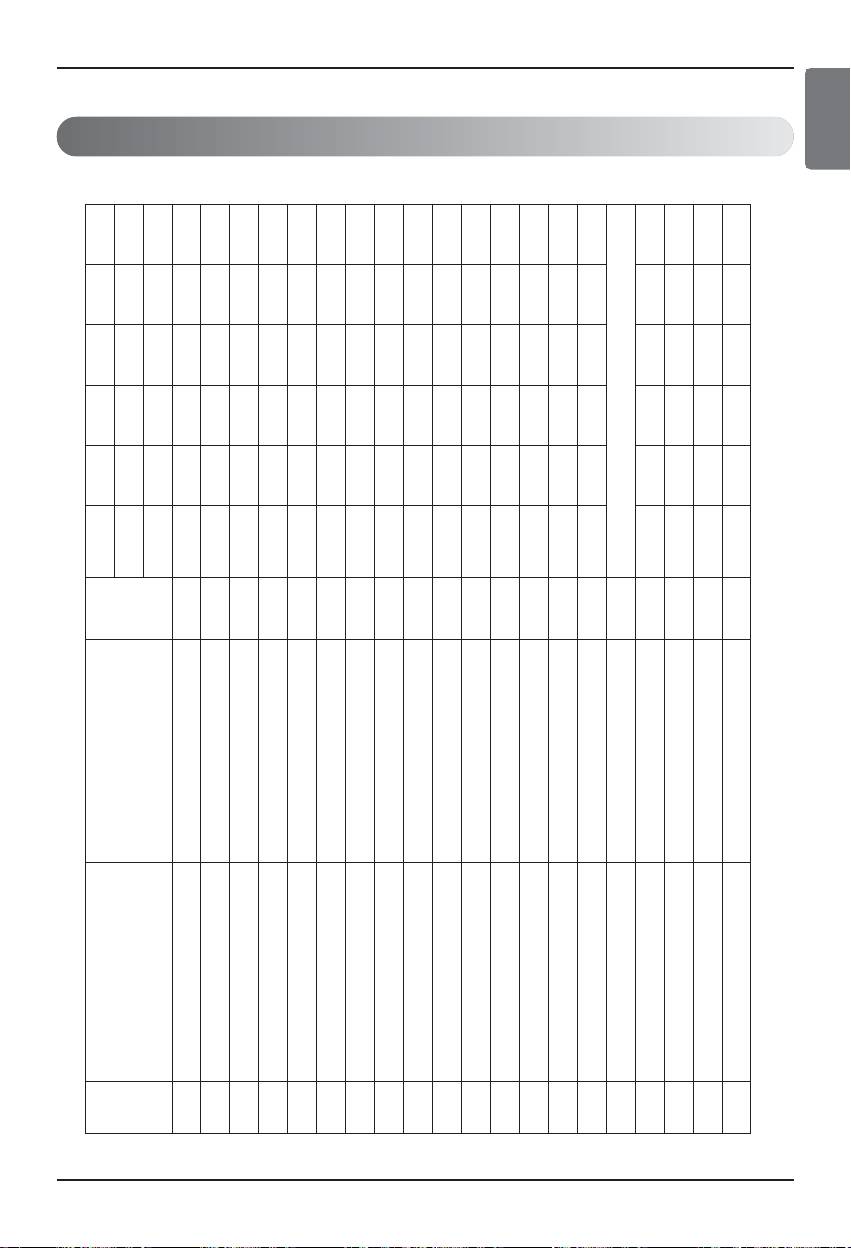

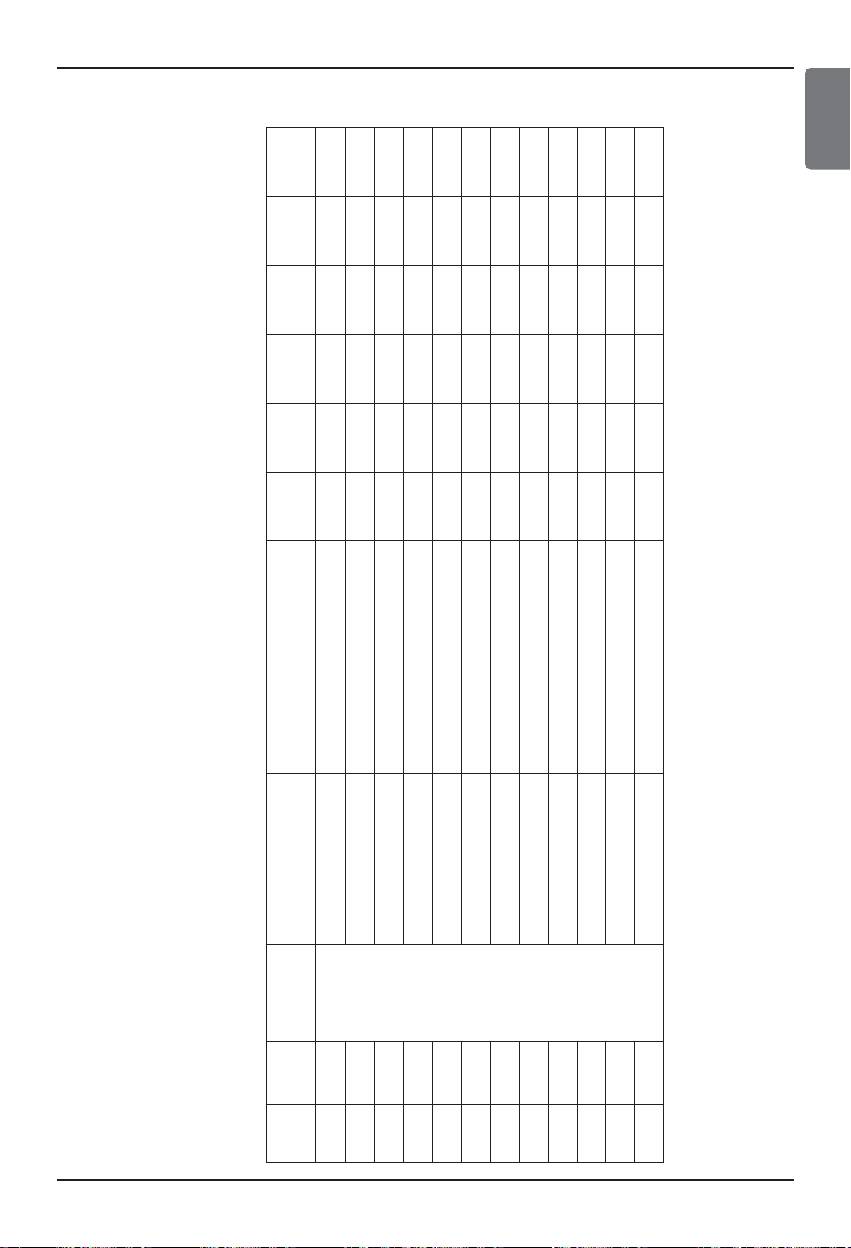

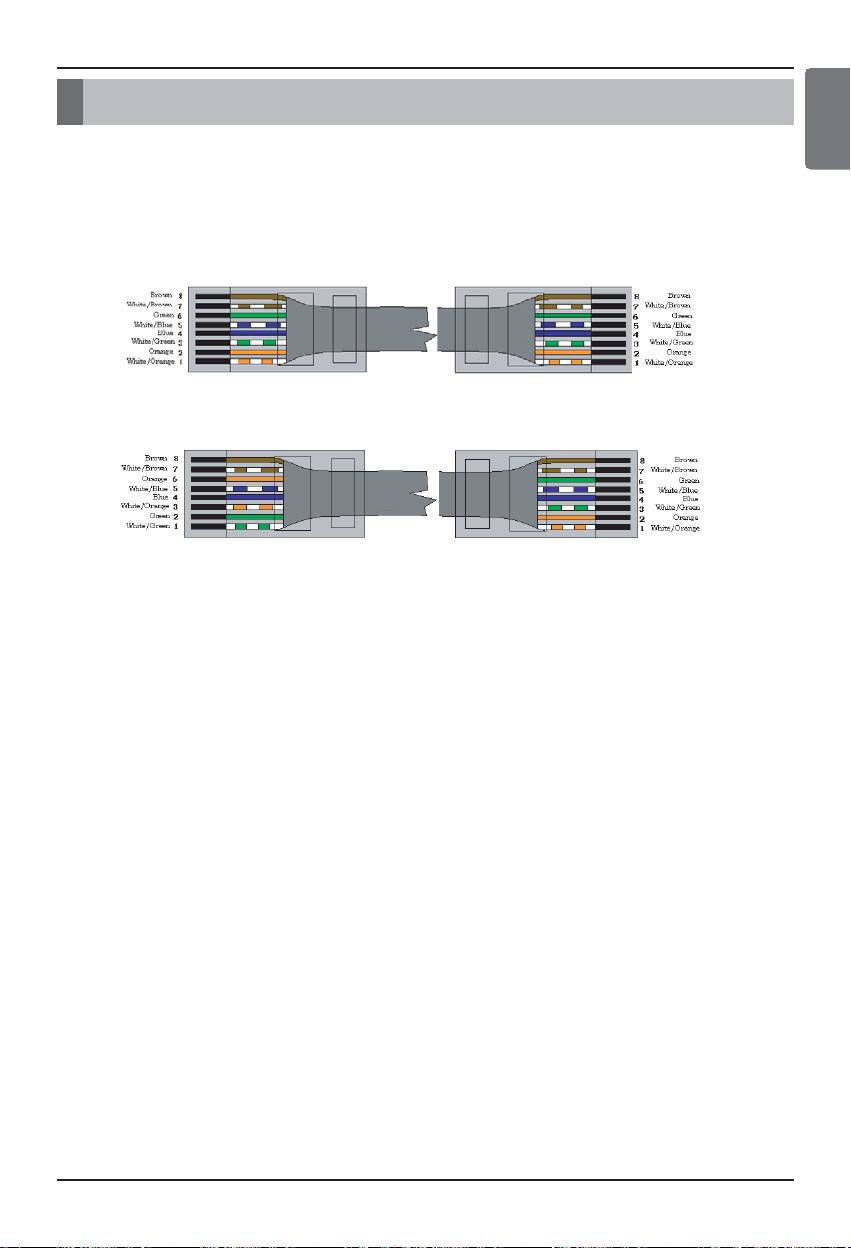

(4) Connecting Internet – BACnet Gateway

• In the case connecting a BACnet Gateway to the internet which is already installed in the site, there

should be a HUB which is already installed.

In the case, being able to inter-work with the BMS system using the internet and connecting a

BACnet Gateway to the internet which is already installed in the site : Use the HUB

Note: Through the test operation of BACnet Gateway, it can be judged whether the installation is

properly done or not (instead of using the HUB, connecting the BACnet Gateway with a cross

cable)

• Be aware the type of the cable youʼre using (the Direct cable or the Cross cable)

• Prior to the Connecting, Check whether the cable works properly or not through the LAN tester.

• After applying the power to the DC adapter provided, Turn on the power switch.

■ In the case using HUB

Use a LAN cable (Direct cable) and connect it to Ethenet1 of the BACnet Gateway

(Ethernet2 is reserved in case)

■ In the case NOT using HUB

(to check the communication status using web control/monitoring function in the site)

Use a LAN cable (Cross cable) and connect it to Ethenet1 of the BACnet Gateway

(Ethernet2 is reserved in case)

Note: If know Detail web control/monitoring function, refer web control/monitoring part

LG-NET 1

TX

RX

LG-NET 2

TX

RX

2

1

DI

LG-NET 3

TX

RX

RS-485 port

4

3

TX

5

LG-NET 4

RX

6

8

7

Ext 1

TX

RX

10

9

Ext 2

TX

RX

Ethernet 1

12

11

14

13

16

15

Ethernet 1

ACT

LNK

18

17

SELECT

MENU/

Ethernet 2

ACT

19

LNK

Ethernet port

20

Console

TX

RX

LAN Cable(Direct Cable)

Console port

Hub

2

1

DO

Run

4

3

Power

Power switch

& power port

LG-NET 1

TX

RX

LG-NET 2

TX

1

RX

2

DI

3

LG-NET 3

TX

RX

RS-485 port

4

TX

6

5

LG-NET 4

RX

8

7

TX

10

9

Ext 1

RX

TX

12

11

Ext 2

RX

Ethernet 1

14

13

Ethernet 1

16

15

ACT

LNK

18

17

SELECT

MENU/

Ethernet 2

ACT

19

LNK

Ethernet port

20

Console

TX

RX

LAN Cable(Cross Cable)

Console port

2

1

DO

Run

4

3

Power

Power switch

& power port

Connect DC Adaptor

ENGLISH

Installation/Owner Manual 21

How to install

Software Installation

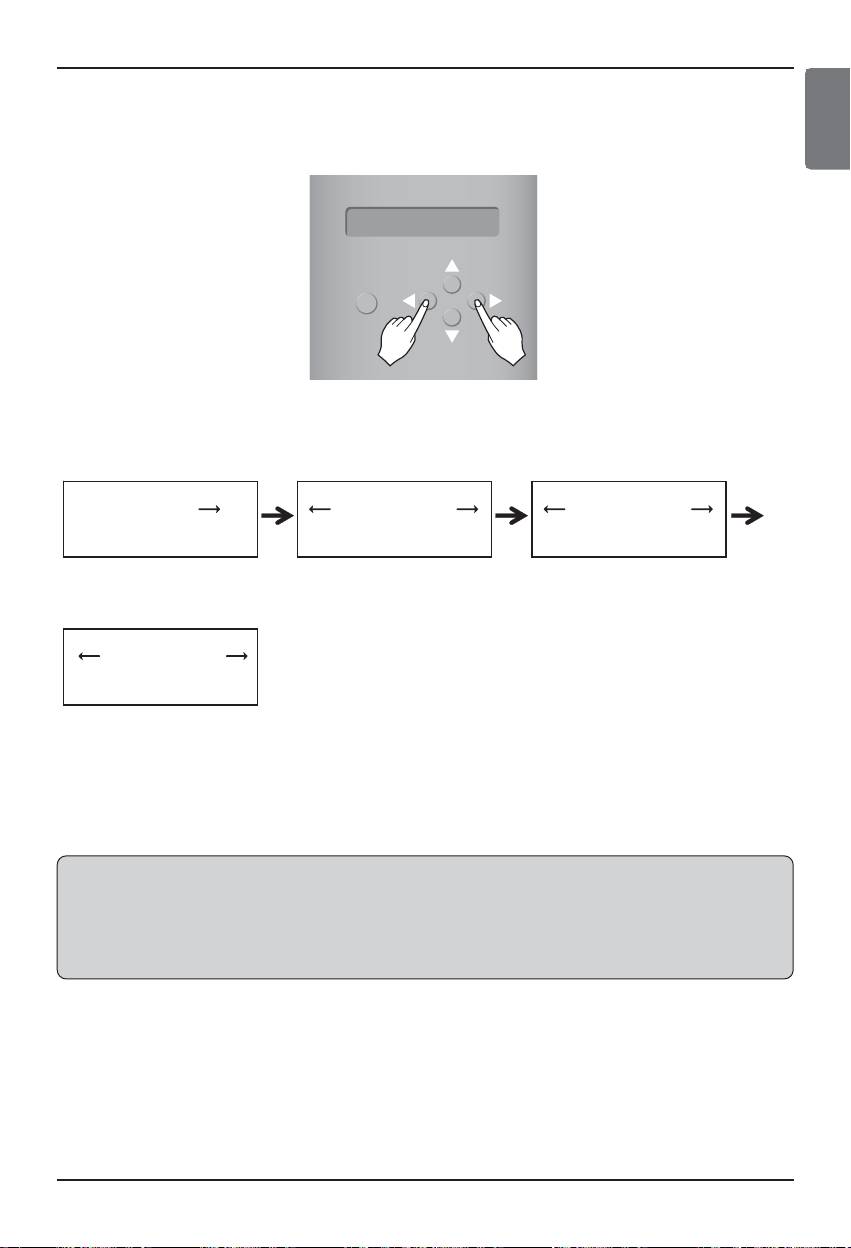

(1) How to set the BACnet Gateway

The following information should be set to use the BACnet Gateway

• BACnet Gateway network environment Setting IP address, Gateway address and Net mask address

■ Setup Order

1. Turn on the BACnet Gateway.

(The following screen will be displayed on the BACnet Gateway LCD screen about 5 seconds after

the power is turned on.)

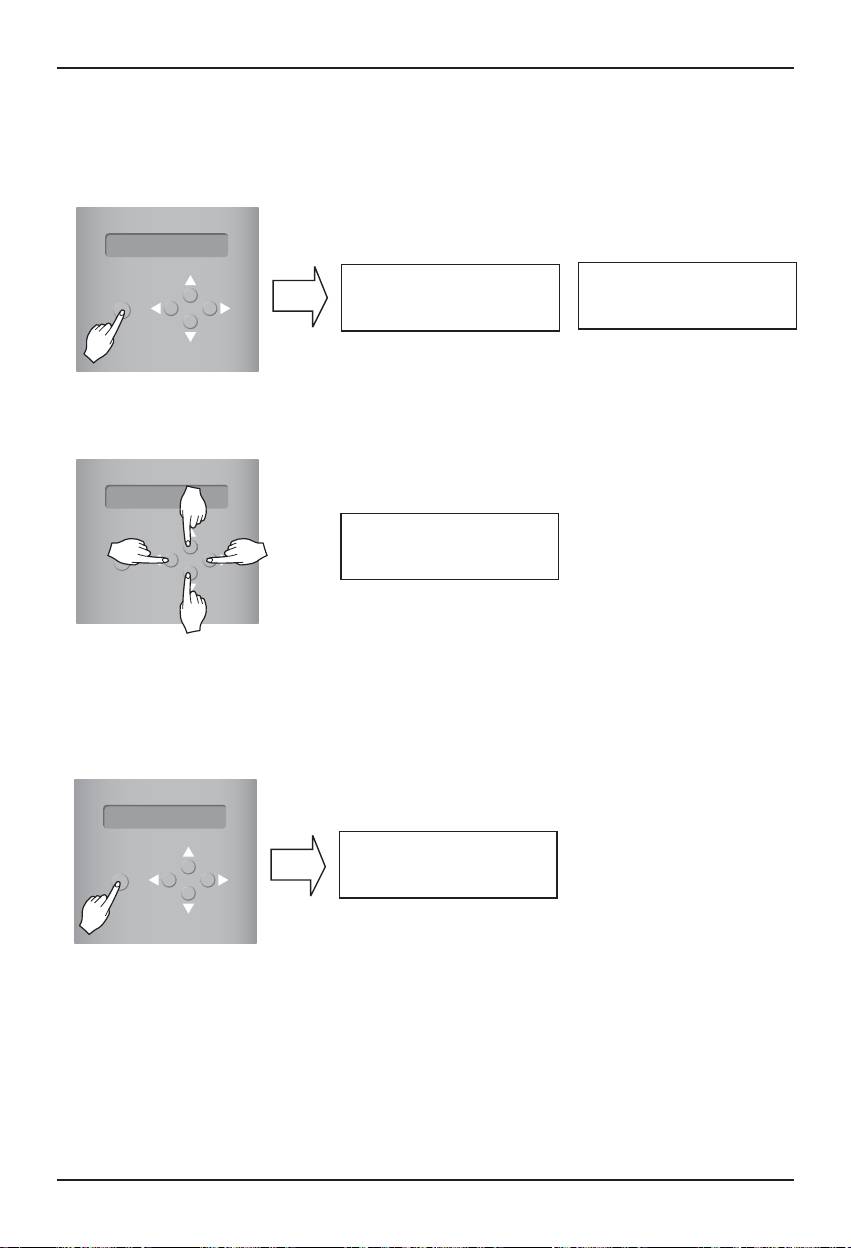

[LCD screen] [Start-up screen]

• S/W Ver. No. may be different

according to the manufactured date.

2.Press “MENU/SELECT” button of the BACnet Gateway to enter the environment setup mode.

• Menu selection displayed on the screen.

When the "MENU/SELECT" button is pressed

for the first time.

Select "Setting" mode to change setup. Select

"Information" mode to confirm setup state.

LG-NET 1

TX

RX

LG-NET 2

TX

1

RX

2

DI

LG-NET 3

TX

3

RX

4

LG-NET 4

TX

5

RX

6

7

8

Ext 1

TX

LCD Display

9

RX

10

Ext 2

TX

11

RX

12

13

14

ACT

15

Ethernet 1

LNK

BACnet Gateway Button

16

17

MENU/

ACT

18

SELECT

Ethernet 2

LNK

19

20

Console

TX

RX

1

2

DO

Run

3

4

Power

BACnet Gateway

LG Electronics

wait for booting

SW Ver.1.0.0

MENU/

SELECT

Setting

Information

22 BACnet Gateway

How to install

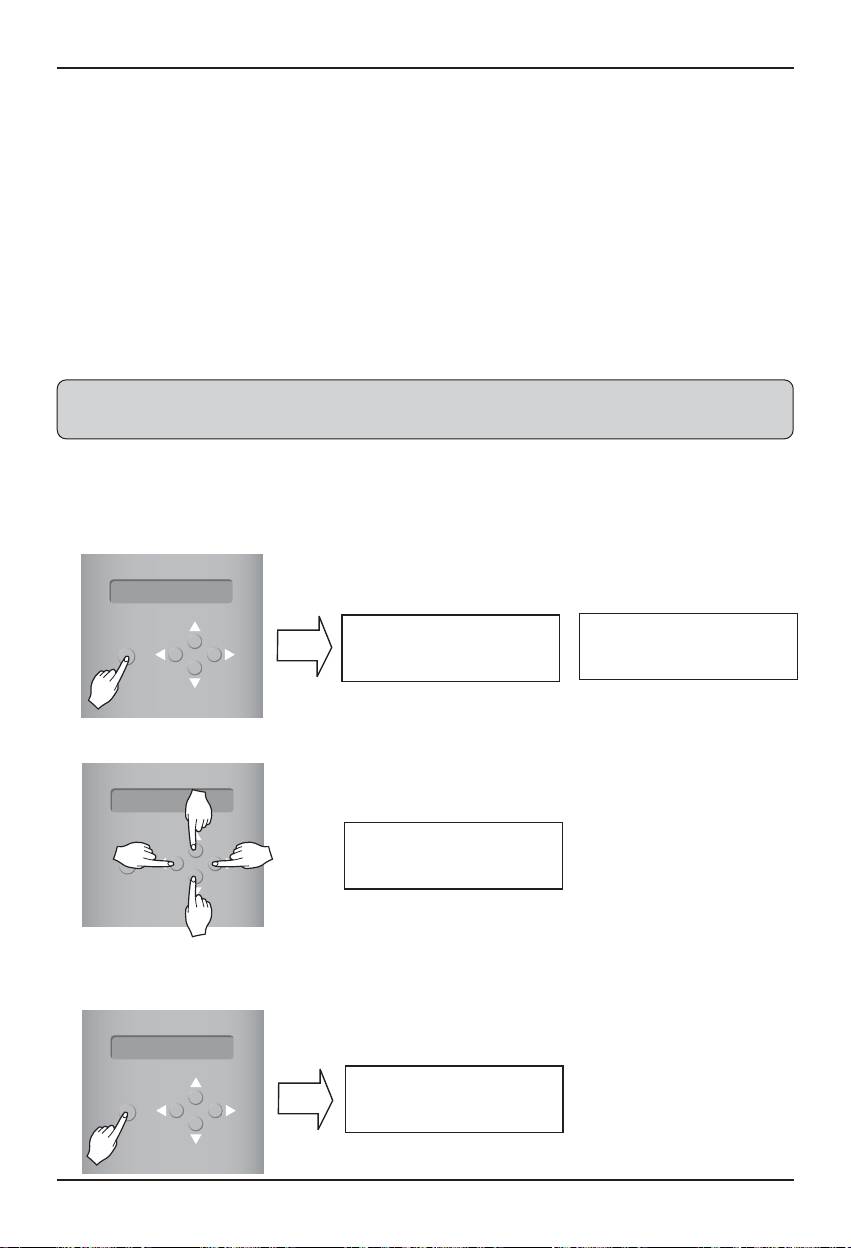

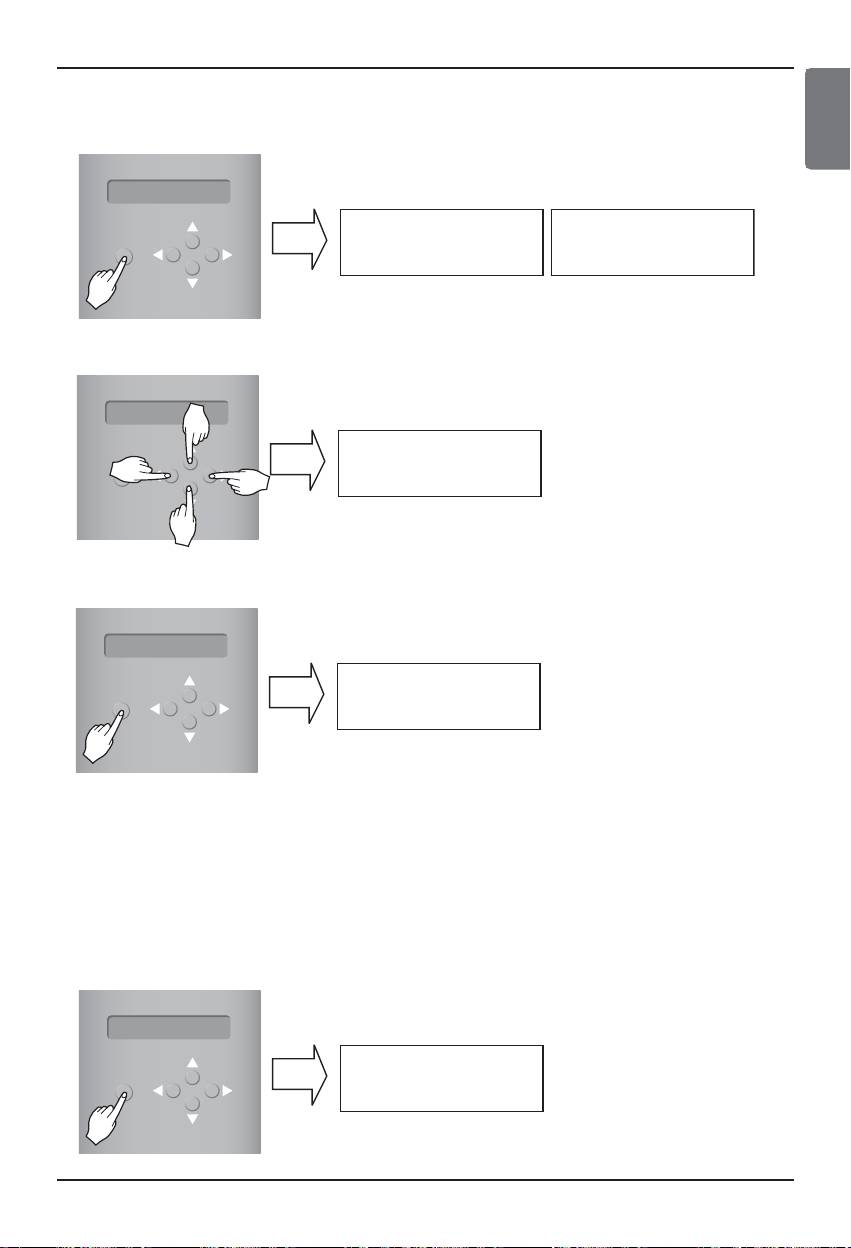

3. After selection "Setting" mode using the up/down(▲, ▼) button, use the left/right(◀, ▶) button to

select the desired function.

Enter the IP address Enter the Gateway address Enter the Net mask

Enter the Set BACnet Type

4. Press the “MENU/SELECT” button at the desired function to enter into the setup window for the

said mode.

Note: LG BACnet Gateway support two type Gateway depend on selection type "A" and type " B".

Type "A" support multi device per one IP address and Type " B" support only one device per

one IP address.

After asking BMS engineer about multi device or one device per one IP address, select LG

BACnet Gateway's "Set BACnet Type".

MENU/

SELECT

[MENU]

[MENU]

[MENU]

Set IP address

Set GW address

Set Netmask

[MENU]

Set BACnet Type

ENGLISH

Installation/Owner Manual 23

How to install

(2) Network environment setup of the BACnet Gateway

• After getting the IP address of the BACnet Gateway assigned from the network administrator, use

the button of the BACnet Gateway to set up the IP address and the network environment of the

BACnet Gateway.

■ Setup procedure

• Set the IP address

• Enter the Gateway address

• Enter the net mask

• Enter the Set BACnet Type

• Check the network environment setting

Note: If the above items are not entered, it is impossible to control the BACnet Gateway or it causes

the communication error, so make sure that all of them are correctly entered.

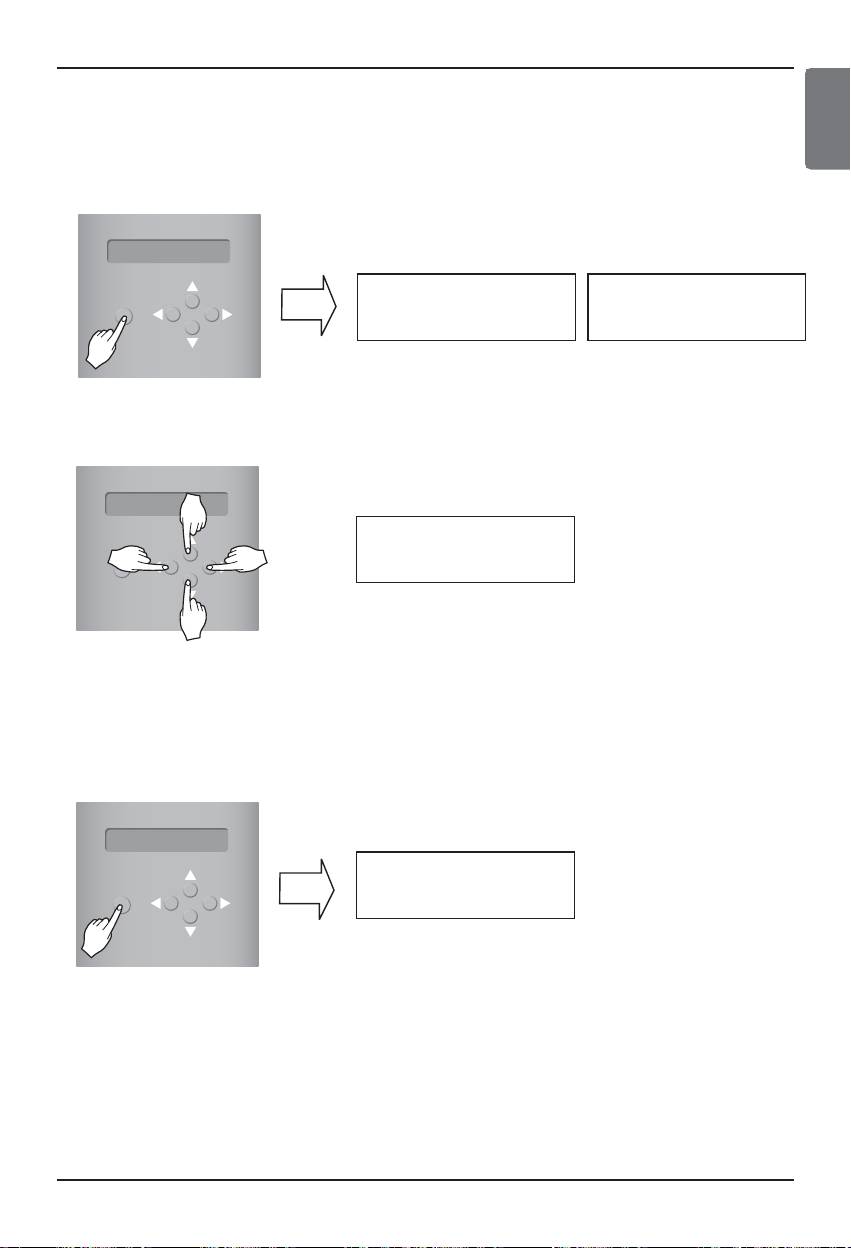

1. Setting the IP address

① First, press the "MENU/SELECT" button of the BACnet Gateway and selecting "Setting" menu.

When the following menu is displayed on the BACnet Gateway LCD screen, press the

“MENU/SELECT” button again to enter the IP address.

② Use the up/down/left/right button (▲,▼,◀,▶) to select the desired address.

③ After entering the last address, press the “MENU/SELECT” button to set the entered address to the

IP address. (When there is no “MENU/SELECT” button input for 5 seconds, the set value is ignored

to return to the existing address.

MENU/

SELECT

[LCD screen]

[MENU]

[Set IP address]

Set IP address

192.168.000.000

MENU/

SELECT

[Example for setting the Gateway address]

[Set IP address]

165.186.002.101

MENU/

SELECT

[LCD screen after completing the setup]

BACnet Gateway

SW ver. 1.0.0

24 BACnet Gateway

How to install

2. Setting the Gateway address

① Press the buttons by the following order. And then, when the following menu is displayed on the

BACnet Gateway LCD screen, press the “MENU/SELECT” button to enter the Gateway address.

② Use the up/down/left/right button (▲,▼,◀,▶) to select the desired address.

3 After entering the last address, press the “MENU/SELECT” button to set the entered address

to the Gateway address.

(When there is no “MENU/SELECT” button input for 5 seconds, the set value is ignored to return to

the existing address.

MENU/

SELECT

[LCD screen]

[MENU]

[Set GW address]

Set GW address

192.168.000.000

MENU/

SELECT

[Example for setting the Gateway address]

[Set GW address]

165.186.002.001

MENU/

SELECT

[LCD screen after completing the setup]

BACnet Gateway

SW ver. 1.0.0

ENGLISH

Installation/Owner Manual 25

How to install

3.Setting the net mask address

① Press the buttons by the following order. And then, when the following menu is displayed on the

BACnet Gateway LCD screen, press the “MENU/SELECT” button to enter the net mask address.

② Use the up/down/left/right button (▲,▼,◀,▶) to select the desired address.

3 After entering the last address, press the “MENU/SELECT” button to set the entered address

to the net mask address. (When there is no “MENU/SELECT” button input for 5 seconds, the

set value is ignored to return to the existing address.

MENU/

SELECT

[LCD screen]

[MENU]

[Set Netmask]

Set Netmask

192.168.000.000

MENU/

SELECT

[Set Netmask]

255.255.255.000

MENU/

SELECT

[LCD screen after completing the setup]

BACnet Gateway

SW ver.1.0.0

26 BACnet Gateway

How to install

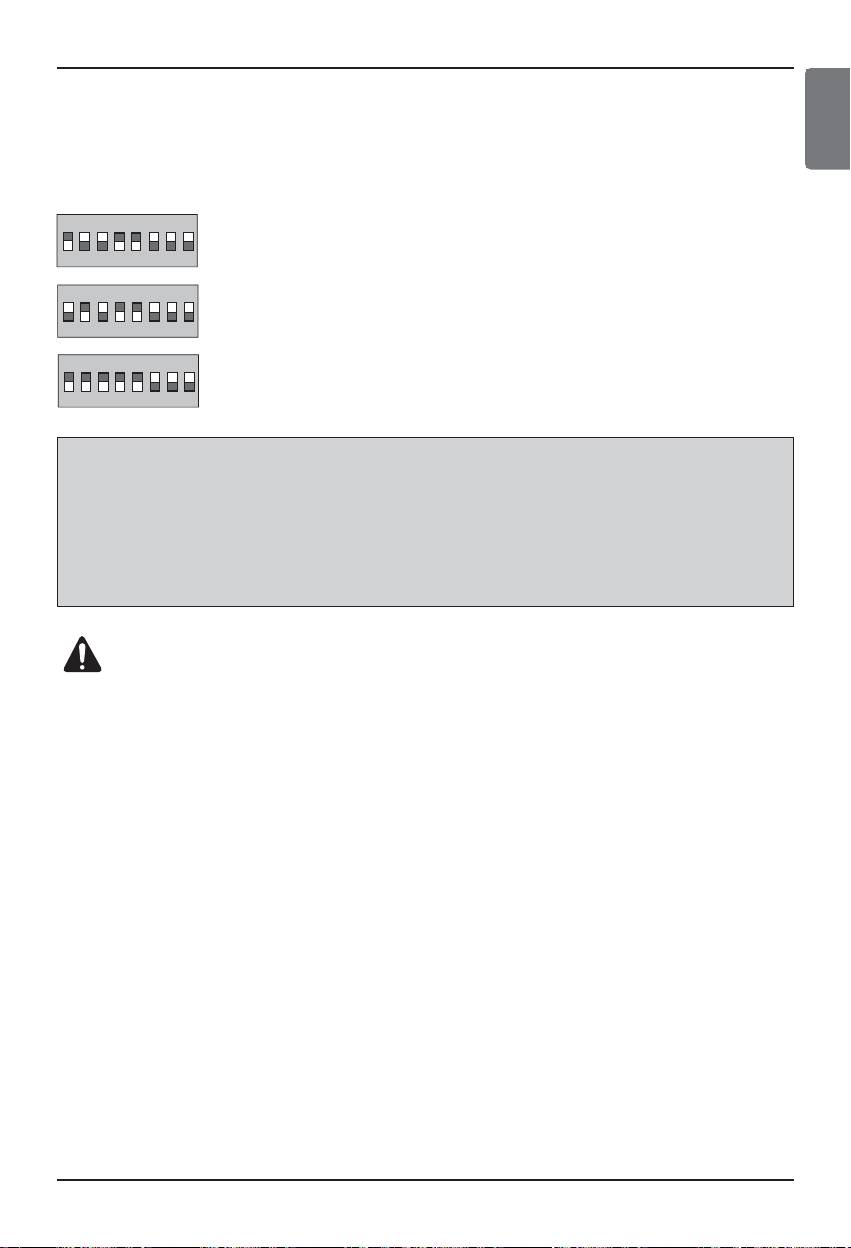

4. Setting the Set BACnet Type

① Pres4s the button by the following order. When the following menu is displayed on the BACnet

Gateway LCD screen, press the "MENU/SELECT" button to enter the Set BACnet Type.

② Use the up/down/left/right button (▲,▼,◀,▶) to select the desired BACnet Type.

③ After selecting the BACnet Type, press the "MENU/SELECT" button to set the selected BACnet

Type to the Set BACnet Type.

5. Checking the network environment setting

Press the buttons by the following order. And then, when the following menu is displayed on the

BACnet Gateway LCD screen, press the “MENU/SELECT” button to check the set network

information.

The other information is displayed on the screen every 3 seconds.

(Order to display the information : MAC address → IP address → Gateway address → Net mask

address → Set BACnet Type)

MENU/

SELECT

[LCD screen]

Setting

Information

MENU/

SELECT

[MENU]

[Set BACnet Type]

Set BACnet Type

A ‘

MENU/

SELECT

[Example for setting the gateway Set BACnet Type]

[Set BACnet Type]

A ‘ B

MENU/

SELECT

[LCD screen after completing the setup]

BACnet Gate way

SW ver.1.0.0

ENGLISH

Installation/Owner Manual 27

LGʼs BACnet Gateway Agreement

LGʼs BACnet Gateway Agreement

JMT (Joint Matching Test) – This is necessary for every independent BMS.

The case where a JMT is not necessary is where previously a successful JMT has been carried

out and the BMS system has not been updated by software or hardware changes. In the case

that the BMS has updated their system by either changes, a following JMT will be required.

BNU-BAC Diagnosis – Use of LG's BNU-BAC setup-tool is for confirming the operation/state of

connected A/C units & address ID's, prior to connection with the BMS system.

BMS Engineering – Creating of the Points. This is NOT to be done by LG since it is directly related to

the BMS side. The BMS engineer is to carry out the engineering of the Point, however LG is

responsible for providing the method of how the Points are calculated.

Commission – First step, only using LG's BACnet Gateway, without connecting BMS. This is to be

carried out by LG engineering staff with the use of the BNU-BAC set up tool.

Discrepancy of operation of Gateway by BMS - In the case that the BMS maker feels that the

BACnet Gateway is not functioning correctly via the BACnet Protocol, a test with the use of LG's

BACnet Client software can confirm this. (This test is generally not required)

Hub

BACnetBACnet

LG-NET 1

TX

RX

1

LG-NET 2

TX

2

4

3

DI

RX

LG-NET 3

TX

RX

6

5

LG-NET 4

TX

RX

8

7

9

Ext 1

TX

10

RX

Ext 2

TX

12

11

RX

14

13

16

15

Ethernet 1

ACT

LNK

BACnet Gateway Diagnosis

18

17

MENU/

ACT

20

19

SELECT

Ethernet 2

LNK

Console

TX

RX

2

1

DO

Run

1. Creating of indoor and vent points.

4

3

Power

LG-NET

2. Test of all units and operations.

LG Engineering Side BMS Engineering Side

Note : After the LC BACnet Gateway agreement part, please scrutinize with Companies specialized

in BMS.

28 BACnet Gateway

Test operation procedure

ENGLISH

Test operation procedure

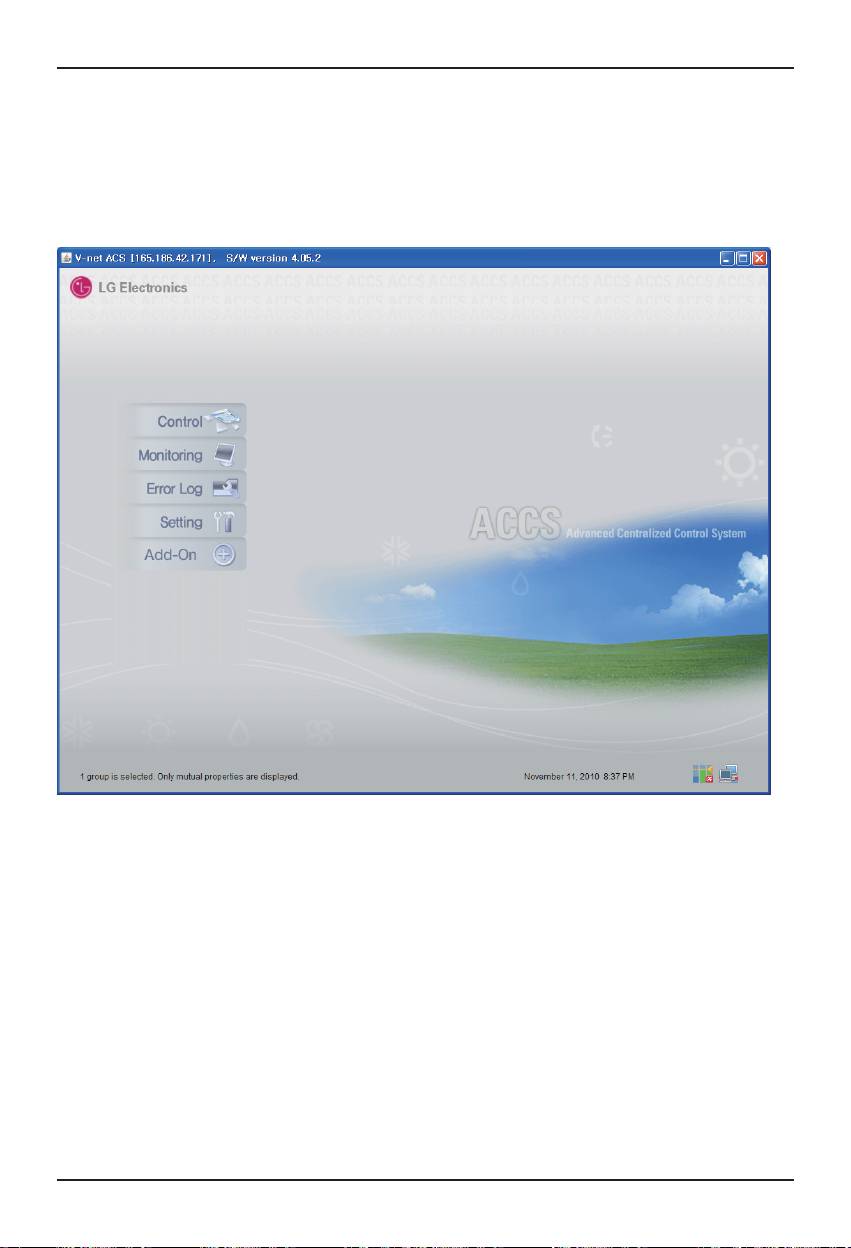

Web control and monitoring

The following procedure is BACnet Gateway test operation for remote control function.

■ Connecting to BACnet Gateway server.

In order to connect to the BACnet Gateway server connect the Ethernet1 (LAN port) in the Gateway

to the PC Input the default IP address on the URL address box for connection.

ID and PW are bacnet, bacnet.

Installation/Owner Manual 29

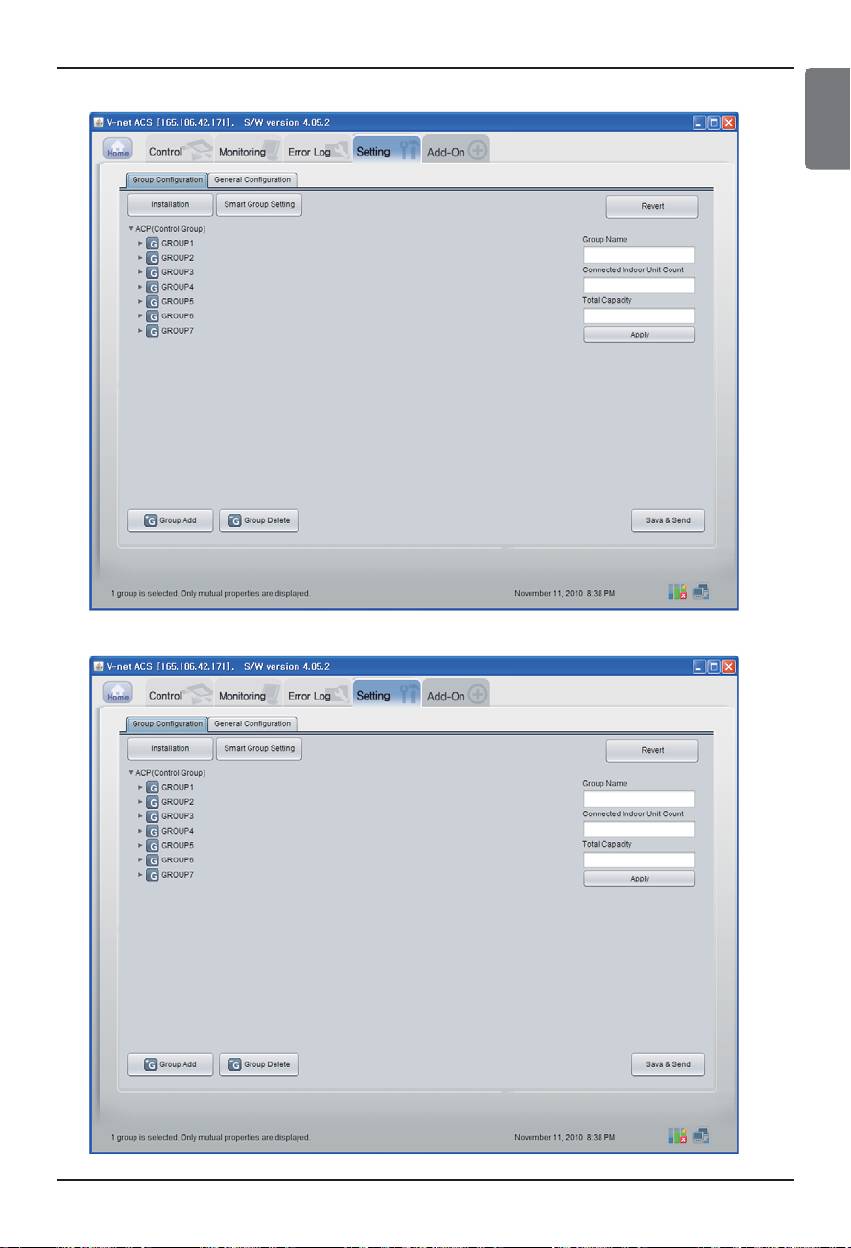

Test operation procedure

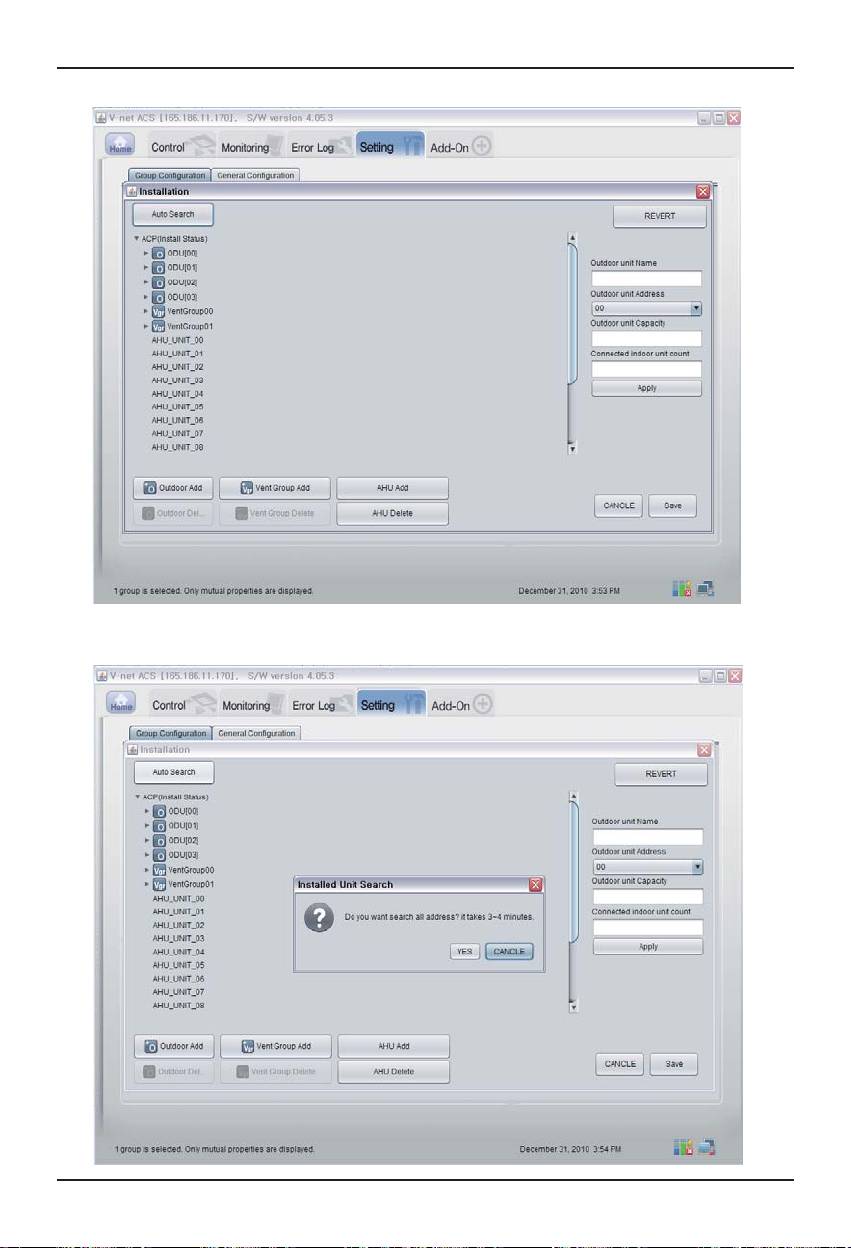

■ Auto address search

The address of the installed indoor unit can automatically be searched.

To search the indoor unit automatically, proceed as follows.

1. When the program is launched normally, the following screen will be displayed.

Click “Setting” menu.

30 BACnet Gateway

Test operation procedure

ENGLISH

2. As shown below, Setting screen will be appeared

3. Click on ʻInstallationʼ button.

Installation/Owner Manual 31

Test operation procedure

4. Click on ʻAuto searchʼ button.

5. Click on ʻYesʼ button to search the address of the indoor unit.

32 BACnet Gateway

Test operation procedure

ENGLISH

6. Screen when search is in progress.

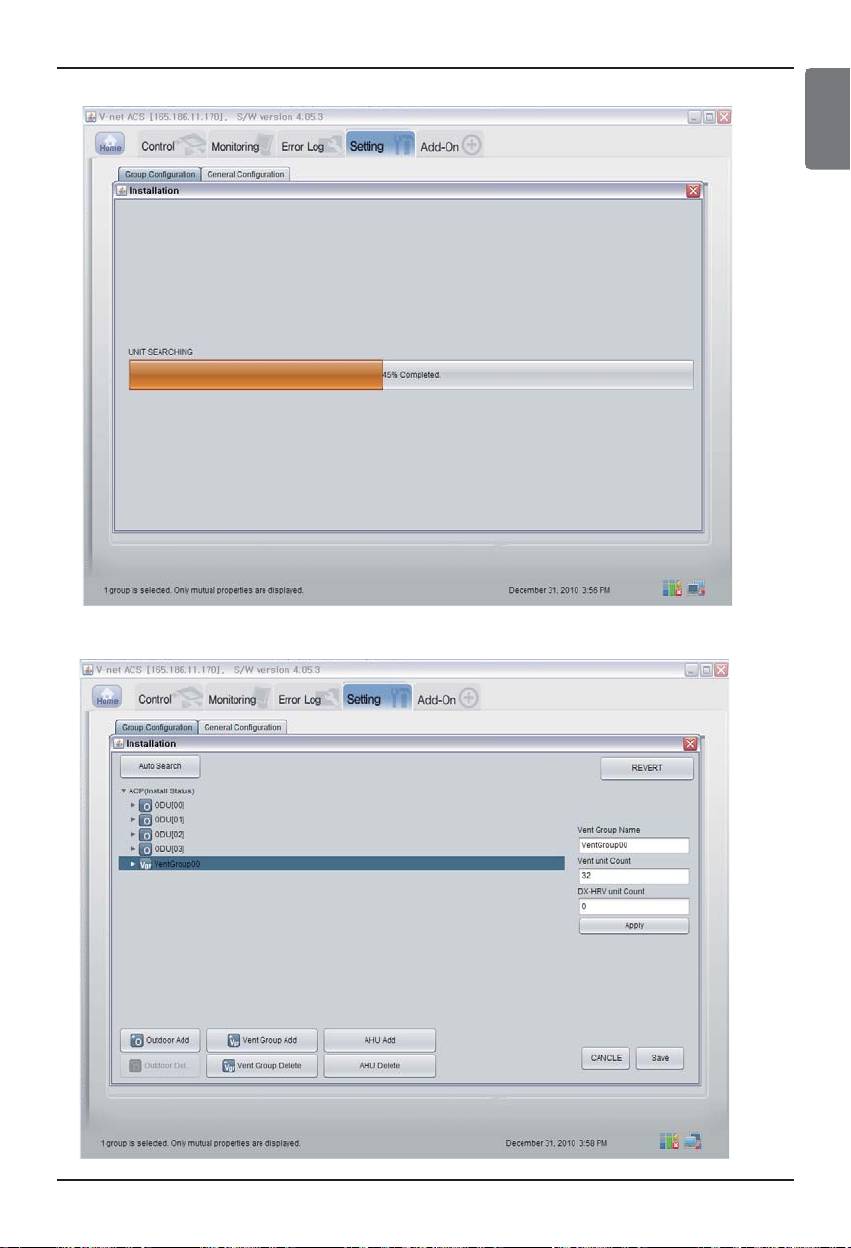

7. Screen when search is completed. If There is no AHU, go to the step 10.

Installation/Owner Manual 33

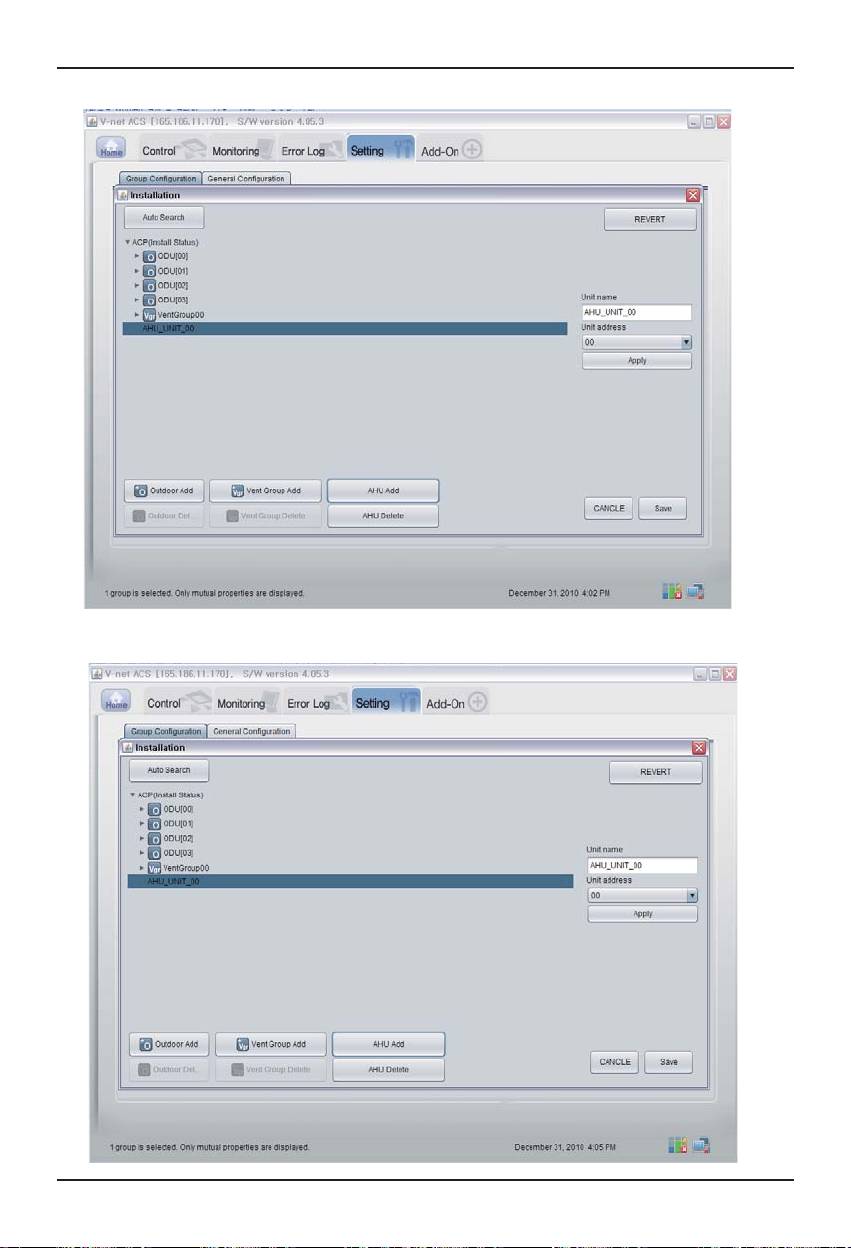

Test operation procedure

8. Click ʻAHU Addʼ button.

9. Click on “Save” button.

34 BACnet Gateway

Test operation procedure

ENGLISH

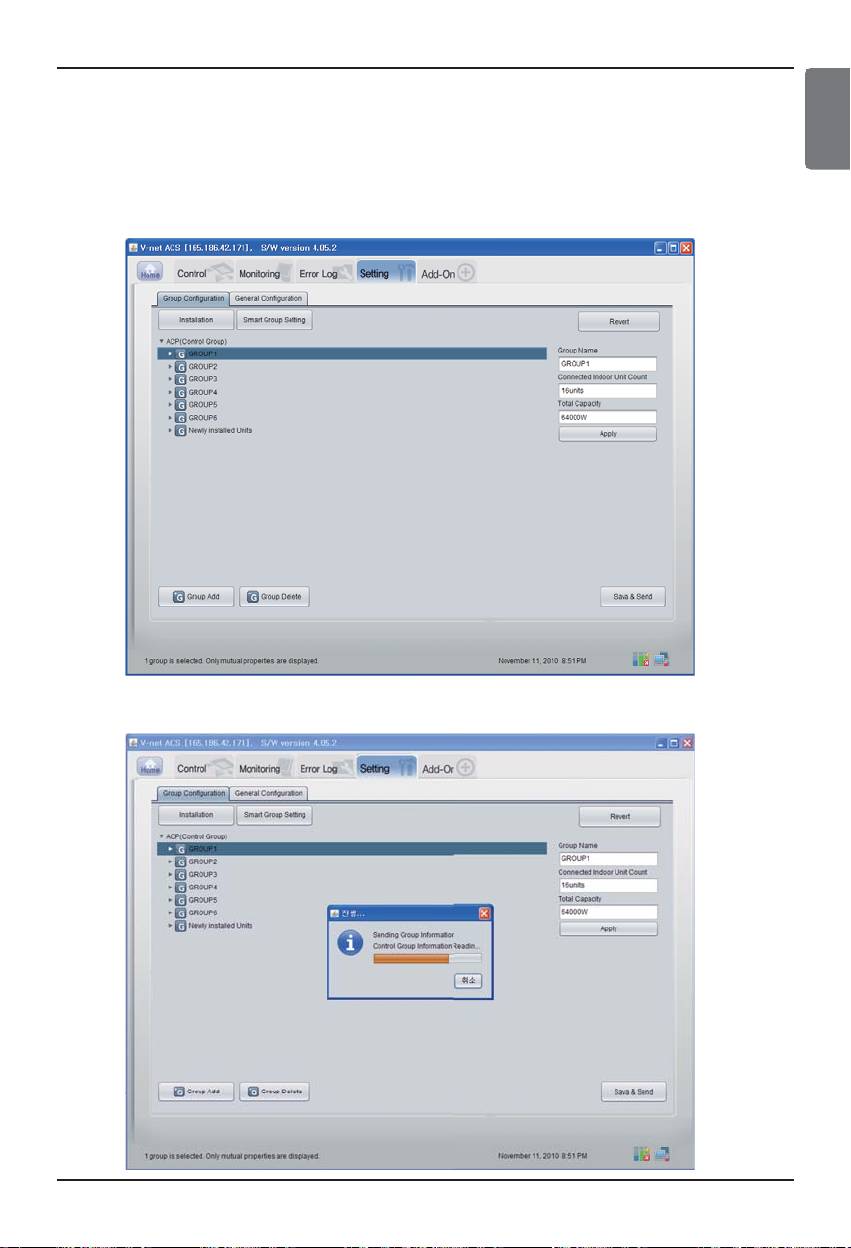

10. As shown below, Setting screen will appear.

1) Click on ʻSmart Group Settingʼ button to automatically create the group based on the

outdoor unit.

2) If you want to move the indoor unit to a different group, click the indoor unit with the

mouse and drag.

3) If you want to rename the group or indoor unit, change the name on the right window and

click on the ʻApplyʼ button.

4) When the group setting is completed, click on the ʻSave & Sendʼ button.

11. When all items are set, click “Save & Send” button to save.

The saving process is performed.

Installation/Owner Manual 35

Test operation procedure

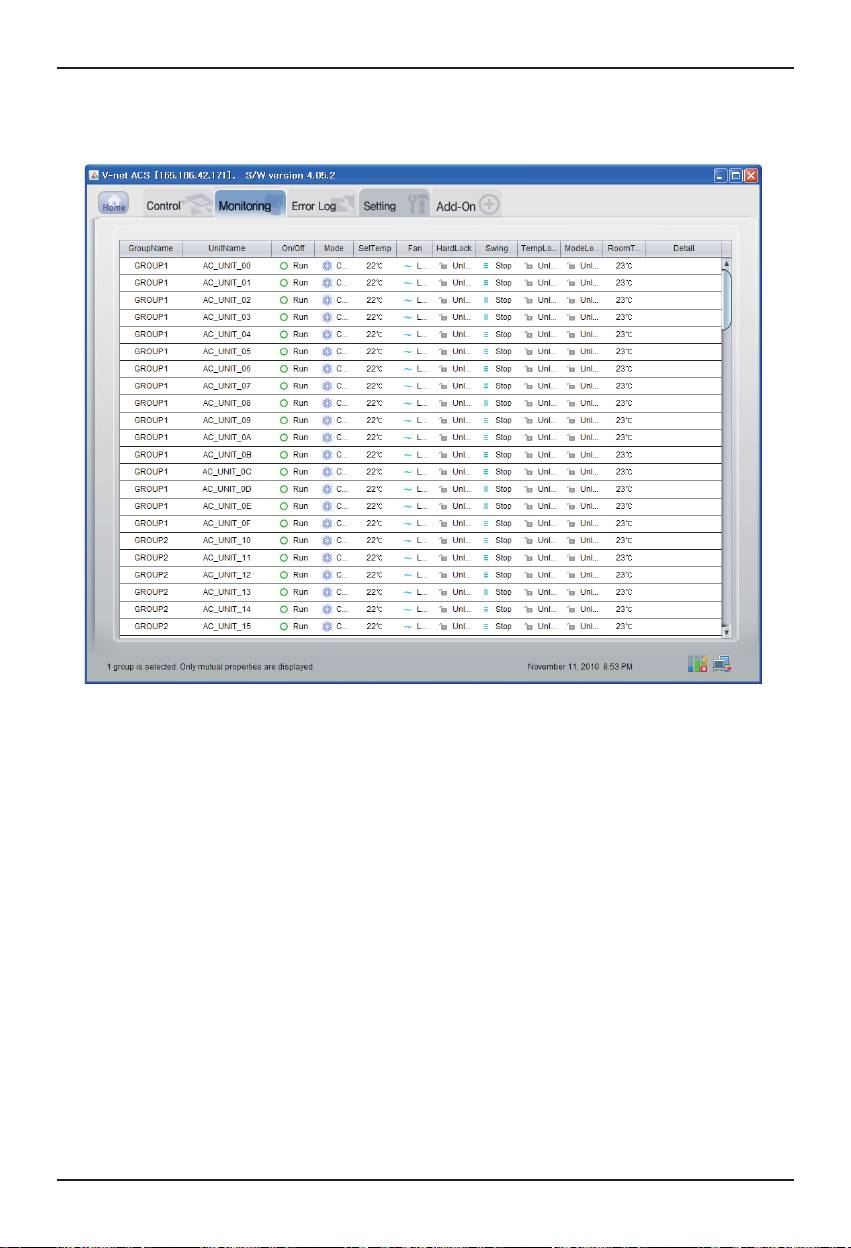

■ Confirmation of monitoring data function

Click the "Monitoring(Indoor Unit/Vent/AHU)" button at the top Remote Diagnosis page, and you

can confirm the information of Indoor Unit/Vent/AHU.

36 BACnet Gateway

Test operation procedure

ENGLISH

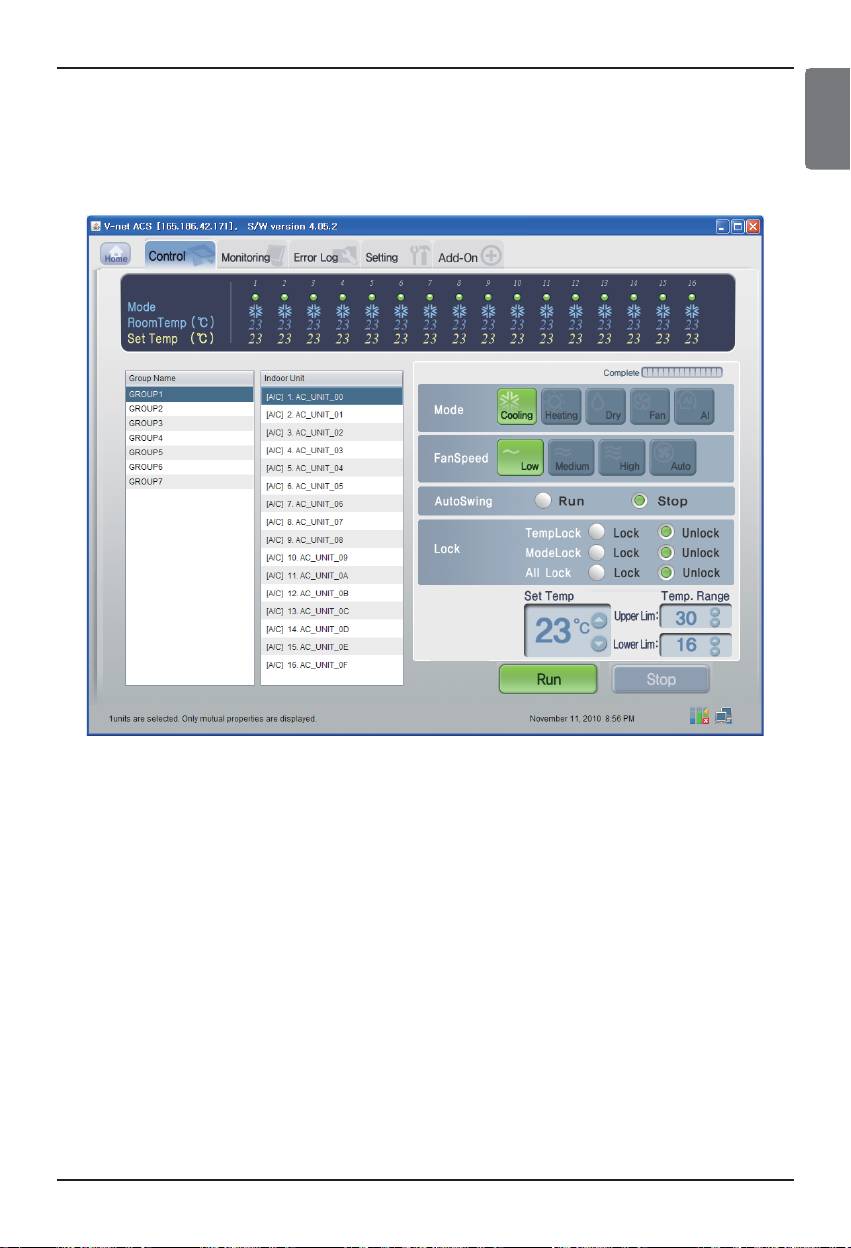

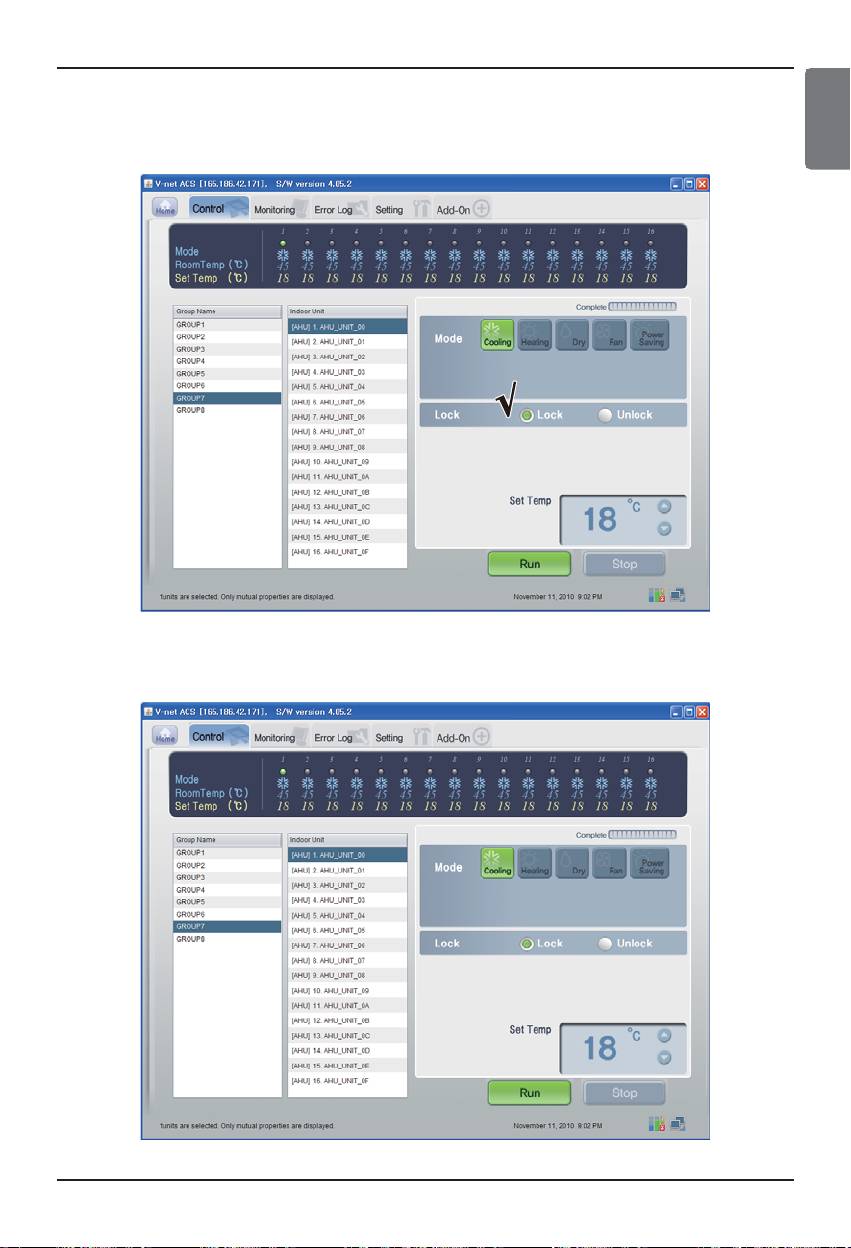

■ Confirmation of Control Function (Indoor Unit/Vent/AHU)

Click the "Control(Indoor Unit/Vent/AHU)" button at the top Remote Diagnosis page, and you can

confirm the data of Indoor Unit/Vent/AHU in real-time.

Installation/Owner Manual 37

Test operation procedure

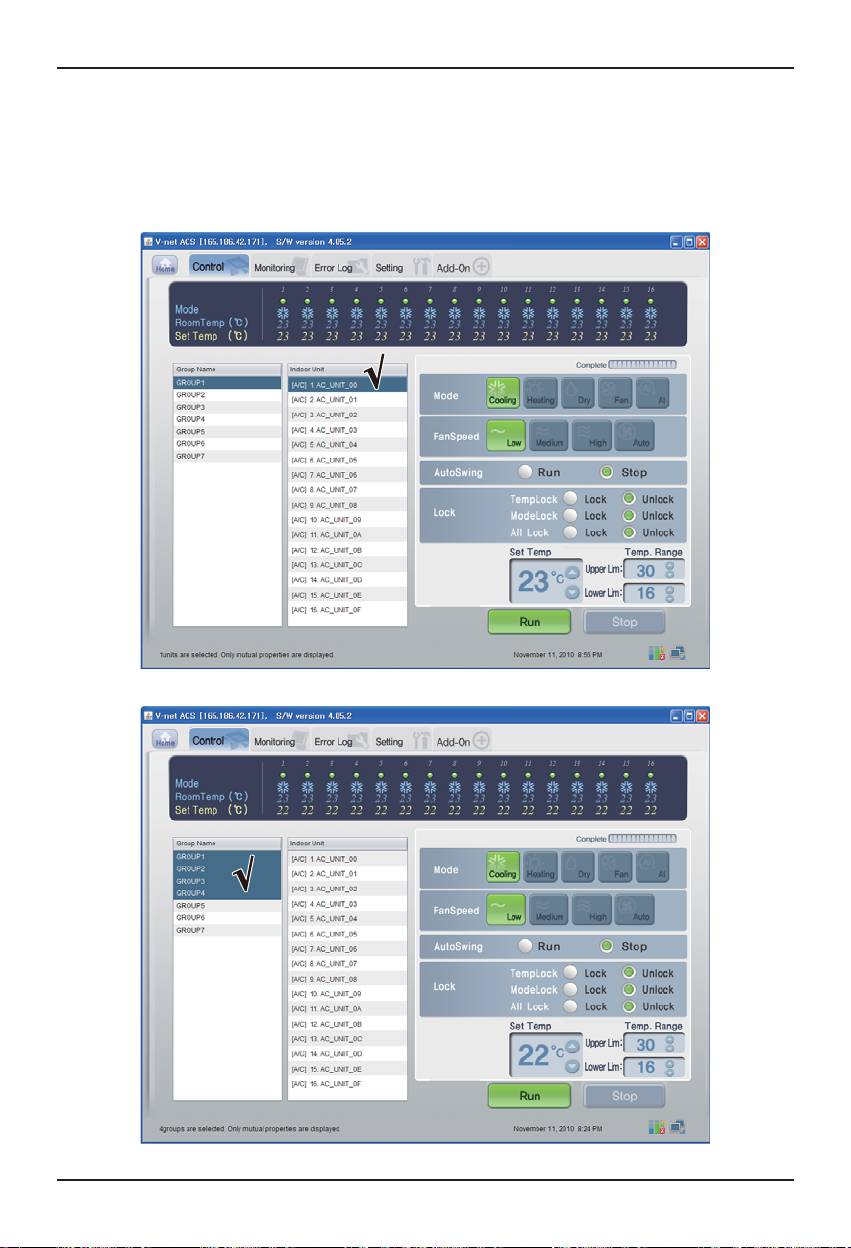

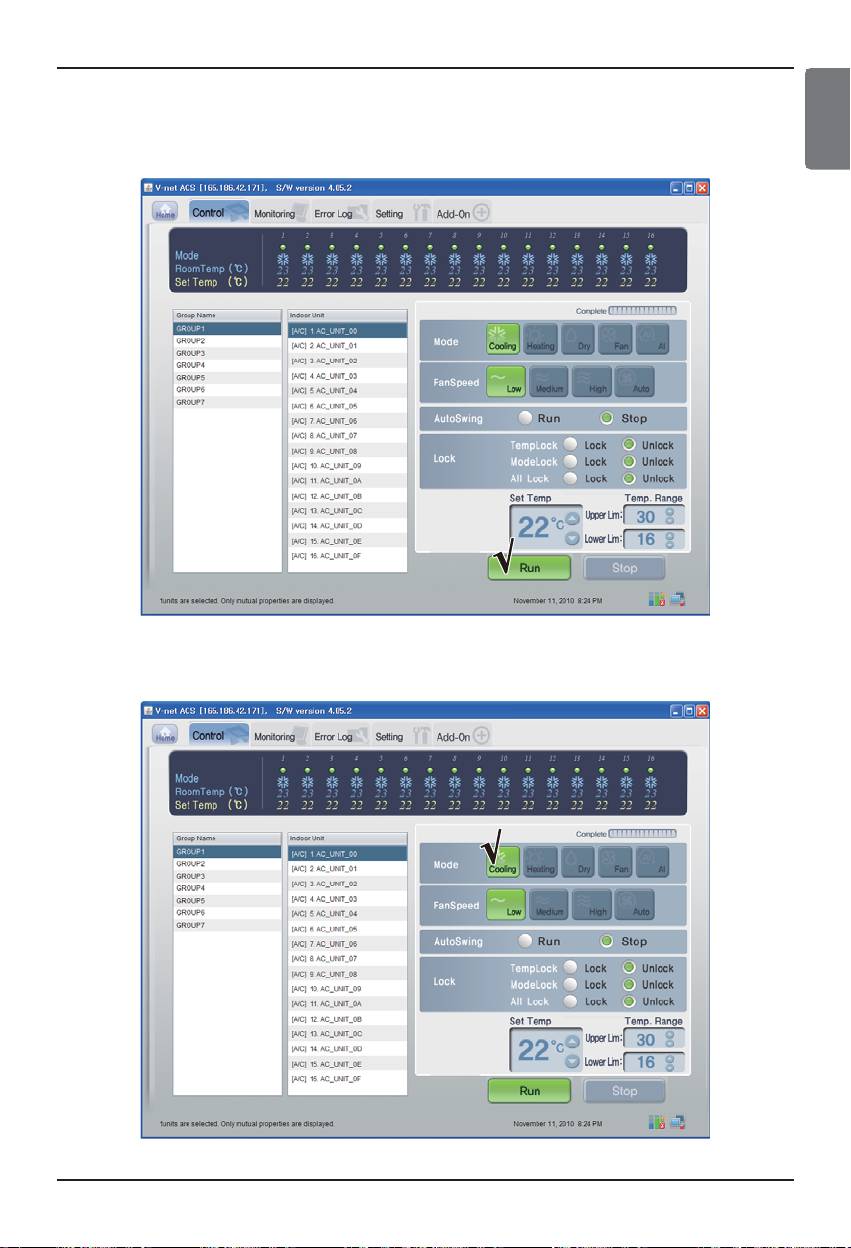

■ Indoor Control

Click the Indoor's Control Group

- Individual / Total Control

Click the unit which will be controlled for individual control or click ALL for total control.

< Individual Control >

< Total Control >

38 BACnet Gateway

Test operation procedure

ENGLISH

- Control : Run/Stop

(1) Click the Run/Stop button.

< Run/Stop Control >

- Control :Mode

(1) Click the Mode button. (Cooling/Heating/Dry/Fan/AI)

< Mode Control >

Installation/Owner Manual 39

Test operation procedure

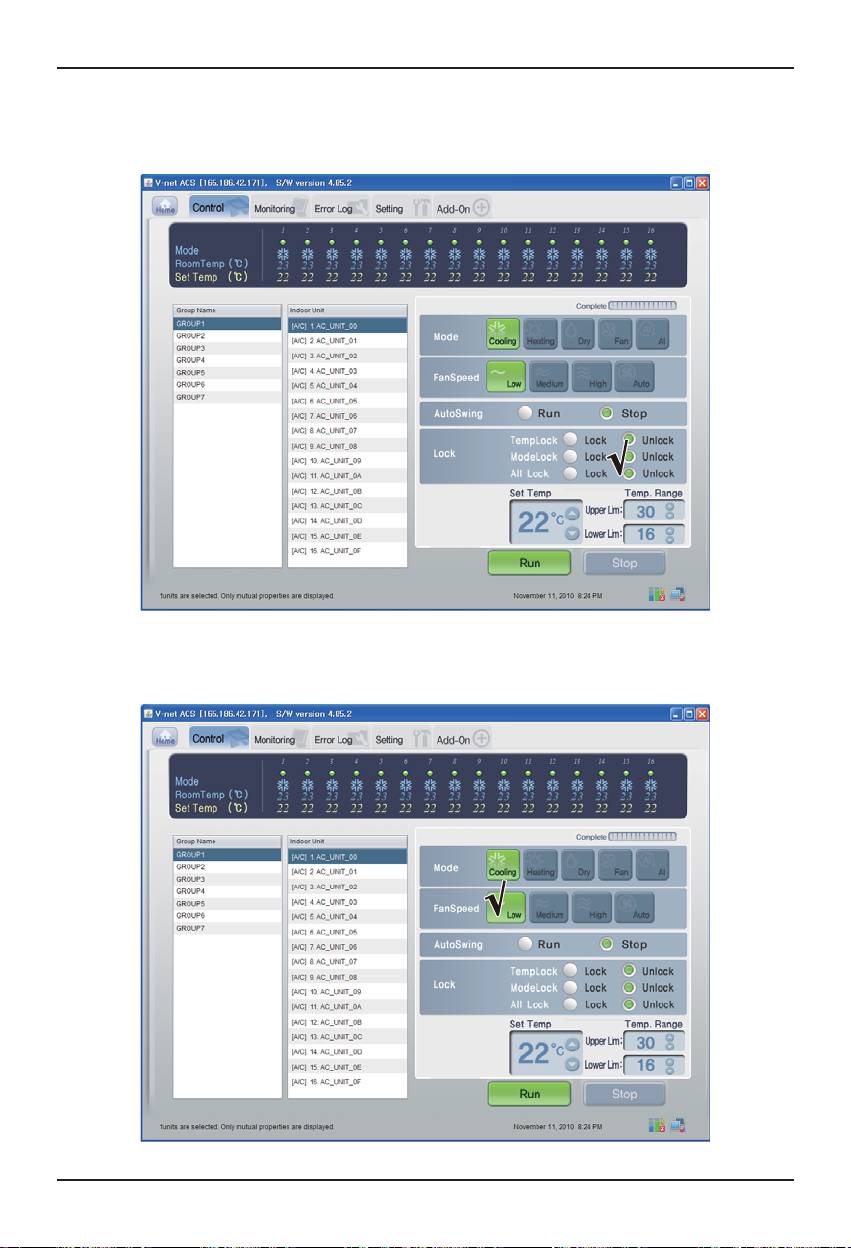

- Control : Lock/Unlock

(1) Select the Lock button. (Temp Lock/Mode Lock/ All Lock)

< Lock/Unlock Control >

- Control : Fan Speed

(1) Click the Fan Speed button. (Low/Medium/High/Auto)

< Fan Speed Control >

40 BACnet Gateway

Test operation procedure

ENGLISH

- Control : Swing

(1) Select the Auto Swing button. (Run/Stop)

< Swing Control >

- Control:Temp.

(1) Click the Up/Down button for Set Temp.

< Temp. Control >

Installation/Owner Manual 41

Test operation procedure

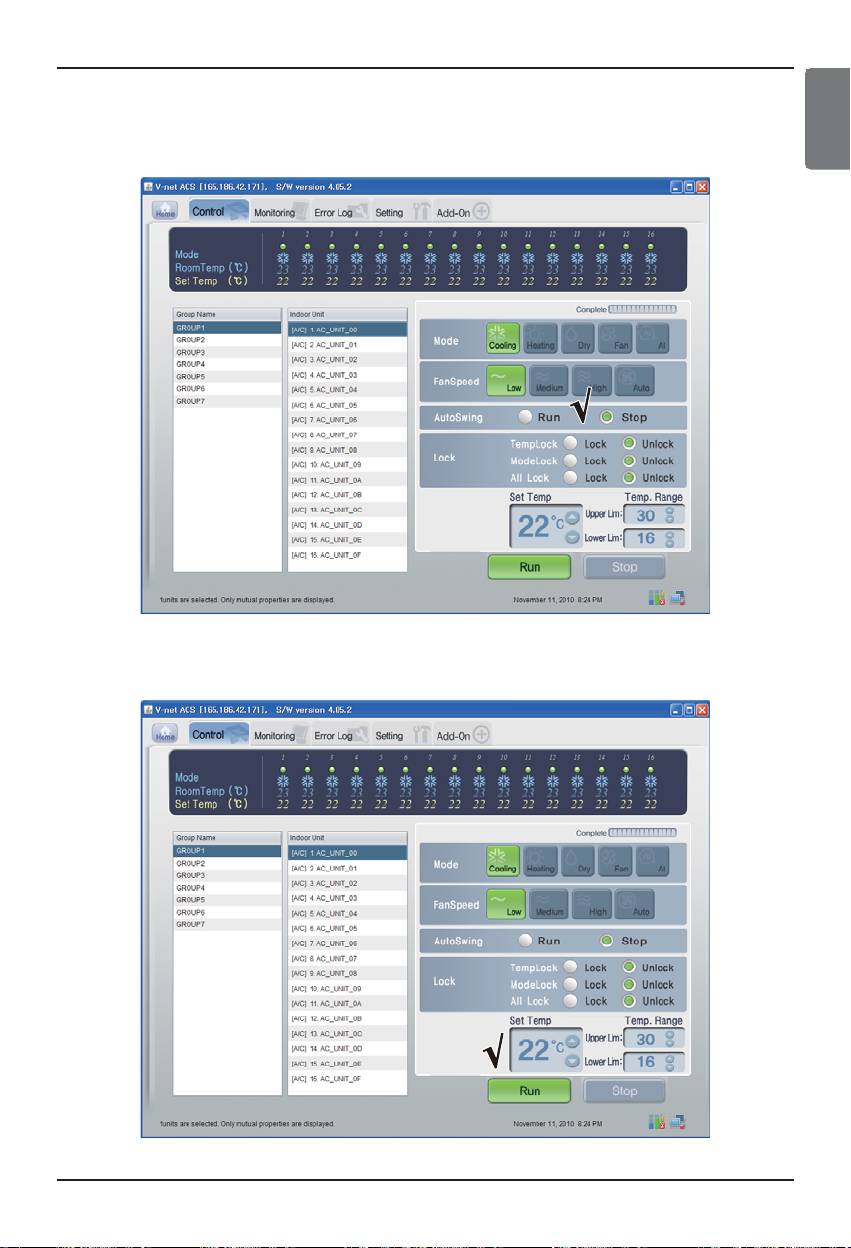

■ Vent Control

Click the Vent Control Group

- Individual Control / Total Control

Click the unit which will be controlled for individual control or Click ALL for total control.

< Individual Control >

< Total Control >

42 BACnet Gateway

Test operation procedure

ENGLISH

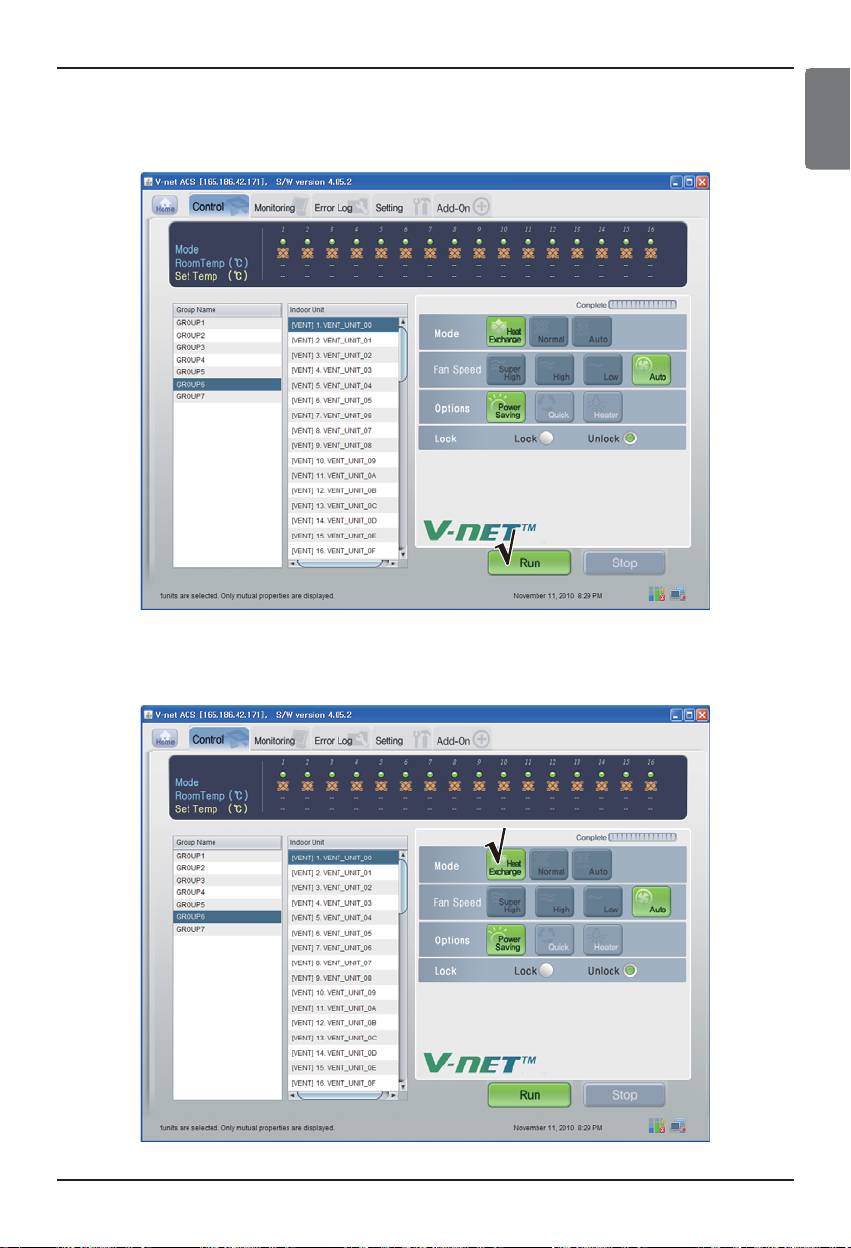

- Control : Run/Stop

(1) Click the Run/Stop button.

< Run/Stop Control >

- Control : Mode

(1) Click the Mode button. (Heat Exchange/Normal/Auto)

< Mode Control >

Installation/Owner Manual 43

Test operation procedure

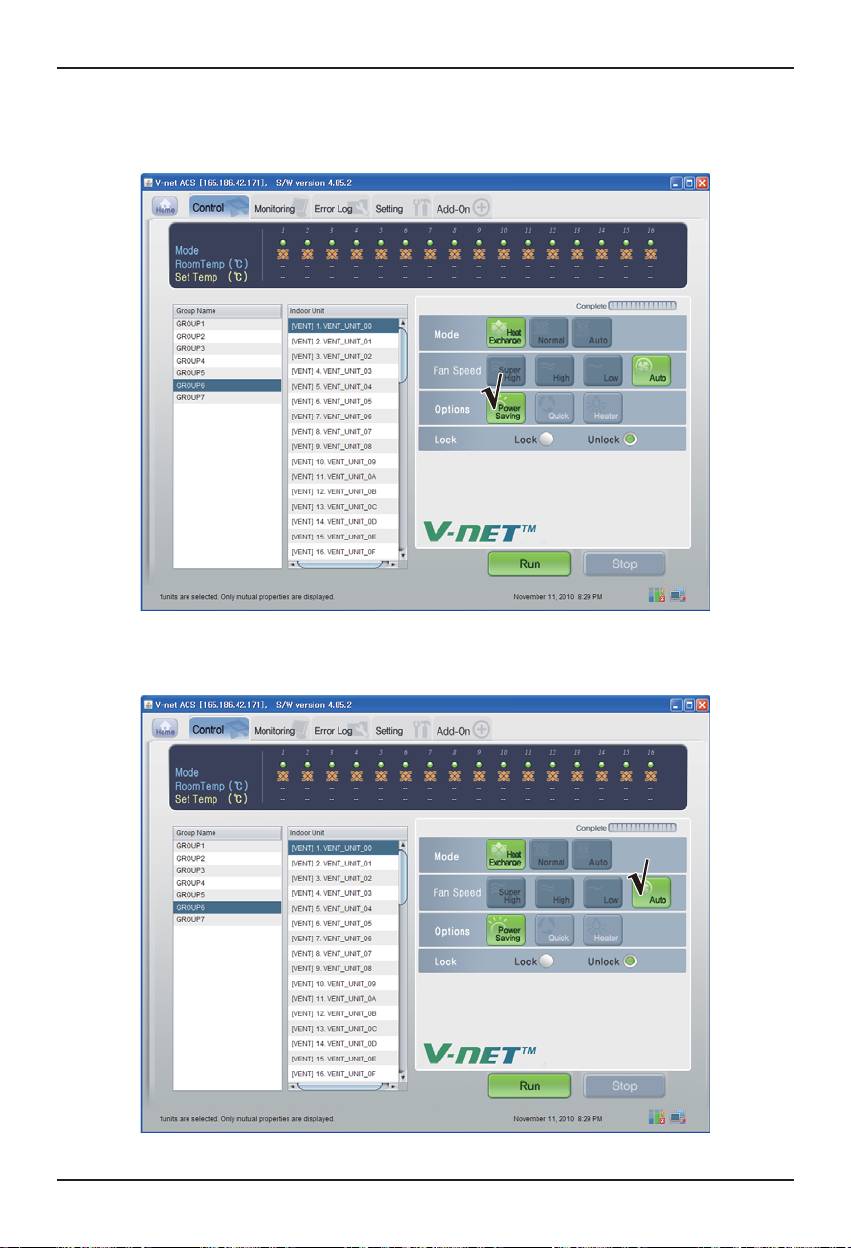

- Control : User Mode

(1) Click the Options(User Mode) button. (Power Saving/Quick/Heater)

< User Mode Control >

- Control : Fan Speed

(1) Click the Fan Speed button. (Super High/High/Low/Auto)

< Fan Speed Control >

44 BACnet Gateway

Test operation procedure

ENGLISH

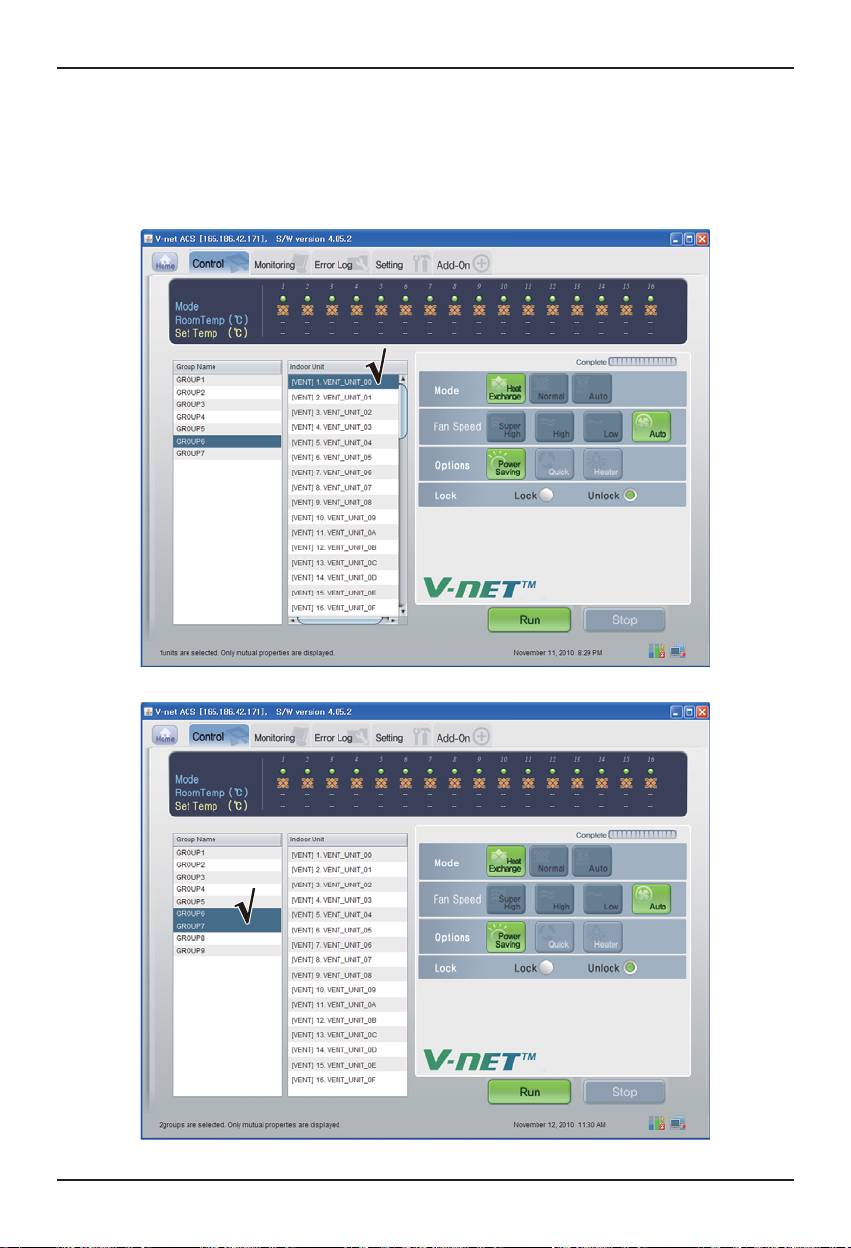

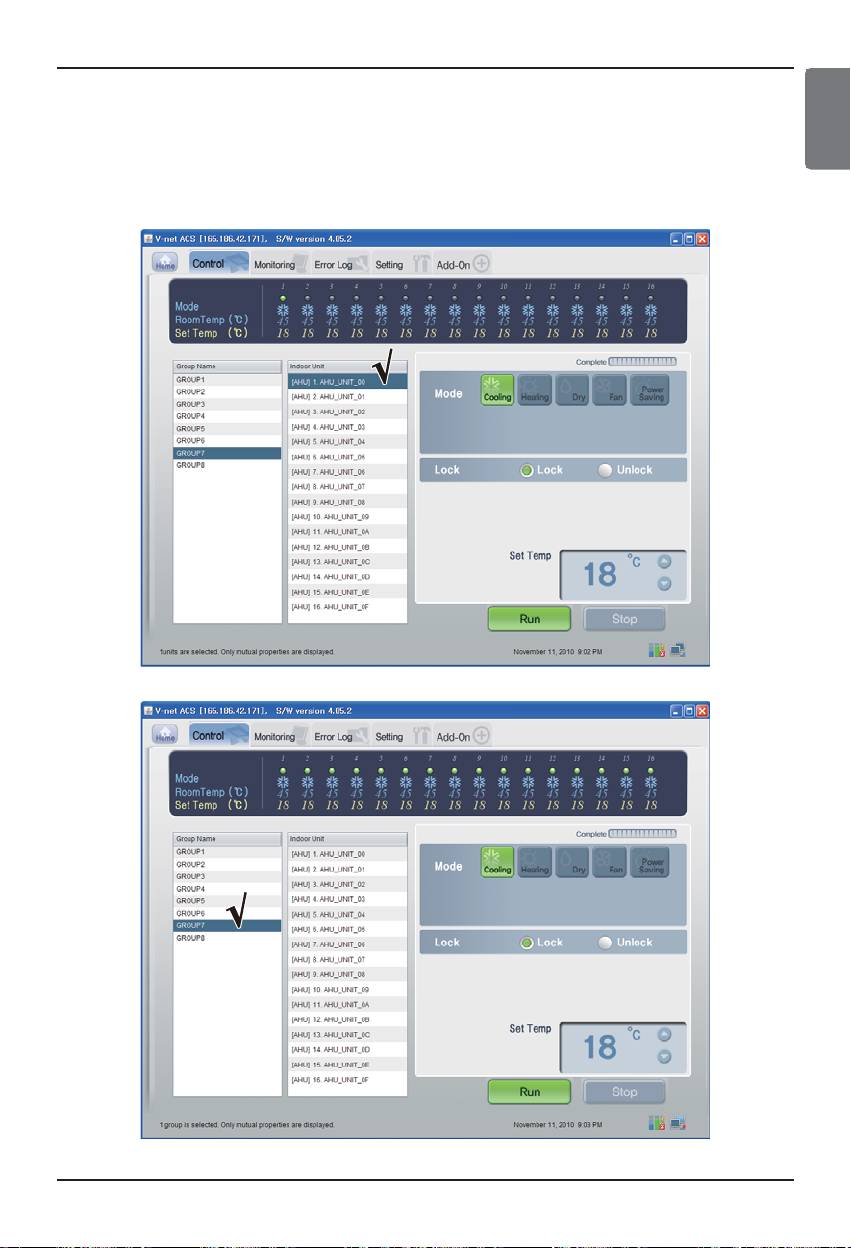

■ AHU Control

Click the AHU Control Group

- Individual Control / Total Control

Click the unit which will be controlled for individual control or Click ALL for total control.

< Individual Control >

< Total Control >

Installation/Owner Manual 45

Test operation procedure

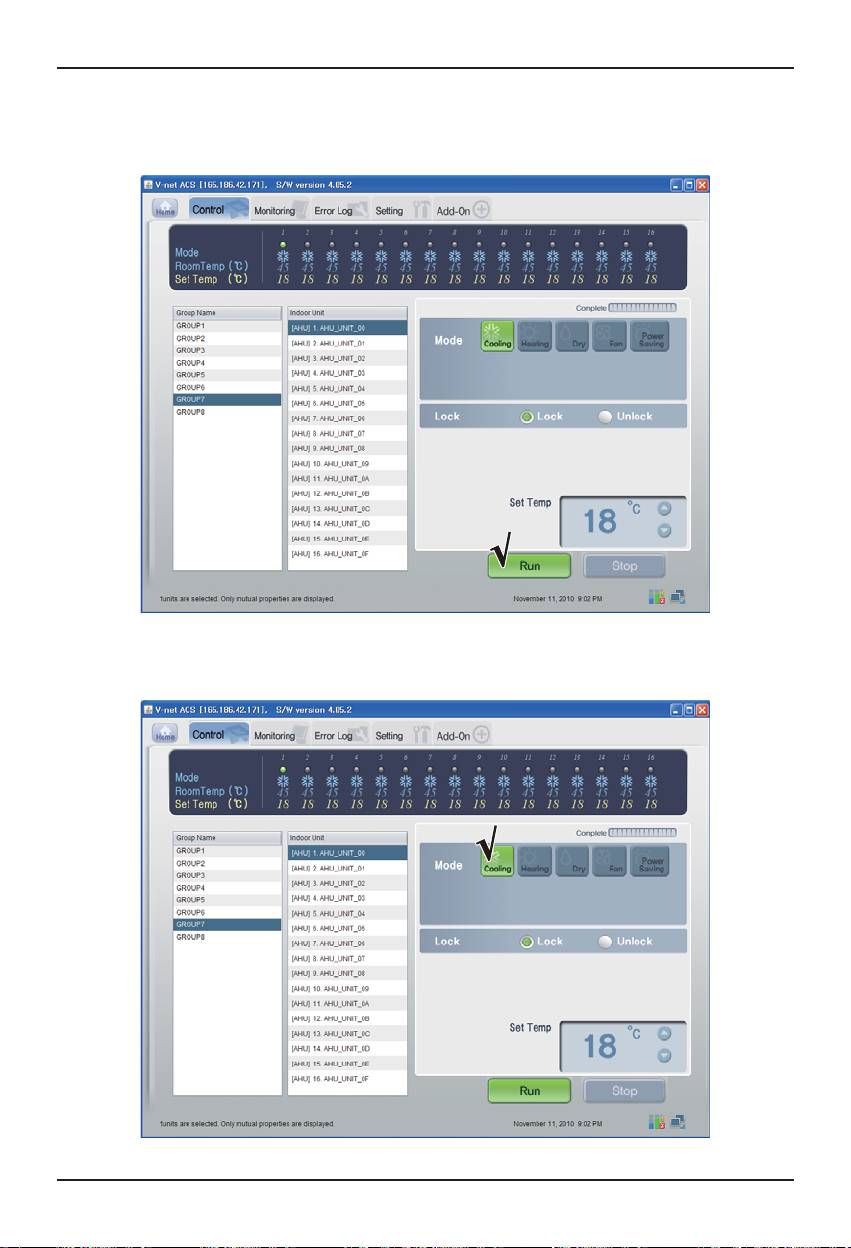

- Control : Run/Stop

(1) Click the Run/Stop button.

< Run/Stop Control >

- Control : Mode

(1) Click the Mode button. (Cooling/Heating/Dry/Fan/Power Saving)

< Mode Control>

46 BACnet Gateway

Test operation procedure

ENGLISH

- Control : Lock/Unlock

(1) Click the Lock button. (Lock/Unlock)

< Lock/Unlock Control >

- Control:Temp.

(1) Click the Up/Down button for Set Temp.

< Temp. Control >

Installation/Owner Manual 47

Test operation procedure

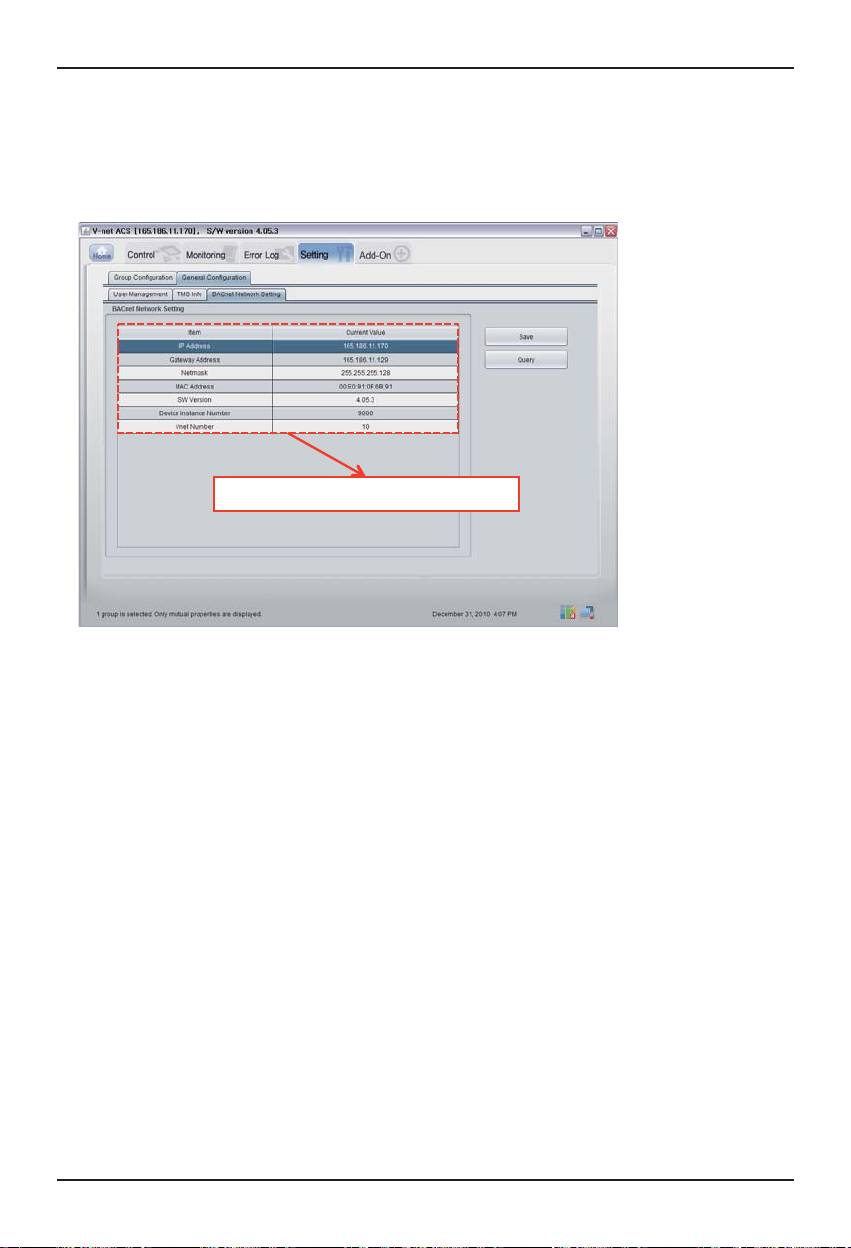

■ Confirming and adjusting the System Setting Information

(1) Click the ʻSettingʼ and General Configuration

(2) Confirm the BACnet Network Setting Information

Information of BACnet Gateway

48 BACnet Gateway

Functional Specifications BACnet Gateway

Functional Specifications BACnet Gateway

Summary

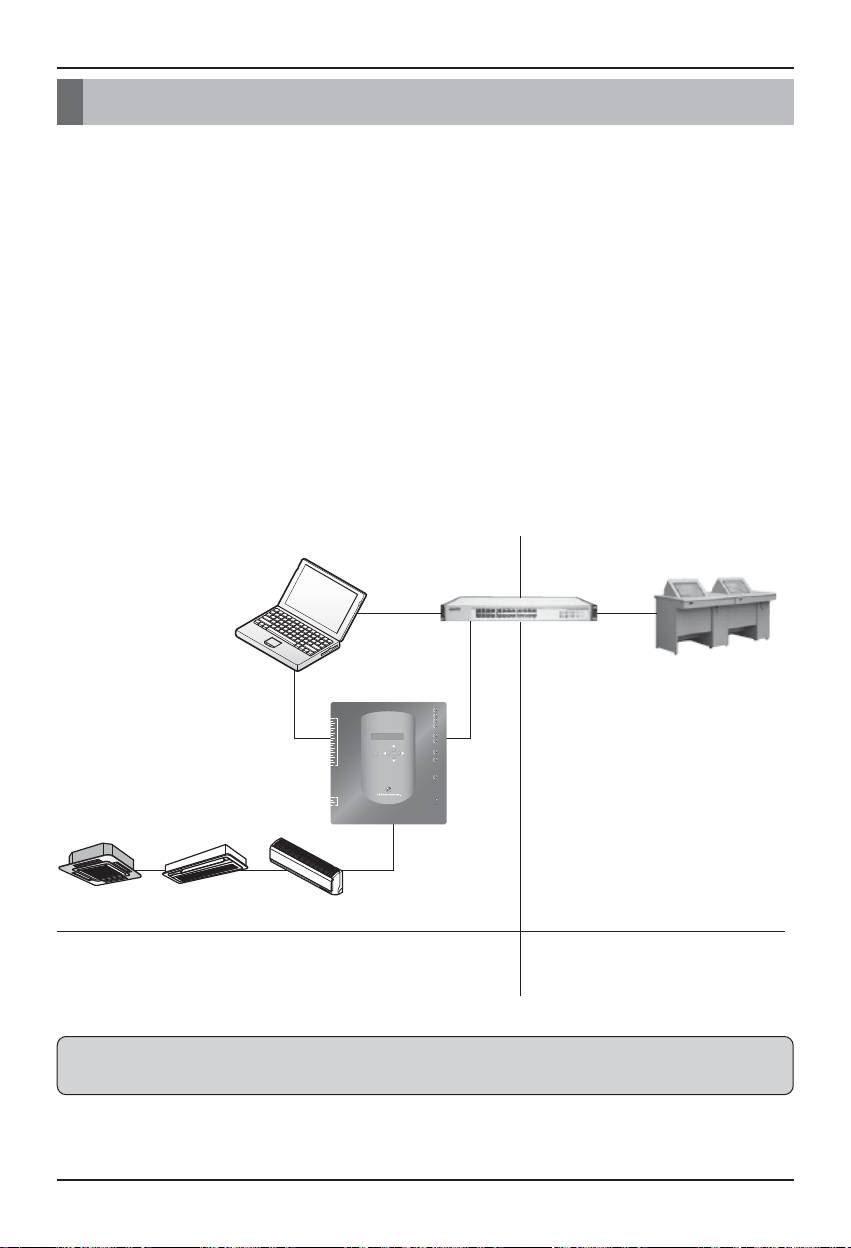

The BACnet G/W, in response to the requests from the BMS (Building management system which

supports BACnet-ANSI/ASHRAE135 protocol), status information of A/C/vent that are connected to

the BACnet G/W's internal LG-NET will be sent in BACnet service form, and BACnet client provides a

function that transmits control command to the A/C/vent system.

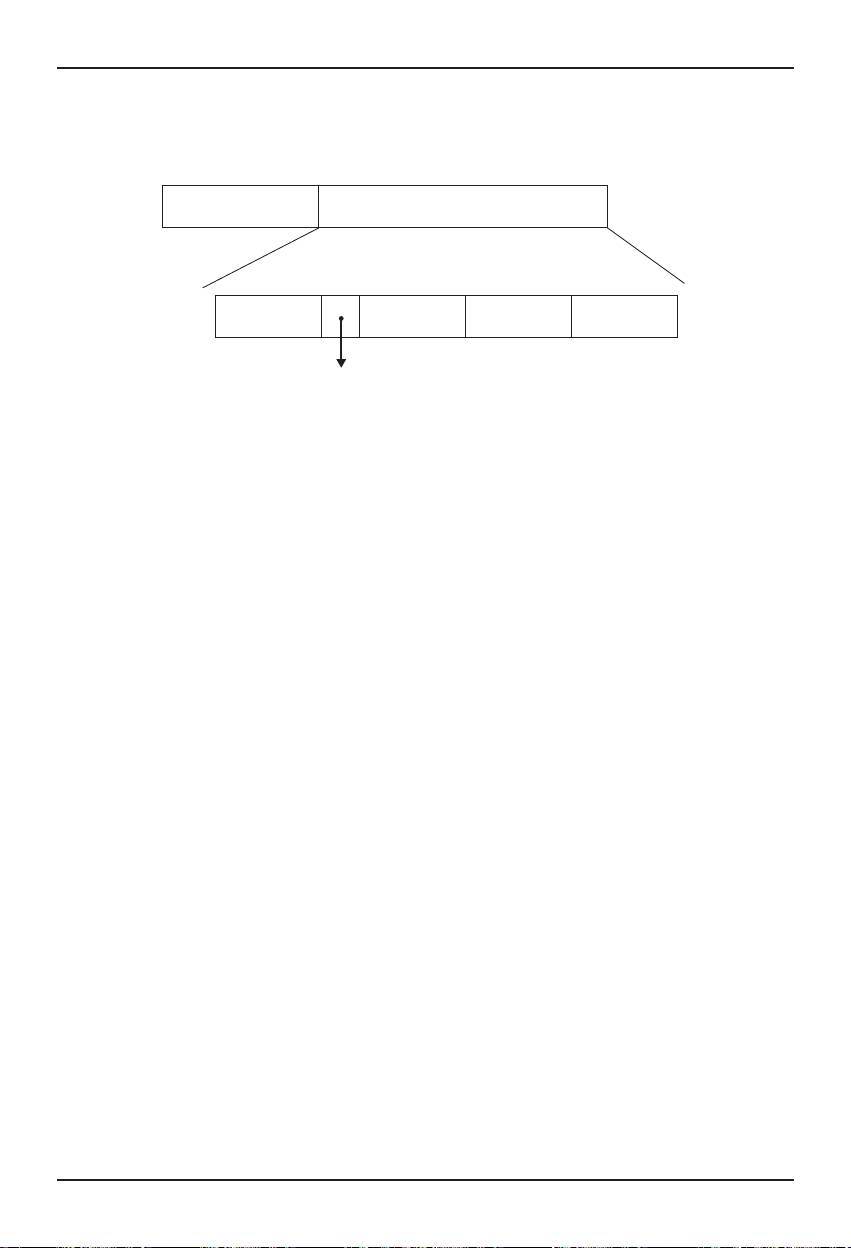

Configuration of Connection

A BACnet client that supports BACnet-ANSI/ASHRAE135 protocol allows direct connection via

generally used HUBs or Ethernet. The image of its connection configuration is as shown below.

BMS

Hub

Hub

LG-NET 1

TX

Outdoor unit

RX

TX

2

1

LG-NET 2

DI

RX

LG-NET 3

TX

L1 2 3 4

KSDO4H

4

3

RX

ON

LG-NET 4

TX

6

5

RX

8

7

Ext 1

TX

10

9

RX

12

11

Ext 2

TX

RX

14

13

16

15

Ethernet 1

ACT

LNK

18

17

SELECT

MENU/

Ethernet 2

ACT

19

LNK

20

Console

TX

RX

Centralized

2

1

Run

4

3

DO

Power

Remote controller

Indoor unit

Outdoor unit

ON

L1 2 3 4

KSDO4H

Centralized

Max.

Remote controller

Indoor unit

256

unit

Outdoor unit

ON

L1 2 3 4

KSDO4H

Centralized

Remote controller

Ventilation units

ENGLISH

Installation/Owner Manual 49

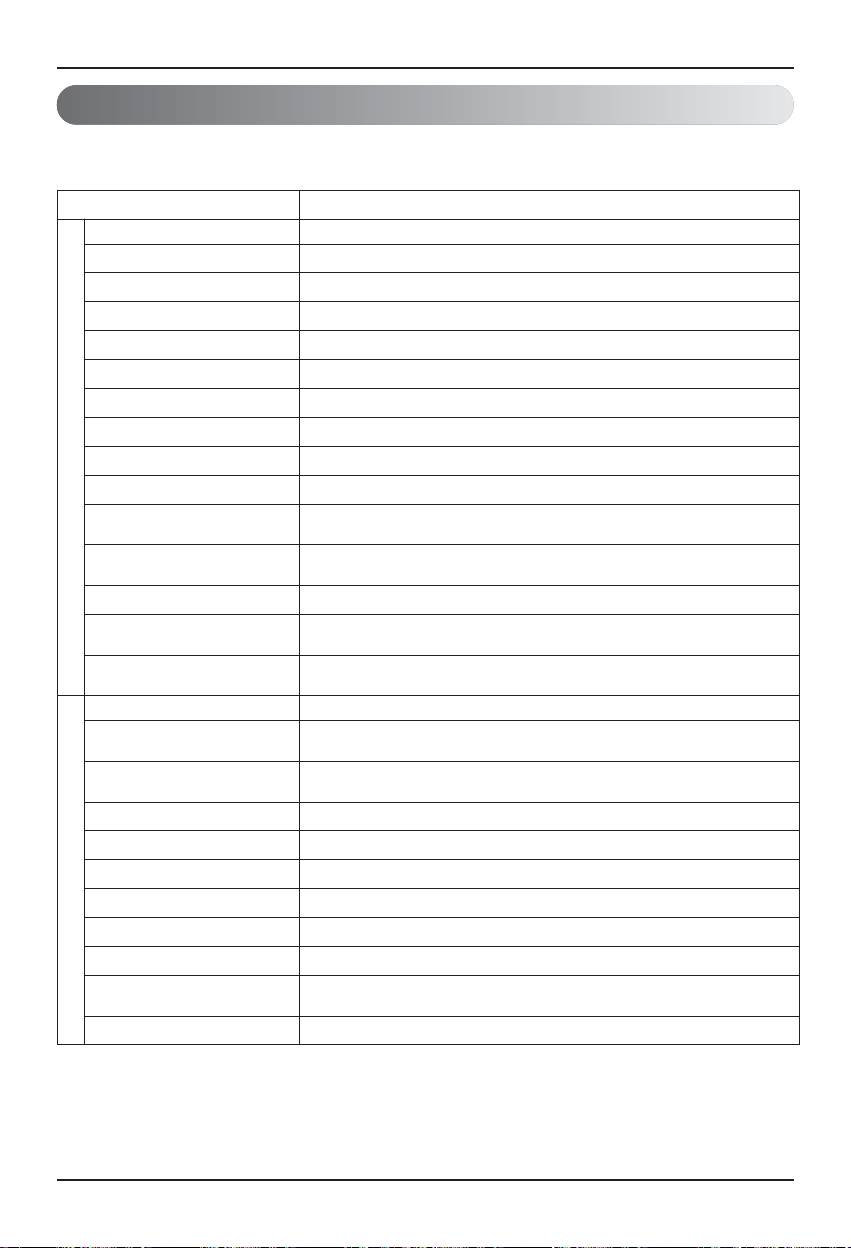

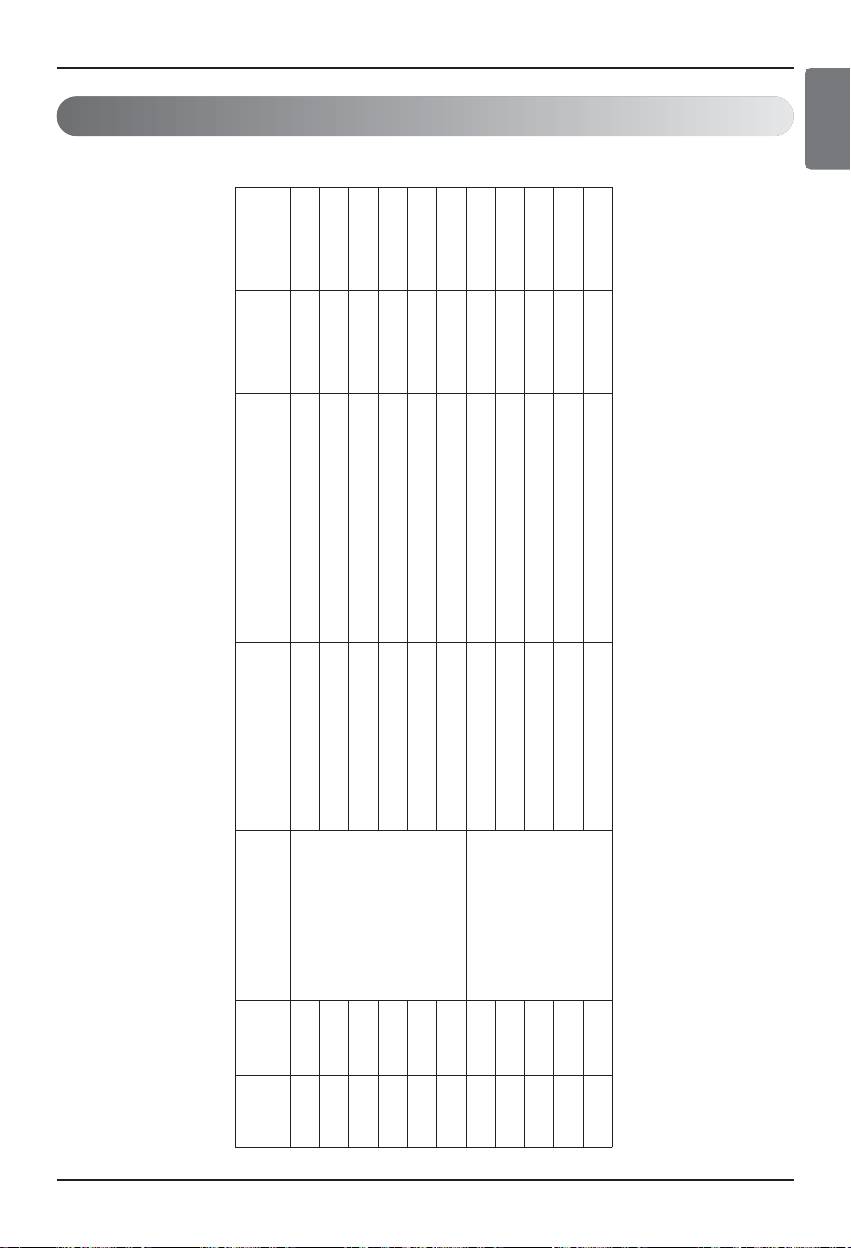

Functional Specifications BACnet Gateway

Monitoring and Controlling Items of A/C

The items to monitor and control A/C from BACnet communication as well as descriptions of each

item are listed below.

Function Description

Run/Stop (status) Monitors Run/Stop status of each A/C.

Operation Mode (status) Monitors cooling, heating, and vent operation status.

Lock (status) Indicates whether LOCK function of the A/C is active.

Set Temperature (status) Monitors the status of set temperature for A/C

Accumulator Power distribution (status)

Monitor the status of power distribution of A/C

Set Upper Temperature (status)

Monitors the status of upper temperature for A/C

Set Lower Temperature (status)

Monitors the status of lower temperature for A/C

Mode Lock (status) Indicates whether mode lock function of the A/C is active.

Fan speed (status) Monitors Fan speed of the functioning A/C.

Monitoring

Swing (status) Monitors swing mode of the indoor units.

Monitors the operation status of user mode (Quickoperation/Power

User Mode (status)

saving /Heater) while vent is functioning.

Monitors the room temperature and indicates the actual room

Room Temperature

temperature.

Filter Sign Monitors the status of the filters for vent

Monitors whether the A/C are operating properly and if not, alarm is set

Alarm

off.

Indicates the respective code for the errors occurred from the A/C

Error Code

system or the network.

Run/Stop (setting) Starts and stops the respective A/C and monitors control results.

Sets the operation mode (cooling, heating, vent or auto mode) and

Operation Mode (setting)

monitors the setting results.

Sets the additional operation mode in vent (quick fresh, energy

User Mode (setting)

efficiency, heating)

Swing (setting) Sets the air direction of the indoor unit.

Fan Speed (setting) Sets the airflow of the A/C

Lock (setting) Sets the lock of the A/Cʼs control authority.

Set Upper Temperature (setting)

Sets upper temperature of the respective A/C

Set Lower Temperature (setting)

Sets lower temperature of the respective A/C

Mode Lock (setting) Sets the mode lock of the A/Cʼs control authority.

Operation, Setting and Monitoring

Sets room temperature of the respective A/C and monitors the setting

Set Room Temperature

results.

Filter Sign Reset Resets the ventilationʼs filter limit indication.

50 BACnet Gateway

Functional Specifications BACnet Gateway

ENGLISH

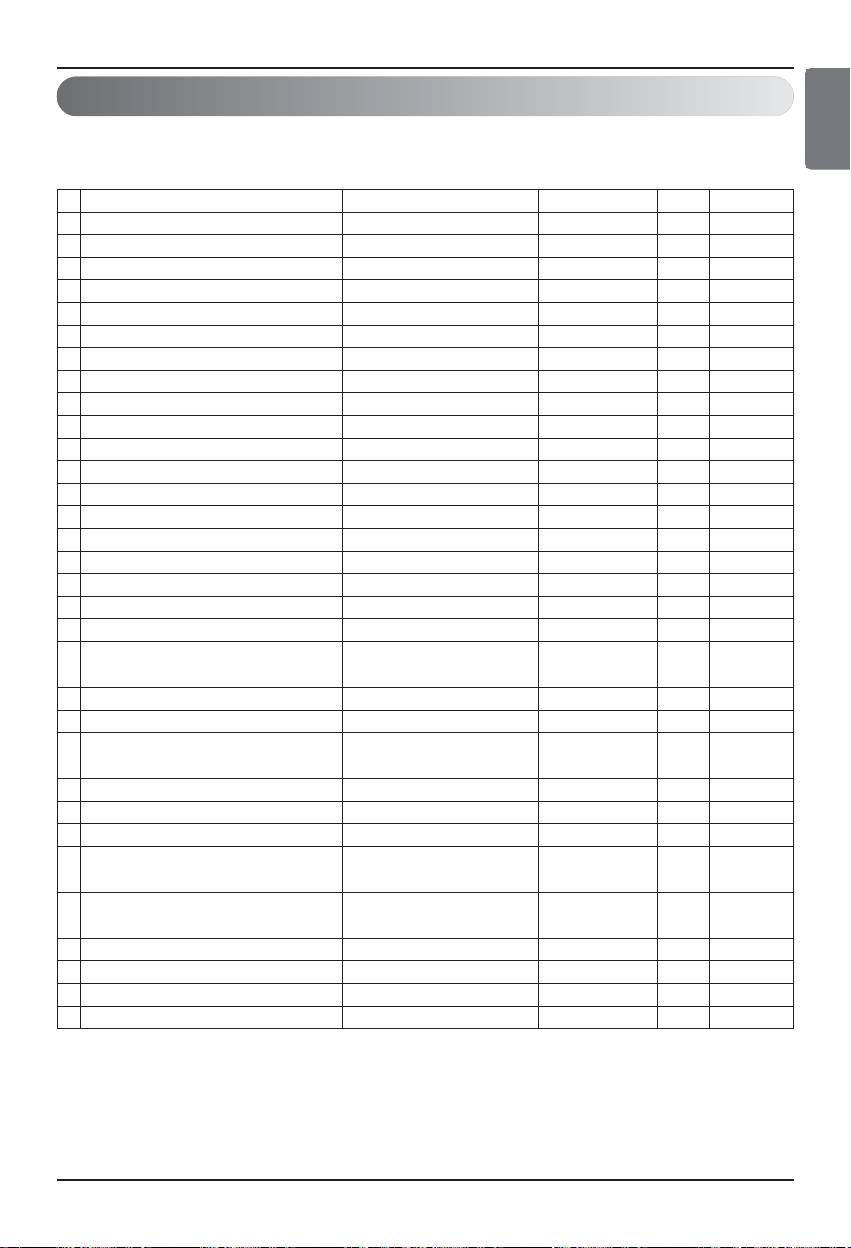

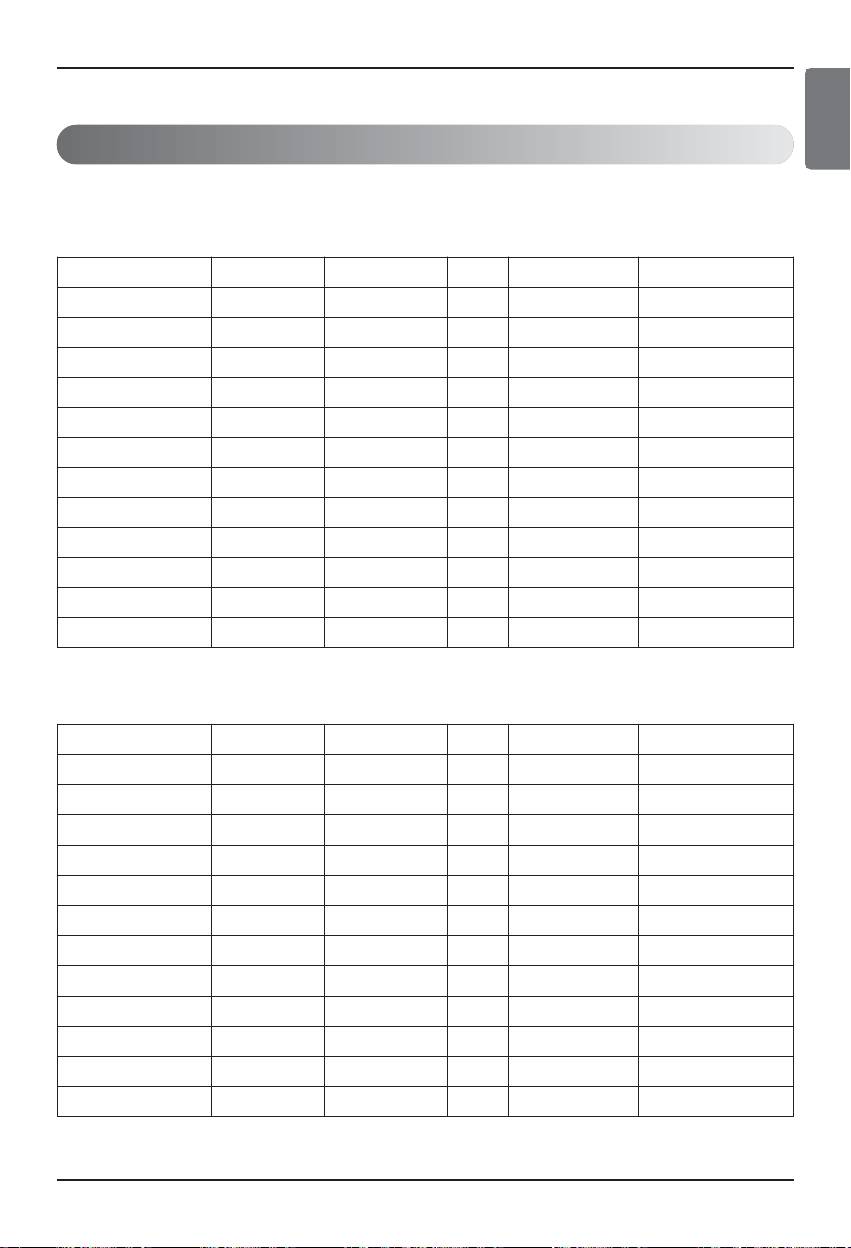

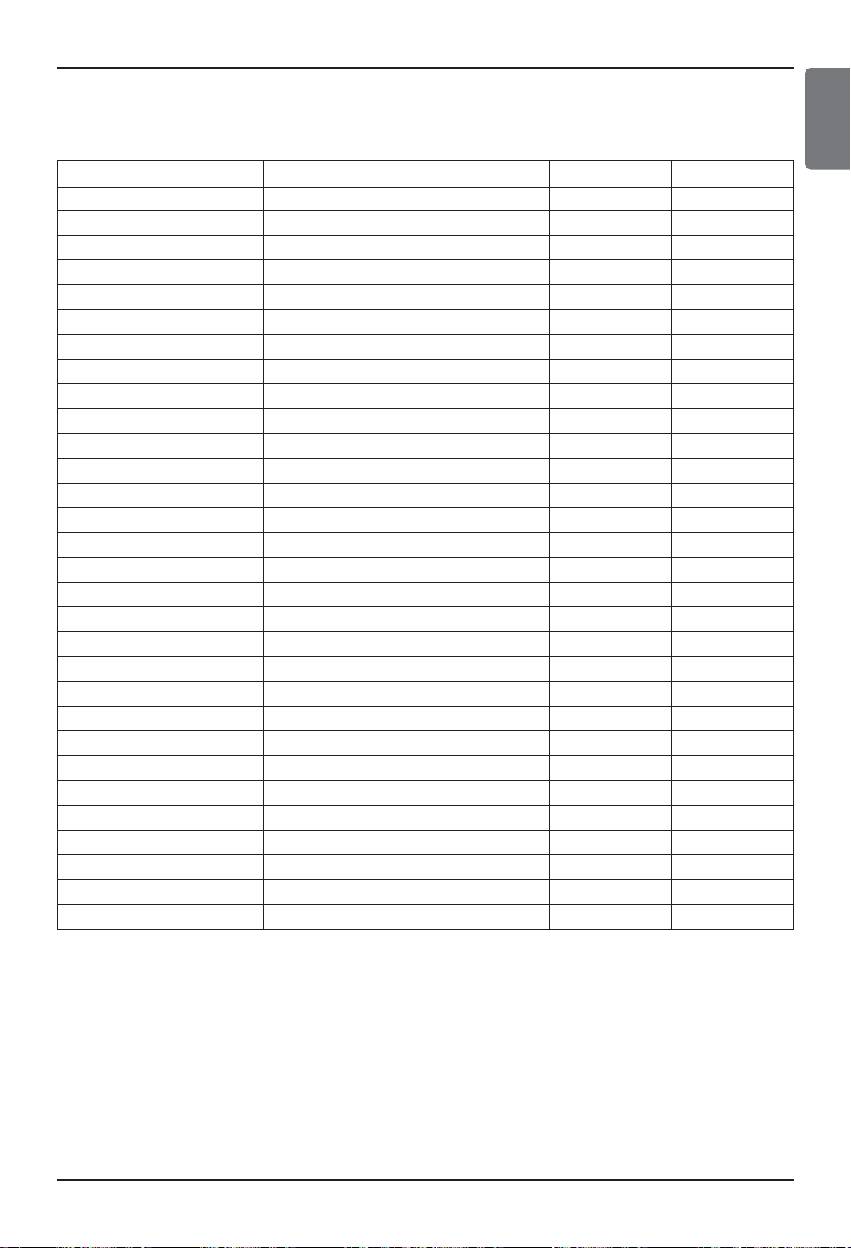

Monitoring and Controlling point of indoor and ventilator

Applicable monitoring and controlling point for the indoor and ventilator are listed below.

Object Name's XX is indoor's address number.

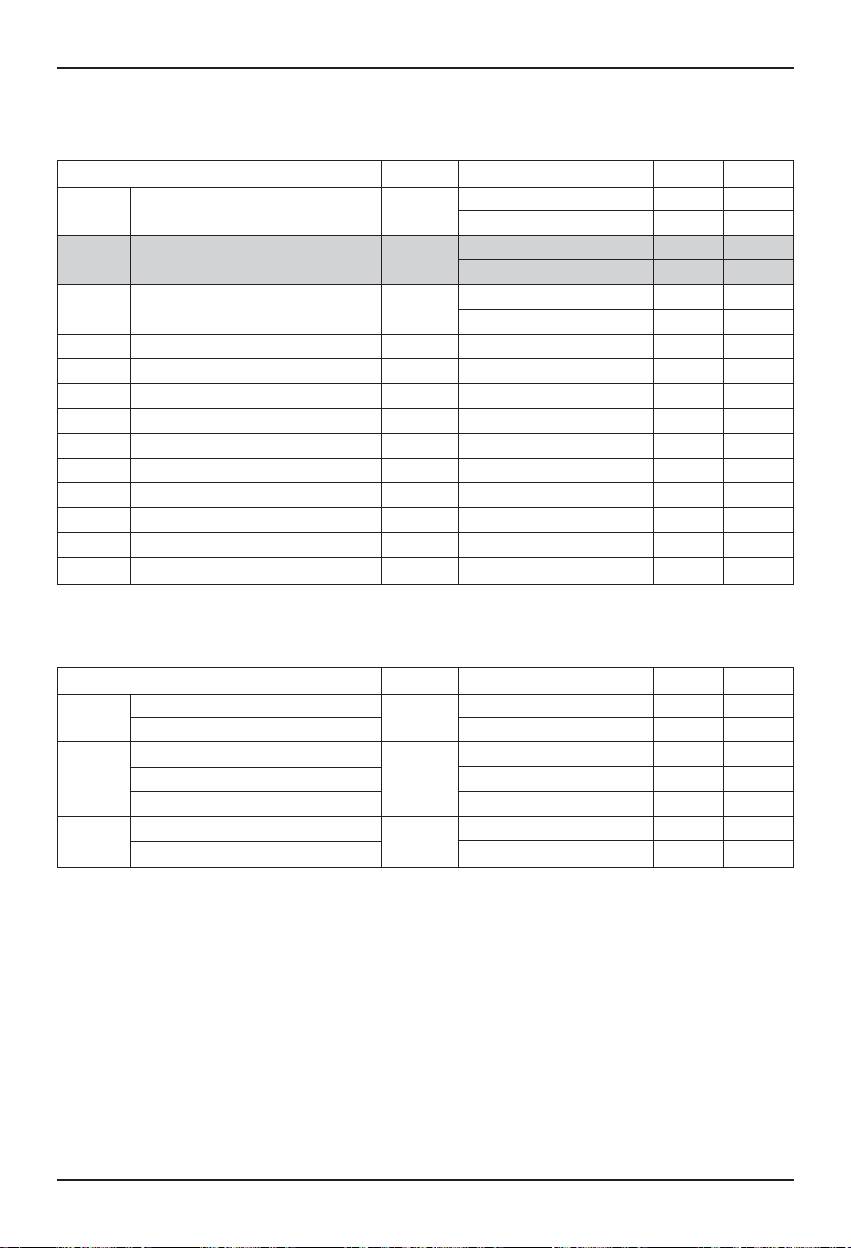

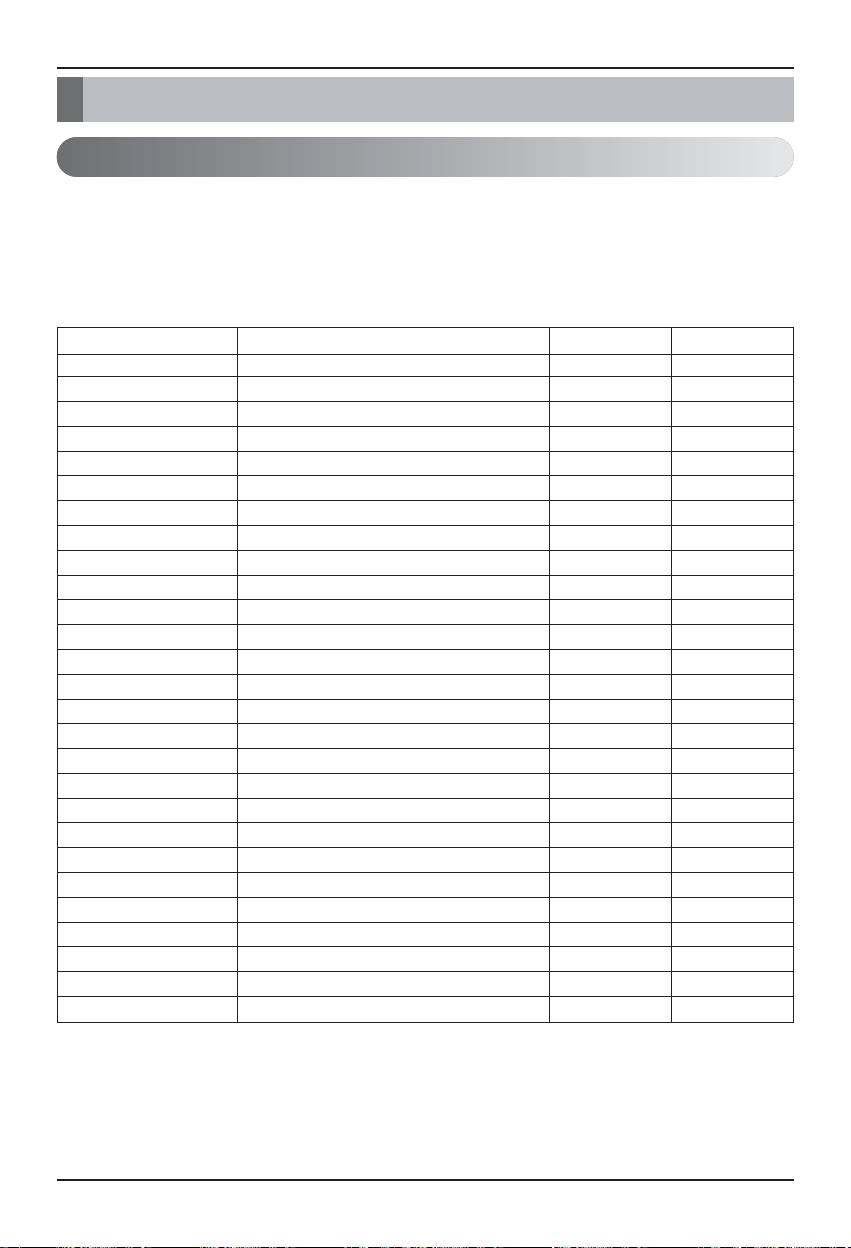

Name Object Name Object Type Indoor Vent

1 Run/Stop (setting) StartStopCommand_XXX Binary Output O O

2 Run/Stop (status) StartStopStatus_XXX Binary Input O O

3 Lock (setting) LockCommand_XXX Binary Output O O

4 Lock (status) LockStatus_XXX Binary Input O O

5 Filter Sign FilterSign_XXX Binary Input X O

6 Filter Sign reset FilterSignReset_XXX Binary Value X O

7 Operation Mode (setting) ModeCommand_XXX Multistate Output O O

8 Operation Mode (status) ModeStatus_XXX Multistate Input O O

9 Swing (setting) SwingCommand_XXX Binary Output O X

10 Swing (status) SwingStatus_XXX Binary Input O X

11 Fan speed (setting) FanSpeedCommand_XXX Multistate Output O O

12 Fan speed (status) FanSpeedStatus_XXX Multistate Input O O

13 Set Room Temperature SetRoomTemp_XXX Analog Value O X

14 Room Temperature RoomTemp_XXX Analog Input O X

15 Alarm Alarm_XXX Binary Input O O

16 Error Code MalfunctionCode_XXX Analog Input O O

17 User Mode(setting) UserModeCommand_XXX Multistate Output X O

18 User Mode(status) UserModeStatus_XXX Multistate Input X O

19 Set Temperature (status) SetTempStatus_XXX Analog Input O X

Accumulator Power Distribution

20

AccumPowerStatus_XXX Analog Input O X

(status)

21 AC Operation Mode (setting) Hrv_ModeCommand_XXX Multistate Output X O

22 AC Operation Mode (status) Hrv_ModeStatus_XXX Multistate Input X O

HrvStartStopCommand_XX

23 AC ON/OFF (setting)

Binary Output X O

X

24 AC ON/OFF (status) HrvStartStopStatus_XXX Binary Input X O

25 Humidify (setting) HrvHumidifyCommand_XXX Binary Output X O

26 Humidify (status) HrvHumidifyStatus_XXX Binary Input X O

SetUpperTempCommand_X

27 Set Upper Temperature (setting)

Analog Value O X

XX

SetLowerTempCommand_X

28 Set Lower Temperature (setting)

Analog Value O X

XX

29 Set Upper Temperature (status) SetUpperTempStatus_XXX Analog Input O X

30 Set Lower Temperature (status) SetLowerTempStatus_XXX Analog Input O X

31 Mode Lock (setting) ModeLockCommand_XXX Binary Output O X

32 Mode Lock (status) ModeLockStatus_XXX Binary Input O X

Installation/Owner Manual 51

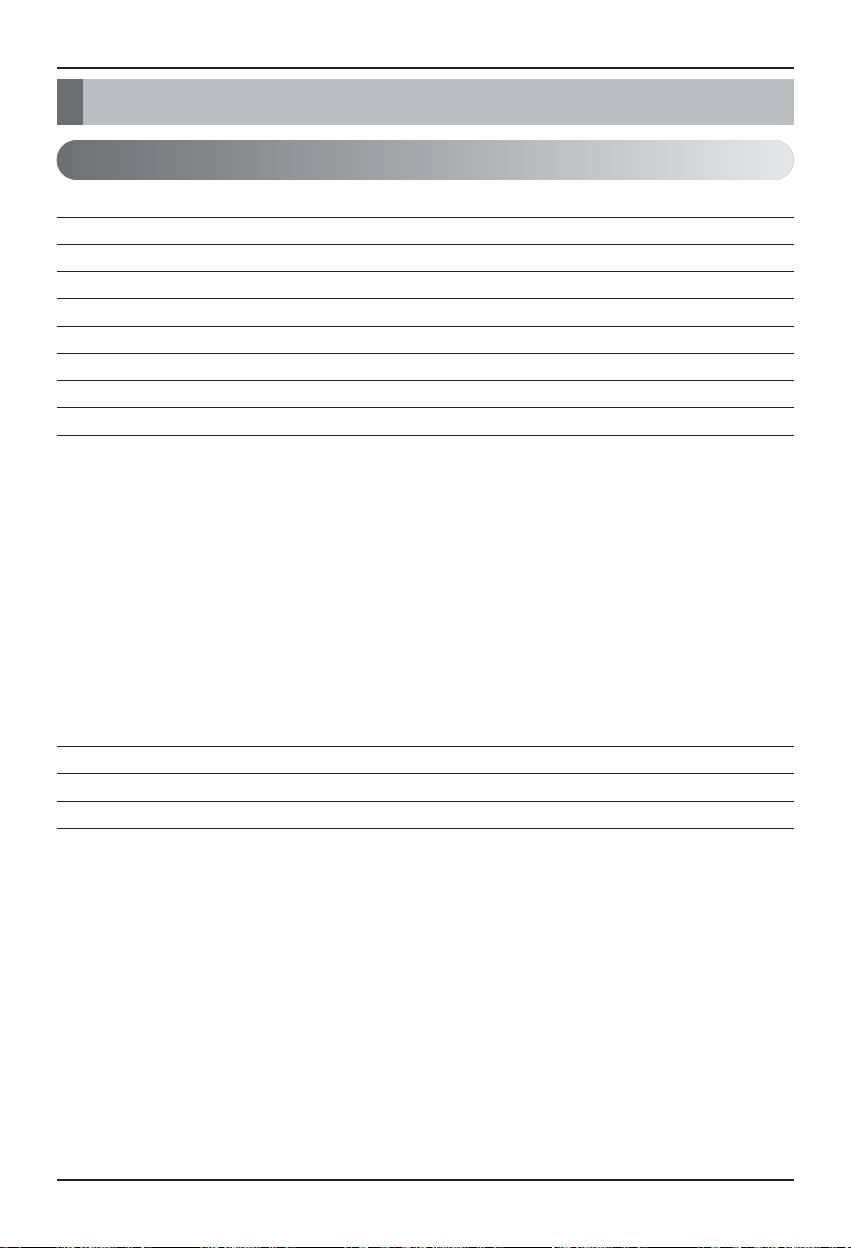

BACnet Protocol Implementation Conformance Statement (PICS)

BACnet Protocol Implementation Conformance Statement (PICS)

BACnet Protocol Implementation Conformance Statement

Date: 2007.06.01

Vendor name: LG Electronics Co. Ltd

Product name: BNU-BAC BACnet Gateway

Product Model Number:

Application Software version: 1.0 Firmware Revision:1.0 BACnet Revision: 1.0

Product Description:

This Gateway supports BACnet/IP and has a built-in Web-server that does not need any program-install.

It is able to interlock with the fire alarm through the separated Input/Output ports

BACnet Standardized Device Profile (Annex L):

❏ BACnet Operator Workstation (B-OWS)

❏ BACnet Building Controller (B-BC)

❏ BACnet Advanced Application Controller (B-AAC)

■ BACnet Application Specific Controller (B-ASC)

❏ BACnet Smart Senor (B-SS)

❏ BACnet Smart Actuator (B-SA)

Additional BACnet Interoperability Building Blocks Supported (Annex K)

Reference of BIBBs List(Appendix 1)

Segmentation Capability:

■ Segmented requests supported Window Size 16

■ Segmented responses supported Window Size 16

Standard Object Types Supported:

An object type is supported if it may be present in the device. For each standard Object Type

supported provide the following data:

1) Whether objects of this type are dynamically creatable

2) Whether objects of this type are dynamically deletable

52 BACnet Gateway

BACnet Protocol Implementation Conformance Statement (PICS)

ENGLISH

Data Link Layer Options:

BACnet IP, (Annex J)

■ BACnet IP, (Annex J), Foreign Device

❏ ISO 8802-3, Ethernet (Clause 7)

❏ ANSI/ATA 878.1, 2.5 Mb. ARCNET (Clause 8)

❏ ANSI/ATA 878.1, RS-485 ARCNET (Clause 8), baud rate(s)

❏ MS/TP master (Clause 9), baud rate(s):

❏ MS/TP slave (Clause 9), baud rate(s):

❏ Point-To-Point, EIA 232 (Clause 10), baud rate(s):

❏ Point-To-Point, modem, (Clause 10), baud rate(s):

❏ LonTalk, (Clause 11), medium:

❏ Other:

Device Address Binding:

Is static device binding supported? (This is currently necessary for two-way communication with

MS/TP slaves and certain other devices.) ❏ Yes ■ No

Networking Options:

❏ Router, Clause 6 - List all routing configurations, e.g., ARCNET-Ethernet, Ethernet-MS/TP, etc.

❏ Annex H, BACnet Tunneling Router over IP

❏ BACnet/IP Broadcast Management Device (BBMD)

Does the BBMD support registrations by Foreign Devices? ❏ Yes ■ No

Character Sets Supported:

Indicating support for multiple character sets does not imply that they can all be supported

simultaneously.

■ ANSI x 3.4 ❏ IBM™‚/Microsoft¢‚ DBCS ❏ ISO 8859-1

❏ ISO 10646 (UCS-2) ❏ ISO 10646 (UCS-4) ❏ JIS C 6226

If this product is a communication Gateway, describe the types of non-BACnet equipment/networks(s)

that the Gateway supports:

This Gateway converts BACnet protocol into LGAP(LG Aircon protocol), so that the outdoor unit of the

A/C which is connected to the Gateway is able to communicate in 485-communication.

Installation/Owner Manual 53

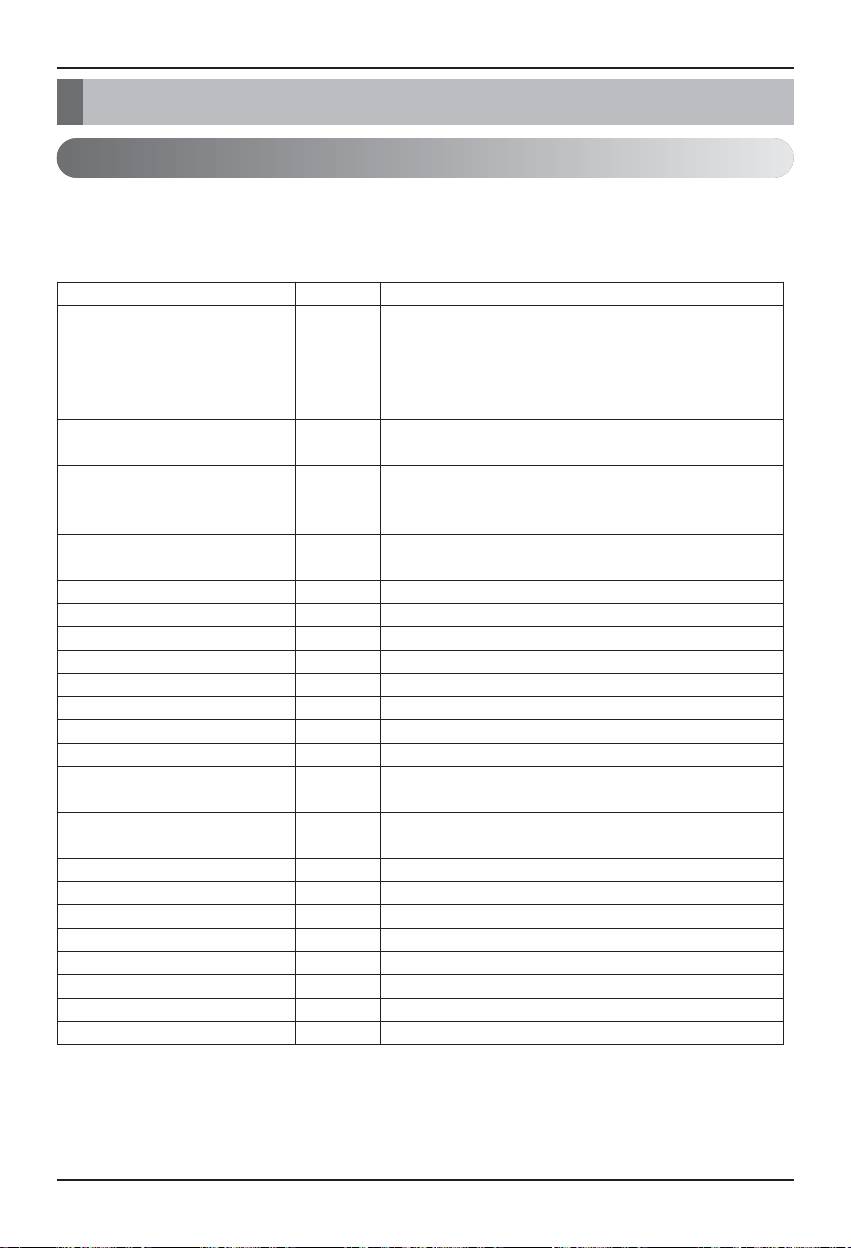

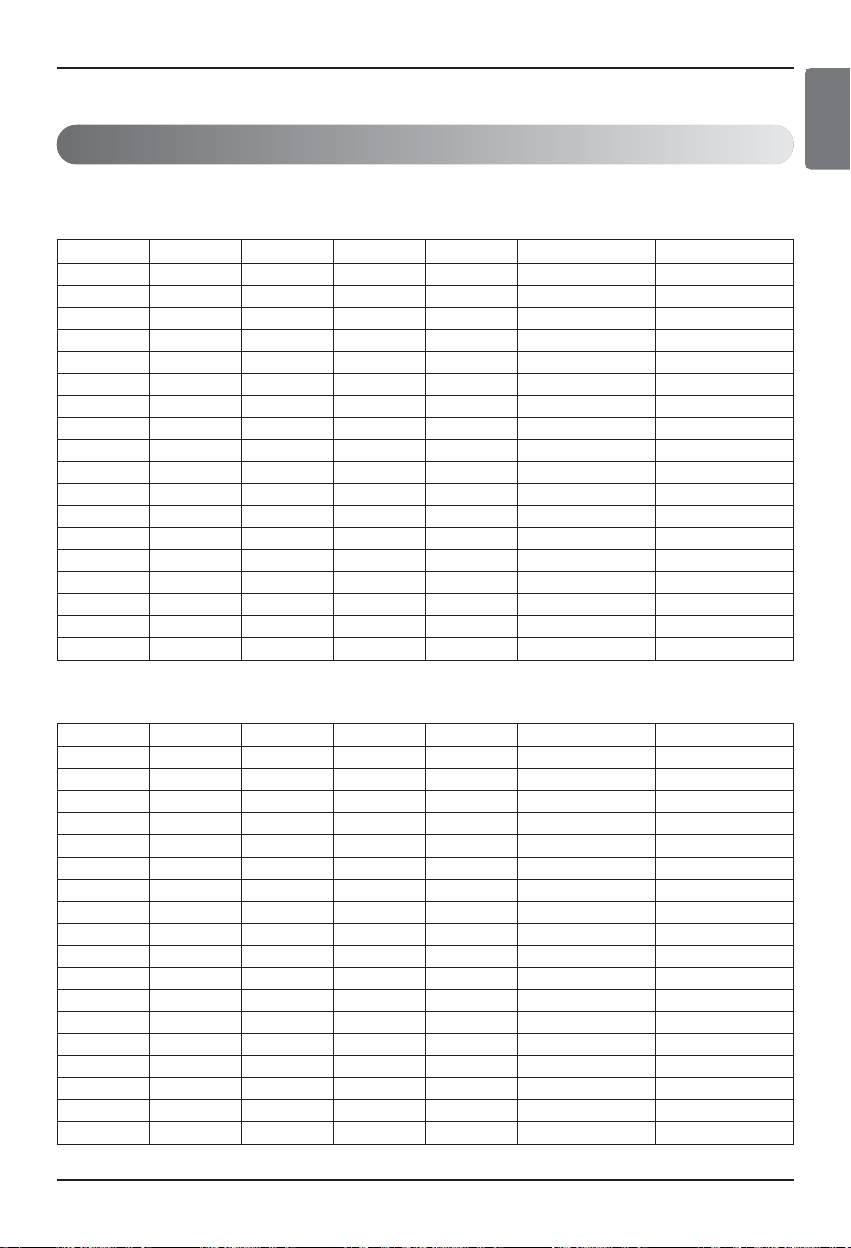

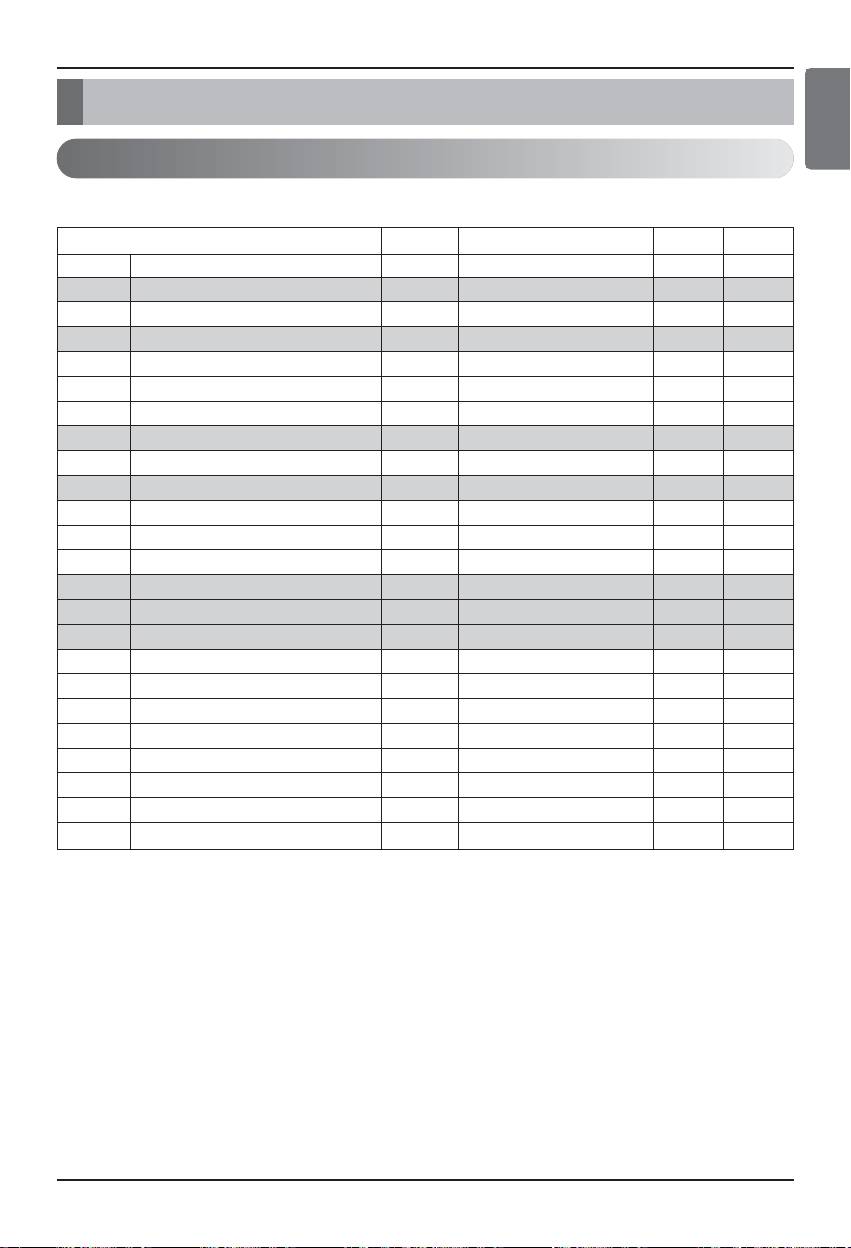

Objects (BACnet/IP)

Objects (BACnet/IP)

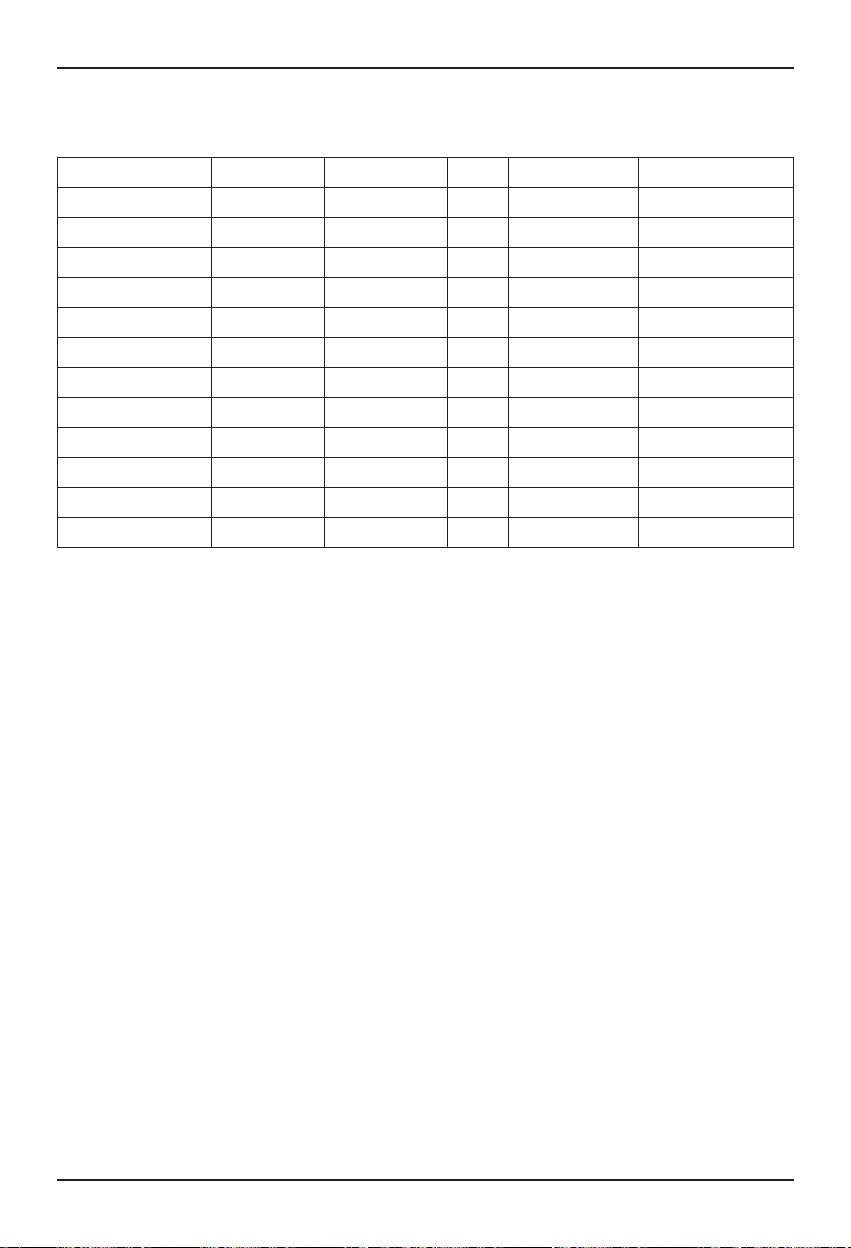

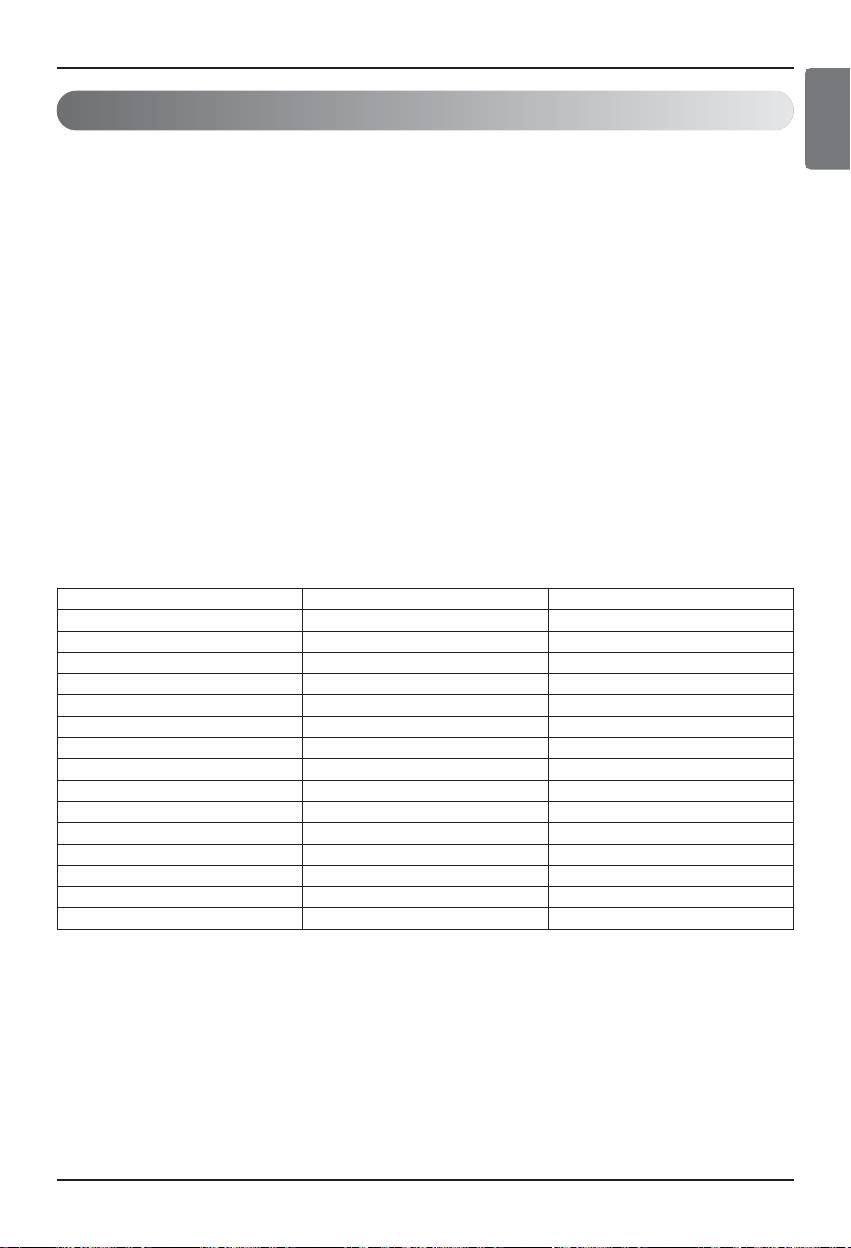

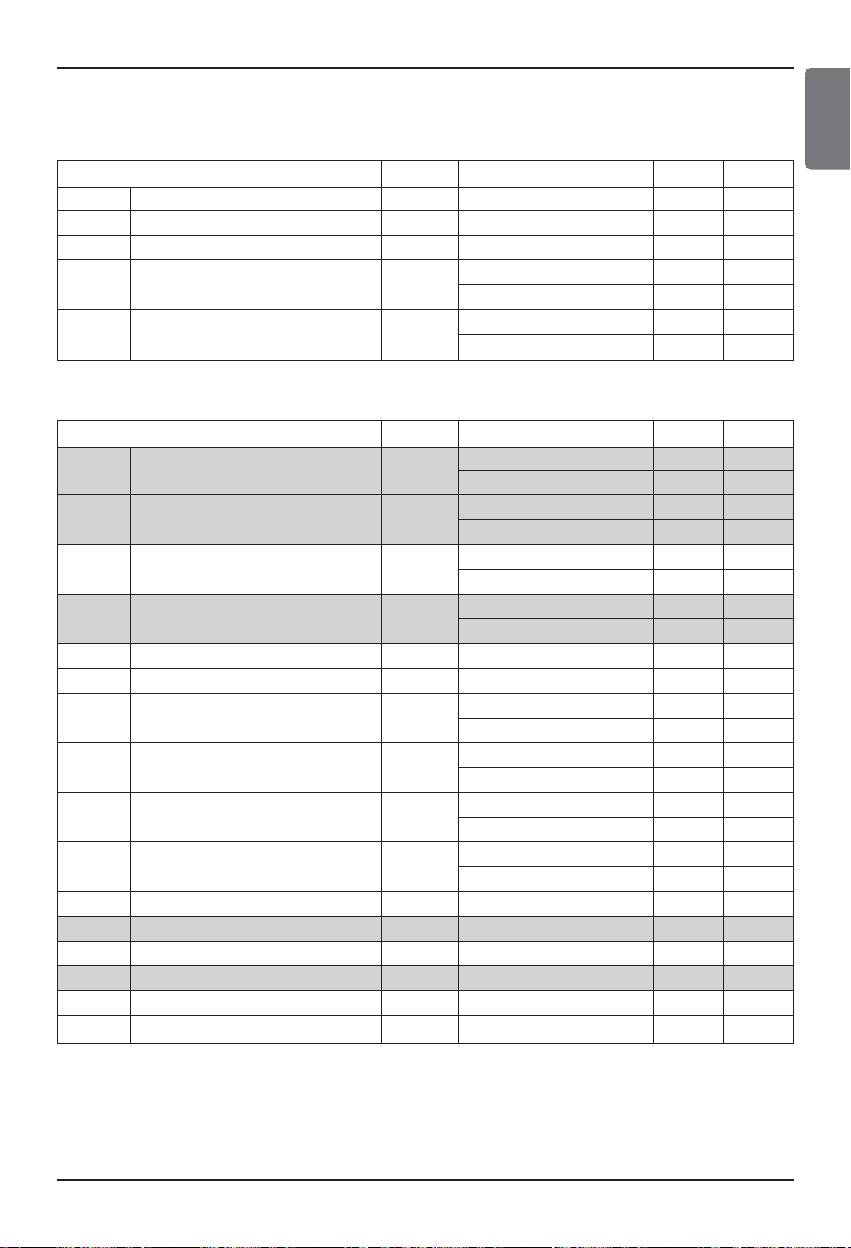

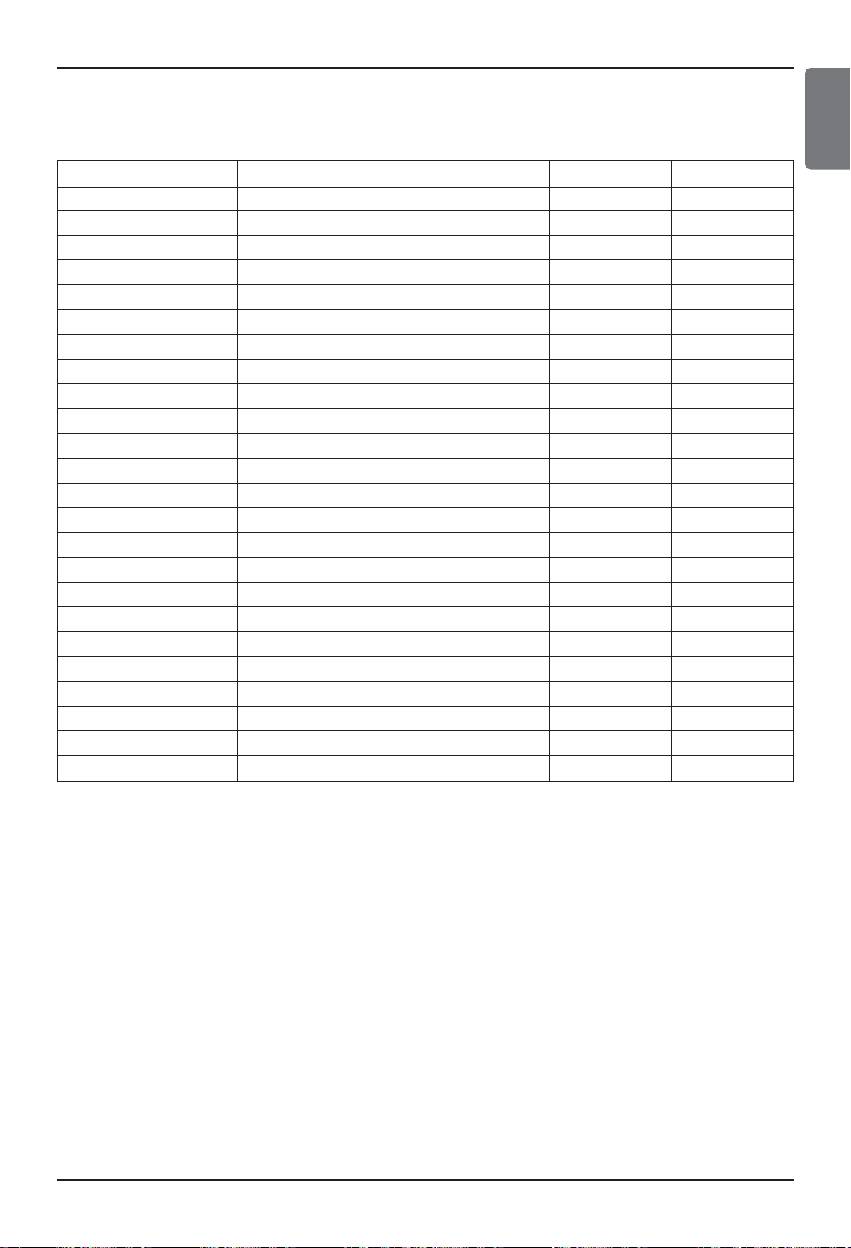

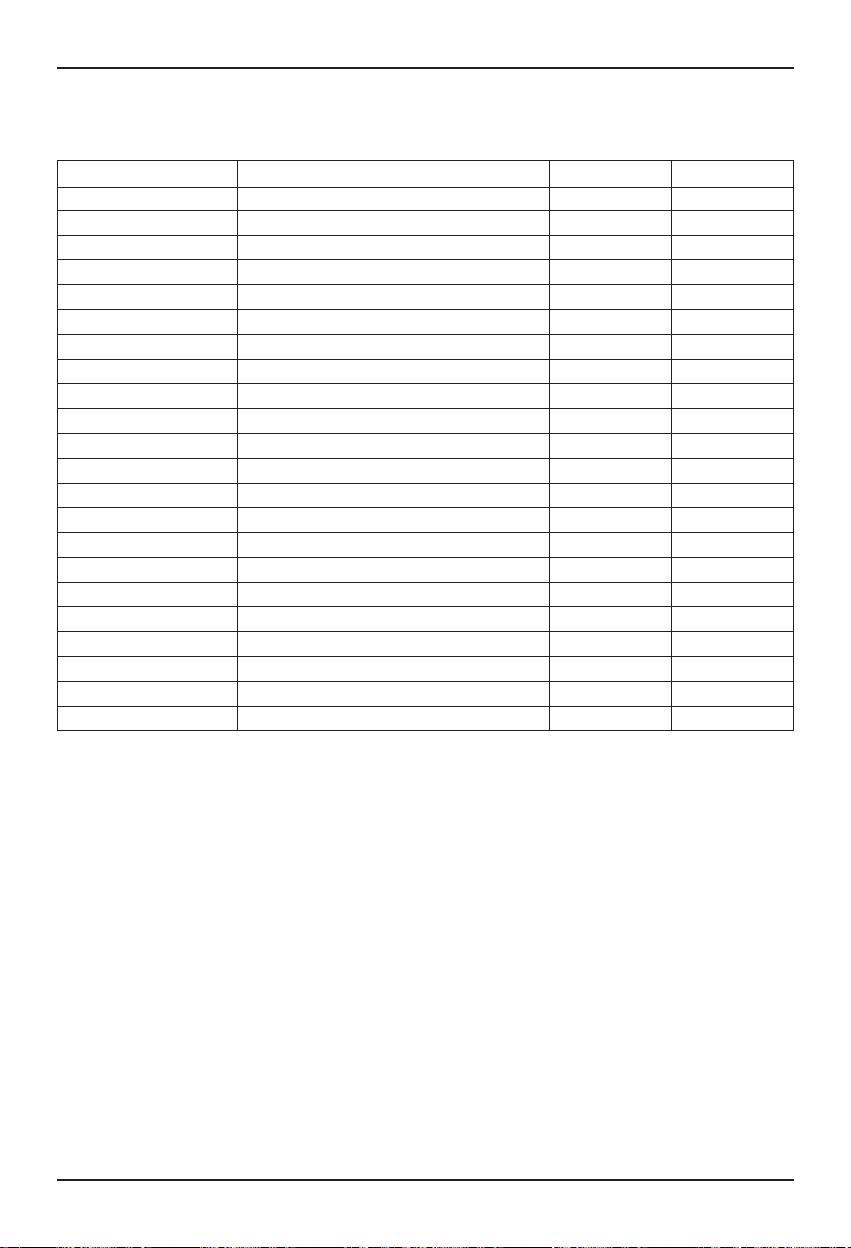

Supported Object Type

Monitoring and controlling items of air conditioners supported are assigned with general object types

specified by BACnet. Support status of each object type is shown in the table below.

(■ : Supported, ❏ : Unsupported)

Object Type Supported Description

Room Temperature, Error Code, Set Humidity,

Supply/Outer/Vent/Mixing Temperature,

Analog Input 0

Supply/Outer/Vent/Mixing Humidity, CO2 Value, Current

■

OA/EA/Mix Damper, Cool OA/EA/Mix Damper, Heat

OA/EA/Mix Damper, Fan OA/EA/Mix Damper

Set Humidity, Cool OA/EA/Mix Damper, Heat OA/EA/Mix

Analog Value 2

■

Damper, Fan OA/EA/Mix Damper

Run/Stop, Lock, Filter Sign, Swing, Alarm, Humidity,

Binary Input 3

Auto Ventilation, Humidifier, Heater, Ventilation Fan, Supply

■

Fan

Run/Stop, Lock, Mode Lock, Set Upper/Lower Temperature,

Binary Output 4

■

Swing, Humidity, Auto Ventilation

Binary-Value 5 Filter Sign Reset

■

Calendar 6

❏

Command 7

❏

Device 8

■

Event-Enrollment 9

❏

File 10

❏

Group 11

❏

Loop 12

❏

Operation Mode(Setting), Fan Speed(Setting)

Multistate-Output 13

■

User Mode(Setting)

Operation Mode(Status), Fan Speed(Status)

Multistate-Input 14

■

User Mode(Status)

Notification-Class 15

❏

Program 16

❏

Schedule 17

❏

Averagin 18

❏

Multistate-Value 19

❏

Trend-Log 20

❏

Life-Safety-Point 21

❏

Life-Safety-Zone 22

❏

54 BACnet Gateway

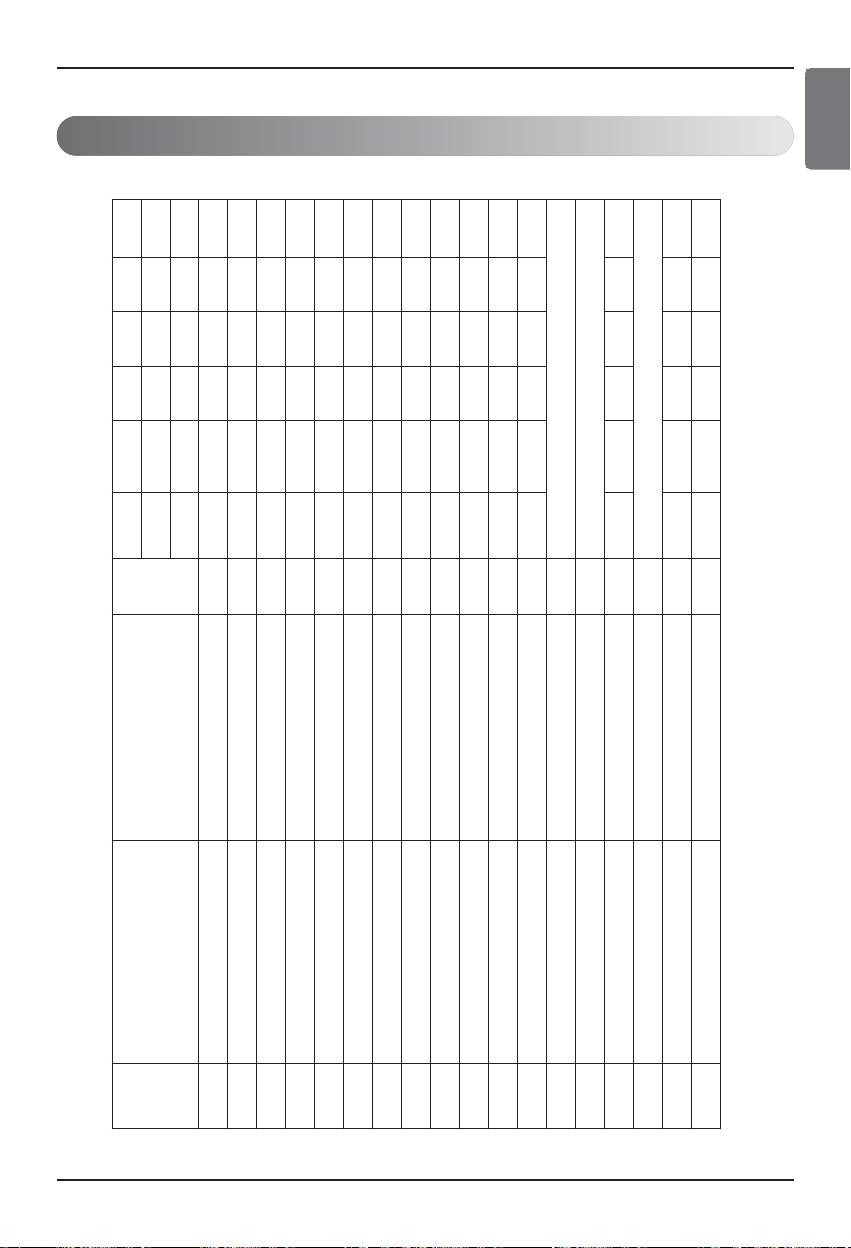

Objects (BACnet/IP)

ENGLISH

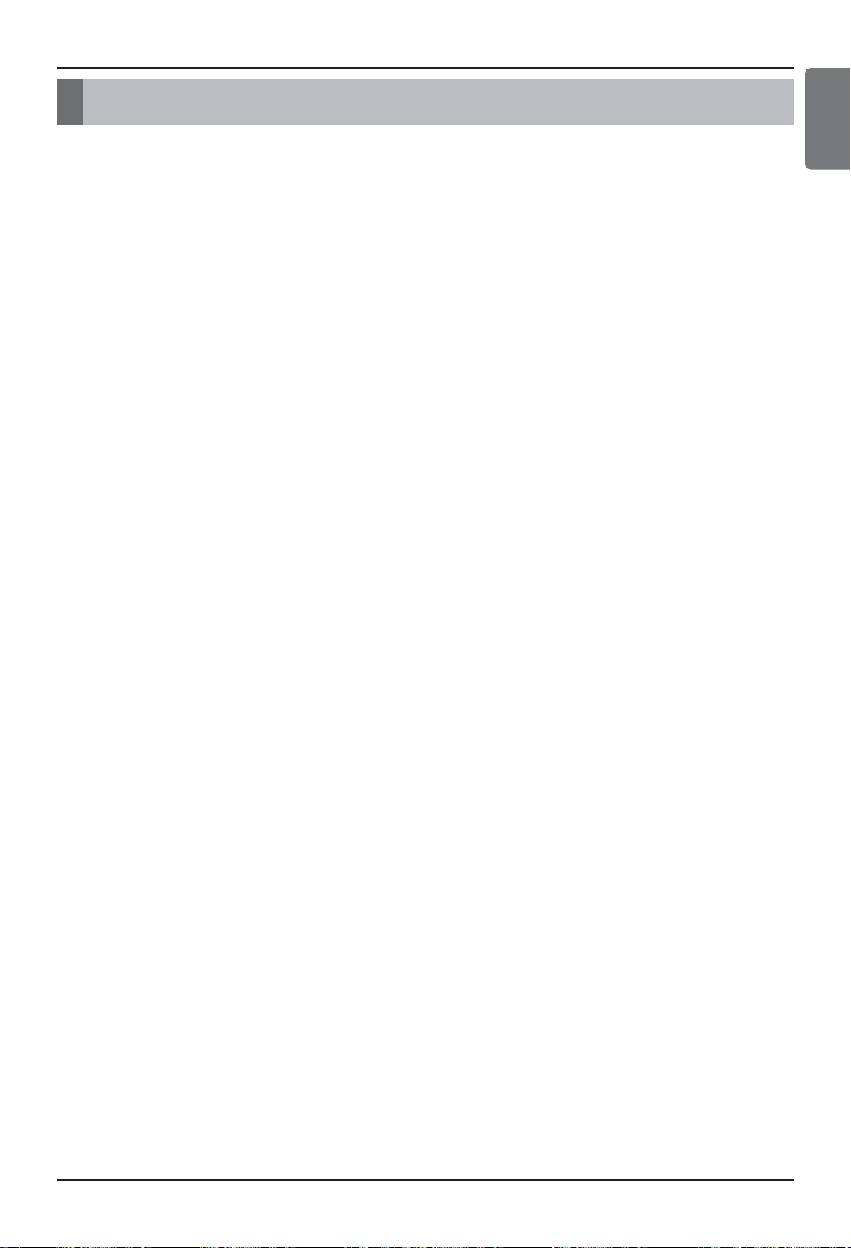

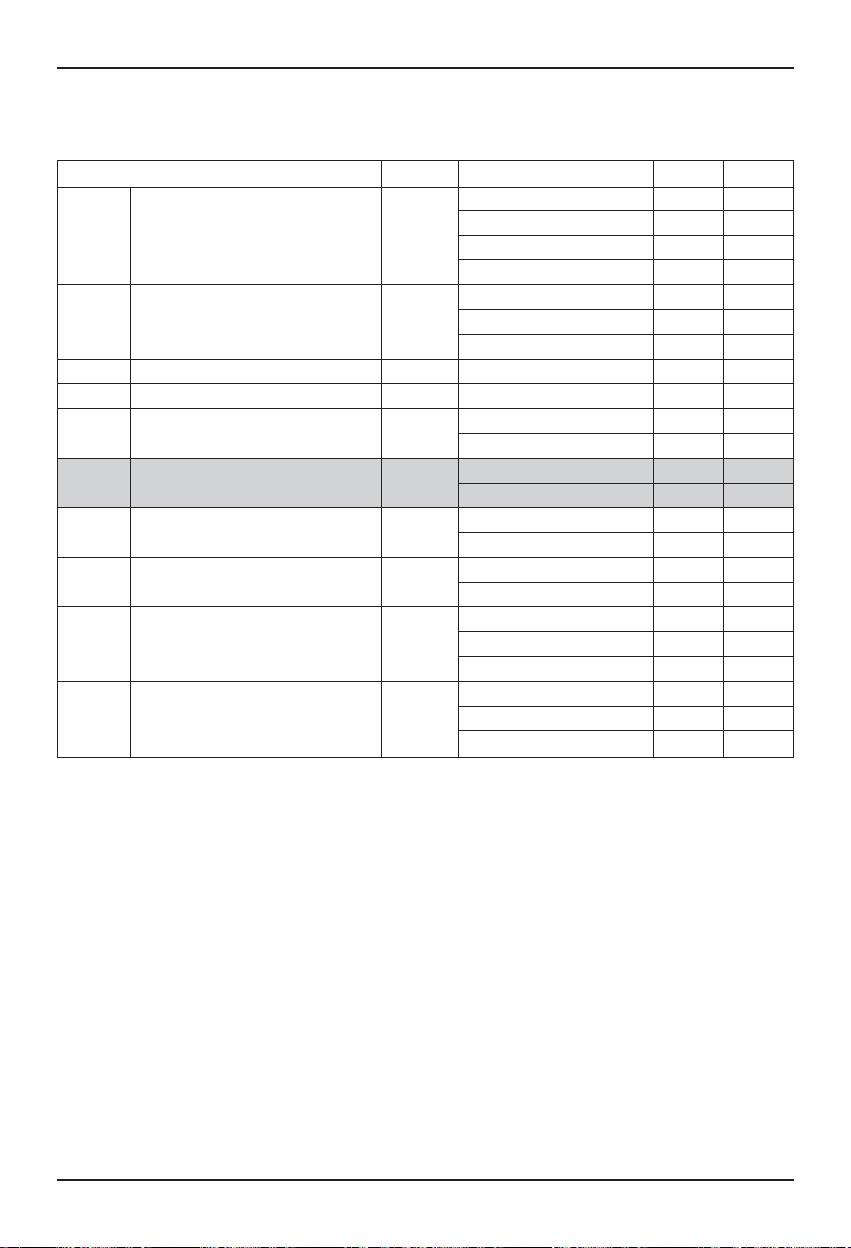

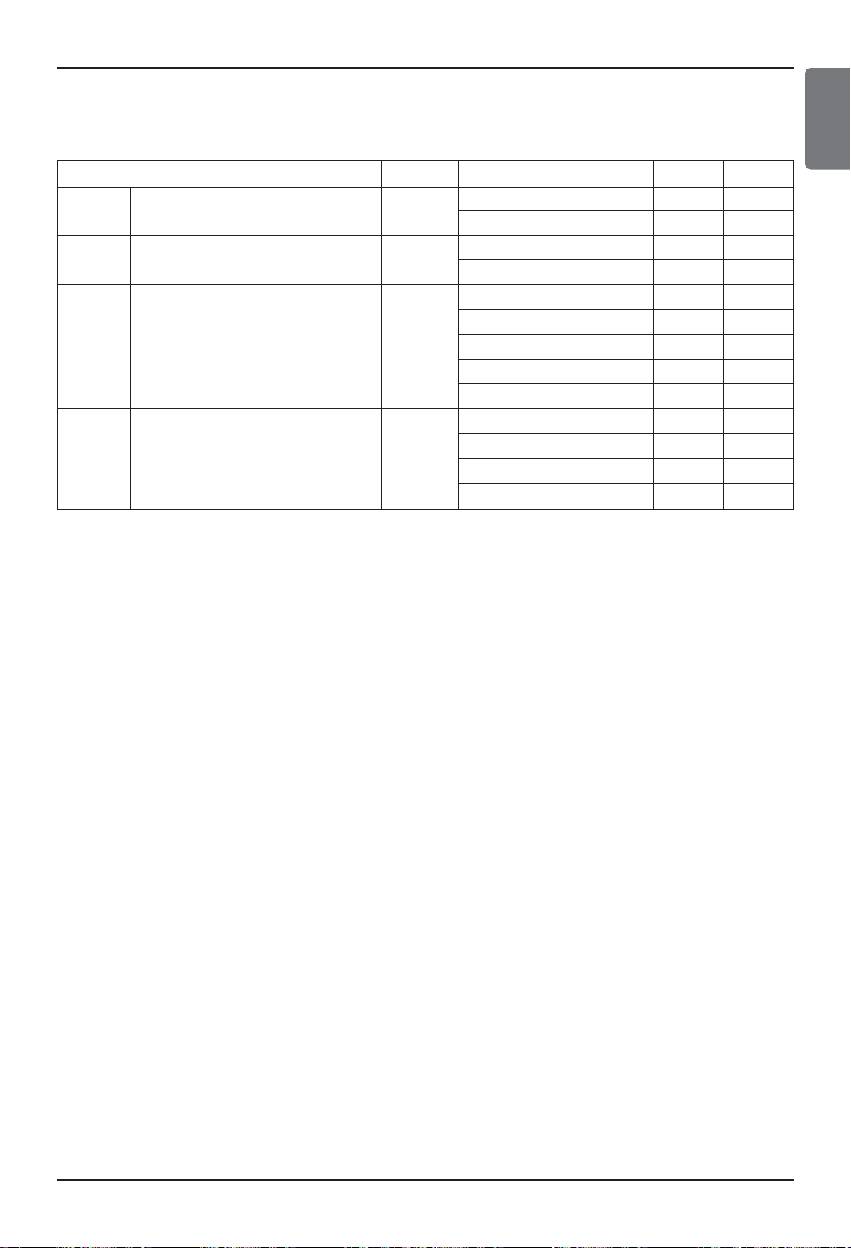

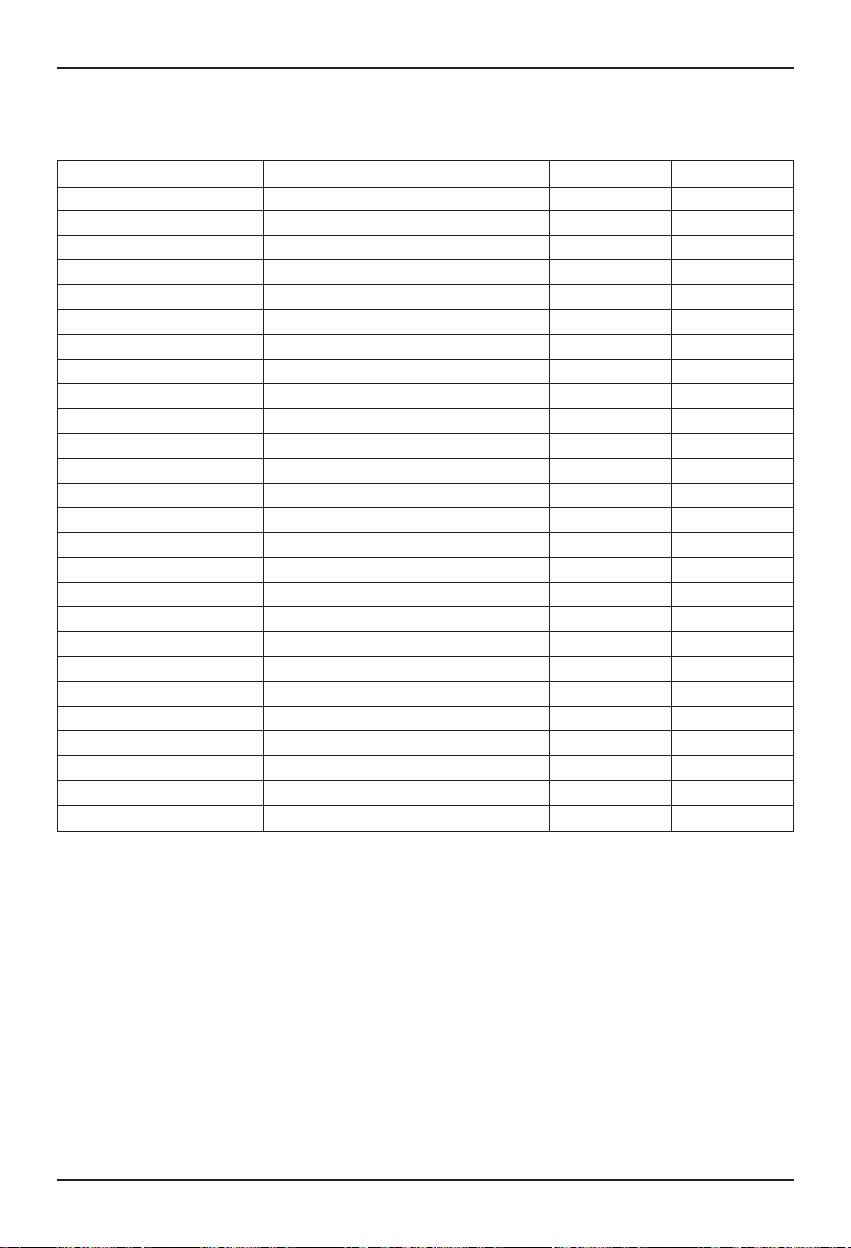

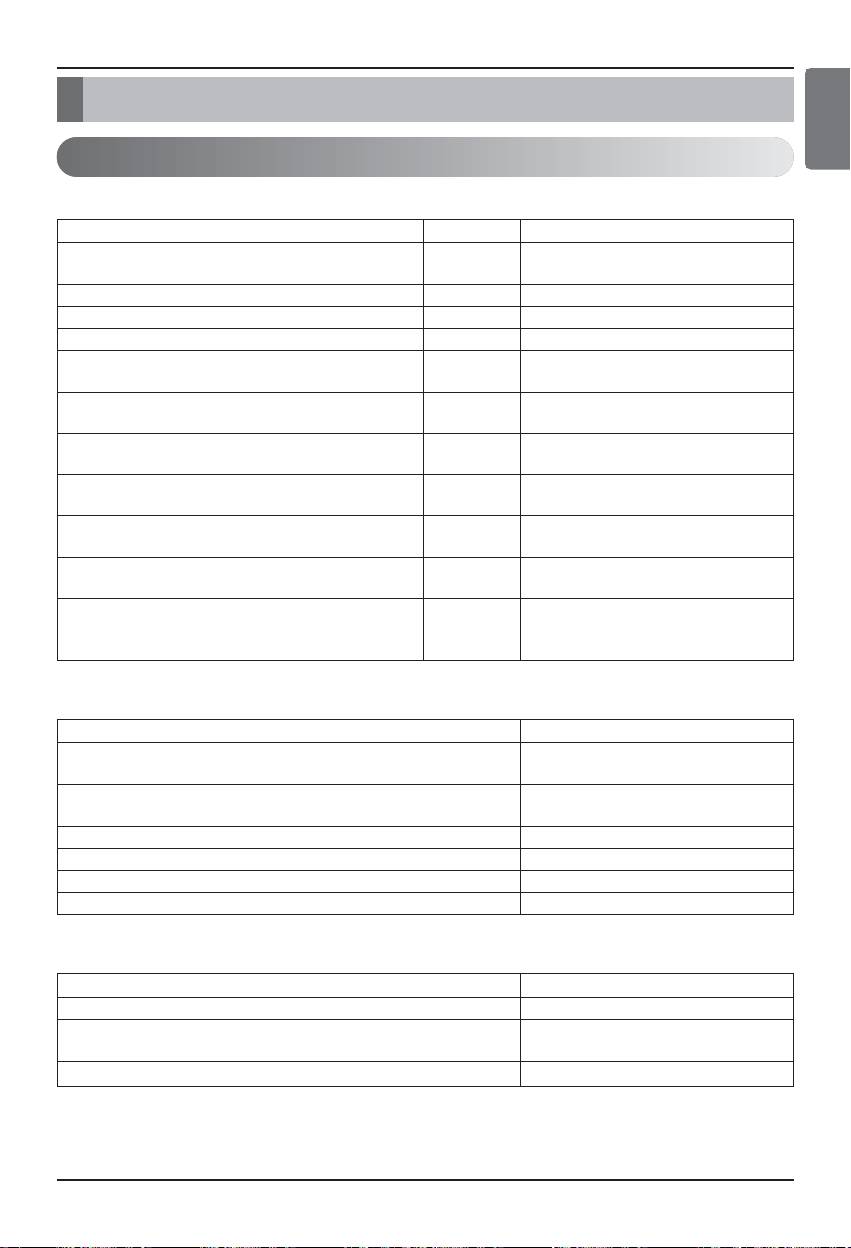

BACnet Point List : Indoor Unit

One indoor unit has the following 22 objects.

Text-5

Auto Heat

Auto

Auto

Text-4

High

Text-3

°C

Text-2

Middle

Start

Cool Dry Fan

Run

Run

Active

Prohibit

Prohibit

Abnormal

Unit

Stop

Text-0 Text-1

Permit

Inactive

-

-

BO Permit

BI

BI Stop

BI Normal

AI Reference LG Original Error Code

MO

BO

MO Low

MI Low Middle High

Type

Object

(XXX : Unit address)

ObjectName Product Name

StartStopCommand_XXX BO Stop

- -

-

ModeStatus_XXX MI Cool Dry Fan Auto Heat

SwingCommand_XXX

FanSpeedCommand_XXX

FanSpeedStatus_XXX

MalfunctionCode_XXX

-