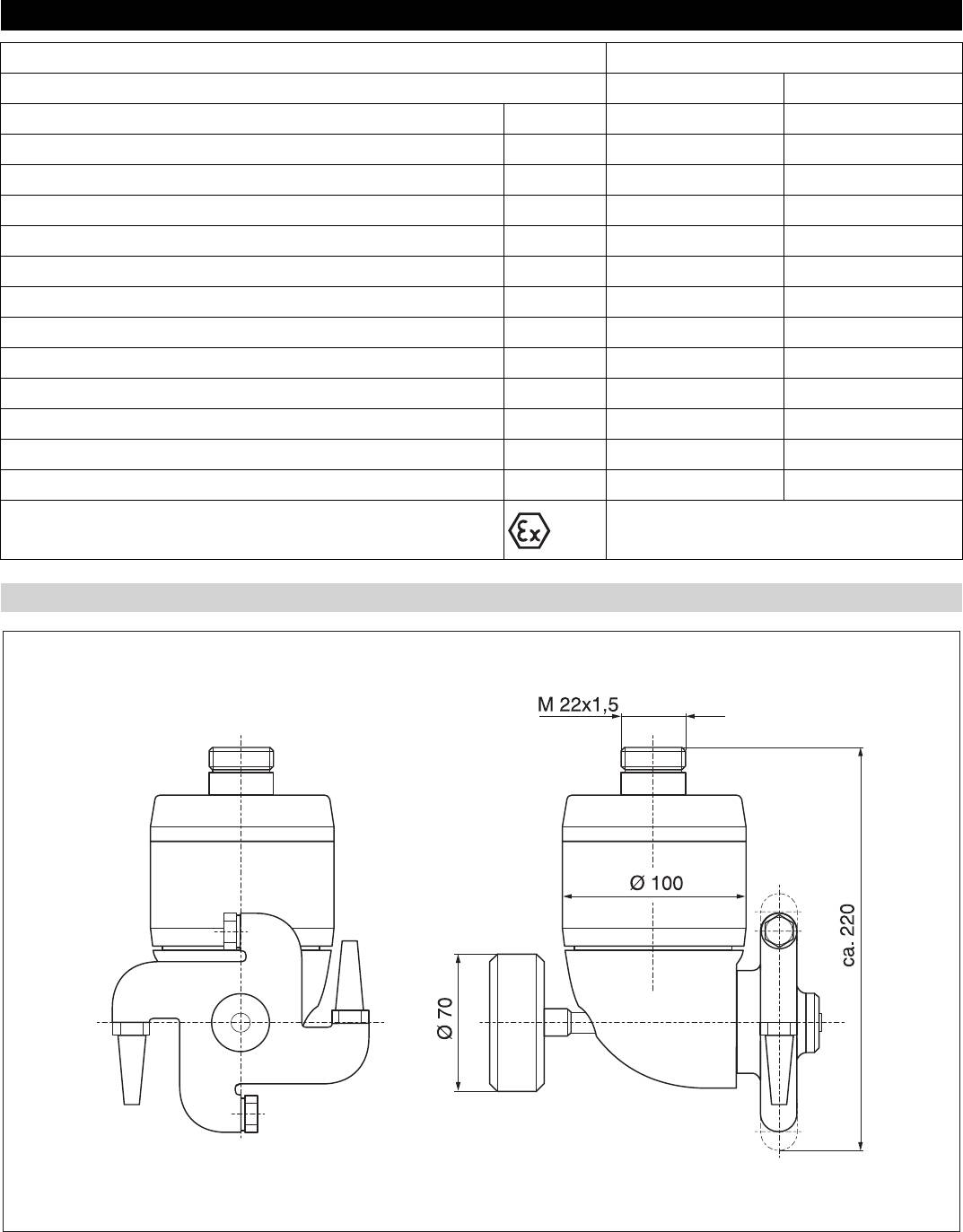

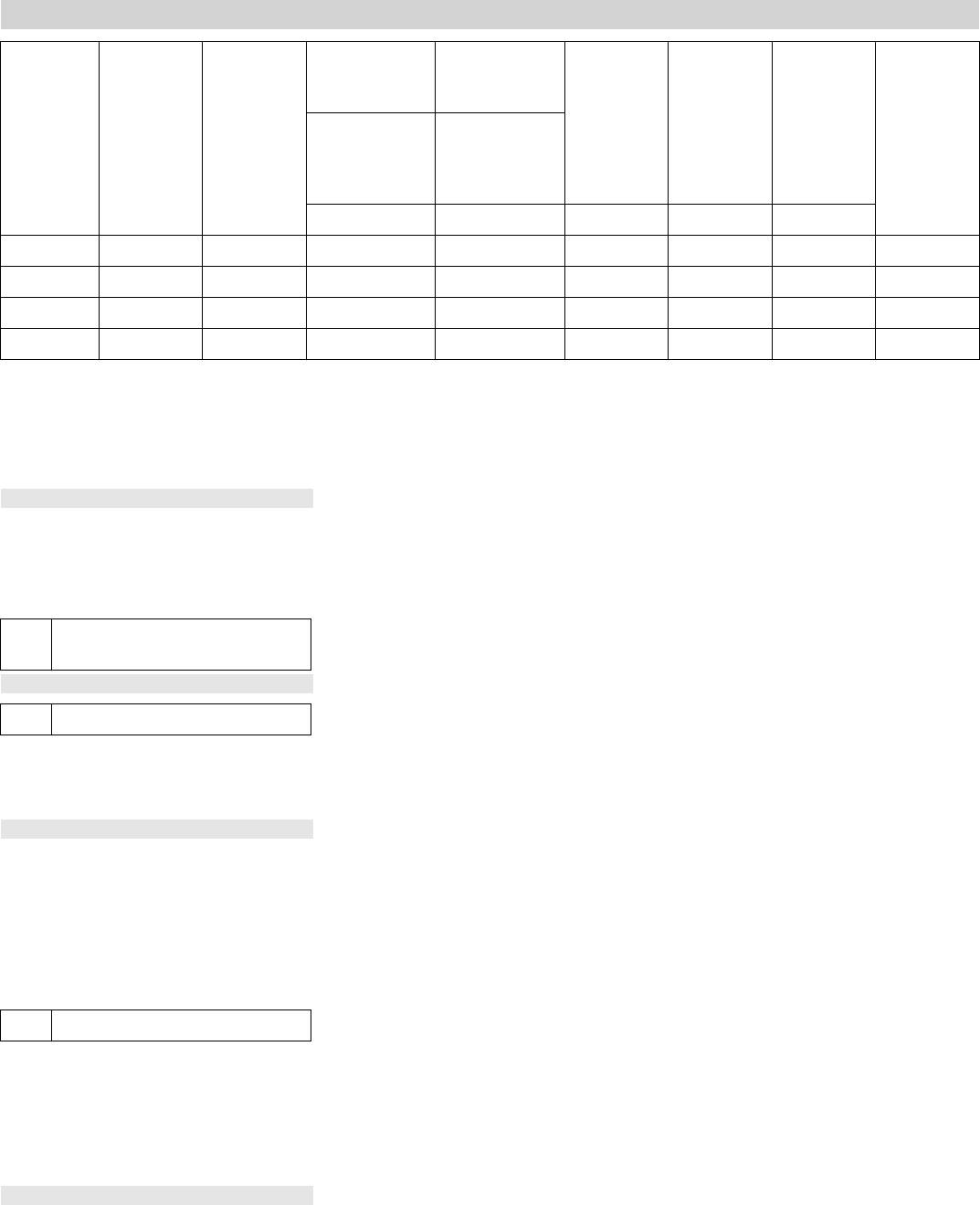

Karcher HKS 100 LM: Technical specifications

Technical specifications: Karcher HKS 100 LM

Technical specifications

HKS 100

Order No. 3.632-030, 3.632-032 3.632-035, 3.632-049

Max. flow rate l/h (l/min) 2400-6000 (40-100) 2400-6000 (40-100)

Max. flow rate with solvent operation l/h (l/min) -- 3000 (50)

Max. temperature with water with cleaning agents °C 60 60

Max. temperature with solvents, brines, acids °C 20 20

Max. operating pressure MPa (bar) 10 (100) 10 (100)

Max. operating pressure with solvent operation MPa (bar) 5 (50) 5 (50)

Functional speed - drive 1/min 8-40 8-40

Sound pressure level (EN 60704-1) dB(A) 70 70

High pressure connection -- DN 15 - M22x1.5 DN 15 - M22x1.5

Minimum container opening mm 200 200

Total length mm 220 220

Weight kg 6 6

Ambient temperature °C +2...+40 +2...+40

Ignition protection class II 1 G D c T4

Dimensional sheet HKS 100

18 EN

- 4

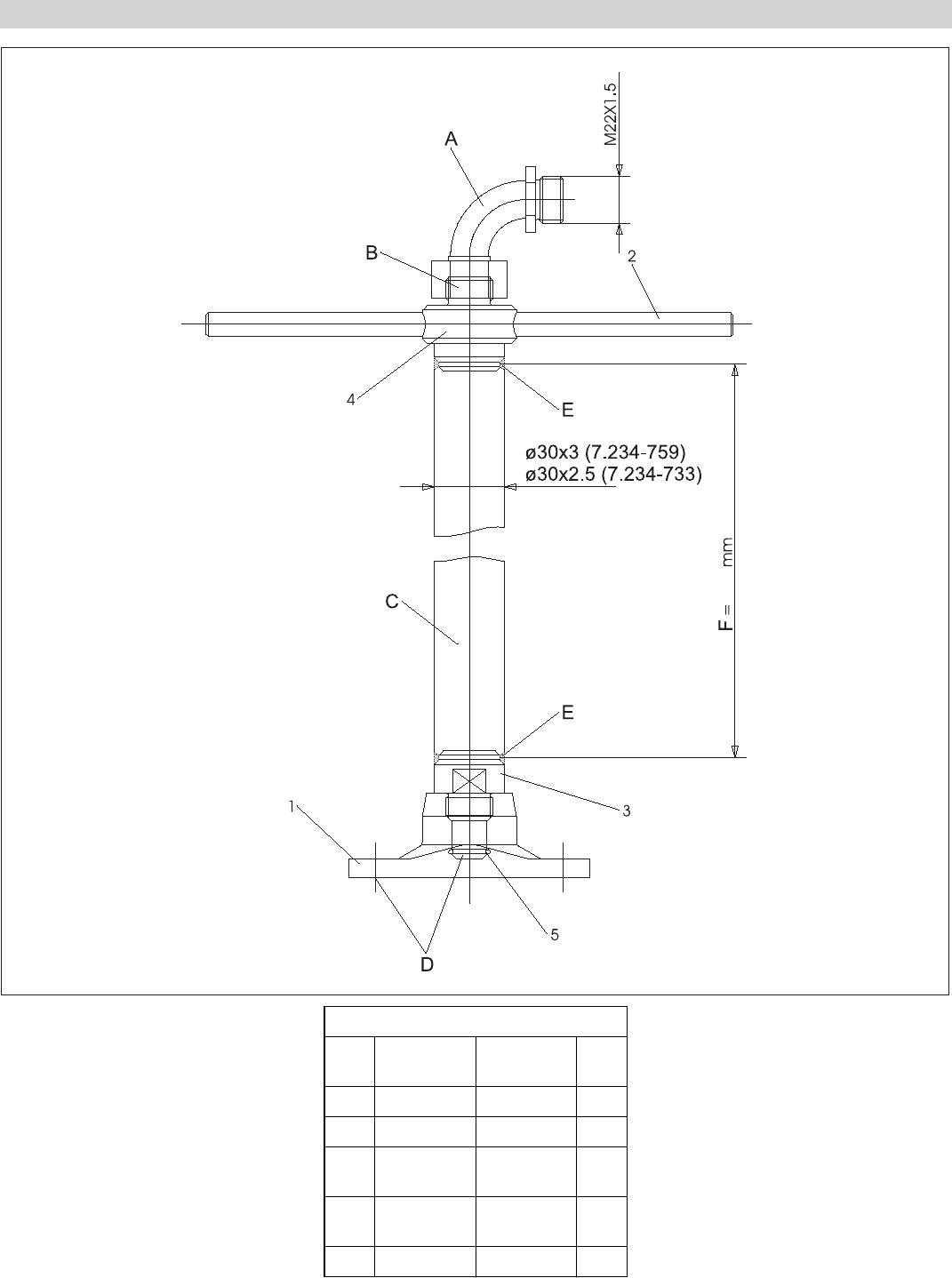

Dimensional sheet - parts set for frame

A Bow

2.637-015 (without pipe)

Order no. 4.408-023 (stainless steel)

Order no. 6.387-299 (steel, nickel-plat-

Item: Descrip-

Order No. Qua

ed)

tion

ntity

B High-pressure connection M22x1.5

1 Flange 5.122-026 1

C Pipe

(order the desired length, in addition,

2 Bolts 5.316-016 2

weld on items 2+3+4)

3 Welding

5.425-239 1

D Connection HKS 100

stub

E welded

F Pipe length

4 Welding

5.426-240 1

stub

5 O ring 5.362-223 1

- 5

19EN

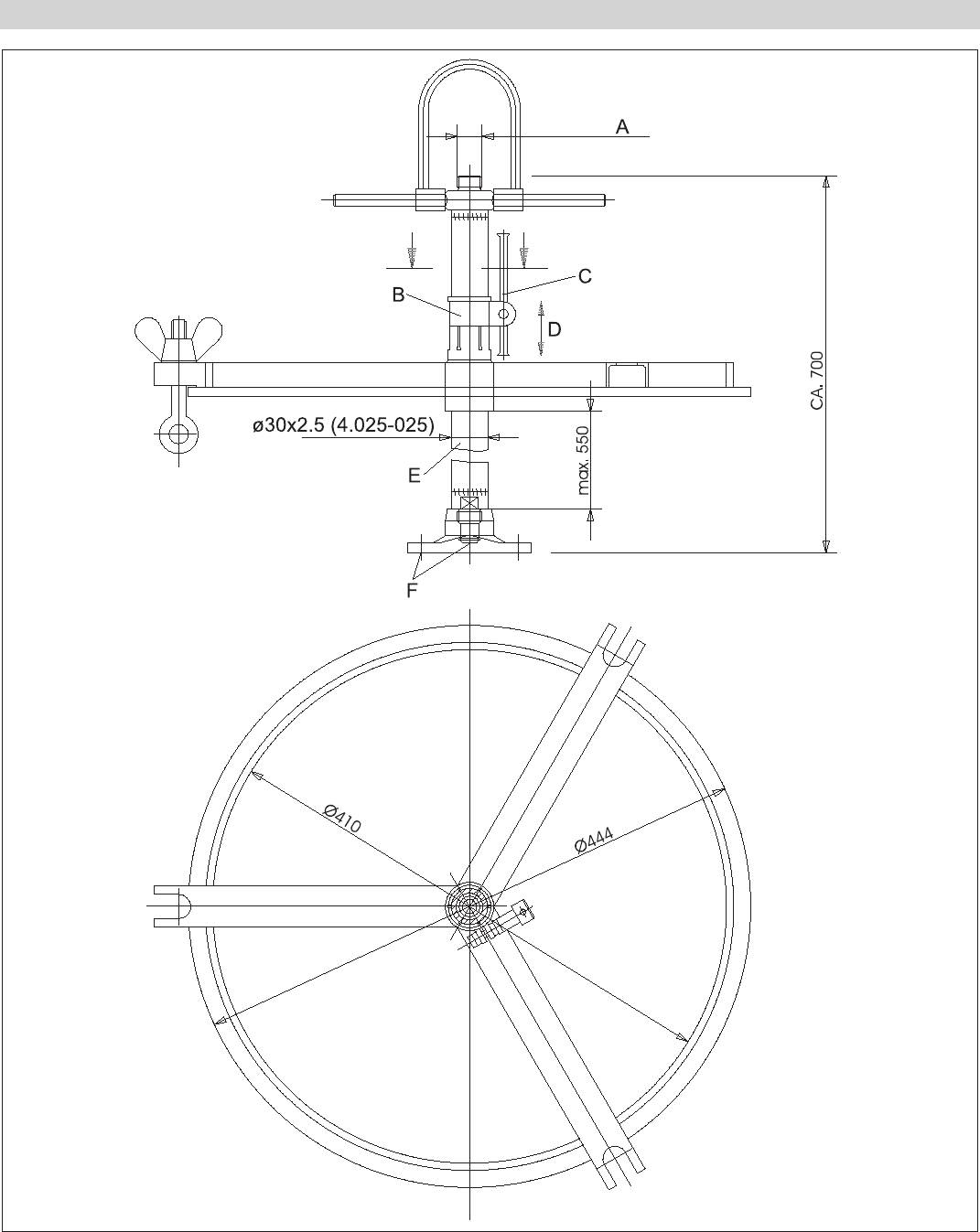

Dimensional sheet - cover with frame

A High-pressure connection M22x1.5

B Tension clamp

C Fastening toggle

D adjustable height

E Pipe

F Connection HKS 100

20 EN

- 6

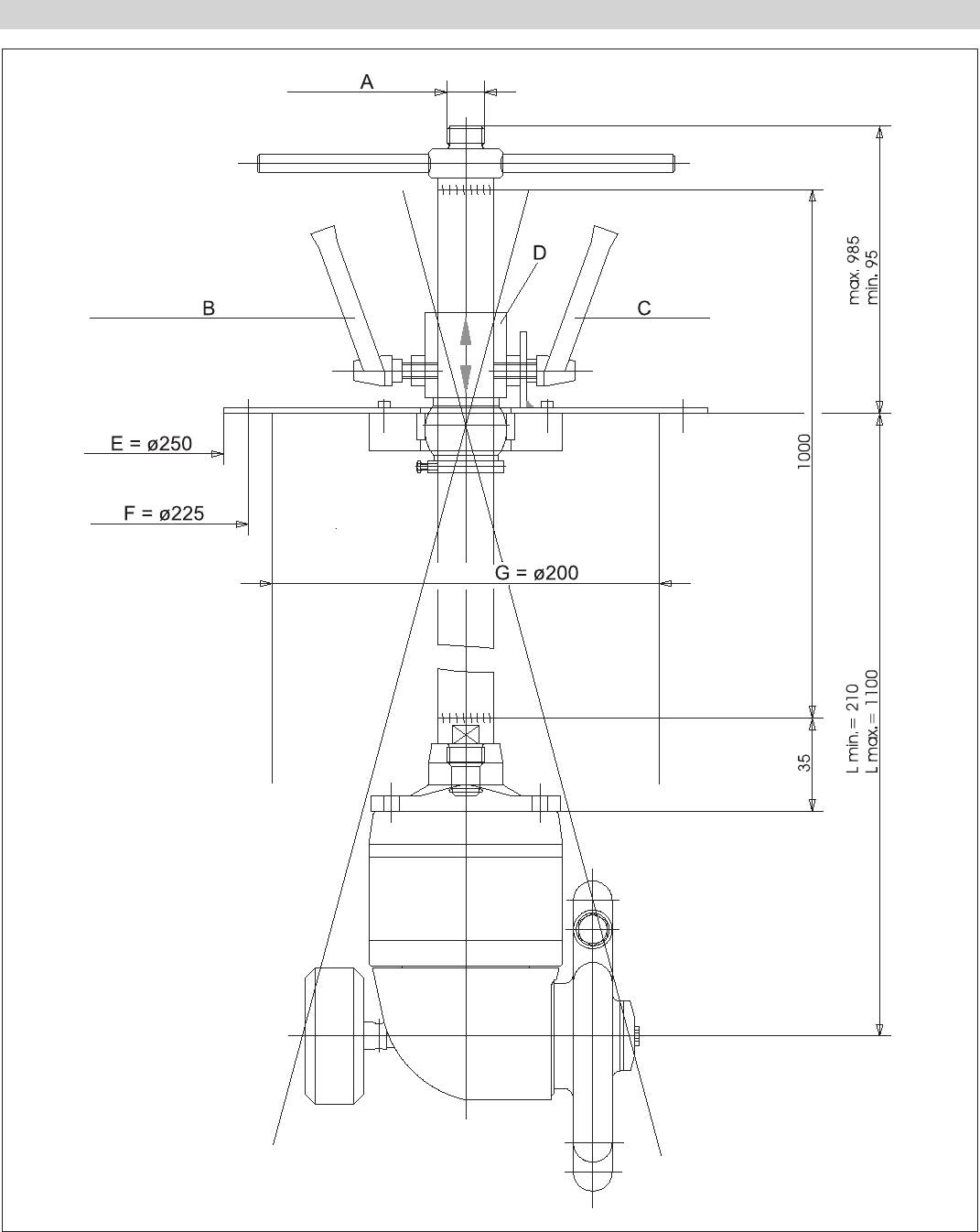

Dimensional sheet swivel frame

A High-pressure connection M22x1.5

B Fastening toggle for height adjustment

C Fastening toggle for tilting

D drawn offset by 90°

E Flange

F Screw-hole circle with 6 borings (diam-

eter 9 mm)

G Minimum insertion diameter

- 7

21EN

Cleaning liquids

Order No. Water Fully de-

Water with al-

Water with

Brines Acids solvents Use in the

salted wa-

kaline clean-

acid cleaning

food sector

ter

ing agent

agent

Example:

Example:

Kärcher clean-

Kärcher clean-

ing agents

ing agents

RM31

RM25

max. +60 °C max. +60 °C max. +20 °C max. +20 °C max. +20 °C

3.632-030 x x 0-2% 0-1% LA SR -- --

3.632-032 x x 0-2% 0-1% LA SR -- x

2)

3.632-035 x x 0-2% 0-1% LA SR LM

1)

--

3.632-049 x x 0-2% 0-1% LA SR acetone --

1)

= acetone operation impossible

2)

= Regulator fluid as per USDA H1, not

suitable for the cleaning of beer tanks

-- = inconsistent, use impossible

x = consistent

solvents

Notice

When operating with solvents, the sealing

materials are less resistent, therefore they

must be flushed immediately after use! En-

quire with Kärcher!

LM Solvents (max. temperature

+20 °C)

Brines

LA Brines (max. temperature +20 °C)

1 Caustic soda max. 10%, without hy-

pochlorite particles

2 Potassium hydroxide max. 10%, with-

out hypochlorite particles

Acids

Notice

– The material will be worn off faster

when using hydrochloric or sulfuric ac-

ids; therefore it must be rinsed/neutral-

ised immediately!

– Contaminated acids will decrease the

resilience!

– Enquire with Kärcher if needed!

SR Acids (max. temperature +20 °C)

1 Nitric acid max. 10%.

2 Acetic acid max. 10%.

3 Formic acid max. 10%.

4 Phosphoric acid max. 10%.

5 Citric acid max. 10%.

6 Sulfuric acid max. 0.5%.

7 Hydrochloric acid max. 0.5%.

Other cleaning liquids

If other cleaning liquids are used, their resil-

ience must be checked by means of the

materials list! These cleaning liquids can

only be used after being released by Kärch-

er!

22 EN

- 8

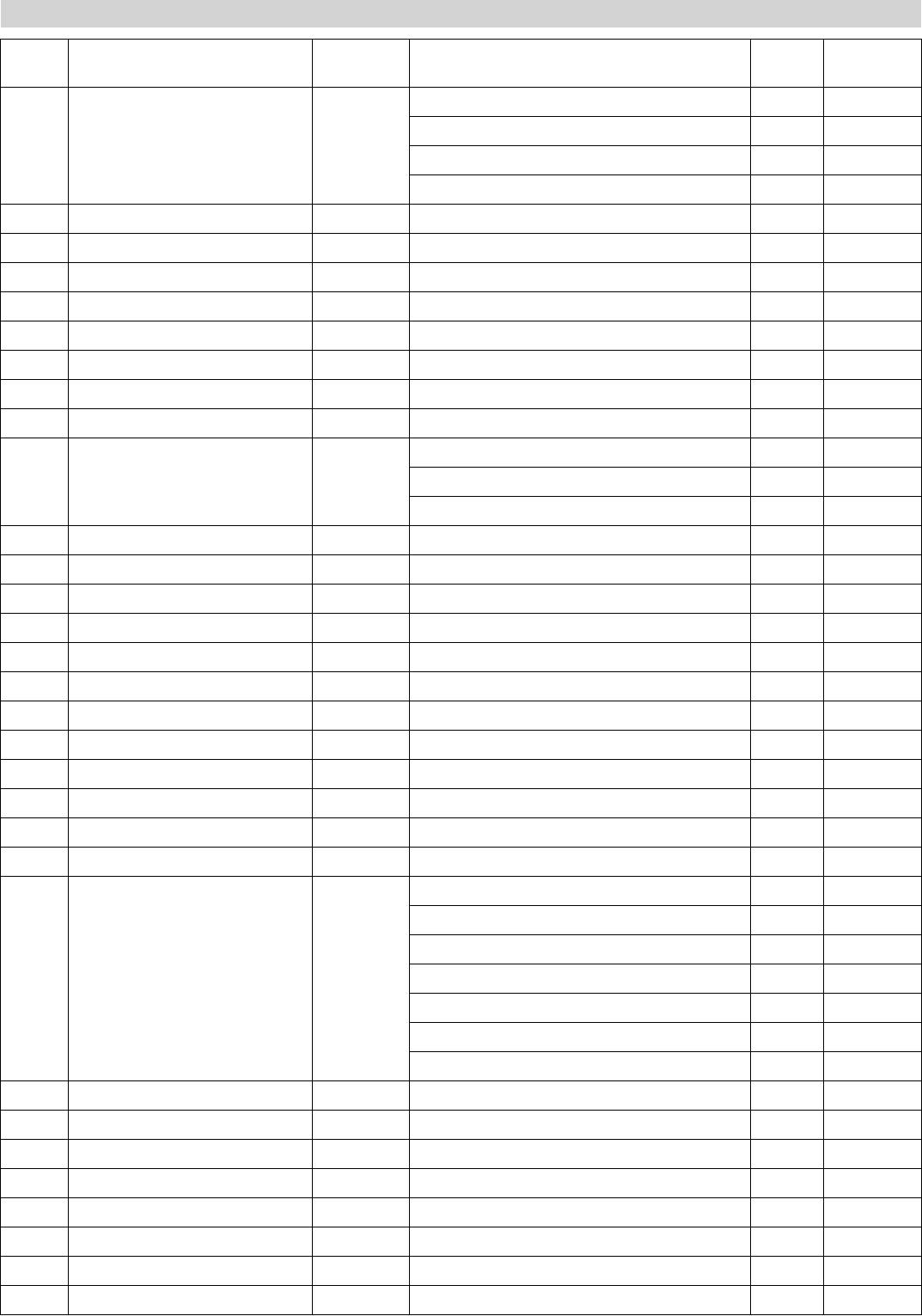

Materials list

Item: Description Order No. Material Quanti-

touching

ty

media

1 Shaft, complete 4.100-005 (5.100-040) shaft 1.4305 1 x

(5.343-003) safety ring FeSt 1 --

(6.365-428) grooved ring PTFE 1 x

(5.570-035) ring CuSn8F60 1 --

2 Bevel wheel 5.354-002 1.4541 1 x

3 Grooved ring 6.365-427 PTFE 1 x

4 Ball bearing 7.401-031 1 --

5 Support disc 6.343-096 1.4301 1 --

6 Safety ring 5.343-001 FeSt 1 --

7 O-ring 50.47x2.62 6.362-190 Ethylene propylene 1 x

8 Lower part 5.081-011 1.4305 1 x

9 Fitting key 7.318-015 FeSt 1 --

10 Circulation pump 4.542-002 (5.060-072) housing 1 --

(5.352-007) spur wheel gear 1 --

(5.352-006) spur wheel gear 3 --

12 Ring 5.570-036 Hostalen (PTFE) 1 x

13 Cover 5.063-069 GJS 400-15, 0.7040 1 --

14 O-ring 85,32x3,53 6.362-192 Ethylene propylene (EPDM) 2 x

15 Sleeve 5.110-066 1.4541 1 x

16 Grooved ring 6.365-426 PTFE 1 x

17* Disc 5.115-120 1.4305 1 x

18* Bolts 5.316-064 1.4305 1 x

19 Screw socket 5.402-163 1.4305 (WrC, coated) 1 x

20 Upper section 5.080-014 1.4305 1 x

21 O-ring 7,65x1,78 6.362-185 FPM (Viton) 3 x

22 Cylinder screw M8x60 6.304-126 12.9, A4-70 3 x

23 Axle stub 5.106-011 1.4305 (Cr-Oxyd, ceramic-coated) 1 x

24 Nozzle-holder 4.764-005 (5.005-107) circular blank 1.4301 2 x

(5.343-002) safety ring FeSt 2 x

(5.354-001) bevel wheel 1.4541 1 x

(5.570-034) ring CuSn8F60 2 x

(5.764-005) nozzle holder G-X7CrNiNb18.9 1 x

(6.365-429) grooved ring PTFE 2 x

(7.307-300) threaded pin 1 x

25 Circular blank 5.005-071 1.4301 2 x

26 Disc 5.115-121 1.4305 1 x

27 Cylinder screw M6x10 7.306-130 12.9, A4-70 1 x

28 Form screw 5.305-017 1.4305 1 x

29 O-ring 8.0x2.0 6.362-101 Perbunan (70°, Shore A) 1 --

30 Ring 5.570-037 Teflon bronze 1 x

33* Protective hood 5.392-003 PE 1 x

40 Protective cover 6.368-012 PE 1 --

* Parts omitted when used in zone 0

- 9

23EN

Оглавление

- Sicherheitshinweise

- Technische Daten

- Inbetriebnahme

- Bedienung

- Zubehör EG-Konformitätserklärung

- Proper use Safety instructions

- Technical specifications

- Start up

- Operation

- Accessories EC Declaration of Conformity

- Utilisation conforme

- Caractéristiques techniques

- Mise en service

- Utilisation

- Accessoires Déclaration de conformité CE

- Uso conforme a destinazione Norme di sicurezza

- Dati tecnici

- Messa in funzione

- Uso

- Accessori Dichiarazione di conformità

- Veiligheidsinstructies

- Technische gegevens

- Inbedrijfstelling

- Bediening

- Toebehoren EG-conformiteitsverklaring

- Uso previsto

- Datos técnicos

- Puesta en marcha

- Manejo

- Accesorios Declaración de conformidad CE

- Innehållsförteckning

- Tekniska data

- Idrifttagning

- Handhavande

- Tillbehör Försäkran om EU-

- Символы в руководстве по Назначение

- Технические данные

- Начало работы

- Управление

- Помощь в случае неполадок

- Принадлежности Заявление о соответствии

- Biztonsági tanácsok

- Műszaki adatok

- Üzembevétel

- Használat

- Tartozékok EK konformitási nyiltakozat

- Użytkowanie zgodne z

- Dane techniczne

- Uruchamianie

- Obsługa

- Akcesoria Deklaracja zgodności UE