Karcher HKS 100 LM: Accessories EC Declaration of Conformity

Accessories EC Declaration of Conformity: Karcher HKS 100 LM

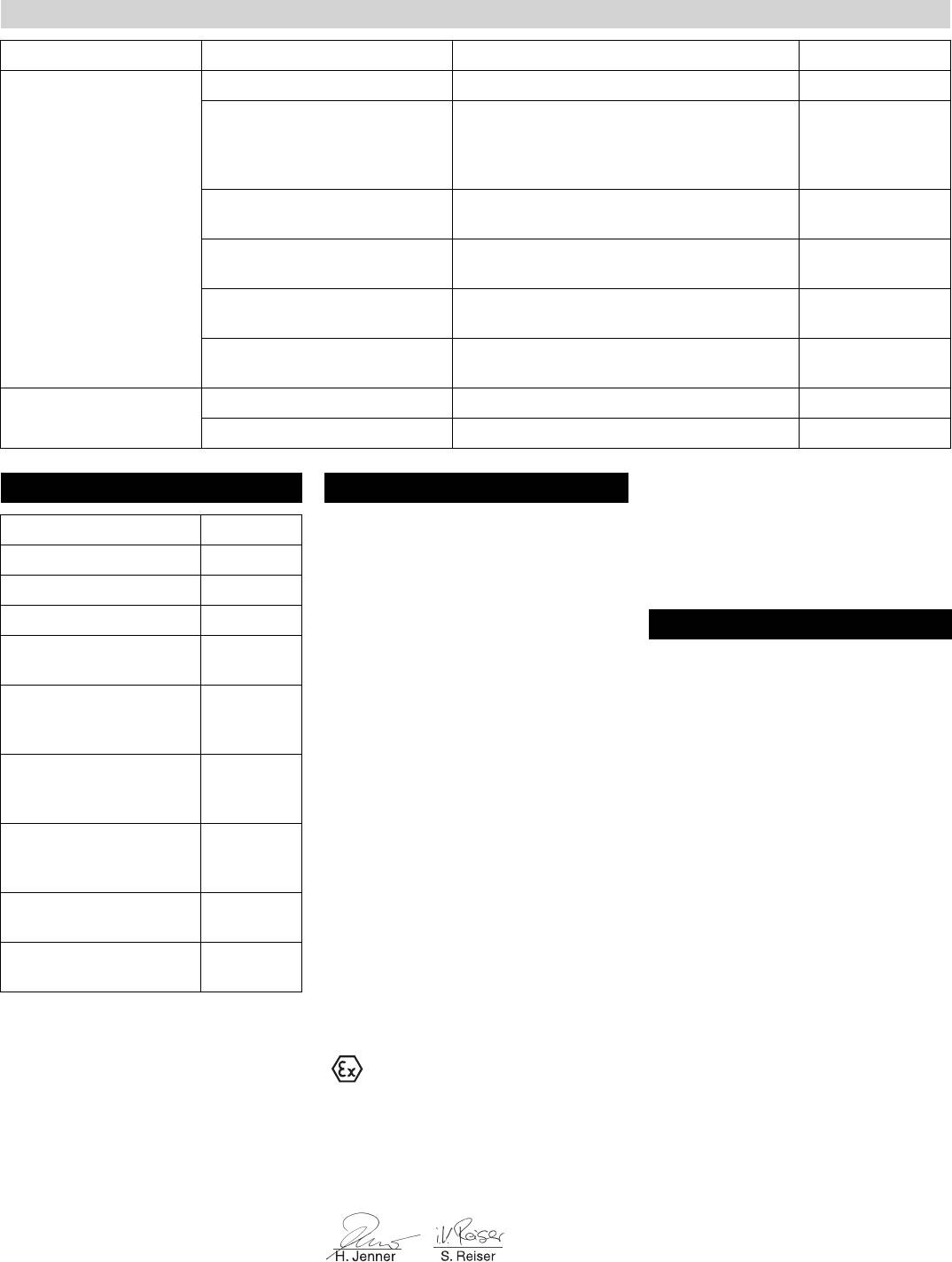

Troubleshooting

Fault Possible cause Remedy of whom

The interior cleaner does

The speed is set too low. Adjust higher speed on the regulator screw. Operator

not turn or only turn partial-

The pressure of the cleaning

Adjust the nozzles on the interior cleaner to the

Operator

ly or abruptly

agent is too low or the wrong noz-

feed flow of the high-pressure pump (smaller

zles have been installed on the in-

nozzle opening means higher pressure).

terior cleaner.

Air in the reguator fluid. Replace regulator fluid (see Maintenance Pro-

Operator

cedures).

Wrong regulator fluid has been

Replace the regulator fluid completely. Customer Service

used.

The seals on the shafts are leak-

Replace washers. Customer Service

ing.

Bevel wheels dirty. Clean bevel wheels (see Maintenance Proce-

Operator

dures).

Uneven cleaning jet Spray nozzles clogged. Clean spray nozzles. Operator

Spray nozzles damaged. Replace spray nozzles. Operator

Alfred Kärcher GmbH Co. KG

Accessories

EC Declaration of Conformity

Alfred-Kärcher-Str. 28 - 40

We hereby declare that the machine de-

71364 Winnenden (Germany)

Description Order No.

scribed below complies with the relevant

Phone: +49 7195 14-0

Parts kit for frame on request

basic safety and health requirements of the

Fax: +49 7195 14-2212

EU Directives, both in its basic design and

Cover with frame on request

construction as well as in the version put

Winnenden, 2013/12/01

Swivel frame on request

into circulation by us. This declaration shall

Warranty

cease to be valid if the machine is modified

High-pressure connection

4.408-023

without our prior approval.

The warranty terms published by our com-

bow 90°, M22x1.5

petent sales company are applicable in

Product: Internal cleaner

each country. We will repair potential fail-

Regulator fluid for normal

6.288-021

Type: HKS 100

ures of the appliance within the warranty

operation - cold/warm run

period free of charge, provided that such

0.25 liters

Relevant EU Directives

2006/42/EC (+2009/127/EC)

failure is caused by faulty material or de-

Regulator fluid for normal

4.070-020

94/9/EC

fects in fabrication.

operation - cold run 0.25

Applied harmonized standards

liters

EN ISO 12100

EN 1127-1: 2011

Regulator fluid for food op-

4.070-033

EN 13463-1: 2009

erations - cold run 0.25 lit-

EN 13463-5: 2011

ers

Applied national standards

-

Regulator fluid for food op-

4.070-047

ID no. of notified body

erations - cold run 1 liters

0123

TÜV SÜD

Regulator fluid for solvent

6.288-007

Ridlerstr. 65

operations - cold run 1 liter

80339 München

Test report no.

Ex5 0307 10088 097

Marking

II 1 G D c T4

5.957-455

The undersigned act on behalf and under

the power of attorney of the company man-

agement.

CEO

Head of Approbation

Authorised Documentation Representative

S. Reiser

26 EN

- 12

Оглавление

- Sicherheitshinweise

- Technische Daten

- Inbetriebnahme

- Bedienung

- Zubehör EG-Konformitätserklärung

- Proper use Safety instructions

- Technical specifications

- Start up

- Operation

- Accessories EC Declaration of Conformity

- Utilisation conforme

- Caractéristiques techniques

- Mise en service

- Utilisation

- Accessoires Déclaration de conformité CE

- Uso conforme a destinazione Norme di sicurezza

- Dati tecnici

- Messa in funzione

- Uso

- Accessori Dichiarazione di conformità

- Veiligheidsinstructies

- Technische gegevens

- Inbedrijfstelling

- Bediening

- Toebehoren EG-conformiteitsverklaring

- Uso previsto

- Datos técnicos

- Puesta en marcha

- Manejo

- Accesorios Declaración de conformidad CE

- Innehållsförteckning

- Tekniska data

- Idrifttagning

- Handhavande

- Tillbehör Försäkran om EU-

- Символы в руководстве по Назначение

- Технические данные

- Начало работы

- Управление

- Помощь в случае неполадок

- Принадлежности Заявление о соответствии

- Biztonsági tanácsok

- Műszaki adatok

- Üzembevétel

- Használat

- Tartozékok EK konformitási nyiltakozat

- Użytkowanie zgodne z

- Dane techniczne

- Uruchamianie

- Obsługa

- Akcesoria Deklaracja zgodności UE