Karcher HKS 100 LM: Operation

Operation: Karcher HKS 100 LM

Check regulator fluid

Operation

Who may perform maintenance?

Note: The speed can only be set easily

Danger

Operator

when the interior cleaner is completely

Risk of injury on account of the escaping

Work designated with the sign “Opera-

filled with regulator fluid. Only fill in the

water jet that could be hot!

tor” may only be carried out by persons

same regulator fluid; mixing with other reg-

– Only use the interior cleaner in closed

who have been instructed in the safe

ulator fluids or contained air lead to jerky

containers.

operation and maintenance on the high

revolutions.

– Only insert the interior cleaner into a

pressure plant.

container or switch it into another con-

Maintenance contract

tainer while the separate high pressure

pump is turned off.

In order to guarantee a reliable operation

Place interior cleaner onto container

og the equipment, we success, you signed

and lock it.

a maintenance agreement. Please refer to

Connect the high pressure pump to the

you local Kärcher service department.

interior cleaner via a high pressure

Maintenance intervals

hose.

– monthly or after 200 operating hours

Open the cleaning liquid supply.

Switch on the separate high pressure

Maintenance Works

pump.

Insert the interior cleaner into the vice

Check whether all screws are fastened

with the regulator screw pointing up.

Shutting down

tightly (operator).

Turn out the regulator screw.

Check drive parts (operator).

Note: Flush the interior cleaner for 30 sec-

Fill in regulator fluid.

Check regulator fluid (operator).

onds without adding detergents prior to

Turn the nozzle holder slowly by hand

shutting it down. This will avoid crusting

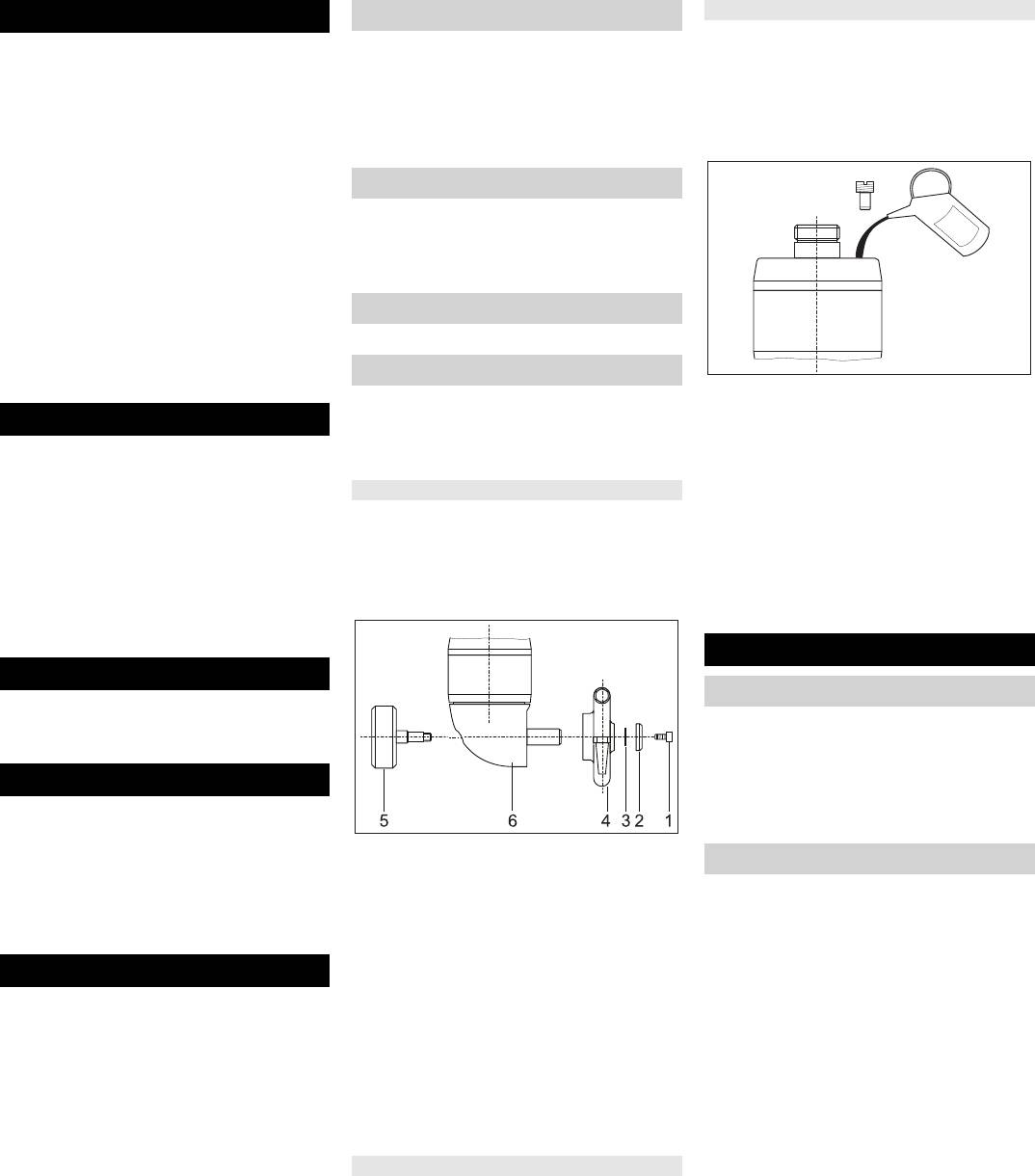

Remove nozzle holder

(5 to 10 minutes) until regulator fluid

and adhesion and thus premature wear of

Note: The chart shows the interior cleaners

drains. Immediately replace the regula-

the seals.

with the order no. 3.632-030 and 3.632-

tor fluid. Turn the nozzle holder until it is

Switch off the separate high pressure

032. The interior cleaners with the order no.

completely filled with regulator fluid.

pump.

3.632-035 and 3.632-049 do not have a

Then, the regulator fluid will no longer

Shut off the cleaning liquid supply.

counter weight and no protective cap.

drain.

Remove the interior cleaner from the

Turn in the regulator screw.

container.

Troubleshooting

Storage

Troubleshooting notes

몇 Caution

Risk of injury and damage! Note the weight

Danger

of the appliance in case of storage.

Risk of accident while working on the unit!

During all tasks:

Transport

Remove voltage from and secure high

몇 Caution

pressure pump at the main switch.

Risk of injury and damage! Observe the

Shut off the cleaning liquid supply.

1 Screw

weight of the appliance when you transport

Who may remedy faults?

2 Shoulder disc

it.

3 Balancing disc

Who may remedy faults?

When transporting in vehicles, secure

4 Nozzle-holder

Operator

the appliance according to the guide-

5 Counterweight

Work designated with the sign “Opera-

lines from slipping and tipping over.

6 Protective cover

tor” may only be carried out by persons

Maintenance and care

Loosen the screw.

who have been instructed in the safe

Remove the shoulder disc and the bal-

operation and maintenance on the high

The basis for a safe operational plant is

ancing discs.

pressure plant.

regular maintenance.

Pull off the nozzle holder.

Customer Service

Use only original parts of the manufacturer

Only for appliances order nos. 3.632-

Work designated with the sign “Cus-

or part suggessted by him, such as

030 and 3.632-032: Unscrew the coun-

tomer Service” may only be done by the

– replacement and wear parts

terweight and remove the protective

fitters of Kärcher Customer Service.

– Accessory parts

cover.

– Fuel

Clean the bevel wheels.

– Detergent

Install nozzle holder

Danger

Risk of accident while working on the unit!

Only for appliances order nos. 3.632-

During all tasks:

030 and 3.632-032: Attach the protec-

Remove voltage from and secure high

tive cover and screw on counterweight.

pressure pump at the main switch.

Install the nozzle holder.

Shut off the cleaning liquid supply.

Insert the shoulder disc and the balanc-

ing discs.

Attach the screw.

- 11

25EN

Оглавление

- Sicherheitshinweise

- Technische Daten

- Inbetriebnahme

- Bedienung

- Zubehör EG-Konformitätserklärung

- Proper use Safety instructions

- Technical specifications

- Start up

- Operation

- Accessories EC Declaration of Conformity

- Utilisation conforme

- Caractéristiques techniques

- Mise en service

- Utilisation

- Accessoires Déclaration de conformité CE

- Uso conforme a destinazione Norme di sicurezza

- Dati tecnici

- Messa in funzione

- Uso

- Accessori Dichiarazione di conformità

- Veiligheidsinstructies

- Technische gegevens

- Inbedrijfstelling

- Bediening

- Toebehoren EG-conformiteitsverklaring

- Uso previsto

- Datos técnicos

- Puesta en marcha

- Manejo

- Accesorios Declaración de conformidad CE

- Innehållsförteckning

- Tekniska data

- Idrifttagning

- Handhavande

- Tillbehör Försäkran om EU-

- Символы в руководстве по Назначение

- Технические данные

- Начало работы

- Управление

- Помощь в случае неполадок

- Принадлежности Заявление о соответствии

- Biztonsági tanácsok

- Műszaki adatok

- Üzembevétel

- Használat

- Tartozékok EK konformitási nyiltakozat

- Użytkowanie zgodne z

- Dane techniczne

- Uruchamianie

- Obsługa

- Akcesoria Deklaracja zgodności UE