Karcher HKS 100 LM: Proper use Safety instructions

Proper use Safety instructions: Karcher HKS 100 LM

Please read and comply with

Proper use

Safety instructions

these original instructions prior

to the initial operation of your appliance and

– The interior cleaners HKS 100 are

– Please follow the national rules and

store them for later use or subsequent own-

spray devices to clean drums and con-

regulations of the respective country.

ers.

tainers.

– Please follow the safety instructions

– Before first start-up it is definitely nec-

– The cleaning head is inserted into the

which are attached to the used deter-

essary to read the operating instruc-

container through an opening with a

gents (normally on the packing label).

tions and safety indications Nr. 5.951-

suitable minimum inner diameter.

– In order to avoid improper operation,

949.0!

the system may only be used by per-

Cleaning head Minimum con-

– In case of transport damage inform ven-

sons who have been instructed in han-

tainer opening

dor immediately

dling the system or have proven qualifi-

HKS 100 200 mm

cation and expertise in operating the

Contents

system or have been explicitly assigned

– A separate high pressure pump is con-

the task of handling the system.

Environmental protection . . . . EN . . 1

nected to the interior cleaner via a high

– The operating instructions must be ac-

Symbols in the operating in-

pressure hose.

cessible for every user.

structions . . . . . . . . . . . . . . . . EN . . 1

Note: The chapter "Specifications" con-

Wrong operation or misuse are hazardous

Proper use . . . . . . . . . . . . . . . EN . . 1

tains a list of the permitted cleaning liquids.

to the operator and other persons on ac-

Function . . . . . . . . . . . . . . . . . EN . . 1

count of:

Safety instructions . . . . . . . . . EN . . 1

– high pressure

Technical specifications . . . . . EN . . 4

Operation outside closed containers and

– Cleaning agents or used cleaning liquid

Start up . . . . . . . . . . . . . . . . . . EN . 10

with higher pressure and temperatures

– hot system parts, if hot cleaning liquids

Operation . . . . . . . . . . . . . . . . EN . 11

than those listed in the "Specifications" is

are used

Shutting down . . . . . . . . . . . . . EN . 11

prohibited.

– Danger of explosion

Storage . . . . . . . . . . . . . . . . . . EN . 11

Danger

Please do not allow cleaning liquids to

Transport. . . . . . . . . . . . . . . . . EN . 11

– Danger of injury by high pressure jet -

enter the environment. Protect the

Maintenance and care . . . . . . EN . 11

therefore only use interior cleaner in-

ground and dispose of used oil in an en-

Troubleshooting . . . . . . . . . . . EN . 11

side closed containers.

vironmentally-clean manner.

– Health hazards posed by residue in

Accessories . . . . . . . . . . . . . . EN . 12

EC Declaration of Conformity . EN . 12

Please do not let mineral oil contaminat-

containers that are cleaned or by the

ed waste water reach soil, water or the

cleaning liquid used. Therefore, the list-

Warranty . . . . . . . . . . . . . . . . . EN . 12

sewage system.

ed protective measures must be ad-

Environmental protection

hered to.

The regulator in the interior cleaner has

– Risk of injury due to interior cleaner top-

The packaging material can be

the same characteristics as mineral oil.

pling over at low submerge depth. In

recycled. Please do not throw

When you change the regulator fluid, you

this case, the interior cleaner must be

the packaging material into

can return the used regulator fluid to the

supported.

household waste; please send

respective collection sites. Polluting the

– Risk of injury by toppling container -

it for recycling.

environment with used regulator fluid is a

therefore use extra support for contain-

punishable offence.

er and interior cleaner.

Old appliances contain valua-

– Risk of burns by hot hoses and hot rack

ble materials that can be recy-

Function

when using hot cleaning liquids. When

cled; these should be sent for

operating with hot cleaning liquids, do

recycling. Batteries, oil, and

– The nozzles on the cleaning head turn

not touch the rack and supply lines and

similar substances must not

around two axles and therefore touch

wear protective clothing.

enter the environment. Please

every place in the container.

dispose of your old appliances

– The interior cleaner drives itself pow-

using appropriate collection

ered by the pushback force of the

systems.

cleaning liquid on the nozzles. The

Risk of explosion and fire when using

speed depends on pressure, volume

cleaning agents and residue in the contain-

Notes about the ingredients (REACH)

and temperature of the cleaning liquid

ers. Please contact Kärcher in such cases

You will find current information about the

and can be adjusted via the regulator

to find out, how the respective cleaning

ingredients at:

screw.

agents should be used.

www.kaercher.com/REACH

Notice

Symbols in the operating

In order to avoid damage to the cleaning

instructions

head, ensure a free layout inside the con-

tainer. The cleaning head must never touch

Danger

the container wall.

Immediate danger that can cause severe

injury or even death.

몇 Warning

Possible hazardous situation that could

lead to severe injury or even death.

몇 Caution

Pointer to a possibly dangerous situation,

which can lead to minor injuries.

Notice

Pointer to a possibly dangerous situation,

which can lead to property damage.

- 1

15EN

– Zone 22

Personal safety gear

Zone 22 is an area where (during nor-

mal operation) dangerous explosion-

Wear ear plugs to protect

risk atmosphere as a cloud of flamma-

your ears against hearing

ble dust is not normally present and if

loss while cleaning parts

present, only for a short time.

that produce high sound

levels.

Special conditions in the Ex area

Depending on the concentration and health

risk of the used cleaning liquid, wear the fol-

lowing protective gear:

1 The interior cleaner must only be used

– Liquid resistant protective clothing

in Zone 0 if the containers are at least 3

– Protective glasses or face shield

m in diameter with the usual container

– Protective gloves

height or do not exceed a comparable

– Protective shoes

container size.

Approved operators

2 The mass content of non-diluted solid

substances in the cleaning liquid must

Approved operators are persons who are at

not exceed 1%.

least 18 years old and are able to operate

3 The interior cleaner must be ground

this system (exceptions: apprentices, see

electro-statically.

BGV D15 §6).

4 The pump for the cleaning liquid must

Behaviour in emergency situations

only be operated while it is filled with flu-

id.

Switch off the separate high pressure

5 The nominal pressure of the pump must

pump.

not exceed 5 MPa when operating with

Shut off the cleaning liquid supply.

solvents.

Zone layout

6 The flow volume of the pump must not

exceed 50 l/m when operating with sol-

vents.

7 The speed of the cleaning head must

Areas that bear the risk of explosion are di-

not exceed 40 rpm.

vided into zones, according to the frequen-

8 The operating temperature of the clean-

cy and duration of explosion-risk atmos-

ing liquid water with cleaning agents

phere in BetrSichV and EN 1127-1.

must not exceed 60 °C.

The definition of the zones lies in the re-

9 The operating temperature of the clean-

sponsibility of the operator.

ing liquid solvents, brines and acids

Tips for zoning are included in the BetrSi-

must not exceed 20 °C.

chV, EN 1127-1, BGR 104 – Ex-guideline

10 The interior cleaner must be checked

of BG Chemie and in the EN 60079-10.

for flawless condition and function after

– Zone 0

an appropriate operating period

Zone 0 is an area where dangerous ex-

(among others, bearings for wear and

plosion-risk atmosphere is present as a

brake system for its function). If applica-

mixture of air and flammable gases, va-

ble, a repair needs to be conducted.

pors or mists at all times, across long

11 The interior cleaner must only be used

time periods or frequently.

with cleaning liquids and in such media,

– Zone 1

whose affect on the materials is not

Zone 1 is an area where (during normal

damaging.

operation) dangerous explosion-risk at-

12 Cleaning liquids that contain flammable

mosphere is present as a mixture of air

solvent particles, must comply with the

and flammable gases, vapors or mists

ignition groups IIA and IIB. Solvents of

from time to time.

the ignition group IIC must not be

– Zone 2

sprayed.

Zone 2 is an area where (during normal

13 The interior cleaner must not be con-

operation) dangerous explosion-risk at-

stantly located in Zone 0, but only dur-

mosphere as a mixture of air and flam-

ing the actual container cleaning. The

mable gases, vapors or mists is not

operating guidelines as per BetrSichV

normally present and if present, only for

as well as other national guidelines

a short time.

must be adhered to. Take into consider-

– Zone 20

ation, that the mixture of the container/

Zone 20 is an area where dangerous

interior cleaner brought into the con-

explosion-risk atmosphere is present

tainer is not resistant to breakdown

as a cloud of flammable dust contained

from flames.

in the air, at all times, across long time

14 Hoses must be conductive (electrostat-

periods or frequently.

ically) (resistance R < 1000000 Ohm).

– Zone 21

15 Only cleaning agents with a conductivi-

Zone 21 is an area where (during nor-

ty G > 1000 pS/m may be used.

mal operation) dangerous explosion-

16 All parts that touch media must be con-

risk atmosphere is present as a cloud of

nected to the grounding system.

flammable dust in the air from time to

time.

16 EN

- 2

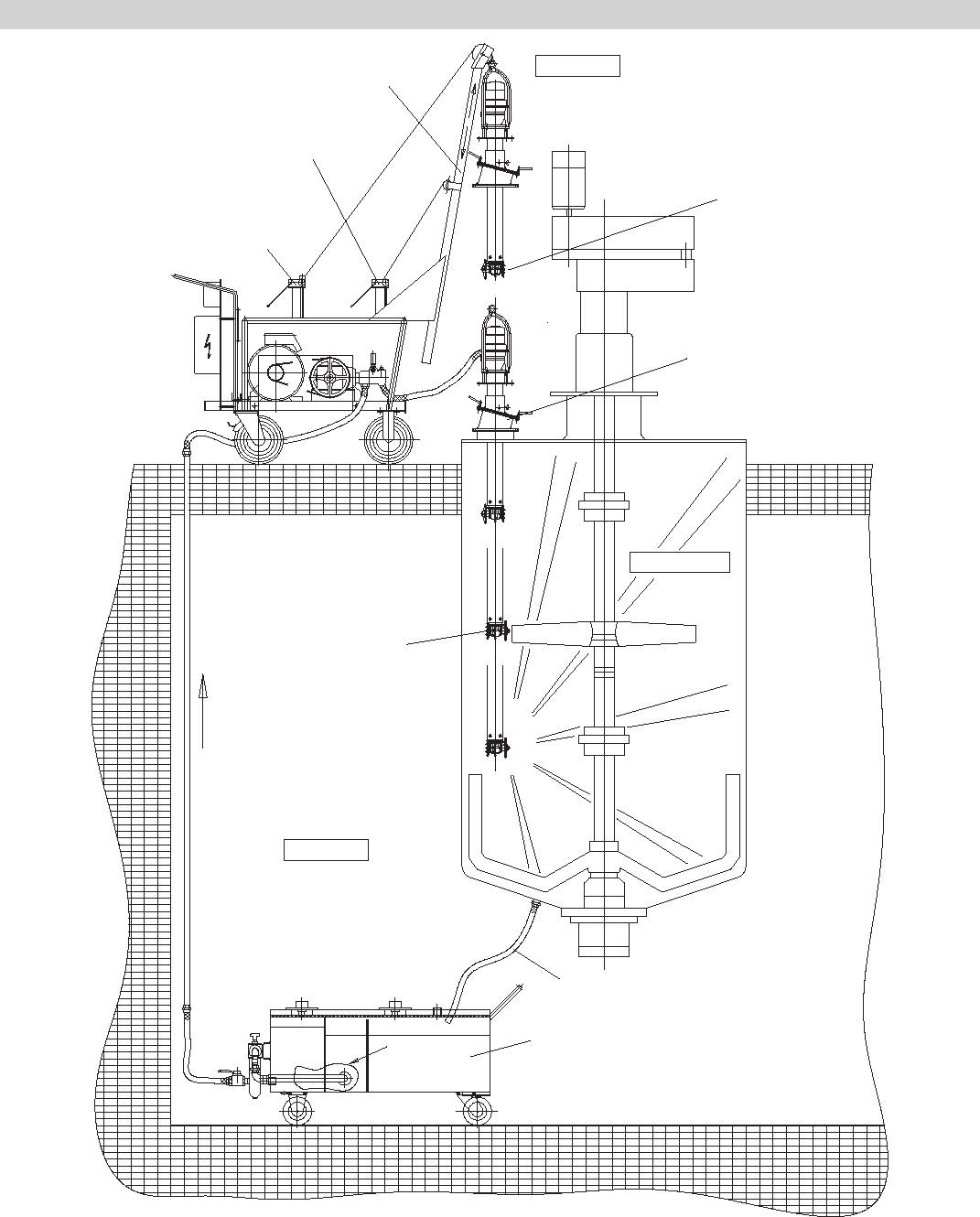

Basic sketch - zone layout

A

L

K

B

J

C

D

I

A

E

F

H

G

A Zone 1

I Rotating cleaning head

B High-pressure cleaning head

J Hoist to lift and lower the cleaning head

C Swivelling device

K Hoist for telescoping boom

D Zone 0/20

L Telescoping boom

E Electricity conducting hose

F Circuit container with filter unit (sieve,

suction basket, fine filter)

G Circuit medium

H Clear medium

- 3

17EN

Оглавление

- Sicherheitshinweise

- Technische Daten

- Inbetriebnahme

- Bedienung

- Zubehör EG-Konformitätserklärung

- Proper use Safety instructions

- Technical specifications

- Start up

- Operation

- Accessories EC Declaration of Conformity

- Utilisation conforme

- Caractéristiques techniques

- Mise en service

- Utilisation

- Accessoires Déclaration de conformité CE

- Uso conforme a destinazione Norme di sicurezza

- Dati tecnici

- Messa in funzione

- Uso

- Accessori Dichiarazione di conformità

- Veiligheidsinstructies

- Technische gegevens

- Inbedrijfstelling

- Bediening

- Toebehoren EG-conformiteitsverklaring

- Uso previsto

- Datos técnicos

- Puesta en marcha

- Manejo

- Accesorios Declaración de conformidad CE

- Innehållsförteckning

- Tekniska data

- Idrifttagning

- Handhavande

- Tillbehör Försäkran om EU-

- Символы в руководстве по Назначение

- Технические данные

- Начало работы

- Управление

- Помощь в случае неполадок

- Принадлежности Заявление о соответствии

- Biztonsági tanácsok

- Műszaki adatok

- Üzembevétel

- Használat

- Tartozékok EK konformitási nyiltakozat

- Użytkowanie zgodne z

- Dane techniczne

- Uruchamianie

- Obsługa

- Akcesoria Deklaracja zgodności UE