Karcher HDS 8-17-4M Classic EU – страница 2

Инструкция к Karcher HDS 8-17-4M Classic EU

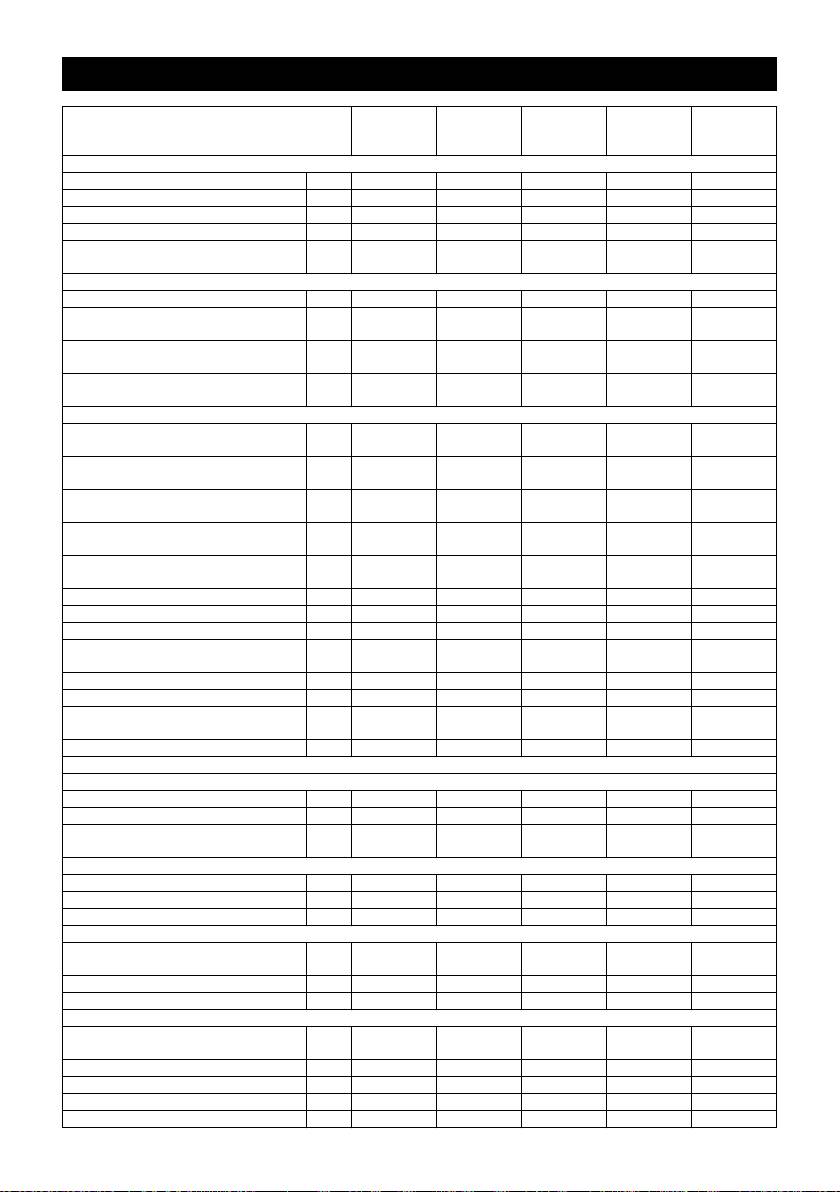

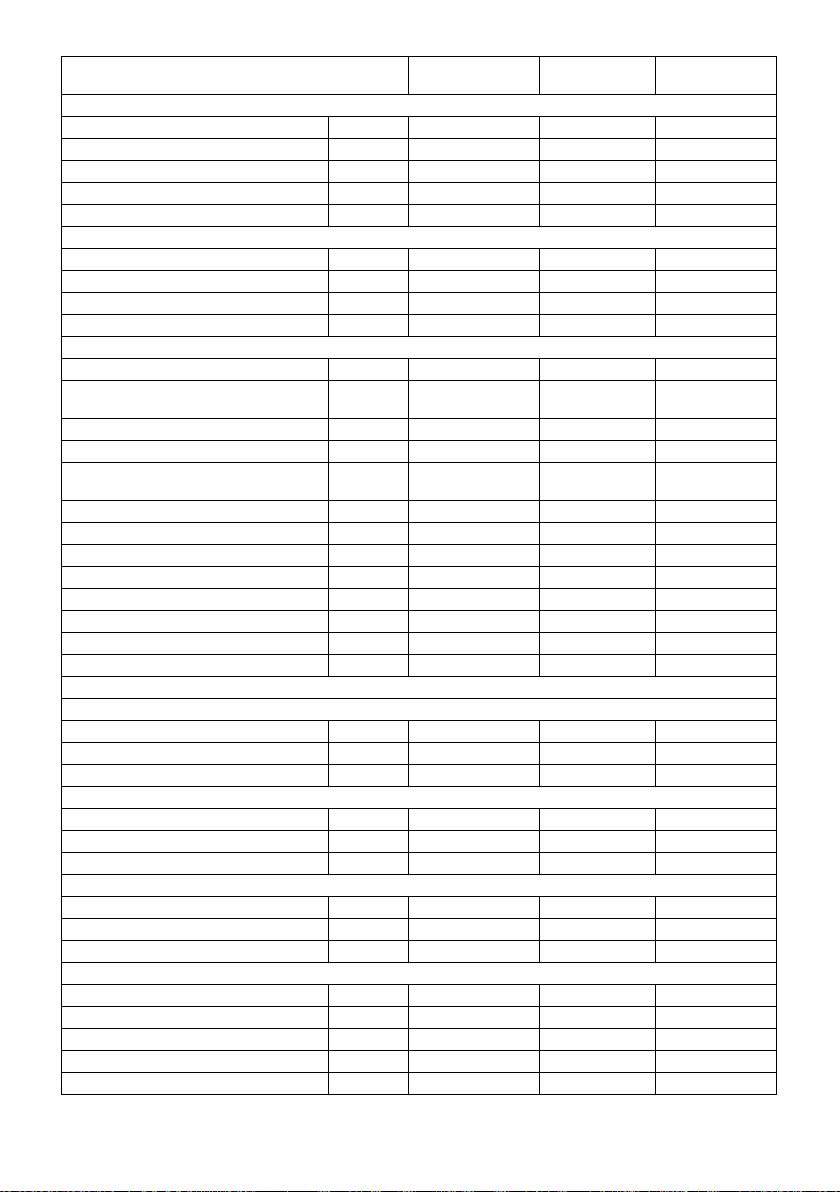

Technische Daten

HDS 7/12

HDS 8/17

HDS 10/20

HDS 10/20

HDS 12/18

*AU

Classic

Classic

*AU/Clas-

*AU/Clas-

*KAP

*KAP

sic *EU

sic *EU

Netzanschluss

Spannung V 240 220 220 400-420 400-420

Stromart Hz 1~ 50 3~ 60 3~ 60 3~ 50 3~ 50

Anschlussleistung kW 3,4 5,5 7,8 7,8 8,4

Absicherung (träge) A 15 32 32 16 16

Maximal zulässige Netzimpedanz Ohm (0,321+

-- -- (0,169+

(0,163+

j0,200)

j0,105)

j0,102)

Wasseranschluss

Zulauftemperatur (max.) °C 30 30 30 30 30

Zulaufmenge (min.) l/h (l/

1000 (16,7) 1100 (18,3) 1500 (25) 1300 (21,7) 1500 (25)

min)

Saughöhe aus offenem Behälter

m 0,5 0,5 0,5 0,5 0,5

(20 °C)

Zulaufdruck (max.) MPa

0,6 (6) 0,6 (6) 0,6 (6) 0,6 (6) 0,6 (6)

(bar)

Leistungsdaten

Fördermenge Wasser l/h (l/

350-700

400-800

500-1000

500-1000

600-1200

min)

(5,8-11,7)

(6,7-13,3)

(8,3-16,7)

(8,3-16,7)

(10-20)

Arbeitsdruck Wasser (mit Standarddüse) MPa

3-12 (30-

3-17 (30-

5-20 (50-

3-20 (30-

3-18 (30-

(bar)

120)

170)

200)

200)

180)

Max. Betriebsüberdruck (Sicherheits-

MPa

15 (150) 20,5 (205) 24 (240) 24 (240) 21,5 (215)

ventil)

(bar)

Fördermenge Dampfbetrieb l/h (l/

330-360

340-420

460-520

460-520

550-610

min)

(5,5-6)

(5,6-7)

(7,6-8,6)

(7,6-8,6)

(9,1-10,1)

Max. Arbeitsdruck Dampfbetrieb (mit

MPa

3,2 (32) 3,2 (32) 3,2 (32) 3,2 (32) 3,2 (32)

Dampfdüse)

(bar)

Teile-Nr. Dampfdüse -- 2.885-039.0 2.885-119.0 2.885-041.0 2.885-041.0 2.885-120.0

Max. Arbeitstemperatur Heißwasser °C 98 98 98 98 98

Arbeitstemperatur Dampfbetrieb °C 155 155 155 155 155

Reinigungsmittelansaugung l/h (l/

0-45 (0-

0-50 (0-0,8) 0-60 (0-1) 0-60 (0-1) 0-72 (0-1,2)

min)

0,75)

Brennerleistung kW 53 63 83 75 91

Maximaler Heizölverbrauch kg/h 4,6 5,3 6,7 6,4 7,7

Rückstoßkraft der Handspritzpistole

N 17,9 24,3 33,0 33,0 37,6

(max.)

Düsengröße -- 048 047 054 054 068

Ermittelte Werte gemäß EN 60335-2-79

Geräuschemission

Schalldruckpegel L

pA

dB(A) 70 71 73 73 73

Unsicherheit K

pA

dB(A) 22222

Schallleistungspegel L

WA

+ Unsicher-

dB(A) 88 88 90 90 90

heit K

WA

Hand-Arm Vibrationswert

2

Handspritzpistole m/s

1,1 1,0 1,2 1,2 1,5

2

Strahlrohr m/s

3,4 3,4 5,2 5,2 4,8

2

Unsicherheit K m/s

1,0 1,0 1,0 1,0 1,0

Betriebsstoffe

Brennstoff -- Heizöl EL

Heizöl EL

Heizöl EL

Heizöl EL

Heizöl EL

oder Diesel

oder Diesel

oder Diesel

oder Diesel

oder Diesel

Ölmenge l 0,75 0,75 1,0 1,0 1,0

Ölsorte -- 0W40 SAE 90 SAE 90 SAE 90 SAE 90

Maße und Gewichte

Länge x Breite x Höhe mm 1330 x 750

1330 x 750

1330 x 750

1330 x 750

1330 x 750

x 1060

x 1060

x 1060

x 1060

x 1060

Gewicht ohne Zubehör, M/S kg 146 155 171 171 178

Gewicht ohne Zubehör, MX/SX kg 154 163 180 180 185

Brennstofftank l 25 25 25 25 25

Reinigungsmitteltank l 10+20 10+20 10+20 10+20 10+20

– 15

21DE

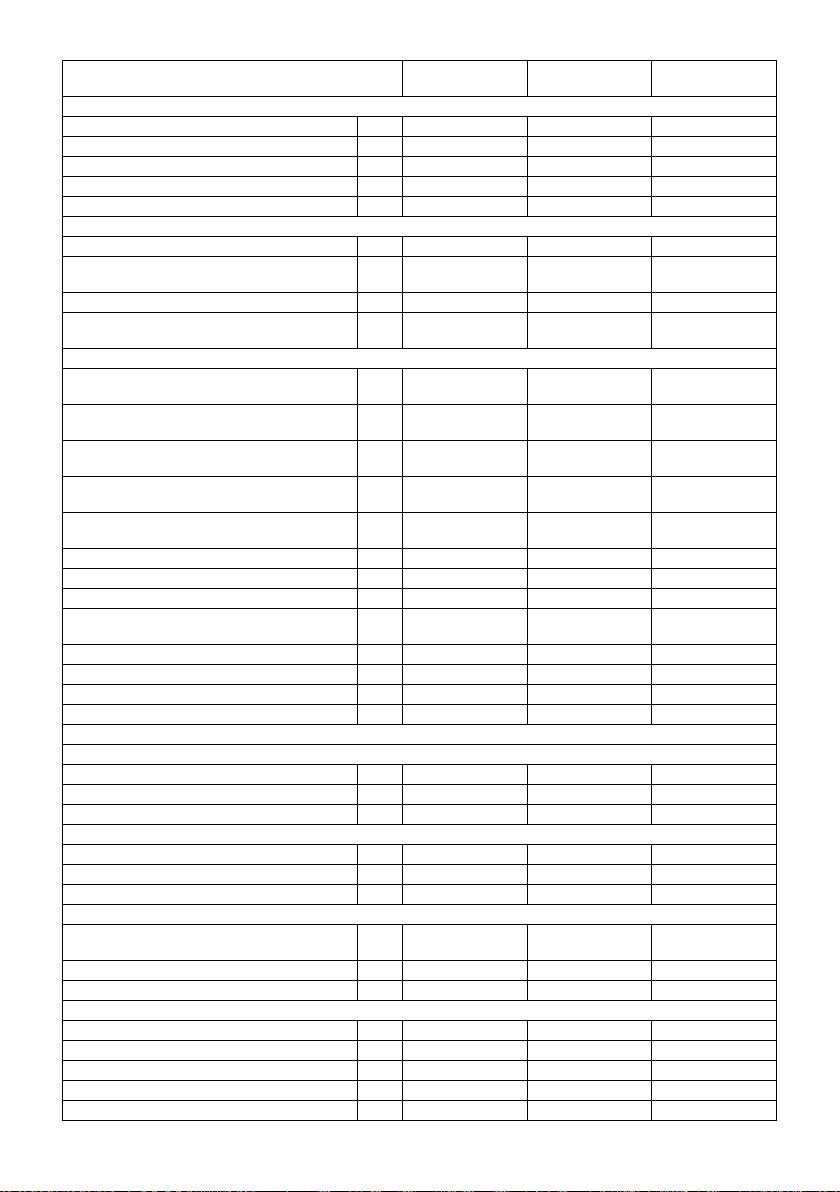

HDS 7/11 Classic

HDS 8/17 *AU/

HDS 12/18 Clas-

*KAP

Classic *EU

sic *KAP

Netzanschluss

Spannung V 220 400-420 220

Stromart Hz 1~ 60 3~ 50 3~ 60

Anschlussleistung kW 3,4 5,5 8,4

Absicherung (träge) A 16 16 32

Maximal zulässige Netzimpedanz Ohm (0,321+ j0,200) -- (0,163+ j0,102)

Wasseranschluss

Zulauftemperatur (max.) °C 30 30 30

Zulaufmenge (min.) l/h (l/

1000 (16,7) 1100 (18,3) 1500 (25)

min)

Saughöhe aus offenem Behälter (20 °C) m 0,5 0,5 0,5

Zulaufdruck (max.) MPa

0,6 (6) 0,6 (6) 0,6 (6)

(bar)

Leistungsdaten

Fördermenge Wasser l/h (l/

350-700 (5,8-11,7) 400-800 (6,7-13,3) 600-1200 (10-20)

min)

Arbeitsdruck Wasser (mit Standarddüse) MPa

3-11 (30-110) 3-17 (30-170) 3-18 (30-180)

(bar)

Max. Betriebsüberdruck (Sicherheitsventil) MPa

14 (140) 20,5 (205) 21,5 (215)

(bar)

Fördermenge Dampfbetrieb l/h (l/

330-360 (5,5-6) 340-420 (5,6-7) 550-610 (9,1-10,1)

min)

Max. Arbeitsdruck Dampfbetrieb (mit Dampf-

MPa

3,2 (32) 3,2 (32) 3,2 (32)

düse)

(bar)

Teile-Nr. Dampfdüse -- 2.885-039.0 2.885-119.0 2.885-120.0

Max. Arbeitstemperatur Heißwasser °C 98 98 98

Arbeitstemperatur Dampfbetrieb °C 155 155 155

Reinigungsmittelansaugung l/h (l/

0-45 (0-0,75) 0-50 (0-0,8) 0-72 (0-1,2)

min)

Brennerleistung kW 53 63 91

Maximaler Heizölverbrauch kg/h 4,6 5,3 7,7

Rückstoßkraft der Handspritzpistole (max.) N 17,9 24,3 37,6

Düsengröße -- 048 047 068

Ermittelte Werte gemäß EN 60335-2-79

Geräuschemission

Schalldruckpegel L

pA

dB(A) 70 71 73

Unsicherheit K

pA

dB(A) 2 2 2

Schallleistungspegel L

WA

+ Unsicherheit K

WA

dB(A) 88 88 90

Hand-Arm Vibrationswert

2

Handspritzpistole m/s

1,1 1,0 1,5

2

Strahlrohr m/s

3,4 3,4 4,8

2

Unsicherheit K m/s

1,0 1,0 1,0

Betriebsstoffe

Brennstoff -- Heizöl EL oder

Heizöl EL oder

Heizöl EL oder

Diesel

Diesel

Diesel

Ölmenge l 0,75 0,75 1,0

Ölsorte -- 0W40 SAE 90 SAE 90

Maße und Gewichte

Länge x Breite x Höhe mm 1330 x 750 x 1060 1330 x 750 x 1060 1330 x 750 x 1060

Gewicht ohne Zubehör, M/S kg 146 155 178

Gewicht ohne Zubehör, MX/SX kg 154 163 185

Brennstofftank l 25 25 25

Reinigungsmitteltank l 10+20 10+20 10+20

22 DE

– 16

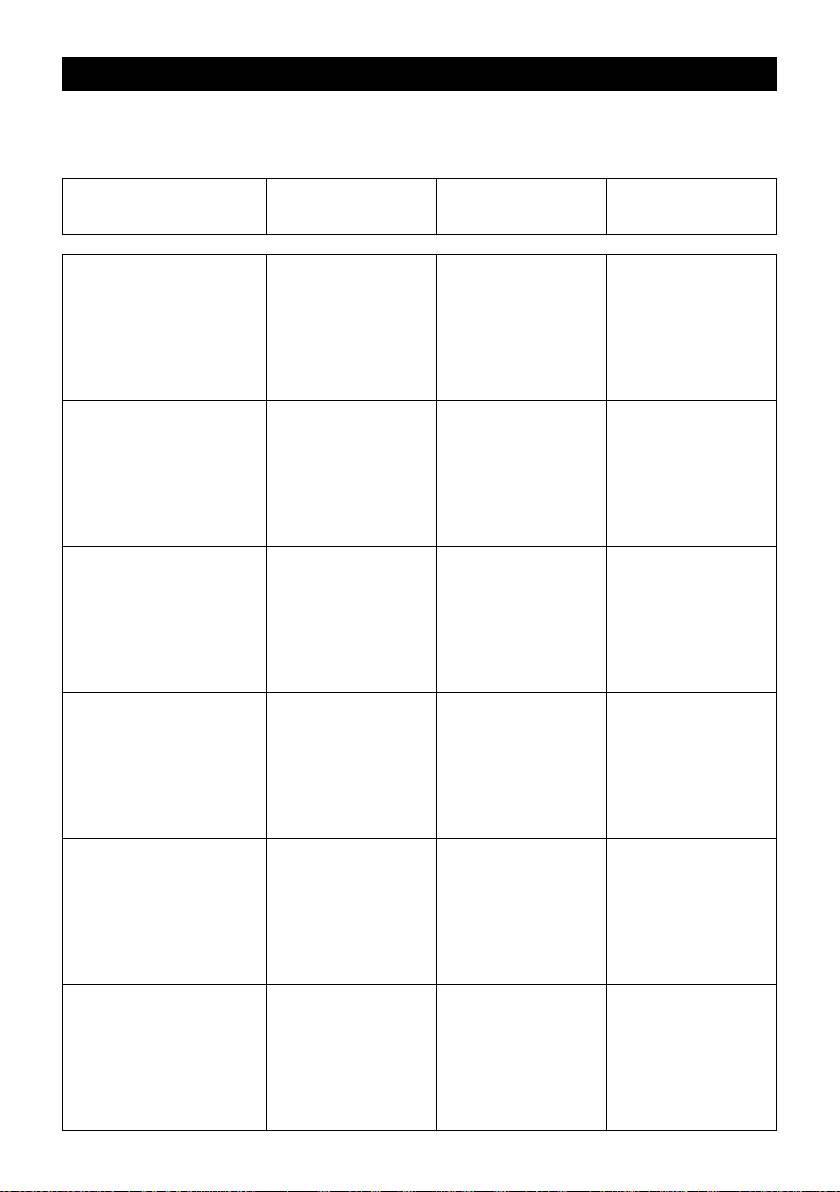

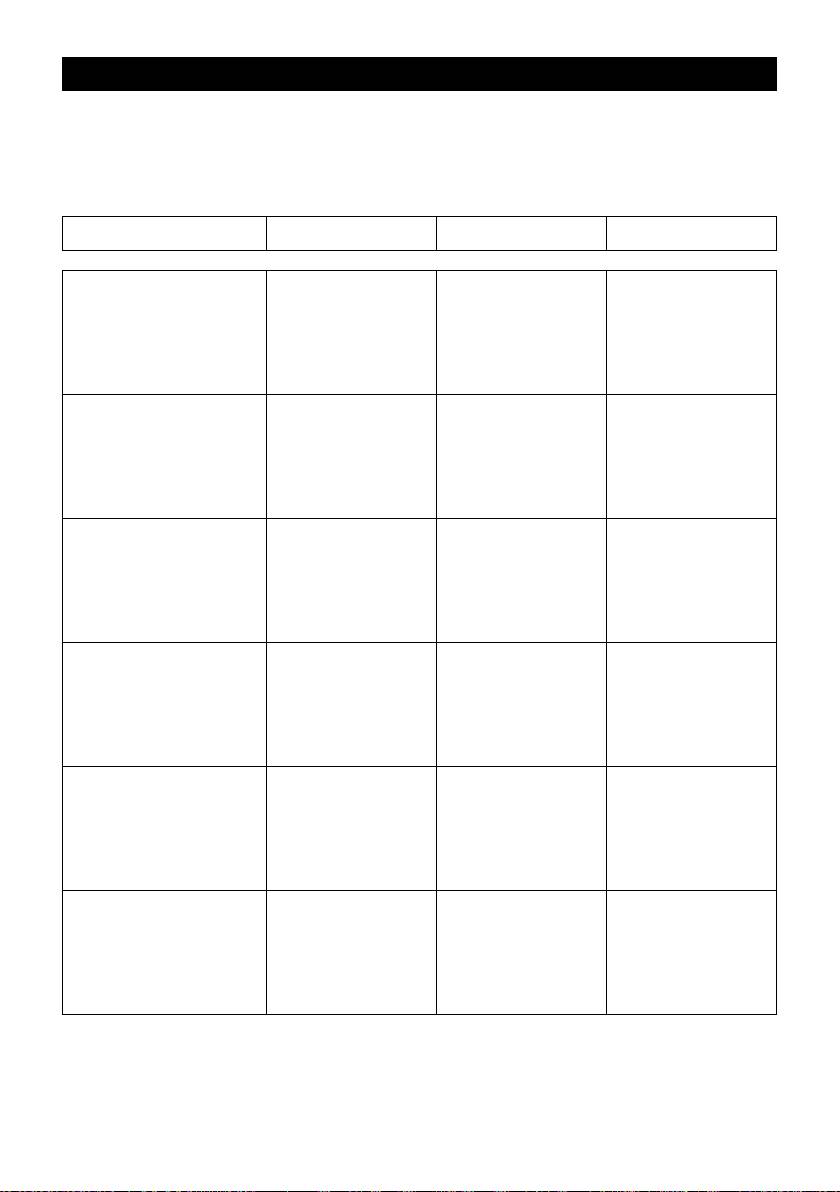

Wiederkehrende Prüfungen

Hinweis

Die Prüffristempfehlungen entsprechend der jeweiligen nationalen Anforderungen des Be-

treiberlandes sind zu beachten.

Prüfung durchge-

Äußere Prüfung Innere Prüfung Festigkeitsprü-

führt durch:

fung

Name Unterschrift der be-

Unterschrift der be-

Unterschrift der be-

fähigten Person/

fähigten Person/

fähigten Person/

Datum

Datum

Datum

Name Unterschrift der be-

Unterschrift der be-

Unterschrift der be-

fähigten Person/

fähigten Person/

fähigten Person/

Datum

Datum

Datum

Name Unterschrift der be-

Unterschrift der be-

Unterschrift der be-

fähigten Person/

fähigten Person/

fähigten Person/

Datum

Datum

Datum

Name Unterschrift der be-

Unterschrift der be-

Unterschrift der be-

fähigten Person/

fähigten Person/

fähigten Person/

Datum

Datum

Datum

Name Unterschrift der be-

Unterschrift der be-

Unterschrift der be-

fähigten Person/

fähigten Person/

fähigten Person/

Datum

Datum

Datum

Name Unterschrift der be-

Unterschrift der be-

Unterschrift der be-

fähigten Person/

fähigten Person/

fähigten Person/

Datum

Datum

Datum

– 17

23DE

Please read and comply with

Environmental protection

these original instructions prior to

English

the initial operation of your appliance and

The packaging material can be

store them for later use or subsequent own-

recycled. Please do not throw

ers.

the packaging material into

– Before first start-up it is definitely nec-

household waste; please send it

essary to read the operating instruc-

for recycling.

tions and safety indications Nr. 5.951-

Old appliances contain valuable

949!

materials that can be recycled;

– In case of transport damage inform ven-

these should be sent for recy-

dor immediately

cling. Batteries, oil, and similar

– Check the contents of the pack before

substances must not enter the

unpacking.

environment. Please dispose of

your old appliances using ap-

Contents

propriate collection systems.

Environmental protection . . EN . . .1

Please do not release engine oil, fuel oil,

Symbols in the operating in-

structions . . . . . . . . . . . . . . EN . . .1

diesel and petrol into the environment Pro-

tect the ground and dispose of used oil in

Overview . . . . . . . . . . . . . . EN . . .2

an environmentally-clean manner.

Symbols on the machine . . EN . . .2

Proper use . . . . . . . . . . . . . EN . . .3

Notes about the ingredients (REACH)

Safety instructions . . . . . . . EN . . .3

You will find current information about the

Safety Devices . . . . . . . . . . EN . . .3

ingredients at:

Start up. . . . . . . . . . . . . . . . EN . . .4

www.kaercher.com/REACH

Operation . . . . . . . . . . . . . . EN . . .6

Symbols in the operating

Storage. . . . . . . . . . . . . . . . EN . . .9

instructions

Transport . . . . . . . . . . . . . . EN . . .9

Maintenance and care . . . . EN . . .9

Danger

Troubleshooting . . . . . . . . . EN . .10

Immediate danger that can cause severe

Warranty. . . . . . . . . . . . . . . EN . .12

injury or even death.

Accessories and Spare Parts EN . .12

몇 Warning

EC Declaration of Conformity EN . .13

Possible hazardous situation that could

Technical specifications . . . EN . .14

lead to severe injury or even death.

Recurring tests . . . . . . . . . . EN . .16

Caution

Possible hazardous situation that could

lead to mild injury to persons or damage to

property.

24 EN

– 1

31 Pressure/quantity regulation of the

Overview

pump unit

32 Oil drain screw

Device elements

33 Backflow valve of the detergent infeed

Figure 1

34 Detergent suction hose 1 with filter

1 Cover

35 Detergent suction hose 2 with filter

2 Support for spray lance

36 Fuel filter

(both sides)

37 Service switch

3 Fill opening for system care Advance

38 Water shortage safe guard with sieve

RM 110/RM 111

39 Float tank

4 Steering roller with fixed position brake

40 Fine filter (water)

5 Mounting location for transport

Operating field

(both sides)

6 Folding compartment

Figure 2

(M/S only)

A Power switch

7 High pressure connection

B Temperature controller

(M/S only)

C Dosage valve for detergent

8 High pressure hose

D Manometer

9 Hand spraygun

1 Indicator lamp pump

10 Spray lance

2 Indicator lamp rotation direction

11 High-pressure nozzle (stainless steel)

(not HDS 7/11, HDS 7/12)

12 Steam nozzle (brass)

3 “Ready for use” indicator lamp

13 Power supply

4 Fuel indicator lamp

14 Safety latch of the hand spray gun

5 Indicator lamp : Detergent 1

15 Pressure/ quantity regulation at the

(HDS 12/18 only)

hand spray gun

6 Engine indicator lamp

16 Connection for water supply with filter

7 Indicator lamp burner failure

17 Exit opening of the high-pressure hose

8 Indicator lamp service

(MX/SX only)

9 Indicator lamp system care

18 Step depression

10 Indicator lamp : Detergent 2

19 Pouring vent for detergent 2

(HDS 12/18 only)

20 Hand crank for hose drum

Symbols on the machine

(MX/SX only)

21 Pouring vent for detergent 1

High-pressure jets can be dan-

22 Hose drum

gerous if improperly used. The

(MX/SX only)

jet may not be directed at per-

sons, animals, live electrical equipment or

23 Pouring vent for fuel

at the appliance itself.

24 Handle

25 Operating field

26 Closing flap for storage compartment

27 Storage compartment for accessories

28 Nameplate

29 Cover lock

30 Oil tank

– 2

25EN

Proper use

Safety Devices

Cleaning of: Machines, Vehicles, Struc-

Safety devices serve for the protection of

tures, Tools, Facades, Terraces, Garden-

the user and must not be put out of opera-

ing tools, etc.

tion or bypassed with respect to their func-

tion.

Danger

Risk of injury! Follow the respective safety

Overflow valve with two pressure

regulations when operating at gas stations

switches

or other dangerous areas.

– While reducing the water supply at the

Please do not let mineral oil contaminated

pump head or with the Servopress -

waste water reach soil, water or the sew-

regulation the overflow valve opens and

age system. Perform engine cleaning and

part of the water flows back to the pump

bottom cleaning therefore only on speci-

suck side.

fied places with an oil trap.

– If the hand-spray gun is closed, so that

the whole water flows back to the pump

Safety instructions

suck side, the pressure switch at the

overflow valve shuts down the pump.

– Please follow the national rules and

– If the hand spray gun is opened, the

regulations for fuel spray jets of the re-

pressure switch on the cylinder head

spective country.

turns the pump back on.

– Please follow the national rules and

The overflow valve is set by the manufac-

regulations for accident prevention of

turer and sealed. Setting only by customer

the respective country. Fuel spray jets

service.

must be tested regularly and the results

of these tests must be documented in

Safety valve

writing.

– The safety valve opens, when the over-

– The heating appliance of the machine is

flow valve resp. the pressure switch is

an ignition plant. All national laws and

broken.

regulations about heating systems must

The safety valve is set by the manufacturer and

also be followed.

sealed. Setting only by customer service.

– As per the applicable national guide-

lines, the first time this high-pressure

Water shortage safeguard

cleaner must be taken into operation by

– The water shortage safeguard prevents

a skilled person. KÄRCHER has al-

the burner to be turned on when there is

ready performed this initial start-up for

water shortage.

you and has documented it accordingly.

– A sieve prevents the contamination of

The documentation can be requested at

the safeguard and must be cleaned reg-

your KÄRCHER partner. Please have

ulary.

the part and plant number of the appli-

ance available when enquiring about

Temperature stop for exhaust gases

the documentation.

– The temperature stop switches off the

– We would like to point out that the appli-

machine when the waste gases have

ance must be repeatedly checked by a

reached very high temperatures.

skilled person as prescribed by the ap-

plicable national regulations. Please

contact your KÄRCHER partner.

26 EN

– 3

Note: Observe the following when using

Start up

system care Advance 2 RM 111:

– Calcification protection: See table

몇 Warning

– Pump care and black water protection: Set

Risk of injury! Device, tubes, high pressure

the service switch to at least setting 3.

hose and connections must be in faultless

condition. Otherwise, the appliance must

Refill fuel

not be used.

Lock parking brake.

Danger

Risk of explosion! Only refill diesel oil or

Installing the handle

light fuel oil. Unsuitable fuels, e.g. petrol,

Figure 3

are not to be used.

Caution

Caution

Hook the electric supply line into the cable

Never operate device with empty fuel tank

guide of the right handle bow. Ensure that

The fuel pump will otherwise be destroyed.

the cable is not damaged.

Refill fuel.

Close tank lock.

Refill system care

Wipe off spilled fuel.

Note: To protect the device, the burner is

Refill detergent

switched off 5 hours after the system care

container is empty.

Caution

– The system care prevents the calcifica-

Risk of injury!

tion of the heating spiral while operating

– Use Kärcher products only.

with calciferous tap water. It is dosed

– Under no circumstances fill solvents

into the supply in the float container

(petrol, aceton, diluting agent etc.)

drop by drop.

– Avoid eye and skin contact.

– The metering is set to medium water ri-

– Observe safety and handling instruc-

gidity by the manufacturer

tions by the detergent manufacturer.

Note: A sample bundle of system care is in-

Kärcher offers an individual cleaning

cluded.

and care appliances program.

Refill system care.

Your dealer will consult you gladly.

Adjusting the dosage of the system

Refill detergent.

care Advance RM 110/RM 111

Install the hand-spray gun, the jet

Determining the hardness of tap water:

pipe, the nozzle and the high

– through the public water supply works,

pressure hose

– using a hardness tester (order no.

Figure 4

6.768-004)

Connect ray tube with hand spray gun

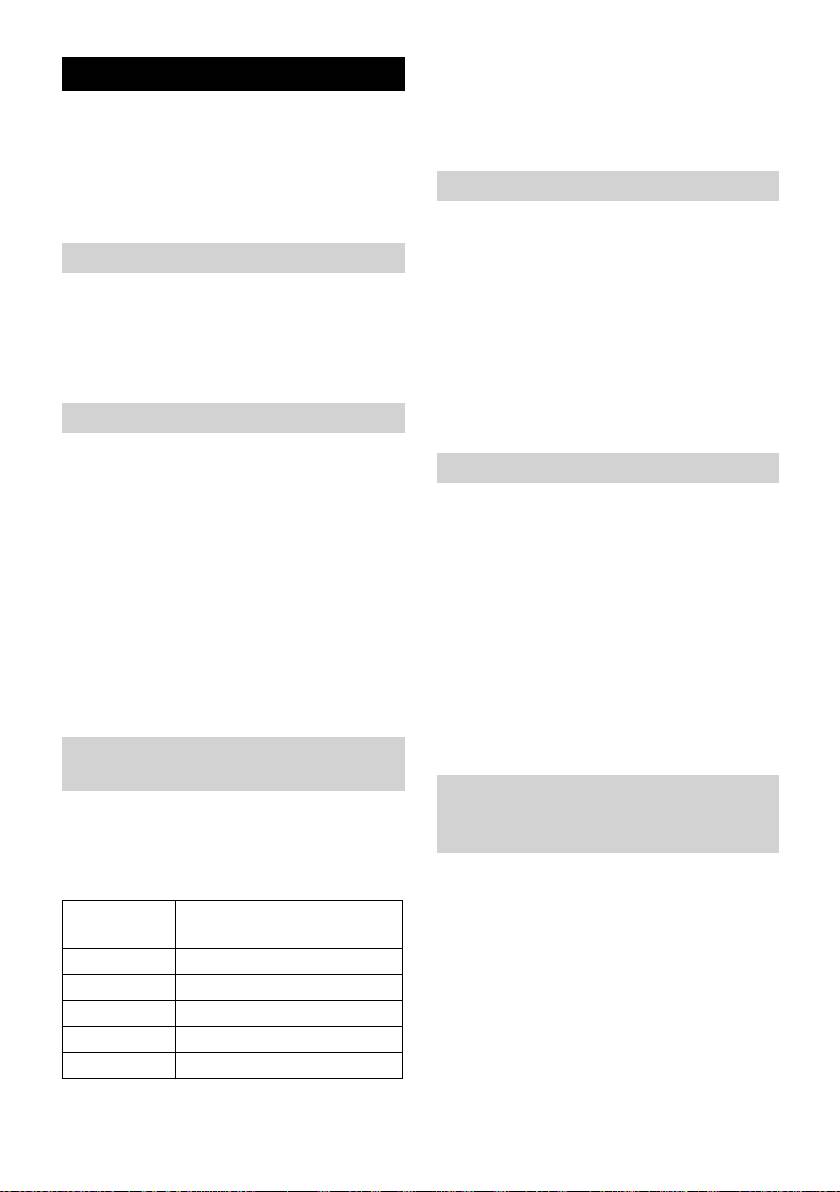

Water hard-

Scale on the service switch

Tighten the screw connection of the

ness (°dH)

spray lance fingertight.

<3 OFF (no dosing)

Insert high pressure nozzle into cover-

3...7 1

ing nut

7...14 2

Install covering nut and tighten firmly

– Appliance without hose drum:

14...21 3

Connect the high pressure host to the

>21 4

high pressure connection point of the

Set the service switch according to the

machine.

water hardness in the table.

– 4

27EN

– Device with hose drum:

Suck in water from vessel

Connect the high pressure hose to the

If you want to suck in water from an exter-

hand-spray gun.

nal vessel, the following modification is

Caution

necessary:

Always unwind high pressure hose com-

Figure 8

pletely

Open fill opening for system care.

Installing the replacement

Release and remove the cover of the

high-pressure hose (appliances

system care.

without hose drum)

Remove water connection from the fine

filter.

Figure 5

Unscrew the fine filter from the pump

Installing the replacement

head.

high-pressure hose (appliances

Figure 9

with hose drum)

Remove the system care reservoir.

Unscrew the top supply hose to the

Figure 6

swimmer container.

Completely roll off the high-pressure

Figure 10

hose from the hose drum.

Connect the top supply hose at pump

Rotate the hose drum until the screwed-

head.

on semibowl is pointing toward the top.

Replug the rinse line of the detergent

Loosen all three screws and remove the

dosing valve.

loosened semibowl.

Connect suction hose (minimum diame-

Figure 7

ter 3/4“) with filter (accessory) to the

Unlatch the fastening clamp for the

water connection point.

high-pressure hose and pull the hose

out.

– Max. suck height: 0.5 m

Route the new high-pressure hose

Until the pump sucked in water, you should:

through the intended hose guide and

Set the pressure/quantity regulation at

the deflection pulley at the bottom of the

the pump unit to maximum quantity.

appliance.

Close the dosing valve for the deter-

Slide the hose nipple all the way into the

gent.

knot section of the hose drum and se-

Danger

cure with the fastening clamp.

Never suck in water from a drinking water

Replace the half bowl.

container. Never suck in liquids which con-

tain solvents like lacquer thinner, petrol, oil

Water connection

or unfiltered water. The sealings within the

For connection values refer to technical

device are not solvent resistant. The spray

specifications

mist of solvents is highly inflammable, ex-

Connect the supply hose (minimum

plosive and poisonous.

length 7.5 m, minimum diameter 3/4“) to

the water connection point of the ma-

chine and at the water supply point (for

e.g. a tap).

Note: The supply hose is not included.

28 EN

– 5

Power connection

Safety instructions

– For connection values, see technical

몇 Warning

data and type plate.

Long hours of using the appliance can

– The electrical connections must be

cause circulation problems in the hands on

done by an electrician according to IEC

account of vibrations.

60364-1.

It is not possible to specify a generally valid

Danger

operation time, since this depends on sev-

eral factors:

Danger of injury by electric shock.

– Proneness to blood circulation deficien-

– Unsuitable extension cables can be

cies (cold, numb fingers).

hazardous. Only use extension cables

outdoors which have been approved for

– Low ambient temperature. Wear warm

this purpose and labelled with a suffi-

gloves to protect hands.

cient cable cross section:

– A firm grip impedes blood circulation.

– Always unwind extension lines com-

– Continuous operation is worse than an

pletely.

operation interrupted by pauses.

– The plug and coupling of the extension

In case of regular, long-term operation of

cable used must be watertight.

the device and in case of repeated occur-

rence of the symptoms (e.g. cold, numb fin-

Caution

gers) please consult a physician.

The highest allowed net impedance at the

electrical connection point (refer to techni-

Replace the nozzle

cal data) is not to be exceeded. In case of

Danger

confusion regarding the power impedance

Switch the appliance off prior to replacing

present on your connection, please contact

nozzel and activate hand spray gun until

your utilities provider.

device is pressureless.

Operation

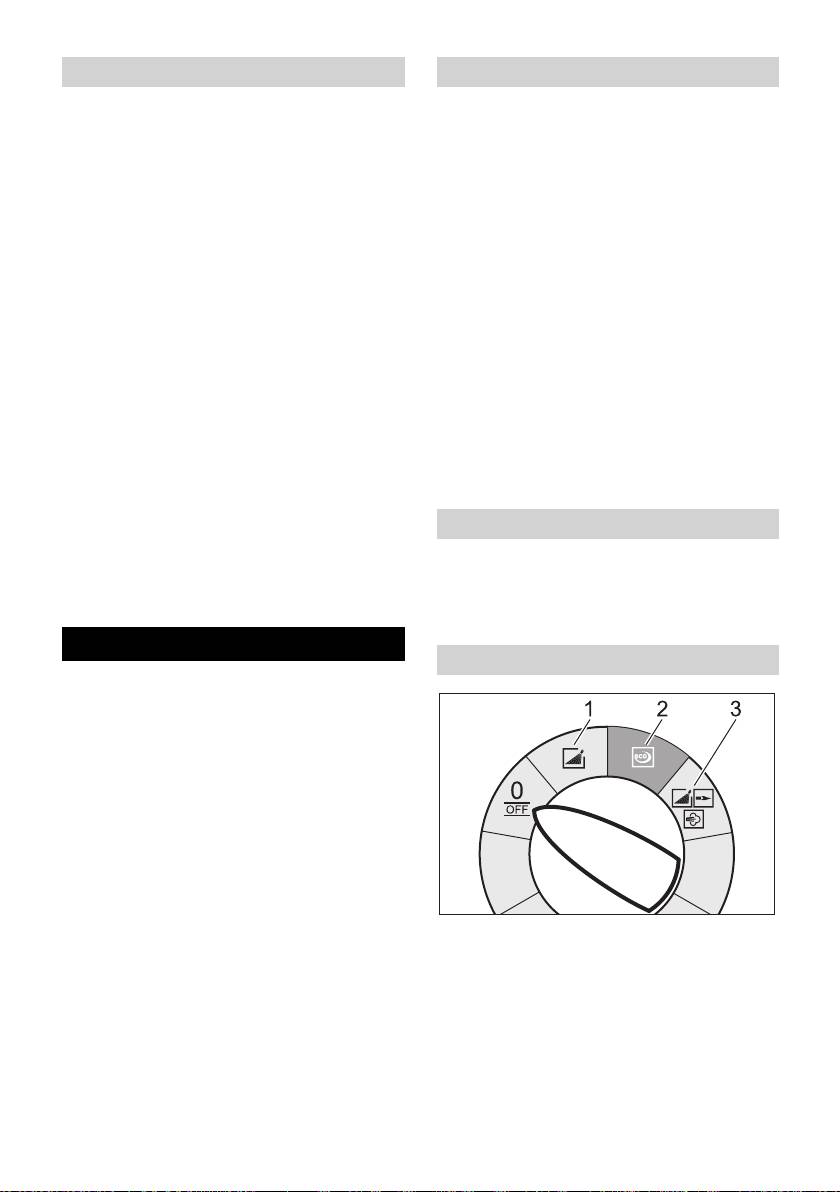

Operating modes

Danger

Risk of explosion!

Do not spray flammable liquids.

Danger

Risk of injury! Never use the appliance

without the spray lance attached. Check

and ensure proper fitting of the spray lance

prior to each use. The screw connection of

the spray lance must be fingertight.

Caution

Never operate device with empty fuel tank

0/OFF =Off

The fuel pump will otherwise be destroyed.

1 Operating with cold water

2 Eco operation (hot water max. 60 °C)

3 Operating with hot water/steam

– 6

29EN

Set the working pressure and feed

Turning on the Appliance

quantity by turning (steplessly) the

Set appliance switch to desired operat-

pressure/quantity regulation mecha-

ing mode.

nism at the hand spray gun (+/-).

Indicator lamp for operational readiness

Danger

lights up.

When adjusting the pressure/quantity regu-

The device starts briefly and turns off, as

lation, make sure that the screw connection

soon as the working pressure is reached.

of the spray lance does not become loose.

Note: If the indicator lamps for pump, rota-

Note: For long term work with low pres-

tion direction, burner malfunction or engine

sure, set pressure at the pump unit.

are on during operation, turn off the appli-

Operation with detergent

ance immediately and repair malfunction,

refer to "Help with malfunctions".

– For considerate treatment of the envi-

Release the trigger gun.

ronment use detergent economically.

When activating the hand spray gun the de-

– The detergent must be suitable for the

vice switches back on.

surface to be cleaned.

Note:If no water comes out of the high

With support of the detergent dose

pressure nozzle, vent pump. Refer to "Help

valve set detergent concentration as

with malfunctions - appliance is not building

determined by the manufacturer.

up pressure".

Note: Recommended values at the control

Adjust cleaning temperature

panel at maximum working pressure.

Set temperature regulator to desired

Cleaning

temperature.

Set pressure/temperature and deter-

30 °C to 98 °C

gent concentration according to the sur-

– Clean with hot water.

face to be cleaned.

100 °C to 150 °C

Note: To prevent damage due to too much

– Clean using steam.

pressure, always position high pressure ray

first from a greater distance towards object

Replace the high-pressure nozzle

to be cleaned.

(stainless steel) with steam nozzle

Recommended cleaning method

(brass), (refer to "Using steam").

– Loosen the dirt:

Spray detergent economically and let it

Set working pressure and flow rate

work for 1...5 minutes but do not let it

Pressure/quantity regulation of the

dry up.

pump unit

– Remove the dirt:

Turn the regulation spindle in a clock-

Spray off loosened dirt with the high-

wise direction: Increase working pres-

pressure jet.

sure (MAX).

Operating with cold water

Turn the regulation spindle in an anti-

clockwise direction: Reduce working

Removal of light contaminations and clear

pressure (MIN).

rinse, i.e.: Gardening tools, terrace, tools,

etc.

Pressure/ quantity regulation at the

Set operating pressure according to

hand spray gun

need.

Set thermostat to max. 98 °C.

Set the operating pressure on the pump

unit to the maximum value.

30 EN

– 7

Eco operation

After operation with detergent

The appliance works in the most economi-

Set dosing value for detergent to "0".

cal temperature range.

Set the appliance switch to "1" (opera-

Note: The temperature can be regulated

tion with cold water).

up to 60 °C.

Open the hand spray gun and rinse the

appliance for at least 1 minute.

Operating with hot water/steam

Turn off the appliance

We recommend the following cleaning tem-

peratures:

Danger

– Light contaminations

Danger of scalding by hot water. After the

30-50 °C

operation with hot water or steam, the de-

– Contaminations containing protein, i.e.

vice must be operated with openend gun

in the food processing industry

with cold water for at least two minutes.

max. 60 °C

Set the appliance switch to "0/OFF“.

– Vehicle cleaning, machine cleaning

Shut off water supply.

60-90 °C

Turn on pump shortly (appr. 5 seconds)

– De-preserve, contaminations contain-

with device switch.

ing strong fat contents

Pull main plug out of socket with dry

100-110 °C

hands only.

– De-frosting of surcharge substances,

Remove water connection.

partially facade cleaning

Activate hand spray gun until device is

up to 140 °C

pressure less.

Operating with hot water

Lock the trigger gun.

Danger

Storing the Appliance

Scalding danger!

Lock in the steel pipe into the holder of

Set temperature regulator to desired

the appliance hood.

temperature.

Roll up high pressure hose and electri-

Operating with steam

cal conduit and hang them into the re-

Danger

spective holders.

Scalding danger! The operating pressure

Device with hose drum:

must not exceed 3,2 MPa (32 bar) when

Before rolling up, stretch out the high

operating with temperatures above 98 °C.

pressure hose.

Therefore the following measures must

Turn the hand crank clockwise (Direc-

definitely be performed:

tion of the arrow).

Note: Do not twist high pressure hose and

Replace high pressure nozzle (stain-

electrical conduit.

less steel) with steam nozzle (brass,

Frost protection

order see specification).

Open up the pressure/ quantity regula-

Caution

tor on the hand spray gun completely,

Frost will destroy the not completely water

direction + until stop.

drained device.

Set the operating pressure on the pump

Store in a frost free area.

unit to the minimum value.

If the device is connected to a chimney, the

Set temperature regulator to min. 100 °C.

following must be observed:

– 8

31EN

Caution

When transporting in vehicles, secure

the appliance according to the guide-

Threat of damage by penetrating cold air

lines from slipping and tipping over.

through the chimney.

Disconnect device from chimney when

Maintenance and care

outside temperature drops below 0 °C.

If it is not possible to store frost free, shut

Danger

down device.

Risk of injury by inadvertent startup of ap-

pliance and electrical shock.

Shutdown

First pull out the plug from the mains before

For longer work breaks or if a frost free stor-

carrying out any tasks on the machine.

age is not possible:

Set the appliance switch to "0/OFF“.

Drain water.

Shut off water supply.

Flush device with anti-freeze agent.

Turn on pump shortly (appr. 5 seconds)

Empty detergent tank.

with device switch.

Dump water

Pull main plug out of socket with dry

Screw off water supply hose and high

hands only.

pressure hose.

Remove water connection.

Screw off supply hose at boiler bottom

Activate hand spray gun until device is

and drain heating spiral empty.

pressure less.

Operate device for max. 1 minute until

Lock the trigger gun.

the pump and conduits are empty.

Allow device to cool down.

Your Kärcher vender will inform you

Flush device with anti-freeze agent

about the performance of a periodic

Note: Observe handling instructions of the

safety inspection resp. signing of a

anti-freeze agent manufacturer.

maintenance contract.

Fill anti-freeze agent of the trade into

swimmer container.

Maintenance intervals

Switch on appliance (without heater) till

Weekly

the appliance has been completely

rinsed.

Clean the sieve in the water connection.

A certain corrosion protection is achieved

Clean the fine filter.

with this as well.

Check oil level.

Caution

Storage

In case of lacteous oil inform Kärcher cus-

Caution

tomer service immediately

Risk of injury and damage! Note the weight

Monthly

of the appliance in case of storage.

Clean sieve in the water shortage safe

guard.

Transport

Clean filter at the detergent suck hose.

Figure 11

After 500 operating hours, at least annu-

Caution

ally

Risk of damage! When loading the appli-

Oil change.

ance with a forklift, observe the illustration.

At least every 5 years, recurring

Caution

Perform the pressure test as per manu-

Risk of injury and damage! Observe the

facturer's instructions.

weight of the appliance when you transport

it.

32 EN

– 9

Maintenance Works

Indicator lamp pump

Clean the sieve in the water connection

1x blinking

Take out sieve.

– Lack of oil

Clean sieve in water and reinstall.

Replenish oil.

Cleaning the fine filter

2x blinking

Unpressurize the appliance.

– Leak in the high pressure system

Unscrew the fine filter from the pump

Check high pressure system and con-

head.

nections for tightness.

Remove the fine filter and the filter insert.

3x blinking

Clean the filter with clean water or com-

– Water shortage

pressed air.

Check water supply, check connections.

Reinstall in reverse sequence.

4x blinking

Clean sieve in the water shortage safe

– Obstructed reed switch in the water

guard

shortage safe guard.

Loosen covering nut and take off hose.

Check water shortage safe guard.

Take out sieve.

Indicator lamp of rotational

Note: If necessary turn in screw M8 appr. 5

direction is blinking (not HDS 7/11,

mm inwards and therewith pull out sieve.

Clean sieve in water.

HDS 7/12)

Push sieve inwards.

Figure 12

Put on hose.

Exchange the poles at the appliance plug.

Tighten covering nut firmly.

Indicator lamp "Ready for use"

Clean filter at the detergent suck hose

turns off

Take out detergent suck supports.

– No line voltage, see "Appliance is not

Clean filter in water and reinstall.

running".

Oil change

Engine indicator lamp

Ready a catch bin for appr. 1 Liter oil.

Loosen release screw.

1x blinking

Dispose of old oil ecologically or turn in at

– Contactor error

a gathering point.

Set the appliance switch to "0/OFF“.

Turn on the appliance.

Tighten release screw.

– Error occurs repeatedly.

Fill oil slowly up to the MAX marking.

Inform Customer Service

Note: Air pockets must be able to leak out.

For oil type refer to technical specifica-

2x blinking

tions.

– Engine overload/overheat

Set the appliance switch to "0/OFF“.

Troubleshooting

Allow device to cool down.

Danger

Turn on the appliance.

Risk of injury by inadvertent startup of ap-

– Error occurs repeatedly.

pliance and electrical shock.

Inform Customer Service

First pull out the plug from the mains before

carrying out any tasks on the machine.

– 10

33EN

3x blinking

Indicator lamp system care is

– Fault in the voltage supply.

blinking

Check main connections and mains

Note: Burner operation no longer possible.

fuse.

– System care container is empty.

4x blinking

Refill system care.

– Excessive power consumption.

Indicator lamp detergent 1 is

Check main connections and mains

illuminated (HDS 12/18 only)

fuse.

Inform Customer Service

– Detergent tank 1 is empty.

Refill detergent.

Indicator lamp burner failure

Indicator lamp detergent 2 is

1x blinking

illuminated (HDS 12/18 only)

– The exhaust temperature limiter has

been triggered.

– Detergent tank 2 is empty.

Set the appliance switch to "0/OFF“.

Refill detergent.

Allow device to cool down.

Appliance is not running

Turn on the appliance.

– No power

– Error occurs repeatedly.

Check power connection/conduit.

Inform Customer Service

2x blinking (option)

Device is not building up pressure

– The flame sensor turned the burner off.

– Air within the system

Inform Customer Service

Vent pump:

3x blinking

Set dosing value for detergent to "0".

– System care detection defective

With open hand spray gun turn device

Inform Customer Service

on and off multiple times with the device

switch.

4x blinking

Open and close the pressure/quantity

– Temperature sensor defective

regulation at the pump unit with the

Inform Customer Service

hand spray gun open.

Indicator lamp service

Note: By dismantling the high pressure

hose from the high pressure connection the

– Service interval

venting process is accelerated.

Perform service work.

If detergent tank is empty, refill.

Fuel indicator lamp glows

Check connections and conduits.

– Pressure is set to MIN

– Fuel tank empty.

Set pressure to MAX.

Refill fuel.

– Sieve in the water connection is dirty

Indicator lamp system care is

Clean sieve.

illuminated

Clean the fine filter; replace it, if neces-

Note: Burner can operate 5 more hours.

sary.

– System care tank is empty, due to tech-

– Amount of water supply is too low.

nical reasons a remainder stays in the

Check water supply level (refer to tech-

tank.

nical data).

Refill system care.

34 EN

– 11

Device leaks, water drips from the

Set temperature is not achieved

bottom of the device

while using hot water

– Pump leaky

– Working pressure/flow rate to high

Note: 3 drops/minute are allowed.

Reduce working pressure/flow quantity

With stronger leak, have device

at the pressure/volume regulator in the

checked by customer service.

pump unit.

– Sooty heating spiral

Device turns on and off while hand

Have device de-sooted by customer

spray gun is closed

service.

– Leak in the high pressure system

If malfunction can not be fixed, the device

Check high pressure system and con-

must be checked by customer service.

nections for tightness.

Warranty

Device is not sucking in detergent

The warranty terms published by our com-

Leave device running with open deter-

petent sales company are applicable in

gent dosage valve and closed water

each country. We will repair potential fail-

supply, until the swimmer tank is

ures of the appliance within the warranty

sucked empty and the pressure falls to

period free of charge, provided that such

"0".

failure is caused by faulty material or de-

Open the water supply again.

fects in fabrication.

If the pump still is not sucking in any deter-

Accessories and Spare Parts

gent, it could be because of the following

reasons:

Note: When connecting the appliance to a

– Filter in the detergent suck hose dirty

chimney or if the device cannot be ac-

Clean filter.

cessed visually, we recommend the instal-

– Backflow valve stuck

lation of a flame monitor (option).

– Only use accessories and spare parts

Remove the detergent hose and loosen

which have been approved by the man-

the backflow valve using a blunt object.

ufacturer. The exclusive use of original

Burner does not start

accessories and original spare parts

ensures that the appliance can be oper-

– System care container is empty.

ated safely and trouble free.

Refill system care.

– At the end of the operating instructions

– Fuel tank empty.

you will find a selected list of spare parts

Refill fuel.

that are often required.

– Water shortage

– For additional information about spare

Check water supply, check connections.

parts, please go to the Service section

Clean sieve in the water shortage safe

at www.kaercher.com.

guard.

– Fuel filter dirty

Change fuel filter.

– No ignition spark

If device is in use and no ignition spark

can be seen through the viewing glas,

have device checked by customer serv-

ice.

– 12

35EN

Name of the appointed agency:

EC Declaration of Conformity

for 97/23/EG

TÜV Rheinland Industrie Service GmbH

We hereby declare that the machine de-

Am Grauen Stein

scribed below complies with the relevant

51105 Köln

basic safety and health requirements of the

ID No. 0035

EU Directives, both in its basic design and

construction as well as in the version put

Certificate no.:

into circulation by us. This declaration shall

01 202 111/Q-08 0003

cease to be valid if the machine is modified

without our prior approval.

Applied conformity evaluation method

for 2000/14/EG

Product: High-pressure cleaner

Appendix V

Type: 1.071-xxx

Type: 1.077-xxx

Sound power level dB(A)

HDS 8/17

Relevant EU Directives

Measured: 86

97/23/EC

Guaranteed: 88

2006/42/EC (+2009/127/EC)

HDS 10/20

2004/108/EC

Measured: 88

1999/5/EC

Guaranteed: 90

2000/14/EC

HDS 12/18

Component category

Measured: 88

II

Guaranteed: 90

Conformity procedure

Module H

5.957-902

Heating coil

Conformity assessment Module H

Safety valve

The undersigned act on behalf and under

Conformity assessment Art. 3 para 3

the power of attorney of the company man-

control block

agement.

Conformity assessment Module H

various pipes

Conformity assessment Art. 3 para 3

CEO

Head of Approbation

Applied harmonized standards

EN 55014–1: 2006 + A1: 2009

Authorised Documentation Representative

EN 55014–2: 1997 + A2: 2008

S. Reiser

EN 60335–1

EN 60335–2–79

Alfred Kärcher GmbH Co. KG

EN 61000–3–2: 2006 + A2: 2009

Alfred-Kärcher-Str. 28 - 40

EN 62233: 2008

71364 Winnenden (Germany)

HDS 8/17:

Phone: +49 7195 14-0

EN 61000–3–3: 2008

Fax: +49 7195 14-2212

HDS 10/20, HDS 12/18:

EN 61000–3–11: 2000

EN 300 330-2 V1.5.1 : 2010

Winnenden, 2011/05/01

EN 301 489-1 V1.8.1 : 2008

EN 301 489-3 V1.4.1 : 2002

Applied specifications:

Based on AD 2000

Based on TRD 801

36 EN

– 13

Technical specifications

HDS 7/12

HDS 8/17

HDS 10/20

HDS 10/20

HDS 12/18

*AU

Classic

Classic

*AU/Clas-

*AU/Classic

*KAP

*KAP

sic *EU

*EU

Main Supply

Voltage V 240 220 220 400-420 400-420

Current type Hz 1~ 50 3~ 60 3~ 60 3~ 50 3~ 50

Connected load kW 3,4 5,5 7,8 7,8 8,4

Protection (slow) a 15 32 32 16 16

Maximum allowed net impedance Ohm (0,321+

-- -- (0,169+

(0,163+

j0,200)

j0,105)

j0,102)

Water connection

Max. feed temperature °C 30 30 30 30 30

Min. feed volume l/h (l/min) 1000 (16,7) 1100 (18,3) 1500 (25) 1300 (21,7) 1500 (25)

Suck height from open container (20 °C) m 0,5 0,5 0,5 0,5 0,5

Max. feed pressure MPa (bar) 0,6 (6) 0,6 (6) 0,6 (6) 0,6 (6) 0,6 (6)

Performance data

Water flow rate l/h (l/min) 350-700 (5,8-

400-800 (6,7-

500-1000

500-1000

600-1200

11,7)

13,3)

(8,3-16,7)

(8,3-16,7)

(10-20)

Operating pressure of water (using stand-

MPa (bar) 3-12 (30-120) 3-17 (30-170) 5-20 (50-200) 3-20 (30-

3-18 (30-180)

ard nozzle)

200)

Max. excess operating pressure (safety

MPa (bar) 15 (150) 20,5 (205) 24 (240) 24 (240) 21,5 (215)

valve)

Steam flow rate l/h (l/min) 330-360 (5,5-

340-420 (5,6-

460-520 (7,6-

460-520

550-610 (9,1-

6)

7)

8,6)

(7,6-8,6)

10,1)

Max. operating pressure for working with

MPa (bar) 3,2 (32) 3,2 (32) 3,2 (32) 3,2 (32) 3,2 (32)

steam (using steam nozzle)

Part no. of steam nozzle -- 2.885-039.0 2.885-119.0 2.885-041.0 2.885-

2.885-120.0

041.0

Max. operating temperature of hot water °C 98 98 98 98 98

Working temperature steam operation °C 155 155 155 155 155

Detergent suck in l/h (l/min) 0-45 (0-0,75) 0-50 (0-0,8) 0-60 (0-1) 0-60 (0-1) 0-72 (0-1,2)

Burner performance kW 53 63 83 75 91

Maximum consumption of heating oil kg/h 4,6 5,3 6,7 6,4 7,7

Max. recoil force of hand spray gun N 17,9 24,3 33,0 33,0 37,6

Nozzle size -- 048 047 054 054 068

Values determined as per EN 60355-2-79

Noise emission

Sound pressure level L

pA

dB(A) 70 71 73 73 73

Uncertainty K

pA

dB(A) 22222

Sound power level L

WA

+ Uncertainty K

WA

dB(A) 88 88 90 90 90

Hand-arm vibration value

2

Hand spraygun m/s

1,1 1,0 1,2 1,2 1,5

2

Spray lance m/s

3,4 3,4 5,2 5,2 4,8

2

Uncertainty K m/s

1,0 1,0 1,0 1,0 1,0

Fuel

Fuel -- Fuel oil EL or

Fuel oil EL or

Fuel oil EL or

Fuel oil EL

Fuel oil EL or

Diesel

Diesel

Diesel

or Diesel

Diesel

Amount of oil l 0,75 0,75 1,0 1,0 1,0

Oil grade -- 0W40 SAE 90 SAE 90 SAE 90 SAE 90

Dimensions and weights

Length x width x height mm 1330 x 750 x

1330 x 750 x

1330 x 750 x

1330 x 750

1330 x 750 x

1060

1060

1060

x 1060

1060

Weight without attachments, M/S kg 146 155 171 171 178

Weight without attachments, MX/SX kg 154 163 180 180 185

Fuel tank l 25 25 25 25 25

Detergent Tank l 10+20 10+20 10+20 10+20 10+20

– 14

37EN

HDS 7/11 Classic

HDS 8/17 *AU/

HDS 12/18 Classic

*KAP

Classic *EU

*KAP

Main Supply

Voltage V 220 400-420 220

Current type Hz 1~ 60 3~ 50 3~ 60

Connected load kW 3,4 5,5 8,4

Protection (slow) a 16 16 32

Maximum allowed net impedance Ohm (0,321+ j0,200) -- (0,163+ j0,102)

Water connection

Max. feed temperature °C 30 30 30

Min. feed volume l/h (l/min) 1000 (16,7) 1100 (18,3) 1500 (25)

Suck height from open container (20 °C) m 0,5 0,5 0,5

Max. feed pressure MPa (bar) 0,6 (6) 0,6 (6) 0,6 (6)

Performance data

Water flow rate l/h (l/min) 350-700 (5,8-11,7) 400-800 (6,7-13,3) 600-1200 (10-20)

Operating pressure of water (using standard

MPa (bar) 3-11 (30-110) 3-17 (30-170) 3-18 (30-180)

nozzle)

Max. excess operating pressure (safety valve) MPa (bar) 14 (140) 20,5 (205) 21,5 (215)

Steam flow rate l/h (l/min) 330-360 (5,5-6) 340-420 (5,6-7) 550-610 (9,1-10,1)

Max. operating pressure for working with steam

MPa (bar) 3,2 (32) 3,2 (32) 3,2 (32)

(using steam nozzle)

Part no. of steam nozzle -- 2.885-039.0 2.885-119.0 2.885-120.0

Max. operating temperature of hot water °C 98 98 98

Working temperature steam operation °C 155 155 155

Detergent suck in l/h (l/min) 0-45 (0-0,75) 0-50 (0-0,8) 0-72 (0-1,2)

Burner performance kW 53 63 91

Maximum consumption of heating oil kg/h 4,6 5,3 7,7

Max. recoil force of hand spray gun N 17,9 24,3 37,6

Nozzle size -- 048 047 068

Values determined as per EN 60355-2-79

Noise emission

Sound pressure level L

pA

dB(A) 70 71 73

Uncertainty K

pA

dB(A) 2 2 2

Sound power level L

WA

+ Uncertainty K

WA

dB(A) 88 88 90

Hand-arm vibration value

2

Hand spraygun m/s

1,1 1,0 1,5

2

Spray lance m/s

3,4 3,4 4,8

2

Uncertainty K m/s

1,0 1,0 1,0

Fuel

Fuel -- Fuel oil EL or Diesel Fuel oil EL or Diesel Fuel oil EL or Diesel

Amount of oil l 0,75 0,75 1,0

Oil grade -- 0W40 SAE 90 SAE 90

Dimensions and weights

Length x width x height mm 1330 x 750 x 1060 1330 x 750 x 1060 1330 x 750 x 1060

Weight without attachments, M/S kg 146 155 178

Weight without attachments, MX/SX kg 154 163 185

Fuel tank l 25 25 25

Detergent Tank l 10+20 10+20 10+20

38 EN

– 15

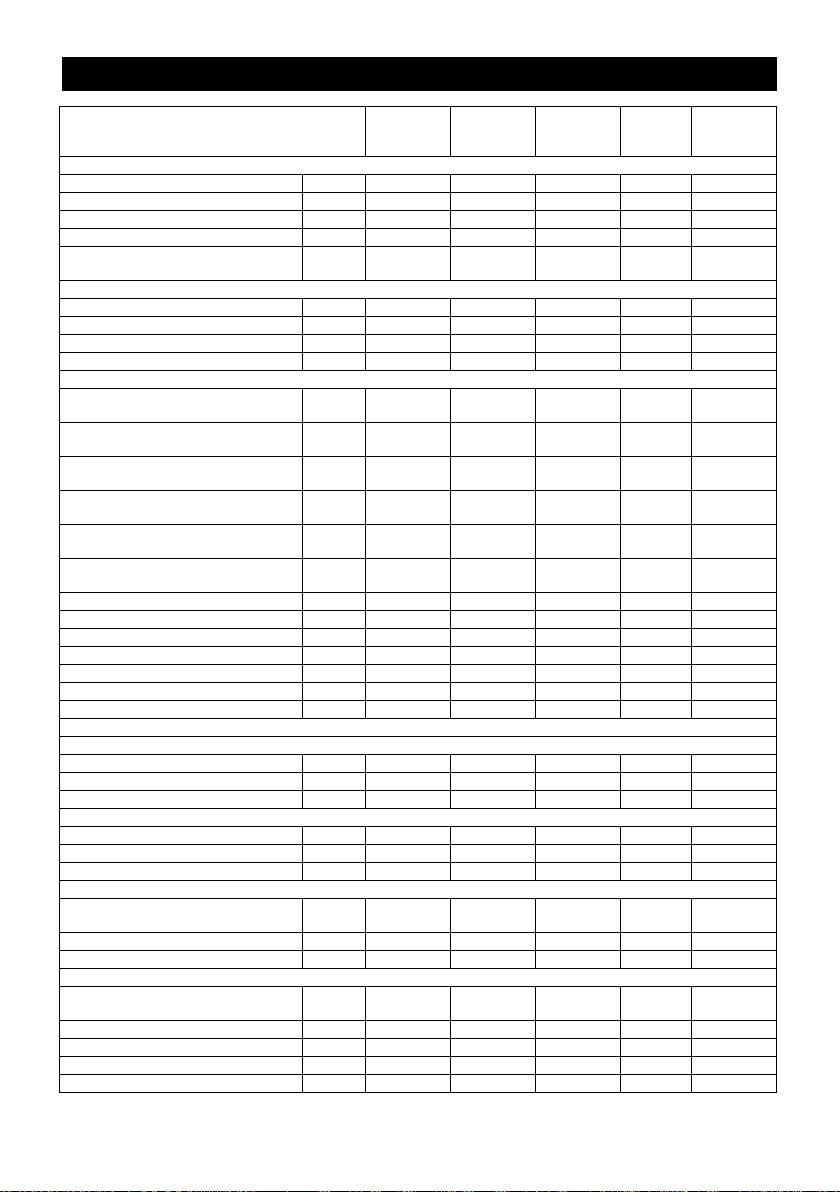

Recurring tests

Note

The recommended testing frequencies of

the respective statutory regulations of the

country of operation are to be followed.

Testing done by: External testing Internal testing Leak-proof tests

Name Signature of the au-

Signature of the au-

Signature of the au-

thorised person/ date

thorised person/ date

thorised person/ date

Name Signature of the au-

Signature of the au-

Signature of the au-

thorised person/ date

thorised person/ date

thorised person/ date

Name Signature of the au-

Signature of the au-

Signature of the au-

thorised person/ date

thorised person/ date

thorised person/ date

Name Signature of the au-

Signature of the au-

Signature of the au-

thorised person/ date

thorised person/ date

thorised person/ date

Name Signature of the au-

Signature of the au-

Signature of the au-

thorised person/ date

thorised person/ date

thorised person/ date

Name Signature of the au-

Signature of the au-

Signature of the au-

thorised person/ date

thorised person/ date

thorised person/ date

– 16

39EN

Lire ces notice originale avant la

Protection de

première utilisation de votre ap-

Français

l’environnement

pareil, se comporter selon ce qu'elles re-

quièrent et les conserver pour une

Les matériaux constitutifs de

utilisation ultérieure ou pour le propriétaire

l’emballage sont recyclables.

futur.

Ne pas jeter les emballages

– Avant la première mise en service, vous

dans les ordures ménagères,

devez impérativement avoir lu les

mais les remettre à un système

consignes de sécurité N° 5.951-949 !

de recyclage.

– Contactez immédiatement le revendeur

Les appareils usés contiennent

en cas d'avarie de transport.

des matériaux précieux recy-

– Vérifier le contenu du paquet lors de

clables lesquels doivent être ap-

l'ouverture de l'emballage.

portés à un système de

Table des matières

recyclage. Il est interdit de jeter

les batteries, l'huile et les subs-

Protection de l’environnement FR . . .1

tances similaires dans l'environ-

Symboles utilisés dans le mode

nement. Pour cette raison,

d'emploi . . . . . . . . . . . . . . . FR . . .1

utiliser des systèmes de collecte

Aperçu général. . . . . . . . . . FR . . .2

adéquats afin d'éliminer les ap-

Symboles sur l'appareil . . . FR . . .2

pareils hors d'usage.

Utilisation conforme . . . . . . FR . . .3

Ne jetez pas l'huile moteur, le fuel, le die-

Consignes de sécurité . . . . FR . . .3

sel ou l'essence dans la nature. Protéger

Dispositifs de sécurité . . . . FR . . .3

le sol et évacuer l'huile usée de façon fa-

Mise en service . . . . . . . . . FR . . .4

vorable à l'environnement.

Utilisation . . . . . . . . . . . . . . FR . . .6

Entreposage. . . . . . . . . . . . FR . .10

Instructions relatives aux ingrédients

Transport . . . . . . . . . . . . . . FR . .10

(REACH)

Les informations actuelles relatives aux in-

Entretien et maintenance . . FR . .10

grédients se trouvent sous :

Assistance en cas de panne FR . .11

www.kaercher.com/REACH

Garantie . . . . . . . . . . . . . . . FR . .14

Accessoires et pièces de re-

Symboles utilisés dans le

change . . . . . . . . . . . . . . . . FR . .14

mode d'emploi

Déclaration de conformité CE FR . .15

Caractéristiques techniques FR . .16

Danger

Essais périodiques . . . . . . . FR . .18

Pour un danger immédiat qui peut avoir

pour conséquence la mort ou des bles-

sures corporelles graves.

몇 Avertissement

Pour une situation potentiellement dange-

reuse qui peut avoir pour conséquence des

blessures corporelles graves ou la mort.

Attention

Pour une situation potentiellement dange-

reuse qui peut avoir pour conséquence des

blessures légères ou des dommages maté-

riels.

40 FR

– 1