Karcher KMR 1250 D KAT: Transport Maintenance and care

Transport Maintenance and care: Karcher KMR 1250 D KAT

Maintenance by Customer Service

Transport

Maintenance and care

Maintenance to be carried out after 8 oper-

Caution

General notes

ating hours:

Risk of injury and damage! Observe the

Î Carry out initial inspection.

– Maintenance work may only be carried

weight of the appliance when you transport it.

Maintenance to be carried out every 100

out by approved customer service out-

When transporting in vehicles, secure the

operating hours

lets or experts in this field who are famil-

appliance according to the guidelines from

Maintenance to be carried out every 200

iar with the respective safety

slipping and tipping over.

operating hours

regulations.

몇 Warning

Maintenance to be carried out every 300

– Mobile appliances used for commercial

operating hours

The appliance must be secured against

purposes are subject to safety inspec-

slippage during transport.

Note

tions according to VDE 0701.

Î Turn ignition key to "0" and remove it.

In order to safeguard warranty claims, all

Î Lock parking brake.

Cleaning

service and maintenance work during the

Î Secure the appliance at the transport

warranty period must be carried out by the

몇 Warning

eyelets using tension belts, ropes or

authorised Kärcher Customer Service in

Risk of damage! Do not clean the appliance

chains.

accordance with the maintenance booklet.

with a water hose or high-pressure water jet

Î Secure the wheels of the machine with

(danger of short circuits or other damage).

Maintenance Works

wheel chocks.

Cleaning the inside of the machine

Preparation:

Danger

Î Park the sweeper on an even surface.

Risk of injury! Wear dust mask and protec-

Î Turn ignition key to "0" and remove it.

tive goggles.

Î Lock parking brake.

Î Open the device hood.

General notes on safety

Î Clean machine with a cloth.

Î Clamp off the minus pole of the battery

Î Blow through machine with com-

to avoid formation of sparks and pre-

pressed air.

vent the device from starting.

Î Close cover.

Danger

External cleaning of the appliance

Risk of injury! Always apply the safety bar

Î Clean the machine with a damp cloth which

when the waste container is raised.

Note

has been soaked in mild detergent.

Observe markings for fixing points on base

frame (chain symbols). When loading or

Note

unloading the machine, it may only be op-

Do not use aggressive cleaning agents.

erated on gradients of max. 18%.

Maintenance intervals

Storing the device

Note

Caution

The elapsed-time counter shows the timing

Risk of injury and damage! Note the weight

of the maintenance intervals.

of the appliance in case of storage.

Maintenance by the customer

This appliance must only be stored in inte-

Daily maintenance:

rior rooms.

Î Use the safety bar for emptying from a

Î Check engine oil level.

height.

Î Check air filter.

Shutdown

Î Check tyre pressure.

Danger

If the sweeper is going to be out of service

Î Check the sweeping roller and the side

Risk of injury due to engine overrun. Once

for a longer time period, observe the follow-

brush for wear and wrapped belts.

the engine has been switched off, wait for 5

ing points:

Î Check dust filter.

seconds. Stay well clear of the working

Î Park the sweeper on an even surface.

Î Check function of all operator control el-

area for this time.

ements.

Î Raise the roller brush and the side-

– Allow the machine sufficient time to cool

Weekly maintenance:

brushes to prevent the bristles from be-

down before carrying out any mainte-

Î Check leakage and functioning of all hy-

ing damaged.

nance and repair work.

draulic components.

Î Turn ignition key to "0" and remove it.

– Do not touch any hot parts, such as the

Î Check for smooth running of the Bow-

Î Lock parking brake.

drive motor and exhaust system.

den cables and the moveable parts

Î Lock the sweeper to ensure that it does

Maintenance following wear:

Please do not release engine

not roll off.

Î Replace sealing strips.

oil, fuel oil, diesel and petrol

Î Fill fuel tank and close fuel cock.

Î Replace roller brush.

into the environment Protect

Î Change engine oil.

Î Replace side brush.

the ground and dispose of used

Î Clean the inside and outside of the

Note

oil in an environmentally-clean

sweeper.

For description, see section on Mainte-

manner.

Î Park the machine in a safe and dry

nance work.

place.

Follow the instructions in Maintenance

Î Disconnect battery.

Manual 5.950-536!

Î Charge battery approx. every 2 months.

Note

Where maintenance is carried out by the

Close fuel cock

customer, all service and maintenance

Î Open the device hood.

work must be undertaken by a qualified

Î Turn the lever upward.

specialist. If required, a specialised Kärch-

Î Close cover.

er dealer may be contacted at any time.

22 EN

- 7

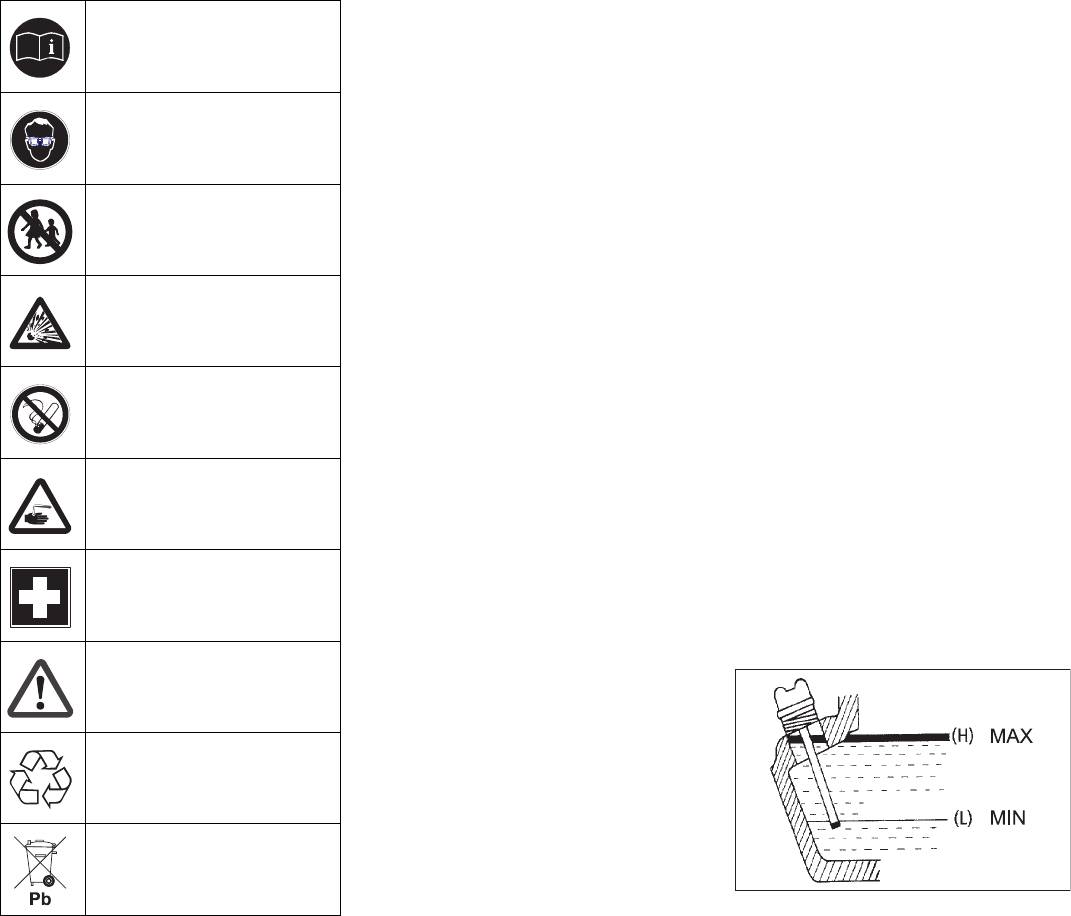

Safety notes regarding the batteries

Installing and connecting the battery

Check the tyre pressure

Please observe the following warning notes

Î Open the device hood.

Î Park the sweeper on an even surface.

when handling batteries:

Î Insert battery in battery mount.

Î Connect air pressure testing device to

tyre valve.

Observe the directions on the

Î Screw on mounts on battery base.

battery, in the instructions for

Î Connect pole terminal (red cable) to

Î Check air pressure and adjust if re-

use and in the vehicle operat-

positive pole (+).

quired.

ing instructions!

Î Connect pole terminal to negative pole

Î Set air pressure for the front and rear

Wear an eye shield!

(-).

tyres at 6 bar.

Note

Manually clean the dust filter

Before removing the battery, make sure

The filter can also be cleaned manually in

that the negative pole lead is disconnected.

addition to the automatic interval.

Keep away children from acid

Check that the battery pole and pole termi-

Note

and batteries!

nals are adequately protected with pole

During operations, the dust filter should be

grease.

shaken and cleaned every 15-30 minutes

Charging battery

depending on the amount of collected dust.

Risk of explosion!

Danger

Î Stop the machine.

Risk of injury! Comply with safety regula-

Î Set the lever to "wet" sweeping operations.

tions on the handling of batteries. Observe

Î Briefly press the dust filter cleaning

the directions provided by the manufacturer

switch. The dust filter is cleaned for ap-

Fire, sparks, open light, and

of the charger.

prox. 10 seconds.

smoking not allowed!

Danger

Î Set the lever to "dry" sweeping opera-

tions.

Charge the battery only with an appropriate

charger.

Check engine oil level and top up, if re-

Danger of causticization!

Î Disconnect battery.

quired

Î Unscrew all cell caps.

Danger

Î Connect positive terminal cable from

Risk of burns!

the charger to the positive pole connec-

Î Allow engine to cool down.

First aid!

tion on the battery.

Î Wait for at least 5 minutes after switch-

Î Connect negative terminal cable from

ing off the engine before checking the

the charger to the negative pole con-

engine oil fill level.

nection on the battery.

Î Open the device hood.

Warning note!

Î Plug in mains connector and switch on

charger.

Î Charge battery using lowest possible

level of charging current.

Disposal!

Î Screw in cell caps.

Note

When the battery is charged, first remove

Do not throw the battery in the

the charger from the mains and then dis-

dustbin!

connect it from the battery.

Check fluid level in the battery and ad-

just if required

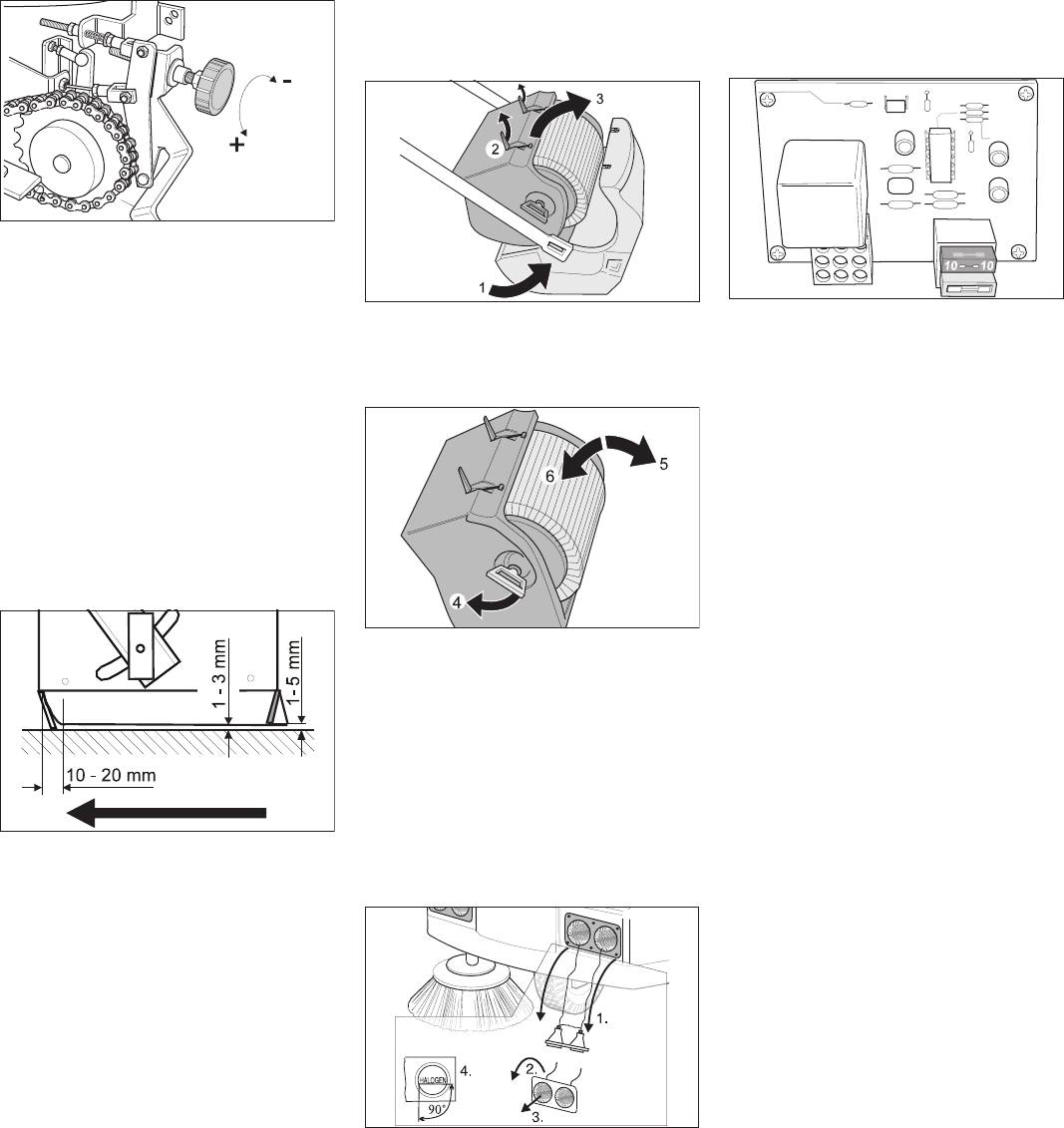

Î Pull out oil dipstick.

몇 Warning

Î Wipe off oil dipstick and insert.

Danger

Regularly check the fluid level in acid-filled

Î Pull out oil dipstick.

Risk of explosion! Do not put tools or similar

batteries.

Î Read the value of the oil level.

on the battery, i.e. on the terminal poles

– The acid in a fully charged battery has a

– The oil level must lie between “MIN“

and cell connectors.

specific weight of 1.28 kg/l at a temper-

and “MAX“ marking.

Danger

ature of 20 °C.

– Add motor oil if the oil level is below the

Risk of injury! Ensure that wounds never come

– The acid in a partially discharged bat-

"MIN" marking.

into contact with lead. Always clean your hands

tery has a specific weight between 1.00

– Do not fill oil above the "MAX" marking.

after having worked with batteries.

and 1.28 kg/l.

Î Fill engine oil in the opening of the oil

Danger

– The specific weight of the acid must be

dip stick.

Risk of fire and explosion!

uniform in all cells.

Oil grade: see Technical Data

– Smoking and naked flames are strictly

Î Unscrew all cell caps.

Î Insert the oil dip again.

prohibited.

Î Take a sample from each cell using the acid

– Rooms where batteries are charged

Î Wait at least 5 minutes.

must have good ventilation because

tester.

Î Check engine oil level.

highly explosive gas is emitted during

Î Put the acid sample back into the same cell.

charging.

Î Where fluid level is too low, top up cells to

Danger

the mark provided with distilled water.

Danger of causticization!

Î Charge battery.

– Rinse thoroughly with lots of clear water

Î Screw in cell caps.

if acid gets into the eye or comes in con-

tact with the skin.

– Then consult a doctor immediately.

– Wash off the acid If it comes in contact

with the clothes.

- 8

23EN

Î Turn in the adjustment screw of the roll-

Change the engine oil

Check hydraulic unit

er brush in clockwise direction (-) up to

Danger

Î Do visual inspection. Infom oil loss to

the stop.

hydraulic unit, cylinder or hoses to

Risk of burns due to hot oil!

Kärcher Customer Service.

Î Assemble it back in the reverse se-

Î Ready a catch bin for appr. 1.5 litre oil.

quence.

Î Allow engine to cool down.

Replacing side brush

Î Open the device hood.

Î Park the sweeper on an even surface.

Î The side-brushes lift up.

Î Turn ignition key to "0" and remove it.

Installation position of roller brush in direc-

tion of travel

Î Remove the oil drain hose from the

Note

holder.

When installing the new roller brush, en-

Î Unscrew oil drain plug.

Î Loosen the fastening screws.

sure correct positioning of the bristle as-

Î Pull out oil dipstick.

Î Remove the wiper blade.

sembly.

Î Drain off oil.

Î Fix in the new wiper blade.

Note

Î Screw in the oil drain screw along with

Checking roller brush

Once the new roller brush has been in-

the new washer.

Î Park the sweeper on an even surface.

stalled, the sweeping track must be read-

Î Insert the oil drain hose in the holder.

Î Raise roller brush.

justed.

Î Fill engine oil in the opening of the oil

Î Turn ignition key to "0" and remove it.

dip stick.

Check and adjust roller brush sweeping

Î Secure the machine with wheel chock(s)

track

Oil grade: see Technical Data

to prevent it from rolling away.

Î Check tyre pressure.

Î Insert the oil dip again.

Î Lock parking brake.

Î Remove belts or cords from roller brush.

Î Switch off dust suction; set the lever to

Î Wait at least 5 minutes.

"wet" sweeping operations.

Î Check engine oil level.

Replacing roller brush

Î Raise roller brush.

Cleaning and replacing the fuel filter

Replacement is due if a visible deteriora-

tion in sweeping performance caused by

Î The side-brushes lift up.

Danger

bristle wear is evident.

Î Drive sweeper on to a smooth, even

Never use petrol or cleaning solutions with

Î Park the sweeper on an even surface.

surface covered with a visible layer of

low infllamation point to clean the filter insert.

Î Lower roller brush.

dust or chalk.

Î Open the device hood.

Î Turn ignition key to "0" and remove it.

Î Lower roller brush (central position) and

Î Secure the machine with wheel

allow it to briefly rotate.

chock(s) to prevent it from rolling away.

Î Raise roller brush.

Î Lock parking brake.

Î Open bulk waste flap.

Î Drive machine backwards.

Î Check sweeping mirror.

Î Remove filter inlay (1) and check.

Î Clean filter inlay or replace if too dirty.

– Cleaning: Blow out the filter inlay from

the inside using compressed air or

Î Open right side-flap (1).

knock it on a hard surface. Do not brush

Î Loosen the safety bolts at the lower end

it off because the dirt will get pressed

of the fork (2) and tilt the drawbar to the

The sweeping track should have an even

into the fiber. Do not clean with soap so-

rear.

rectangular shape which is between 30 and

lution because this is a wet oil filter.

Î Loosen knurled-head screw (3).

50 mm wide.

Î Insert cleaned or new inlay.

Note

Cleaning the fuel filter

The shape of the sweeping track must not

Danger

be trapezoidal. If so, consult Customer

Risk of fire and explosion!

Service.

– Smoking and naked flames are strictly

Adjust sweeping track:

prohibited.

Note

Î Blow out fuel from the tank.

Only for "Fine tuning" mode.

Î Loosen the screws of the fuel tap and re-

Î Open the device hood.

move the filter.

Î Clean the filter thoroughly with diesel.

Î Remove roller brush arm (4).

Î Insert cleaned filter and fasten the fuel tap.

Î Open roller brush flap (rotating lock) (5).

Î Draw out the roller brush (6).

24 EN

- 9

Note

Replacing fuses

A clear deposit of dust at the air exit of the

Note

blower is an indicator that the dust filter has

Only use fuses with identical safety ratings.

not been inserted correctly or is defective.

Enlarging sweeping track:

Î Turn the adjustment screw in an anti-

clockwise direction (+).

Reducing sweeping track:

Î Raise waste container up to the half (1).

Î Open the device hood.

Î Turn the adjustment screw in a clock-

Î Open catches (2).

Î Replace defective fuses.

wise direction (-).

Î Tilt the filter box towards the front and

Note

Adjusting and replacing sealing strips

remove it (3).

Multiple defect of the same fuse indicates a

Note

technical defect in the electrical system. In-

Replace damaged or worn out sealing

form Kärcher Customer Service.

strips immediately.

Î Park the sweeper on an even surface.

Î Raise roller brush.

Î Turn ignition key to "0" and remove it.

Î Secure the machine with wheel

chock(s) to prevent it from rolling away.

Î Lock parking brake.

Î Fold up the handle (4), pull it out and

turn it by 90° (lock).

Î Remove filter cartridge (5).

Î Insert new filter cartridge; bolts must

have been inserted into the holes (6).

Î Reset handle in the starting position

and lock it. Check correct position of

the filter.

Î Insert filter box and lock it.

Front sealing strip

Replacing electric bulb

Î Stop the machine.

Î Unscrew fasteners of sealing strip.

Î Turn ignition key to "0" and remove it.

Î Remove the sealing strip.

Î Screw on new sealing strip.

Note

The front sealing strip cannot be adjusted.

Rear sealing strip

Î Unscrew fasteners of sealing strip.

Î Remove the sealing strip.

Î Screw on the new sealing strip.

Î Adjust sealing strip.

Î Set the ground clearance of the sealing

strip to 1-5 mm.

Î Loosen the fasteners of the columns.

Î Screw on new sealing strip.

Î Remove column (1).

Side sealing strips

Î Loosen the screw between the struts of

Î Unscrew the fasteners of the sealing

the lamp holder of the defective head-

strips.

lights.

Î Turn the diffusing lens of the defective

Î Remove sealing strips.

headlamp in the anti-clockwise direc-

Î Insert new sealing strips.

tion by approx. 1/4 rotation (2) and take

Î Adjust sealing strips.

out the reflector housing (3).

Î Set the ground clearance of the sealing

Î Take out the bulb.

Î Insert new bulb.

strip to 1-3 mm.

Î Insert the reflector housing from the bottom

Î Screw on new sealing strips.

into the column and fasten it by turning ap-

Replacing dust filter

prox. 1/4 rotation in the clockwise direction.

Ensure that it has locked in properly; the let-

Danger

ters HALOGEN must be clearly legible on

Empty waste container before replacing

the headlights glass in a horizontal manner

(4).

dust filter. Wear a dust mask when working

Î Turn in the screw between the struts of

around the dust filter. Observe safety regu-

the lamp holder.

lations on the handling of fine particulate

Î Fasten the column.

material.

- 10

25EN

Оглавление

- Symbole auf dem Gerät

- Bestimmungsgemäße Verwendung

- Geräteelemente

- Vor Inbetriebnahme

- Transport

- Lagerung des Gerätes

- Hilfe bei Störungen

- Technische Daten

- Garantie CE-Erklärung

- Symbols on the machine

- Proper use

- Device elements

- Before Startup

- Transport Maintenance and care

- Troubleshooting

- Technical specifications

- Warranty CE declaration

- Symboles sur l'appareil

- Utilisation conforme

- Éléments de l'appareil

- Avant la mise en service

- Transport

- Assistance en cas de panne

- Caractéristiques techniques

- Garantie Déclaration CE

- Simboli riportati

- Uso conforme a destinazione

- Parti dell'apparecchio

- Prima della messa in funzione

- Fermo dell'impianto

- Guida alla risoluzione dei guasti

- Dati tecnici

- Garanzia Dichiarazione CE

- Symbolen op het toestel

- Reglementair gebruik

- Apparaat-elementen

- Voor de inbedrijfstelling

- Vervoer

- Hulp bij storingen

- Technische gegevens

- Garantie CE-verklaring

- Símbolos del manual de

- Función

- Elementos del aparato

- Antes de la puesta en marcha

- Transporte Cuidados y mantenimiento

- Ayuda en caso de avería

- Datos técnicos

- Garantía Declaración CE

- Symboler på aggregatet

- Ändamålsenlig användning

- Aggregatelement

- Före ibruktagande

- Transport

- Skötsel och underhåll

- Åtgärder vid störningar

- Tekniska data

- Garanti CE-försäkran

- Σύμβολα στο εγχειρίδιο

- Λειτουργία Χρήση σύμφωνα με τους κανονισμούς

- Στοιχεία συσκευής

- Πριν τη θέση σε λειτουργία

- Χειρισμός

- Αποθήκευση της συσκευής

- Αντιμετώπιση βλαβών

- Τεχνικά χαρακτηριστικά

- Εγγύηση Δήλωση συμμόρφωσης CE

- Символы в руководстве по

- Использование по

- Элементы прибора

- Перед началом работы

- Уход и техническое

- Помощь в случае неполадок

- Технические данные

- Гарантия Заявление о соответствии требованиям СЕ