Karcher KM 90-60 R Lpg Adv: Maintenance and care

Maintenance and care: Karcher KM 90-60 R Lpg Adv

-

8

Switch off the appliance and remove

the ignition key prior to performing any

cleaning or maintenance tasks on the

appliance, replacing parts or switching

over to another function.

Always disconnect the battery when

working on the electrics.

–

Maintenance work may only be carried

out by approved customer service out-

lets or experts in this field who are famil-

iar with the respective safety

regulations.

–

Mobile appliances used for commercial

purposes are subject to safety inspec-

tions according to VDE 0701.

–

Use only roller brushes/ side-brushes

that are provided with the appliance or

specified in the Operations Manual.

The use of other roller brushes/ side-

brushes can affect the safety of the ap-

pliance.

–

The battery installed in the appliance is

maintenance-free.

Caution

Risk of damage! Do not clean the appliance

with a water hose or high-pressure water

jet (danger of short circuits or other dam-

age).

Do not use aggressive and abrasive clean-

ing agents.

Danger

Risk of injury! Wear dust mask and protec-

tive goggles.

Open the device hood.

Blow through machine with com-

pressed air.

Clean the machine with a damp cloth

which has been soaked in mild deter-

gent.

Close cover.

Clean the machine with a damp cloth

which has been soaked in mild deter-

gent.

Observe the inspection checklist!

Note:

The elapsed-time counter shows the

timing of the maintenance intervals.

Note:

Where maintenance is carried out by

the customer, all service and maintenance

work must be undertaken by a qualified

specialist. If required, a specialised Kärch-

er dealer may be contacted at any time.

Note:

For description, see section on Main-

tenance work.

Daily maintenance:

Check engine oil level.

Check tyre pressure.

Check fill level of hydraulic oil.

Check function of all operator control el-

ements.

Check function of seat contact switch.

Weekly maintenance:

Check gas pipes.

Check air filter.

Check moving parts for freedom of

movement.

Check the sealing strips in the sweep-

ing area for position and wear.

Check dust filter and clean filter box, if

required.

Maintenance to be carried out every 100

operating hours:

Change engine oil (initial change after

20 operating hours).

Check spark plug.

Check tension, wear and function of

drive belts (V-belt and circular belt).

Clean air filter.

Maintenance following wear:

Replace sealing strips.

Replace roller brush.

Replace side brush.

Note:

In order to safeguard warranty claims,

all service and maintenance work during the

warranty period must be carried out by the

authorised Kärcher Customer Service in ac-

cordance with the maintenance booklet.

Maintenance to be carried out after 20

operating hours:

Carry out initial inspection.

Maintenance to be carried out every 100

operating hours

Have maintenance tasks performed ac-

cording to the inspection check list.

Maintenance to be carried out every 200

operating hours

Have maintenance tasks performed ac-

cording to the inspection check list.

Maintenance to be carried out every 300

operating hours

Have maintenance tasks performed ac-

cording to the inspection check list.

Danger

Risk of injury!

The engine requires approx. 3-4 seconds

to come to a standstill once it has been

switched off. During this time, stay well

clear of the working area.

Risk of burns!

Allow the machine sufficient time to cool

down before carrying out any maintenance

and repair work.

Caution

Please do not release engine oil, fuel oil,

diesel and petrol into the environment. Pro-

tect the ground and dispose of used oil in

an environmentally-clean manner.

Park the sweeper on an even surface.

Turn ignition key to "0" and remove it.

Allow device to cool down sufficiently.

For certain maintenance tasks (e.g. change

of the battery) it is necessary to the remove

the rear panel first.

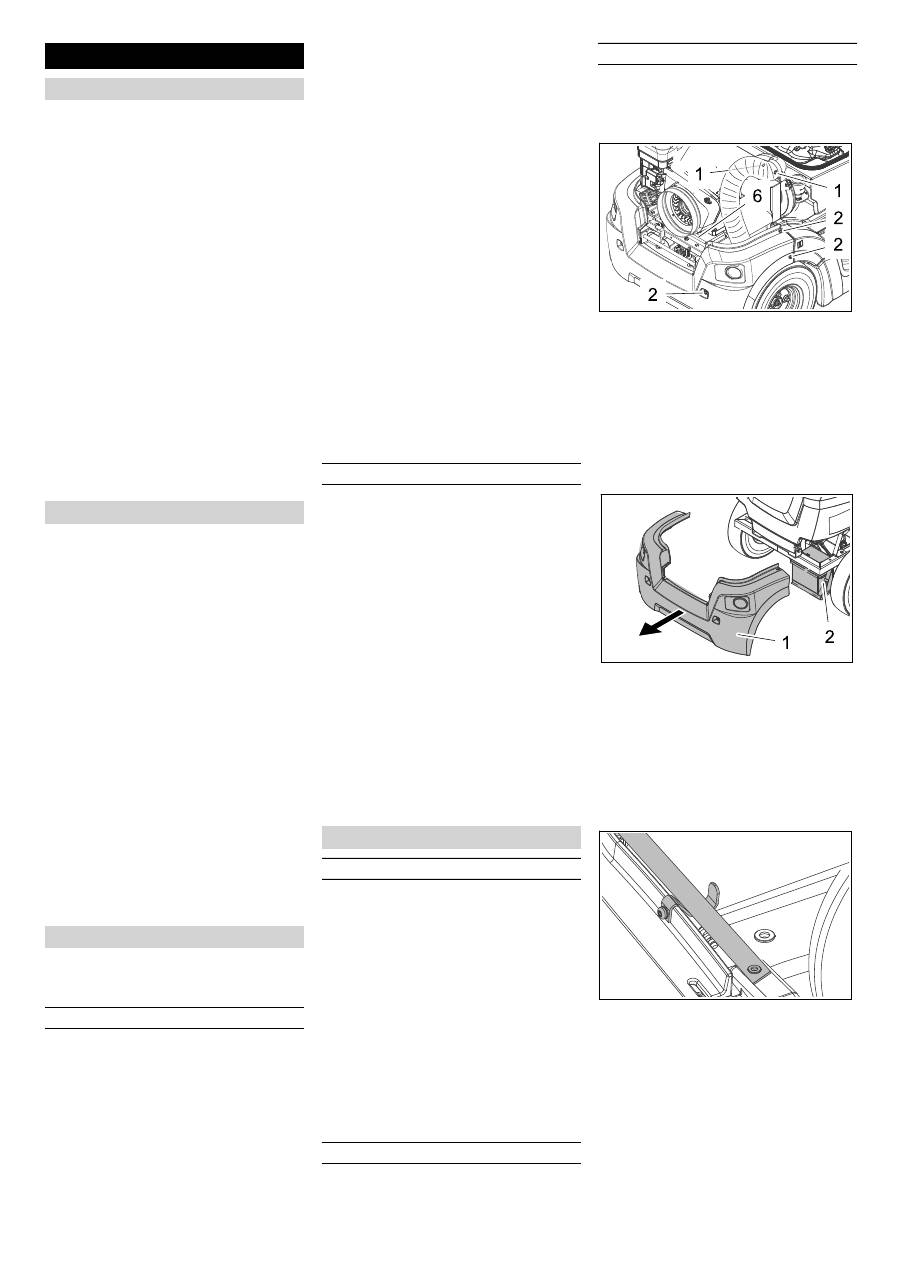

Open the device hood.

1 Screws suction blower hose

2 Screws rear panel

Loosen the 2 screws at the suction

blower hose and pull off the suction

hose.

Loosen all 6 screws on the left side,

right side, and at the back of the rear

panel.

Close cover.

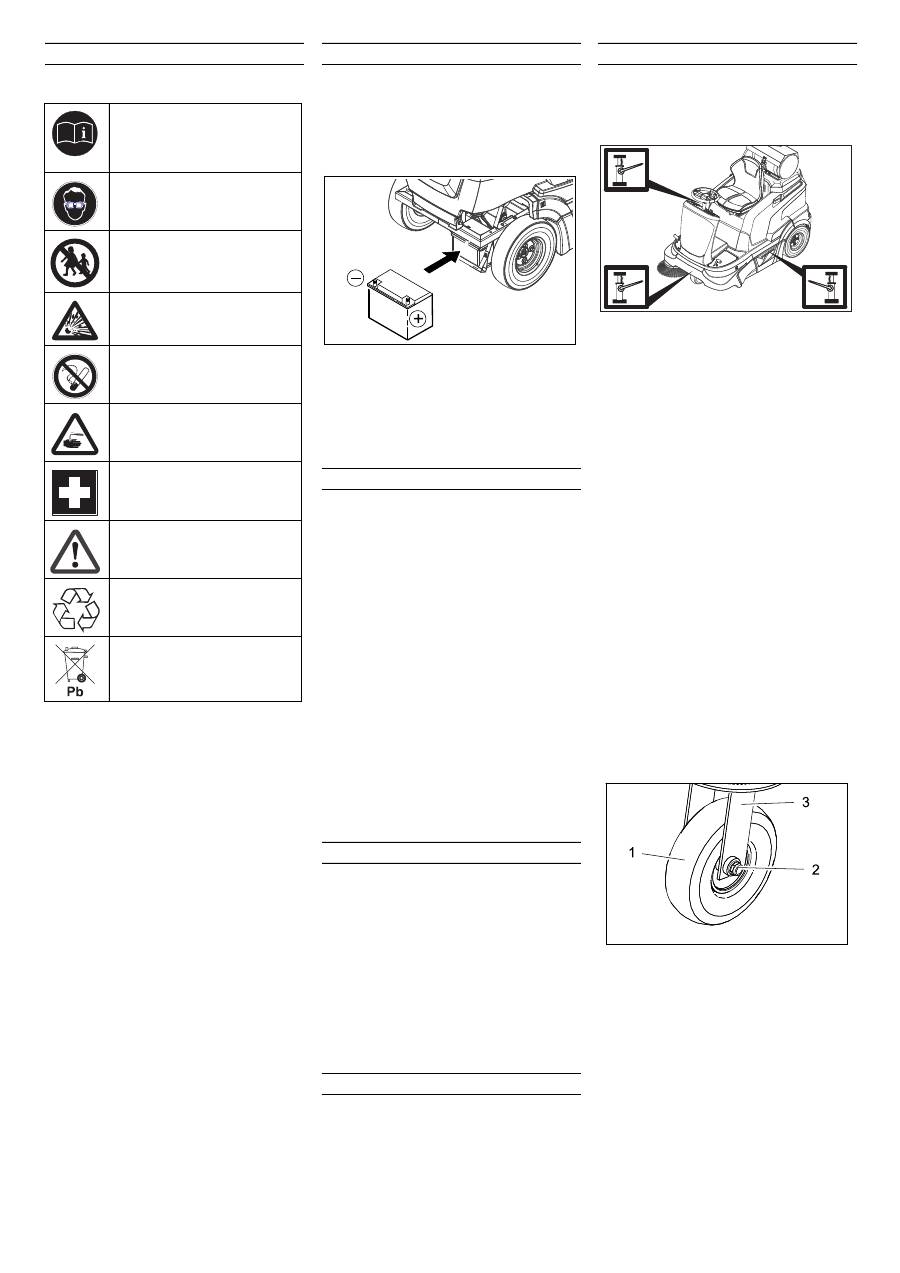

1 Tail panel

2 Battery

Remove the rear panel together with

the suction blower hose towards the

back.

When installing the rear panel, ensure

that the retaining strap is always locat-

ed above the sheet metal bracket.

Maintenance and care

General notes

Cleaning

Cleaning the inside of the machine

External cleaning of the appliance

Maintenance intervals

Maintenance by the customer

Maintenance by Customer Service

Maintenance Works

General notes on safety

Preparation

Remove rear panel

24 EN

-

9

Please observe the following warning notes

when handling batteries:

Danger

Risk of explosion! Do not put tools or similar

on the battery, i.e. on the terminal poles

and cell connectors.

Danger

Risk of injury! Ensure that wounds never

come into contact with lead. Always clean

your hands after having worked with batter-

ies.

Danger

Risk of fire and explosion!

–

Smoking and naked flames are strictly

prohibited.

–

Rooms where batteries are charged

must have good ventilation because

highly explosive gas is emitted during

charging.

Danger

Danger of causticization!

–

Rinse thoroughly with lots of clear water

if acid gets into the eye or comes in con-

tact with the skin.

–

Then consult a doctor immediately.

–

Wash off the acid If it comes in contact

with the clothes.

–

Change clothing.

Remove the tail panel.

Refer to Chapter "Maintenance tasks/

removing the rear panel".

Insert battery in battery mount.

Note

: Observe the mounting direction

concerning the polarity of the connection!

Connect pole terminal (red cable) to

positive pole (+).

Connect pole terminal to negative pole

(-).

Note:

Check that the battery pole and pole

terminals are adequately protected with

pole grease.

Danger

Risk of injury! Comply with safety regula-

tions on the handling of batteries. Observe

the directions provided by the manufacturer

of the charger.

Danger

Charge the battery only with an appropriate

charger.

Disconnect battery.

Connect positive terminal cable from

the charger to the positive pole connec-

tion on the battery.

Connect negative terminal cable from

the charger to the negative pole con-

nection on the battery.

Plug in mains connector and switch on

charger.

Note:

When the battery is charged, first re-

move the charger from the mains and then

disconnect it from the battery.

Remove the tail panel.

Disconnect pole terminal to negative

pole (-).

Disconnect pole terminal to positive

pole (-).

Remove the battery from the battery

holder.

Used batteries are to be disposed ac-

cording to the EC guideline 91/ 157

EWG or the corresponding national

regulations in an environment-friendly

manner.

Park the sweeper on an even surface.

Connect air pressure testing device to

tyre valve.

Check air pressure and adjust if re-

quired.

For permissible tyre inflation pressure

see Chapter "Technical specifications".

Park the sweeper on an even surface.

Remove ignition key.

Check stability of ground. Lock the ap-

pliance to ensure that it does not roll off.

Position vehicle jack at the appropriate

mounting point for the front or rear

wheel.

Note

Use a suitable commercially available vehi-

cle jack.

Loosen the wheel nuts/wheel bolts by

about 1 revolution using a suitable tool.

Replace the rear wheel

Raise slightly the waste container on

the appropriate side and pull it out.

Raise machine using vehicle jack.

Unscrew the wheel nuts/wheel bolts

and remove them.

Remove wheel.

Have the defective wheel repaired by a

specialised repair shop.

Place the wheel and screw in the wheel

nuts/wheel bolts all the way; tighten

them lightly.

Lower machine using vehicle jack.

Torque the wheel nuts/wheel bolts to

the required torque.

Push in the waste container and lock it.

Replace the front wheel

1 Front wheel

2 Nut

3 Intake

Raise machine using vehicle jack.

Loosen both screws on the wheel axle

by 1-2 rotations. If necessary, hold up a

second wrench to loosen them.

Remove the wheel together with the ax-

le.

Have the defective wheel repaired by a

specialised repair shop.

Tighten the repaired front wheel with

the axle and nut to the retainer.

Lower machine using vehicle jack.

Safety notes regarding the batteries

Observe the directions on the

battery, in the instructions for

use and in the vehicle operat-

ing instructions!

Wear an eye shield!

Keep away children from acid

and batteries!

Risk of explosion!

Fire, sparks, open light, and

smoking not allowed!

Danger of causticization!

First aid!

Warning note!

Disposal!

Do not throw the battery in the

dustbin!

Installing and connecting the battery

Charging battery

Remove the battery

Check the tyre pressure

Replacing wheel

Tightening torque (Nm)

56 Nm

25 EN

-

10

Danger

Risk of burns on account of hot surfaces!

Allow engine to cool down.

Wait for at least 5 minutes after switch-

ing off the engine before checking the

engine oil fill level.

Open the device hood.

1 Oil drain hose

2 Oil dipstick

Unscrew and withdraw oil dipstick.

Wipe off and insert the oil dipstick (do

not turn it in).

Remove the oil dip one more time and

check the oil level.

–

The oil level must lie between “MIN“

and “MAX“ marking.

–

Add motor oil if the oil level is below the

"MIN" marking.

–

Do not fill oil above the "MAX" marking.

Fill motor oil into the oil fill neck.

Note

: For filling in the motor oil, use ac-

cessories such as a bent funnel tube or

an oil-change pump 6.491-538.

For oil type refer to Chapter "Technical

specifications".

Wait at least 5 minutes.

If the engine oil level is correct, screw in

the oil dipstick.

Danger

Risk of burns due to hot oil!

Allow engine to cool down.

Open the device hood.

Ready a catch bin for appr. 1 litre oil.

Unscrew the locking screw of the oil

drain hose and drain the oil.

Screw in the locking screw and tighten

it again.

Unscrew and withdraw oil dipstick.

Fill motor oil into the oil fill neck.

For oil type and filling quantity refer to

Chapter "Technical specifications".

Wait at least 5 minutes.

Check engine oil level.

If the engine oil level is correct, screw in

the oil dipstick.

Deliver the old oil to the respective col-

lection centres.

Danger

Risk of burns on account of hot surfaces!

Allow engine to cool down.

1 Wing bolt

2 Air filter housing

3 Filter inlay

Remove the wing screw.

Remove the air filter housing.

Take out the filter inlay.

Clean the interior of the air filter reser-

voir.

Clean or replace the filter inlay.

Install a new filter inlay.

Fit the air filter casing and secure it by

means of the butterfly nut.

Caution

Risk of injury! Do not remove the spark plug

connector manually.

1 Vacuum line

2 Ignition plug

3 Casing

Pull the vacuum line out of the casing.

Remove the spark plug connector using

suitable tools/tongs.

Unscrew and clean spark plug.

Screw in cleaned or new spark plug.

Push on spark-plug connector.

Reinsert the vacuum pipe into the cas-

ing.

Danger

Risk of burns on account of hot surfaces!

Caution

This inspection may only be carried out

when the engine is warm

Open the device hood.

1 Equalising container

2 MAX oil level

3 MIN oil level

Check oil level in the equalisation con-

tainer.

The filling level should be between the

"Max" and "Min" marking.

If hydraulic oil is missing:

Remove the lid of the equalising reser-

voir and refill hydraulic oil.

For oil type refer to Chapter "Technical

specifications".

Close the lid.

Check tyre pressure.

The side-brushes lift up.

Drive sweeper on to a smooth, even

surface covered with a visible layer of

dust or chalk.

Lower side-brushes and allow them to

briefly rotate.

The side-brushes lift up.

Drive machine backwards.

Park the sweeper on an even surface.

Check sweeping mirror.

The width of the sweeping track should lie

between 40-50 mm.

Note:

The side brush floating mounting ad-

justs the sweeping track as the bristles

wear down. The side brush must be re-

placed if it becomes too worn.

Park the sweeper on an even surface.

Set programme switch to step 1 (driv-

ing). Side brushes lift up.

Turn ignition key to "0" and remove it.

Loosen 3 fastening screws on the un-

derside.

Remove the wiper blade.

Clip new side brushes on to driver and

screw on.

Check engine oil level and top up, if re-

quired

Change the engine oil

Change the air filter

Clean or replace the spark plug

Check hydraulic oil level and refill hy-

draulic oil

Checking the sweeping mirror of the

side-brushes

Replacing side brush

26 EN

-

11

Park the sweeper on an even surface.

Set programme switch to step 1 (driv-

ing). Roller brush is raised.

Turn ignition key to "0" and remove it.

Secure the machine with wheel

chock(s) to prevent it from rolling away.

Remove belts or cords from roller

brush.

Note:

The side brush floating mounting of

the roller brush adjusts the sweeping track

as the bristles wear down. The roller brush

must be replaced if it becomes too worn.

Set programme switch to step 1 (driv-

ing). The side brush and roller brush are

raised.

Drive sweeper on to a smooth, even

surface covered with a visible layer of

dust or chalk.

Lower roller brush and allow it to briefly

rotate.

Raise roller brush.

Press pedal which raises bulk waste

flap and keep pressed.

Drive machine backwards.

The sweeping track should have an even rectan-

gular shape which is between 50 and 70 mm

wide.

Replacement is due if a visible deteriora-

tion in sweeping performance caused by

bristle wear is evident.

Park the sweeper on an even surface.

Set programme switch to step 1 (driv-

ing). Roller brush is raised.

Turn ignition key to "0" and remove it.

Secure the machine with wheel

chock(s) to prevent it from rolling away.

Raise slightly the waste container on

the left side and pull it out.

Loosen the fastening screw on the left

side-panel.

Remove side panel.

Hook the draw spring out.

1 Fastening screw of the under-pressure

can

2 Fastening nut of the bulk waste flap

3 Screw of the roller brush crank

Unscrew the fastening screws of the

vacuum socket and release the lever.

Turn the fastening nut of the bulk waste

flap and unhook the bulk waste flap.

Unscrew and withdraw bolt on the roller

brush swinging arm.

Push the roller brush cover backwards

and remove it.

Pull out roller brush.

Push new roller brush into the roller

brush housing and onto the drive pin.

Note:

When installing the new roller

brush, ensure correct positioning of the

bristle assembly.

Installation position of roller brush in direction of

travel

Position roller brush cover.

Fit the fastening screws and nuts.

Hook the draw spring in.

Screw on side panel.

Push in the waste containers on both

the sides and lock them.

Park the sweeper on an even surface.

Set programme switch to step 1 (driv-

ing). Roller brush is raised.

Turn ignition key to "0" and remove it.

Secure the machine with wheel

chock(s) to prevent it from rolling away.

Raise slightly the waste containers on

both sides and pull them out.

Open the fastening screws of the side

panels on both sides.

Remove side panels.

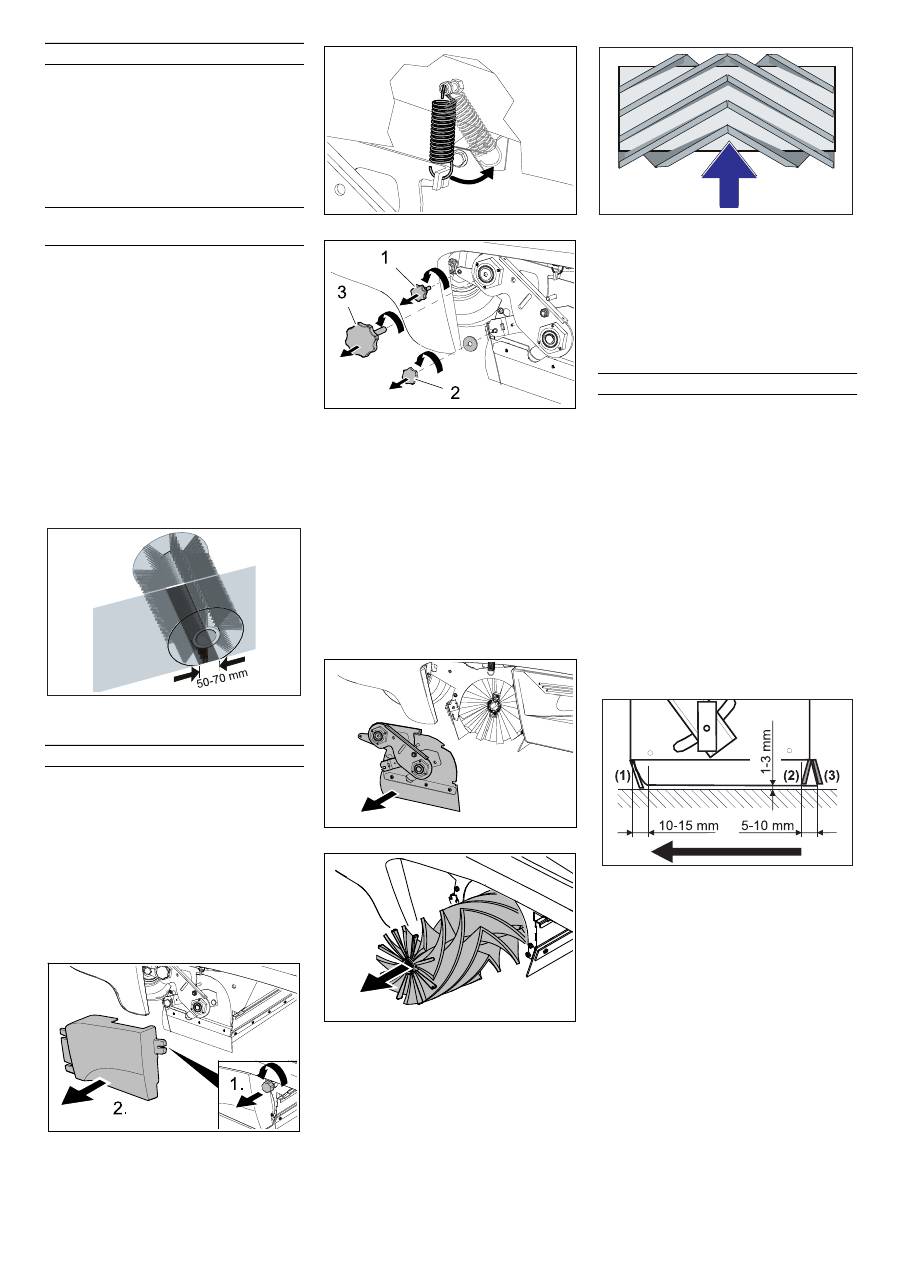

Front sealing strip

Loosen retaining nuts for the front seal-

ing strip (1) slightly (to replace, un-

screw).

Screw on new sealing strip without fully

tightening the nuts.

Adjust sealing strip.

Set the distance between the sealing

strip and the floor so that the bottom

edge trails behind at a distance of be-

tween 10-15 mm.

Tighten nuts.

Rubber strip

If worn, replace.

Unscrew retaining nuts for the rubber

strip (2).

Screw on new rubber strip.

Rear sealing strip

Set the distance between the sealing

strip and the floor so that the bottom

edge trails behind at a distance of be-

tween 5 and 10 mm.

If worn, replace.

Unscrew retaining nuts for rear sealing

strip (3).

Screw on new sealing strip.

Checking roller brush

Check the sweeping mirror of the

sweeping roller

Replacing roller brush

Adjusting and replacing sealing strips

27 EN

-

12

Side sealing strips

Slightly loosen retaining nuts for the

side sealing strip (to replace, unscrew).

Screw on new sealing strip without fully

tightening the nuts.

To set the floor clearance, insert a

sheet with a thickness of between 1 and

3 mm under the sealing strip.

Adjust sealing strip.

Tighten nuts.

Screw on side panels.

Push in the waste containers on both

the sides and lock them.

몇

Warning

Wear a dust mask when working around

the dust filter. Observe safety regulations

on the handling of fine particles.

Note

: Wait at least 1 minute before remov-

ing the dust filter so that the dust can settle.

Open the device hood.

1 Screws (2x)

2 Lid with cleaning device

3 Support

4 Dust filter (flat-fold filter)

5 Suction blower

Loosen the screws.

Fold the lid up and secure it by means

of the support.

Take out the dust filter.

Check dust filter, clean or replace

Insert cleaned or new dust filter.

Close the lid.

Tighten the screws.

Check hoses at the suction blower for

leaks and tight seating from time to

time.

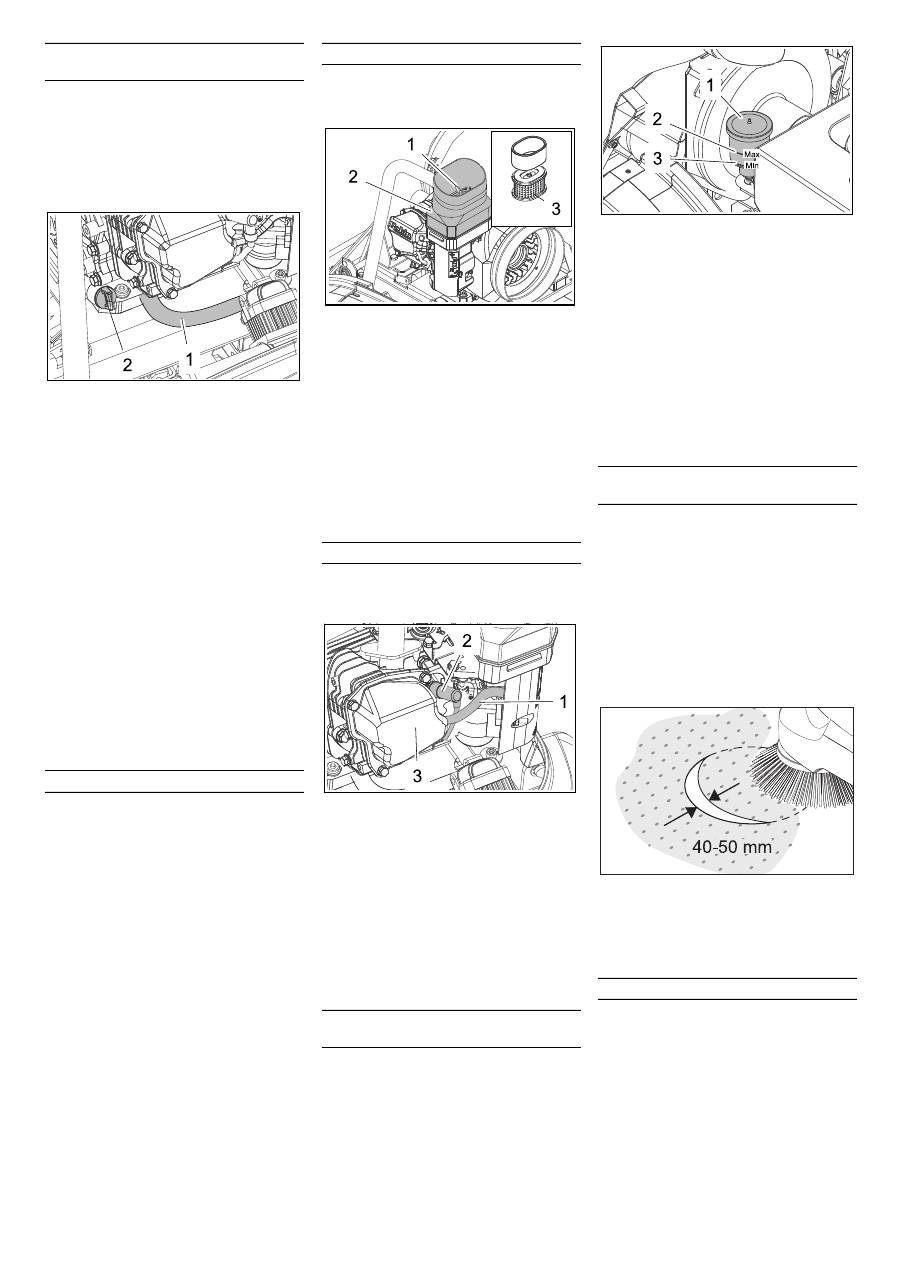

Turn ignition key to "0" and remove it.

Danger

The engine requires approx. 3-4 seconds

to come to a standstill once it has been

switched off. During this time, stay well

clear of the working area.

Open the device hood.

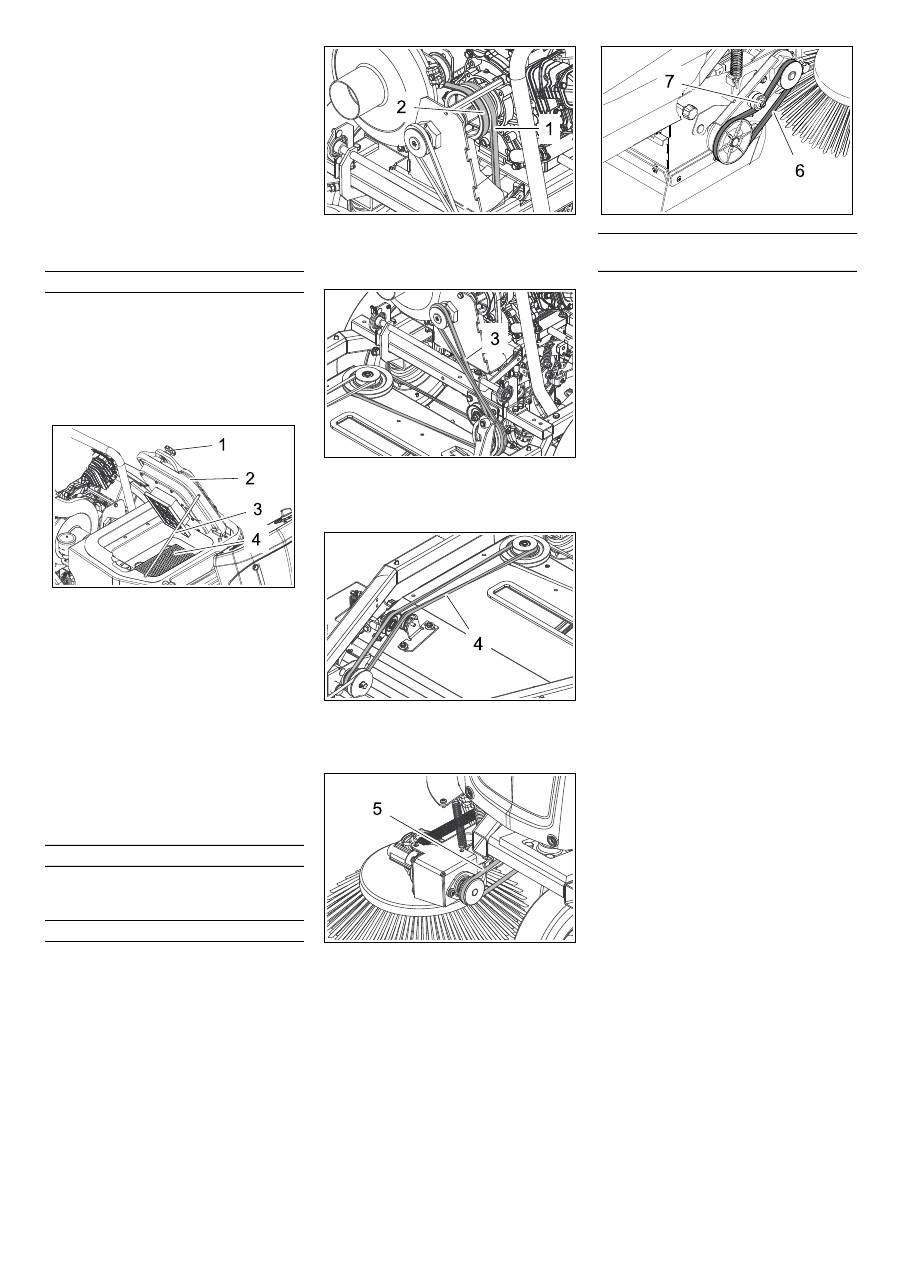

Check the V-belt axle drive (1) and V-

belt suction blower (2) for tension, wear

and damage.

V-belt axle drive (1) and V-belt suction blower (2)

Check drive belt (3) for tension, wear

and damage.

Drive belt (3)

Check drive belt (4) for tension, wear

and damage.

Drive belt (4)

Check circular belt side brush (5) for

tension, wear and damage.

Circular belt side brush (5)

Check V-belt of the roller brush drive (6)

for tension, wear and damage.

Tighten the V-belt at the screw if neces-

sary.

V-belt sweeping drive (6) and screw (7)

The drive control/electronic system is in-

stalled behind the front panel. To replace a

fuse, the front panel must be removed.

Loosen the front panel screws.

Remove front panel.

Replace defective fuses.

Note:

The assignment of fuses is indi-

cated on the inside of the panel. Only

use fuses with identical safety ratings.

Replace front panel.

Check/replace dust filter

Check suction blower

Checking drive belt

Replacing fuses of drive control/ elec-

tronic system

28 EN

Оглавление

- Inhaltsverzeichnis

- Bestimmungsgemäße Ver- wendung

- Bedien- und Funktionselemente

- Vor Inbetriebnahme

- Betrieb

- Stilllegung

- Pflege und Wartung

- Hilfe bei Störungen

- Technische Daten

- EG-Konformitätserklärung

- Contents

- Proper use

- Operating and Functional Elements

- Before Startup

- Operation

- Shutdown

- Maintenance and care

- Troubleshooting

- Technical specifications

- EC Declaration of Conformity

- Table des matières

- Utilisation conforme

- Eléments de commande et de fonction

- Avant la mise en service

- Fonctionnement

- Remisage Entretien et maintenance

- Assistance en cas de panne

- Caractéristiques techniques

- Déclaration de conformité CE

- Indice

- Uso conforme a destinazione

- Elementi di comando e di funzione

- Prima della messa in funzione

- Funzionamento

- Fermo dell'impianto Cura e manutenzione

- Guida alla risoluzione dei guasti

- Dati tecnici

- Dichiarazione di conformità CE

- Inhoudsopgave

- Reglementair gebruik

- Elementen voor de bediening en de functies

- Voor de inbedrijfstelling

- Werking

- Stillegging

- Onderhoud

- Hulp bij storingen

- Technische gegevens

- EG-conformiteitsverklaring

- Índice de contenidos

- Uso previsto

- Elementos de operación y funcionamiento

- Antes de la puesta en marcha

- Funcionamiento

- Parada

- Cuidados y mantenimiento

- Ayuda en caso de avería

- Datos técnicos

- Declaración de conformidad CE

- Índice

- Utilização conforme o fim a que se destina a máquina

- Elementos de comando e de funcionamento

- Antes de colocar em funcionamento

- Funcionamento

- Desactivação da máquina Conservação e manutenção

- Ajuda em caso de avarias

- Dados técnicos

- Declaração de conformidade CE

- Indholdsfortegnelse

- Bestemmelsesmæssig‚ anvendelse

- Betjenings- og funktionselementer

- Inden ibrugtagning

- Drift

- Afbrydning/nedlæggelsePleje og vedligeholdelse

- Hjælp ved fejl

- Tekniske data

- EU-overensstemmelseser- klæring

- Innholdsfortegnelse

- Forskriftsmessig bruk

- Betjenings- og funksjonelementer

- Før den tas i bruk

- Drift

- Sette bort

- Pleie og vedlikehold

- Feilretting

- Tekniske data

- EU-samsvarserklæring

- Innehållsförteckning

- Ändamålsenlig användning

- Manövrerings- och funktionselement

- Före ibruktagande

- Drift

- Nedstängning Skötsel och underhåll

- Åtgärder vid störningar

- Tekniska data

- Försäkran om EU-överens- stämmelse

- Sisällysluettelo

- Käyttötarkoitus

- Ohjaus- ja käyttölaitteet

- Ennen käyttöönottoa

- Käyttö

- Seisonta-aika

- Hoito ja huolto

- Häiriöapu

- Tekniset tiedot

- EU-standardinmukaisuusto- distus

- Πίνακας περιεχομένων

- Χρήση σύμφωνα με τους κανονισμούς

- Στοιχεία χειρισμού και λειτουργίας

- Πριν τη θέση σε λειτουργία

- Λειτουργία

- Διακοπή της λειτουργίας Φροντίδα και συντήρηση

- Αντιμετώπιση βλαβών

- Τεχνικά χαρακτηριστικά

- Δήλωση Συμμόρφωσης των Ε . Κ .

- İ çindekiler

- Kurallara uygun kullan ı m

- Kullan ı m ve çal ı ş ma elemanlar ı

- Cihaz ı çal ı ş t ı rmaya ba ş lamadan önce

- Çal ı ş t ı rma

- Durdurma

- Koruma ve Bak ı m

- Ar ı zalarda yard ı m

- Teknik Bilgiler

- AB uygunluk bildirisi

- Оглавление

- Использование по назначению

- Описание элементов управления и рабочих узлов

- Перед началом работы

- Эксплуатация

- Вывод из эксплуатации Уход и техническое обслуживание

- Помощь в случае неполадок

- Технические данные

- Заявление о соответствии ЕС

- Tartalomjegyzék

- Rendeltetésszer ű használat

- Kezelési- és funkciós elemek

- Üzembevétel el ő tt

- Üzem

- Leállítás

- Ápolás és karbantartás

- Segítség üzemzavar esetén

- M ű szaki adatok

- EK konformitási nyiltakozat

- Obsah

- Používání v souladu s ur č ením

- Ovládací a funk č ní prvky

- P ř ed uvedením do provozu

- Provoz

- Odstavení

- Ošet ř ování a údržba

- Pomoc p ř i poruchách

- Technické údaje

- Prohlášení o shod ě pro ES

- Vsebinsko kazalo

- Namenska uporaba

- Upravljalni in funkcijski elementi

- Pred zagonom

- Obratovanje

- Mirovanje naprave

- Nega in vzdrževanje

- Pomo č pri motnjah

- Tehni č ni podatki

- ES-izjava o skladnosti

- Spis tre ś ci

- U ż ytkowanie zgodne z przeznaczeniem

- Elementy urz ą dzenia

- Przed pierwszym uruchomieniem

- Dzia ł anie

- Wy łą czenie z eksploatacji Czyszczenie i konserwacja

- Usuwanie usterek

- Dane techniczne

- Deklaracja zgodno ś ci UE

- Cuprins

- Utilizarea corect ă

- Elemente de utilizare ş i func ţ ionale

- Înainte de punerea în func ţ iune

- Func ţ ionarea

- Scoaterea din func ţ iune

- Îngrijirea ş i între ţ inerea

- Remedierea defec ţ iunilor

- Date tehnice

- Declara ţ ie de conformitate CE

- Obsah

- Používanie výrobku v súlade s jeho ur č ením

- Ovládacie a funk č né prvky

- Pred uvedením do prevádzky

- Prevádzka

- Odstavenie

- Starostlivos ť a údržba

- Pomoc pri poruchách

- Technické údaje

- Vyhlásenie o zhode s normami EÚ

- Pregled sadržaja

- Namjensko korištenje

- Komandni i funkcijski elementi

- Prije prve uporabe

- U radu

- Stavljanje ure đ aja van pogo- na

- Njega i održavanje

- Otklanjanje smetnji

- Tehni č ki podaci

- EZ izjava o uskla đ enosti

- Pregled sadržaja

- Namensko koriš ć enje

- Komandni i funkcioni elementi

- Pre upotrebe

- Rad

- Stavljanje ure đ aja van pogona Nega i održavanje

- Otklanjanje smetnji

- Tehni č ki podaci

- Izjava o uskla đ enosti sa propisima EZ

- Съдържание

- Употреба по предназначение

- Обслужващи и функционални елементи

- Преди пускане в експлоатация

- Експлоатация

- Спиране от експлоатация Грижи и поддръжка

- Помощ при неизправности

- Технически данни

- Декларация за съответствие на ЕО

- Sisukord

- Sihipärane kasutamine

- Teenindus- ja funktsioonielemendid

- Enne seadme kasutuselevõttu

- Käitamine

- Seismapanek

- Korrashoid ja tehnohooldus

- Abi häirete korral

- Tehnilised andmed

- EÜ vastavusdeklaratsioon

- Satura r ā d ī t ā js

- Noteikumiem atbilstoša lietošana

- Vad ī bas un funkcijas elementi

- Pirms ekspluat ā cijas uzs ā kšanas

- Darb ī ba

- Iekonserv ē šana

- Kopšana un tehnisk ā apkope

- Pal ī dz ī ba darb ī bas trauc ē jumu gad ī jum ā

- Tehniskie dati

- EK Atbilst ī bas deklar ā cija

- Turinys

- Naudojimas pagal paskirt į

- Valdymo ir funkciniai elementai

- Prieš pradedant naudoti

- Naudojimas

- Laikinas prietaiso nenaudojimas

- Prieži ū ra ir aptarnavimas

- Pagalba gedim ų atveju

- Techniniai duomenys

- EB atitikties deklaracija

- Перелік

- Правильне застосування

- Елементи управління і функціональні вузли

- Перед початком роботи

- Експлуатація

- Зберігання Догляд та технічне обслуговування

- Допомога у випадку неполадок

- Технічні характеристики

- Заява при відповідність Європейського співтовариства