Karcher B 60 W Bp Pack – страница 2

Инструкция к Пылесосу Karcher B 60 W Bp Pack

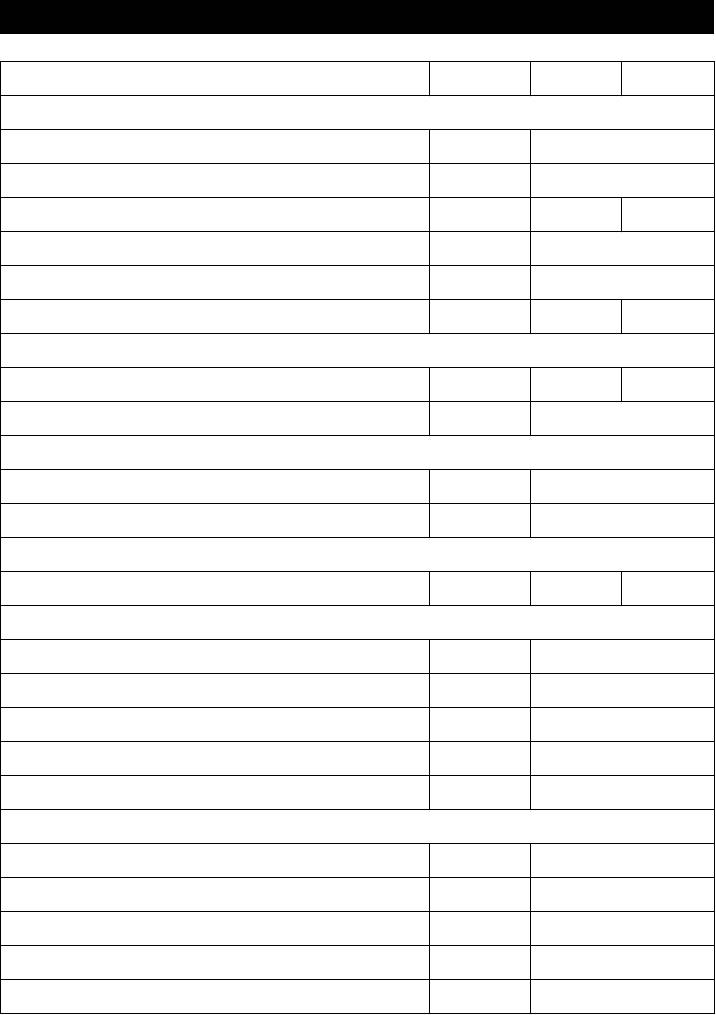

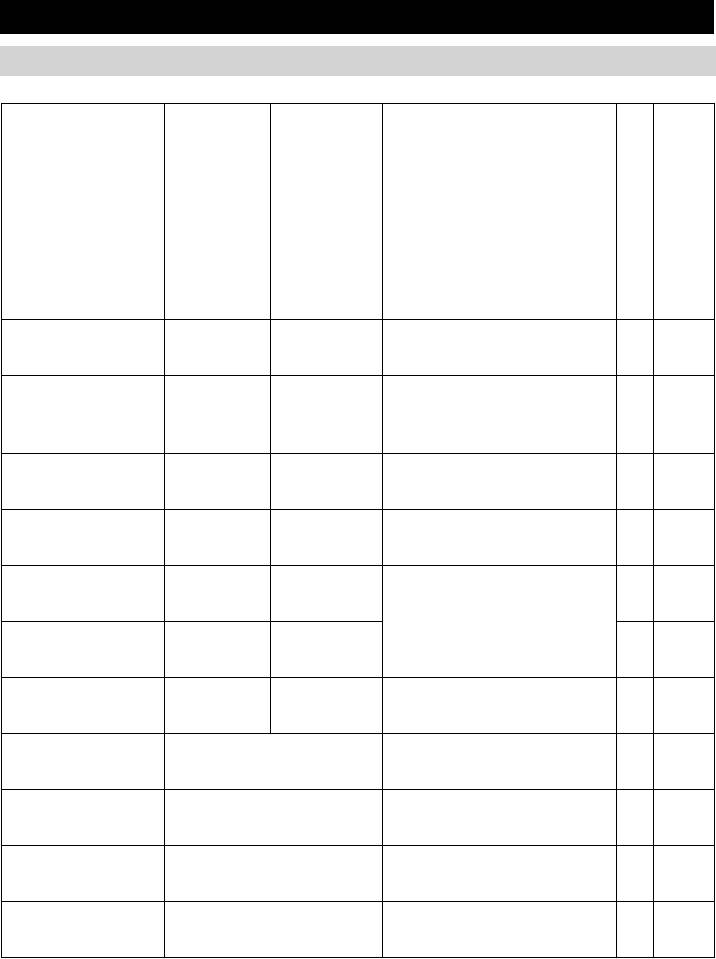

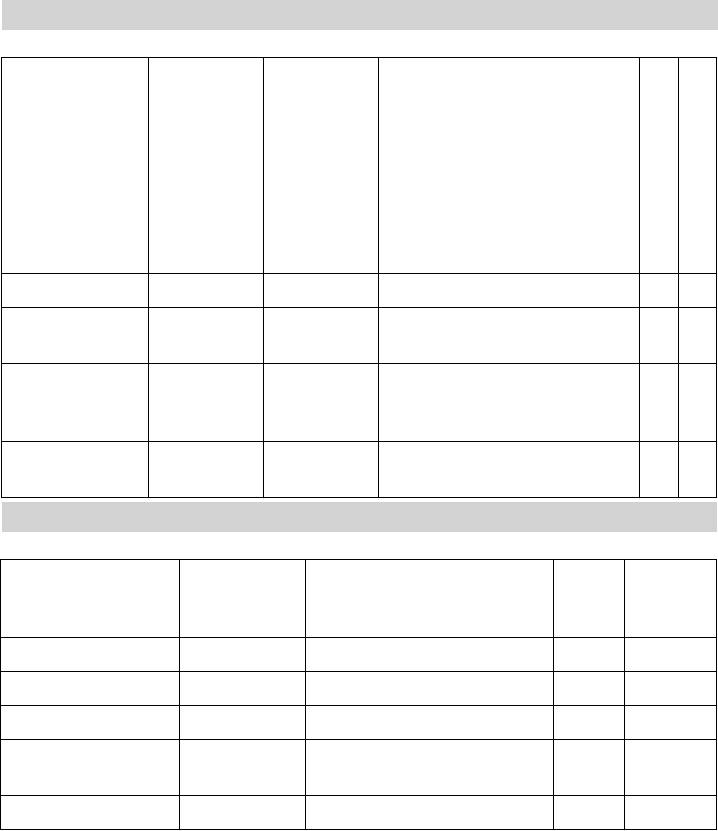

Technische Daten

BR BD

Leistung

Nennspannung V 24

Batteriekapazität Ah (5h) max. 180/205

Mittlere Leistungsaufnahme W 1900 1500

Fahrmotorleistung (Nennleistung) W 200

Saugmotorleistung W 500

Bürstmotorleistung W 2x 600 1x 800

Sicherungen

F1 (Hauptsicherung) A 125 150

F2 (Steuerung) A 3

Saugen

Saugleistung, Luftmenge l/s 22

Saugleistung, Unterdruck kPa 11,5

Reinigungsbürsten

Bürstendrehzahl 1/min 1350 180

Maße und Gewichte

Theoretische Flächenleistung m²/h 2475

Volumen Frisch-/Schmutzwassertank l 60/55

max. Wassertemperatur °C 60

Transportgewicht kg 235

Gesamtgewicht kg (295) 300*

Ermittelte Werte gemäß EN 60335-2-72

2

Schwingungsgesamtwert m/s

<2,5

2

Unsicherheit K m/s

0,2

Schalldruckpegel L

pA

dB(A) 72

Unsicherheit K

pA

dB(A) 1

Schallleistungspegel L

WA

+ Unsicherheit K

WA

dB(A) 91

* Package-Geräte

– 19

21DE

CE-Erklärung

Garantie

Hiermit erklären wir, dass die nachfolgend

In jedem Land gelten die von unserer zu-

bezeichnete Maschine aufgrund ihrer Kon-

ständigen Vertriebsgesellschaft herausge-

zipierung und Bauart sowie in der von uns

gebenen Garantiebedingungen. Etwaige

in Verkehr gebrachten Ausführung den ein-

Störungen an Ihrem Zubehör beseitigen wir

schlägigen grundlegenden Sicherheits-

innerhalb der Garantiefrist kostenlos, so-

und Gesundheitsanforderungen der EG-

fern ein Material- oder Herstellungsfehler

Richtlinien entspricht. Bei einer nicht mit

die Ursache sein sollte. Im Garantiefall

uns abgestimmten Änderung der Maschine

wenden Sie sich bitte mit Kaufbeleg an Ih-

verliert diese Erklärung ihre Gültigkeit.

ren Händler oder die nächste autorisierte

Kundendienststelle.

Produkt: Bodenreiniger

Typ: 1.384-xxx

Ersatzteile

Einschlägige EG-Richtlinien

2006/42/EG (+2009/127/EG)

– Es dürfen nur Zubehör und Ersatzteile

2004/108/EG

verwendet werden, die vom Hersteller

Angewandte harmonisierte Normen

freigegeben sind. Original-Zubehör und

EN 55014–1: 2006

Original-Ersatzteile bieten die Gewähr

EN 55014–2: 1997 + A1: 2001

dafür, dass das Gerät sicher und stö-

EN 60335–1

rungsfrei betrieben werden kann.

EN 60335–2–29

– Eine Auswahl der am häufigsten benö-

EN 60335–2–72

EN 61000–3–2: 2006 + A2: 2009

tigten Ersatzteile finden Sie am Ende

EN 61000–3–3: 2008

der Betriebsanleitung.

Angewandte nationale Normen

– Weitere Informationen über Ersatzteile

-

erhalten Sie unter www.kaercher.com

im Bereich Service.

Die Unterzeichnenden handeln im Auftrag

und mit Vollmacht der Geschäftsführung.

CEO

Head of Approbation

Dokumentationsbevollmächtigter:

S. Reiser

Alfred Kärcher GmbH & Co. KG

Alfred-Kärcher-Str. 28 - 40

71364 Winnenden (Germany)

Tel.: +49 7195 14-0

Fax: +49 7195 14-2212

Winnenden, 2010/07/14

22 DE

– 20

Please read and comply with

Safety Devices

these original instructions prior

English

to the initial operation of your appliance and

Safety devices serve to protect the user

store them for later use or subsequent own-

and must not be rendered inoperational or

ers.

their functions bypassed.

Emergency-stop button

Contents

To put all functions out of operation imme-

diately.

Safety instructions EN - 1

Function EN - 1

Symbols in the operating instruc-

Proper use EN - 2

tions

Environmental protection EN - 2

Danger

Operating and Functional El-

EN - 3

Immediate danger that can cause severe

ements

injury or even death.

Before Startup EN - 5

몇 Warning

Operation EN - 6

Possible hazardous situation that could

Shutting Down the Appliance EN - 10

lead to severe injury or even death.

Transport EN - 11

Caution

Storage EN - 11

Possible hazardous situation that could

Maintenance and care EN - 11

lead to mild injury to persons or damage to

property.

Faults EN - 15

Accessories EN - 16

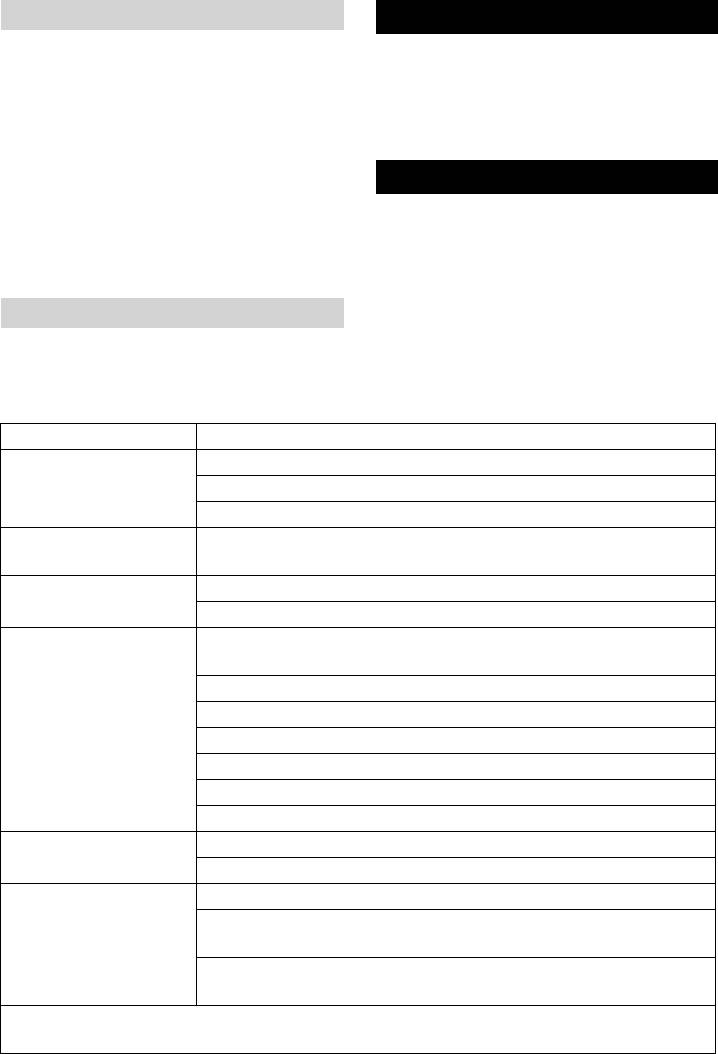

Symbols on the machine

Technical specifications EN - 18

CE declaration EN - 19

Warranty EN - 19

Spare parts EN - 19

Risk of injury on account of being crushed.

Safety instructions

Hold the tank only in this area while tilting

downward.

Before using the appliance for the first time,

read and observe these operating instruc-

Function

tions and the accompanying brochure:

The scrubber vacuum is used for wet clean-

Safety information for brush cleaning units

ing or polishing of level floors.

and spray-extraction units, No. 5.956-251.

– It can be easily adjusted to suit the re-

The machine has been approved for use on

quired cleaning task by adjusting the

surfaces with gradients of up to 2%.

water quantity, the contact pressure of

While working at place with an upward/

the brushes and the waste water suc-

downward inclination between 2 - 10%, the

tion.

attachment set (ABS) for additional brake

– A working width of 550 mm and a ca-

2.640-376 must have been installed for

pacity of 60 l each of the fresh and 55 l

your own safety.

of the dirt water reservoirs enable an ef-

The appliance may only be operated

fective cleaning when the machine is to

when the hood and all lids are closed.

be used for a longer period of time.

During operations, the key switch

– The device is self-moving; the drive mo-

should not have been set to "O“. Press

tor is feed by four batteries.

emergency stop button in case of dan-

ger.

– 1

23EN

– The batteries can be charged using a

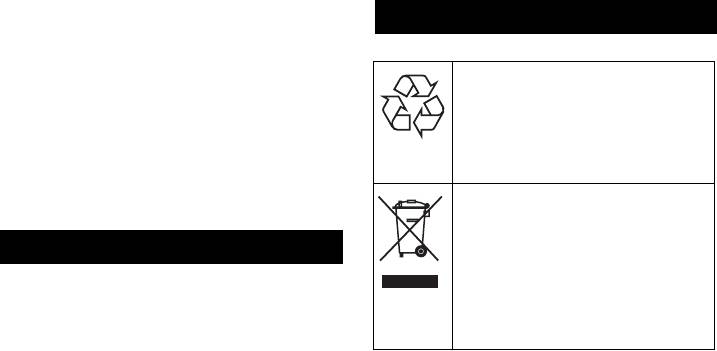

Environmental protection

charger connected to a 230 V socket.

– Depending on the package type, bat-

tery and charger are already integrated.

The packaging materials are

Note

recyclable. Please do not throw

packaging in the domestic

The appliance can be equipped with vari-

waste but pass it on for recy-

ous accessories depending on the cleaning

cling.

task.

Please request our catalogue or visit us on

Old units contain valuable recy-

the Internet at www.kaercher.com.

clable materials. Batteries, oil

and similar substances may

Proper use

not be released into the envi-

Use this appliance only as directed in these

ronment. Therefore please dis-

operating instructions.

pose of old units through

– The appliance may only be used for the

suitable collection systems.

cleaning of hard surfaces that are not

Notes about the ingredients (REACH)

sensitive to moisture and polishing op-

You will find current information about the

erations.

ingredients at:

– The appliance is not suited for the

http://www.karcher.de/de/unternehmen/

cleaning of frozen grounds (e.g. in cold

umweltschutz/REACH.htm

stores).

– The appliance may only be equipped

with original accessories and spare

parts.

– The appliance is not suited for the use

in potentially explosive environments.

– The machine should not be used to

suck in inflammable gases, undiluted

acids or solvents.

This includes petrol, thinning agents or

hot oil that can form an explosive mix-

ture when it comes in contact with

sucked air. Do not use acetone, undi-

luted acids and solvents as they are ag-

gressive towards the materials from

which the appliance is made.

– The machine has been approved for

use on surfaces with gradients of up to

2%.

While working at place with an upward/

downward inclination between 2 - 10%,

the attachment set (ABS) for additional

brake 2.640-376.0 must have been in-

stalled for your own safety.

24 EN

– 2

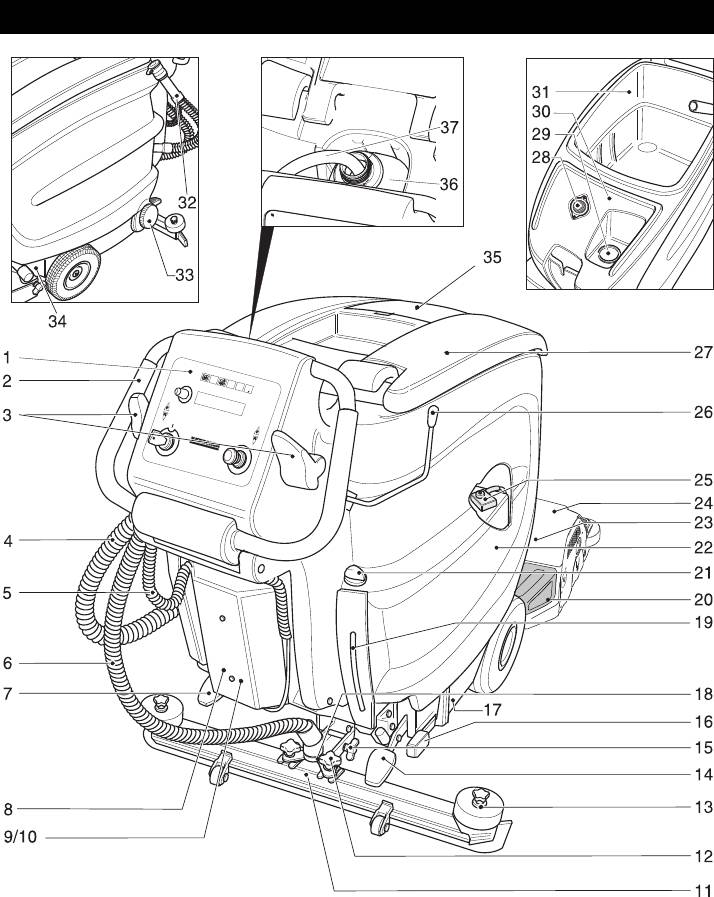

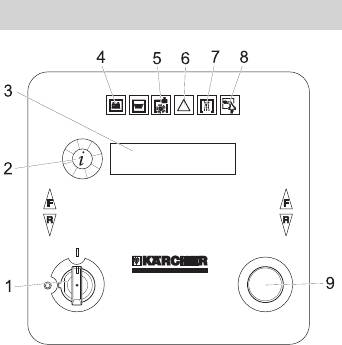

Operating and Functional Elements

1 Operator console

7 Pedal for operating the parking brake

2 Push handle

(Optional)

3 Driving lever

8 Charger (only Pack model)

4 Dirt water discharge hose

9 Electronics and fuses

5 Connecting cable for charger (only

10 Screws of electronics cabinet cover

Pack model)

11 Vacuum bar *

6 Suction hose

– 3

25EN

12 Cross handles for fastening the vacuum

Operator console

bar

13 Cross-handles for replacing the vacu-

um lips

14 Pedal for raising/ lowering the cleaning

head

15 Wing nuts for tilting the vacuum bar

16 Level for adjusting the brush contact

pressure

17 Nameplate

18 Vacuum bar suspension

19 Fresh water level display

20 Waste container (only BR)

21 Water quantity regulator

22 Battery (only package model)

23 Brush rollers (BR model) Disk brushes

1 Key switch

(BD model) *

2 Info button

24 Cleaning head *

3 Display for

25 Main fuse F1

– Battery status

26 Vacuum bar lowering lever

- Cleaning speed

27 Cover dirt water reservoir

- Brush speed

28 Fluff filter

- WDB function

29 Filling nozzle for fresh water tank

– Operating hours

30 Fresh water tank

– Speed

31 Dirt water reservoir

- Detergent dosing (only Dose model)

32 Dosing equipment for dirt water

– Manufacturer

33 Fresh water tank lock

– Programme version

34 Locking the tank

4 Indicator lamp (red), lights up when the

35 Lid of air channel (installed firmly; can

batteries are discharged

only be removed by an expert)

5 Indicator lamp (red), lights up when the

36 2.5 l detergent bottle *

detergent bottle is empty (only Dose

37 Suction hose for detergent (only Dose

model)

model)

6 Indicator lamp (red), lights up when the

brushes are overloaded

* not included in the delivery

7 Indicator lamp (green), lights up when

the water is added

8 Indicator lamp (green), lights up when

vacuum is on

9 Emergency-stop button (turn to re-

lease)

26 EN

– 4

Drive the machine directly to the charg-

Charger (only Pack model)

ing station; avoid any steep gradients in

the process.

Note

While using other batteries (for e.g. batter-

ies from other manufacturers) the total dis-

charge protection level must be reset by the

Kärcher aftersales service according to the

respective battery.

1 red LED lights up = Problem with charg-

Danger

er/ battery; inform Customer Service

Risk of electric shock. Observe supply net-

2 green LED lights up = batteries are full

work and fuse protection - see "Charger".

3 yellow LED lights up = batteries are be-

Only use the charger in dry rooms with suf-

ing charged

ficient ventilation!

Before Startup

Note

Average charging time is approx. 10 -15

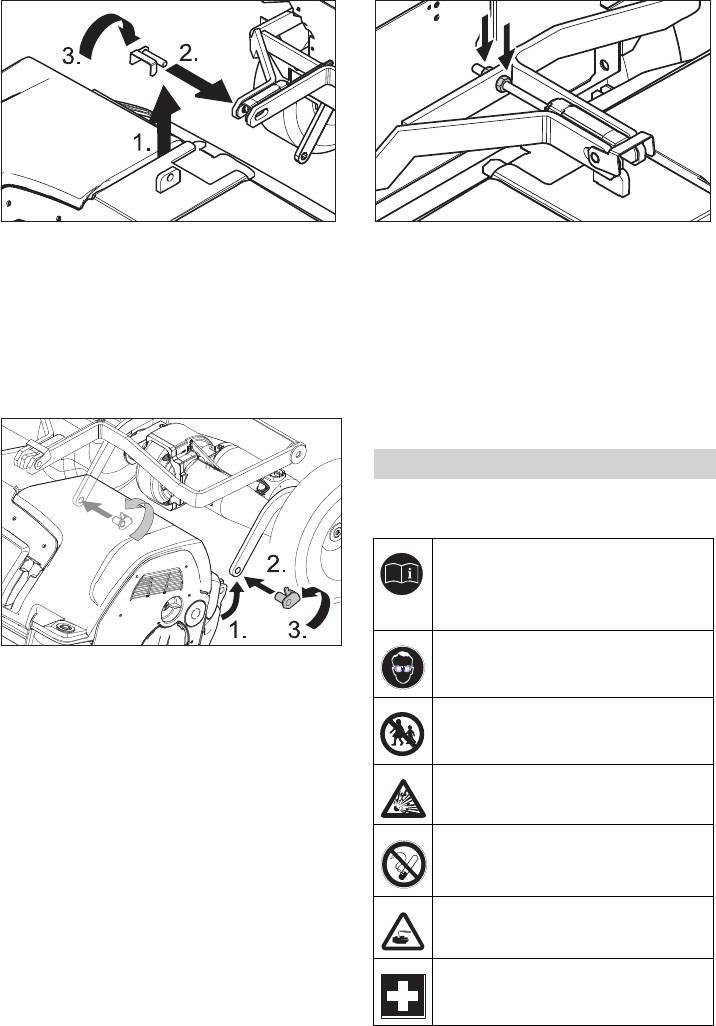

Installing the Brushes

hours.

The recommended chargers (matching the

BD model

batteries used) are regulated electronically

The sweep brushes must be installed be-

and will automatically switch off the charg-

fore the initial operation (see "Maintenance

ing process.

work").

All functions of the machine are automati-

BR model

cally interrupted during the charging proc-

The brushes are mounted.

ess.

Install batteries

Charging procedure for Pack model

Insert the plug of the connecting cable

The "Pack" model contains built-in batter-

into the socket.

ies.

With the other models, the batteries must

Charging process without integrated

be installed (see "Care and Maintenance /

charger

Installing and Connecting Batteries").

Empty the dirt and fresh water tank.

Loosen the tank lock and tilt the tank

Charging battery

upwards.

Danger

Remove battery plug and join it to the

Danger of explosion. Wet batteries can

charging cable.

only be charged with opened hood.

Connect the charger to the mains and

turn it on.

Note

The device is equipped with a safety mech-

Low maintenance batteries (wet batter-

anism to prevent total discharge, i.e. when

ies)

the permissible minimum capacity is

Add distilled water one hour before the

reached, then the brush motors and the tur-

charging process comes to an end; fol-

bine are switched off. In such a case, the

low the correct acid level. There are

battery status display on the control con-

corresponding indicators on the battery.

sole glows red. From this moment onwards,

몇 Warning

only driving mechanism is possible.

Danger of causticization!

– 5

27EN

– Adding water to the battery in its dis-

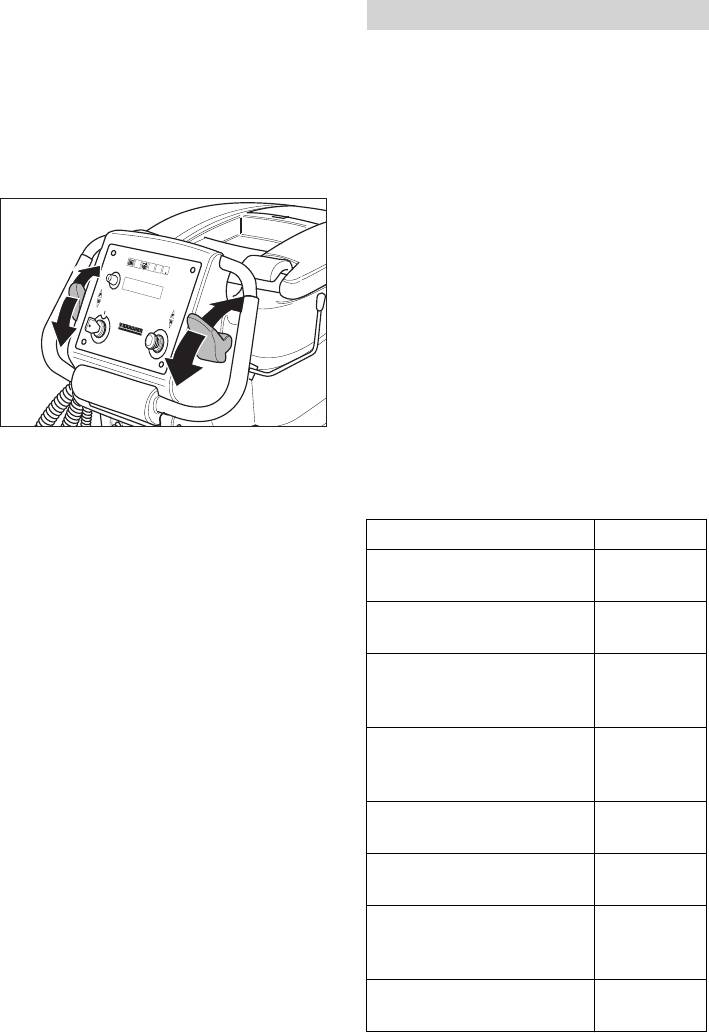

Place long lateral boards of the packag-

charged state can cause the acid to

ing as a ramp next to the pallet.

leak.

– Use safety glasses while handling bat-

tery acid and follow the safety instruc-

tions to avoid personal injury or damage

to clothes.

– Should the acid spray on to the skin or

clothes, rinse immediately with lots of

water.

Caution

Risk of damage!

– Use only distilled or desalinated water

(EN 50272-T3) for filling the battery.

Fix the ramp on the pallet with nails.

– Do not add any substances (so-called

Place short boards as a support under-

performance improving agents), else

neath the ramp.

warranty claims will not be entertained.

Remove the wooden bars in front of the

몇 Warning

wheels.

Only use maintenance-free batteries while

Lift cleaning head with pedal and re-

replacing batteries in package appliances.

move the carton packing.

Set main switch to “1”.

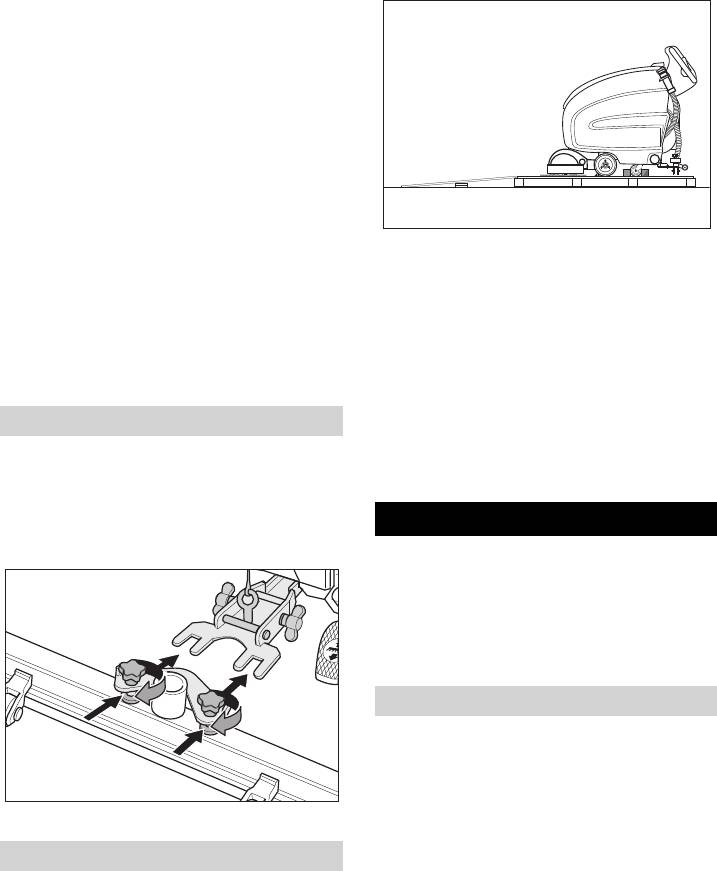

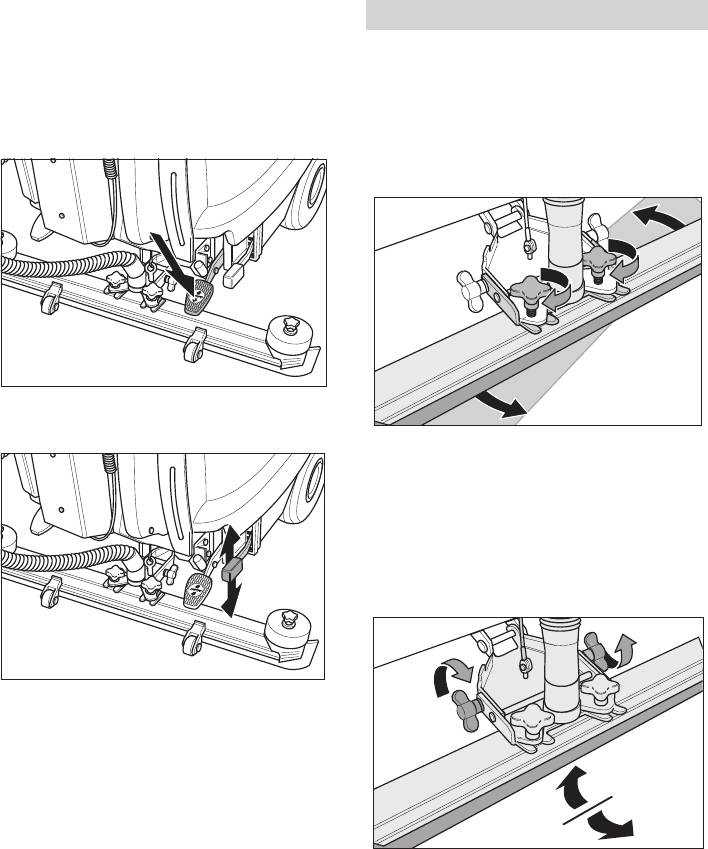

Installing the Vacuum Bar

Press the driving lever and slowly move

Insert the vacuum bar into the vacuum

the machine down from the ramp.

bar suspension in such a manner that

Set main switch to “0”.

the profiled sheet is positioned above

the suspension.

Operation

Tighten the cross-handles.

Danger

Risk of injury. Press on the foot pedal only

with one foot. The other foot must firmly be

placed on the floor. Press emergency-stop

switch to immediately switch off all func-

tions of the machine.

Driving

Caution

Risk of damage. The vacuum bar must be

liften to move in reverse direction.

Note

Insert the suction hose.

The machine is designed in such a way that

Unloading

the brush head protrudes on the right. This

helps in working in a proper way even close

Danger

to the edges.

Risk of injury. Press emergency-stop

Release emergency-stop button by

switch to immediately switch off all func-

turning.

tions of the machine.

Insert key in key switch at the operator

Insert batteries and connect (see "Be-

console and turn to "1".

fore Start-up").

28 EN

– 6

Release parking brake (optional); move

Filling in detergents

the pedal downward and turn to the left.

Then let the pedal move upwards.

Fresh water

Drive the machine.

Open cover.

Forwards:

Fill fresh water (maximum 60 °C) until

Press the driving lever to the front.

the lower edge of the filling nozzle.

Backward:

Close the lid.

Press the driving lever to the rear.

Detergent

몇 Warning

Risk of damage. Only use the recommend-

ed detergents. With respect to different de-

tergents the operator bears the increased

risk regarding the operational safety and

danger of accident.

Only use detergents that are free from sol-

vents, hydrochloric acid and hydrofluoric

acid.

Follow the safety instructions for using de-

tergents.

Note

Note

The machine moves only when the driving

Do not use highly foaming detergents.

lever is moved by 15°.

Recommended detergents:

Set the working speed.

Application Detergent

– Forwards:

Turn the info button clockwise until

Routine cleaning of all wa-

RM 745

"CleanSpd Fwd=xxx%" is displayed.

ter resistant floors

RM 746

– Backward:

Routine cleaning of glossy

RM 755 es

Turn the info button clockwise until

surfaces (e.g. granite)

"CleanSpd Rev=xxx%" is displayed.

Routine cleaning and ba-

RM 69 ASF

sic cleaning of industrial

Note

floors

If the info button is not pressed for 10 sec-

Routine cleaning and ba-

RM 753

onds the display toggles to the battery dis-

sic cleaning of fine stone-

play.

ware tiles

– Shortly press the info button - display

Routine cleaning of tiles in

RM 751

blinks.

sanitary areas

– Set the speed by turning the info button.

The value can be set in increments of

Cleaning and disinfection

RM 732

10% between 30% and 100%.

in sanitary areas

– Press the info button to confirm the set

Removal of coating from

RM 752

value.

all alkali-resistant floors

Stop the machine: Release driving le-

(e.g. PVC)

ver.

Removal of coating from li-

RM 754

noleum floors

– 7

29EN

Model with dosing equipment "Dose"

Adjust detergent dose

Detergent is added to the fresh water on

Turn the info button clockwise until "RM

the way to the cleaning head with the help

- Dosierung“ or "RM - Dosing" is dis-

of a dosaging device.

played.

Shortly press the info button - display

Note

blinks.

The metering device can be used to add

Adjust the detergent dose by turning the

3% of detergent at maximum. In case of a

info button (0.5% to 3%).

higher dose the detergent must be poured

Press the info button to confirm the set

into the fresh water tank.

value.

Place the bottle with the detergent in

Note

the holder behind the operator console.

If no water is to be added to the detergent,

Close the bottle lid.

then the dosing must be set to 0%.

Insert the suction hose of the dosaging

equipment into the bottle.

Lower the vacuum bar

Turn the lever downwards; the vacuum

Note

bar is lowered and the suction turbine is

If the fresh water tank is empty, then the

switched on.

function of adding detergent gets deactivat-

ed. The cleaning head continues to work

without the addition of any liquid. Detergent

addition is also stopped when the detergent

can is empty.

Models without dosing equipment Dose

Add the detergent to the fresh water

reservoir.

Settings

Setting the water quantity

Adjust the water quantity using the reg-

Note

ulating button according to the dirt on

For cleaning tiled floors, set the straight

the floor covering.

vacuum bar in such a way that cleaning is

done at right angles to the joints.

The inclined position and the inclination of

the vacuum bar can be adjusted to achieve

better suction results (see "Setting the Vac-

uum Bar").

Setting the brush speed

Turn the info button clockwise until

"FACT" is displayed.

Shortly press the info button - display

blinks.

Set the brush speed by turning the info

button.

Note

– "...Power" - high speed (100%).

Carry out the initial cleaning attempts with

– "...Whisper" - medium speed (60%).

little quantities of water. Increase water

– "...Fine" - low speed (40%).

quantity step-by-step until the desired

Press the info button to confirm the set

cleaning result is achieved.

value.

30 EN

– 8

requirements until the desired polishing re-

Switching on the cleaning head

sult is achieved.

Caution

Risk of damage to the floor covering. Do

Setting the Vacuum Bar

not operate the appliance on the spot.

Oblique position

Press the pedal downwards; move it to

To improve the vacuuming result on tiled

the left and release it upward. The

floors the vacuum bar can be turned to an

cleaning head is lowered and the brush

oblique position of up to 5°.

motor starts automatically.

Loosen cross-handles.

Turn the vacuum bar.

Adjust brush contact pressure at the le-

ver.

Tighten the cross-handles.

Inclination

If the vacuum result is unsatisfactory the in-

clination of the straight vacuum bar can be

modified.

Release the wing nuts.

Tilt the vacuum bar.

Note

Carry out the initial cleaning attempts with

less contact pressure. Increase contact

pressure step-by-step until the desired

cleaning result is achieved. A correct set-

ting of the contact pressure reduces power

consumption and the wear and tear of the

brushes.

Tighten the wing nuts.

The brush motors come to a halt when the

machine stops and when there is overload.

Caution

Floors can get damaged on account of too

high contact pressure. Carry out the initial

polishing attempts with less contact pres-

sure. Increase the contact pressure as per

– 9

31EN

Set the key switch at the operator con-

Turning on/off WDB

sole to "0" and remove the key.

This function is required for operating the

Charge battery, if required.

spray suction attachment (accessory).

Drain off dirt water

Turn the info button clockwise until

"WDB-Funktion" or "WDB-Function" is

몇 Warning

displayed.

Please observe the local provisions regard-

Shortly press the info button.

ing the wastewater treatment.

Select "ON" or "OFF" by turning the info

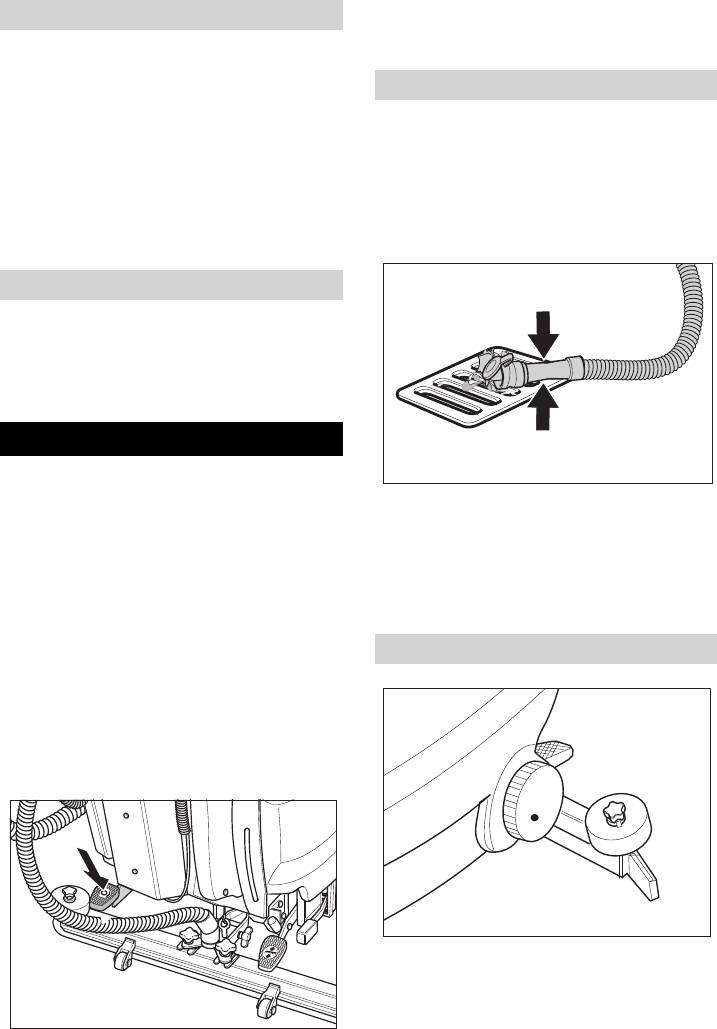

Take the water discharge hose from the

button.

support and lower above a suited col-

Press the info button to confirm the set

lection device.

value.

Stand-by

If the operational break exceeds 30 min-

utes, the machine goes into stand-by

mode. To restart the machine, turn the key

switch briefly to "0" and then turn it again to

"1".

Shutting Down the Appliance

Close the regulatory button for setting

the water quantity.

Crush or bend the dosing equipment.

Release driving lever.

Open the lid of the dosing equipment.

Lift the cleaning head.

Drain off the dirt water - regulate the wa-

Briefly drive forward and suck of the re-

ter quantity by pressing or bending.

maining water.

Rinse the dirt water tank with clear wa-

Raise the vacuum bar.

ter.

The suction turbine will continue to run

Drain off clean water

for 5 more seconds to suck off residual

water from the vacuum bar and the vac-

uum hose.

Apply parking brake (optional). Press

the pedal downwards and move it to the

right to lock it.

Loosen the lid for emptying the fresh

water - do not remove it fully. Drain wa-

ter.

Remove the lid with washer fully to

rinse off the fresh water tank.

32 EN

– 10

Check the fluff filter, clean if required

Transport

Only BR model: Remove bulk waste

Danger

container and empty it.

Clean the vacuum lips and the wiping

Risk of injury! When loading or unloading

lips, check for wear and replace if re-

the machine, it may only be operated on

quired.

gradients of max. 10%. Drive slowly.

Check the brushes for wear, replace if

Caution

required.

Risk of injury and damage! Observe the

weight of the appliance when you transport

Monthly

it.

Check battery pole for oxidation; brush

Raise the cleaning head to avoid dam-

it if required and lubricate it using pole

age to the brushes.

grease. Ensure that the connection ca-

Remove the brush to avoid damage to

ble sits firmly.

the brushes.

Check the function of the immobilizing

Apply parking brake (optional).

brake (optional).

When transporting in vehicles, secure

Clean the seals between dirt water res-

the appliance according to the guide-

ervoir and cover and check for tight-

lines from slipping and tipping over.

ness, replace if required.

Check the acid density of the cells if the

Storage

batteries are not maintenance-free bat-

teries.

Caution

Clean the brush tunnel (only BR mod-

Risk of injury and damage! Note the weight

el).

of the appliance in case of storage.

This appliance must only be stored in inte-

Yearly

rior rooms.

Have the prescribed inspection carried

out by the customer service.

Maintenance and care

Maintenance Works

Danger

Risk of injury! Before carrying out any tasks

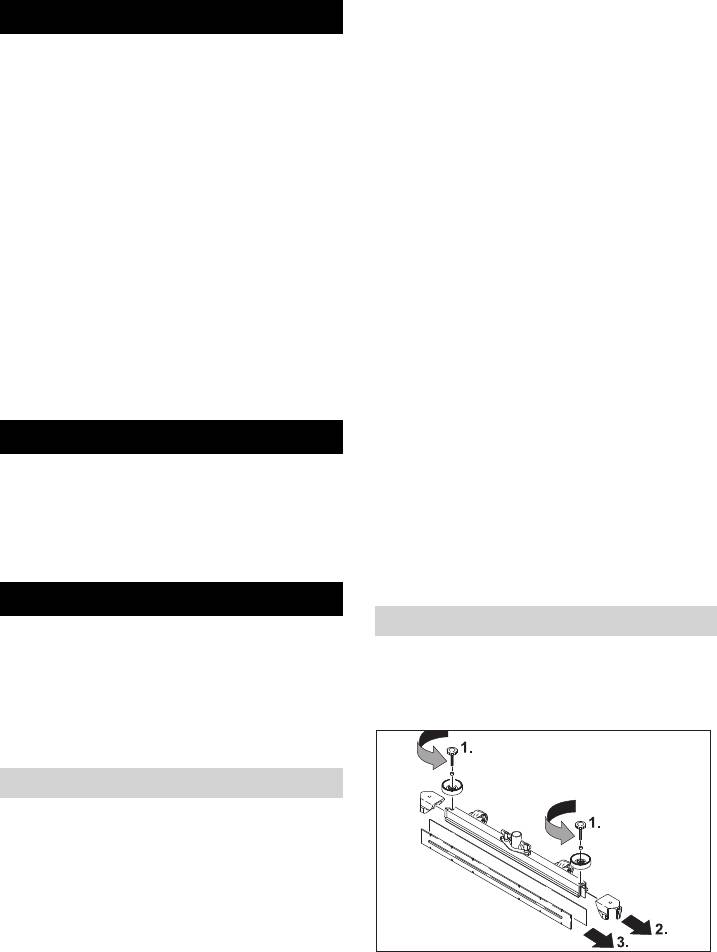

Replace or turn vacuum lips

on the machine, set the main key to "0" and

Remove the vacuum bar.

remove key and plug of the charger.

Unscrew the star grips.

Drain and dispose of the dirt water and

the residual fresh water.

Maintenance schedule

After each operation

Caution

Risk of damage. Do not wash down the ap-

pliance with water and do not use aggres-

sive detergents.

Drain off dirt water.

Rinse the dirt water tank with clear wa-

Remove the plastic parts.

ter.

Remove the vacuum lips.

Clean the outside of the appliance with

Insert new vacuum lips.

a damp cloth which has been soaked in

Insert the plastic parts.

mild detergent.

Screw in and tighten the star grips.

– 11

33EN

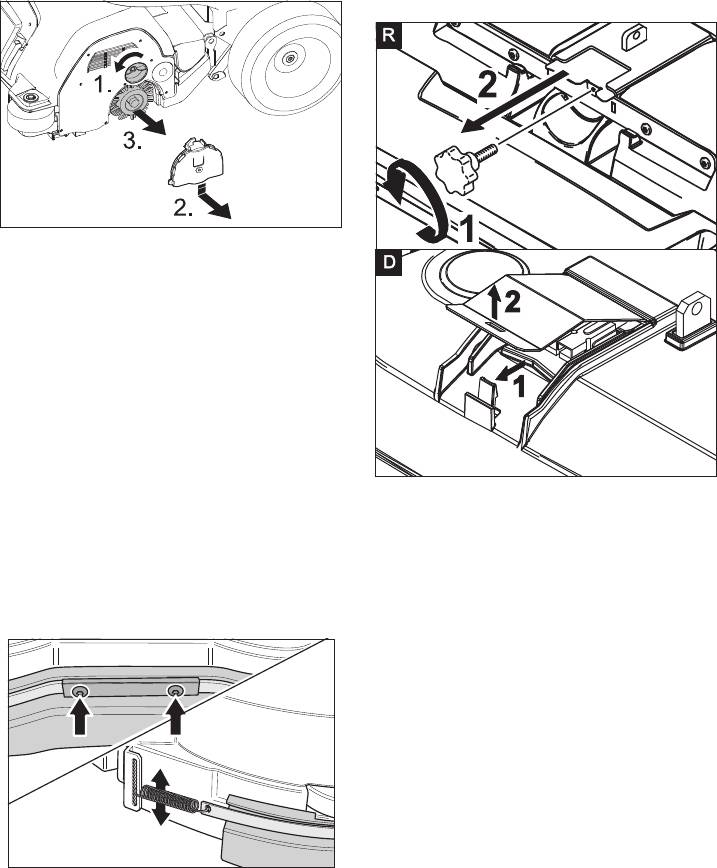

Replacing the brush rollers

Install cleaning head

Lift the cleaning head.

Release the screw for locking the tank

and swing up the tank.

Loosen the lock of the wiper flap.

Push the bearing lid down and remove.

Pull out the brush roller.

Insert a new brush roller.

Reassemble the bearing lid in the re-

verse sequence.

Repeat process on the opposite side.

Replacing the Disk Brushes

Lift the cleaning head.

Press the pedal for changing the brush-

es downward beyond its resistance.

R cleaning head: Unscrew the star han-

Pull the disc brush out of the side below

dle and remove the lid.

the cleaning head.

D cleaning head: Remove the lid of the

Hold the new disc brush under the

cleaning head.

cleaning head, push upward and lock.

Place the cleaning head halfway in front

Mount splash guard

of the appliance.

Connect the power cord of the cleaning

head to the appliance (same colours

must meet).

R cleaning head: Slide the lid in and

tighten the screw.

D cleaning head: Replace the lid and

lock it.

Connect the hose couplers on the

cleaning head to the hose on the appli-

ance.

Loosen both screws.

Move both the drawing springs in the

desired position.

Align the splash guard.

Tighten both the screws.

34 EN

– 12

Insert the tab into the middle of the

Loosen the nuts of the adjustment

cleaning head, between the fork of the

screw and align the cleaning head in

lever.

such a way that the brush rollers touch

Position the lever on the pedal for rais-

the floor in an even manner.

ing/lowering so that the borings in the

Then tighten the nuts of the adjustment

lever and the cleaning head align.

screw.

Insert the stop pin through the bushings

Dismantling the cleaning head

and swivel the locking plate downward.

The removal will take place in the opposite

order of the installation.

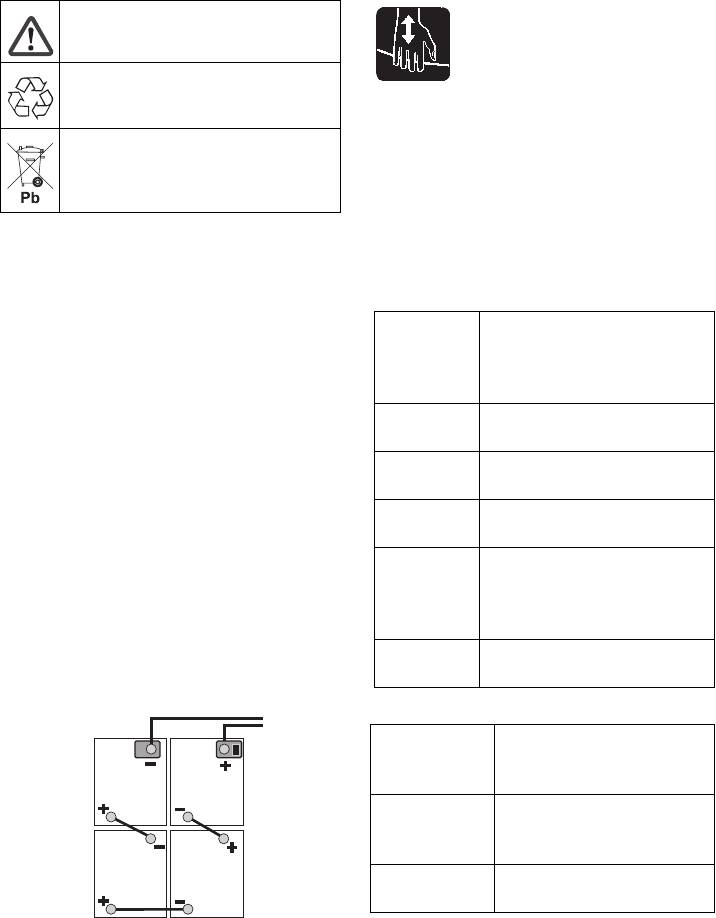

Batteries

Please observe the following warning notes

when handling batteries:

Observe the directions on the bat-

tery, in the instructions for use

and in the vehicle operating in-

structions

Wear eye protection

Align the pushing rod in the handle at

the cleaning head.

Insert the stop pin from the right through

Keep children away from acid and

the bushings and swivel the locking

batteries

plate downward.

Repeat process on the pushing rod on

Danger of explosion

the opposite side.

Note

Fire, sparks, naked flames and

Both the pins at the pushing rods are

smoking must be strictly avoided

pushed in from the same side through the

bushings (not in opposite directions).

Danger of chemical burns

First aid

– 13

35EN

Warning note

Disposal

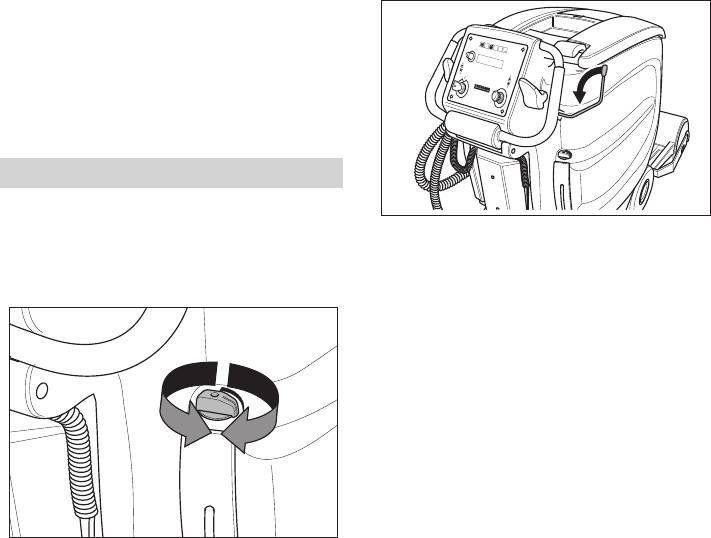

몇 Warning

Risk of injury on account of being crushed.

Do not throw the battery into the

Hold the tank only in this area while tilting

regular waste

downward.

Tilt the water tank towards the front.

몇 Warning

Danger

Charge the battery before commissioning

Danger of explosion. Do not put tools or

the machine.

similar on the battery, i.e. on the terminal

Recommended batteries

poles and cell connectors.

Risk of injury. Ensure that wounds never

Manufac-

Description

come into contact with lead. Always clean

turer,

your hands after having worked with batter-

Kärcher or-

ies.

der no.

Insert batteries and connect

DETA

24 V GtV 180 DTP, mainte-

The BAT package model contains built-in

6.654-130

nance-free, 180 Ah, 4 x 6 V

batteries.

DETA 24 V PzS 170 (5), low main-

Loosen the tank lock and tilt the tank

tenance, 170 Ah, 4 x 6 V

upwards.

DETA

24 V GiV 160 DT, mainte-

Place the batteries close to each other

6.654-089

nance-free, 160 Ah, 4 x 6 V

towards the cleaning head in the tray

SONNEN-

020 8517 405, low mainte-

and fasten them using the fastening

SCHEIN

nance, 175 Ah, 4 x 6 V

bracket behind the batteries.

(SUN-

Grease the battery poles using pole

SHINE)

grease.

TROJAN T-145, low maintenance,

Connect poles with the enclosed con-

205 Ah, 4 x 6 V

necting cables.

Recommended chargers

Manufactur-

Description

er, Kärcher

order no.

KÄRCHER

Charger 2425 for low

6.654-072.0

maintenance batteries, 24

V

KÄRCHER

Charger 2425 for mainte-

6.654-078.0

nance-free batteries, 24 V

A supply cable/ adapter 6.648-582 is re-

quired for both the chargers.

몇 Warning

Batteries and chargers are available in spe-

Pay attention to correct poles.

cialised stores.

Connect the connection cable to the

free battery poles (+) and (-).

36 EN

– 14

Removing the batteries

Frost protection

Set the key switch at the operator con-

In case of danger of frost:

sole to "0" and remove the key.

Empty the fresh and dirt water reser-

Loosen the tank lock and tilt the tank

voirs.

upwards.

Store the appliance in a frost-protected

Clamp off the minus pole of the battery.

room.

Clamp off the remaining cables from the

Faults

battery.

Unscrew the fastening angle.

Danger

Remove the batteries.

Risk of injury! Before carrying out any tasks

Dispose of the used batteries according

on the machine, set the main key to "0" and

to the local provisions.

remove key and plug of the charger.

Drain and dispose of the dirt water and

Maintenance contract

the residual fresh water.

To ensure a reliable operation of the appli-

In case of faults that cannot be remedied

ance maintenance contracts can be con-

using the table below please contact the

cluded with the competent Kärcher sales

customer service.

office.

Fault Remedy

Appliance cannot be

Stand-by, turn key switch to "0", then set it back to "1".

started

Check fuse F2*, replace if required. *

Check battery; charge it if required.

Machine does not

Check whether the immobilizing brake (optional) has been ap-

move

plied.

Insufficient water

Check fresh water level, refill tank if necessary.

quantity

Check hoses for blockages; clean if required.

Insufficient vacuum

Clean the seals between dirt water reservoir and cover and

performance

check for tightness, replace if required.

Clean the fluff filter.

Clean the vacuum lips on the vacuum bar, replace if required

Check suction hose for blockages; clean if required.

Check the suction hose for tightness; replace if required.

Check if the cover on the dirt water discharge hose is closed

Check the setting of the vacuum bar.

Insufficient cleaning

Set/ adjust contact pressure.

result

Check the brushes for wear, replace if required.

Brushes do not turn Reduce contact pressure.

Check if foreign matters block the brushes; remove foreign mat-

ter if required.

If over-current switch in the electronics system has been trig-

gered, turn key switch to "0", then set it back to "1".

* Remove screws of the electronics system and tilt the electronics cover with charger

downwards

– 15

37EN

Accessories

Accessories BR...

Description Part no.:

Part no.:

Description

Working

Working

width 550

width 650

mm

mm

Piece

Machine requires piece

Cleaning head 2.763-

2.763-004.0 1 1

002.0

Brush roller, red

6.906-

6.906-935.0 Also for regular cleaning of

12

(medium, stand-

934.0

heavily dirtied floors.

ard)

Brush roller, white

6.906-

6.906-981.0 For polishing and cleaning

12

(soft)

977.0

sensitive floors.

Brush roller, or-

6.906-

6.906-982.0 For scrubbing structured

12

ange (high/ low)

978.0

floors (safety tiles, etc.).

Brush roller, green

6.906-

6.906-983.0 For thoroughly cleaning

12

(grit)

979.0

heavily dirtied floors and for

removing the coating (for

Brush roller, grey

6.906-

6.906-984.0 1 2

e.g. of wax, acrylate).

(1 mm grit)

980.0

Pad roller shaft 4.762-

4.762-433.0 For intake of roller pads. 1 2

432.0

Roller pad, white

6.369-389.0 For cleaning and polishing

20 60 80

(very soft)

sensitive floorings.

Roller pad, yellow

6.369-454.0 For polishing floors. 20 6080

(soft)

Roller pad, red

6.369-456.0 For cleaning slightly dirtied

20 60 80

(medium)

floors.

Roller pad, green

6.369-455.0 For cleaning normal to

20 6080

(hard)

heavily dirtied floors.

38 EN

– 16

Accessories BD...

Description Part no.:

Part no.:

Description

Working

Working

width 550

width 650

mm

mm

Piece

Machine requires piece

Cleaning head 2.763-001.0 2.763-003.0 1 1

Disk brush, nat-

4.905-016.0 4.905-012.0 For polishing floors. 1 2

ural (white)

Disk brush, red

4.905-014.0 4.905-010.0 For cleaning slightly dirtied or

12

(medium, stand-

sensitive floors.

ard)

Disk brush,

4.905-017.0 4.905-013.0 For cleaning heavily dirtied

12

black (hard)

floors.

Accessories BR.../BD...

Description Part no.: Description Piece Machine

requires

piece

Rubber lip, blue 6.273-214.0 Standard pair 1 pair

Rubber lip, brown 6.273-208.0 oil-resistant pair 1 pair

Rubber lip, brown 6.273-205.0 Non-scarring pair 1 pair

Vacuum bar,

4.777-302.0 Standard 1 1

straight

Vacuum bar, bent 4.777-312.0 Standard 1 1

– 17

39EN

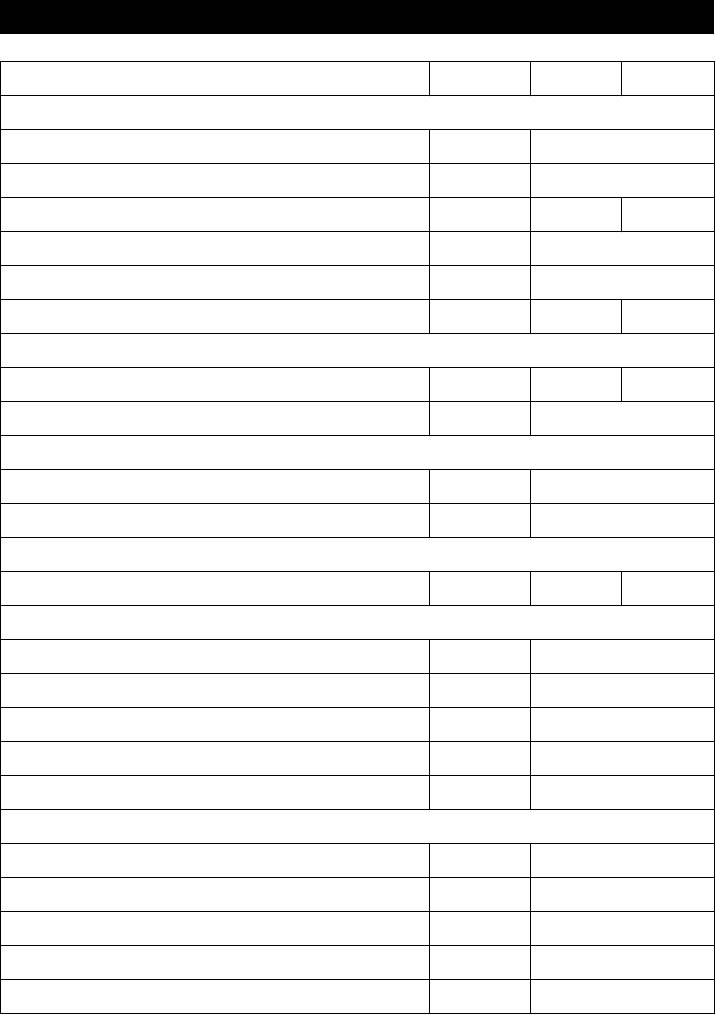

Technical specifications

BR BD

Power

Nominal voltage V 24

Battery capacity Ah (5h) max. 180/205

Average power consumption W 1900 1500

Drive motor output (rated output) W 200

Suction engine output W 500

Brush engine output W 2x 600 1x 800

Fuses

F1 (main fuse) A 125 150

F2 (control) A 3

Vacuuming

Cleaning power, air quantity l/s 22

Cleaning power, negative pressure kPa 11,5

Cleaning brushes

Brush speed 1/min 1350 180

Dimensions and weights

Theoretical surface cleaning performance m²/h 2475

Fresh/dirt water reservoir volume l 60/55

Max. water temperature °C 60

Transport weight kg 235

Total weight kg (295) 300*

Values determined as per EN 60335-2-72

2

Total oscillation value m/s

<2,5

2

Uncertainty K m/s

0,2

Sound pressure level L

pA

dB(A) 72

Uncertainty K

pA

dB(A) 1

Sound power level L

WA

+ Uncertainty K

WA

dB(A) 91

* Package appliances

40 EN

– 18