Karcher ICC 2 D ECO 2SB STAGE IIIa – страница 2

Инструкция к Karcher ICC 2 D ECO 2SB STAGE IIIa

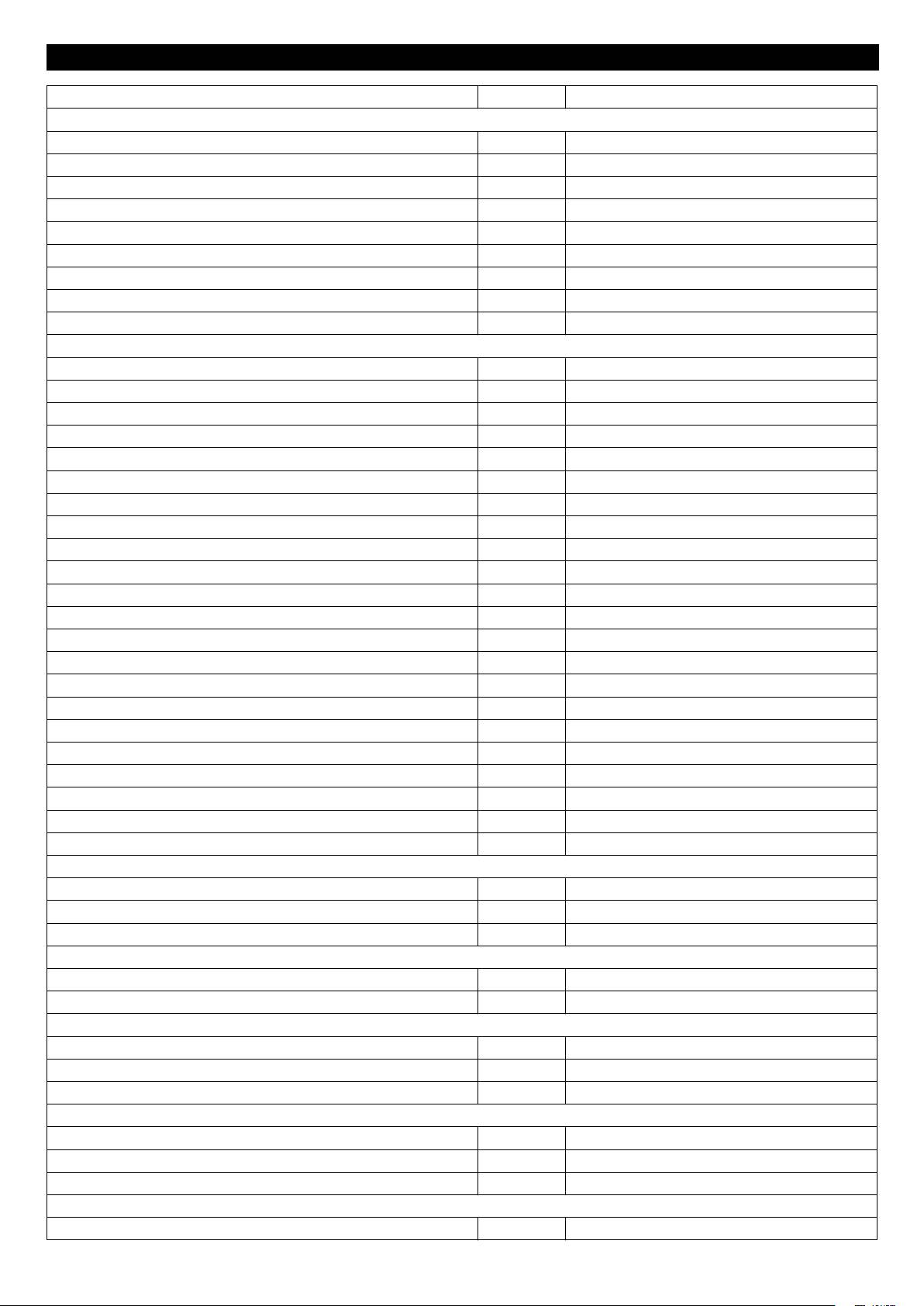

Technische Daten

ICC 2 Euro 3

Gerätedaten

Fahrgeschwindigkeit, vorwärts km/h 0-40

Fahrgeschwindigkeit, rückwärts km/h 0-6

Arbeitsgeschwindigkeit km/h 3-5

Steigfähigkeit (max.) % 25

Theoretische Flächenleistung m

2

/h 28000

Arbeitsbreite (4-Besensystem) mm 1130-2350

Arbeitsbreite (2-Besensystem) mm 1500-2000

Schutzart -- spritzwassergeschützt

Einsatzdauer bei vollem Tank h ca. 20

Motor

Hersteller -- VM-Detroit Diesel

Typ -- HR 494 HT3

Bauart -- 4-Zylinder-Euro 3-Viertakt-Dieselmotor

Gewicht kg 250

Kühlart -- Wasserkühlung

Bohrung mm 94

Hub mm 100

Hubraum cm

3

2776

Verdichtungsverhältnis -- 21,5:1

Betriebsdrehzahl 1/min 1600-2300

Leerlaufdrehzahl 1/min 750-850

Motorleistung bei 2300 1/min kW/PS 55/75

Höchstdrehmoment bei 2300 1/min Nm 225

Spezifischer Verbrauch g/kWh 260

Kraftstoff-Verbrauch l/h ca. 4

Vorglühung s ca. 8

Einspritzpumpe -- Bosch

Ölmenge l 6,4

Öldruck bei 800 1/min bar 1,2

Druckgeber für Warnleuchte bar 0,8

Ölfilter -- Filterpatrone

Ansaugluftfilter -- Außenfilterpatrone

Elektrische Anlage

Batterie V, Ah 12, 88

Anlasser kW/PS 1,4/1,8

Generator W 1000

Hydraulische Anlage

Ölmenge in der kompletten Hydraulikanlage l ca. 45

Ölmenge im Hydrauliktank l ca. 40

Ölsorten

Motor -- SAE 15W30, SAE 15W40

Hydraulik -- SHELL Tellus HV 46

Wasserpumpe -- SAE 15W40

Kehrgutbehälter

Max. Entladehöhe mm 1550

Volumen des Kehrgutbehälters l 1300

Nutzbares Gewicht kg 1300

Seitenbesen

Seitenbesen-Durchmesser (4-Besensystem) mm 600

- 20

21DE

Seitenbesen-Durchmesser (2-Besensystem) mm 925

Drehzahl (stufenlos) 1/min 30-90

Bereifung

Räder -- 6J 16 H2 5 68

Reifen -- 185/16R XCA TL 104 N

Luftdruck vorne bar 3,75

Luftdruck hinten bar 4,75

Bremse

Vorderräder -- hydraulisch

Hinterräder -- hydrostatisch

Feststellbremse -- mechanisch

Schmierfette

Für manuell abzuschmierende Schmierstellen -- NLGI-Klasse 2

Für automatische Schmieranlagen -- NLGI-Klasse 00

Umgebungsbedingungen

Temperatur °C -5 bis +40

Luftfeuchtigkeit, nicht betauend % 0 - 90

Geräuschemission

Schalldruckpegel (EN 60704-1) dB(A) 77

Garantierter Schallleistungspegel (2000/14/EC) dB(A) 107

Gerätevibrationen

Schwingungsgesamtwert (ISO 5349)

Arme, Lenkrad m/s

2

<2,5

Füße, Pedal m/s

2

<0,5

Sitzfläche m/s

2

<0,5

Maße und Gewichte

Länge x Breite x Höhe (4-Besensystem) mm 4150 x 1130 x 1904

Länge x Breite x Höhe (2-Besensystem) mm 3815 x 1250 x 1904

Leergewicht kg 2200-2290

Zulässiges Gesamtgewicht kg 3300

Inhalt Kraftstofftank, Diesel l 78

Wenderadius mm 3100

Wassertank l 300

Schallleistungspegel dB(A)

EG-Konformitätserklärung

Garantie

ICC 2

Hiermit erklären wir, dass die nachfolgend

Gemessen: 100

In jedem Land gelten die von unserer zu-

bezeichnete Maschine aufgrund ihrer Kon-

Garantiert: 102

ständigen Vertriebsgesellschaft herausge-

zipierung und Bauart sowie in der von uns

gebenen Garantiebedingungen. Etwaige

in Verkehr gebrachten Ausführung den ein-

Die Unterzeichnenden handeln im Auftrag

Störungen an Ihrem Gerät beseitigen wir

schlägigen grundlegenden Sicherheits-

und mit Vollmacht der Geschäftsführung.

innerhalb der Garantiefrist kostenlos, so-

und Gesundheitsanforderungen der EG-

fern ein Material- oder Herstellungsfehler

Richtlinien entspricht. Bei einer nicht mit

die Ursache sein sollte. Im Garantiefall

uns abgestimmten Änderung der Maschine

wenden Sie sich bitte mit Kaufbeleg an Ih-

verliert diese Erklärung ihre Gültigkeit.

CEO

Head of Approbation

ren Händler oder die nächste autorisierte

Kundendienststelle.

Produkt: Straßenkehrmaschine

Dokumentationsbevollmächtigter:

Typ: 1.183-xxx

S. Reiser

Einschlägige EG-Richtlinien

Alfred Kärcher GmbH & Co. KG

2006/42/EG (+2009/127/EG)

Alfred-Kärcher-Str. 28 - 40

2004/108/EG

71364 Winnenden (Germany)

2000/14/EG

Tel.: +49 7195 14-0

Angewandte harmonisierte Normen

Fax: +49 7195 14-2212

EN 13019

CISPR 12

Angewandtes Konformitätsbewer-

tungsverfahren

2000/14/EG: Anhang V

22 DE

- 21

Leaf suction (accessory)

– It is strictly prohibited to take co-pas-

Please read and comply with

EN

. . .9

sengers.

these instructions prior to the

Transport . . . . . . . . . . . .

EN

. .10

initial operation of your appliance. Retain

– The appliance may only be started after

Towing . . . . . . . . . . . . . .

EN

. .10

these operating instructions for future refer-

the operator has occupied the driver's

Shutdown. . . . . . . . . . . . . . . EN . .10

ence or for subsequent possessors.

seat.

Maintenance and care . . . . . EN . .10

Before first start-up it is definitely neces-

Please remove the ignition key, when

General notes . . . . . . . .

EN

. .10

sary to read the safety indications Nr.

not in use, to avoid unauthorised use of

5.956-250!

Cleaning. . . . . . . . . . . . .

EN

. .10

the appliance.

Maintenance intervals . .

EN

. .11

Never leave the machine unattended

Contents

Maintenance Works . . . .

so long as the engine is running. The

EN

. .12

operator may leave the appliance only

Accessories . . . . . . . . . . . . . EN . .18

Safety instructions . . . . . . . EN . . 1

when the engine has come to a stand-

Troubleshooting . . . . . . . . . . EN . .19

General notes . . . . . . . .

. . 1

still, the appliance has been protected

EN

Technical specifications . . . . EN . .20

against accidental movement, if neces-

Symbols on the machine

EN

. . 2

EC Declaration of Conformity EN . .21

sary, by applying the immobilization

Symbols in the operating in-

Warranty . . . . . . . . . . . . . . . EN . .21

brake and the ignition key has been re-

structions. . . . . . . . . . . . EN

. . 2

moved.

Function . . . . . . . . . . . . . . . EN . . 2

Safety instructions

Proper use . . . . . . . . . . . . . EN . . 2

Appliances with combustion engine

Suitable surfaces. . . . . .

EN

. . 2

Danger

General notes

Environmental protection . . EN . . 2

Risk of injury!

Your sales outlet should be informed about

Operating and Functional Ele-

– Do not close the exhaust.

any transit damage noted when unpacking

ments . . . . . . . . . . . . . . . . . EN . . 3

– Do not bend over the exhaust or touch

the product.

4-brush system . . . . . . .

EN

. . 4

it (risk of burns).

Please read the operating instructions

2-brush system . . . . . . .

EN

. . 4

– Do not touch the drive motor (risk of

for your machine before using it, and

burns).

Operator console. . . . . .

EN

. . 4

pay particular attention to the following

– Exhaust gases are poisonous and haz-

Console. . . . . . . . . . . . .

EN

. . 4

safety instructions.

ardous to health, do not inhale them.

Switch strip . . . . . . . . . .

. . 4

– Warning and information plates on the

EN

– The engine requires approx. 3-4 sec-

machine provide important directions

Operation . . . . . . . . . . . . . . EN . . 5

onds to come to a standstill once it has

for safe operation.

Warning system . . . . . .

EN

. . 5

been switched off. During this time, stay

– In addition to the information contained

Multifunction display . . .

EN

. . 5

well clear of the working area.

in the operating instructions, all statuto-

Wiper. . . . . . . . . . . . . . .

EN

. . 5

ry safety and accident prevention regu-

Turbine casing

Windscreen washer system

EN

. . 5

lations must be observed.

Adjust rear mirror . . . . .

EN

. . 5

Drive mode

Adjust exterior mirror. . .

EN

. . 5

Danger

Heating for exterior mirror

Risk of injury!

(attachment) . . . . . . . . . EN

. . 5

Danger of tipping if gradient is too high.

Working light . . . . . . . . .

EN

. . 5

– The gradient in the direction of travel

Overall lamp . . . . . . . . .

EN

. . 5

should not exceed 25%.

Combination switch. . . .

EN

. . 5

Danger of tipping when driving round

Driving direction lever . .

EN

. . 5

bends at high speed.

– Drive slowly when cornering.

Parking brake . . . . . . . .

EN

. . 6

Danger of tipping on unstable ground.

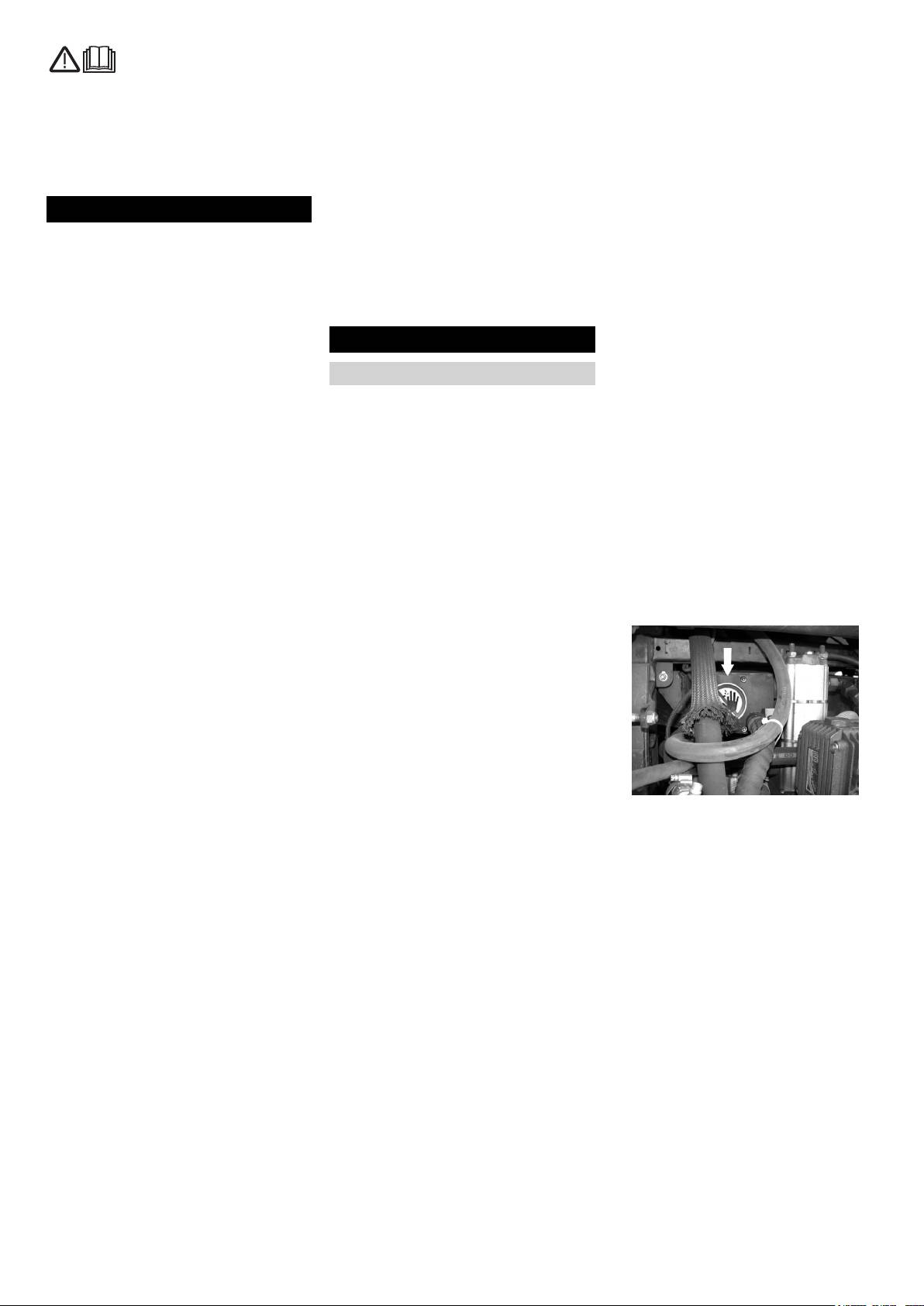

Danger

Adjusting driver's seat . .

EN

. . 6

– Only use the machine on sound surfac-

Risk of injury if the diesel motor is running!

Comfortable seat (accesso-

es.

ry) . . . . . . . . . . . . . . . . . EN

. . 6

– Never open the side panel of the turbine

Danger of tipping with excessive sideways

casing (below the turbine).

12V connection . . . . . . .

EN

. . 6

tilt.

– Do not put your hands inside the turbine

Blower . . . . . . . . . . . . . .

EN

. . 6

– The gradient perpendicular to the direc-

casing.

Air-conditioner (accessory)

EN

. . 6

tion of travel should not exceed 10%.

– Do not spray water into the turbine cas-

Fresh air circulation. . . .

EN

. . 6

– It is important to follow all safety instruc-

ing.

Heating . . . . . . . . . . . . .

EN

. . 6

tions, rules and regulations applicable

Accessories and Spare Parts

Before Startup. . . . . . . . . . . EN . . 6

for driving motor vehicles.

– Only use accessories and spare parts

Unloading . . . . . . . . . . .

– The operator must use the appliance

EN

. . 6

which have been approved by the man-

properly. He must consider the local

Start up . . . . . . . . . . . . . . . . EN . . 6

ufacturer. The exclusive use of original

conditions and must pay attention to

General notes . . . . . . . .

EN

. . 6

accessories and original spare parts

third parties, in particular children, when

ensures that the appliance can be oper-

Refuelling . . . . . . . . . . .

EN

. . 6

working with the appliance.

ated safely and troublefree.

Inspection and maintenance

– The appliance may only be used by per-

work. . . . . . . . . . . . . . . . EN

. . 6

– At the end of the operating instructions

sons who have been instructed in han-

you will find a selected list of spare

Operation . . . . . . . . . . . . . . EN . . 6

dling the appliance or have proven

parts that are often required.

Starting the machine . . .

EN

. . 6

qualification and expertise in operating

– For additional information about spare

Drive the machine . . . . .

EN

. . 6

the appliance or have been explicitly

parts, please go to the Service section

Sweeping mode . . . . . .

EN

. . 7

assigned the task of handling the appli-

at www.kaercher.com.

ance.

Emptying waste container

EN

. . 9

– The appliance must not be operated by

Emptying the waste contain-

er manually . . . . . . . . . . EN

. . 9

children, young persons or persons

who have not been instructed accord-

Turn off the appliance . .

EN

. . 9

ingly.

- 1

23EN

Symbols on the machine

Proper use

Environmental protection

Use this appliance only as directed in these

Risk of burns on ac-

The packaging material can be

operating instructions.

count of hot surfaces!

recycled. Please do not throw

The machine with working equipment

Allow the exhaust to

the packaging material into

must be checked to ensure that it is in

cool down sufficiently

household waste; please send

proper working order and is operating

before starting work on

it for recycling.

safely prior to use. Otherwise, the appli-

the machine.

ance must not be used.

Old appliances contain valua-

Symbols in the operating instruc-

– This sweeper has been designed to

ble materials that can be recy-

cled; these should be sent for

tions

sweep dirt and debris from outdoor sur-

faces.

recycling. Batteries, oil, and

Danger

– The appliance should not be used in

similar substances must not en-

indicates an immediate threat of danger.

closed rooms.

ter the environment. Please dis-

Failure to observe the instruction may re-

pose of your old appliances

– The machine is not suitable for vacuum-

sult in death or serious injuries.

using appropriate collection

ing dust which endangers health.

systems.

몇 Warning

– The machine may not be modified.

indicates a possibly dangerous situation.

– Never vacuum up explosive liquids,

Failure to observe the instruction may re-

combustible gases or undiluted acids

sult in light injuries or damage to property.

and solvents. This includes petrol, paint

Note

thinner or heating oil which can gener-

ate explosive fumes or mixtures upon

indicates useful tips and important informa-

contact with the suction air. Acetone,

tion.

undiluted acids and solvents must also

be avoided as they can harm the mate-

Function

rials on the machine.

– Do not sweep/vacuum up any burning

or glowing objects.

– The machine is only suitable for use on

the types of surfaces specified in the

operating instructions.

– The machine may only be operated on

the surfaces approved by the company

or its authorised representatives.

– The machine may not be used or stored

in hazardous areas. It is not allowed to

use the appliance in hazardous loca-

– The generated dust is bound through

tions.

water (1) that is sprayed.

– The following applies in general: Keep

– The side brushes (2) transport the dust

highly-flammable substances away

to the front of the suction opening (3).

from the appliance (danger of explo-

– The suction turbine (4) sucks in the

sion/fire).

waste and transports it to the waste

container (5).

Suitable surfaces

– Asphalt

– Industrial floor

– Screed

– Concrete

– Paving stones

24 EN

- 2

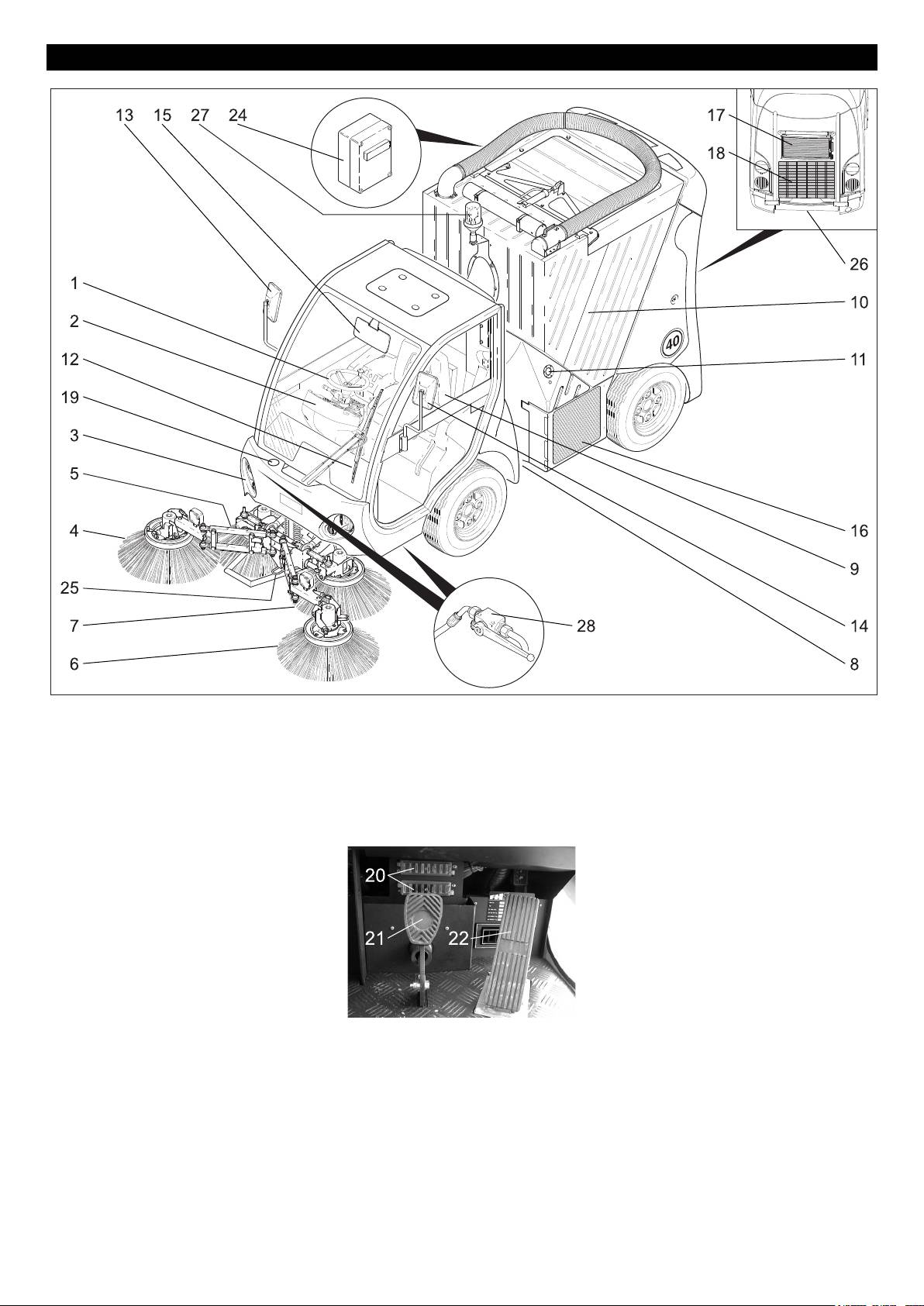

Operating and Functional Elements

Figure 1

1 Steering wheel

24 Fuse box motor room

2 Operator console

25 Towing eye, front

3 Lights

26 Towing eye, rear

4 Right side bush, front

27 Overall lamp

(only 4 brush system)

28 Stop for side brush elevation

5 Right side bush, rear

(only 2-brush system)

(only 4 brush system)

6 Left side bush, front

(only 4 brush system)

7 Left side bush, rear

(only 4 brush system)

8 Bulk waste flap

9 Driver seat

10 Waste container

11 Fuel tank

12 Wiper

Figure 2

13 Right exterior mirror

14 Left exterior mirror

15 Rear-view mirror

16 Water cooler

17 Oil cooler

18 Cooler for air-conditioner (accessory)

19 Container for wiper water

20 Fuse box driver cabin

21 Brake pedal

22 Drive pedal

23 Pedal for raising/lowering bulk waste

flap

- 3

25EN

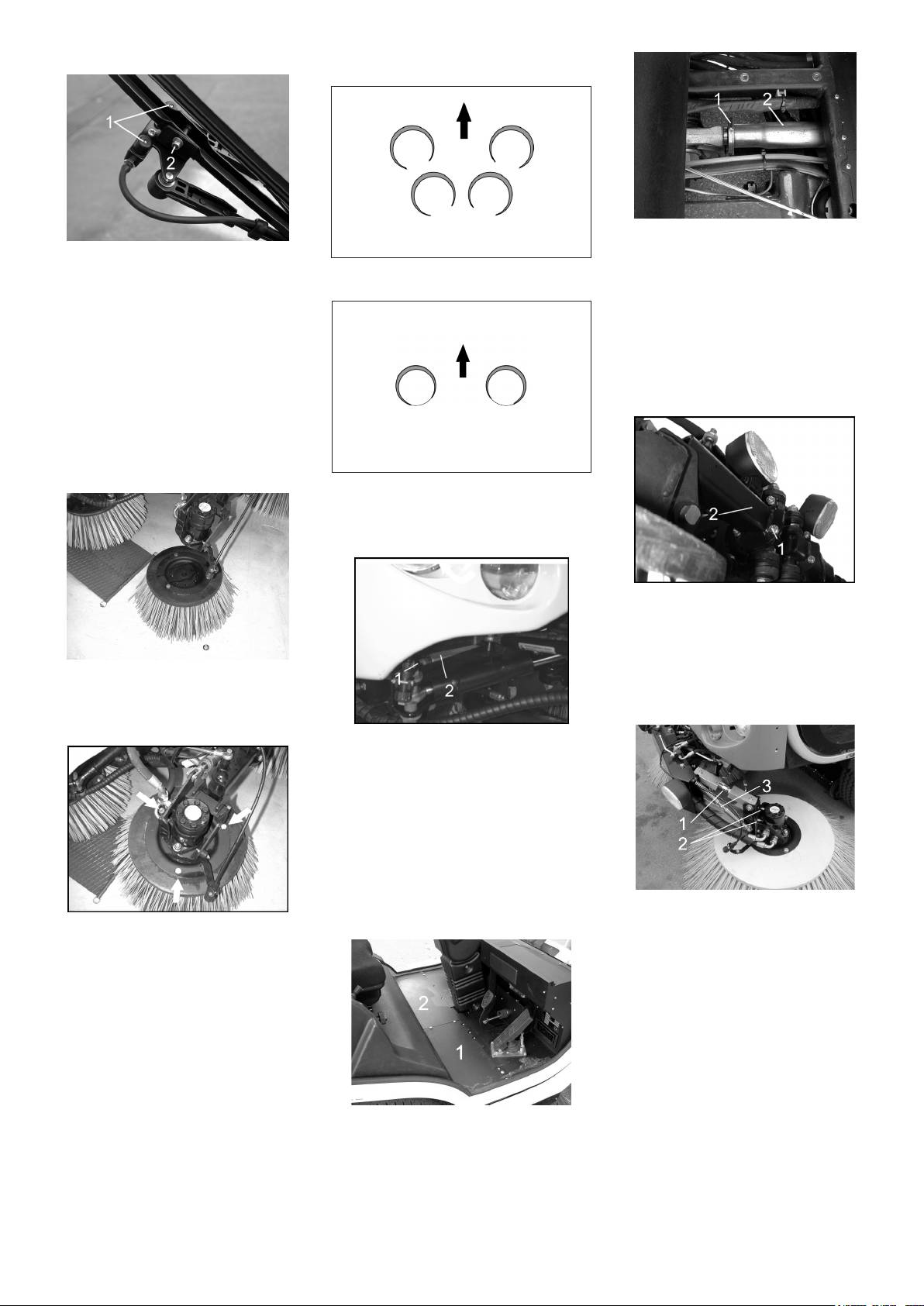

4-brush system

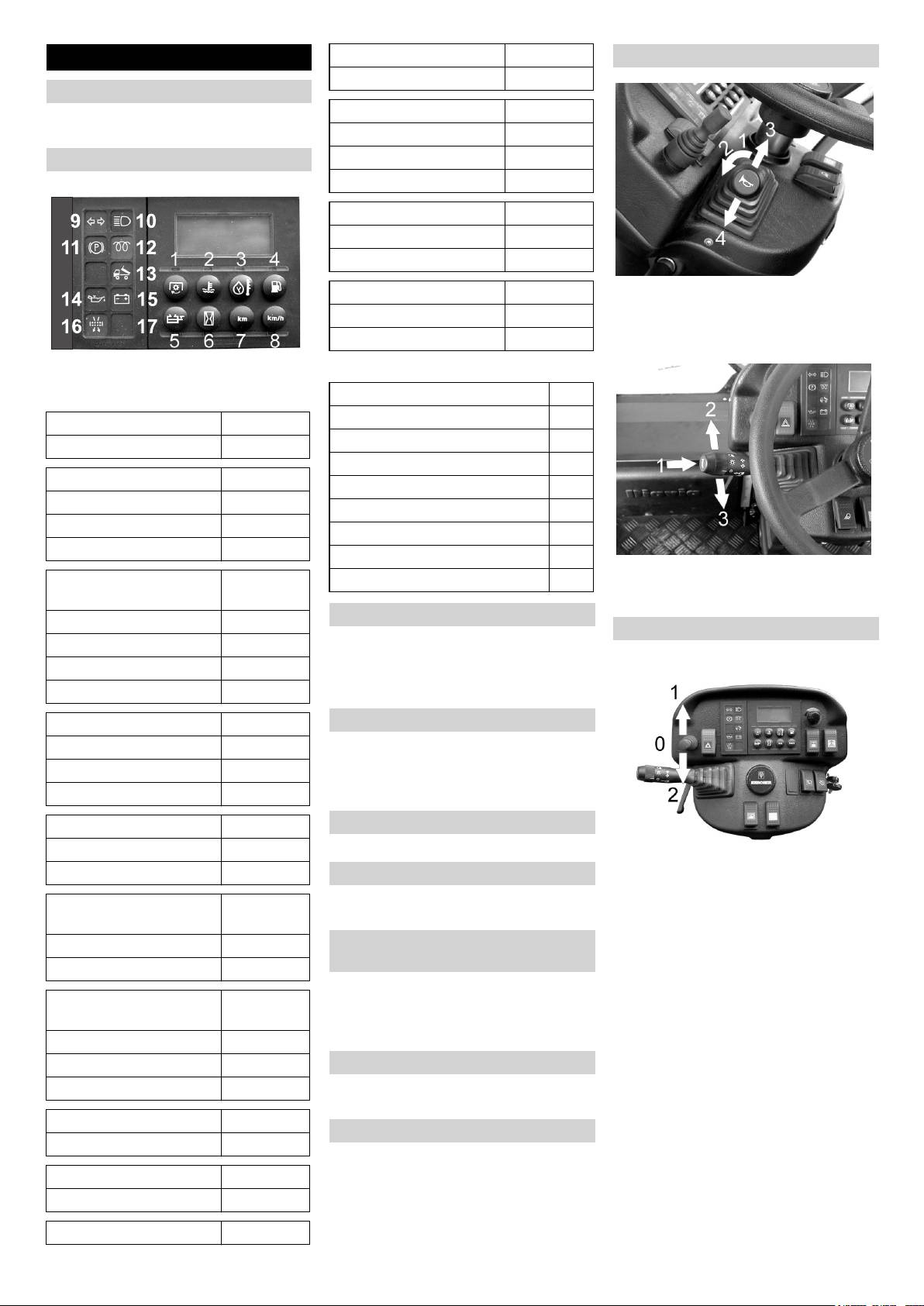

Operator console Console

– Pedal for raising/lowering bulk waste

flap

Figure 6

Figure 7

1 Display

1 Raise/lower side-brushes

Figure 3

2 Setting the speed of the side-brushes

Hydraulic side-brush release (attach-

3 Working hydraulics

ment)

2-brush system

1. Step = switch on the working hydrau-

2 Move in/out the joystick of the side-

–

Pedal for raising/lowering bulk waste

lics

brush

flap

2. step = switch on the suction turbine

3 Lock side-brush

and the side-brushes

4 Inclination of side-brush, left

4 raising the suction mouth

(only 4 brush system)

5 Ignition lock

5 Setting the motor rpm

6 Windscreen washer system

6 Turn on/off the spray water

7 Wiper

7 Raise/lower waste container

8 Heating for exterior mirror (attachment)

8 Inclination of side-brush, right

9 Overall lamp

(only 4 brush system)

10 Switch for working lamp

Switch strip

11 Adjusting the steering column

12 Combination switch

Figure 4

13 Driving direction lever

14 Warning system

Figure 8

1 12V connection

Figure 5

2 Blower

A Right side brush

3 Switch on/off air-conditioner (accesso-

B Left side brush

ry)

4 Fresh air circulation

5 Heating

26 EN

- 4

Motor on

Operation

Combination switch

Display row 2

Warning system

Battery voltage

Turning on/off the warning system:

Press the switch for warning system.

Motor off

Ignition on

Multifunction display

Display row 1

Vehicle voltage

Motor on

Display row 1

Service interval SIA

1 Parking light

2 Dipped beam

Display row 2

3 Flashing

Filter replacement > 320 h

4 Full beam

Indicator lamps

Figure 9

Keys

Blinker left/right (9)

Full beam (10)

Motor rpm (1)

Activate parking brake (11)

Display row 1

Preglowing (hold for 3 seconds) (12)

Cool water temperature (2)

Waste container is raised (13)

Display row 1

Motor oil pressure is too low (14)

Warning tone 1 (- - - -) > 108 °C

Battery charge is low (15)

Warning tone 2 (____) > 115 °C

Air filter is dirty (16)

1 Horn

Temperature of hydraulic

(3)

Spray water pump is switched on (17)

2 Right indicator

oil

3 Left indicator

Wiper

Display row 1

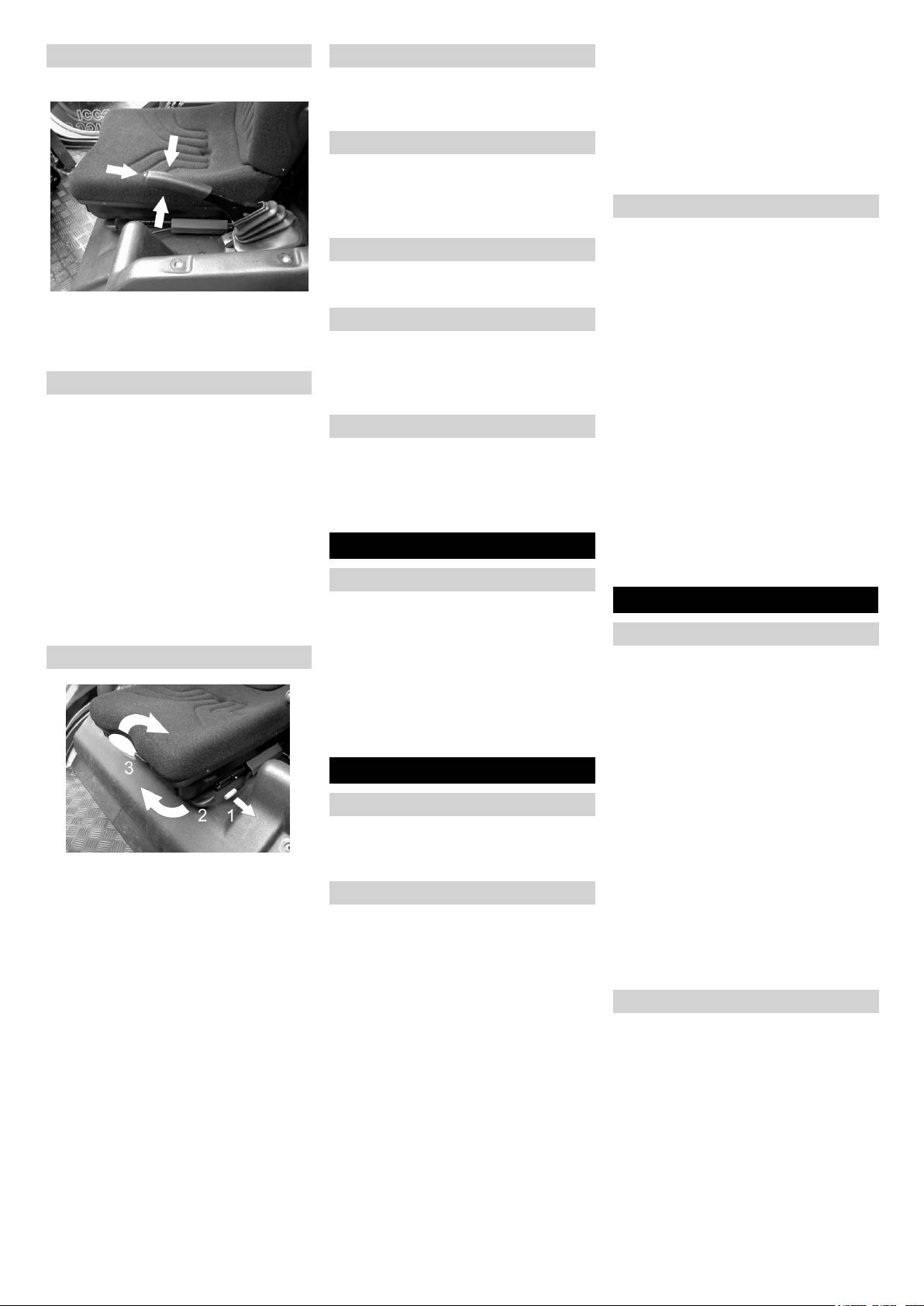

Driving direction lever

Warning tone 1 (- - - -) > 75 °C

Turn on/off the wiper:

Press the switch for wiper.

Warning tone 2 (____) > 80 °C

– 1. stage = interval

Acknowledgement (3)

– 2. stage = constant

Fuel tank level (4)

Windscreen washer system

Display row 1

Turn on/off the windscreen washer system.

Press the switch for windscreen washer

Warning tone 1 (- - - -) < 15 l

system.

Acknowledgement (4)

Spray water for the front wiper is activated.

Water tank level (5)

Adjust rear mirror

Display row 2

Adjust rear mirror manually.

Call off (5)

0 = Neutral

Adjust exterior mirror

1 = Forward drive

Adjust the left and right exterior mirror

Operating hours meter for

(6)

2 = Reverse

manually.

motor

Display row 2

Heating for exterior mirror (attach-

ment)

Call off (6)

Turn on/off the heating for the exterior mir-

Operating hours meter for

(6)

ror.

turbine

Press the switch for heating for exterior

Motor off

mirror.

Ignition on

Working light

Display row 2

Turning on/off the working light:

Press the switch for the working light.

Driving route (7)

Overall lamp

Display row 2

Turning on/off the overall lamp:

Speed (8)

Press the switch for the overall lamp.

Display row 2

Time (1)-(8)

- 5

27EN

Parking brake

12V connection

Fuelling using a can

– Estimate the fuel requirement in order

Insert the consumer load at 12V-con-

Lock parking brake

to avoid overflows.

nection.

Fuelling using the fuelling gun

(see switch strip)

– Insert the fuelling gun as deep as possi-

Blower

ble into the fuel nozzle. Do not add any

more fuel once the fuelling gun stops

Switch on/off the blower.

according to the settings.

(see switch strip)

– for heating: level 2

Inspection and maintenance work

– for air-conditioner: level 3

Check engine oil level. *

Air-conditioner (accessory)

Check water cooler and maintain it. *

Check tyre pressure. *

Turn on/off the air-conditioner.

Check fill level of fuel tank. *

(see switch strip)

Pull up the handle.

Adjust driver's seat.

Release parking brake

Fresh air circulation

Check suction channel. *

Press the locking button and release

Activate the slide.

Check setting of suction opening. *

the handle.

(see switch strip)

Check lights and ensure that they are

functioning properly. *

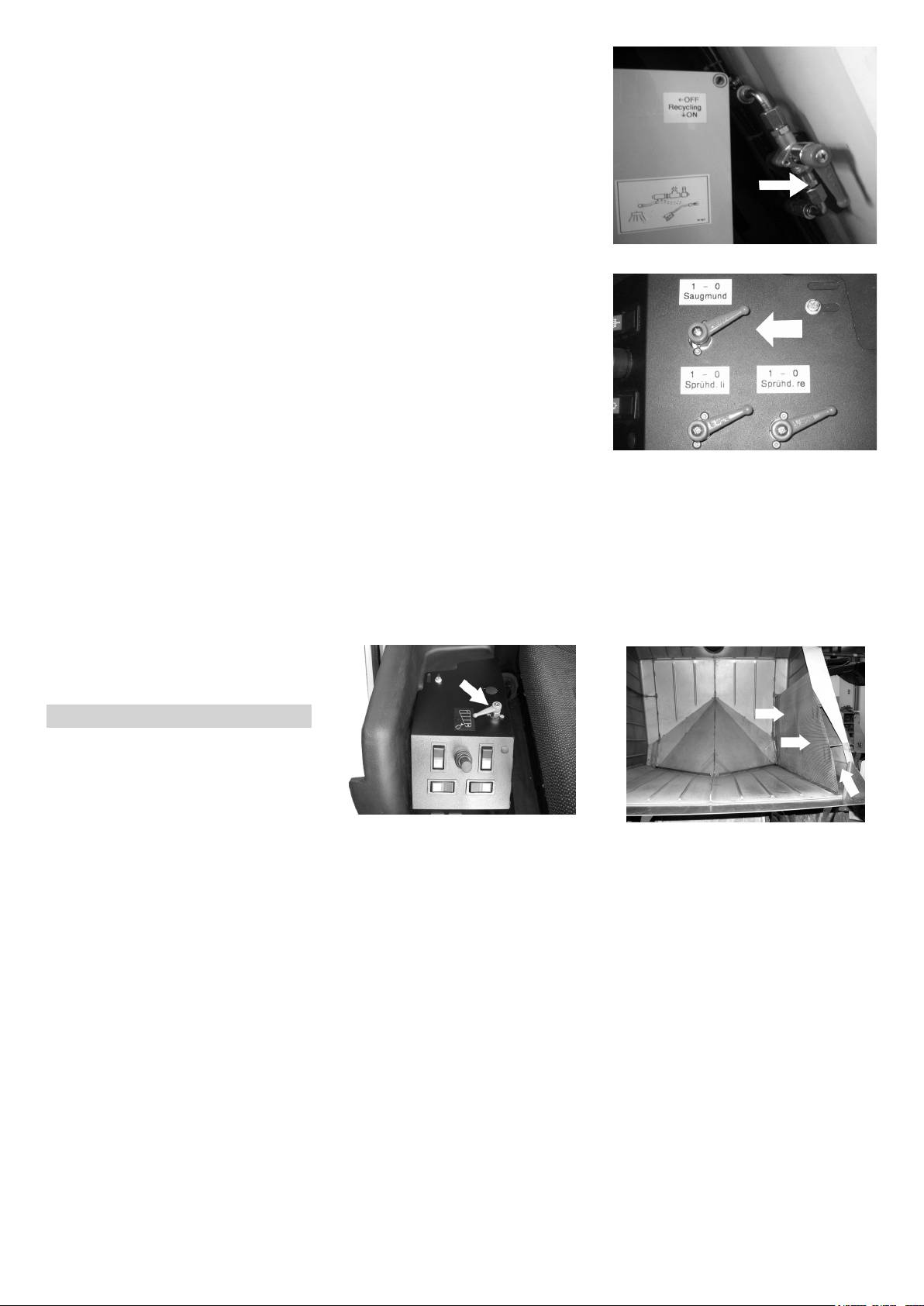

Adjusting driver's seat

– Slide is pushed in = fresh air

– Slide is pulled out = air circulation

Check signaling and warning systems

Adjusting the seat position

for proper functioning. *

Heating

Pull upwards the lever located under

Fill the water reservoir. *

the seat.

Activate the slide.

Check side brush. *

Slide seat, release lever and lock in

(see switch strip)

Empty waste container.

place.

– Slide is pushed in = cold

* For description, see section on Care and

Check that the seat is properly locked in

– Slide is pulled out = warm

maintenance.

position by attempting to move it back-

몇 Warning

wards and forwards.

Before Startup

Rectify any defect you may find immediate-

Adjusting the seat springs

ly or bring the vehicle to a halt.

Turn the hand-wheel at the rear of the

Unloading

seat.

Operation

Note

– In clock-wise direction: Spring harder

The appliance is fitted with tension belts for

– Anti-clockwise direction: Spring softer

Starting the machine

safe transport.

Comfortable seat (accessory)

To unload the machine, proceed as follows:

Sit on the driver's seat.

Remove tension belts.

Do NOT press the accelerator pedal.

Release parking brake.

Lock parking brake.

Drive down the appliance from the

Switch off the working hydraulic.

transport vehicle.

Set the drive direction indicator to posi-

tion (0) (neutral).

Start up

Pre-heat

Turn the ignition key to position "I".

General notes

Pre-heat lamp glows.

Park the sweeper on an even surface.

Start the engine

Remove ignition key.

When the pre-heating lamp goes off,

Adjusting the seat position

Lock parking brake.

turn the ignition key to position "II".

Press the lever (1).

If the machine starts, release the igni-

Refuelling

Slide seat, release lever and lock in

tion key.

place.

Danger

Note

Check that the seat is properly locked in

Risk of explosion!

Never operate the starter motor for longer

position by attempting to move it back-

– Only use the fuels specified in the Op-

than 10 seconds. Wait at least 10 seconds

wards and forwards.

erations Manual.

before operating the starter motor again.

– Do not refuel the machine in enclosed

Adjusting the seat springs

Drive the machine

spaces.

Tilt the lever (2) until the scales show

– Smoking and naked flames are strictly

your body weight.

Drive forward

prohibited.

– Set the body weight between 50-130

Press the brake pedal.

– Ensure that no fuel reaches the hot

kg.

Set the drive direction indicator to posi-

open surfaces.

– If you tilt until the end, the setting is

tion (1) (drive forwardl).

Switch off engine.

done for 50 kg.

Release parking brake.

Open fuel filler cap.

Press accelerator pedal down slowly.

Adjust seat position

Fill in diesel.

Tilt the handle (3).

Reverse drive

Fill in the tank up to a level 1 cm below

Adjust the seat.

Danger

the lower edge of the filling nozzle be-

Risk of injury! While reversing, ensure that

cause the fuel expands on heating.

there is nobody in the way, ask them to

Wipe off any spilt fuel and close fuel fill-

move if somebody is around.

er cap.

Press the brake pedal.

28 EN

- 6

Set the drive direction indicator to posi-

Switching on the working hydraulics

tion (2) (reverse drive).

Turn on the working hydraulics (1st lev-

Release parking brake.

el).

Press accelerator pedal down slowly.

(see operating panel).

Note

Switch on the suction turbine and the

Driving method

side-brushes (2nd step).

– A warning tone is sounded while revers-

Note

ing.

Only driving is possible if the working hy-

– The accelerator pedal can be used to

draulics is switched off.

vary the driving speed infinitely.

Adjusting the side-brush speed

– Avoid pressing the pedal suddenly as

Set the side-brush speed on the speed

this may damage the hydraulic system.

regulator.

Set the lever for recycling to ON.

– In the event of power loss on inclined

(see operating panel).

surfaces, slightly reduce the pressure

– In clock-wise direction: Side-brush

on the accelerator pedal.

speed increases

– Change the driving direction only after

– Anti-clockwise direction: Side-brush

the vehicle has come to a halt.

speed decreases

Brakes

Turn on/off the spray water

Release the accelerator pedal, the ma-

Press spray water button.

chine brakes automatically and stops.

(see console ).

Note

Spray water for side-brushes and suction

The braking effect can be supported by

opening gets activated.

pressing the foot-brake.

Regulate additional supply of fresh wa-

Note

Driving over obstacles

ter to the suction opening using the le-

The function of the spray-water pump is

몇 Warning

ver for suction opening.

displayed on a yellow indicator lamp, see

Switch on the suction turbine; start

Raise the side-brushes and the suction

multi-functional display.

cleaning work.

opening before overtaking hurdles.

If the tank is empty, the yellow indicator

Hurdles up to 150 mm in height:

After finishing operations, switch off the

lamp goes off.

Bypass the hurdle slowly and carefully

suction turbine approx. 30 seconds af-

Switch-off spray water.

at an angle of 45°.

ter the suction opening has got raised.

Fill the water reservoir.

This will prevent water from leaking

Hurdles more than 150 mm in height:

Regulate the water flow to the side-

when the appliance has been switched

Only drive over these obstacles using a

brushes.

off.

suitable ramp.

몇 Warning

Risk of damage! Ensure that the vehicle

does not get stuck up.

Sweeping mode

Danger

Risk of injury! If the bulk waste flap is open,

stones or gravel may be flung forwards by

the roller brush. Make sure that this does

not endanger persons, animals or objects.

Adjust the water flow to the side-brush-

몇 Warning

es using the regulation valve.

Every time you empty the waste con-

Do not sweep up packing strips, wire or

– In clock-wise direction: Water flow in-

tainer, rinse the sieve in the waste con-

similar objects as this may choke up the

creases

tainer using the water hose and clean

suction canal.

– Anti-clockwise direction: Water flow de-

the space behind the sieve.

몇 Warning

creases

Set the lever for recycling to OFF while

To avoid damaging the floor, do not contin-

operating without water circulation.

Note

ue to operate the sweeping machine in the

There is an accessory with 2 regulation

Operating without water circulation sys-

same position.

valves for separately controlling the water

tem

Note

flow to both the sides.

When the appliance is switched off,

To achieve an optimum cleaning result, the

make sure the lever for recycling is set

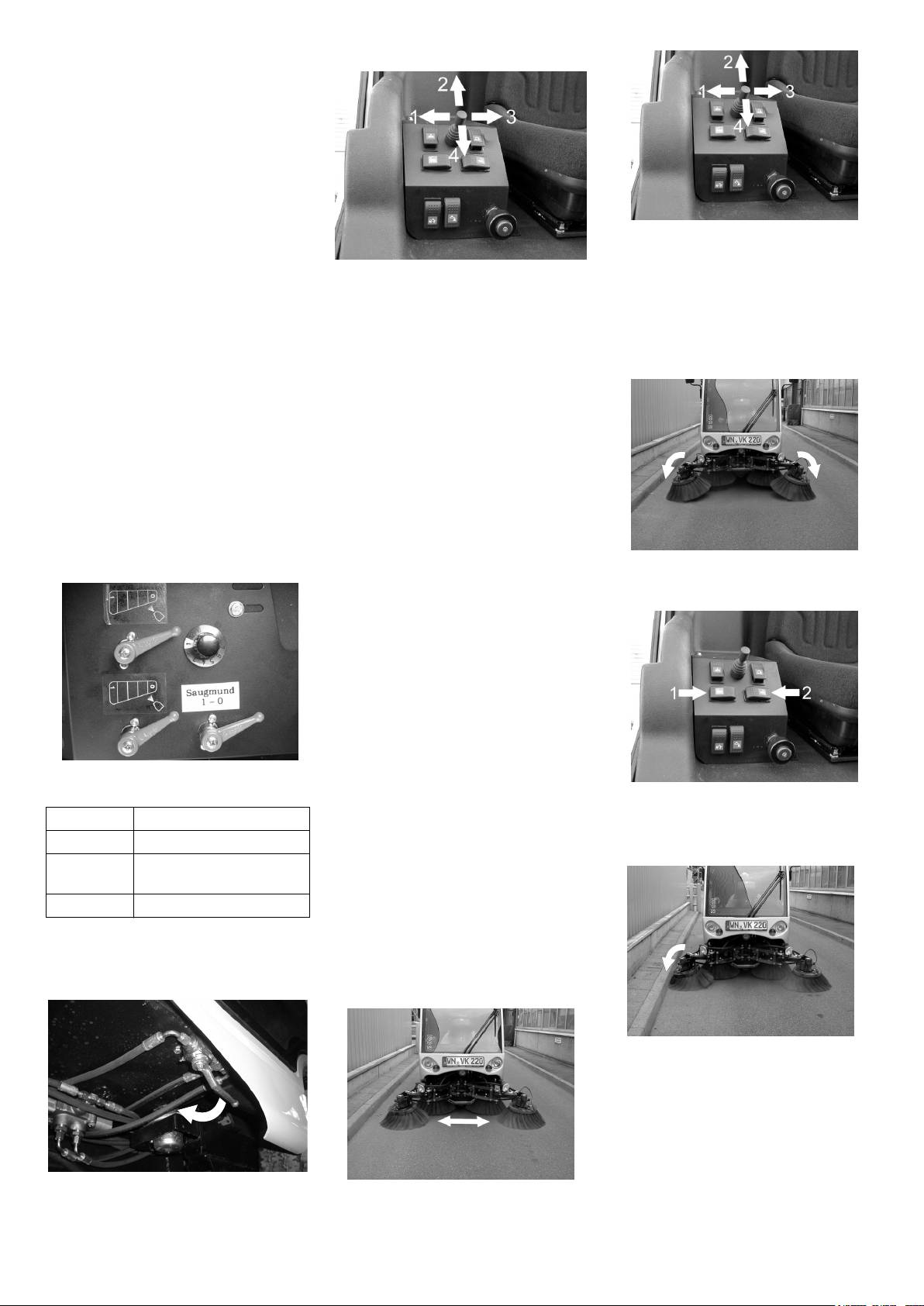

Water circulation system

driving speed should be adjusted to take

to OFF because otherwise the hoses

The applicance is fitted with a water circu-

specific situations into account.

leading to the suction opening will get

lation system for increasing the duration of

Note

blocked.

usage (fresh water reservoir). In the water

circulation system, the water from the

The sieve and the space behind the

During operation, the waste container

sieve must be cleaned every time you

should be emptied at regular intervals.

waste container is guided to the suction

opening and thus circulated. Further, it is

empty the waste container even if you

Setting the motor rpm

also possible to add fresh water.

are operating the appliance without wa-

Set the idle running for the motor rpm

Fill the waste container with water up to

ter circulation.

setting to 1600-1800 1/min.

the end of the front slant. To suck in

Raise/lower side-brushes

(see console ).

leaves, fill lesser quantity of water in the

4-brush system:

Note

waste container.

Press the toggle switch downward. The

The motor rpm can be called via the multi-

side-brushes will be lowered.

functional display.

(see console ).

- 7

29EN

Press the toggle switch upward. Side

Move in/out the side-brush

brushes lift up.

2-brush system:

Press the toggle switch downward. The

side-brushes will be lowered.

(see console ).

Press the toggle switch upward. Side

brushes lift up.

Hydraulic side-brush relief (attachment)

– The hydraulic side-brush relief reduces

the contact pressure of the brush on the

Drive out the side-brushes (2).

track.

Drive in the side-brushes (4).

– The floor is protected against friction

Note

Move joystick to position (2). Side-

and wear if the brushes are relieved

brushes are driven out.

The sweeping width should be adjusted ac-

and this also increases the life of the

Move joystick to position (4). Side-

cording to how dirty the plane surface is so

brushes.

brushes are drawn in.

that the waste can be sucked in completely.

– The relief can be adjusted in infinitely

Note

Inclination of the front side-brushes (on-

variable steps depending on the track

ly 4-brush system)

surface and the dirt that appears.

Only 2-brush system: The side-brushes

can only be driven out when they are rotat-

Raise/lower side-brushes:

ing.

Press the toggle switch downward. The

side-brushes are lowered; the relief is

Sweeping in larger objects

deactivated.

Note

(see console ).

To sweep in larger objects such as bever-

Toggle switch in central position. The

age cans or larger quantities of leaves, it is

side-brushes are lowered; the relief is

necessary to briefly raise the bulk waste

activated.

flap.

Press the toggle switch upward. Side

Raising bulk waste flap:

brushes lift up.

Press the pedal for the bulk waste flap

The inclination of the front side-brushes

Setting the hydraulic side-brush relief:

forwards and keep pressed down.

can be adjusted according to the geometry

To lower it, take foot off pedal.

of the driving path.

Note

An optimum cleaning result can only be

achieved if the bulk waste flap has been

lowered completely.

Sweeping dry floors

To avoid deposits in the suction channel

and durst formation, the water supply to the

brush nozzles must be on.

Switch on the spray water.

(see console ).

Setting the relief of the brushes at the

speed regulator.

Sweeping damp or wet floors

Tilt the right side-brushes (1).

Switch off the water supply to the brush

Tilt the left side-brushes (2).

Position Relief on the brushes

nozzles if there is practically no dust forma-

Sweeping along the limitations of the

1 minimum

tion.

driving path (only 4-brush system)

Switch-off spray water.

5-8 medium (recommended

setting)

(see console ).

Note

11 maximum

To achieve an optimum cleaning result, the

Stop side-brush lift up (only 2-brush

driving speed or rahter the sweeping width

system)

should be adjusted to take specific situa-

The side-brushes can individually be

tions into account.

stopped in a raised position.

Sweeping plane surfaces

Tilt the right side-brushes if required.

Close the ball tap when the side-brush-

The front side-brushes can be driven in or

es are lifted up.

out depending on how dirty the plane sur-

face is.

30 EN

- 8

that no persons or animals are within its

Sweeping at narrow places

몇 Warning

swivelling range.

Manually lift the lid of the waste container

Danger

before starting the pumping operations.

Danger of crushing. Never reach into the

This will help in avoiding damage to the

rod assembly for the drainage mechanism.

rear panel.

Raise the waste container through

Note

pumping.

Always raise the waste container complete-

ly until its end position.

Turn off the appliance

Switch off the spray water for side-

Switch off the spray water for side-

brushes and suction opening.

brushes and suction opening.

Stop the machine.

Stop the machine.

To sweep in edge area on right-hand side:

Lock parking brake.

Lock parking brake.

Drive in the left side-brush and drive out

Set the drive direction indicator to posi-

Set the drive direction indicator to posi-

the right side-brush (1).

tion (0) (neutral).

tion (0) (neutral).

Drive in the side-brushes.

Drive in the side-brushes.

The side-brushes lift up.

The side-brushes lift up.

Switch off the suction turbine and the

Switch off the suction turbine and the

side-brushes (2nd step).

side-brushes (2nd step).

Turn off the working hydraulics (1st lev-

el).

Set the dry run speed.

Turn ignition key to "0" and remove it.

Leaf suction (accessory)

To sweep in edge area on left-hand side:

Drive in the right side-brush and drive

out the left side-brush (3).

Open the side-flaps.

Drain off water on both sides.

Open the screw cap.

Hang in the special tool (accessory)

and turn in anti-clockwise direction.

– The left side-brushes can be locked to

sweep narrow passages or foot-paths.

– The right side-brushes can still be

moved using the joystick in position (1)

Raise waste container (1).

and (3).

Empty waste container.

– If you move the joystick to position (2)

Lower waste container (2).

and (4), both the side-brushes in or out.

Note

– At narrow bends, turn in the external

There is a warning sound signal when the

brushes.

waste container is lowered.

Emptying waste container

Emptying the waste container man-

Danger

Loosen the fasteners of the suction

ually

hose.

Risk of injury! While reversing, ensure that

Lock parking brake.

Connect the hose to the nozzle.

there is nobody in the way, ask them to

Open the side-flaps.

move if somebody is around.

Drain off water on both sides.

Danger

Danger of tipping. Place the machine on an

even surface during emptying.

Danger

Danger of tipping. Maintain the required

safety distance while emptying on dumps

or ramps.

Danger

Risk of injury! Switch off the suction turbine

Loosen the fasteners of the suction

before emptying the waste container.

nozzle

Danger

Remove the operating lever for the

Risk of injury! When emptying the waste

pump.

container, care should be taken to ensure

Insert the operating lever on the pump

lever.

- 9

31EN

Shift the water supply from leaf suction

Open the bypass valve using the hand

to sweeping operations.

gear from the tool box or a flat spanner

(SW 9).

Transport

몇 Warning

Shutdown

The appliance must be secured against

If the sweeper is going to be out of service

slippage during transport.

for a longer time period, observe the follow-

Turn ignition key to "0" and remove it.

ing points:

Lock parking brake.

Park the sweeper on an even surface.

Secure the wheels of the machine with

Raise the side-brushes to prevent the

Connect the suction nozzle to the suc-

wheel chocks.

bristles from being damaged.

tion hose.

Turn ignition key to "0" and remove it.

Set the dry run speed to approx. 1800

Secure sweeper to prevent it rolling

1/min.

away, lock parking brake.

Note

Tank up the fuel tank fully.

The motor rpm can be called via the multi-

Change the engine oil and the oil filter.

functional display.

Drain off the spray water if frost is ex-

Turn on the working hydraulics (1st lev-

pected and check whether is adequate

el).

anti-frosting agent in the cooling water.

Press switch for raising the suction

Empty the water tank and the pipe sys-

mouth.

tem.

– 1. step = raise the suction opening

Secure the appliance with tension

Disconnect battery.

– 2. step = switch on/off the side-brushes

straps at the fastening eyes on the left

Charge battery approx. every 2 months.

and the right.

Clean the inside and outside of the

몇 Warning

sweeper.

Risk of damage! The front towing eye

Park the machine in a safe and dry

should not be used to fasten the appliance.

place.

Towing

Maintenance and care

Danger

When carrying out rescue work on public

General notes

highways, wear warning clothing when

working close to passing traffic.

First switch off the appliance and re-

move the ignition key before performing

Raise waste container.

Danger

any cleaning or maintenance tasks on

Cover the suction pipe with a plate

The hydro-static drive of the sweeper per-

the appliance, replacing parts or switch-

when sucking in leaves.

mits towing out of the danger area only for

ing over to another function.

Lower waste container.

a few metres at walking speed. Do not

Pull out the battery plug or clamp the

move the sweeper at a speed higher than

battery while working on the electrical

walking speed.

unit.

Danger

– Maintenance work may only be carried

The appliance is not suitable for crane

out by approved customer service out-

loading.

lets or experts in this field who are famil-

Note

iar with the respective safety

Make sure the brush-system is not dam-

regulations.

aged while towing.

– Mobile appliances used for commercial

Drain off spray water.

purposes are subject to safety inspec-

Empty waste container.

tions according to VDE 0701.

Shift the water supply from sweeping to

Fasten the towing rope to the towing

Cleaning

leaf suction operations.

eye in the front or the rear.

Turn on the suction turbine (1st level).

Drag the appliance on to the transport

Park the sweeper on an even surface.

Switch on the spray water.

vehicle.

Empty waste container.

Raise the suction opening and the side-

Bypass valve (accessory)

brushes.

Note

Lock parking brake.

It is easier to move the appliance when the

몇 Warning

bypass valve is opened.

Risk of damage! The electrical components

in the engine room should not be cleaned

using a high-pressure jet.

Cleaning the appliance

Clean appliance daily after finishing work.

Note

Adjust the water flow using the valve.

Do not use aggressive cleaning agents.

After leaf suction operations

Remove the covering on the suction

pipe.

32 EN

- 10

Cleaning the suction channel and the

waste container

Start the appliance.

Set the dry run speed to approx. 1800

1/min.

Turn on the working hydraulics (1st lev-

el).

Place the water hose in front of the suc-

tion opening.

Switch on the suction turbine and the

Shift the water supply to the side-brush-

Remove the suction hose from the claw

side-brushes (2nd step).

es and suction opening to operating

coupling under the vehicle.

Note

with high pressure cleaning.

Let the suction turbine run for approx. 2

Turn on the high-pressure cleaner.

minutes.

Raise waste container.

Cleaning the covering grid of the suction

channel

Raise waste container.

Switch off engine.

Clean the covering grid.

Cleaning the suction channel

Raise waste container.

Open the hand wheel of the valve by

Switch off engine.

turning it in anti-clockwise direction.

Danger

Connect the hoses at the claw coupling

Risk of injury! Wait for at least 1 minute until

Remove the hand-spray gun.

to the water supply and rinse.

the blower wheel stops rotating.

Wind off the high pressure hose.

Remove the connection to the water

supply and join the hose back to the

suction opening.

Close by turning the hand wheel of the

valve in clockwise direction.

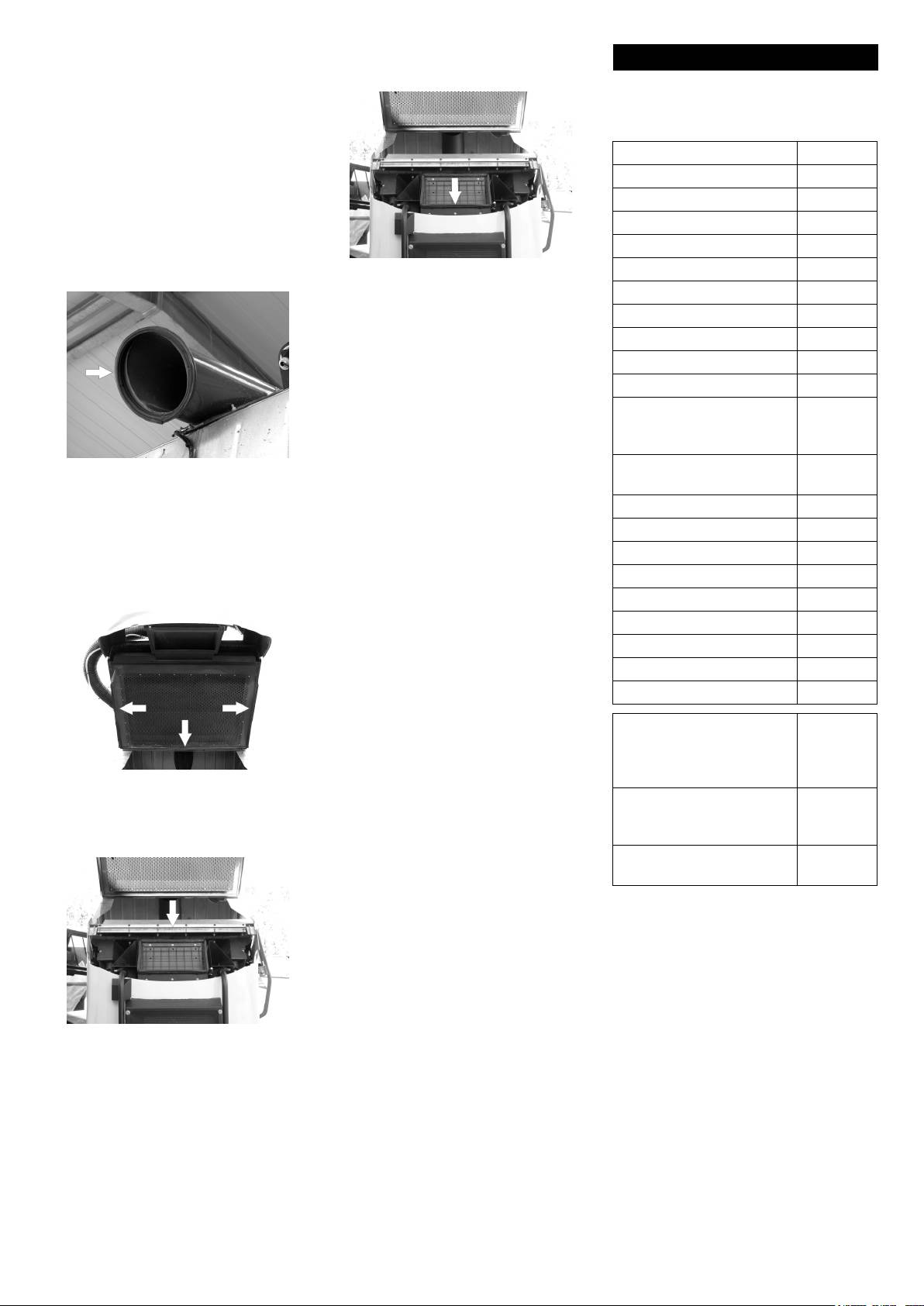

Clean the cooler

Remove the upper screws (1).

Clean the waste container.

Remove the strip (2).

Clean the perforated plate of the water

Loosen the lower screws (3).

drain on both the sides.

Remove the covering grid and clean the

suction channel.

Maintenance intervals

Open the clamps of the covering grid.

Remove the covering grid.

Note

The operating meter of the motor shows

the timing of the maintenance intervals.

Maintenance by the customer

Daily maintenance:

Clean the lighting.

Check engine oil level.

Clean the sealing areas of the suction

Check the hydraulic oil level.

channel.

Clean the cooler.

Clean the side-brushes.

Clean the covering grid of the suction

Clean the suction opening.

channel.

Clean the bulk waste flap.

1 Cooler for air-conditioner (accessory)

Check cooler water level.

Clean the hose connections.

2 Oil cooler

Check the air filter, clean if required.

If the hose connection between the waste

3 Water cooler

Check tube air filter/ motor.

container and the suction opening is

– Clean the cooler only when the motor

Check the side-brushes and suction

blocked, then proceed as follows:

has been switched off.

opening for wear and wrapped belts.

– Use a low-pressure water jet or com-

Check function of all operator control el-

pressed air to clean the cooler accord-

ements.

ing to the procedure described above.

Weekly maintenance:

– Do not clean using a high-pressure

Check sealing washer of suction pipe.

cleaner.

Check washers of the waste container.

Grease the bearings.

Check tyre pressure.

- 11

33EN

Check water level of wiper.

upward and lower the brush system to re-

Do not throw the battery in the

Clean water filter (frequently depending

move the pressure from the hydraulic sys-

dustbin!

on the water quality).

tem.

Check oil level of the water pump.

Danger

Check functioning and easy movement

Risk of injury! Secure the lid while working

Danger

of the bulk-waste flap.

inside the waste container.

Follow accident prevention regulations as

Check rollers to see that they move

Danger

well as DIN VDE 0510, VDE 0105 T.1.

easily.

Risk of injury due to engine overrun. Once

Danger

Lubricate the side-brush system.

the engine has been switched off, wait for 5

Risk of explosion! Do not put tools or similar

Additional maintenance to be carried out

seconds. Stay well clear of the working

on the battery, i.e. on the terminal poles

every 50 operating hours:

area for this time.

and cell connectors.

Check the function of the immobilizing

Allow the machine sufficient time to cool

brake.

Danger

down before carrying out any mainte-

Check the hydraulic system for leakag-

nance and repair work.

Risk of injury! Ensure that wounds never

es.

come into contact with lead. Always clean

– Cooling water is hot.

Check V-Belt for wear and tear.

your hands after having worked with batter-

– Do not touch any hot parts, such as the

ies.

Check coolant to see that it does not

drive motor and exhaust system.

frost.

Danger

Please do not release engine

Check hoses and clamps.

Risk of fire and explosion!

oil, fuel oil, diesel and petrol

Check wheels.

– Smoking and naked flames are strictly

into the environment. Protect

Check connections and conduits.

prohibited.

the ground and dispose of

Additional maintenance to be carried out

– Rooms where batteries are charged

used oil in an environmentally-

every 150 operating hours:

must have good ventilation because

clean manner.

Change engine oil.

highly explosive gas is emitted during

charging.

Replace motor oil filter inlay.

Safety notes regarding the batteries

Change the air filter.

Please observe the following warning notes

Danger

Empty the wate separator at the fuel fil-

when handling batteries:

Danger of causticization!

ter.

– Rinse thoroughly with lots of clear water

Observe the directions on the

Check battery acid level.

if acid gets into the eye or comes in con-

battery, in the instructions for

tact with the skin.

Clean the ventilation slits of the lights.

use and in the vehicle operat-

– Then consult a doctor immediately.

For description, see section on Mainte-

ing instructions!

nance work.

– Wash off the acid If it comes in contact

Wear an eye shield!

with the clothes.

Note

Where maintenance is carried out by the

Installing and connecting the battery

customer, all service and maintenance

Raise waste container.

work must be undertaken by a qualified

Insert battery in battery mount.

Keep away children from acid

specialist. If required, a specialised Kärch-

Screw on mounts on battery base.

and batteries!

er dealer may be contacted at any time.

Connect pole terminal (red cable) to

Maintenance by Customer Service

positive pole (+).

Maintenance to be carried out after 50 op-

Connect pole terminal to negative pole

Risk of explosion!

erating hours:

(-).

Carry out initial inspection.

Note

Additional maintenance to be carried out

Before removing the battery, make sure

every 150 operating hours:

that the negative pole lead is disconnected.

Fire, sparks, open light, and

Note

Check that the battery pole and pole termi-

smoking not allowed!

In order to safeguard warranty claims, all

nals are adequately protected with pole

service and maintenance work during the

grease.

warranty period must be carried out by the

Check fluid level in the battery and ad-

Danger of causticization!

authorised Kärcher Customer Service in

just if required

accordance with the maintenance booklet.

몇 Warning

Maintenance Works

Regularly check the fluid level in acid-filled

batteries.

Preparation:

First aid!

– The acid in a fully charged battery has a

Park the sweeper on an even surface.

specific weight of 1.28 kg/l at a temper-

Raise waste container completely.

ature of 20 °C.

Lower the side-brushes.

– The acid in a partially discharged bat-

Turn ignition key to "0" and remove it.

Warning note!

tery has a specific weight between 1.00

Lock parking brake.

and 1.28 kg/l.

Danger

– The specific weight of the acid must be

When carrying out repairs on public high-

uniform in all cells.

ways, wear warning clothing when working

Disposal!

Unscrew all cell caps.

close to passing traffic.

Take a sample from each cell using the

General notes on safety

acid tester.

Put the acid sample back into the same

Danger

cell.

Risk of injury! While carrying out mainte-

nance tasks, tilt the waste container fully

34 EN

- 12

Where fluid level is too low, top up cells

Use suitable, commercially available

Check engine oil level and top up, if re-

to the mark provided with distilled wa-

materials to carry out tyre repairs.

quired

ter.

Note

Danger

Charge battery.

Observe the manufacturer's recommenda-

Risk of burns!

Screw in cell caps.

tions. The journey may be resumed provid-

Allow engine to cool down.

Charging battery

ing that the directions supplied by the

Wait for at least 5 minutes after switch-

product manufacturer have been observed.

Danger

ing off the engine before checking the

The tyre/wheel change should nonetheless

Risk of injury! Comply with safety regula-

engine oil fill level.

be carried out as soon as possible.

tions on the handling of batteries. Observe

Raise waste container.

the directions provided by the manufacturer

of the charger.

Danger

Charge the battery only with an appropriate

charger.

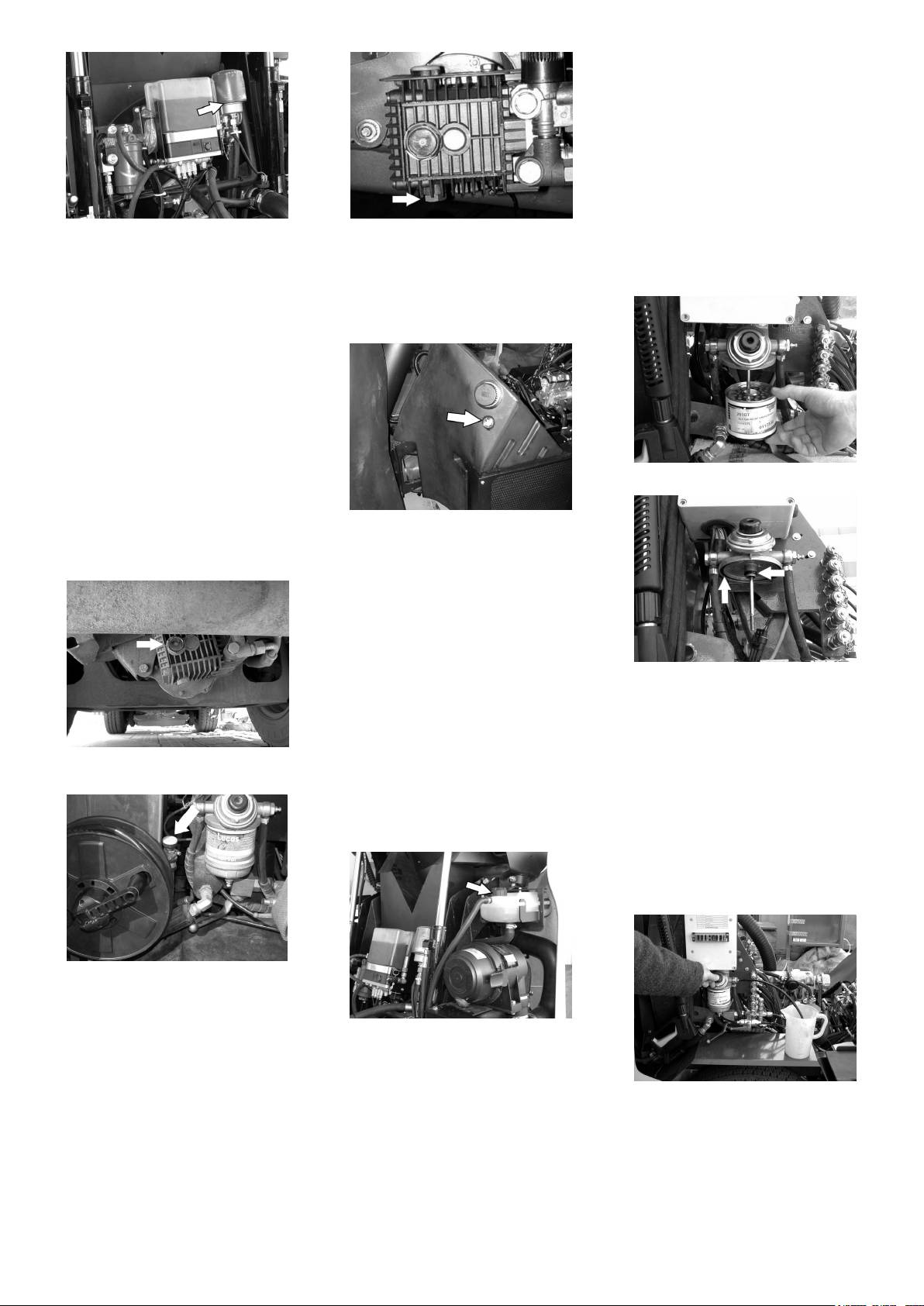

Intake point for the jack (front wheels)

Pull out oil dipstick.

Wipe off oil dipstick and insert.

Pull out oil dipstick.

Disconnect battery.

Connect positive terminal cable from

the charger to the positive pole connec-

tion on the battery.

Connect negative terminal cable from

the charger to the negative pole con-

Use the corresponding intake delivered

nection on the battery.

along with the vehicle.

Plug in mains connector and switch on

charger.

Read the value of the oil level.

Charge battery using lowest possible

Insert the oil dip again.

level of charging current.

– The oil level must lie between “MIN“

Note

and “MAX“ marking.

When the battery is charged, first remove

– Add motor oil if the oil level is below the

the charger from the mains and then dis-

"MIN" marking.

connect it from the battery.

– Do not fill oil above the "MAX" marking.

Check the tyre pressure

Loosen the screw cap of the oil filling

Park the sweeper on an even surface.

opening.

Connect air pressure testing device to

Fill in motor oil.

Intake point for the jack (rear wheels)

tyre valve.

Position vehicle jack at the appropriate

Oil grade: see Technical Data

Check air pressure and adjust if re-

mounting point for the front or rear

Close oil filler opening.

quired.

wheel.

Wait at least 5 minutes.

Loosen wheel nuts/ wheel bolts.

Check engine oil level.

Air pressure, front 3,75 bar

Raise machine using vehicle jack.

Change the motor oil and the oil filter

Air pressure, rear 4,75 bar

Remove wheel nuts/ wheel bolts.

Danger

Replacing wheel

Remove wheel.

Risk of burns due to hot oil!

Mount spare wheel.

Danger

Ready a catch bin for appr. 6 litre oil.

Insert the wheel nuts/ wheel bolts.

When carrying out repairs on public high-

Allow engine to cool down.

Lower machine using vehicle jack.

ways, wear warning clothing when working

close to passing traffic.

Tighten the wheel nuts/ wheel bolts.

Danger

Tightening torque for front

140 Nm

Risk of injury!

tyres

Park the sweeper on an even surface.

Tightening torque for rear tyres 120 Nm

Remove ignition key.

Check stability of ground. Also secure

Note

the machine with wheel chock(s) to pre-

Use a suitable commercially available vehi-

vent it rolling away.

cle jack.

Lock parking brake.

Check tyres

Unscrew oil drain plug.

Check tyre contact face for foreign ob-

Loosen the screw cap of the oil filling

jects.

opening.

Remove objects found.

Drain off oil.

- 13

35EN

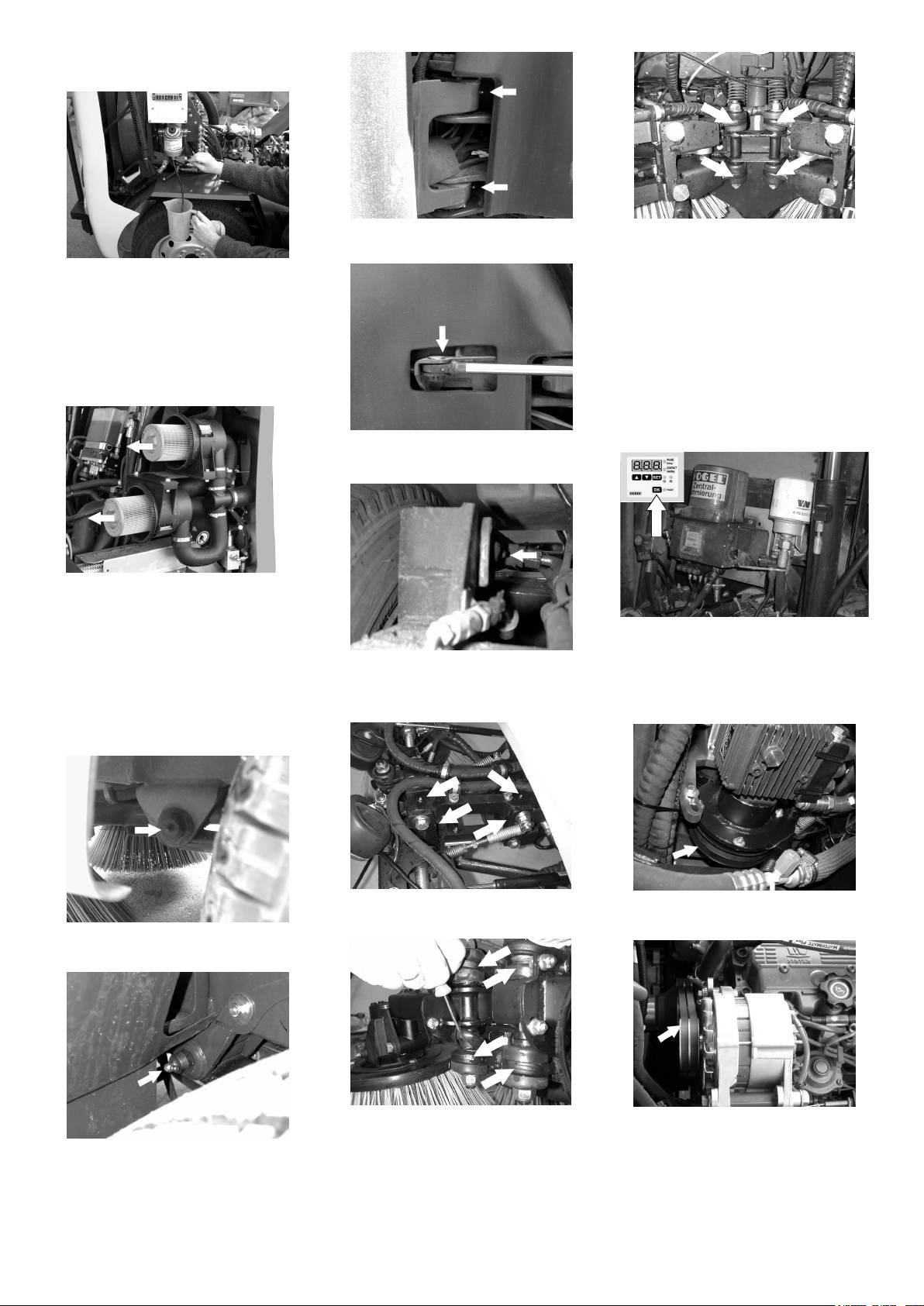

Clean and replace fuel filter

Danger

Risk of explosion!

– Do not carry out maintenance tasks in

closed rooms.

– Smoking and naked flames are strictly

prohibited.

Switch off engine.

Raise waste container.

Keep a suitable catch bin ready.

Unscrew the oil filter.

Oil change:

Loosen the fuel filter casing.

Clean the intake and sealing areas.

Ready a catch bin for appr. 1 litre oil.

Empty the fuel filter casing.

Coat the washer of the new oil filter with

Unscrew oil drain plug.

Remove the fuel filter casing.

oil before fitting it.

Oil grade: see Technical Data

Fit in the new oil filter and tighten it by

Check hydraulic oil level and refill hy-

hand.

draulic oil

Screw in the oil drain screw along with

the new washer.

Note

Tighten the oil drain screw using a torque

wrench to 25 Nm.

Fill in motor oil.

Oil grade: see Technical Data

Close oil filler opening.

Clean or replace fuel filter.

Let the motor run for approx. 10 sec-

onds.

Check engine oil level.

The oil level must be within the viewing

glass.

Check oil level in the water pump; refill

Clean the filling area.

and change oil

Loosen the screw cap of the oil filling

opening.

Refill hydraulic oil.

Oil grade: see Technical Data

Check hydraulic unit

Check all hydraulic hoses and connec-

Replace washers.

tions and ensure that they are leak-

Fit the fuel filter again.

proof.

Check fuel tubes and clamps for dam-

Only Kärcher Customer Service is author-

ages and make sure they are leak-

ised to carry out maintenance tasks on the

proof.

The oil level must be within the viewing

hydraulic unit.

Deaerate the fuel system

glass.

Check water cooler and maintain it

Deaerating the fuel system

Danger

Raise waste container.

Danger of scalding by boiling water! Let the

Insert the hose on the deaeration

cooler cool down for at least 20 minutes.

screw.

Turn the deaeration screw by one rota-

tion.

Keep a suitable catch bin ready.

Refill oil:

Clean the filling area.

Loosen the screw cap of the oil filling

opening.

Fill in cold water in the cooling water

Refill oil.

compensation tank.

Close oil filler opening.

If the motor is cold:

Check oil level.

– Cooling water level must be above the

Pump until fuel free of air bubbles is re-

lower marking.

leased.

If the motor is warm:

Close the deaeration screw.

– Cooling water level must be below the

upper marking.

– The percentage of anti-frost agent in

the cooling water should not be more

than 50%.

36 EN

- 14

Emptying the water separator of the fuel

system

Grease the lubrication nipple at the

Only 4-brush system:

swivel joint.

Lift the covering flaps at the swivel

heads.

Raise waste container.

Grease the swivel joints (8x).

Insert the hose on the drain screw.

Turn the drain screw by one rotation.

Central lubrication unit (accessory)

Keep a suitable catch bin ready.

The central lubrication unit automatically lu-

Close the release screw.

brications all the lubrication points at spec-

ified intervals.

Cleaning and replacing the fuel filter

Note

Raise waste container.

It is necessary to do an additional round of

greasing after the appliance has been

cleaned thoroughly.

Grease the lubrication nipple at the

steering cylinder.

Loosen the fasteners of the air filter

casing.

Remove covering lid.

Press the button on the central lubrica-

Remove and clean the filter cartridge.

tion unit.

Insert new filter cartridge, if required.

Grease the lubrication nipple at the

The central lubrication unit will not lubricate

Clean the screw cap.

steering cylinder.

the brush-system.

Replace the screw cap and clamp it.

Greasing the brush-system

Checking the V-Belt

Fix the fasteners of the air filter casing.

Greasing the bearings

Grease the lubrication nipple at the

Check the V-Belt of the spray-water

brush-system (8x).

pump for damage and wear and tear.

Grease the left end right lubrication nip-

ples of the front axle.

Only 4-brush system:

Raise waste container.

Lift the covering flaps at the swivel

Check the V-Belt of the lighting system

Grease the left end right lubrication nip-

heads.

for damage and wear and tear.

ples of the rear axle.

Grease the swivel joints (8x).

Refilling wiper water

Refill water for the wiper.

- 15

37EN

Drive machine backwards.

Maintaining the wiper

Check sweeping mirror.

Loosen the fastening screw (1).

Clean/ set the spray nozzles:

Adjust the inclination of the side-brush-

Clean the spray nozzle opening (1) us-

Contact surfaces of the side-brushes dur-

es in the drive direction by adjusting the

ing a wire.

ing optimal setting (4-brush system).

holder (2).

Adjust the spraying direction by turning

Note

the spray head with a wire.

Set the left and right side always at the

Change the wiper blades:

same value.

Remove the fastening screw (2).

Adjusting the inclination of the front

Change the wiper blade.

side-brushes in drive direction (only 4-

Replacing side brush

brush system)

Lock parking brake.

The side-brushes lift up.

Clip side brush on to driver and screw

on.

Contact surfaces of the side-brushes dur-

ing optimal setting (2-brush system).

Adjusting the side inclination of the rear

side-brushes (only 4-brush system)

Loosen the fastening screws (1) of the

side-brush attachment .

Adjust the inclination of the side-brush-

es in the drive direction by turning the

holder (2).

Changing the wiper blade with the intake:

Loosen the central screw.

Adjusting the inclination of the side-

Remove the wiper blade.

brushes (only 2-brush system)

Fix in the new wiper blade.

Loosen the fastening screw (1).

Adjust the side inclination of the side-

brushes by adjusting the holder (2).

Adjusting the inclination of the rear side-

brushes in drive direction (only 4-brush

system)

Note

Always set the rear side-brushes first be-

cause changes to the rear inclination will

have an effect on the inclination of the front

Loosen the fastening screws (1) and (2)

brushes.

of the side-brush attachment .

Changing the wiper blade without the in-

take:

Set the inclination of the side-brushes.

Loosen the hexagonal nuts:

Setting the brush contact pressure

Remove the wiper blade.

Increase/ reduce the brush pressure by

Fix in the new wiper blade.

adjusting the setting screw (3).

Checking the sweeping mirror of the

Note

side-brushes

In the 4-brush system, the contact pressure

Check tyre pressure and adjust if re-

can only be set for the front side-brushes.

quired.

Set the idle running for the motor rpm

setting to 1600-1800 1/min.

Remove floor mat.

The side-brushes lift up.

Remove the floor plates (1) and (2).

Drive sweeper on to a smooth, even

surface covered with a visible layer of

dust or chalk.

Lower side-brushes and allow them to

briefly rotate.

The side-brushes lift up.

38 EN

- 16

Loosen the fastening screws of the

Filling up the water tank

Cleaning and replacing the water filter

sealing strip.

Remove the stabilising plate.

Remove the sealing strip.

Insert the new sealing strip and fasten it

with screws along with the stabilising

plate.

Drain off the suction opening.

Adjust the sealing strip.

Tighten the fastening screws of the

sealing strip.

Unscrew the tank coupling.

Turn off tap (1).

Changing the running rollers of the suc-

Connect a textile hose to the tank cou-

Unscrew the water filter casing (2).

tion opening (only 4-brush system)

pling and hydrant.

Clean or replace the water filter.

Fill up the water tank:

Clean the water filter casing.

Note

Check rubber washers.

Fill up the water tank until it overflows.

Install the water filter.

Turn on the tap (1).

Deaerating the spray-water system

Note

Cleaning the spray nozzles on the side-

If the water tank had got completely empty,

brushes

then it is necessary to deaerate the spray

water system after the tank has been filled

up.

Remove wheel.

Remove the fastening nuts of the run-

ning rollers.

Replace the running rollers.

Replace the fastening nuts of the run-

ning rollers.

Changing the slide bar of the bulk waste

flap (only 4-brush system)

Unscrew the union joint (1).

Pull out the spray nozzle (2).

Clean the spray nozzle.

Open the valve until bubble free water

Setting and replacing the sealing strip of

comes out.

the suction opening (only 4-brush sys-

Now close the valve.

tem)

Emptying the water tank

Remove the fastening screws of the

slide bar.

Replace the side bar.

Fasten the slide bar.

Setting and replacing the sealing strip of

the suction opening (only 2-brush sys-

Adjusting the sealing strip:

tem)

Open the drain screw below the water

Loosen the fastening screws of the

tank.

sealing strip.

Note

Drain off the suction opening.

Ensure that the water flowing out does not

cause any damage.

Adjusting the sealing strip:

Loosen the screws.

Drain off the suction opening.

Adjust the sealing strip on the side and

the rear so as to have a distance of 10

Adjust the rear running rollers (3) in

mm from the floor.

such a way that the side sealing strip (1)

has a floor clearance of 20 mm at the

Tighten the fastening screws of the

rear.

sealing strip.

Replacing the sealing strip:

- 17

39EN

Adjust the front sealing strip (2) so that

Changing the washer of the turbine suc-

Accessories

it touches the floor.

tion

Tighten the fastening screws of the

Note

sealing strip.

Attachment sets for new vehicles are also

Replacing the sealing strip:

available ex-factory.

Loosen the screws.

Spare wheel, complete 6.996-001

Remove the sealing strip.

Screw on the new sealing strip.

Bush plate 6.996-002

Drain off the suction opening.

Side brushes, plastic/ plastic 6.996-003

Adjust the sealing strip.

Side-brushes, steel plate 6.996-004

Tighten the fastening screws of the

sealing strip.

Side-brushes, PE/Steel 6.906-258

Changing the washer of the suction pipe

Remove the washer.

Breakdown triangle 6.996-005

Clean the sealing area.

Bulbs/ fuse set 6.996-006

Insert the new washer and paste it.

Wheel wedge 6.996-007

Changing the headlight bulb

Air-conditioner 2.639-614

Loosen the screws.

Radio 2.639-615

Remove the headlights.

Remove defective bulb.

Leaf suction hose 2.639-616

Insert new bulb.

Overall warning lamp, rear

2.639-617

Changing the bulb of the travel direction

(only for appliances without

indicator

leaf suction)

Loosen the screws.

Comfort seat (higher back-

2.639-618

Raise waste container.

Remove the glass of the travel direction

rest)

Remove the washer.

indicator.

Clean the sealing area.

Rear mirror, with heating 2.639-619

Remove defective bulb.

Insert the new washer and paste the

Battery charger 6.654-116

Insert new bulb.

ends using silicon.

Central lubrication unit 2.639-635

Replacing the bulb of the tail lamp

Changing the washer of the waste con-

Loosen the screws.

Bumper at the rear 2.639-636

tainer

Remove the glass of the tail lamp.

Reverse drive camera 2.639-641

Remove defective bulb.

Jack 6.369-518

Insert new bulb.

Hose holder for filling hose 2.639-645

Replacing the fuses in the fuse box in

the driver cabin

Safety warnings 2.639-869

Note

Hydraulic side-brush relief 2.850-816

Only use fuses with identical safety ratings.

2. Regulation valve (for reg-

2.640-216

Replace defective fuses.

ulating the spray water

Replacing the fuses in the fuse box of

quantity separately on the

the motor compartment

right and the left)

Raise waste container.

Replace defective fuses.

Remove the washer.

Solenoid valve (for stopping

2.640-217

Clean the sealing area.

the spray water and lifting

the brushes)

Insert the new washer and paste it.

Attachment set for bypass

2.641-197

valve

Remove the washer.

Clean the sealing area.

Insert the new washer and paste it us-

ing silicon.

40 EN

- 18