Karcher B 250 R I + R 120: Operation

Operation: Karcher B 250 R I + R 120

-

5

Release the park brake (see "Pushing

the appliance").

One person must sit on the seat and ac-

tivate the brake pedal during the push-

ing if necessary.

Push down the appliance through the

ramp from the pallet.

Re-tighten the screws of the park brake.

The sweep brushes must be installed be-

fore the initial operation (see "Maintenance

work").

The brushes are mounted.

Insert the vacuum bar into the vacuum

bar suspension in such a manner that

the profiled sheet is positioned above

the suspension.

Tighten the wing nuts.

Insert the suction hose.

Note:

Press emergency-stop switch to immedi-

ately switch off all functions of the machine.

DANGER

Risk of accident. Prior to every operation,

the parking brake must be checked for

proper function on a level ground.

Take the seating position.

Release emergency-stop button by

turning.

Set main switch to “1”.

Select direction of travel.

Gently depress drive pedal.

The brake must get released and you must

be able to hear it (the control lamp for im-

mobilizing brake on the console switches

off). The machine must roll slightly on a

plane surface. When the pedal is released,

the brake falls in an audible manner.

Switch off the machine and call the after-

sales service if the above-mentioned

events do not occur.

DANGER

Risk of accident! If the machine does not

brake, then proceed as follows:

If the machine does not come to a halt

on a ramp with a gradient of 2% when

you release the drive pedal, then the

emergency-stop button may be

pressed for safety reasons only if the

mechanical functioning of the immobi-

lizing brake has been checked properly

before commissioning the machine.

Press the brake pedal if the machine

does not brake properly.

Switch off the machine only after it

comes to a complete halt (on an even

surface) and call up the aftersales ser-

vice!

Further, follow all warning instructions

for braking.

DANGER

Danger of tipping if gradient is too high.

The gradient in the direction of travel

should not exceed 15%.

Danger of tipping when driving round

bends at high speed.

Danger of slipping on wet floors.

Drive slowly when cornering.

Danger of tipping on unstable ground.

Only use the machine on sound surfac-

es.

Danger of tipping with excessive sideways

tilt.

The gradient perpendicular to the direc-

tion of travel should not exceed 15%.

DANGER

Increased risk of accident on account of tilt-

ing sweeper for B 250 RI models. Be extra

careful while driving reverse and pay atten-

tion to the swiveling movement while steer-

ing the sweeper.

Move the seat adjustment lever away

from the seat and hold it.

Then push the seat forwards or back-

wards.

Release the seat adjustment lever and

lock the seat in place.

Loosen the wing nut to adjust the steer-

ing wheel.

Position the steering wheel.

Tighten the wing nuts.

Release emergency-stop button by

turning.

Sit on the seat and set main switch to

“1”.

Set the drive direction using the drive

direction button at the operator console.

Determine the driving speed by press-

ing the drive pedal.

Stop the machine: Release driving ped-

al; press brake, if necessary.

Note:

The direction of travel can also be changed

while driving. This way, even heavily soiled

spots can be cleaned by driving back and

forth several times.

In case of overloading, the drive motor au-

tomatically switches off after a certain peri-

od. A fault message is displayed on the

console. The concerned unit gets switched

off if the controls get overheated.

Allow machine to cool down at least for

15 minutes.

Turn the key switch to "0", wait for a few

seconds and then turn it to "1".

Loosen the three hexagonal screws by

key width 7 mm (arrow) by three revolu-

tions each to unlock the emergency

brake.

Push the appliance.

Retighten the screw.

DANGER

Danger of accident by failing brakes.

Retighten the screws immediately after the

sliding process.

ATTENTION

Risk of damage to the suction turbine if op-

erated without flat folded filter.

Prior to operating the appliance, check

the flat folded filter inside the lid of the

waste water tank for its presence, cor-

rect installation and condition.

Replace damaged flat folded filter.

ATTENTION

Risk of damage. Only use the recommend-

ed detergents. With other detergents, the

operator bears the increased risk regarding

the operational safety and danger of acci-

dent.

Only use detergents that are free from sol-

vents, hydrochloric acid and hydrofluoric

acid.

몇

CAUTION

Follow the safety instructions for using de-

tergents.

Note:

Do not use highly foaming detergents.

Recommended detergents:

Without battery

Installing the Brushes

BD model

BR model

Installing the Vacuum Bar

Operation

Check immobilizing brake

Driving

Ajdust the seat

Adjusting the steering wheel

Drive the machine

Overload

Pushing the device

Check flat folded filter

Filling in detergents

Detergent

21 EN

-

6

Open the cover of the fresh water reser-

voir.

Fill fresh water (max. 60 °C) until 15 cm

below the upper edge of the tank.

Pour in detergent.

Close the cover of the fresh water res-

ervoir.

Note:

Fill up the fresh water tank completely prior

to the initial start-up to bleed the water pipe

system.

With automatic fill of fresh water reser-

voir (option)

Note:

It is recommended to use a hose that is

equipped with an Aquastop coupling on the

appliance side. This minimises the spout-

ing of water when the hose is disconnected

after the filling process.

Connect the hose to the automatic fill-

ing system and open the water supply

(max. 60 °C, max. 5 bars).

Wait briefly - the automatic filling sys-

tem will interrupt the water supply when

the tank is full.

Shut off the water supply and discon-

nect the hose from the appliance.

Detergent is added to the fresh water on

the way to the cleaning head with the help

of a dosaging device.

Note:

The dosing unit can be used to add 3% de-

tergent at maximum. With higher dosage

the detergent must be put into the fresh wa-

ter tank.

Place the canister with the detergent in

the trough behind the seat.

Unscrew the canister lid.

Insert the suction hose of the dosing

equipment into the canister.

Note:

– The appliance is equipped with a fresh

water indicator in the display. If the

fresh water tank is empty, the function

of adding detergent gets deactivated.

The cleaning head continues to work

without liquid supply.

– Detergent addition is also stopped

when the detergent can is empty. Indi-

cator lamp: "detergent tank empty"

glows red. Only fresh water is supplied

to the cleaning head.

The sweeper picks up loose dirt before

cleaning the floor.

ATTENTION

Risk of damage to the sweeper.

–

Do not sweep in packing tapes, wires or

similar objects.

–

Only drive over steps with a maximum

height of 2 cm with the B 250 RI mod-

els.

–

The dust filter can get blocked or germs

can form in it. Use the sweeper only to

sweep dry surfaces.

몇

WARNING

Risk of injury!

Suction turbine, side brushes and filter

cleaner continue to run for a while after

switching off.

Switch on "sweeping" button.

The sweeper is activated. The indicator

lamp "sweeping" is on during the opera-

tions.

The bulk waste flap can be raised to sweep

in larger objects (up to max. 6 cm height).

몇

DANGER

Risk of injury on account of electric shock.

Raise the bulk waste flap only when there

is no person standing close by.

Press the pedal for raising the bulk

waste flap.

Note:

The vacuuming and sweeping performance

is lower when the bulk waste flap is raised.

Hence, raise the bulk waste flap only when

needed.

Set "sweeping" button to "0".

The sweeper is deactivated. Once you

have stopped sweeping, the dust filter is

cleaned for approx. 15 seconds. The indi-

cator lamp "dust filter shaking" glows.

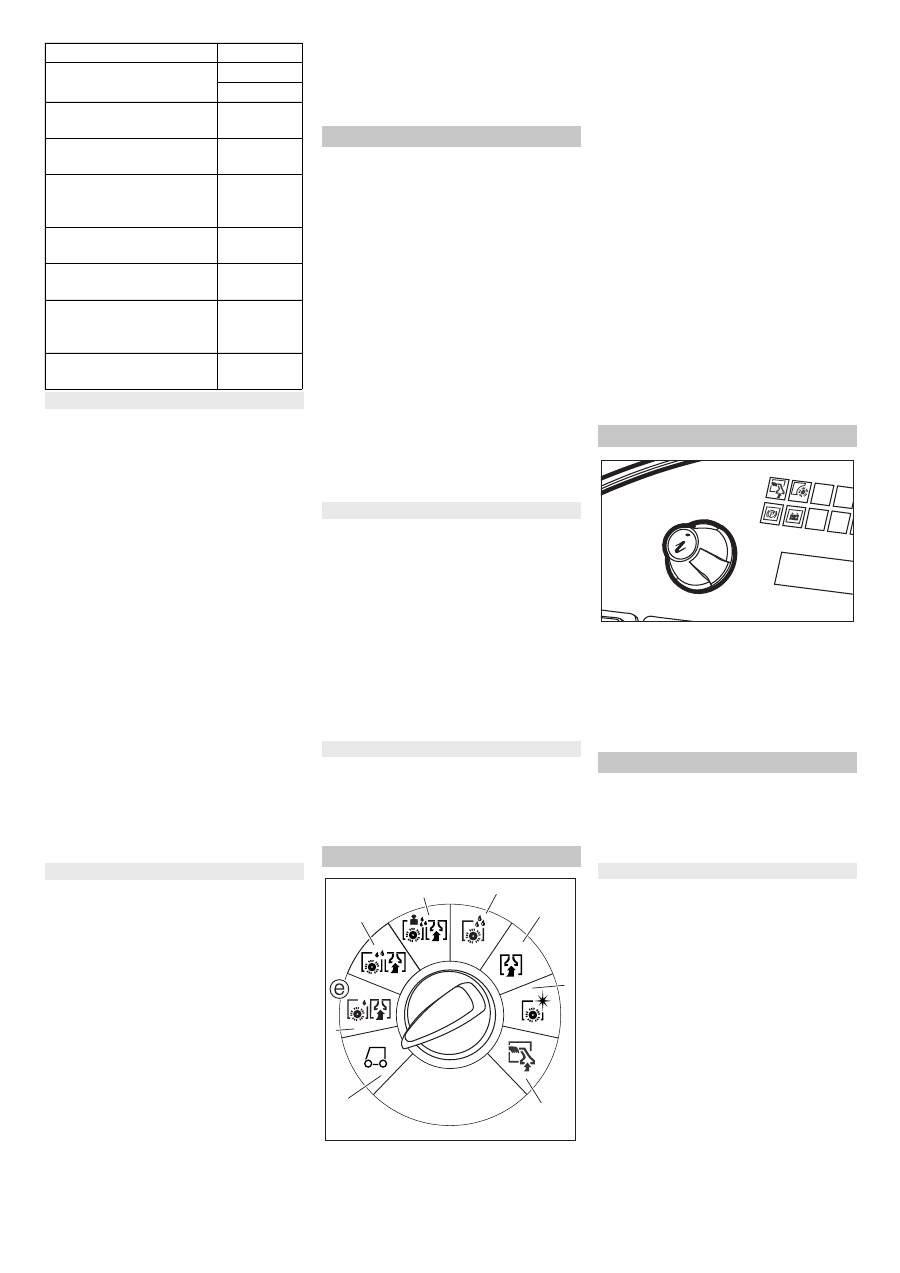

1

Transport mode

Driving to the Place of Use.

2

Eco mode

Wet clean the floor (with reduced brush

speed) and vacuum up wastewater

(with reduced suction).

3

Normal mode

Wet clean the floor and vacuum up dirt

water.

4 Increased brush contact pressure

Wet clean the floor (with increased

brush contact pressure) and vacuum up

dirt water.

5

Intense mode

Wet clean the floor and allow the deter-

gent to react.

6

Vacuum mode

Suck in the dirt fleet.

7

Polishing mode

Polishing the floor without the applica-

tion of liquid.

8 Manual cleaning

Apply liquid detergent using the wall-

ceiling-floor nozzle (optional) and vacu-

um it again.

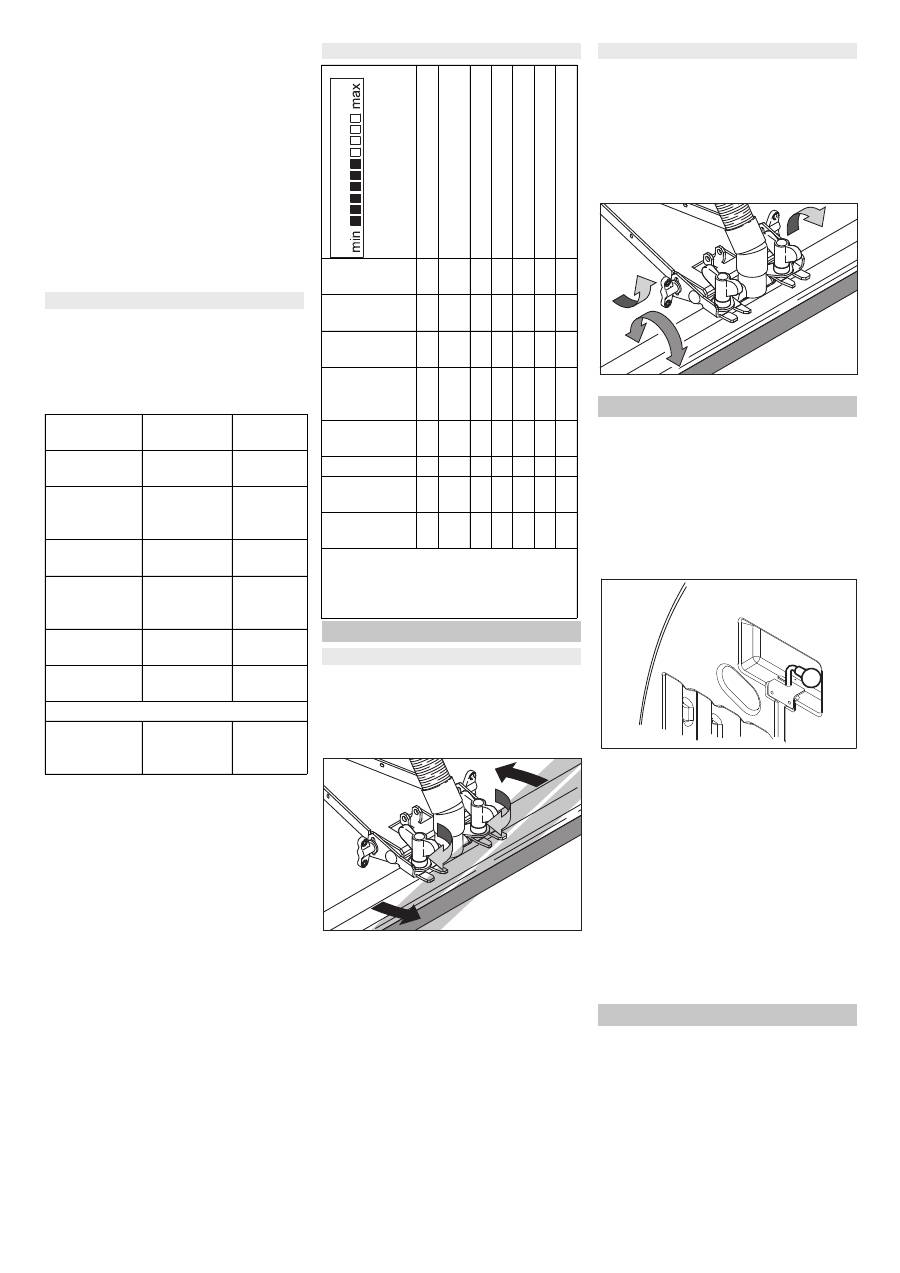

Use the Info button to select the menu

items and do the settings.

– Turning the button to the right/left

scrolls through the menus forward/

backward.

– The selected setting gets accepted by

pressing the button.

You can make the settings for the different

cleaning programs in the operator menu.

Different parameters can be set based on

the cleaning program. The settings are

done using the Info button.

Release emergency-stop button by

turning.

Sit on the seat and set main switch to

“1”.

The display shows the battery charging

status and the fresh water level.

Select cleaning program.

Call the operator menu by turning the

info button.

Select the desired parameter by turning

the Info button. The currently set value

is displayed as a bar.

Press Info button, the bar display blinks.

Reset the parameter by turning the Info

button between "min" and "max".

Accept modified setting by pressing the

Info button or wait till the set value is ac-

cepted automatically.

Application

Detergent

Routine cleaning of all water

resistant floors

RM 745

RM 746

Routine cleaning of glossy

surfaces (e.g. granite)

RM 755 ES

Routine cleaning and basic

cleaning of industrial floors

RM 69 ASF

Routine cleaning and basic

cleaning of fine stoneware

tiles

RM 753

Routine cleaning of tiles in

sanitary areas

RM 751

Cleaning and disinfection in

sanitary areas

RM 732

Removal of coating from all

alkali-resistant floors (e.g.

PVC)

RM 752

Removal of coating from li-

noleum floors

RM 754

Fresh water

Metering device (option)

Sweeping (B 250 RI only)

Bulk waste flap

Stopping sweeping

Program selection switch

1

2

3

4

5

6

7

8

Info button

Settings

Operations menu

22 EN

-

7

Note:

– If the selected parameter does not

change within 10 seconds, then the dis-

play goes back to displaying the battery

charging status and the fresh water lev-

el.

– The same cleaning parameter can have

individual settings for each cleaning

program.

– The brush pressure can be set only

when the machine is on in the programs

brush suction, wet brushing, polishing

and polishing suction.

– All settings are saved in the powerless

state of the machine.

Select the menu item "Accept default

values?" in the operator menu by turn-

ing the Info button

Press Info button. The factory settings

of all parameters are restored for each

cleaning program.

The table given below gives details of the

factory settings of the parameters for the

cleaning programs. If no values are en-

tered, then the respective parameter can-

not be set in the given cleaning program.

To improve the vacuuming result on tiled

floors the vacuum bar can be turned to an

oblique position of up to 5°.

Release the wing nuts.

Turn the vacuum bar.

Tighten the wing nuts.

If the vacuum result is unsatisfactory the in-

clination of the straight vacuum bar can be

modified.

Note:

The bent vacuum bar must be adjusted

horizontally.

Release the wing nuts.

Tilt the vacuum bar.

Tighten the wing nuts.

– During normal operations (fresh water

mode), water is taken from the fresh

water tank and collected in dirt water

tank after use.

– Water can be circulated for floors with

dirt levels of slight to normal.

First clean in the fresh water mode till

the water in the fresh water tank has

been consumed.

The set the switching of recyling/ fresh

water mode to Recycling.

Note:

– The dirt water is cleaned by a filter be-

fore being reused.

– For recycling operations, the entire re-

cycling filter must lie below the dirt wa-

ter level.

ATTENTION

Risk of damage due to overdose of deter-

gent. Very often, the detergent contained

in the dirt water has only been partially

used. Hence, in the recycling mode, the

detergent quantity to be added is to be set

to 0.

Note:

Overflow waste water tank. If the dirt water

tank is full, the suction turbine switches off

and the indicator lamp "dirt water tank full"

begins to blink. All cleaning programs with

suction are blocked for one minute. Empty

the waste water tank.

Reset parameters

Adjustable pa-

rameters

min:step:ma

x

Remark

Water quantity 1:1:8

1=min.,

8=max.

Detergent dos-

ing unit

0:1:3

0=Off,

1=min.,

3=max.

Brush pressure 0:1:8

0=min.,

8=max.

FACT (brush

speed)

–

Power,

Whisper,

Fine Clean

Brush rotation

time after stop

0s:1s:3s

From idling

to lifting

Working speed 1:1:6

1=1km/h,

6=6km/h

For B 250 RI only:

Trailing time for

sweeper after

stopping

0s:1s:5s

From idling

to lifting

Factory setting BR...:

Water quantity

Detergent dosage (%)

Brush pressure

FACT (brush speed)

Brush trailing time (s)

Working speed

Suction blower value

Transport

mode

– –

– – – – –

Eco mode

2 0,5 2 W

P

2 8 W

Normal mode

3 1

4 P

C

2 6 P

Increased

brush contact

pressure

4 3

7 P

C

2 6 P

Intense mode

5 3

4 P

C

2 6 –

Vacuum mode

– –

– – – 6 P

Polishing

mode

– –

2 – – 6 –

Manual clean-

ing

– –

– – – – P

P=Power

PC=Power Clean

W=Whisper

WP=Whisper Clean

Setting the Vacuum Bar

Oblique position

Inclination

Recycling operations (option)

Empty tanks

23 EN

Оглавление

- Inhaltsverzeichnis

- Bedien- und Funktionselemente

- Vor Inbetriebnahme

- Betrieb

- Pflege und Wartung

- Hilfe bei Störungen

- Technische Daten

- EG-Konformitätserklärung

- Contents

- Operating and Functional Elements

- Before Startup

- Operation

- Maintenance and care

- Troubleshooting

- Technical specifications

- EC Declaration of Conformity

- Table des matières

- Eléments de commande et de fonction

- Avant la mise en service

- Fonctionnement

- Entretien et maintenance

- Assistance en cas de panne

- Caractéristiques techniques

- Déclaration de conformité CE

- Indice

- Elementi di comando e di funzione

- Prima della messa in funzione

- Funzionamento

- Cura e manutenzione

- Guida alla risoluzione dei guasti

- Dati tecnici

- Dichiarazione di conformità CE

- Inhoud

- Elementen voor de bediening en de functies

- Voor de inbedrijfstelling

- Werking

- Onderhoud

- Hulp bij storingen

- Technische gegevens

- EG-conformiteitsverklaring

- Índice de contenidos

- Elementos de operación y funcionamiento

- Antes de la puesta en marcha

- Funcionamiento

- Cuidados y mantenimiento

- Ayuda en caso de avería

- Datos técnicos

- Declaración de conformidad CE

- Índice

- Elementos de comando e de funcionamento

- Antes de colocar em funcionamento

- Funcionamento

- Conservação e manutenção

- Ajuda em caso de avarias

- Dados técnicos

- Declaração de conformidade CE

- Indholdsfortegnelse

- Betjenings- og funktionselementer

- Inden ibrugtagning

- Drift

- Pleje og vedligeholdelse

- Hjælp ved fejl

- Tekniske data

- EU-overensstemmelses- erklæring

- Innholdsfortegnelse

- Betjenings- og funksjonelementer

- Før den tas i bruk

- Drift

- Pleie og vedlikehold

- Feilretting

- Tekniske data

- EU-samsvarserklæring

- Innehållsförteckning

- Manövrerings- och funktionselement

- Före ibruktagande

- Drift

- Skötsel och underhåll

- Åtgärder vid störningar

- Tekniska data

- Försäkran om EU- överensstämmelse

- Sisällysluettelo

- Ohjaus- ja käyttölaitteet

- Ennen käyttöönottoa

- Käyttö

- Hoito ja huolto

- Häiriöapu

- Tekniset tiedot

- EU- standardinmukaisuustodistus

- Πίνακας περιεχομένων

- Στοιχεία χειρισμού και λειτουργίας

- Πριν τη θέση σε λειτουργία

- Λειτουργία

- Φροντίδα και συντήρηση

- Αντιμετώπιση βλαβών

- Τεχνικά χαρακτηριστικά

- Δήλωση Συμμόρφωσης των Ε . Κ .

- İ çindekiler

- Kullan ı m ve çal ı ş ma elemanlar ı

- Cihaz ı çal ı ş t ı rmaya ba ş lamadan önce

- Çal ı ş t ı rma

- Koruma ve Bak ı m

- Ar ı zalarda yard ı m

- Teknik Bilgiler

- AB uygunluk bildirisi

- Оглавление

- Защита окружающей среды Гарантия

- Описание элементов управления и рабочих узлов

- Перед началом работы

- Эксплуатация

- Уход и техническое обслуживание

- Помощь в случае неполадок

- Технические данные

- Заявление о соответствии ЕС

- Tartalomjegyzék

- Kezelési- és funkciós elemek

- Üzembevétel el ő tt

- Üzem

- Ápolás és karbantartás

- Segítség üzemzavar esetén

- M ű szaki adatok

- EK konformitási nyiltakozat

- Obsah

- Ovládací a funk č ní prvky

- P ř ed uvedením do provozu

- Provoz

- Ošet ř ování a údržba

- Pomoc p ř i poruchách

- Technické údaje

- Prohlášení o shod ě pro ES

- Vsebinsko kazalo

- Upravljalni in funkcijski elementi

- Pred zagonom

- Obratovanje

- Nega in vzdrževanje

- Pomo č pri motnjah

- Tehni č ni podatki

- ES-izjava o skladnosti

- Spis tre ś ci

- Elementy urz ą dzenia

- Przed pierwszym uruchomieniem

- Dzia ł anie

- Czyszczenie i konserwacja

- Usuwanie usterek

- Dane techniczne

- Deklaracja zgodno ś ci UE

- Cuprins

- Elemente de utilizare ş i func ţ ionale

- Înainte de punerea în func ţ iune

- Func ţ ionarea

- Îngrijirea ş i între ţ inerea

- Remedierea defec ţ iunilor

- Date tehnice

- Declara ţ ie de conformitate CE

- Obsah

- Ovládacie a funk č né prvky

- Pred uvedením do prevádzky

- Prevádzka

- Starostlivos ť a údržba

- Pomoc pri poruchách

- Technické údaje

- Vyhlásenie o zhode s normami EÚ

- Pregled sadržaja

- Komandni i funkcijski elementi

- Prije prve uporabe

- U radu

- Njega i održavanje

- Otklanjanje smetnji

- Tehni č ki podaci

- EZ izjava o uskla đ enosti

- Pregled sadržaja

- Komandni i funkcioni elementi

- Pre upotrebe

- Rad

- Nega i održavanje

- Otklanjanje smetnji

- Tehni č ki podaci

- Izjava o uskla đ enosti sa propisima EZ

- Съдържание

- Обслужващи и функционални елементи

- Преди пускане в експлоатация

- Експлоатация

- Грижи и поддръжка

- Помощ при неизправности

- Технически данни

- Декларация за съответствие на ЕО

- Sisukord

- Teenindus- ja funktsioonielemendid

- Enne seadme kasutuselevõttu

- Käitamine

- Korrashoid ja tehnohooldus

- Abi häirete korral

- Tehnilised andmed

- EÜ vastavusdeklaratsioon

- Satura r ā d ī t ā js

- Vad ī bas un funkcijas elementi

- Pirms ekspluat ā cijas uzs ā kšanas

- Darb ī ba

- Kopšana un tehnisk ā apkope

- Pal ī dz ī ba darb ī bas trauc ē jumu gad ī jum ā

- Tehniskie dati

- EK Atbilst ī bas deklar ā cija

- Turinys

- Valdymo ir funkciniai elementai

- Prieš pradedant naudoti

- Naudojimas

- Prieži ū ra ir aptarnavimas

- Pagalba gedim ų atveju

- Techniniai duomenys

- EB atitikties deklaracija

- Зміст

- Елементи управління і функціональні вузли

- Перед початком роботи

- Експлуатація

- Догляд та технічне обслуговування

- Допомога у випадку неполадок

- Технічні характеристики

- Заява при відповідність Європейського співтовариства