Karcher Balayeuse KM 120-150 R D – страница 2

Инструкция к Воздушной Завесе Karcher Balayeuse KM 120-150 R D

Please read and comply with

Maintenance and care . . . . . EN . 10

dling the appliance or have proven

these original instructions prior

qualification and expertise in operating

General notes . . . . . . . .

EN

. 10

to the initial operation of your appliance and

the appliance or have been explicitly

Cleaning the inside of the

store them for later use or subsequent own-

assigned the task of handling the appli-

machine . . . . . . . . . . . . . EN

. 10

ers.

ance.

External cleaning of the ap-

Before first start-up it is definitely neces-

pliance . . . . . . . . . . . . . . EN

. 10

– The appliance must not be operated by

sary to read the safety indications no.

Maintenance intervals . .

EN

. 10

children, young persons or persons

5.956-250!

who have not been instructed accord-

Maintenance Works . . . .

EN

. .11

ingly.

Troubleshooting . . . . . . . . . . EN . 16

Contents

– It is strictly prohibited to take co-pas-

Technical specifications . . . . EN . 17

sengers.

Accessories . . . . . . . . . . . . . EN . 18

Appliance description . . . . . EN . . . 1

– Ride-on appliances may only be started

Installation set suction hose

EN

. 18

Safety instructions . . . . . . . EN . . . 1

after the operator has occupied the driv-

EC Declaration of Conformity EN . 18

General notes . . . . . . . .

EN

. . . 1

er's seat.

Warranty . . . . . . . . . . . . . . . EN . 18

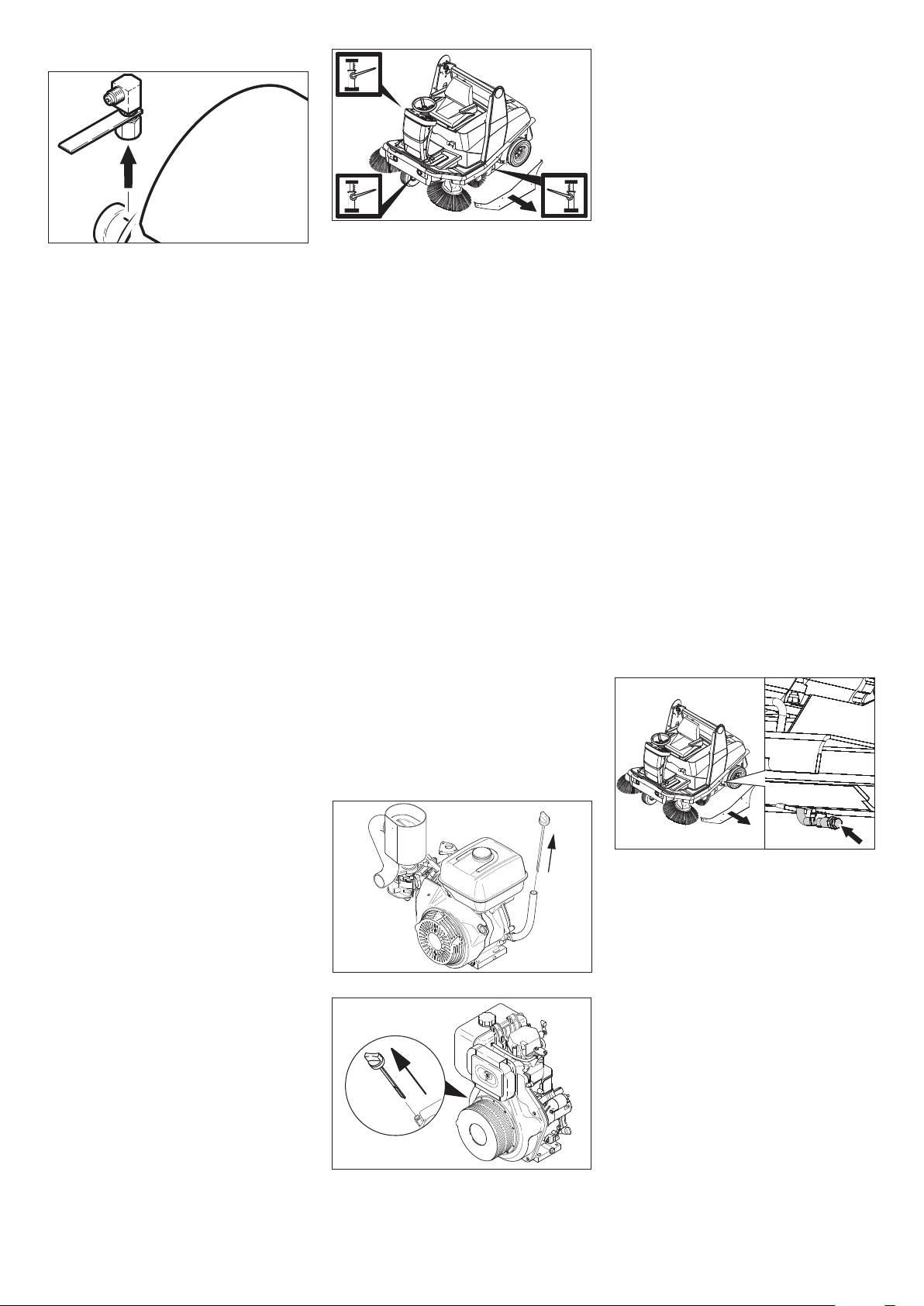

Symbols on the machine

Please remove the ignition key, when

EN

. . . 2

not in use, to avoid unauthorised use of

Symbols in the operating in-

structions. . . . . . . . . . . . EN

. . . 2

Appliance description

the appliance.

Safety Guidelines for liqui-

Never leave the machine unattended

– KM 120/150 R G = Petrol engine

fied gas vehicles (only KM

so long as the engine is running. The

– KM 120/150 R D = diesel engine

120/150 R LPG) . . . . . . EN

. . . 2

operator may leave the appliance only

– KM 120/150 R LPG = gas engine

Function . . . . . . . . . . . . . . . EN . . . 3

when the engine has come to a stand-

Proper use . . . . . . . . . . . . . EN . . . 3

still, the appliance has been protected

Suitable surfaces. . . . . .

EN

. . . 3

Safety instructions

against accidental movement, if neces-

sary, by applying the immobilization

Environmental protection . . EN . . . 3

– The machine (without driver cabin) has

brake and the ignition key has been re-

Operating and Functional Ele-

been approved for use on surfaces with

ments . . . . . . . . . . . . . . . . . EN . . . 4

moved.

gradients of up to 18%.

Machines without driver cab-

Appliances with combustion engine

– The machine (with driver cabin) has

in . . . . . . . . . . . . . . . . . . EN

. . . 4

been approved for use on surfaces with

Danger

Machines with driver cabin

EN

. . . 4

gradients of up to 10%.

Risk of injury!

Colour coding . . . . . . . .

EN

. . . 4

– Do not close the exhaust.

General notes

Opening/closing and secur-

– Do not bend over the exhaust or touch

ing cover . . . . . . . . . . . . EN

. . . 5

Your sales outlet should be informed about

it (risk of burns).

Operator console. . . . . .

EN

. . . 6

any transit damage noted when unpacking

– Do not touch the drive motor (risk of

Before Startup. . . . . . . . . . . EN . . . 7

the product.

burns).

Unloading . . . . . . . . . . .

EN

. . . 7

– Warning and information plates on the

– Only KM 120/150 R LPG: Ensure that

machine provide important directions

Moving sweeper without en-

there is adequate ventilation or provi-

gaging self-propulsion. . EN

. . . 7

for safe operation.

sion for diverting the exhaust gas while

Moving sweeper by engag-

– In addition to the information contained

operating the appliance in closed

ing self-propulsion. . . . . EN

. . . 7

in the operating instructions, all statuto-

rooms (risk of poisoning).

Start up . . . . . . . . . . . . . . . . EN . . . 7

ry safety and accident prevention regu-

– Exhaust gases are poisonous and haz-

General notes . . . . . . . .

EN

. . . 7

lations must be observed.

ardous to health, do not inhale them.

Refuelling (only KM 120/150

Drive mode

– The engine requires approx. 3-4 sec-

R G and R D) . . . . . . . . EN

. . . 7

Danger

onds to come to a standstill once it has

Connect/ change gas cylin-

been switched off. During this time, stay

Risk of injury!

der (only KM 120/150 R

well clear of the working area.

LPG) . . . . . . . . . . . . . . . EN

. . . 7

Danger of tipping if gradient is too high.

Inspection and maintenance

– Drive up the slopes only with max. 18%

Machines with driver cabin

work. . . . . . . . . . . . . . . . EN

. . . 8

gradient (without driver cabin) or 10%

Note

Operation . . . . . . . . . . . . . . EN . . . 8

(with driver cabin).

The driver cabin only provides protection

Adjusting driver's seat . .

EN

. . . 8

Danger of tipping when driving round

against weather; it is not a safety roof or a

bends at high speed.

Adjusting the external mirror

lock against overrolling!

(only KM 120/150 without

– Drive slowly when cornering.

Danger

driver cabin) . . . . . . . . . EN

. . . 8

Danger of tipping on unstable ground.

The plastic sheet doors of the driver cabin

Switching on/off the wipers

– Only use the machine on sound surfac-

(only KM 120/150 without

have ventilation slots. Always leave these

es.

driver cabin) . . . . . . . . . EN

. . . 8

open to ensure adequate ventilation.

Danger of tipping with excessive sideways

Programme selection . .

EN

. . . 8

tilt.

Starting the machine . . .

Risk of hearing impair-

EN

. . . 8

– The gradient perpendicular to the direc-

ment. Always use

Drive the machine . . . . .

EN

. . . 8

tion of travel should not exceed 10%.

proper ear-protection

Sweeping mode . . . . . .

EN

. . . 8

– It is important to follow all safety instruc-

aids while working with

Emptying waste container

tions, rules and regulations applicable

EN

. . . 9

the appliance.

for driving motor vehicles.

Turn off the appliance . .

EN

. . . 9

– The operator must use the appliance

Shutdown . . . . . . . . . . . . . . EN . . . 9

properly. He must consider the local

Accessories and Spare Parts

Close fuel tap (only KM 120/

conditions and must pay attention to

. . 10

– Only use accessories and spare parts

150 R G and R D) . . . . . EN

third parties, in particular children, when

which have been approved by the man-

Close gas supply (only KM

. . 10

working with the appliance.

120/150 R LPG) . . . . . . EN

ufacturer. The exclusive use of original

– The appliance may only be used by per-

accessories and original spare parts

Transport. . . . . . . . . . . . . . . EN . . 10

sons who have been instructed in han-

Storing the device . . . . . . . . EN . . 10

- 1

21EN

ensures that the appliance can be oper-

– Ensure the correct positioning of the

Safety Guidelines for liquified gas

ated safely and trouble free.

cylinder with the "top" marking while

vehicles (only KM 120/150 R LPG)

– At the end of the operating instructions

connecting a full cylinder (the connec-

you will find a selected list of spare

Hauptverband der gewerblichen Beruf-

tion screw points vertically upward).

parts that are often required.

sgenossenschaften e.V. (HVBG / Germa-

Perform the replacement of the gas cylin-

– For additional information about spare

ny). Liquified gases (propellants) are

der carefully. During assembly and disas-

parts, please go to the Service section

butane and propane or a mixture of butane/

sembly, the gas outlet nozzle of the

at www.kaercher.com.

propane. They are available in special cyl-

cylinder valve must be sealed by means of

inders. The operating pressure of these

a cap nut that is tightened using a wrench.

Symbols on the machine

gases depends on the outside tempera-

– Discontinue the use of leaky gas cylin-

ture.

ders. Such cylinders are to be emptied

Risk of burns on ac-

Danger

by slowly letting out the gas in open

count of hot surfaces!

spaces by conforming to all safety reg-

Risk of explosion! Do not handle liquified

Allow the exhaust to

ulations and are to be indicated as

gas like petrol. Petrol evaporates slowly,

cool down sufficiently

leaky. Also inform the issuing company

liquified gas immediately turns into gas.

before starting work on

or its representative (the filling-station

The risk of gas spreading in the room and

the machine.

attendant) in writing about the damage

getting ignited is thus higher in case of liq-

to the cylinder while delivering or re-

uefied gas than in petrol.

Symbols in the operating instruc-

ceiving the cylinders.

Danger

tions

– Before connecting the gas cylinder,

Risk of injury! Use only liquefied gas cylin-

check that its connection neck is in a

DANGER

ders with propellant filled according to DIN

proper state.

Immediate danger that can cause severe

51622 of A or B quality, depending on the

– After connecting the cylinder, regularly

injury or even death.

surrounding temperature.

check that it is not leaky by using a

몇 WARNING

CAUTION

foaming agent.

Possible hazardous situation that could

Use of cooking gas is strictly prohibited. For

– Open the valves slowly. Do not use

lead to severe injury or even death.

the gas engine, use only liquid gas mix-

hammers to open and close the cylin-

tures of propane/ butane or their mixtures

CAUTION

ders.

where the mixing ratio lies between 90/10

Possible hazardous situation that could

– Use only dry fire extinguishers (with

to 30/70. On account of better cold start be-

lead to mild injury to persons or damage to

carbonic acid gas) in case of fire

haviour even at low outside sub-zero tem-

property.

caused by liquefied gases.

peratures (below 0° C / 32 °F) always

– The entire LPG unit must be continu-

prefer a mixture with a higher propane

ously checked to ensure that there are

share because evaporation takes place

no leaks and the unit is functioning

even at low temperatures.

properly. Using the vehicle with a leaky

Liabilities of the factory management

gas unit is strictly prohibited.

and the employee

– First close the cylinder valve before

– All persons handling liquid gases are li-

loosening the pipe or tube connection.

able to acquaint themselves with the

Unscrew and loosen the connection nut

special properties of the liquefied gases

of the gas cylinder slowly because oth-

for hazard-free handling of operations.

erwise the gas under pressure in the

The current documentation is always to

tube will flow out instantly.

be kept with the sweeper.

– If the gas is refilled from a larger tank,

Maintenance by expert

then ask the sales agent of the LPG

– Propellant-operated units are to be

about the important regulations to be

checked at regular intervals, at least

followed.

once a year, by an expert against leaks

Danger

(according to BGG 936) and ensure

Risk of injury!

that the unit is functioning properly.

– LPG in a liquid state can cause frost

– The inspection must be certified and

bites on bare skin.

documented. The inspection guidelines

– After disconnecting the cylinder, tighten

are § 33 and § 37 UVV (occupation ac-

the closing nut firmly on the connecting

cident prevention regulations) "Use of

threading of the cylinder.

liquid gas" (BGV D34).

– Use soap water or some such foaming

– General applicable regulations are the

agent to check whether the cylinder is

guidelines for inspecting vehicles

leaking. The use of open flames to illu-

whose engines are driven by liquefied

minate the LPG unit is strictly prohibit-

gases of the Federal Transportation

ed.

Minister.

– Follow the manufacturer's installation

Commissioning/Operations

specifications while changing individual

– Gas must always be drawn only from

parts of the LPG unit. Close all cylinder

one cylinder. Drawing gas from multiple

and locking valves while doing so.

cylinders simultaneously can cause liq-

– Regularly check the status of the elec-

uid gas from one cylinder flowing into

trical unit of the LPG vehicles . Sparks

the other. This causes the over-filled

can cause explosions if the gas-carry-

cylinder to be subjected to an unpermit-

ing parts of the unit are leaky.

ted excess pressure when the cylinder

– If a LPG-driven vehicle has been idling

valve is closed later (refer B.1 of these

for a long time, then first ventilate the

guidelines).

22 EN

- 2

setting room before commissioning the

use the appliance in hazardous loca-

Function

vehicle or its electrical unit.

tions.

– Immediately inform the trade associa-

– The following applies in general: Keep

tion and the concerned trade superviso-

highly-flammable substances away

ry authority about accidents with gas

from the appliance (danger of explo-

cylinders or LPG units. Store the dam-

sion/fire).

aged parts carefully until all investiga-

Suitable surfaces

tions have been completed.

– Asphalt

In the installation and storage rooms as

– Industrial floor

well as the workshops

– Propellants or LPG cylinders must al-

– Screed

ways be stored according to the regula-

– Concrete

tions of TRF 1996 (Technical

Figure 1

– Paving stones

Regulations for Liquid Gases, refer DA

The sweeper operates using the overthrow

to BGV D34, Appendix 4).

principle.

Environmental protection

– Always store the gas cylinders in a ver-

– The side brushes (3) clean the corners

tical position. Use of open flames and

and edges of the surface, moving dirt

smoking at the installation site of the

and debris into the path of the roller

The packaging material can be

cylinders and during repairs is strictly

brush.

recycled. Please do not throw

prohibited. Protect the stored cylinders

– The rotating roller brush (4) moves the

the packaging material into

against unauthorised access. Close all

dirt and debris directly into the waste

household waste; please send

empty cylinders properly.

container (5).

it for recycling.

– Close the cylinder and main locking

– The dust raised in the container is sep-

Old appliances contain valua-

valves immediately when you switch off

arated by the dust filter (2) and the fil-

ble materials that can be recy-

the vehicle.

tered clean air is drawn off by the

cled; these should be sent for

– Follow the regulations for garages and

suction fan (1).

recycling. Batteries, oil, and

the construction guidelines of the re-

similar substances must not

spective State about the location and

Proper use

enter the environment. Please

structure of the parking areas for LPG-

dispose of your old appliances

driven vehicles.

Use this appliance only as directed in these

using appropriate collection

– Gas cylinders are to be stored in sepa-

operating instructions.

systems.

rate rooms away from the parking areas

The machine with working equipment

(refer DA to BGV D34, Appendix 2).

must be checked to ensure that it is in

proper working order and is operating

Please do not release engine oil, fuel oil,

– The electrical hand-held lamps used in

safely prior to use. Otherwise, the appli-

diesel and petrol into the environment

the rooms are to be equipped with

ance must not be used.

Protect the ground and dispose of used

closed, sealed case and a strong pro-

oil in an environmentally-clean manner.

tection cover.

– This sweeper has been designed to

sweep dirt and debris from outdoor sur-

– Close all cylinder and main valves be-

Notes about the ingredients (REACH)

faces.

fore working in repair workshops and

You will find current information about the

protect the gas cylinders against effect

– Only KM 120/150 R LPG: This sweeper

ingredients at:

of external heat.

is also suitable for sweeping dirty floors

www.kaercher.com/REACH

in closed spaces provided the same are

– A responsible person must check that

ventilated adequately.

all valves, especially the cylinder

valves, are closed during operational

– The machine can only be used on pub-

breaks and before closing the factory.

lic highways with the StVZO extension

Do not carry out any jobs involving fire -

kit.

such as cutting and welding jobs - in the

– The machine is not suitable for vacuum-

vicinity of the gas cylinders. Do not

ing dust which endangers health.

store gas cylinders, not even empty

– The machine may not be modified.

ones, in the workshops.

– Never vacuum up explosive liquids,

– The parking and storage rooms and the

combustible gases or undiluted acids

repair workshops must be ventilated

and solvents. This includes petrol, paint

properly. Please note that liquefied gas-

thinner or heating oil which can gener-

es are heavier than atmospheric air.

ate explosive fumes or mixtures upon

They get collected on the floor, in re-

contact with the suction air. Acetone,

cesses and other holes in the floors and

undiluted acids and solvents must also

form a gas-air mixture that can lead to

be avoided as they can harm the mate-

explosions.

rials on the machine.

– Do not sweep/vacuum up any burning

or glowing objects.

– The machine is only suitable for use on

the types of surfaces specified in the

operating instructions.

– The machine may only be operated on

the surfaces approved by the company

or its authorised representatives.

– The machine may not be used or stored

in hazardous areas. It is not allowed to

- 3

23EN

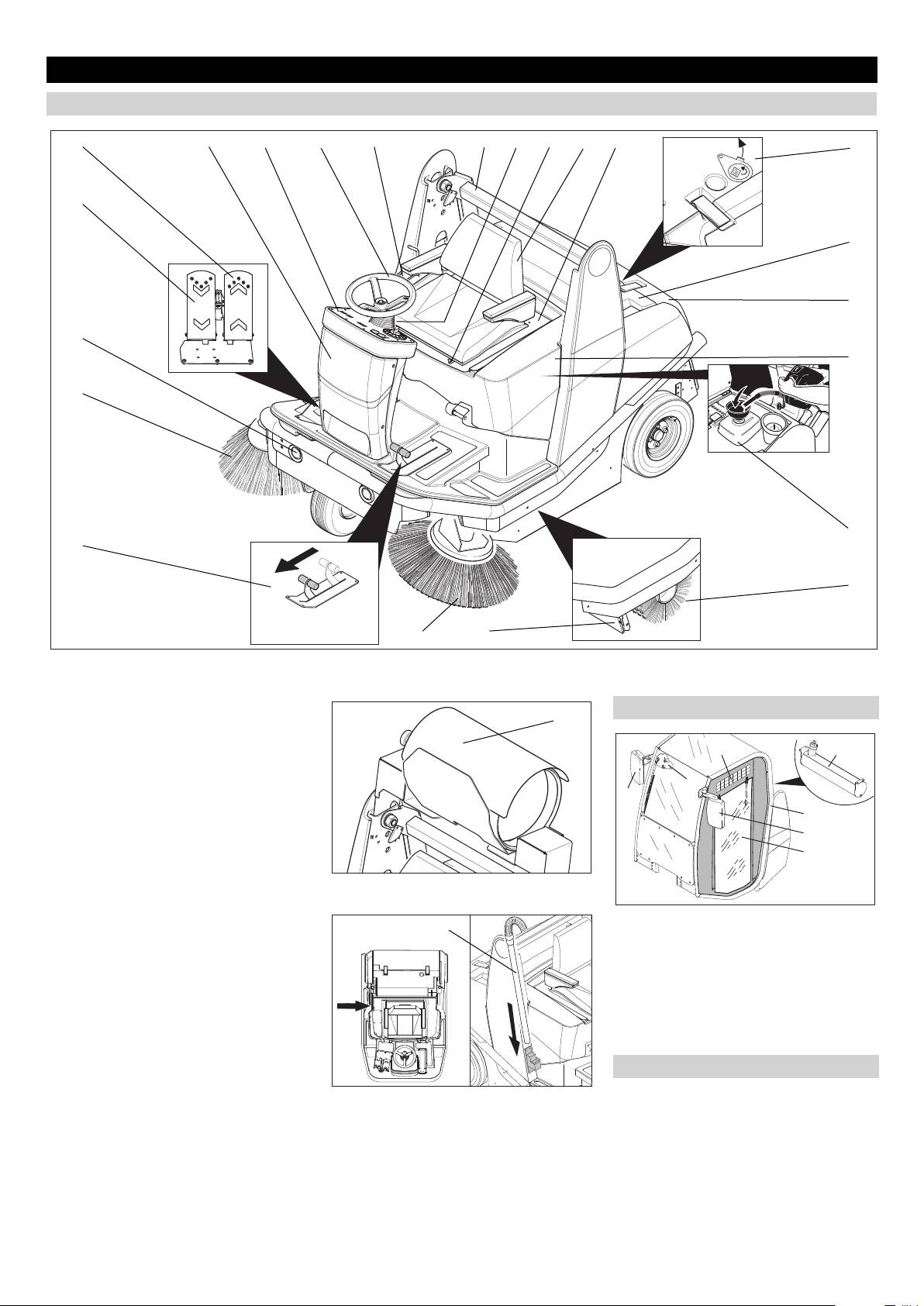

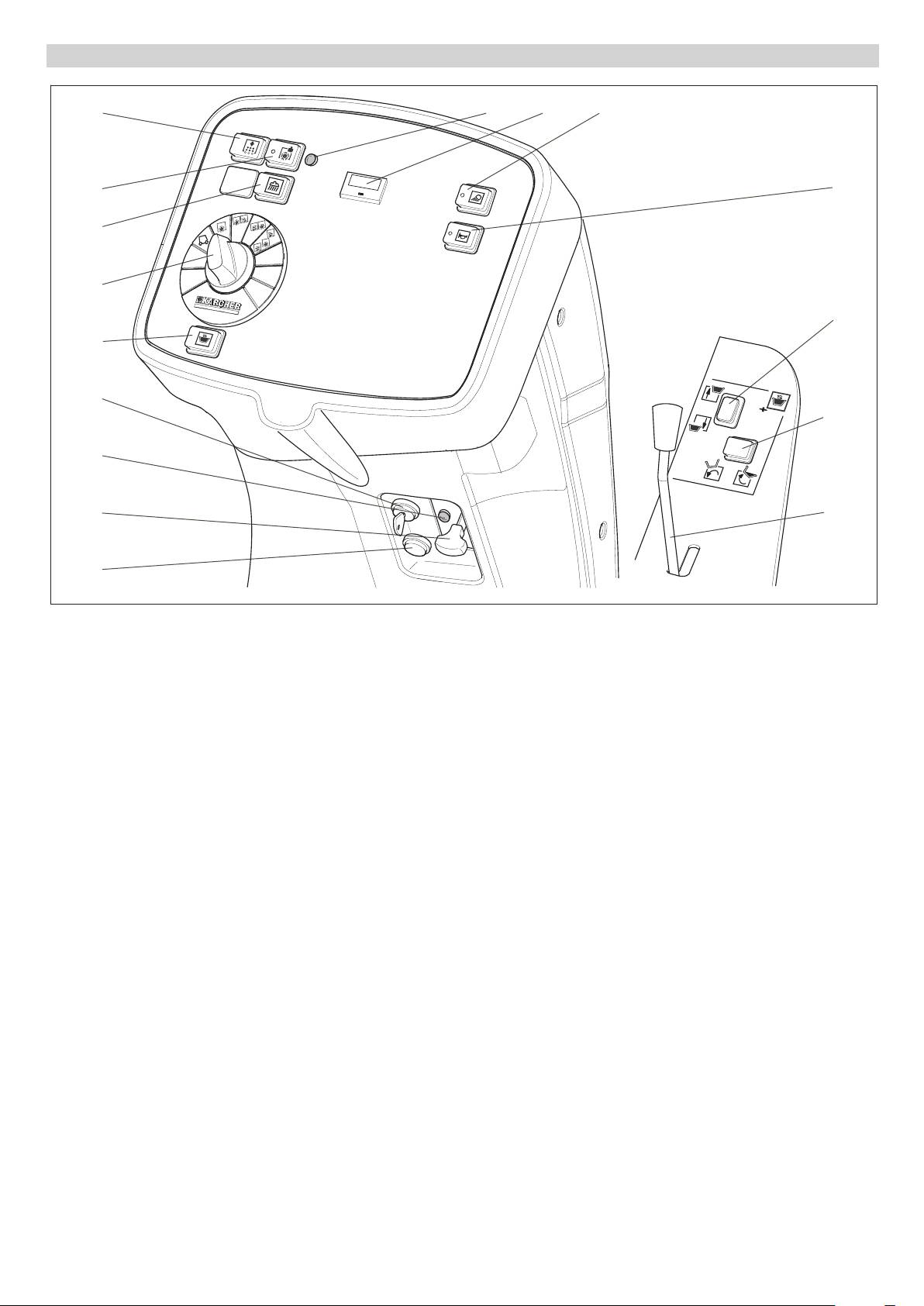

Operating and Functional Elements

Machines without driver cabin

5

4321 1213141516

17

6

18

19

7

20

8

21

11

22

910

Figure 2a

1 Operator control unit for waste contain-

Machines with driver cabin

er and parking brake

23

2 Steering wheel

72

3 Operator console

4 Fuses (behind front panel)

5 Accelerator pedal, forwards

3

4

6 Accelerator pedal, reverse

1

7 Lights

5

8 Right side brush

6

9 Left side brush

Figure 2b

10 Bulk waste flap

11 Pedal for raising/lowering bulk waste

Figure 2d

flap

24

1 Driver cabin (optional)

12 Lift/tilt emptying mechanism

2 Tank

13 Lever for steering wheel adjustment

3 Turn on/off the wipers

14 Lever for seat adjustment

4 Right exterior mirror

15 Seat (with seat contact mat)

5 Left exterior mirror

16 Seat bracket

6 Plastic sheet doors

17 Wet/dry flap

7 Ventilation slots

18 Filter case

19 Waste container

Colour coding

20 Cover

Figure 2c

The operating elements for the cleaning

21 Tank

process are yellow.

22 Roller brush

The controls for the maintenance and

23 Gas cylinder (only KM 120/150 R LPG)

service are light gray.

24 Installation set suction hose (option)

24 EN

- 4

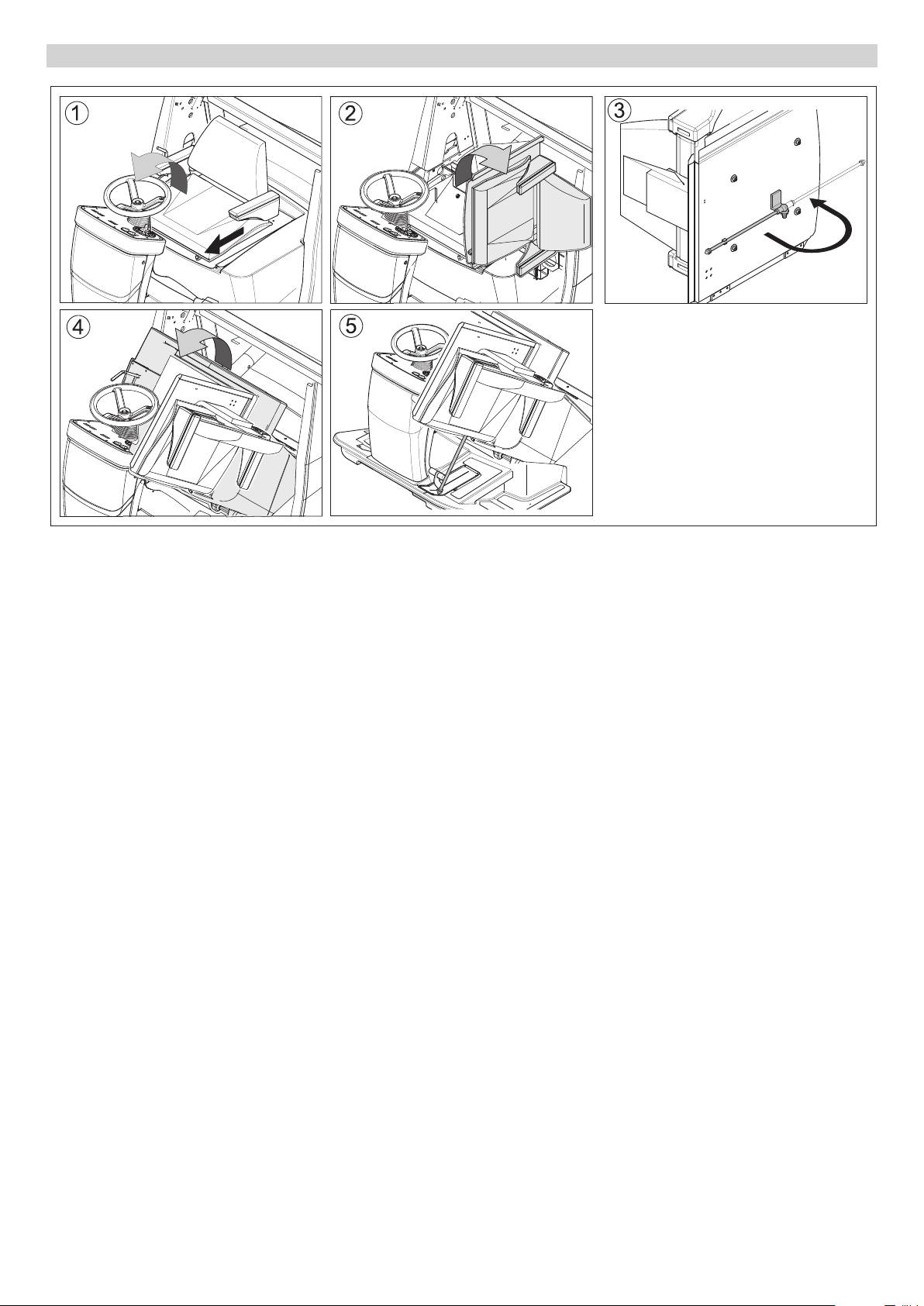

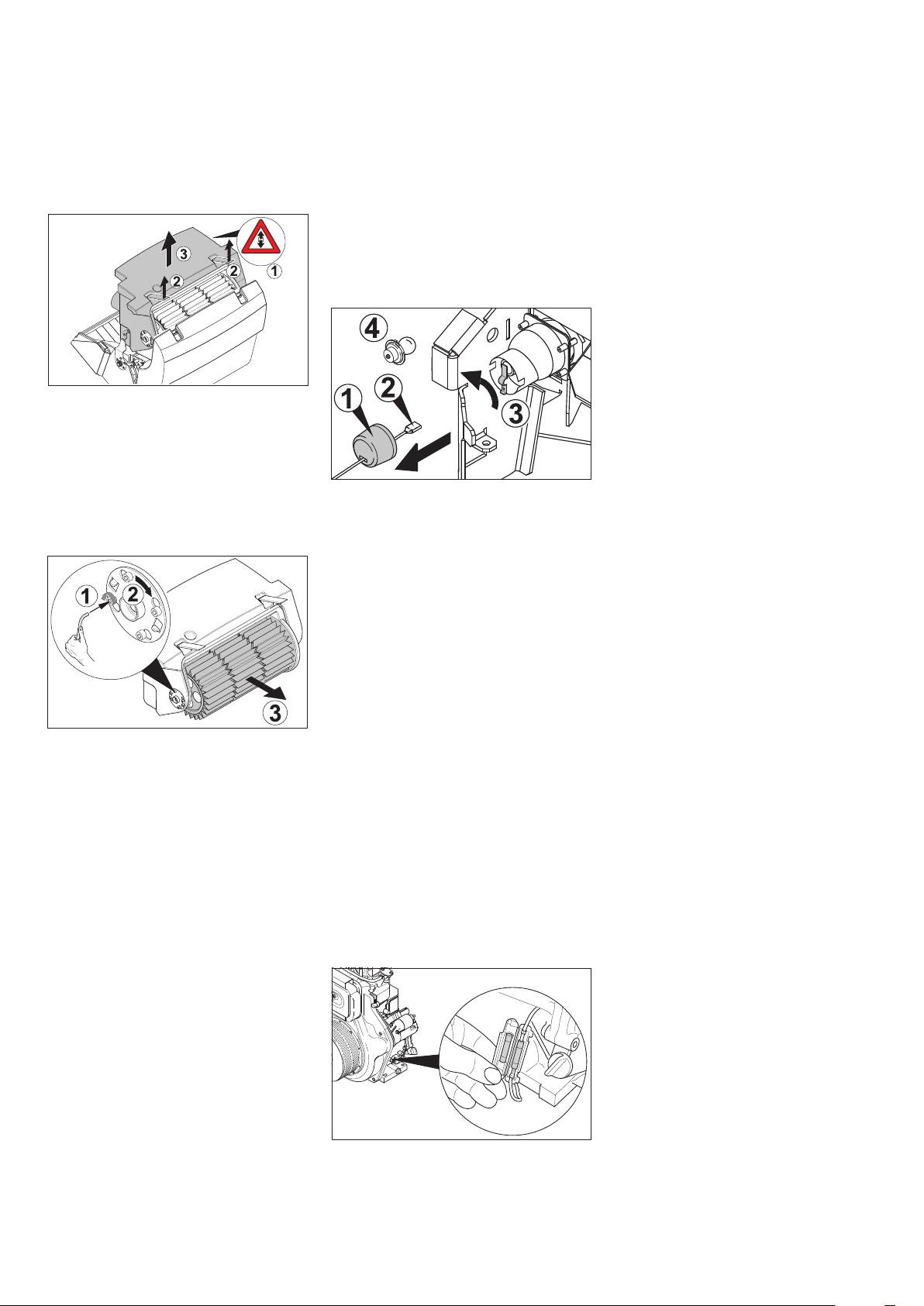

Opening/closing and securing cover

Figure 3

Danger

Risk of injury! When open, the cover must

be propped up using the retaining rod.

Figure 1

Operate steering wheel adjustment le-

ver and fold steering wheel forwards.

Operate seat adjustment lever and

slide seat forwards.

Figure 2

Fold seat bracket to the side.

Figure 3

Fold out retaining rod.

(only 120/150 KM without driver cabin)

Figure 4

Fold cover forwards.

Figure 5

Insert retaining rod into the recess next

to the bulk waste flap pedal.

(only 120/150 KM without driver cabin)

Follow this sequence in reverse order to

close the cover.

- 5

25EN

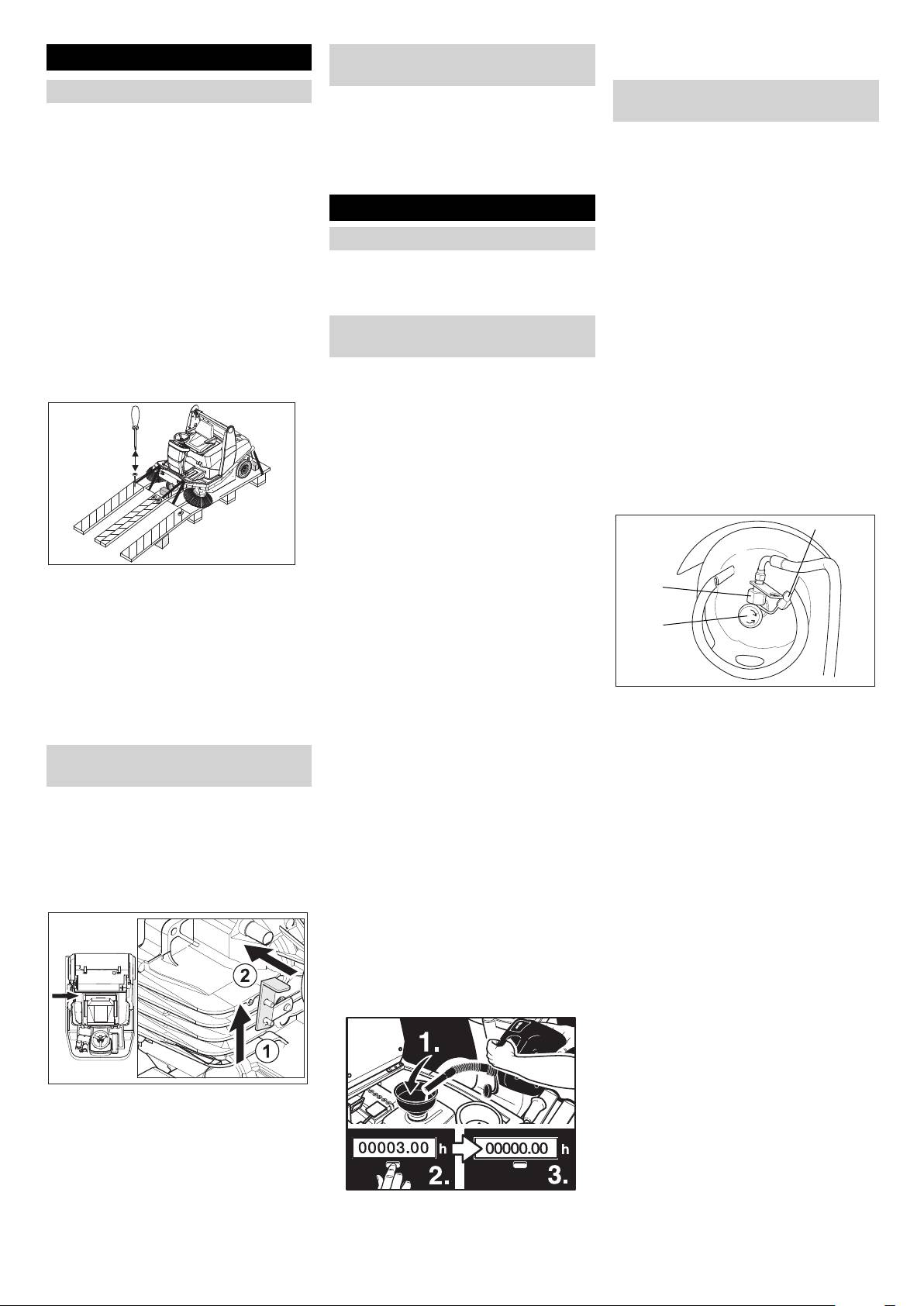

Operator console

3

567

4

8

16

1

9

2

12

10

13

14

11

15

Figure 4

1 Programme switch

2 Switch two-hand operations Lift/tilt

emptying mechanism

3 Button for filter shaker system

4 Button for power-operating mode

5 Indicator lamp for power-operating

mode

6 Elapsed-time counter with reset button

7 Switch for working lamp

8 Horn switch

9 Raise/lower waste container

10 Tilt waste container outwards/inwards

11 Parking brake

12 Ignition lock

13 Charge indicator lamp (only KM 120/

150 R D and LPG)

14 Choke (only KM 120/150 R G)

15 Remote button (only KM 120/150 R

LPG)

16 Wet cleaning switch, installation set

suction hose (option)

26 EN

- 6

Press reset button (2) on the elapsed-

Before Startup

Moving sweeper by engaging self-

time counter.

propulsion

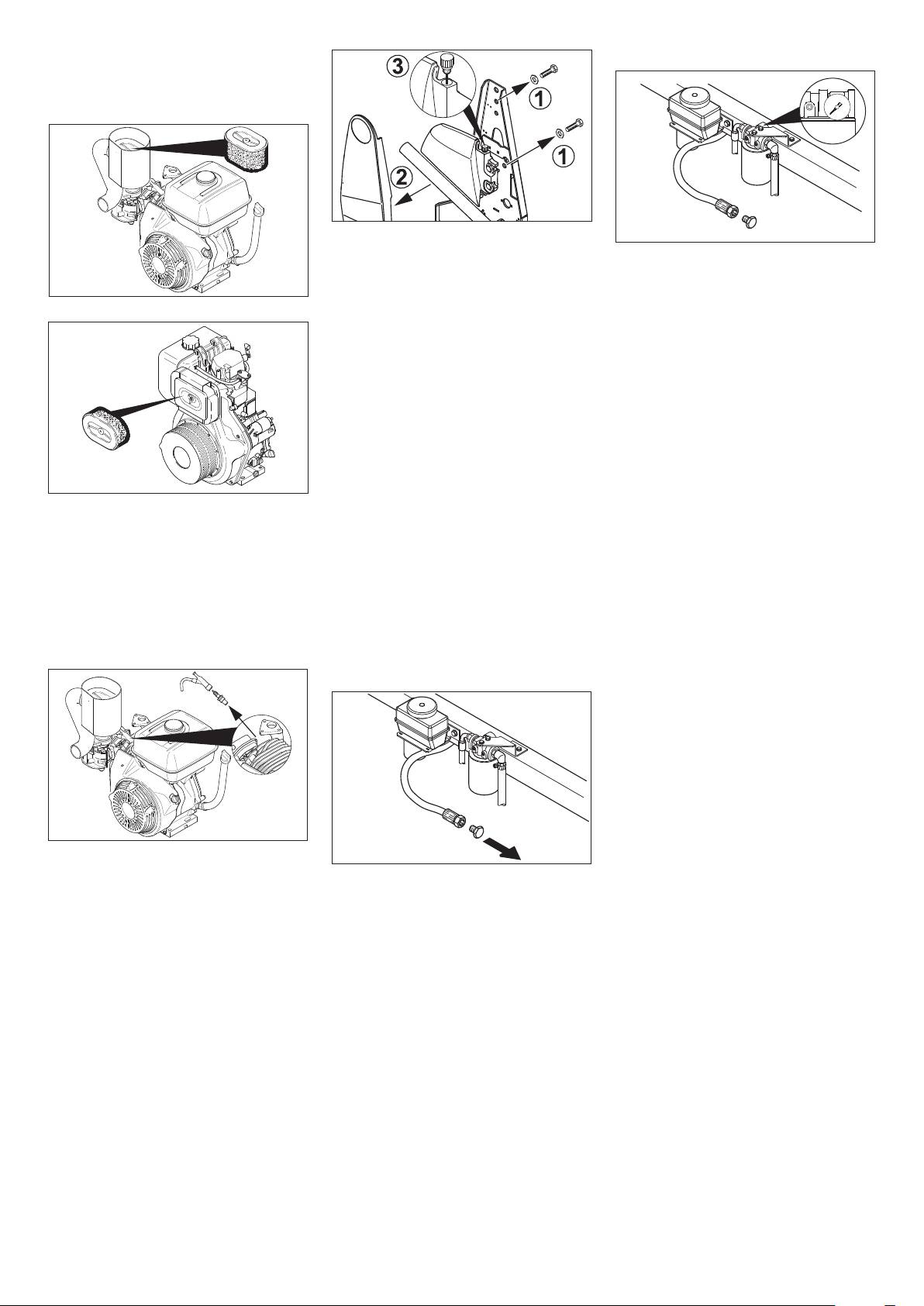

Unloading

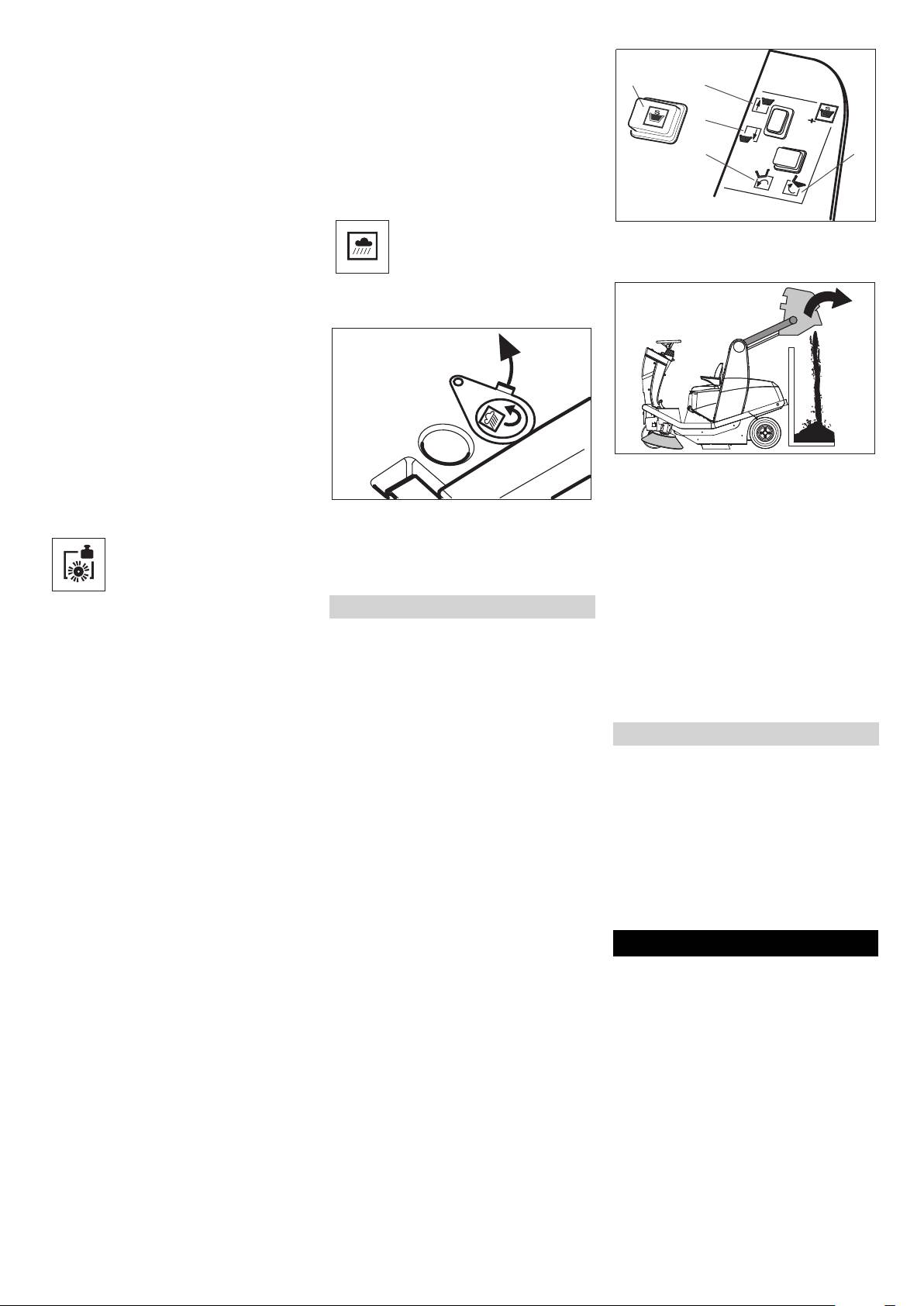

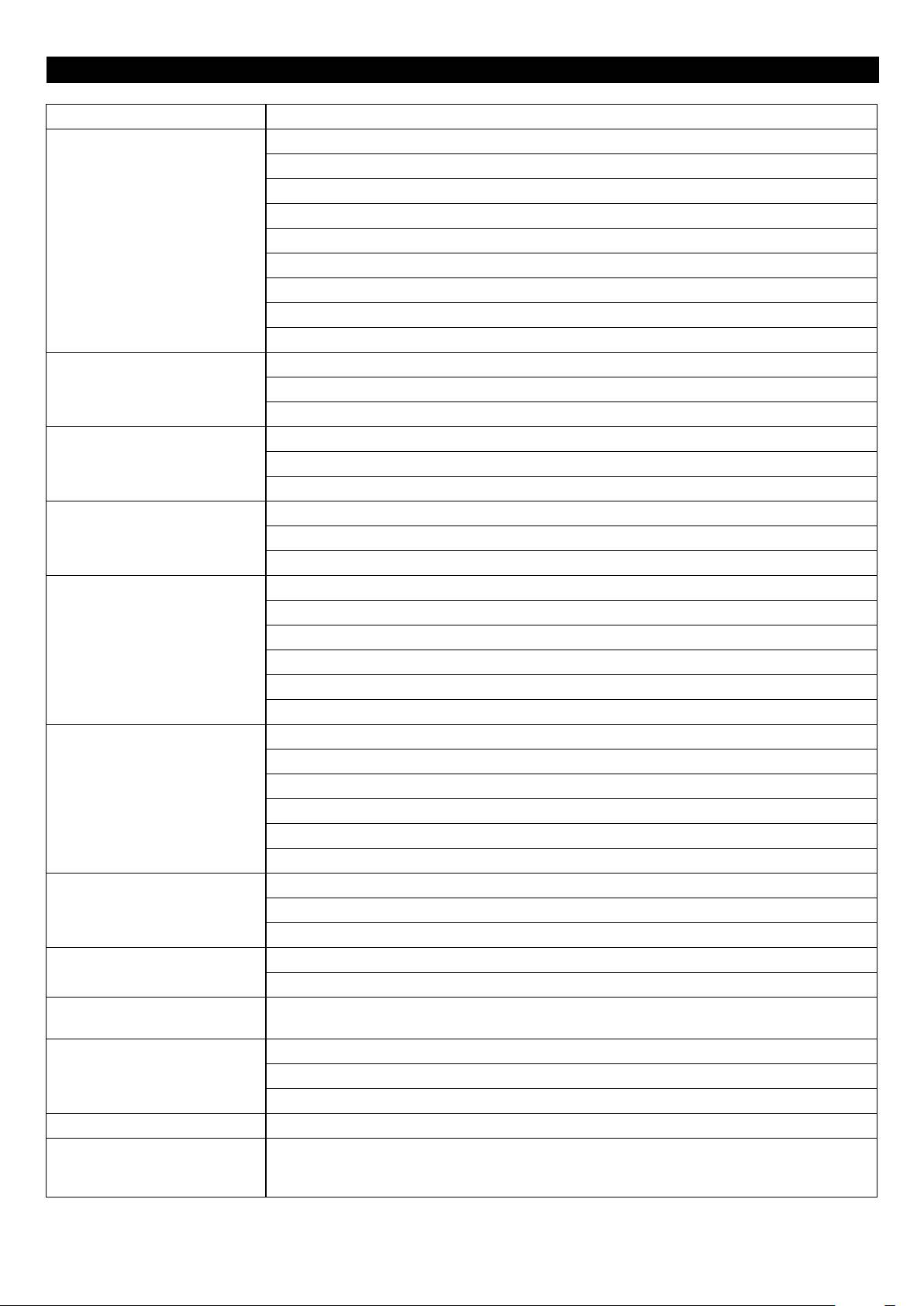

Connect/ change gas cylinder (only

Unhook the free wheel lever.

KM 120/150 R LPG)

몇

Warning

The travel drive is now ready for operation.

Do not use a forklift truck to unload the ma-

Close cover.

몇 Warning

chine as this may damage it.

Release parking brake.

Only use replacement cylinders with 11 kg

To unload the machine, proceed as follows:

The appliance can now be driven.

contents of tested models.

Cut plastic packing belt and remove foil.

Danger

Connect battery (see section on Care

Start up

Risk of injury!

and maintenance)

– Follow safety regulations for LPG vehi-

General notes

Remove the elastic tape fasteners at

cles.

the stop points.

Park the sweeper on an even surface.

– Formation of crusts and yellow-frothing

Four indicated floor boards of the pallet

Remove ignition key.

deposits on the gas cylinder indicate

are fastened with screws. Unscrew

Lock parking brake.

leakiness.

these boards.

– Cylinders must be changed only by in-

Refuelling (only KM 120/150 R G and

Place the boards on the edge of the pal-

structed persons.

let. Place the boards in such a way that

R D)

– Cylinders containing propellant gases

they lie in front of the four wheels of the

Refuelling the machine

must not be changed in garages and

machine. Fasten the boards with screws.

underground areas.

Danger

– Do not smoke and use uncovered light

Risk of explosion!

while changing the cylinder.

– Only use the fuels specified in the Op-

– While changing cylinders, first close the

erations Manual.

locking valve of the LPG cylinder firmly

– Do not refuel the machine in enclosed

and immediately put the protective cap

spaces.

on the empty cylinder.

– Smoking and naked flames are strictly

prohibited.

1

– Ensure that no fuel reaches the hot

open surfaces.

Slide the four support beams included

Switch off engine.

2

in the packaging under the ramp.

Only KM 120/150 without driver cabin:

Remove the wooden blocks used for ar-

Open cover and secure it (Diag. 3).

resting the wheels and slide them under

3

Open fuel filler cap.

the ramp.

Insert funnel provided.

The machine can be moved in 2 ways:

KM 120/150 R G: Use regular unleaded

(1) By pushing it (see Moving sweeper

petrol.

Place the cylinder in such a way that the

without engaging self-propulsion).

KM 120/150 R D: Use diesel.

connection threading of the locking

(2) By driving it (see Moving sweeper by

Fill tank to max. 1 cm below the lower

valve vertically points upwards.

engaging self-propulsion).

edge of the filler nozzle.

Close the bracket closure.

Moving sweeper without engaging

Wipe off any spilt fuel, remove funnel

Attach safety splint.

self-propulsion

and close fuel filler cap.

Remove protective lid (1) from the con-

Only KM 120/150 without driver cabin:

Danger

nection valve of the cylinder.

Close cover.

Risk of injury! Before engaging the free-

Connect the gas tube with Union nut (2)

Resetting fuel gauge

wheel operation, the machine must be se-

(use 30 mm spanner).

cured to prevent it rolling away.

Note

Note

Lock parking brake.

After the machine is switched on, the num-

Connection has a left threading.

Open cover and secure it (Diag. 3).

ber of operating hours is displayed for 10

몇 Warning

seconds. The fuel gauge is then automati-

Open the gas drawing valve (3) only after

cally displayed.

starting the appliance (refer chapter Start-

Note

ing the appliance).

The fuel gauge shows the length of time the

machine has been in operation since the

elapsed-time counter was last reset.

Engage freewheel lever in hole.

This blocks the travel drive function.

Close cover.

Release parking brake.

The machine can now be pushed.

Note

Do not move the machine for long distanc-

Note

es without engaging self-propulsion, a

The machine can be operated for a maxi-

speed of 6 km/h should not be exceeded.

mum of 3 hours on a full tank.

- 7

27EN

Only KM 120/150 R LPG: Press remote

Inspection and maintenance work

Starting the machine

switch for 5 seconds, then release it.

Check engine oil level. *

Note

Turn ignition key past position 1.

Only KM 120/150 R G and R D: Check

The machine is equipped with a seat con-

If the machine starts, release the igni-

fill level of fuel tank. *

tact mat. If the driver's seat is vacated, the

tion key.

Only KM 120/150 R LPG: Check and

machine is switched off.

Note

ensure that the Union nut is fixed prop-

NOTICE

Never operate the starter motor for longer

erly on the gas tube. *

Only KM 120/150 R G and R LPG: Device

than 10 seconds. Wait at least 10 seconds

Check hydraulics fluid fill level. *

starts only if the immobilising brakes are

before operating the starter motor again.

Check side brush. *

applied (parking position).

Note

Check roller brush. *

Open fuel tap (only KM 120/150 R G and

Operation during winter: When starting at

Empty waste container.

R D)

temperatures below +10 °C, the parking

Check tyre pressure. *

Note

brake is to be applied to disengage the en-

* For description, see section on Care and

The fuel cock is supplied from the factory

gine from the transmission and therefore

maintenance.

open. If the machine has been out of use

assist the starting process.

for a longer period of time, open the fuel

Drive the machine

Operation

cock.

Release parking brake.

Open cover and secure it (Diag. 3).

몇 Warning

KM 120/150 R G:

Drive forward

The air inlets next to the driver's seat must

Press right accelerator pedal down

not be covered. Do not store any objects

slowly.

next to or behind the seat.

Reverse drive

Adjusting driver's seat

Danger

Pull seat adjustment lever outwards.

Risk of injury! While reversing, ensure that

Slide seat, release lever and lock in

there is nobody in the way, ask them to

place.

move if somebody is around.

Check that the seat is properly locked in

Press left accelerator pedal down slowly.

position by attempting to move it back-

Note

wards and forwards.

Driving method

Push lever in "ON" direction.

Adjusting the external mirror (only

– The accelerator pedal can be used to

KM 120/150 R D:

KM 120/150 without driver cabin)

vary the driving speed infinitely.

– Avoid pressing the pedal suddenly as

Adjust the left and right exterior mirror

this may damage the hydraulic system.

manually.

– In the event of power loss on inclined

Switching on/off the wipers (only

surfaces, slightly reduce the pressure

KM 120/150 without driver cabin)

on the accelerator pedal.

Press the switch for windscreen washer

Brakes

system.

Release the accelerator pedal, the ma-

chine brakes automatically and stops.

Programme selection

Driving over obstacles

Turn lever to position "O".

Driving over fixed obstacles which are 50

3

4

mm high or less:

Close cover.

Drive forwards slowly and carefully.

2

5

Open gas supply (only KM 120/150 R

Driving over fixed obstacles which are

LPG)

more than 50 mm high:

1

Only drive over these obstacles using a

suitable ramp.

Sweeping mode

Danger

1 Driving

Risk of injury! If the bulk waste flap is open,

Driving to the Place of Use.

stones or gravel may be flung forwards by

2 Sweeping with sweep roller

the roller brush. Make sure that this does

Roller brush is lowered.

not endanger persons, animals or objects.

3 Sweeping with right side brush

몇 Warning

Open the gas drawing valve by turning

Sweep roller and right side brush are

Do not sweep up packing strips, wire or

it in anti-clockwise direction.

lowered.

similar objects as this may damage the

4 Sweep using left side brush (optional)

Turning on the Appliance

sweeping mechanism.

Lock parking brake.

Sweep roller and left side brush are

몇 Warning

lowered.

Sit on the driver's seat.

To avoid damaging the floor, do not contin-

5 Sweep using both brushes (optional)

Do NOT press the accelerator pedal.

ue to operate the sweeping machine in the

Sweep roller and both brushes are low-

Set programme switch to step 1 (driv-

same position.

ered.

ing).

Note

Only KM 120/150 R G: Press choke le-

To achieve an optimum cleaning result, the

ver downwards. Once the engine is run-

driving speed should be adjusted to take

ning, pull choke lever back up.

specific situations into account.

28 EN

- 8

Note

Set programme switch to step 5. Both

side brushes and roller brush are low-

During operation, the waste container

ered.

should be emptied at regular intervals.

1

2

Note

Note

Roller brush and side brush start operating

3

When cleaning surfaces, only lower the

automatically.

roller brush.

45

Note

Sweeping dry floors

Close wet/dry flap on waste container.

Also lower side brush when cleaning along

edges.

Installation set suction hose (option):

Sweeping with roller brush (basic-oper-

Raise waste container. Press button 1

ating mode)

(operator console) and 2 simultaneous-

Note

ly.

Two operating modes are possible with the

Press wet sweeping button repeatedly.

roller brush. In the basic-operating mode,

Sweeping damp or wet floors

the roller brush is only subjected to a small

amount of wear and tear.

Set programme switch to step 2. Roller

brush is lowered.

Sweeping with roller brush (power-oper-

ating mode)

Note

Two operating modes are possible with the

roller brush. Power-operating mode in-

Once the required height has been

creases cleaning performance.

reached:

Set programme switch to step 2. Roller

Tip waste container out. Press button 1

Open wet/dry flap on waste container.

brush is lowered.

(operator console) and 5 simultaneous-

Installation set suction hose (option):

ly.

Press wet sweeping button.

Tip waste container back in. Press but-

Note

ton 1 (operator console) and 4 simulta-

This protects the filter from moisture.

neously.

Press power button. Indicator lamp

Lower waste container. Press button 1

Emptying waste container

lights up.

(operator console) and 3 simultaneous-

Note

ly.

Note

Wait until the automatic filter shaking proc-

The following actions reset the power but-

Note

ess is finished and the dust has settled be-

ton automatically:

The container can only be fully retracted if

fore you open or empty the waste

– Press the power button again.

it is tipped back into its starting position be-

container.

– Set programme switch to step 1 (driv-

forehand.

ing).

Danger

Turn off the appliance

– Switching off the machine.

Risk of injury! When emptying the waste

The indicator lamp goes out and the basic-

container, care should be taken to ensure

Set programme switch to step 1 (driv-

operating mode is activated.

that no persons or animals are within its

ing). The side brush and roller brush are

swivelling range.

raised.

Note

Turn ignition key to "0" and remove it.

Danger

To sweep up larger items with a height of

Lock parking brake.

60 mm, e.g. soft drink cans, the bulk waste

Danger of crushing. Never reach into the

flap must be raised briefly.

rod assembly for the drainage mechanism.

Note

Stay away from the area under the raised

Once the machine has been switched off,

Sweeping with bulk waste flap raised

container.

the dust filter is shaked automatically for

Raising bulk waste flap:

Danger

approx. 15 seconds.

Press the pedal for the bulk waste flap

forwards and keep pressed down.

Danger of tipping. Place the machine on an

even surface during emptying.

Shutdown

To lower it, take foot off pedal.

Stop the machine.

Note

If the sweeper is going to be out of service

Set programme switch to step 1 (driv-

An optimum cleaning result can only be

for a longer time period, observe the follow-

ing).

achieved if the bulk waste flap has been

ing points:

Note

lowered completely.

Park the sweeper on an even surface.

The container can only be tilted and emp-

Only KM 120/150 R G and R D: Fill fuel

Sweeping with side brushes

tied once a set minimum level has been

tank and close fuel cock.

To sweep in edge area on right-hand side:

reached.

Only KM 120/150 R LPG: Close the gas

Set programme switch to step 3. The

Note

cylinder valve and remove the cylinder.

right side brush and roller brush are

Store the gas cylinder according to the

lowered.

A two-handed operation is required to carry

safety regulations for LPG vehicles.

To sweep in edge area on left-hand side:

out the following steps.

Change engine oil.

Set programme switch to step 4. The

Set programme switch to step 1 (driv-

left side brush and roller brush are low-

ing). The roller brush and side brushes

ered.

are raised to prevent the bristles being

To sweep in edge areas on right- and left-

damaged.

hand side:

Turn ignition key to "0" and remove it.

- 9

29EN

Only KM 120/150 R G and R LPG: Un-

– Use only roller brushes/ side-brushes

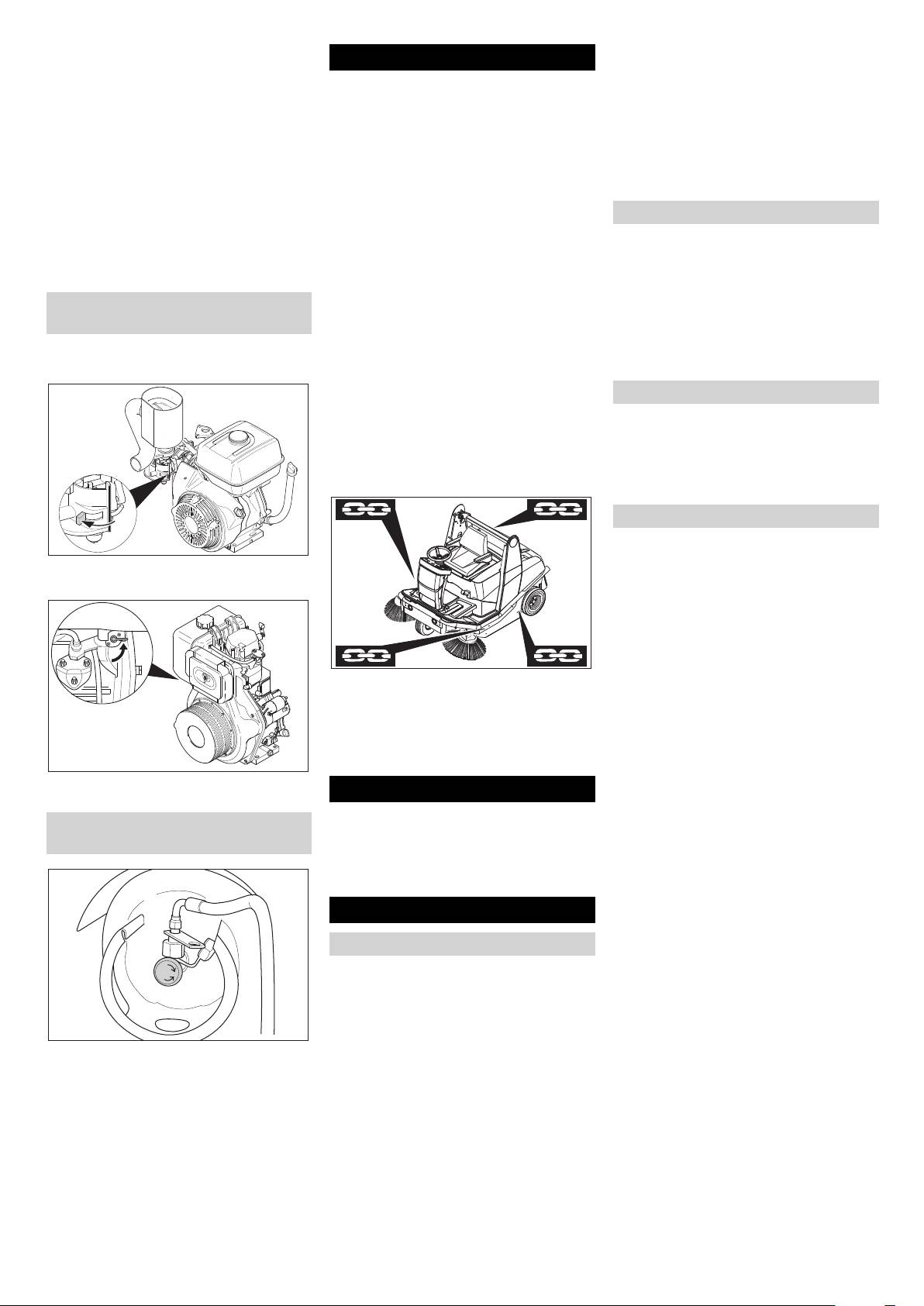

Transport

screw spark plugs and pour approx.

that are provided with the appliance or

3 cm³ of oil into the spark plug hole.

CAUTION

specified in the Operations Manual.

Crank the engine several times before

The use of other roller brushes/ side-

Risk of injury and damage! Observe the

replacing the spark plug. Screw in the

brushes can affect the safety of the ap-

weight of the appliance when you transport

spark plug.

pliance.

it.

Secure sweeper to prevent it rolling

– Do not clean the appliance with a water

몇 Warning

away, lock parking brake.

hose or high-pressure water jet (danger

In general, when shipping the machine, the

Clean the inside and outside of the

of short circuits or other damage).

freewheel lever must be engaged in the up-

sweeper.

per hole. Only once this has been done, will

Cleaning the inside of the machine

Park the machine in a safe and dry

the travel drive be ready for operation. The

place.

Danger

machine must always be moved up or

Disconnect battery.

Risk of injury! Wear dust mask and protec-

down slopes by engaging self-propulsion.

Charge battery approx. every 2 months.

tive goggles.

Turn ignition key to "0" and remove it.

Open cover and secure it (Diag. 3).

Close fuel tap (only KM 120/150 R G

Only KM 120/150 R G and R D: Empty

Clean machine with a cloth.

tank. Draw off fuel using suitable pump.

and R D)

Blow through machine with com-

Only KM 120/150 R LPG: Close the gas

Open cover and secure it (Diag. 3).

pressed air.

cylinder valve and remove the cylinder.

KM 120/150 R G:

Close cover.

Store the gas cylinder according to the

safety regulations for LPG vehicles.

External cleaning of the appliance

Secure the wheels of the machine with

Clean the machine with a damp cloth

wheel chocks.

which has been soaked in mild deter-

Secure the machine with tensioning

gent.

straps or cables.

Note

Lock parking brake.

Do not use aggressive cleaning agents.

Maintenance intervals

Note

Push lever in "OFF" direction.

The elapsed-time counter shows the timing

KM 120/150 R D:

of the maintenance intervals.

Maintenance by the customer

Daily maintenance:

Check engine oil level.

Check axle drive oil level.

Check tyre pressure.

Note

Only KM 120/150 R LPG: Check gas

Observe markings for fixing points on base

pipes and connecting screws.

frame (chain symbols). When loading or

Only KM 120/150 R LPG: Check gas fil-

unloading the machine, it may only be op-

ter in the screw to the gas cylinder to

erated on gradients of max. 18%.

see if it is dirty, clean it if required (every

Turn lever to position "S".

time you change the cylinder).

Storing the device

Close cover.

Check function of all operator control el-

CAUTION

ements.

Close gas supply (only KM 120/150

Weekly maintenance:

Risk of injury and damage! Note the weight

R LPG)

Check leakiness of fuel or gas connec-

of the appliance in case of storage.

tions.

Park the machine in a safe and dry place.

Check return-line filter for sweeping

system.

Maintenance and care

Check air filter.

General notes

Check oil level of sweeper hydraulics.

Check hydraulic lines for leaks.

First switch off the appliance and re-

Check moving parts for freedom of

move the ignition key before performing

movement.

any cleaning or maintenance tasks on

Check the sealing strips in the sweep-

the appliance, replacing parts or switch-

ing area for position and wear.

ing over to another function.

Close gas drawing valve by turning it in

Maintenance to be carried out every 100

Pull out the battery plug or clamp the

clock-wise direction.

operating hours:

battery while working on the electrical

Check leakiness of fuel or gas connec-

unit.

tions.

– Maintenance work may only be carried

Change engine oil (initial change after

out by approved customer service out-

20 operating hours).

lets or experts in this field who are famil-

Only KM 120/150 R G and R LPG:

iar with the respective safety

Check spark plug.

regulations.

Check function of seat contact mat.

– Mobile appliances used for commercial

Check battery acid level.

purposes are subject to safety inspec-

tions according to VDE 0701.

30 EN

- 10

Check tension, wear and function of

Connect pole terminal (red cable) to

drive belts (V-belt and circular belt).

Please do not release engine

positive pole (+).

Maintenance following wear:

oil, fuel oil, diesel and petrol

Connect pole terminal to negative pole

Replace sealing strips.

into the environment. Protect

(-).

Replace roller brush.

the ground and dispose of

Charging battery

Replace side brush.

used oil in an environmentally-

Danger

clean manner.

For description, see section on Mainte-

Risk of injury! Comply with safety regula-

nance work.

Safety notes regarding the batteries

tions on the handling of batteries. Observe

Note

Please observe the following warning notes

the directions provided by the manufacturer

Where maintenance is carried out by the

when handling batteries:

of the charger.

customer, all service and maintenance

Disconnect battery.

work must be undertaken by a qualified

Observe the directions on the

Connect positive terminal cable from

specialist. If required, a specialised Kärch-

battery, in the instructions for

the charger to the positive pole connec-

er dealer may be contacted at any time.

use and in the vehicle operat-

tion on the battery.

Maintenance by Customer Service

ing instructions!

Connect negative terminal cable from

Maintenance to be carried out after 20 op-

the charger to the negative pole con-

Wear an eye shield!

erating hours:

nection on the battery.

Carry out initial inspection.

Plug in mains connector and switch on

Maintenance to be carried out every 100

charger.

operating hours

Charge battery using lowest possible

Maintenance to be carried out every 200

Keep away children from acid

level of charging current.

operating hours

and batteries!

Check fluid level in the battery and ad-

Maintenance to be carried out every 300

just if required

operating hours

몇 Warning

Note

Risk of explosion!

Regularly check the fluid level in acid-filled

In order to safeguard warranty claims, all

batteries.

service and maintenance work during the

Unscrew all cell caps.

warranty period must be carried out by the

Where fluid level is too low, top up cells

authorised Kärcher Customer Service in

Fire, sparks, open light, and

to the mark provided with distilled wa-

accordance with the maintenance booklet.

smoking not allowed!

ter.

Maintenance Works

Charge battery.

Screw in cell caps.

Preparation:

Park the sweeper on an even surface.

Danger of causticization!

Remove the battery

Turn ignition key to "0" and remove it.

Note

Lock parking brake.

Before removing the battery, make sure

General notes on safety

that the negative pole lead is disconnected.

Danger

First aid!

Check that the battery pole and pole termi-

nals are adequately protected with pole

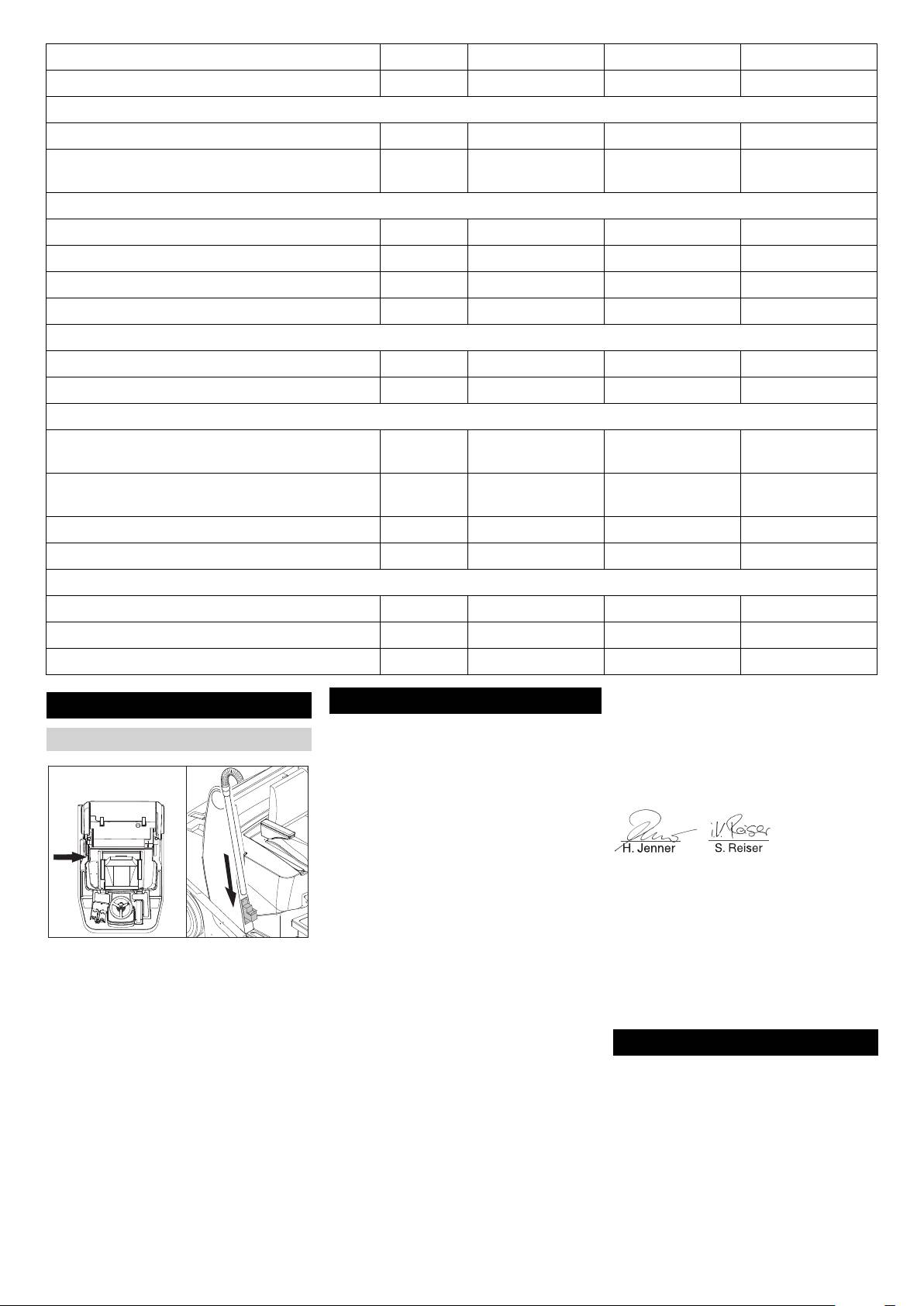

Risk of injury! While working around the lift/

grease.

tilt emptying mechanism, raise the waste

Open cover and secure it (Diag. 3).

container to its highest point and secure.

Disconnect battery.

Warning note!

Remove the battery from the battery

holder.

Dispose of the used battery according

to the local provisions.

Disposal!

Check fuel indicator (only KM 120/150

R G and R D)

Note

After the machine is switched on, the num-

Do not throw the battery in the

ber of operating hours is displayed for 10

dustbin!

Insert safety support into the piston rod

seconds. The fuel gauge is then automati-

for the lifting cylinder and secure it.

cally displayed.

Danger

Note

Risk of injury due to engine overrun. Once

Danger

The fuel gauge shows the length of time the

the engine has been switched off, wait for 5

Risk of explosion! Do not put tools or similar

machine has been in operation since the

seconds. Stay well clear of the working

on the battery, i.e. on the terminal poles

elapsed-time counter was last reset.

area for this time.

and cell connectors.

Note

Allow the machine sufficient time to cool

Danger

The machine can be operated for a maxi-

down before carrying out any mainte-

Risk of injury! Ensure that wounds never

mum of 3 hours on a full tank.

nance and repair work.

come into contact with lead. Always clean

Check fuel gauge for elapsed-time

Do not touch any hot parts, such as the

your hands after having worked with batter-

counter.

drive motor and exhaust system.

ies.

Installing and connecting the battery

Open cover and secure it (Diag. 3).

Insert battery in battery mount.

Screw on mounts on battery base.

- 11

31EN

Check gas filter (only KM 120/150 R LPG)

Note

Oil must be present on at least one third of

the oil dipstick. If the oil level is less than

this, top up engine oil until it reaches the

lower edge of the filler opening.

Only KM 120/150 R G and R LPG: Dis-

mantle the extension piece at the oil fill-

er opening.

Top up engine oil using 6.491-538 oil-

change pump.

Position vehicle jack at the appropriate

Only KM 120/150 R G and R LPG: In-

mounting point for the front or rear

stall the extension piece at the oil filler

Check gas filter in the screw to gas cyl-

wheel.

opening.

inder to see if it is dirty.

Raise machine using vehicle jack.

Close oil filler opening.

Clean dirty filters with compressed air.

Remove wheel nuts.

Wait at least 5 minutes.

Check gas connections (only KM 120/

Remove wheel.

Check engine oil level.

150 R LPG)

Mount spare wheel.

Oil grade: see Technical Data

Note

Screw on wheel nuts.

Change the engine oil

Inspection must be carried out by a quali-

Lower machine using vehicle jack.

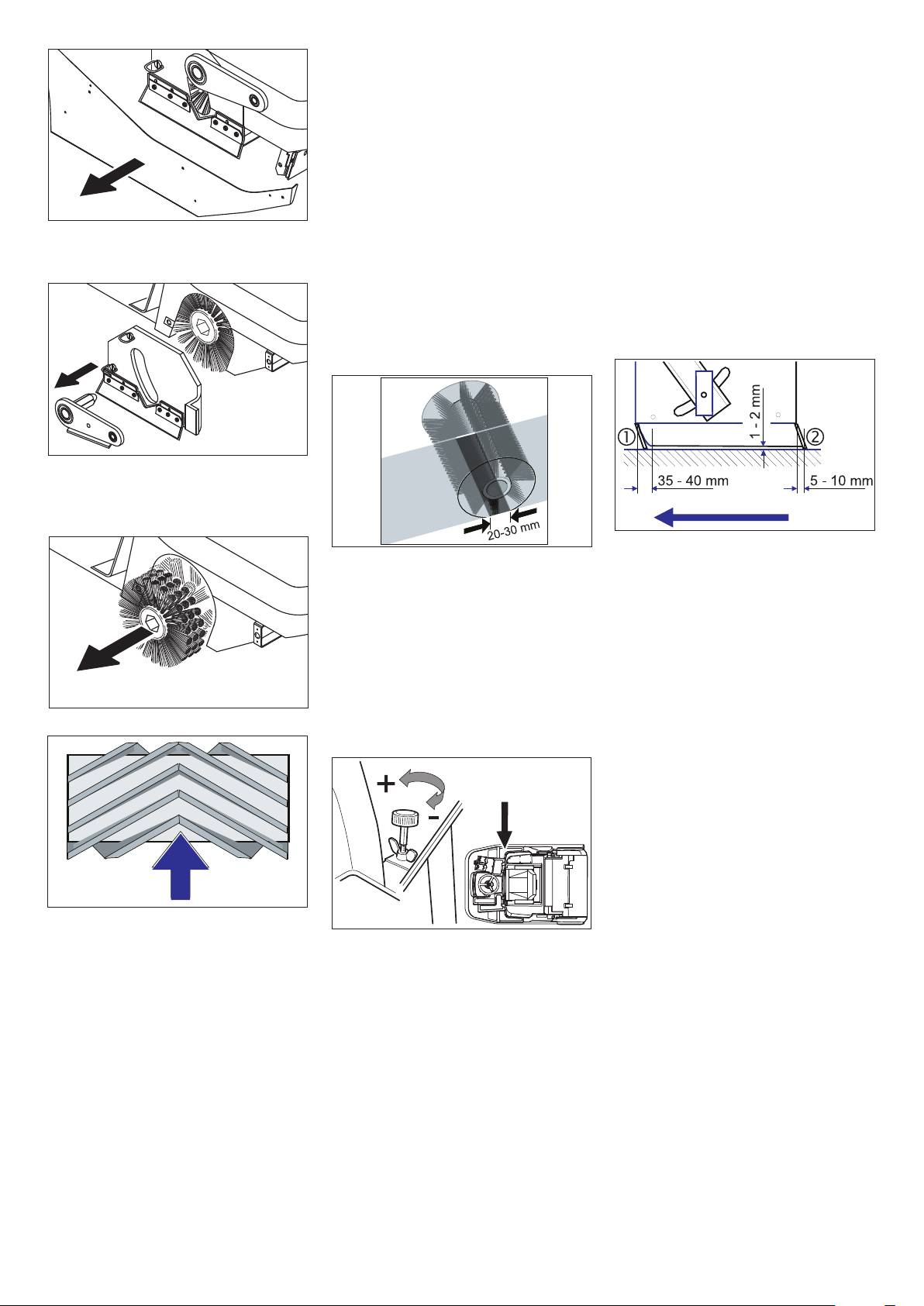

Pull out oil dipstick.

fied specialist.

Tighten wheel nuts.

Only KM 120/150 R G and R LPG: Dis-

Check gas connections, pipes and

Screw on side panel.

mantle the extension piece at the oil fill-

evaporators using leak-search spray for

er opening.

leaks.

Note

Suck off engine oil using 6.491-538 oil-

Note

Use a suitable commercially available vehi-

change pump.

cle jack.

Leaks in the gas cylinder cause formation

Fill in new engine oil using 6.491-538

of crusts or yellow frothy deposits on the

Check engine oil level and top up, if re-

oil-change pump.

gas connections, pipes and evaporator.

quired

Oil grade: see Technical Data

Contact Kärcher Customer Service for

몇 Warning (only KM 120/150 R G and R

Only KM 120/150 R G and R LPG: In-

maintenance of the gas unit.

LPG)

stall the extension piece at the oil filler

Check the tyre pressure

The engine is equipped with an oil deficien-

opening.

Park the sweeper on an even surface.

cy switch. When the fill level is insufficient,

Close oil filler opening.

Connect air pressure testing device to

the engine switches off and can only be re-

Wait at least 5 minutes.

tyre valve.

started once the engine oil has been re-

Check engine oil level.

Check air pressure and adjust if re-

plenished.

Only KM 120/150 R G and R LPG: The mo-

quired.

Danger

tor oil can be drained via a hose.

Set air pressure for the front and rear

Risk of burns!

tyres at 6 bar.

Allow engine to cool down.

Replacing wheel

Wait for at least 5 minutes after switch-

ing off the engine before checking the

Danger

engine oil fill level.

Risk of injury!

Open cover and secure it (Diag. 3).

Park the sweeper on an even surface.

KM 120/150 R G and R LPG:

Remove ignition key.

When carrying out repairs on public

highways, wear warning clothing when

working close to passing traffic.

Check stability of ground. Also secure

Danger

the machine with wheel chock(s) to pre-

Risk of burns due to hot oil!

vent it rolling away.

Ready a catch bin for appr. 1.5 litre oil.

Lock parking brake.

Allow engine to cool down.

Check tyres

Open quick-release locks on the left-

Check tyre contact face for foreign ob-

hand side panel.

jects.

Remove side panel.

Remove objects found.

KM 120/150 R D:

Remove the oil drain hose from the

Use suitable, commercially available

holder.

materials to carry out tyre repairs.

Unscrew oil drain plug.

Note

Pull out oil dipstick.

Observe the manufacturer's recommenda-

Drain off oil.

tions. The journey may be resumed provid-

Screw in oil drain plug.

ing that the directions supplied by the

Insert the oil drain hose in the holder.

product manufacturer have been observed.

The tyre/wheel change should nonetheless

be carried out as soon as possible.

Open quick-release locks on the rele-

vant side panel.

Pull out oil dipstick.

Remove side panel.

Wipe off oil dipstick and insert.

Loosen wheel nuts.

Pull out oil dipstick.

32 EN

- 12

Check air filter and replace, if necessary

Check oil filter/Check backflow pressure

Open cover and secure it (Diag. 3).

KM 120/150 R G and R LPG:

Loosen screws (1).

Remove panel (2).

The oil filter needs to be cleaned or re-

Open the lock with the oil dipstick (3).

placed if the manometer display is in

Check oil level using the oil dipstick.

the red area.

KM 120/150 R D:

Note

Check side brush

The oil level must lie between “MIN“ and

Park the sweeper on an even surface.

“MAX“.

Set programme switch to step 1 (driv-

Top up hydraulic oil if necessary.

ing). Side brushes lift up.

Close container.

Turn ignition key to "0" and remove it.

Screw on panel.

Check side brush.

Oil grade: see Technical Data

Note

Check and adjust hydraulic fluid fill level

The side brush floating mounting adjusts

and change oil – axle drive circuit

the sweeping track as the bristles wear

Note

down. The side brush must be replaced if it

The sweeper is equipped with 2 hydraulic

becomes too worn.

Unscrew wing nut.

circuits.

Replacing side brush

Remove, check and clean filter car-

(1) Checking fill level

Park the sweeper on an even surface.

tridge.

Raise waste container.

Set programme switch to step 1 (driv-

Use either a new or cleaned filter car-

Insert safety support into the piston rod

ing). Side brushes lift up.

tridge in the vacuum container.

for the lifting cylinder and secure it.

Turn ignition key to "0" and remove it.

Screw on wing nut.

Check the fill level in the header tank.

Loosen 3 retaining nuts on underside.

Clean and change spark plug (only KM

Note

Clip side brush on to driver and screw

120/150 R G and R LPG)

The oil level must lie between the “MAX“

on.

Open cover and secure it (Diag. 3).

mark and a distance of 2 cm above the

Checking roller brush

base of the tank.

Park the sweeper on an even surface.

Set programme switch to step 1 (driv-

ing). Roller brush is raised.

Turn ignition key to "0" and remove it.

Secure the machine with wheel

chock(s) to prevent it from rolling away.

Lock parking brake.

Remove belts or cords from roller

brush.

Remove spark-plug connector.

Replacing roller brush

Unscrew and clean spark plug.

Replacement is due if a visible deteriora-

몇 Warning

Screw in cleaned or new spark plug.

tion in sweeping performance caused by

This inspection may only be carried out

bristle wear is evident.

Push on spark-plug connector.

when the engine is cold.

Park the sweeper on an even surface.

Check and adjust fill level of hydraulic

(2) Adjusting fill level

Set programme switch to step 1 (driv-

fluid – sweeping hydraulics circuit

Raise waste container.

ing). Roller brush is raised.

Note

Insert safety support into the piston rod

Turn ignition key to "0" and remove it.

The sweeper is equipped with 2 hydraulic

for the lifting cylinder and secure it.

Secure the machine with wheel

circuits.

Remove the lid of the container.

chock(s) to prevent it from rolling away.

Note

If required, top up oil carefully.

Lock parking brake.

Drive in the waste container to check/ cor-

Close container.

Open quick-release locks on the right-

rect the filling status.

Oil grade: see Technical Data

hand side panel.

The cap with the oil dipstick is located in the

(3) Changing oil

storage tank above the right rear wheel.

Raise waste container.

Open cover and secure it (Diag. 3).

Insert safety support into the piston rod

for the lifting cylinder and secure it.

Unscrew oil drain plug.

Remove the lid of the container.

Drain off oil.

Screw in oil drain plug.

Replenish oil.

Close container.

- 13

33EN

Check and adjust roller brush sweeping

Adjusting and replacing sealing strips

track

Park the sweeper on an even surface.

Note

Set programme switch to step 1 (driv-

To do this, the machine must be in basic-

ing). Roller brush is raised.

operating mode. The power button indica-

Turn ignition key to "0" and remove it.

tor light should not light up.

Secure the machine with wheel

Set programme switch to step 1 (driv-

chock(s) to prevent it from rolling away.

ing). The side brush and roller brush are

Lock parking brake.

raised.

Open the side panel quick-release

Drive sweeper on to a smooth, even

locks on both sides.

Remove side panel.

surface covered with a visible layer of

Remove side panels.

Unscrew and withdraw bolt on the roller

dust or chalk.

Front sealing strip

brush swinging arm.

Lower roller brush and allow it to briefly

Loosen retaining nuts for the front seal-

rotate.

ing strip (1) slightly (to replace, un-

Raise roller brush.

screw).

Press pedal which raises bulk waste

Screw on new sealing strip without fully

flap and keep pressed.

tightening the nuts.

Drive machine backwards.

Pull out roller brush swinging arm.

Remove lifting rod assembly from pins.

Open quick-release locks and remove

cover.

Adjust sealing strip.

The sweeping track should have an even

Set the distance of the sealing strip to

rectangular shape which is between 20 and

the floor so that the bottom edge trails

30 mm wide.

behind at a distance of between 35 and

Note

40 mm.

The shape of the sweeping track must not

Tighten nuts.

be trapezoidal. If so, consult Customer Ser-

Rear sealing strip

vice.

Set the distance between the sealing

Note

strip and the floor so that the bottom

edge trails behind at a distance of be-

The sweeping track can be adjusted using

Pull out roller brush.

tween 5 and 10 mm.

a handwheel in basic-operating mode.

Open cover and secure it (Diag. 3).

If worn, replace.

Remove roller brush.

Unscrew retaining nuts for rear sealing

strip (2).

Screw on new sealing strip.

Side sealing strips

Slightly loosen retaining nuts for the

side sealing strip (to replace, unscrew).

Screw on new sealing strip without fully

tightening the nuts.

Installation position of roller brush in direc-

To set the floor clearance, insert a

tion of travel

Release the wing nut.

sheet with a thickness of between 1 and

Push new roller brush into the roller

2 mm under the sealing strip.

Enlarging sweeping track:

brush housing and onto the drive pin.

Turn the adjustment screw in an anti-

Adjust sealing strip.

Note

clockwise direction (+).

Tighten nuts.

When installing the new roller brush, ensure

Reducing sweeping track:

Screw on side panels.

correct positioning of the bristle assembly.

Turn the adjustment screw in a clock-

Position roller brush cover.

wise direction (-).

Push lifting rod assembly on to pins.

Tighten the wing nut.

Push roller brush mount on to the pins.

Note

Tighten bolt on the roller brush mount.

In power-operating mode, the sweeping

Position retaining screws for the roller

track is automatically adjusted due to the

brush cover and screw home.

floating mounting for the side brush as the

Screw on side panel.

bristles wear down. The roller brush must

Note

be replaced if it becomes too worn.

Once the new roller brush has been in-

stalled, the sweeping track must be read-

justed.

34 EN

- 14

Check tension of drive belt and V-belt of

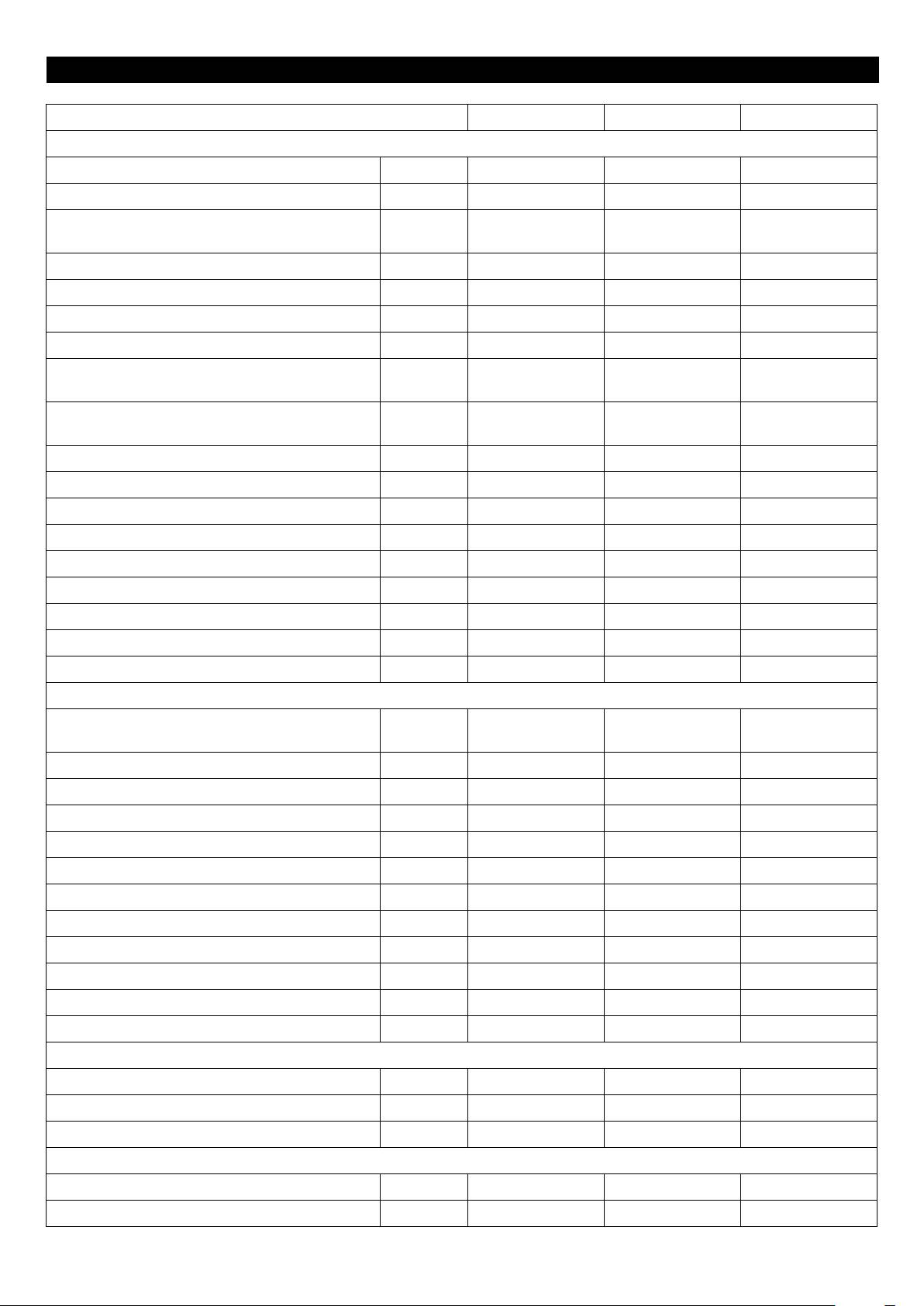

Replacing dust filter

the roller brush also check for wear or

Danger

damage.

Empty waste container before replacing

Only KM 120/150 R LPG and KM 120/

dust filter. Wear a dust mask when working

150 with driver cabin:

around the dust filter. Observe safety regu-

Check tension of drive belt and V-belt of

lations on the handling of fine particulate

the light machine; also check for wear

material.

or damage.

Slightly raise the waste container and

tipp it a little.

Check cup seal

Chek the cup seal at the suction blower

regularly to see that it sits properly.

Replacing electric bulb

Turn ignition key to "0" and remove it.

Remove side brush.

Disconnect filter motor from power sup-

ply (1).

Disconnect the plug connection of the

limit switch.

Loosen the screw joint of the filter agita-

tor motor.

Remove splash guard (1).

Open catches (2).

Disconnect plug (2).

Slightly tip the filter box backwards and

Twist contact plate to one side (3).

take it out (3).

Remove defective bulb (4).

Insert new bulb.

Twist contact plate back into original

position.

Connect plug.

Mount splash guard.

Screw on side brush.

Replacing fuses of drive control/ elec-

tronic system

The drive control/electronic system is in-

stalled behind the front panel. To replace a

Loosen filter mount (1), turn (2) and pull

fuse, the front panel must be removed.

out.

Loosen screws on both sides of the

Remove louver filter (3).

panel.

Insert new filter.

Note

Make sure driver engages with grooves

The assignment of fuses is indicated on the

on drive side.

inside of the front panel. Only use fuses

Snap filter mount back on and tighten

with identical safety ratings.

screws.

Replace defective fuses.

Note

Replace front panel.

Make sure when installing the new filter

Replacing electrical starter in the engine

that the fins are not damaged and the filter

room (only KM 120/150 R D)

case seal does not get jammed.

Open cover and secure it (Diag. 3).

Replacing filter case seal

Lift filter case seal out of groove in the

cover.

Insert new seal.

Checking drive belt

Danger

The engine requires approx. 3-4 seconds

to come to a standstill once it has been

switched off. During this time, stay well

clear of the working area.

Turn ignition key to "0" and remove it.

Replace defective fuse.

Open cover and secure it (Diag. 3).

Check tension of drive belt and V-belt of

the suction blower, also check for wear

or damage.

- 15

35EN

Troubleshooting

Fault Remedy

Appliance cannot be started Sit on the driver seat, activate seat contact mat

Refuel/ replace gas cylinder

Open fuel tap/ gas supply

Check connections and links in petrol or gas lines.

Check fuse of the electrical starter, replace if required (only KM 120/150 R D)

Charging battery

Clean and change spark plug, replace if required (only KM 120/150 R G and R LPG)

Inform Kärcher Customer Service.

For temperatures below +10 °C: Lock parking brake

Engine is running erratically Clean or replace air filter

Check connections and links in petrol or gas lines.

Inform Kärcher Customer Service.

Engine is running but machine is

Release parking brake

not moving

Check setting of freewheel lever

Inform Kärcher Customer Service.

Engine is running but machine is

Release parking brake

only moving slowly

Allow machine to warm up for approx. 3 minutes in sub-zero temperatures

Inform Kärcher Customer Service.

Machine is not sweeping properly Check roller brush and side brushes for wear, replace if necessary.

Check function of bulk waste flap

Check sealing strips for wear, adjust or replace as required

Adjust roller mirror

Check hydraulic system (sweeping) for leaks.

Inform Kärcher Customer Service.

Dust gathers in the machine Empty waste container

Check suction fan drive belt

Check sealing cover on suction fan

Check dust filter, clean or replace

Check filter case seal

Check sealing strips for wear, adjust or replace as required

Poor cleaning performance at

Replace side brush

edges

Check sealing strips for wear, adjust or replace as required

Inform Kärcher Customer Service.

Side brush or roller brush switch-

Check hydraulic system (sweeping) for leaks.

on operation is not working

Inform Kärcher Customer Service.

Side brush or roller brush is not

Inform Kärcher Customer Service.

being lowered

Insufficient vacuum performance Check filter case seal

Check sealing cover on suction fan

Insert lamella filter correct; see Changing dust filter

Roller brush does not turn. Remove belts or cords from roller brush

Charge indicator lamp glows only

Inform Kärcher Customer Service.

during operations (only KM 120/

150 R D and R LPG)

36 EN

- 16

Technical specifications

KM 120/150 R G KM 120/150 R D KM 120/150 R LPG

Machine data

Length x width x height (without driver cabin) mm 1900 x 1230 x 1400 1900 x 1230 x 1400 1900 x 1230 x 1800

Length x width x height (with driver cabin) mm 1900 x 1230 x 2010 1900 x 1230 x 2010 1900 x 1230 x 2010

Length x width x height (with driver cabin and beacon

mm 1900 x 1230 x 2205 1900 x 1230 x 2205 1900 x 1230 x 2205

light)

Unladen weight (without attachment sets) kg 660 670 710

Permissible overall weight kg 1110 1120 1160

Driving speed km/h 10 10 10

Cleaning speed km/h 8 8 8

Max. climbing performance (appliance without driver

%181818

cabin)

Max. climbing performance (appliance with driver

%101010

cabin)

Roller brush diameter mm 300 300 300

Roller brush width mm 850 850 850

Side brush diameter mm 600 600 600

Surface cleaning performance without side brushes m

2

/h 6800 6800 6800

Surface cleaning performance with 2 side brushes m

2

/h 11588 11588 11588

Working width without side brushes mm 850 850 850

Working width with 2 side brushes mm 1470 1470 1470

Volume of waste container l 150 150 150

Protection type, drip-proof -- IPX 3 IPX 3 IPX 3

Engine

Type -- Honda, 1 cyl., four-

Yanmar L100AE, 1

Honda, 1 cyl., four-

stroke

cyl., four-stroke

stroke

Cylinder capacity cm

3

390 406 390

Max. power kW/PS 9,5/13 7,4/10 9,5/13

Maximum torque at 2500 rpm Nm 26,5 -- 26,5

Maximum torque at 2700 rpm Nm -- 27 --

Capacity of fuel tank, normal petrol (unleaded) l 6 -- --

Capacity of fuel tank, diesel l -- 5,5 --

Spark plug, NGK -- BPR 6 ES -- BPR 6 ES

Type of protection -- IP 22 IP 22 IP 22

Battery V, Ah 12, 44 12, 44 12, 44

Fuel consumption l/h ca. 2 ca. 1,3 --

Gas consumption kg/h -- -- ca.

Oil grades

SAE 15 W 40 engine l 1,1 1,65 1,1

Sweeping hydraulics -- HVLP 46 HVLP 46 HVLP 46

Axle drive -- SAE 20 W 50 SAE 20 W 50 SAE 20 W 50

Tyres

Size, front -- 4.00-4 4.00-4 4.00-4

Air pressure, front bar 6 6 6

- 17

37EN

Size, rear -- 4.00-8 4.00-8 4.00-8

Air pressure, rear bar 6 6 6

Brake

Service brake -- hydrostatic hydrostatic hydrostatic

Parking brake -- Hand lever (with

Hand lever (with

Hand lever (with

spring)

spring)

spring)

Filter and vacuum system

Filter surface area, fine dust filter m

2

999

Category of use – filter for non-hazardous dust -- U U U

Nominal vacuum, suction system mbar 12 12 12

Nominal volume flow, suction system l/s 50 50 50

Working conditions

Temperature °C -5 and +40 -5 and +40 -5 and +40

Air humidity, non-condensing % 0 - 90 0 - 90 0 - 90

Noise emission

Sound pressure level L

pA

dB(A) 82 83 82

Machine without driver cabin

Sound pressure level L

pA

dB(A) 88 88 88

Machine with driver cabin

Uncertainty K

pA

dB(A) 2 2 2

Sound power level L

WA

+ Uncertainty K

WA

dB(A) 101 100 100

Machine vibrations

Hand-arm vibration value m/s

2

<2,5 <2,5 <2,5

Seat m/s

2

<0,5 <0,5 <0,5

Uncertainty K m/s

2

0,2 0,2 0,2

KM 120/150 R LPG

EC Declaration of Conformity

Accessories

Measured: 98

We hereby declare that the machine de-

Guaranteed: 100

Installation set suction hose

scribed below complies with the relevant

basic safety and health requirements of the

The undersigned act on behalf and under

EU Directives, both in its basic design and

the power of attorney of the company man-

construction as well as in the version put

agement.

into circulation by us. This declaration shall

cease to be valid if the machine is modified

without our prior approval.

CEO

Head of Approbation

Product: Ride-on vacuum sweeper

Type: 1.511-xxx

Authorised Documentation Representative

S. Reiser

Relevant EU Directives

2006/42/EC (+2009/127/EC)

Alfred Kärcher GmbH Co. KG

Remove suction hose from holder.

2004/108/EC

Alfred-Kärcher-Str. 28 - 40

Suck in the dirt.

2000/14/EC

71364 Winnenden (Germany)

Insert the suction hose in the holder.

Applied harmonized standards

Phone: +49 7195 14-0

Note

EN 60335–1

Fax: +49 7195 14-2212

EN 60335–2–72

After completing the suction, ensure that

EN 61000–6–2: 2005

the tube of the suction hose lies on the floor

Warranty

EN 62233: 2008

of the holder.

Applied national standards

The warranty terms published by the rele-

CISPR 12

vant sales company are applicable in each

Applied conformity evaluation method

country. We will repair potential failures of

2000/14/EC: Appendix V

your appliance within the warranty period

Sound power level dB(A)

free of charge, provided that such failure is

KM 120/150 R D

caused by faulty material or defects in man-

Measured: 99

ufacturing. In the event of a warranty claim

Guaranteed: 101

please contact your dealer or the nearest

KM 120/150 R G

authorized Customer Service centre.

Measured: 98

Please submit the proof of purchase.

Guaranteed: 100

38 EN

- 18

Lire ce manuel d'utilisation origi-

Fermer le robinet de carbu-

Risque de basculement en cas de pente la-

nal avant la première utilisation

rant (Seul KM 120/150 R G et

térale trop importante.

de votre appareil, le respecter et le conser-

R D) . . . . . . . . . . . . . . . . FR

. .10

– N'empruntez aucunes pentes supé-

ver pour une utilisation ultérieure ou pour le

Fermer la bouteille à gaz

rieures à 10% dans le sens perpendicu-

(Seul KM 120/150 R LPG) FR

. .10

futur propriétaire.

laire au sens de la marche.

Avant la première mise en service, vous

Transport . . . . . . . . . . . . . . . FR . .10

– Doivent être respectées les mesures de

devez impérativement avoir lu les

Entreposage de l'appareil . . FR . .10

règlement, les règles et les décrets qui

consignes de sécurité N° 5.956-250 !

Entretien et maintenance. . . FR . .10

sont valables pour les automobiles.

Consignes générales . . .

FR

. .10

– L’utilisateur doit utiliser l’appareil de fa-

Table des matières

Nettoyage intérieur du véhi-

çon conforme. Dans la circulation, il doit

cule. . . . . . . . . . . . . . . . . FR

. . 11

prendre en considération les données

Designation de l'appareil. . . FR . . 1

Nettoyage extérieur de l'ap-

locales et lors du maniement de l’appa-

pareil . . . . . . . . . . . . . . . FR

. . 11

Consignes de sécurité . . . . FR . . 1

reil, il doit prendre garde aux tierces

Fréquence de maintenance

. . 11

Consignes générales . .

FR

. . 1

FR

personnes, et en particulier aux en-

Travaux de maintenance

Symboles utilisés sur l'appa-

FR

. . 11

fants.

reil . . . . . . . . . . . . . . . . . FR

. . 2

Assistance en cas de panne FR . .17

– L'appareil doit uniquement être utilisée

Symboles utilisés dans le

par des spécialistes qui sont instruits

Caractéristiques techniques FR . .18

mode d'emploi. . . . . . . . FR

. . 2

dans la manoeuvre ou par des per-

Accessoires . . . . . . . . . . . . . FR . .19

Directives de sécurité pour

sonnes qui peuvent justifiée leur apti-

Lot d'annexe tuyau d'aspira-

des automobiles de gaz li-

tude d'utilisation et qui sont

tion . . . . . . . . . . . . . . . . . FR

. .19

quéfié (Uniquement KM 120/

explicitement mandatées pour l'utilisa-

150 R LPG) . . . . . . . . . . FR

. . 2

Déclaration de conformité CE FR . .19

tion.

Fonction . . . . . . . . . . . . . . . FR . . 3

Garantie. . . . . . . . . . . . . . . . FR . .19

– Ne jamais laisser des enfants ou des

Utilisation conforme . . . . . . FR . . 3

adolescents utiliser l'appareil.

Revêtements appropriés

. . 3

Designation de l'appareil

FR

– La prise de tierce personnes est inter-

Protection de l’environnement FR . . 3

– KM 120/150 R G = Moteur à essence

dit.

Eléments de commande et de

– KM 120/150 R D = Moteur diesel

– Les appareils qu'arrivent en butée mé-

fonction . . . . . . . . . . . . . . . . FR . . 4

– KM 120/150 R LPG = Moteur à gaz

canique ne peuvent être mis seulement

Balayeuses sans cabine de

qu'à partir du siège.

conducteur . . . . . . . . . . FR

. . 4

Pour éviter une utilisation sans droit de

Balayeuses avec cabine de

Consignes de sécurité

l'appareil, la clé de contact doit être re-

conducteur . . . . . . . . . . FR

. . 4

– Cette balayeuse (sans cabine de

tirée.

Repérage de couleur. . .

FR

. . 4

conducteur) doit être utilisée unique-

Pendant le fonctionnement du moteur,

Ouvrir / fermer le capot et sé-

ment sur des surfaces qui présentent

l'appareil doit être tous le temps surveil-

curiser . . . . . . . . . . . . . . FR

. . 5

une pente maximale de 18%.

lée. L'utilisateur ne peut sortir de l'appa-

Pupitre de commande. .

FR

. . 6

– Cette balayeuse (avec cabine de

reil que lorsque le moteur s'arrête,

Avant la mise en service. . . FR . . 7

conducteur) doit être utilisée unique-

l'appareil est assurée contre des mou-

Déchargement de la ma-

ment sur des surfaces qui présentent

vements involontaires, le frein d'arrêt,

chine . . . . . . . . . . . . . . . FR

. . 7

une pente maximale de 10%.

en cas échéant est actionné et la clé de

Déplacement de la ba-

contact est retirée.

layeuse sans autopropulsion FR

. . 7

Consignes générales

Déplacement de la ba-

Machines avec moteur à combustion

Contacter le revendeur en cas de constata-

layeuse sans autopropulsion FR

. . 7

Danger

tion d'une avarie de transport lors du débal-

Mise en service. . . . . . . . . . FR . . 7

lage de l'appareil.

Risque de blessure !

Consignes générales . .

FR

. . 7

– Afin d'assurer un fonctionnement sans

– Le quatrième trou ne peut être fermé.

Faire le plein (Seul KM 120/

danger, observez les avertissements et

– Ne pas se pencher au-dessus ou tou-

150 R G et R D) . . . . . . FR

. . 7

consignes placés sur l'appareil.

cher le quatrième trou (danger de brû-

Monter/changer la bouteille à

– Outre les instructions figurant dans le

lure).

gaz (Seul KM 120/150 R