Karcher HKF 50 P: Contents

Contents: Karcher HKF 50 P

– Danger of injury by high pressure jet -

Please read and comply with

therefore only use interior cleaner inside

these instructions prior to the

Cleaning head Minimum contain-

er opening

closed containers.

initial operation of your appliance. Retain

these operating instructions for future refer-

– Health hazards posed by residue in

HKF 50 55 mm

ence or for subsequent possessors.

containers that are cleaned or by the

– A separate high pressure pump is con-

– Before first start-up it is definitely neces-

cleaning liquid used. Therefore, the list-

nected to the interior cleaner via a high

sary to read the operating instructions

ed protective measures must be ad-

pressure hose.

and safety indications Nr. 5.951-949!

hered to.

– In case of transport damage inform ven-

Note

– Risk of injury due to interior cleaner top-

dor immediately

The chapter "Specifications" contains a list

pling over at low submerge depth. In

of the permitted cleaning liquids.

this case, the interior cleaner must be

Contents

supported.

– Risk of injury by toppling container -

Environmental protection 11

therefore use extra support for contain-

Symbols in the operating instructions 11

Operation outside closed containers and

er and interior cleaner.

Proper use 11

with higher pressure and temperatures than

– Danger of injury by interior cleaner slid-

those listed in the "Specifications" is prohib-

Function 11

ing off; therefore tighten interior cleaner

ited.

Safety instructions 11

with clamping ring.

Technical specifications 14

Please do not allow cleaning liquids to

Start up 15

enter the environment. Protect the

Operation 16

ground and dispose of used oil in an en-

Risk of explosion and fire when using clean-

Shutting down 16

vironmentally-clean manner.

ing agents and residue in the containers.

Please contact Kärcher in such cases to

Maintenance and care 16

find out, how the respective cleaning

Troubleshooting 17

Please do not let mineral oil contaminat-

agents should be used.

ed waste water reach soil, water or the

Accessories 18

sewage system.

몇 Warning

CE declaration 18

In order to avoid damage to the cleaning

Warranty 18

Function

head, ensure a free layout inside the con-

tainer. The cleaning head must never touch

Environmental protection

– The interior cleaner consists of a drive

the container wall.

unit, a support pipe and the cleaning

head. The nozzles on the cleaning head

Personal safety gear

The packaging material can be

turn around two axles and therefore

recycled. Please do not throw

touch every place in the container.

the packaging material into

Wear ear plugs to protect

– The cleaning head is turned by an elec-

household waste; please send

your ears against hearing

tric or compressed air motor. The speed

it for recycling.

loss while cleaning parts

is independent of the pressure and the

that produce high sound

Old appliances contain valua-

volume of cleaning liquid. With electric

levels.

ble materials that can be recy-

drives, the speed can be set to con-

Depending on the concentration and health

cled; these should be sent for

stant, with compressed air drives, the

risk of the used cleaning liquid, wear the fol-

recycling. Batteries, oil, and

speed can be adjusted via the com-

lowing protective gear:

similar substances must not

pressed air.

– Liquid resistant protective clothing

enter the environment. Please

Safety instructions

dispose of your old appliances

– Protective glasses or face shield

using appropriate collection

– Protective gloves

– Please follow the national rules and reg-

systems.

ulations of the respective country.

– Protective shoes

– Please follow the safety instructions

Approved operators

Symbols in the operating in-

which are attached to the used deter-

structions

Approved operators are persons who are at

gents (normally on the packing label).

least 18 years old and are able to operate

– In order to avoid improper operation, the

Danger

this system (exceptions: apprentices, see

system may only be used by persons

indicates an immediate threat of danger.

BGV D15 §6).

who have been instructed in handling

Failure to observe the instruction may result

the system or have proven qualification

Behaviour in emergency situations

in death or serious injuries.

and expertise in operating the system or

Switch off the separate high pressure

몇 Warning

have been explicitly assigned the task

pump.

indicates a possibly dangerous situation.

of handling the system.

Interior cleaners with electric drives:

Failure to observe the instruction may result

– The operating instructions must be ac-

Pull out the mains plug.

in light injuries or damage to property.

cessible for every user.

Interior cleaners with compressed air

Note

Wrong operation or misuse are hazardous

drives: Shut off the compressed air sup-

indicates useful tips and important informa-

to the operator and other persons on ac-

ply.

tion.

count of:

Shut off the cleaning liquid supply.

– high pressure

Proper use

– high electrical voltages (HKF 50 E)

– The interior cleaners HKF 50 are spray

– Cleaning agents or used cleaning liquid

devices to clean drums and containers.

– Danger of explosion

– The cleaning head is inserted into the

Danger

container through an opening with a

– Danger of crushing by the interior clean-

suitable minimum inner diameter.

er. Only use the interior cleaner's drive

in closed containers.

English 11

5 The nominal pressure of the pump must

Zone layout

not exceed 5 MPa when operating with

solvents.

6 The compressed air motor must only be

Areas that bear the risk of explosion are di-

operated once the interior cleaner has

vided into zones, according to the frequen-

been filled with cleaning liquid.

cy and duration of explosion-risk

7 The speed of the cleaning head must

atmosphere in BetrSichV and EN 1127-1.

not exceed 40 rpm.

The definition of the zones lies in the re-

8 The operating temperature of the clean-

sponsibility of the operator.

ing liquid water with cleaning agents

Tips for zoning are included in the Be-

must not must not exceed 95 °C.

trSichV, EN 1127-1, BGR 104 – Ex-guide-

9 The operating temperature of the clean-

line of BG Chemie and in the EN 60079-10.

ing liquid solvents, brines and acids

– Zone 0

must not must not exceed 20 °C.

Zone 0 is an area where dangerous ex-

10 The interior cleaner must be checked

plosion-risk atmosphere is present as a

for flawless condition and smooth func-

mixture of air and flammable gases, va-

tion after a certain operating time has

pors or mists at all times, across long

passed (incl. bearing bushings and

time periods or frequently.

drive-side seal for wear and tear and

– Zone 1

leakage). If applicable, a repair needs to

Zone 1 is an area where (during normal

be conducted.

operation) dangerous explosion-risk at-

11 The interior cleaner must only be used

mosphere is present as a mixture of air

with cleaning liquids and in such media,

and flammable gases, vapors or mists

whose affect on the materials is not

from time to time.

damaging.

– Zone 2

12 Cleaning liquids that contain flammable

Zone 2 is an area where (during normal

solvent particles, must comply with the

operation) dangerous explosion-risk at-

ignition groups IIA and IIB. Solvents of

mosphere as a mixture of air and flam-

the ignition group IIC must not be

mable gases, vapors or mists is not

sprayed.

normally present and if present, only for

13 The interior cleaner must not be con-

a short time.

stantly located in Zone 0, but only dur-

– Zone 20

ing the actual container cleaning. The

Zone 20 is an area where dangerous

operating guidelines as per BetrSichV

explosion-risk atmosphere is present as

as well as other national guidelines

a cloud of flammable dust contained in

must be adhered to. Take into consider-

the air, at all times, across long time pe-

ation, that the mixture of the container/

riods or frequently.

interior cleaner brought into the contain-

er is not resistant to breakdown from

– Zone 21

flames.

Zone 21 is an area where (during nor-

mal operation) dangerous explosion-

14 Hoses must be conductive (electrostati-

cally) (resistance R < 1000 Ohm).

risk atmosphere is present as a cloud of

flammable dust in the air from time to

15 Only cleaning agents with a conductivity

time.

G > 1000 pS/m may be used.

– Zone 22

16 All parts that touch media must be con-

Zone 22 is an area where (during nor-

nected to the grounding system.

mal operation) dangerous explosion-

risk atmosphere as a cloud of flamma-

ble dust is not normally present and if

present, only for a short time.

Special conditions in the Ex area

1 The interior cleaner must only be used

in Zone 0 if the containers are at least 1

m in diameter with the usual container

height or do not exceed a comparable

container size.

2 The mass content of non-diluted solid

substances in the cleaning liquid must

not exceed 1%.

3 The interior cleaner must be ground

electro-statically.

4 The pump for the cleaning liquid must

only be operated while it is filled with flu-

id.

12 English

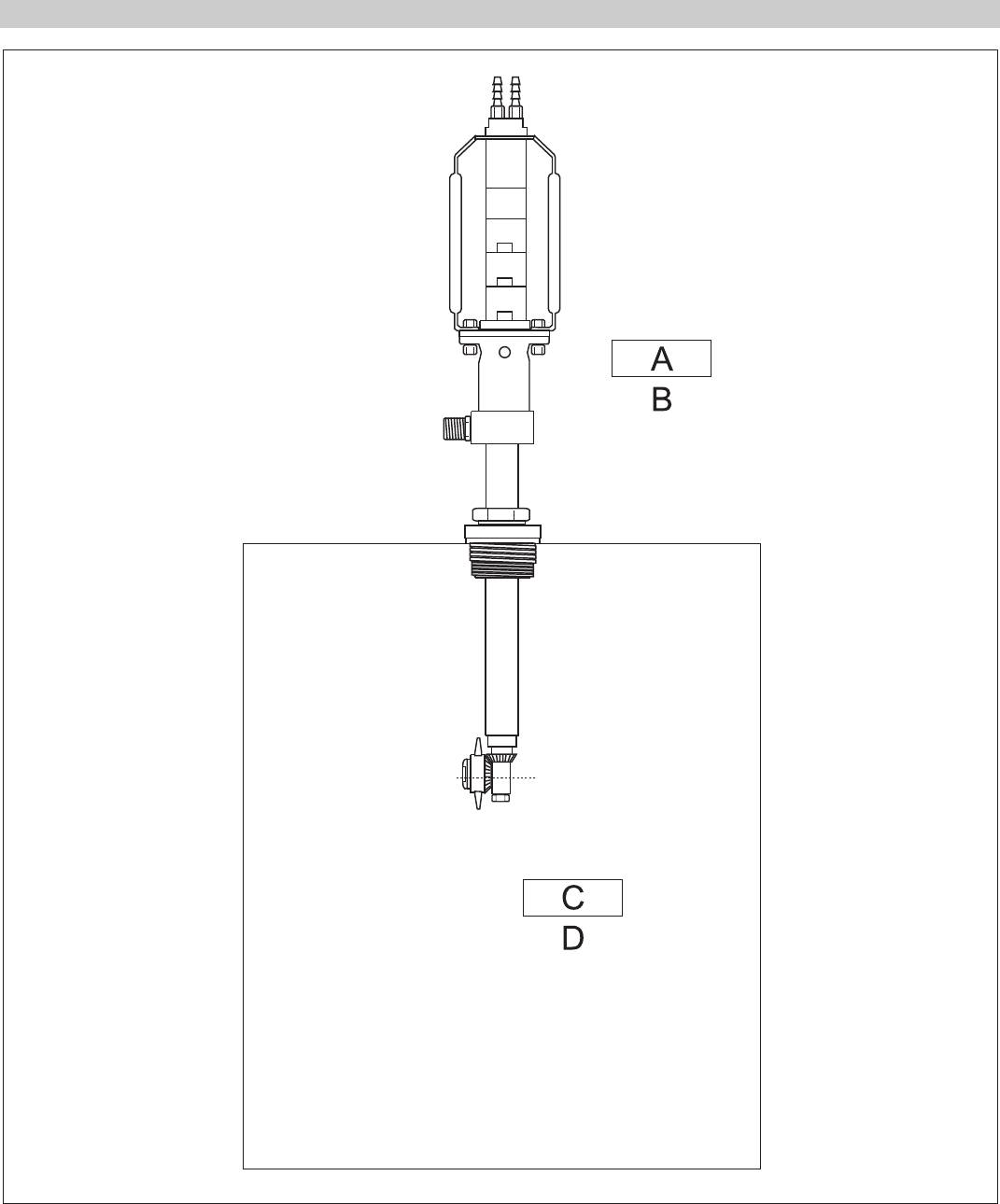

Basic sketch - zone layout

A Zone 1/22

B Category 2/3

C Zone 0/20

D Category 1

English 13

Оглавление

- www .kaercher .com!

- Bestimmungsgemäße Ver-

- Technische Daten

- Inbetriebnahme

- Bedienung

- Hilfe bei Störungen

- Zubehör

- Contents

- Technical specifications

- Start up

- Operation Maintenance and care

- Troubleshooting

- Accessories

- Utilisation conforme

- Caractéristiques techniques

- Mise en service

- Entretien et maintenance

- Assistance en cas de panne

- Accessoires

- Reglementair gebruik

- Technische gegevens

- Inbedrijfstelling

- Bediening

- Hulp bij storingen

- Toebehoren CE-verklaring

- Uso previsto

- Datos técnicos

- Puesta en marcha

- Cuidados y mantenimiento

- Ayuda en caso de avería

- Accesorios

- Указания по технике

- Технические данные

- Начало работы

- Вывод из эксплуатации

- Помощь в случае неполадок

- Принадлежности

- Użytkowanie zgodne z

- Dane techniczne

- Uruchamianie

- Czyszczenie i konserwacja

- Usuwanie usterek

- Akcesoria