Karcher HKF 50 P: Start up

Start up: Karcher HKF 50 P

Cleaning liquids

Water

Connect compressed air hoses to the

1 Water

compressed air motor

solvents

2 Fully desalted water

Note

Danger

Other cleaning liquids

If the silencers are too small, the created

– The explosion protection must be taken

If other cleaning liquids are used, their resil-

backpressure of the exhaust air will cause

into consideration when operating with

ience must be checked by means of the

an unstable run of the compressed air drive.

solvents as well as in EX zones!

materials list! These cleaning liquids can

Connect hoses to the exhaust air openings.

– Maximum pressure with solvent opera-

only be used after being released by Kärch-

tion: 5 MPa

er!

몇 Warning

Selecting the nozzle

When operating with solvents, the sealing

materials are less resistent, therefore they

must be flushed immediately after use! En-

Flow vol-

1200 1200 1000 1000

quire with Kärcher!

ume [l/h]

1 Hydrocarbons

Pressure

9,5 9,5 9,5 9,5

Example: Petroleum

[MPa]

2 Aromates (solvents)

Number of

2121

Example: Benzene, toluene

nozzles

3 Ketones

Example: MEK (Methyle Ethyle Ke-

Nozzle size

1,4 * 2,0 1,2 1,7

tones), Acetone

[mm]

4Ester

Order No.

012 015 014 013

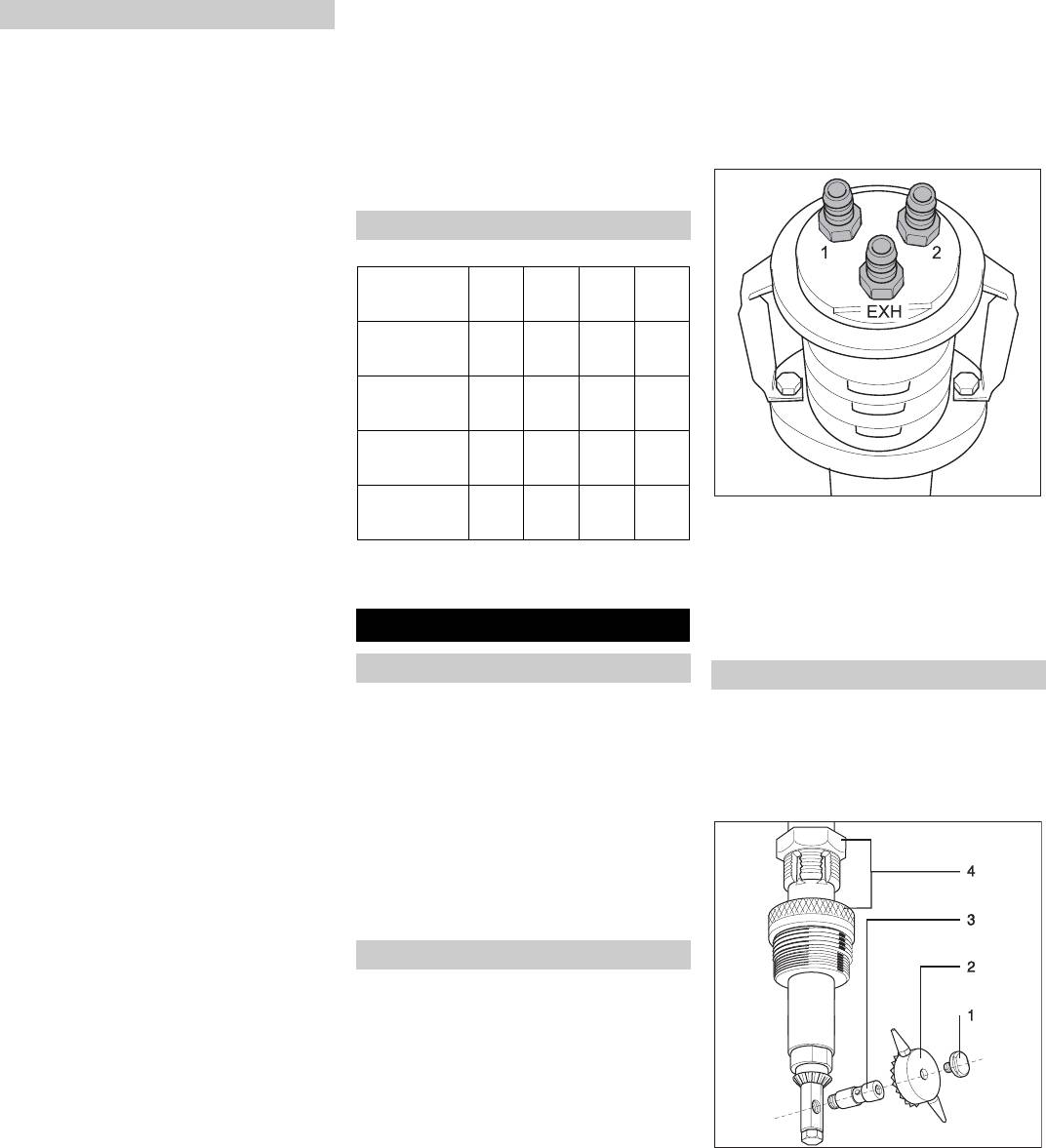

Connect an air supply hose to connec-

Example: Butylacetate, Methylacetate

5.765-

tion no. 2.

5 Glycoles

* Standard

– Hose size for supply air: DN 6

Example: Butyl glycole

Special nozzles for solvent operation on re-

Connect exhaust air hoses to connec-

6 Mixed solvents

quest.

tion no. 1 and EXH.

Example: Butyl acetate 85, Isobutyl ac-

– Hose length: 1 -2 m

etate 85 (85 = 85% Butyl acetate + 15%

Start up

– Hose size for exhaust air: DN 6

n-Butanol)

7 Regenerates, distillates from different

Electric drive

Attach drum screws or hole cone

solvents, which have already been used

Danger

for cleaning purposes or similar applica-

Note

Risk of fatal injuries on account of electric

tions.

Lubricate the threads with a sealant prior to

voltage! Required electrical work must only

installation, so that no cleaning liquid can

Brines

be performed by an electrical specialist.

leak from the threads (e.g. with Drei Bond

1 Water with alkaline cleaning agents

– The socket must be secured through a

no. Nr. 1359, Kärcher order no. 6.869-029).

(max. 0-2%)

wrong current protection switch with a

Example: Kärcher cleaning agents

triggering current of 30 mA.

RM31

– This socket must be located close to the

2 Caustic soda max. 10%, without hy-

work station so that the plug can be

pochlorite particles

pulled immediately in case of an emer-

3 Potassium hydroxide max. 10%, without

gency.

hypochlorite particles

Compressed air drive

Acids

몇 Warning

몇 Warning

In order to avoid damage to the com-

– The material will be worn off faster when

pressed air drive by condensation wear and

using hydrochloric or sulfuric acids;

lack of lubrication, install a maintenance

therefore it must be rinsed/neutralised

unit into the compressed air supply (order

immediately!

no. 6.610-020).

– Contaminated acids will decrease the

This maintenance unit must be laid out as

resilience!

follows:

– Enquire with Kärcher if needed!

1 Screwed sealing plug

– Air throughput of 500 l/min

1 Water with acid cleaning agents (max.

2 Bevel wheel

– Pressures up to 0.7 MPa

0-1%)

3 Axle stub

The maintenance unit consists of:

Example: Kärcher cleaning agents

– Water separator

4 Drum screws or hole cone

RM25

– Pressure regulator with manometer

Loosen the locking screw.

2 Acids (max. temperature +20 °C)

– Proportional oiler

Pull off the bevel wheel.

Nitric acid max. 10%.

Fill the proportional oiler with suitable lu-

Unscrew axel stub by means of a round

Acetic acid max. 10%.

brication oil by unscrewing the reservoir

tool (2.8 mm diameter).

and filling it with lubricating oil (for oil

Insert or replace drum screws or hole

Formic acid max. 10%.

type see "Care and Maintenance“).

cone.

Phosphoric acid max. 10%.

Lubricate axle stub with sealant and

Citric acid max. 10%.

screw it in.

Attach bevel wheel.

Sulfuric acid max. 0.5%.

Lubricate locking screw with sealant

Hydrochloric acid max. 0.5%.

and screw it in.

English 15

Оглавление

- www .kaercher .com!

- Bestimmungsgemäße Ver-

- Technische Daten

- Inbetriebnahme

- Bedienung

- Hilfe bei Störungen

- Zubehör

- Contents

- Technical specifications

- Start up

- Operation Maintenance and care

- Troubleshooting

- Accessories

- Utilisation conforme

- Caractéristiques techniques

- Mise en service

- Entretien et maintenance

- Assistance en cas de panne

- Accessoires

- Reglementair gebruik

- Technische gegevens

- Inbedrijfstelling

- Bediening

- Hulp bij storingen

- Toebehoren CE-verklaring

- Uso previsto

- Datos técnicos

- Puesta en marcha

- Cuidados y mantenimiento

- Ayuda en caso de avería

- Accesorios

- Указания по технике

- Технические данные

- Начало работы

- Вывод из эксплуатации

- Помощь в случае неполадок

- Принадлежности

- Użytkowanie zgodne z

- Dane techniczne

- Uruchamianie

- Czyszczenie i konserwacja

- Usuwanie usterek

- Akcesoria