Karcher Nettoyeur haute pression HDS-C 8-15 E Inox: Maintenance and care

Maintenance and care: Karcher Nettoyeur haute pression HDS-C 8-15 E Inox

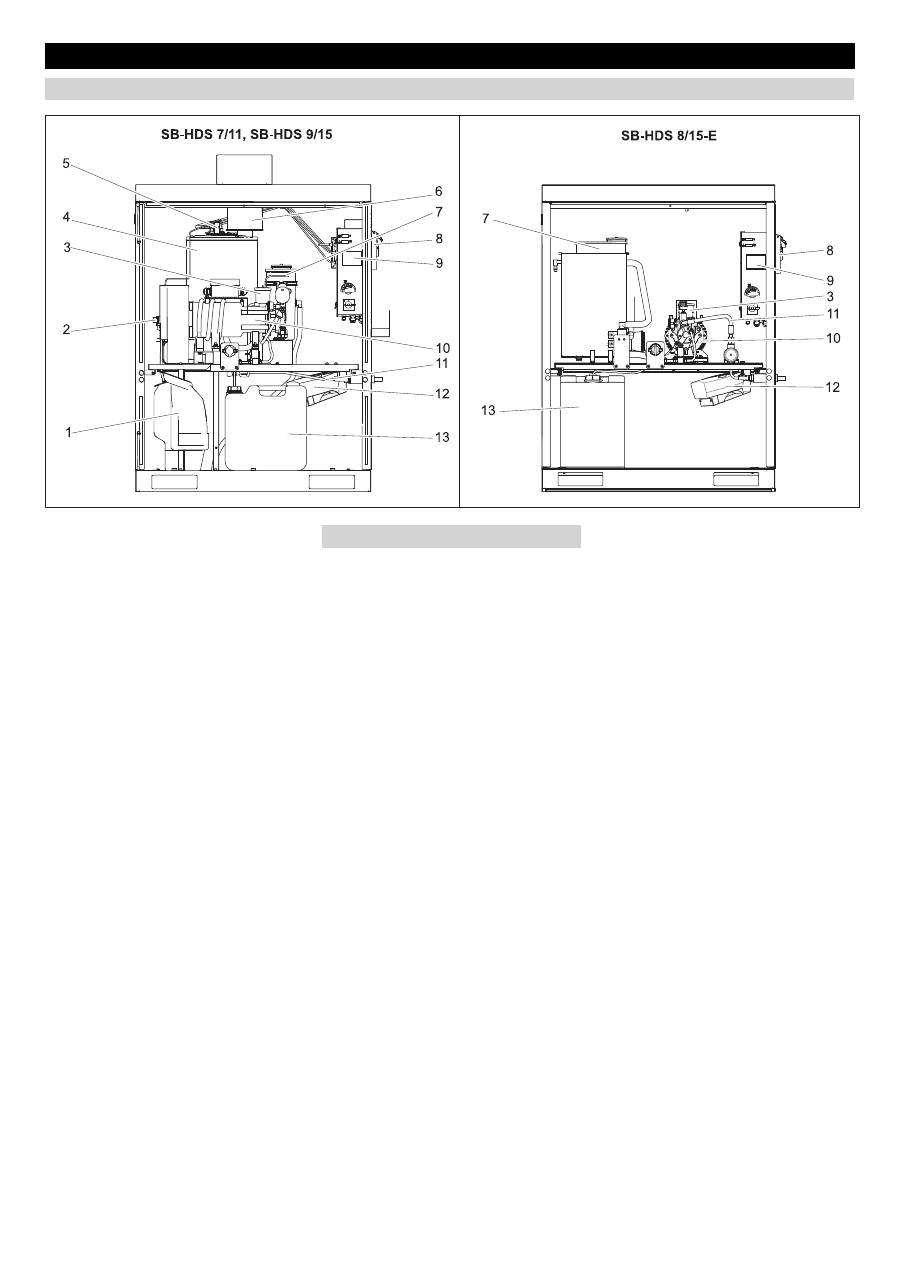

-

7

1 Fuel tank*

2 Fuel filter and fuel pump*

3 Oil tank

4 Burner with continuous heater*

5 Photovoltaic cell for flame monitoring*

6 Exhaust pipe*

7 Container for softener (RM 110)

8 Coin verification unit (optional)

9 Coin container (optional)

10 High pressure pump

11 high pressure hose

12 Fan heater

13 Cleaning agent container

* only HDS-C 7/11, HDS-C 9/15

The bases of a safe operating of the equip-

ment is thr regularly maintenance accord-

ing to the following maintenance plan.

Use only original parts of the manufacturer

or part suggessted by him, such as

–

parts and wearing parts,

–

accessories parts,

–

operating materials,

–

cleaning agents.

Danger

Risk of accident while working on the unit.

During all tasks

Turn off the water supply; close the

fresh water tap,

First switch-on in voltage-less state,

switch off the emergency stop switch in

the building and secure it against being

switched on again.

Caution

Risk of damage. Never use a high-pressure

jet to clean the inside of the system.

–

operator

Performances containing the notice

"operator" may only be performed by in-

structed individualls, who are able to

operate and service high pressure

equipment.

–

Maintenance

Performances with the notice "mainte-

nance" may only be performed by the

Kärcher- Maintenance-Mechanics.

In order to guarantee a reliable operation

og the equipment, we success, you signed

a maintenance agreement. Please refer to

you local Kärcher service department.

Danger!

danger of injury because of possible dam-

aged parts of the high pressure jet, danger

of burns because of hot equipment parts..

When working, while the equipment is open

take special care, and obey all safty notic-

es!.

The following parts are possible to be hot-

ter than 50 °C:

–

Exhaust pipe and exhaust opening (on-

ly HDS-C 7/11, HDS-C 9/15)

–

Burner with continuous heater (only

HDS-C 7/11, HDS-C 9/15)

–

cylinder head of the high pressure

pump

–

high pressure hose

Maintenance and care

System overview

Maintenance instructions

Who may perform maintenance?

Maintenance contract

23 EN

-

8

Maintenance schedule

Time

Activity

Performance

By whom

daily

Visible inspection of the high

pressure hoses

Check high pressure hoses for mechanical damages such as scraping, vis-

ible hose duck, bends, porous and cracked rubber. Replace damaged high

pressure hoses.

Operator

Check warning boards at the

washing place

Check whether the warning boards for the users are available and legible. Operator

Check the unit for leaks

Check pumps and pipes for leaks. Inform Customer Service if there is oil

under the high pressure pump, if more than 3 drops of water drop out of the

high pressure pump when the pump is running.

Operator

Check fill level of detergent

tank

Check filling level, refill if necessary.

Operator

Empty the coin container

Open the plant door and empty the coin container.

Operator

Only HDS-C 7/11, HDS-C 9/

15: Check fill level of fuel tank

Check filling level, refill if necessary.

Operator

Everyday

under frost

conditions

Check frost protection devices Is the hot air blower working?

Operator

After 40

operating

hours or

once a

week

Check oil level of the high

pressure pump

The oil level must lie between the MIN and MAX markings; else refill.

Operator

Check oil level

Milky oil indicates that it contains water. Inform Customer Service.

Operator

Check filling level of softener

liquid

Check filling level; refill the softener RM 110, if required.

Operator

After 80

operating

hours or

once every

two weeks

Clean and maintain housing

Clean the housing thoroughly from inside and outside.

Take care of the stainless steel casing using steel cleaner (order no.: 6.290-

911.0).

Operator

After 160

operating

hours or

once a

month

Clean detergent filter in the

detergent container

Remove filter and rinse it thoroughly with hot water.

Operator

Clean sieve in the water short-

age safe guard.

See Maintenance tasks

Operator

Lubricate the door hinges

Lubricate the hinges with grease (order no.: 6.288-072).

Operator

Door locks

Spray care liquid (order no. 6.288-116) into the locks.

Operator

After 250

operating

hours or

once every

six months

Check pump head

Customer

Service

Only HDS-C 7/11, HDS-C 9/

15: Adjust ignition electrodes,

replace if required

Customer

Service

After 500

operating

hours or

once a

year

Check the high pressure

pump thoroughly

Customer

Service

Oil change in high pressure

pump

See Maintenance tasks

Operator

Only HDS-C 7/11, HDS-C 9/

15: Desoot the heating coil,

adjust burner

Customer

Service

Only HDS-C 7/11, HDS-C 9/

15: Decalcify the heating coil

See Maintenance tasks

Trained op-

erator

Only HDS-C 7/11, HDS-C 9/

15: Clean the fuel container

See Maintenance tasks

Operator

24 EN

-

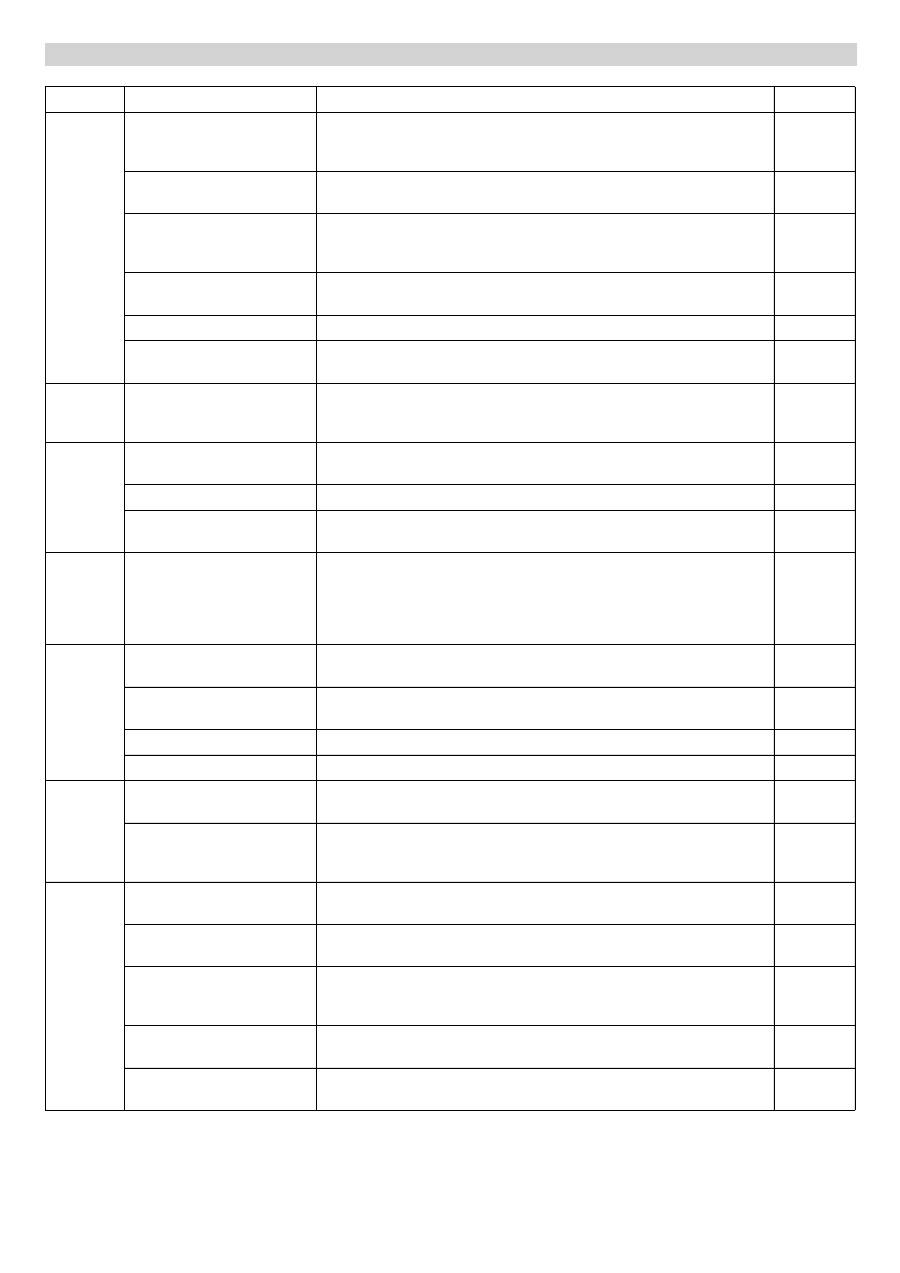

9

Danger

Risk of burns due to hot oil or hot parts of

the plant. Allow pump to cool down for 15

minutes before oil change.

Note

Please dispose off used oil only in the col-

lection points provided for them. Please

hand over old oil, if any, only at such plac-

es. Polluting the environment with used oil

is a punishable offence.

1 Oil container lid

2 Oil drain screw

Keep a collection basin for old oil ready.

Remove the lid of the oil container.

Unscrew the oil drain screw and collect

used oil.

HDS-C 7/11, HDS-C 9/15: Replace O

Ring 11x2 (order no: 6.362-458.0) and

turn in the oild drain screw.

HDS-C 8/15-E: Replace copper washer

14x18 (order no. 7.362-005.0) and turn

in the oil drain screw.

Slowly fill in new oil until the "MAX"

marking on the oil container.

Close the oil container with the lid.

Deliver the old oil to the respective col-

lection centres.

Loosen covering nut and take off hose.

Take out sieve.

Note

If necessary turn in screw M8 appr. 5 mm

inwards and therewith pull out sieve.

Clean sieve in water.

Push sieve inwards.

Put on hose.

Tighten covering nut firmly.

There will be calcium deposits in the plant if

the softening plant (optional) is accidentally

out of operation for a long time. Calcium de-

posits in the plant can lead to following dis-

ruptions:

–

higher pipe resistances,

–

reduced heat transfer at the heat ex-

changers,

–

failure of components spoilt on account

of calcium deposits.

In the interest of environmental safety, use

only tested and approved decalcifying

agents (calcium dissolution acids with test

marking) to decalcify. The high pressure

unit should be decalcified using the Kärch-

er calcium solvent.

Danger

Only persons trained by Kärcher are au-

thorised to decalcify the plant. Risk of ex-

plosion due to combustible gases! Do not

smoke during decalcification; ensure prop-

er ventilation. Risk of burns injury on ac-

count of acid. Wear protective glasses and

protective gloves.

Unscrew the hand-spray gund and in-

sert the hose in the drainage duct so

that the water can flow freely.

Set the hot water temperature to 40 °C.

Shut off water supply.

Start the washing programme with hot

water until the swimmer container for

fresh water is almost empty.

Add 0.5 litre calcium solvent to the

swimmer tank for fresh water.

Leave the water inlet open until the

swimmer tank for fresh water is full

again.

Switch on the plant briefly and then let

the calcium solvent react. Repeat this

process every 4 to 5 minutes until the

swimmer tank for fresh water is almost

empty.

Open the water inlet and let the wash-

ing programme with hot water run for 5

minutes until the tank is rinsed.

Connect the hand-spray gun to the high

pressure hose.

Caution

Danger of damage to the fuel pump. Do not

interchange the forward and backward flow

pipes for fuel. This can cause the fuel

pump to dry run and get damaged.

Pull out the fuel hoses on the fuel pump.

Remove the fuel tank from the plant.

Rinse the fuel tank thoroughly (allow

the fuel tank rinsed with water to dry

properly).

Dispose off fuel residues according to

environment safety laws.

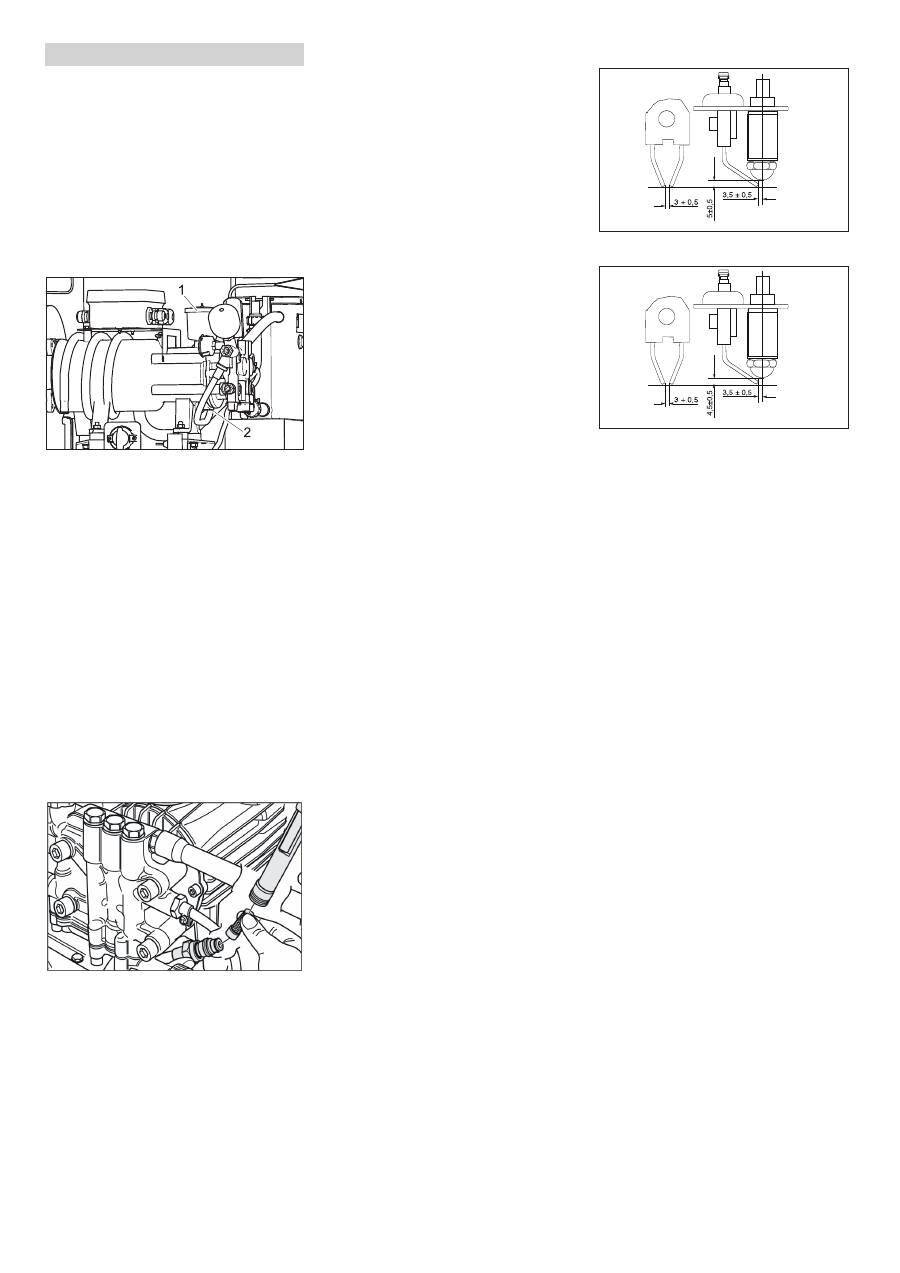

The correct setting of the ignition elec-

trodes is very important for the burner to

function properly. The settings have been

indicated in the above drawing.

Maintenance Works

Oil change

Clean sieve in the water shortage safe-

guard (only HDS-C 7/11, HDS-C 9/15)

Decalcify the heating spiral (only HDS-C

7/11, HDS-C 9/15)

Clean fuel tank (only HDS-C 7/11, HDS-C

9/15)

Electrode setting SB-HDS 7/11

Electrode setting SB-HDS 9/15

25 EN

Оглавление

- Deutsch

- Bedienung

- Betriebsstoffe einfüllen

- Stilllegung

- Funktion

- Technische Daten

- Wartung und Pflege

- Hilfe bei Störungen

- Zubehör

- TransportLagerung Anlage installieren (Nur für Fachkräfte)

- EG-Konformitätserklärung

- Protokoll für Hochdruckprüfung

- English

- Operations

- Filling in detergents

- Shutdown

- Function

- Specifications

- Maintenance and care

- Troubleshooting

- Accessories

- Transport Storage Installing the unit (only for ex- perts)

- EC Declaration of Conformity

- Log of high pressure testing

- Français

- Utilisation

- Réglages

- Protection antigel

- Remisage

- Fonction

- Caractéristiques techniques

- Entretien et maintenance

- Assistance en cas de panne

- Accessoires

- Garantie Transport Entreposage Installation de l'appareil (Uni- quement pour les spécia- listes)

- Déclaration de conformité CE

- Rapport de contrôle de la haute pression

- Italiano

- Uso

- Impostazioni

- Antigelo

- Funzione

- Dati tecnici

- Cura e manutenzione

- Guida alla risoluzione dei guasti

- Accessori

- GaranziaTrasporto Supporto Installazione dell'impianto (solo personale specializzato)

- Dichiarazione di conformità CE

- Protocollo per controllo alta pressione

- Español

- Manejo

- Configuraciones

- Protección antiheladas

- Puesta fuera de servicio

- Datos técnicos

- Mantenimiento y cuidado

- Ayuda en caso de avería

- Accesorios

- Declaración de conformidad CE

- Protocolo para la inspección de alta presión

- Português

- Manuseamento

- Ajustes

- Protecção contra o congela- mento

- Desactivação da máquina

- Dados técnicos

- Manutenção e conservação

- Ajuda em caso de avarias

- Acessórios

- Garantia Transporte Armazenamento Instalar instalação (Apenas para técnicos autorizados)

- Declaração de conformidade CE

- Protocolo para o controlo de alta pressão

- Nederlands

- Bediening

- Bedrijfsstoffen vullen

- Stilllegging

- Functie

- Technische gegevens

- Onderhoud en instandhouding

- Hulp bij storingen

- Toebehoren

- Garantie Vervoer Opslag Installatie installeren (alleen voor vaklui)

- EG-conformiteitsverklaring

- Protocol voor hogedrukcontrole

- Περιεχόμενα

- Χειρισμός

- Ρυθμίσεις

- Αντιπαγετική προστασία

- Ακινητοποίηση

- Τεχνικά χαρακτηριστικά

- Φροντίδα και συντήρηση

- Αντιμετώπιση βλαβών

- Εξαρτήματα

- Δήλωση Συμμόρφωσης των Ε . Κ .

- Πρωτόκολλο ελέγχου υψηλής πίεσης

- Polski

- Obs ł uga

- Ustawienia

- Ochrona przeciwmrozowa

- Przeznaczenie

- Dane techniczne

- Dogl ą d i piel ę gnacja

- Usuwanie usterek

- Akcesoria

- Gwarancja Transport Przechowywanie Instalacja urz ą dzenia (Tylko dla wykwalifikowanych pra- cowników)

- Deklaracja zgodno ś ci UE

- Protokó ł badania wysokiego ci ś nienia

- Оглавление

- Эксплуатация

- Настройки

- Защита от замерзания

- Вывод из эксплуатации

- Назначение

- Технические данные

- Техническое обслуживание и уход

- Помощь в случае непола - док

- Принадлежности

- Гарантия Транспортировка Хранение Монтаж установки - Только для специалистов

- Заявление о соответствии ЕС

- Протокол проверки системы высокого давления