Karcher Nettoyeur haute pression HDS-C 8-15 E Inox: Function

Function: Karcher Nettoyeur haute pression HDS-C 8-15 E Inox

-

5

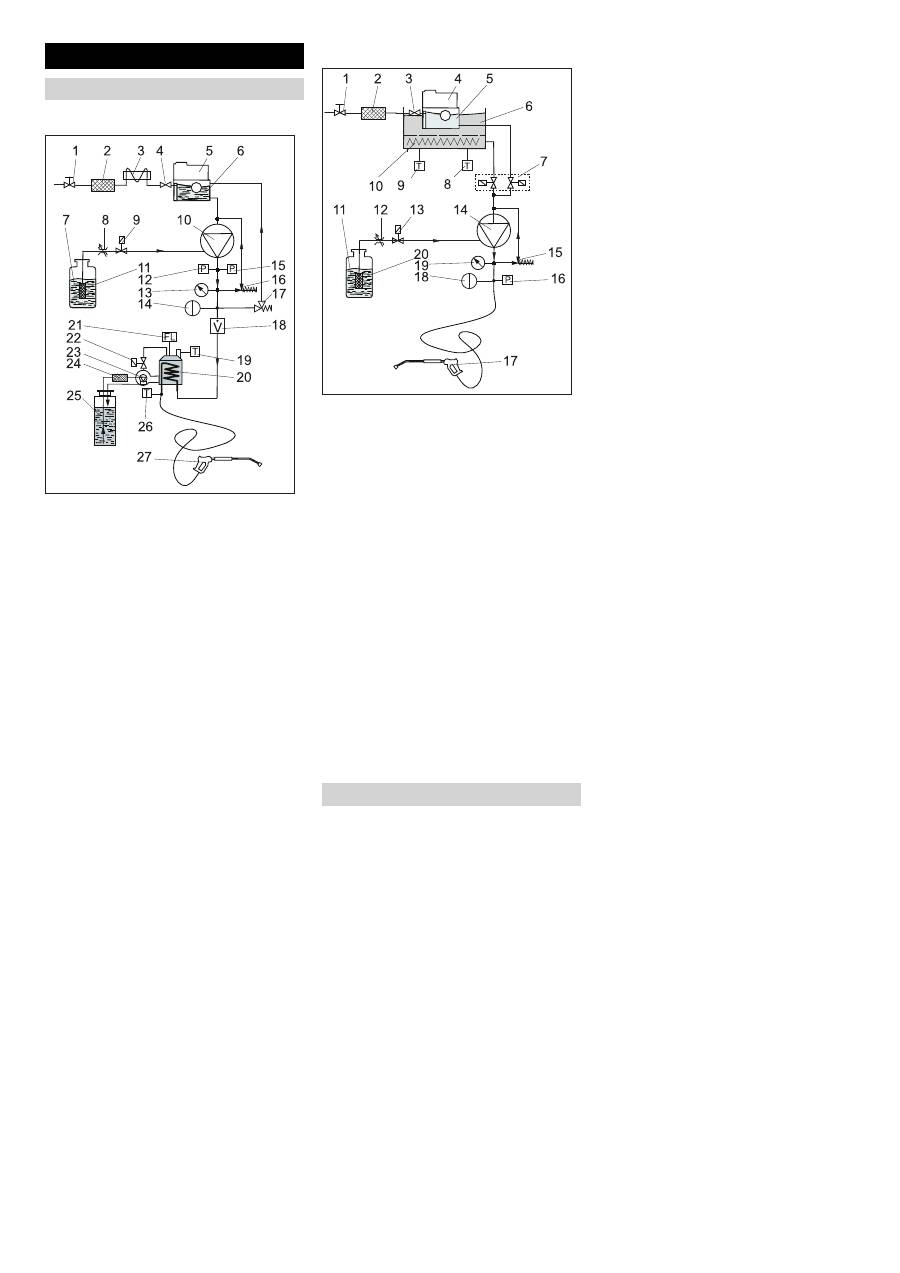

1 Water connection (by customer)

2 Pre-filter (at the site)

3 condensing electro motor

4 swimming valve

5 Dosing container softener (RM 110, op-

tional)

6 Swimming container fresh water

7 Cleaning agent container

8 Dosage valve for detergent

9 Cleaning agent valve

10 High pressure pump

11 Cleaning agent filter

12 Pressure switch ON

13 Manometer

14 Pressure tank

15 Pressure switch OFF

16 Overflow valve

17 Safety valve

18 Flow indicator

19 Temperature stop for exhaust gases

20 Burner inclusive flow-type heater

21 Flame indicator

22 Fuil valve

23 Fuil pump inclusive bypass valve

24 Fuel filter

25 Fuil container

26 Attemperator

27 Hand blowing gun

1 Water connection (by customer)

2 Pre-filter (at the site)

3 swimming valve

4 Dosing container softener (RM 110, op-

tional)

5 Swimming container fresh water

6 Warm water tank

7 Solenoid valve block warm/ cold water

8 Attemperator

9 temerature limiter

10 Heating element

11 Cleaning agent container

12 Dosage valve for detergent

13 Cleaning agent valve

14 High pressure pump

15 Overflow valve

16 ON/OFF pressure switch

17 Hand blowing gun

18 Pressure tank

19 Manometer

20 Cleaning agent filter

–

If the hand-spray gun is closed, so that

the whole water flows back to the pump

suck side, the pressure switch at the

overflow valve shuts down the pump.

–

If the hand spray gun is opened, the

pressure switch on the cylinder head

turns the pump back on.

The overflow valve is set by the manufac-

turer and sealed. Setting only by customer

service.

–

If the hand-spray gun is closed such

that the whole water flows back to the

pump suck side, the pressure switch

shuts down the pump.

–

If the hand spray gun is opened again,

the pressure switch switches on the

pump again.

The overflow valve is set by the manufac-

turer and sealed. Setting only by customer

service.

–

The safety valve opens, when the over-

flow valve resp. the pressure switch is

broken.

The safety valve is set by the manufacturer

and sealed. Setting only by customer serv-

ice.

–

The water shortage safeguard prevents

the burner to be turned on when there is

water shortage.

–

A sieve prevents the contamination of

the safeguard and must be cleaned reg-

ulary.

–

The motor protection switch interrupts

the electric circuit if the motor is over-

loaded.

–

The temperature stop switches off the

machine when the waste gases have

reached very high temperatures.

If the burner does not ignite or the flame ex-

tinguishes during operation, then the flame

monitor switches off the fuel supply.

Function

Flow pattern

HDS-C 7/11, HDS-C 9/15

HDS-C 8/15-E

Monitoring and safety devices

Overflow valve with two pressure

switches (HDS-C 7/11, HDS-C 9/15

Overflow valve with a pressure switch

(HDS-C 8/15-E)

Safety valve

Water shortage safeguard

Motor protection switch

Exhaust temperature limiter (HDS-C 7/

11, HDS-C 9/15

Flame monitoring (HDS-C 7/11, HDS-C 9/

15)

21 EN

Оглавление

- Deutsch

- Bedienung

- Betriebsstoffe einfüllen

- Stilllegung

- Funktion

- Technische Daten

- Wartung und Pflege

- Hilfe bei Störungen

- Zubehör

- TransportLagerung Anlage installieren (Nur für Fachkräfte)

- EG-Konformitätserklärung

- Protokoll für Hochdruckprüfung

- English

- Operations

- Filling in detergents

- Shutdown

- Function

- Specifications

- Maintenance and care

- Troubleshooting

- Accessories

- Transport Storage Installing the unit (only for ex- perts)

- EC Declaration of Conformity

- Log of high pressure testing

- Français

- Utilisation

- Réglages

- Protection antigel

- Remisage

- Fonction

- Caractéristiques techniques

- Entretien et maintenance

- Assistance en cas de panne

- Accessoires

- Garantie Transport Entreposage Installation de l'appareil (Uni- quement pour les spécia- listes)

- Déclaration de conformité CE

- Rapport de contrôle de la haute pression

- Italiano

- Uso

- Impostazioni

- Antigelo

- Funzione

- Dati tecnici

- Cura e manutenzione

- Guida alla risoluzione dei guasti

- Accessori

- GaranziaTrasporto Supporto Installazione dell'impianto (solo personale specializzato)

- Dichiarazione di conformità CE

- Protocollo per controllo alta pressione

- Español

- Manejo

- Configuraciones

- Protección antiheladas

- Puesta fuera de servicio

- Datos técnicos

- Mantenimiento y cuidado

- Ayuda en caso de avería

- Accesorios

- Declaración de conformidad CE

- Protocolo para la inspección de alta presión

- Português

- Manuseamento

- Ajustes

- Protecção contra o congela- mento

- Desactivação da máquina

- Dados técnicos

- Manutenção e conservação

- Ajuda em caso de avarias

- Acessórios

- Garantia Transporte Armazenamento Instalar instalação (Apenas para técnicos autorizados)

- Declaração de conformidade CE

- Protocolo para o controlo de alta pressão

- Nederlands

- Bediening

- Bedrijfsstoffen vullen

- Stilllegging

- Functie

- Technische gegevens

- Onderhoud en instandhouding

- Hulp bij storingen

- Toebehoren

- Garantie Vervoer Opslag Installatie installeren (alleen voor vaklui)

- EG-conformiteitsverklaring

- Protocol voor hogedrukcontrole

- Περιεχόμενα

- Χειρισμός

- Ρυθμίσεις

- Αντιπαγετική προστασία

- Ακινητοποίηση

- Τεχνικά χαρακτηριστικά

- Φροντίδα και συντήρηση

- Αντιμετώπιση βλαβών

- Εξαρτήματα

- Δήλωση Συμμόρφωσης των Ε . Κ .

- Πρωτόκολλο ελέγχου υψηλής πίεσης

- Polski

- Obs ł uga

- Ustawienia

- Ochrona przeciwmrozowa

- Przeznaczenie

- Dane techniczne

- Dogl ą d i piel ę gnacja

- Usuwanie usterek

- Akcesoria

- Gwarancja Transport Przechowywanie Instalacja urz ą dzenia (Tylko dla wykwalifikowanych pra- cowników)

- Deklaracja zgodno ś ci UE

- Protokó ł badania wysokiego ci ś nienia

- Оглавление

- Эксплуатация

- Настройки

- Защита от замерзания

- Вывод из эксплуатации

- Назначение

- Технические данные

- Техническое обслуживание и уход

- Помощь в случае непола - док

- Принадлежности

- Гарантия Транспортировка Хранение Монтаж установки - Только для специалистов

- Заявление о соответствии ЕС

- Протокол проверки системы высокого давления