Karcher WPC 10000 BW-AM: Proper use Environmental protection

Proper use Environmental protection: Karcher WPC 10000 BW-AM

14

Deutsch

– The electrical connections must be

done by an electrician according to

IEC 60364-1.

– Never touch damaged or ripped mains

cables. If required, pull out the plug

from the socket immediately.

– Never operate the unit with damaged

cable.

The following symbols are used in this op-

erating manual:

Danger

Indicates an immediate threat of danger.

Failure to observe the instruction may re-

sult in death or serious injuries.

몇

Warning

Indicates a possibly dangerous situation.

Failure to observe the instruction may re-

sult in light injuries or damage to property.

Note

Indicates useful tips and important infor-

mation about the product.

The plant is used for treating surface wa-

ter, water from natural springs and river

water.

Due to the modular structure, turbid sub-

stances, hardeners, salts, bacteria and

water can be separated depending on the

quality of raw water.

Danger

Risk of injury if the plant is not installed

properly. Risk to health on account of

poorly treated drinking water. The plant

may be put into operation only when set-

up, installed and prepared for operation by

skilled and authorized personnel.

Î

Check the connection of the plant to

the raw water source.

Î

Ensure uninterrupted flow of the gen-

erated drinking water into a tank or a

suitable user-side facility.

Note

The driking water must be able to flow out

without any counter-pressure. The height

difference must not be more than 3 m.

Note

If the plant is fitted with one or more dos-

ing stations, then it needs to be ensured

that this has been connected properly and

filled up.

Î

Fill up dosing station (refer chapter

"Maintenance and Care/ Maintenance

jobs")

Î

Check whether the mains plug of the

dosing pumps of the dosing stations is

connected to the sockets of the plant.

Î

Check the position of the operating

swtich:

"Automatic“ position:

the plant is

controlled by an external floater switch

in the drinking water tank.

"Manual" position: the plant is man-

ually switched on and off using the

main switch.

Î

Turn the main switch to position "1";

drinking water production will start.

– Display time

Alternating display of:

– Plant/ version number and operating

status.

– Drinking water temperature and con-

ductance.

– Operating hours (_ _ _ _ _h_ _min).

몇

Warning

Risk of damage. If the plant is to be shut

down for more than 14 days, then Kärcher

Customer Service must carry out some

preservative tasks.

Î

Turn main switch to "0"; the plant will

stop production of drinking water.

Note

Do not switch off the plant overnight! The

media filter is automatically cleaned dur-

ing the night. There is a risk of damage to

the plant if you do not do this cleaning.

Danger

Health hazard on account of poor quality

of drinking water. . The control tasks out-

lined in this maintenance plan are to be

carried out according to the schedule in

order to ensure the quality of drinking wa-

ter. If the deviations in the target values

cannot be corrected by taking the pre-

scribed measures, then stop production of

drinking water and inform Kärcher Cus-

tomer Service immediately.

Electrical system

Symbols

Proper use Environmental protection

The packaging material can be

recycled. Please do not throw

the packaging material into

household waste; please send

it for recycling.

Old appliances contain valuable

materials that can be recycled;

these should be sent for recy-

cling.. Batteries, oil, and similar

substances must not enter the

environment. Please dispose of

your old appliances using ap-

propriate collection systems.

Start up

Before Commissioning

Filling up the dosing station

Operation

Switching on the plant

Monitoring elements

Display media and active carbon filters

Display of the operating panel

Switching off the plant

Maintenance and care

English

15

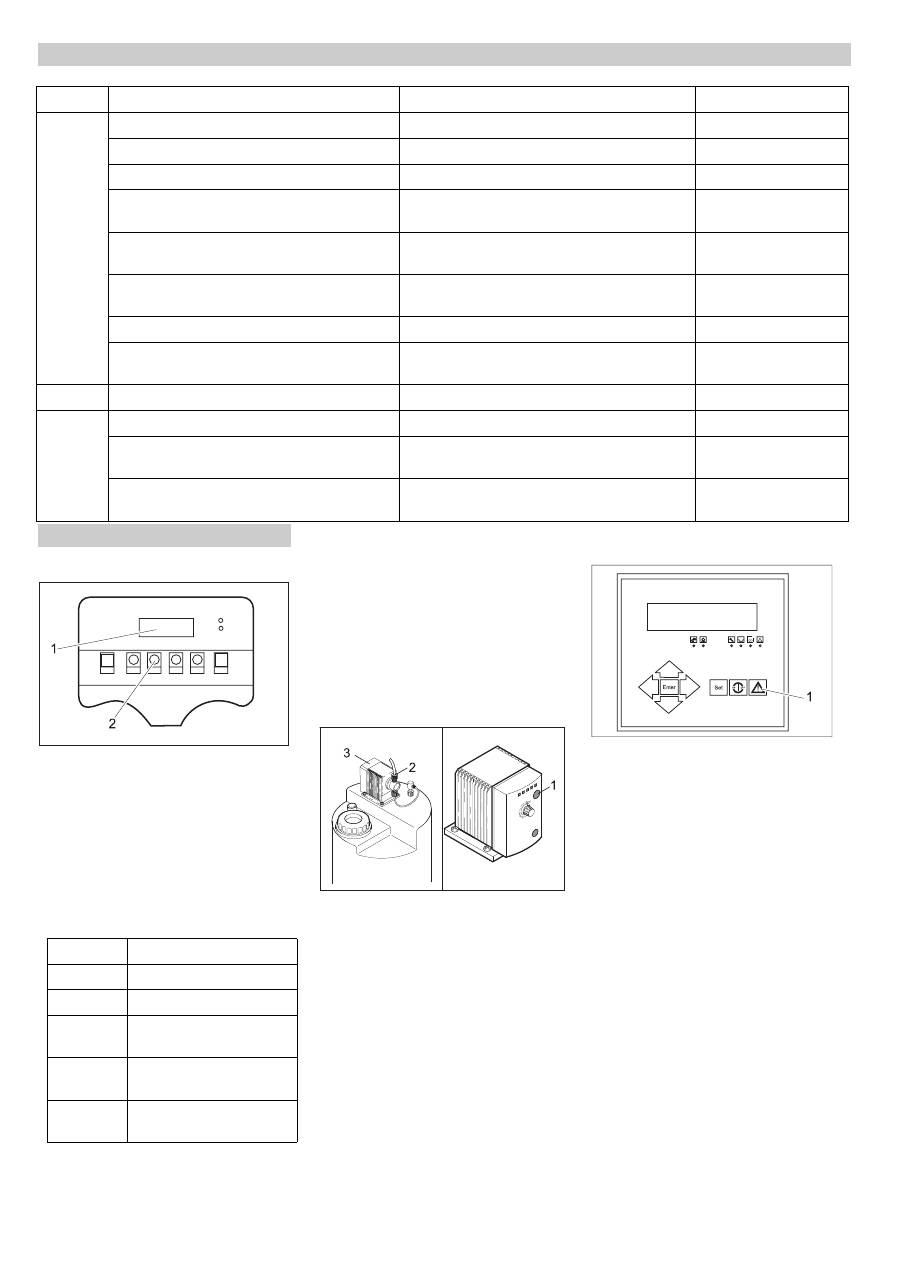

1 Display

2 ADVANCE key

During operations, the current time is

shown in the display.

Î

Press ADVANCE key for 5 to 6 sec-

onds. The display will show the first sta-

tus display from the list shown beloe.

Î

To go to the next display, press once

again the ADVANCE key briefly.

If you do not press the ADVACE key for

some time, the display goes back to show-

ing the time.

The dosing pump must be dearated if the

pump has sucked in air (for e.g. if the dos-

ing container has been completely emp-

tied).

– The unit will stop; the display shows the

interruption "Motor protection".

Note

This errror message is displayed independ-

ent of which dosing container has been

used.

1 Dosing frequency button

2 Screw connections

3 Dosing pump

Î

Refill dosing station (refer chapter on

Startup)

Î

Loosen screws on the dosing pump.

Î

Read and note the dosing frequency

that has been set at the LEDs of the

dosing pump.

Î

Set the dosing frequency to 100% by re-

peatedly pressing the dosing frequency

button and waiting until there are no

more bubbles in the suction pipe (ap-

prox. 1 minute). Absorb the oozing dos-

ing liquid with a piece of cloth.

Î

Tighten the screws.

Î

Set the dosing pump to the original dos-

ing frequency.

1 Return key

Î

Accept the interruption message on the

operating panel by pressing the Return

key; the unit will start.

Î

Check the pressure difference between

the two manometers. Change filter inlay

if value is more that 0.08 MPa (0.8 bar):

Î

Turn the main switch to position "0"

Î

Interrupt raw water inflow.

Î

Open the raw water testing tap to de-

pressurise the filter.

Maintenance schedule

Time

Check / Activity

Target value

In case of deviation

daily

Filling level of dosing container

adequate filling

refill

Air bubbles in the dosing pipes

no air bubbles

Bleed dosing pump.

Drinking water flow based on the startup value Lowered by less than 10%

Fine regulation

Drinking water guide value based on the start-

up value

Increase within 10%

Fine regulation

Pressure difference between pump and con-

centrate pressure

maximum 15% above startup difference

Kärcher Customer

Service

Counter/meter for media and active carbon fil-

ters

Reflushing has taken place in the last 24 hours Kärcher Customer

Service

Pressure difference fine filter

maximum 0.08 MPa (0.8 bar)

Replace fine filter

Visual inspection of the plant

no leaks

Kärcher Customer

Service

weekly

Fill up operations log

monthly

Clean and rinse dosing container

Visual inspection of raw water pump

No damage/ leaks can be detected

Kärcher Customer

Service

Float switch in drinking water tank

no functional disruption can be detected

Kärcher Customer

Service

Maintenance Works

Check media and active carbon filters

Display

Significance

2000

Not important

0000

Not important

D–07

Number of days until the

next reflushing

–001

Number of reflushing that

have been conducted

0–01

days - hours since the last

reflushing

Bleed dosing pump.

Replace fine filter

16

English

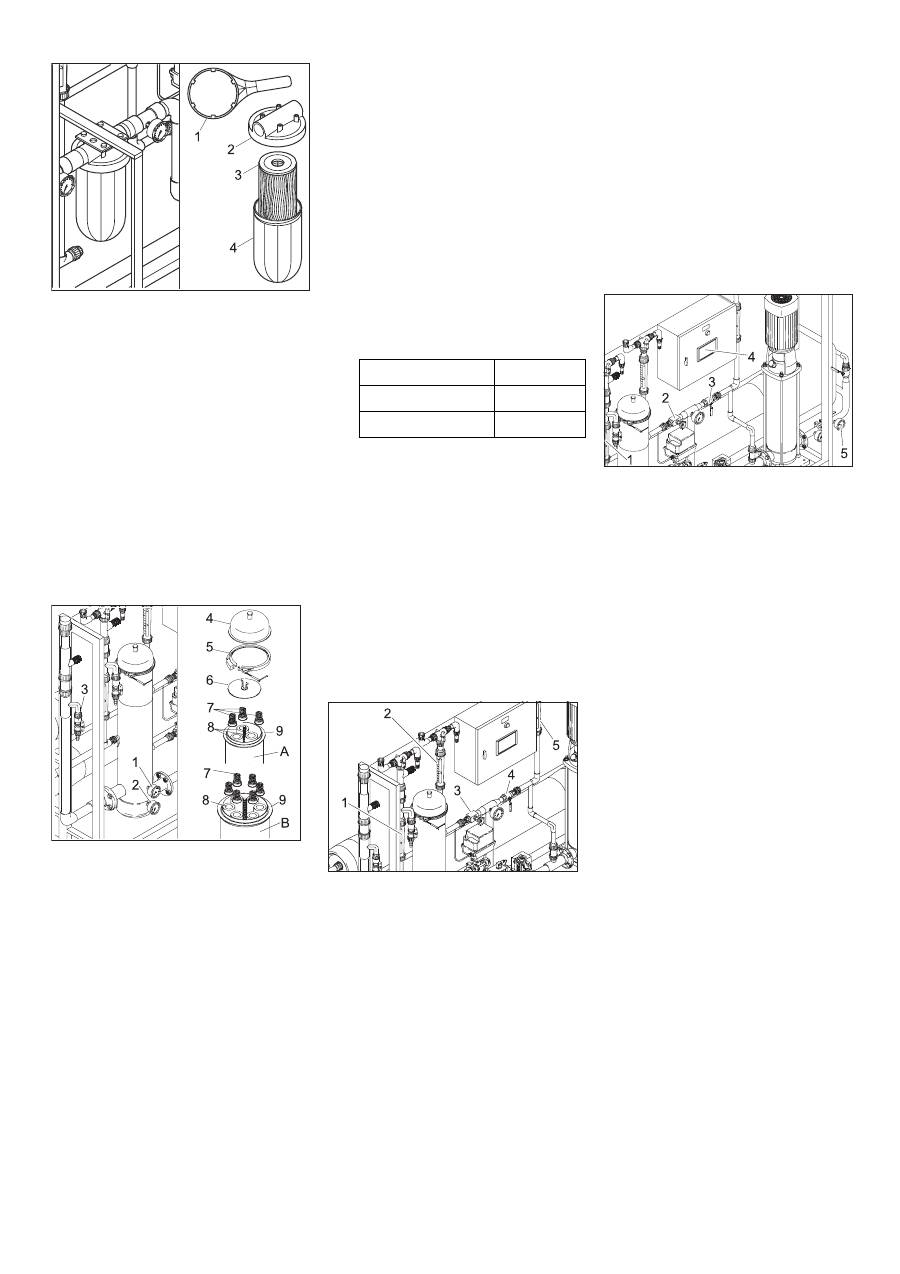

WPC 2500 BW-AM:

1 Filter key

2 Filter casing

3 Filter pot

4 Filter inlay

Î

Unscrew the filter pot using the filter

key.

Î

Take out the filter inlay.

Î

Clean filter casing and filter pot if re-

quired.

Î

Insert new filter inlay into filter pot.

Î

Install and tighten filter pot.

Î

Close raw water testing tap.

Î

Restart the raw water flow.

Î

Set main switch to “1”.

WPC 5000/10000 BW-AM:

1 Manometer

2 Manometer

3 Raw water testing tap

4 Cover

5 Clamp ring

6 Screw plate

7 Spring cap

8 Filter candle

9 Filter casing

A WPC 5000 BW-AM

B WPC 10000 BW-AM

Î

Loosen the clamp ring.

Î

Remove the lid.

Î

Unscrew the screw plate.

Î

Remove spring cap.

Î

Take out the filter candle.

Î

Clean the filter casing.

Î

Insert new filter candle.

Î

Place the spring caps on the filter can-

dles.

Î

Replace the screw plate and fix the

screws.

Î

Replace the lid and fasten the clamping

ring.

Î

Close raw water testing tap.

Î

Restart the raw water flow.

Î

Set main switch to “1”.

몇

Warning

Danger of damage to the plant. The follow-

ing values should not be exceeded when

you make changes to the plant settings:

–

Max. pump pressure 2.1 MPa

(21 bar)

–

Maximum drinking water volume:

– The concentrate quantity should not fall

below the value at the time of startup.

–

Do not change the setting of the pump

regulation valve.

Note

There is a time delay before the plant reacts

to the changes done to the regulating

valves. Hence do the settings at the pres-

sure regulation valve and the concentrate

regulation valve in small steps and wait for

the respective effect.

(1) Drinking water flow has fallen from

_______ l/h to _______ l/h

1 Flow meter for drinking water

2 Flow meter for concentrate

3 Concentrate regulation valve

4 Pressure regulation valve

5 Flow meter for concentrate backflow

Î

Read the quantity of drinking water at

the flow meter for drinking water and

compare it to the value when the plant

was started (see start-up report). If the

drinking water flow ahs fallen to ______

l/h, then do the following fine regulation:

Î

Close the pressure regulation valve in a

clock-wise direction until the flow meter

for the concentrate backflow has almost

achieved the target value.

Î

Close the concentrate regulation valve

slowly in the clock-wise direction until

the required target value is reached for

the two flow meters of the concentrate

and the drinking water.

Î

Readjust both the valves if required.

Note

Inform Kärcher Customer Service if this fine

regulation does not lead to any changes to

the drinking water flow.

(2) Conductivity of drinking water has in-

creased from _____µS/cm to _____µS/cm

Note

Small increases in the conductivity of drink-

ing water does not affect the quality of the

drinking water.

1 Flow meter for drinking water

2 Concentrate regulation valve

3 Pressure regulation valve

4

Display

5 Manometer for membrane input pres-

sure

Î

Read the current conductivity value on

the display of the operating panel and

compare it to the value at the time of

start-up (see start-up report). If the

drinking water conductivity has in-

creased to _____µS/cm, then you need

to rinse the membrane of the RO filter

unit:

Î

Open the concentrate regulation valve

in small step by turning it in the anti-

clockwise direction until the conductivity

has reached the target value.

Î

Close the pressure regulation valve in

small steps in the clock-wise direction

until the flow meter of the drinking water

has reached the target value.

몇

Warning

Danger of damage to the RO membrane.

While closing the pressure regulation valve,

ensure that the membrane input pressure

does not exceed 2.1 MPa (21 bar).

Note

The purpose of this setting procedure is to

increase the concentrate quantity.

Î

Repeat these setting steps if required.

Eventually, the original drinking water

quantity will no longer be reached.

Fine regulation of the operating pres-

sures

WPC 2500 BW-AM

2,500 l/h

WPC 5000 BW-AM

5,000 l/h

WPC 10000 BW-AM 10,000 l/h

Оглавление

- Inhaltsverzeichnis Bedienelemente Sicherheitshinweise

- Bestimmungsgemäße Ver- wendung Umweltschutz

- Verbrauchsmaterial

- Störungen

- Technische Daten

- Rückseite. Bleibt leer, damit das Blatt herausgetrennt werden kann

- Contents Control elements Safety instructions

- Proper use Environmental protection

- Consumables

- Faults

- Technical specifications

- Rear side. Is kept blank so that the sheet can be separated

- Table des matières Eléments de commande

- Consignes de sécurité

- Matériel de consommation

- Caractéristiques techniques

- Déclaration CE Garantie Pièces de rechange

- Verso. Reste vide, afin que la feuille peut être retirer.

- Indice Dispositivi di comando Norme di sicurezza

- Uso conforme a destinazione Protezione dell’ambiente

- Materiale di consumo

- Dati tecnici

- Dichiarazione CE Garanzia Ricambi

- Tergo. Resta vuoto in modo da poter separare il foglio

- Inhoudsopgave Bedieningselementen Veiligheidsinstructies

- Reglementair gebruik Zorg voor het milieu

- Verbruiksmateriaal

- Storingen

- Technische gegevens

- Achterkant. Blijft leeg zodat de pagina eruit gehaald kan worden

- Índice de contenidos Elementos de mando Indicaciones de seguridad

- Uso previsto Protección del medio am- biente

- Material de uso

- Averías

- Datos técnicos

- Parte posterior. En blanco para separar la hoja

- Πίνακας περιεχομένων Στοιχεία χειρισμού Υποδείξεις ασφαλείας

- Χρήση σύμφωνα με τους κανονισμούς Προστασία περιβάλλοντος

- Αναλώσιμα υλικά

- Βλάβες

- Τεχνικά χαρακτηριστικά

- Δήλωση συμμόρφωσης CE Εγγύηση Ανταλλακτικά

- Οπισθόφυλλο Παραμένει κενό για να αποκοπεί το φύλλο

- İ çindekiler Kumanda elemanlar ı Güvenlik uyar ı lar ı

- Kurallara uygun kullan ı m Çevre koruma

- Tüketim malzemesi

- Ar ı zalar

- Teknik Bilgiler

- Arka sayfa. Sayfan ı n ayr ı labilmesi için bo ş kal ı r

- Оглавление Элементы управления Указания по технике безопасности

- Использование по назначению Защита окружающей среды

- Расходный материал

- Неполадки

- Технические данные

- Заявление о соответствии требованиям СЕ Гарантия Запасные части

- Оборотная сторона . ь Остается пустой , чтобы можно было отделить лист