Electrolux EGG6242NOX: 8. INSTALLATION

8. INSTALLATION: Electrolux EGG6242NOX

ENGLISH 11

A B C

MOD.

MOD.

MOD.

TYPE

PROD.NO.

230V-50Hz

PROD.NO.

PROD.NO.

SER.NO.

IP20

0049

SER.NO

SER.NO

03 IT

DATA

DATA

MADE IN ITALY

MODELMODEL

A)

Stick it on Guarantee Card and send

C)

Stick it on instruction booklet

this part (if applicable)

B)

Stick it on Guarantee Card and keep

this part (if applicable)

8. INSTALLATION

WARNING!

If the supplied pressure has not the speci-

Refer to "Safety information"

fied value, it is necessary to assemble a

chapter.

proper pressure regulator in compliance

with the standard UNI EN 88. For Liquid

WARNING!

Gas (LPG) the use of pressure regulator is

The following instructions about

allowed only if they are in compliance with

installation, maintenance and ven-

UNI EN 12864. The adjustable connection

tilation must be carried out by

is fixed to the comprehensive ramp by

qualified personnel in compliance

means of a threaded nut G 1/2". Screw

with the regulation in force (UNI-

the parts without force, adjust the con-

CIG 7129 - 7131). Make sure that

nection in the necessary direction and

the kitchen is well ventilated: keep

tighten everything.

natural ventilation holes open (at

least 100 cm²) or install a me-

chanical extractor hood.

8.1 Gas Connection

Choose fixed connections or use a flexible

pipe in stainless steel in compliance with

the regulation in force. If you use flexible

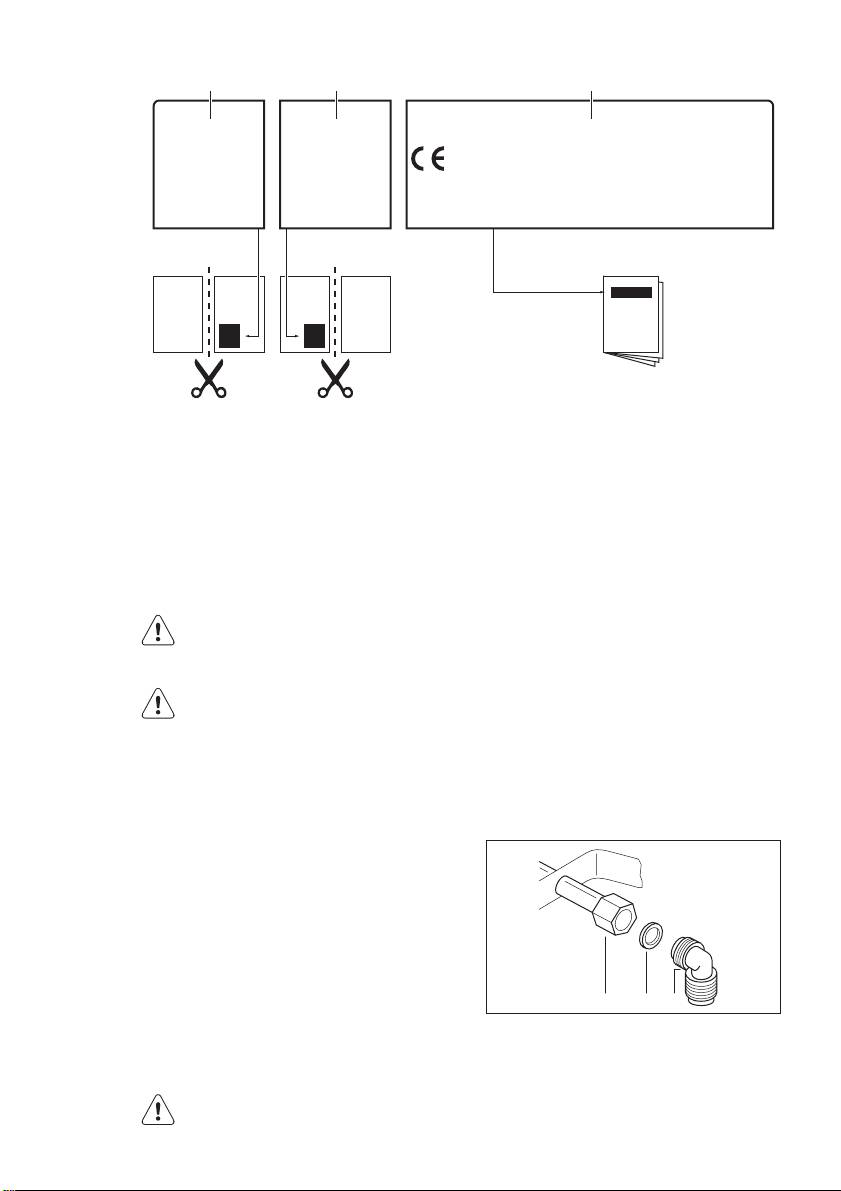

ABC

metallic pipes, be careful they do not

come in touch with mobile parts or they

A)

End of shaft with nut

are not squeezed. Also be careful when

B)

Washer

the hob is put together with an oven.

C)

Elbow

Make sure that the gas supply

pressure of the appliance obeys

the recommended values.

12

www.electrolux.com

Rigid connection:

A

Carry out connection by using metal rigid

pipes (copper with mechanical end) (UNI-

CIG 7129).

Flexible connection:

Use a flexible pipe in stainless steel (UNI-

CIG 9891) with a maximum length 2 m.

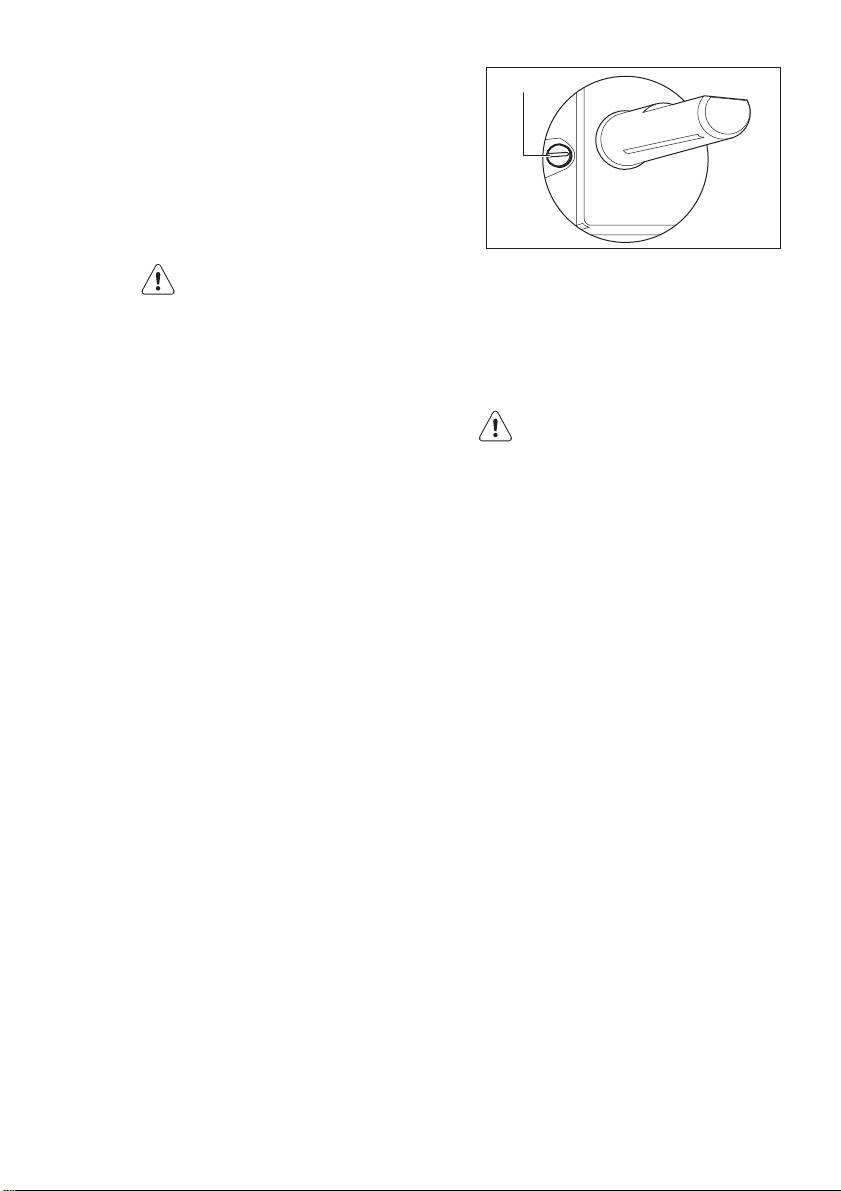

A)

The by-pass screw

When installation is complete,

make sure that the seal of each

• If you change from natural gas G20 20

pipe fitting is correct. Use a soapy

mbar to liquid gas, fully tighten the ad-

solution, not a flame!

justment screw in.

• If you change from liquid gas to natural

gas G20 20 mbar, undo the by-pass

8.2 Injectors replacement

screw approximately 1/4 of a turn.

1.

Remove the pan supports.

WARNING!

2.

Remove the caps and crowns of the

Make sure the flame does not go

burner.

out when you quickly turn the

3.

With a socket spanner 7 remove the

knob from the maximum position

injectors and replace them with the

to the minimum position.

ones which are necessary for the type

of gas you use (see table in "Techni-

8.4 Electrical connection

cal Information" chapter).

4.

Assemble the parts, follow the same

• Ground the appliance according to

procedure backwards.

safety precautions.

5.

Replace the rating plate (it is near the

• Make sure that the rated voltage and

gas supply pipe) with the one for the

type of power on the rating plate agree

new type of gas supply. You can find

with the voltage and the power of the

this plate in the package supplied

local power supply.

with the appliance.

• This appliance is supplied with a mains

If the supply gas pressure is changeable

cable. It has to be supply with a correct

or different from the necessary pressure,

plug, able to support the load marked

you must fit an applicable pressure ad-

on the rating plate. The plug has to be

juster on the gas supply pipe.

fitted in a correct socket.

• Any electrical component must be in-

8.3 Adjustment of minimum level

stalled or replaced by the Service Force

Centre technician or qualified service

To adjust the minimum level of the burn-

personnel.

ers:

• Always use a correctly installed shock-

1.

Light the burner.

proof socket.

2.

Turn the knob on the minimum posi-

• Make sure that there is an access to

tion.

the mains plug after installation.

3.

Remove the knob.

• Do not pull the mains cable to discon-

4.

With a thin screwdriver, adjust the by-

nect the appliance. Always pull the

pass screw position.

mains plug.

• The appliance must not be connected

with an extension cable, an adapter or

a multiple connection (risk of fire).

Check that the ground connection is in

conformity with the standard and regu-

lations force.

ENGLISH 13

• The power cable must be placed in

such a way that it does not touch any

hot part.

• Connect the appliance to the mains

with a device that lets to disconnect the

A

appliance from the mains at all poles

with a contact opening width of mini-

mum 3 mm, eg. automatic line protect-

10 mm

11 mm

ing cut-out, earth leakage trips or fuse.

3 mm

No part of the power cable must heat to a

11 mm

temperature of more than 90° C.

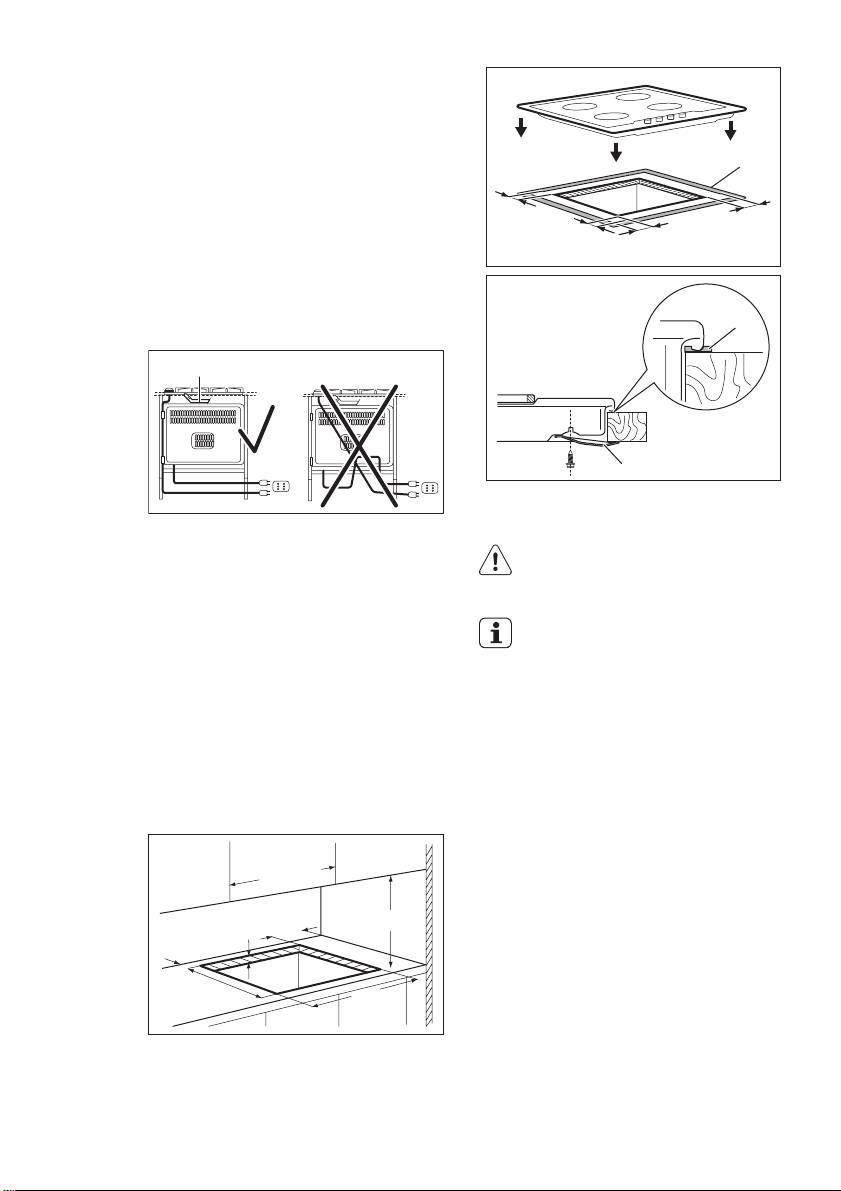

Use clamps installed on the side of the

cabinet to prevent contact with the equip-

ment below the cooktop. See an example

A

of an optimal path in Figure.

A

B

A)

supplied seal

B)

supplied brackets

A)

Rigid copper pipe or flexible pipe in

stainless steel

CAUTION!

Install the appliance only on a

worktop with flat surface.

8.5 Replacement of the

connection cable

If you install the hob under a

hood, please see the installation

To replace the connection cable use only

instructions of the hood for the

H05V2V2-F T90 or equivalent type. Make

minimum distance between the

sure that the cable section is applicable to

appliances.

the voltage and the working temperature.

The yellow/green earth wire must be ap-

proximately 2 cm longer than the brown

8.7 Possibilities for insertion

(or black) phase wire.

Kitchen unit with door

8.6 Building In

The panel installed below the hob must

be easy to remove and let an easy access

in case a technical assistance intervention

min. 600 mm

is necessary.

min. 150 mm

min. 650 mm

min. 55 mm

30 mm

480 mm

560 mm

Оглавление

- CONTENTS

- 1. SAFETY INFORMATION

- 2. SAFETY INSTRUCTIONS

- 3. PRODUCT DESCRIPTION

- 5. HELPFUL HINTS AND TIPS

- 6. CARE AND CLEANING

- 7. TROUBLESHOOTING

- 8. INSTALLATION

- 9. TECHNICAL INFORMATION

- 10. ENVIRONMENT CONCERNS

- INHALT

- 1. SICHERHEITSINFORMATIONEN

- 2. SICHERHEITSHINWEISE

- 3. GERÄTEBESCHREIBUNG

- 4. TÄGLICHER GEBRAUCH

- 5. PRAKTISCHE TIPPS UND HINWEISE

- 7. FEHLERSUCHE

- 8. MONTAGE

- 9. TECHNISCHE DATEN

- 10. UMWELTTIPPS

- СОДЕРЖАНИЕ

- 1. СВЕДЕНИЯ ПО ТЕХНИКЕ БЕЗОПАСНОСТИ

- 2. УКАЗАНИЯ ПО БЕЗОПАСНОСТИ

- 3. ОПИСАНИЕ ИЗДЕЛИЯ

- 4. ЕЖЕДНЕВНОЕ ИСПОЛЬЗОВАНИЕ

- 5. ПОЛЕЗНЫЕ СОВЕТЫ

- 7. ПОИСК И УСТРАНЕНИЕ НЕИСПРАВНОСТЕЙ

- 8. УСТАНОВКА

- 9. ТЕХНИЧЕСКИЕ ДАННЫЕ

- 10. ОХРАНА ОКРУЖАЮЩЕЙ СРЕДЫ