Indesit K6G52S/R: Installation

Installation: Indesit K6G52S/R

Installation

The following instructions should be read by a qualified

opening windows or increasing mechanical venting (if

technician to ensure that the appliance is installed, regu-

present).

lated and technically serviced correctly in compliance with

d) Liquified petroleum gas is heavier than the air and,

current regulations.

therefore, settles downwards. Thus, rooms containing

Important: Disconnect the appliance from the electri-

LPG cylinders must also be equipped with apertures

cal supply before performing any maintenance or

to the outside for ventilation of gas in the case of leaks.

regulating the appliance.

LPG cylinders must not, therefore, be installed or stored

in rooms or storage areas that are below ground level

Positioning

(cellars, etc.) whether they are partially or completely

Important: This unit may be installed and used only in

full. It is a good idea to keep only the cylinder being

permanently ventilated rooms in accordance with current

used in the room, positioned so that it is not subject to

National Regulations. The following requirements must be

heat produced by external sources (ovens, fireplaces,

observed:

stoves, etc. ) which are able to increase the tempera-

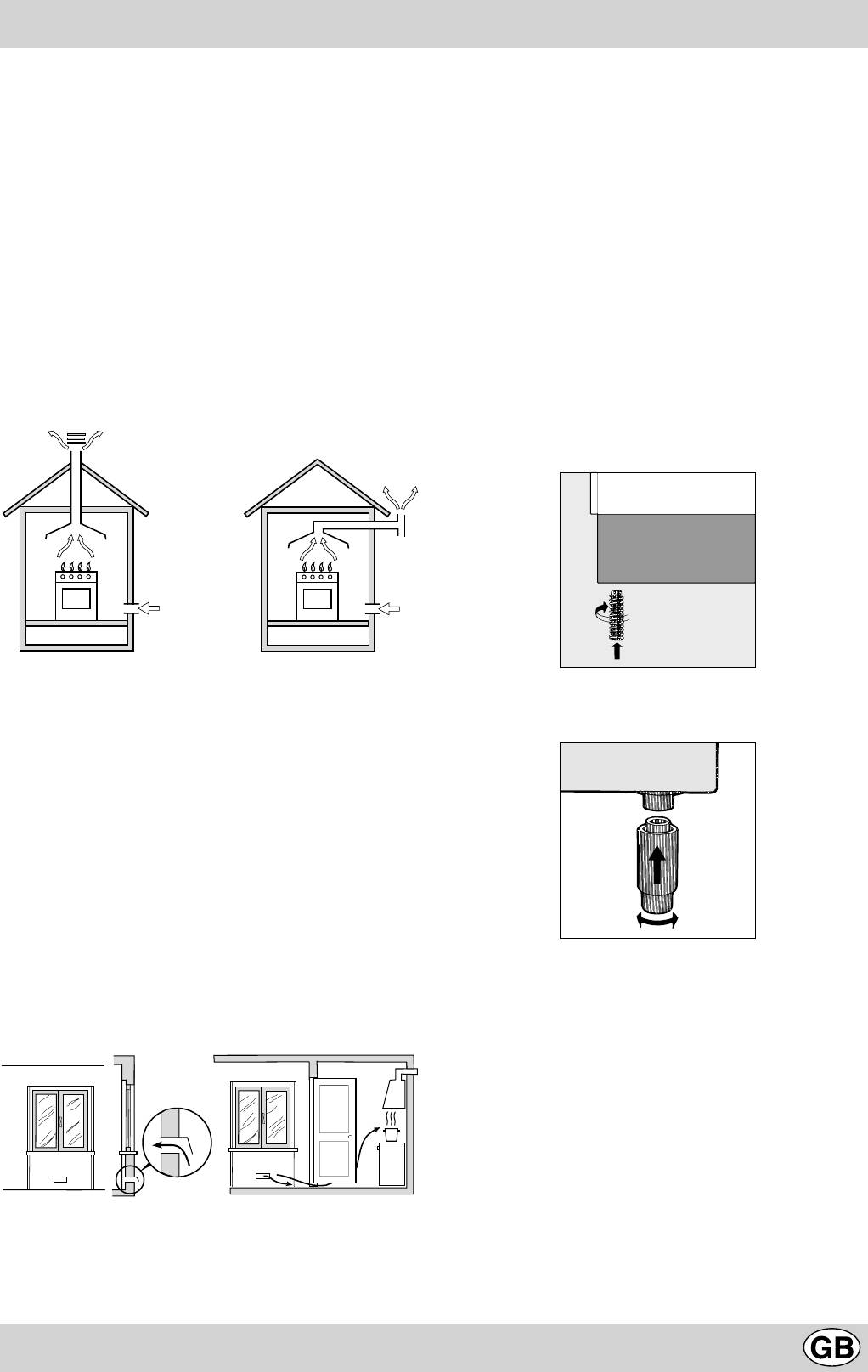

a) The room must be equipped with an exhaust system

ture of the cylinder above 50°C.

that vents the combustion fumes to the outside. It may

consist of a hood or an electric fan that automatically

Levelling your Appliance (only on certain models)

starts each time the appliance is turned on.

4 support feet which are adjusted using screws are located

in the lower part of the cooker. These level off the oven

when necessary. It is essential that the cooker be standing

level.

A Flue or Branched Flue System Directly to the outside

Mounting the Legs (only on certain models)

(only for cooking appliances)

Legs are provided and can be installed under the base of

b)

The room must also have a system to permit proper air

the cooker.

circulation, needed for combustion to occur normally. The

flow of air needed for combustion must not be less than

3

2 m

/h per kW of installed power. The air circulation sys-

tem may take air directly from the outside by means of a

2

pipe with an inner cross section of at least 100 cm

; the

opening must not be able to be accidentally blocked. For

those appliances not equipped with a safety device for

accidental flame loss, the ventilation apertures must be

2

increased by 100%, with the minimum being 200cm

(Fig. A). The system can also provide the air needed for

combustion by indirect means, i.e. from adjacent rooms

fitted with air circulation tubes as described above. How-

Installation of the Cooker

ever, these rooms must not be common rooms or bed-

The appliance can be installed next to furniture units which

rooms. (Fig. B).

are no taller than the top of the cooker hob. The wall in

Detail A Adjacent Room to be

direct contact with the back panel of the cooker must be

Room Ventilated

made of non-flammable material. During operation the

back panel of the cooker could reach a temperature of

50°C above room temperature. For proper installation of

the cooker, the following precautions must be taken:

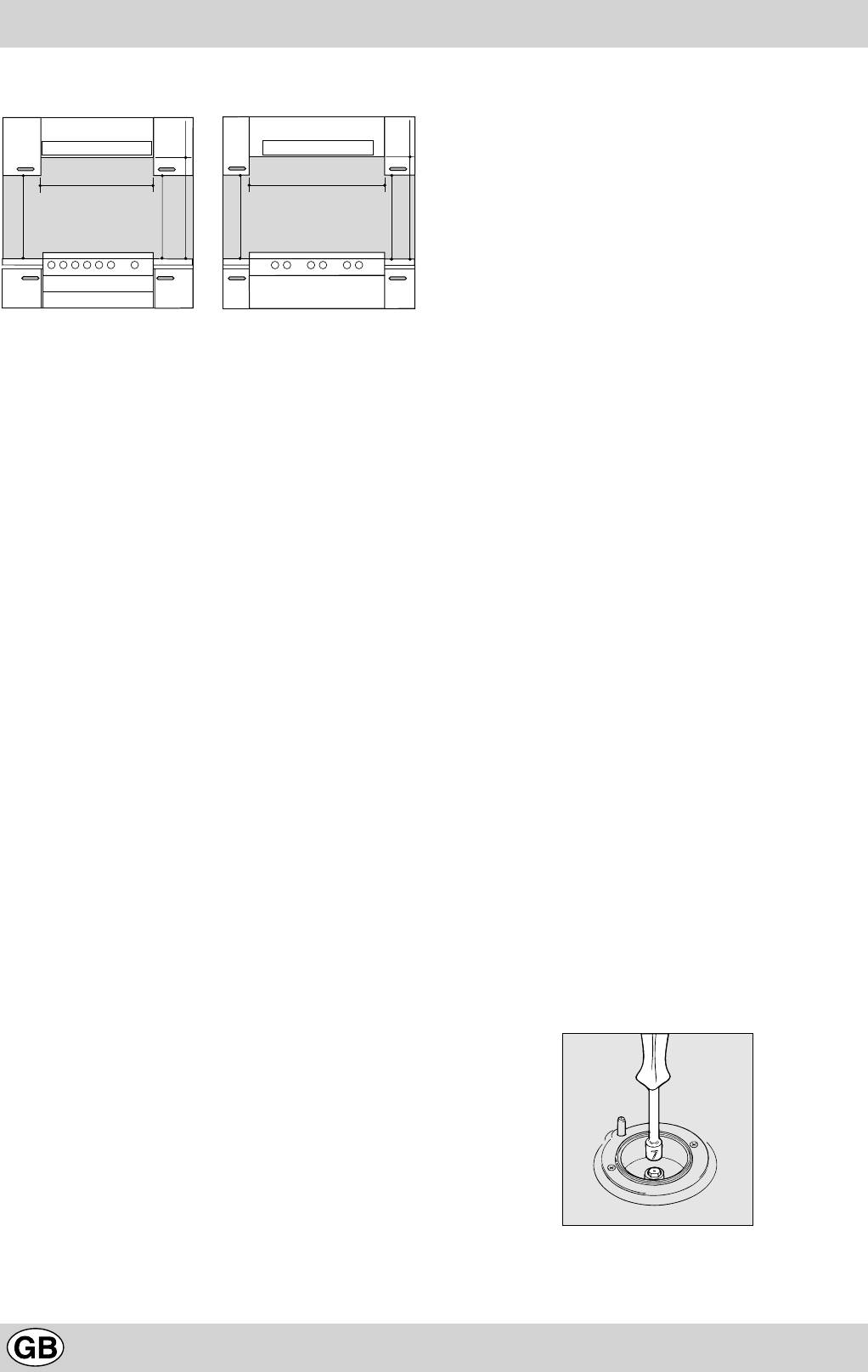

a) Kitchen cabinets installed next to the cooker that are

higher than the top of the hob, must be at least 600 mm

from the edge of the hob itself.

A

b) Hoods must be installed according to the requirements

in the installation manual for the hood and, in any case,

Examples of Ventilation Increased Opening Between

at a minimum height of 650 mm.

Openings Comburent Air Door and Floor

c) If the hood is installed below a wall cabinet, the latter

Fig. A Fig. B

must be at least 700 mm (millimetres) above the surface

c) Intensive and prolonged use of the appliance may re-

of the hob. Cabinets installed adjacent to the hood must

sult in the need for supplemental air circulation, e.g.

be at least 420 mm above the hob, as shown in Figures

15

C and D.

attachment. Only use pipes and gaskets complying with

current standards. The full length of the pipe must not ex-

ceed 2000 mm. Once the connection has been made,

HOOD

HOOD

ensure that the flexible metal pipe does not touch any

moving parts and is not crushed.

Min. mm.

600

Min. mm.

900

Checking that the Connection is Tight

mm.

mm.

Important: When installation has been completed, check the

420

420

mm. with hood

mm. without hood

420

mm. with hood

420

mm. without hood

650

700

650

700

pipe fittings for leaks using a soapy solution. Never use a flame.

Min.

Min. mm.

min.

Min.

Min. mm.

min.

min.

min.

Once the connection has been made, ensure that the flexible

metal pipe does not touch any moving parts and is not crushed.

Connecting the Power Supply Cord to the Mains

Install a normalised plug corresponding to the load indi-

Fig. C Fig. D

cated on the data plate. When connecting the cable di-

Connecting the Gas

rectly to the mains, install an omnipolar circuit-breaker with

The appliance should be connected to the mains or to a

a minimum contact opening of 3 mm between the appli-

gas cylinder in compliance with current National Regula-

ance and the mains. The omnipolar circuit breaker should

tions. Before making the connection, check that the cooker

be sized according to the load and should comply with

is regulated for the gas supply you are using. If not, follow

current regulations (the earth wire should not be inter-

the instructions indicated in the paragraph “Adapting to

rupted by the circuit breaker). The supply cable should be

different types of gas." On some models the gas supply

positioned so that it does not reach a temperature of more

can be connected on the left or on the right, as neces-

than 50°C with respect to the room temperature, along its

sary; to change the connection, reverse the position of

length. Before making the connection, check that:

the hose holder with that of the cap and replace the gas-

• The limiter valve and the home system can support

ket (supplied with the appliance). When using liquid gas

the appliance load (see data plate);

from a cylinder, install a pressure regulator which com-

• The mains are properly earthed in compliance with cur-

plies with the current National Regulations.

rent standards and regulations;

Important: Check that the supply pressure complies with

• There is easy access to the socket and omnipolar cir-

the values indicated in table 1 “Burner and Nozzle Char-

cuit breaker, once the hob has been installed.

acteristics” since this will ensure safe operation, correct

NB: Never use reducers, adaptors or shunts since they

consumption and ensure a longer life for your appliance.

can cause heating or burning.

Connection with a Hose

Converting the Hob for Different Types of Gas

Make the connection using a gas hose that complies with

In order to convert the cooker to a different type of gas

requirements set forth by the current National Regulations.

with respect to the gas for which it was manufactured (in-

The inner diameters of the pipe are as follows:

dicated on the label attached to the lid), follow these steps:

- 8 mm for liquid gas;

a) Replace the hose holder mounted on the appliance

- 13 mm for methane gas.

with that supplied in the bag of “cooker accessories.”

When installing the hose, remember to take the following

Important: The hose holder for liquid gas is marked 8,

precautions:

the hose holder for methane gas is marked 13. Always

• No part of the hose should touch parts whose tem-

use a new sealing gasket.

perature exceeds 50°C;

b) Replace the burner nozzles on the hob:

• The length of the hose should be less than 1500 mm;

• Remove the grids and slide the burners from their

• The hose should not be subject to twisting or pulling,

housings;

and should not have bends or kinks;

• Unscrew the nozzles using a 7 mm socket spanner,

• The hose should not touch objects with sharp edges,

and replace them with nozzles for the new type of gas

moving parts, and it should not be crushed;

(see table 1 “Burner and Nozzle Characteristics”).

• The full length of the hose should be easy to inspect in

order to check its condition.

Check that the hose fits firmly into place at the two ends

and fix it with clamps complying with current National

Regulations. If any of the above recommendations can

not be followed, flexible metal pipes should be used. If the

cooker is installed according to the conditions of Class 2,

subdivision 1, only a flexible metal pipe which is in com-

pliance with current safety standards should be used to

make the connection to the gas mains.

Connecting a Flexible, Jointless, Stainless Steel

Pipe to a Threaded Attachment

• Replace all the components by repeating the steps in

Remove the hose holder fitted on the appliance. The gas

reverse order.

supply pipe fitting is a threaded 1/2 gas cylindrical male

16

Оглавление

- Avvertenze

- Istruzioni per l’installazione

- Caratteristiche dei bruciatori ed ugelli

- Caratteristiche tecniche

- Istruzioni per l’uso

- Consigli pratici per la cottura

- Manutenzione ordinaria e pulizia della cucina

- Important

- Installation

- Burner and Nozzle Specifications

- Technical Specifications

- How To Use Your Appliance

- Practical Cooking Advice

- Routine Maintenance and Cleaning

- Ïðåäóïðåæäåíèÿ

- Istruzioni per l’installazione

- Õàðàêòåðèñòèêè ãàçîâûõ ãîðåëîê è ôîðñóíîê

- Òåõíè÷åñêèå õàðàêòåðèñòèêè

- Ðóêîâîäñòâî ïî ýêñïëóàòàöèè

- Ïðàêòè÷åñêèå ñîâåòû ïî ïðèãîòîâëåíèþ áëþä

- Ðåãóëÿðíîå òåõíè÷åñêîå îáñëóæèâàíèå è ÷èñòêà êóõîííîé ïëèòû

- Merloni Elettrodomestici