Indesit FGIM-K-IX-S: Installation

Installation: Indesit FGIM-K-IX-S

GB

19

Installation

!

Please keep this instruction booklet in a safe place for

future reference. If the appliance is sold, given away or

moved, please make sure the booklet is also passed on to

the new owners so that they may benefit from the advice

contained within it.

!

Please read this instruction manual carefully: it contains

important information concerning the safe operation,

installation and maintenance of the appliance.

Positioning

!

Do not let children play with the packaging material; it

should be disposed of in accordance with local separated

waste collection standards (see Precautions and tips).

!

The appliance must be installed by a qualified professional in

accordance with the instructions provided. Incorrect installation

may damage property or cause harm to people or animals.

!

This unit may be installed and used only in permanently

ventilated rooms in accordance with current National

Regulations. The following requirements must be observed:

• The room must be equipped with an air extraction system

that expels any combustion fumes. This may consist of

a hood or an electric fan that automatically starts each

time the appliance is switched on.

In a chimney stack or branched flue.

(exclusively for cooking appliances)

Directly to

the Outside

• The room must also allow proper air circulation, as air is

needed for combustion to occur normally. The flow of air

must not be less than 2 m

3

/h per kW of installed power.

The air circulation system may

take air directly from the outside

by means of a pipe with an inner

cross section of at least 100 cm

2

;

the opening must not be vulnerable

to any type of blockages.

The system can also provide the air

needed for combustion indirectly,

i.e. from adjacent rooms fitted with

air circulation tubes as described

above. However, these rooms must

not be communal rooms, bedrooms

or rooms that may present a fire

hazard.

• Liquid petroleum gas sinks to the floor as it is heavier

than air. Therefore, rooms containing LPG cylinders must

also be equipped with vents to allow gas to escape in

the event of a leak. As a result LPG cylinders, whether

A

Examples of

ventilation holes

for comburant air.

Enlarging the ventilation slot

between window and floor.

Adjacent

Room

Room to be

Vented

partially or completely full, must not be installed or stored

in rooms or storage areas that are below ground level

(cellars, etc.). It is advisable to keep only the cylinder

being used in the room, positioned so that it is not subject

to heat produced by external sources (ovens, fireplaces,

stoves, etc. ) which could raise the temperature of the

cylinder above 50°C.

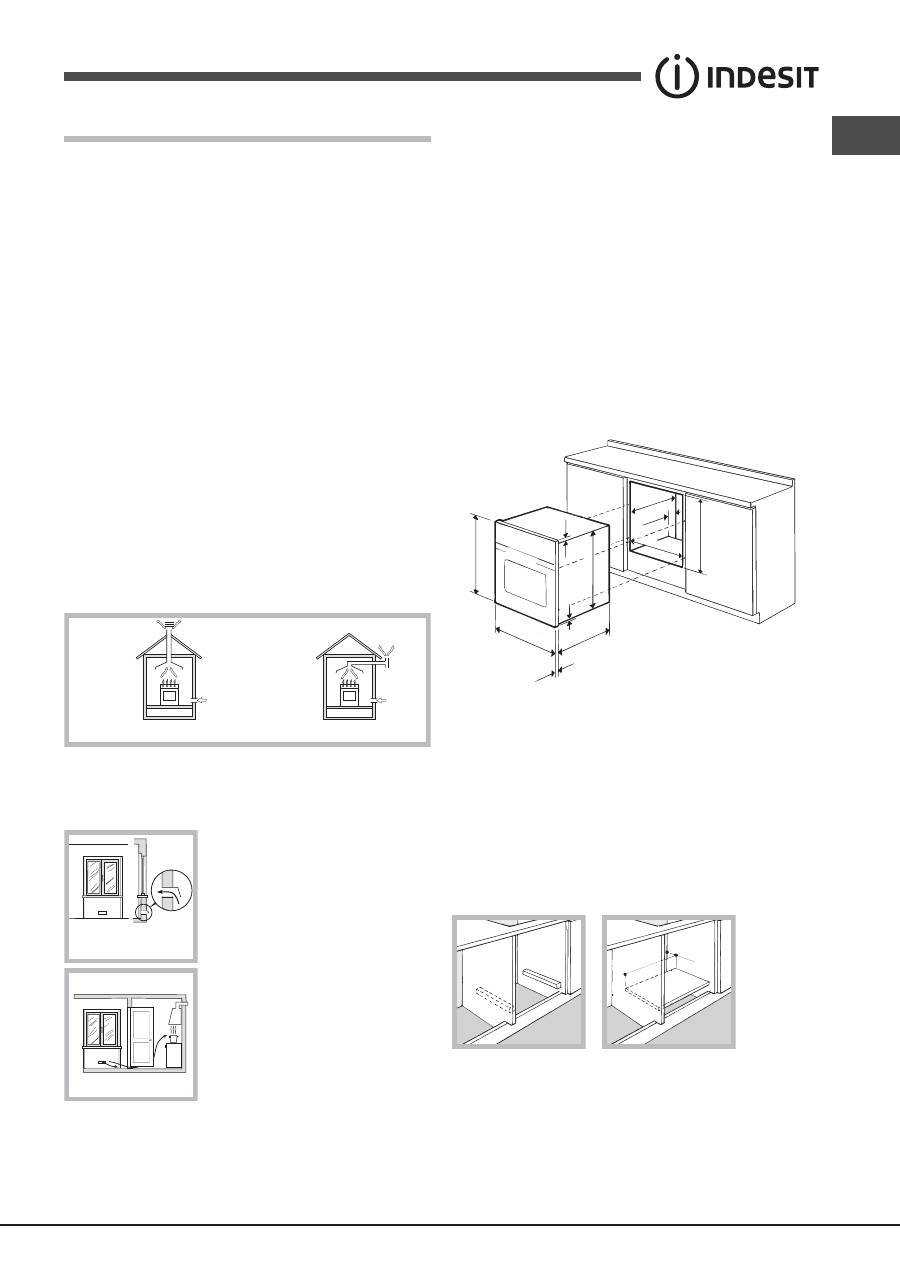

Built-in appliances

Use an appropriate cabinet to ensure that the appliance

operates properly:

• the panels adjacent to the oven must be made of heat-

resistant material.

• cabinets with a veneer exterior must be assembled with

glues which can withstand temperatures of up to 100°C.

• to install the oven

under the counter

(see diagram) or

in a

kitchen unit

, the cabinet must have the following

dimensions:

595 mm.

595 mm.

25 mm.

545 mm.

5 mm.

567 mm.

23 mm.

575-585 mm.

45 mm.

558 mm.

547 mm. min.

!

The appliance must not come into contact with electrical

parts once it has been installed.

The indications for consumption given on the data plate

have been calculated for this type of installation.

Ventilation

To ensure adequate ventilation, the back panel of the

cabinet must be removed. It is advisable to install the oven

so that it rests on two strips of wood, or on a completely

flat surface with an opening of at least 45 x 560 mm (see

diagrams).

560 mm

.

45 mm.

Centring and fixing

Secure the appliance to the cabinet by opening the oven door

and inserting 4 screws into the 4 holes on the outer frame.

20

GB

!

All parts which ensure the safe operation of the appliance

must not be removable without the aid of a tool.

Electrical connection

Ovens equipped with a three-pole power supply cable are

designed to operate with alternating current at the voltage

and frequency indicated on the data plate located on the

appliance (see below).

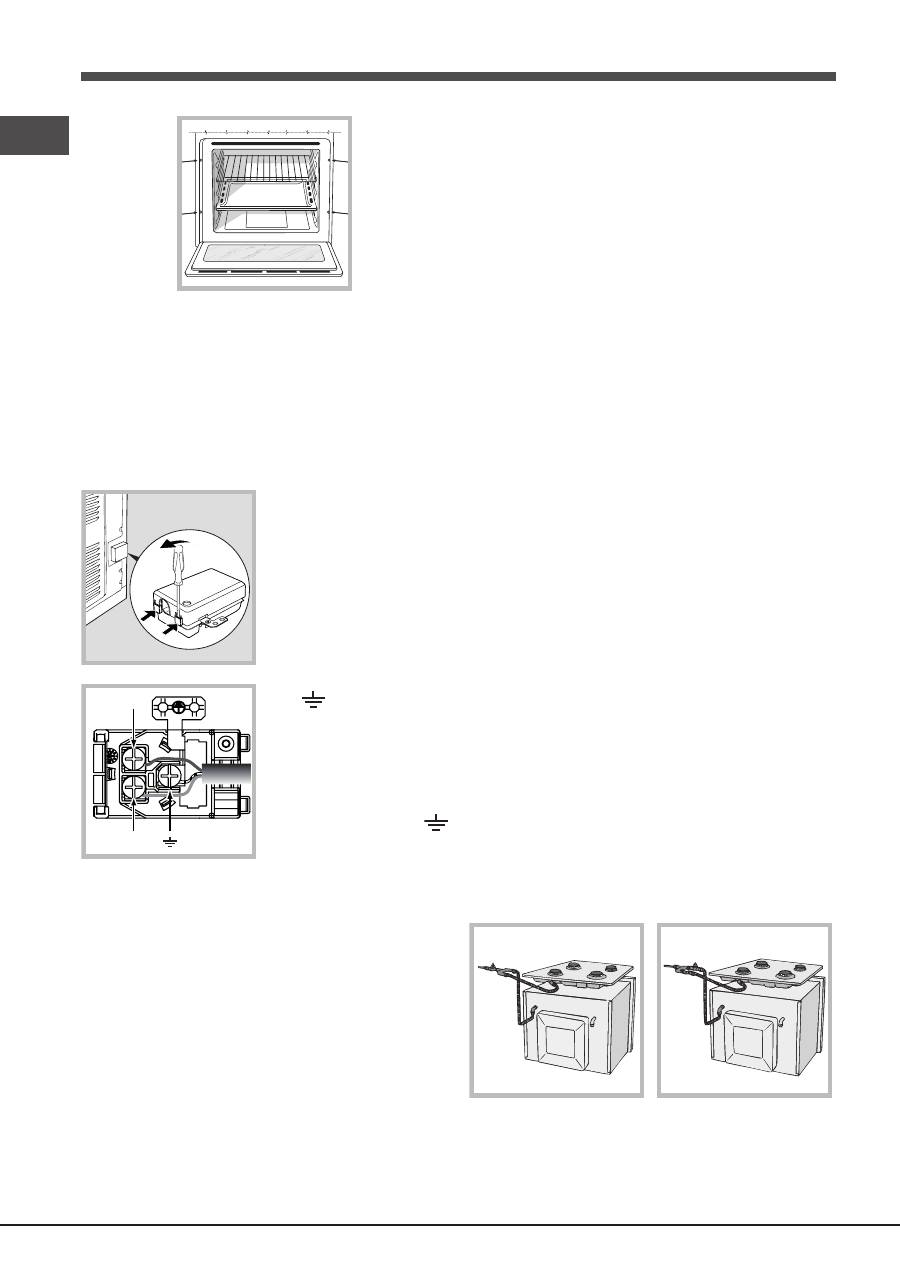

Fitting the power supply cable

1. Open the terminal board

by inserting a screwdriver

into the side tabs of the

cover. Use the screwdriver

as a lever by pushing it

down to open the cover (see

diagram).

2. Install the power supply

cable by loosening the

cable clamp screw and the

three wire contact screws

L-N-

.

Connect the wires to the

corresponding terminals:

the Blue wire to the terminal

marked (N), the Brown wire

to the terminal marked (L)

and the Yellow/Green wire

to the terminal marked

(see diagram).

3. Secure the cable by fastening the clamp screw.

4. Close the cover of the terminal board.

Connecting the supply cable to the mains

Install a standardised plug corresponding to the load

indicated on the data plate (see table).

The appliance must be directly connected to the mains using

an omnipolar switch with a minimum contact opening of 3

mm installed between the appliance and the mains. The

switch must be suitable for the charge indicated and must

comply with current electrical regulations (the earthing wire

must not be interrupted by the switch). The supply cable

must be positioned so that it does not come into contact

with temperatures higher than 50°C at any point (the back

panel of the oven, for example).

!

The installer must ensure that the correct electrical

connection has been performed and that it is fully compliant

with safety regulations.

L

N

N

L

Before connecting the appliance to the power supply, make

sure that:

• the appliance is earthed and the plug is compliant with

the law.

• the socket can withstand the maximum power of the

appliance, which is indicated on the data plate.

• the voltage is in the range between the values indicated

on the data plate.

• the socket is compatible with the plug of the appliance.

If the socket is incompatible with the plug, ask an

authorised technician to replace it. Do not use extension

cords or multiple sockets.

!

Once the appliance has been installed, the power supply

cable and the electrical socket must be easily accessible.

!

The cable must not be bent or compressed.

!

The cable must be checked regularly and replaced by

authorised technicians only (see Assistance).

!

The manufacturer declines any liability should these

safety measures not be observed.

Gas connection

The appliance should be connected to the main gas supply

or to a gas cylinder in compliance with current National

regulations. Before carrying out the connection, make sure

the cooker is compatible with the gas supply you wish to

use. If this is not the case, follow the instructions indicated

in the paragraph “Adapting to different types of gas.”

When using liquid gas from a cylinder, install a pressure

regulator that complies with current National regulations.

!

Check that the pressure of the gas supply is consistent

with the values indicated in Table 1 (“Burner and nozzle

specifications”) since this will ensure the safe operation

and longevity of your appliance while maintaining efficient

energy consumption.

!

Should you need to install a gas hob on top of a built-in gas

oven, it is strictly forbidden to connect the two or to use a

single cut-off tap. The two appliances should be connected

separately, and each one should have its own stop tap

in order to make them completely independent from one

another (see figures).

NO

OK

Connection with a rigid pipe (copper or steel)

!

Connection to the gas system must be carried out in such a

way as not to place any strain of any kind on the appliance.

There is an adjustable

L

-shaped pipe fitting on the appliance

GB

21

supply ramp and this is fitted with a seal in order to prevent

leaks. The seal must always be replaced after rotating the pipe

fitting (the seal is provided with the appliance). The gas supply

pipe fitting is a threaded 1/2 gas cylindrical male attachment.

Connecting a flexible jointless stainless steel pipe to a

threaded attachment

The gas supply pipe fitting is a threaded 1/2 gas cylindrical male

attachment. These pipes must be installed so that they are never

longer than 2000 mm when fully extended. Once connection has

been carried out, make sure that the flexible metal pipe does

not touch any moving parts and is not compressed.

!

Only use pipes and seals that comply with current National

regulations.

Checking the tightness of the connection

!

When installation has been completed, check the pipe

fittings for leaks using a soapy solution. Never use a flame.

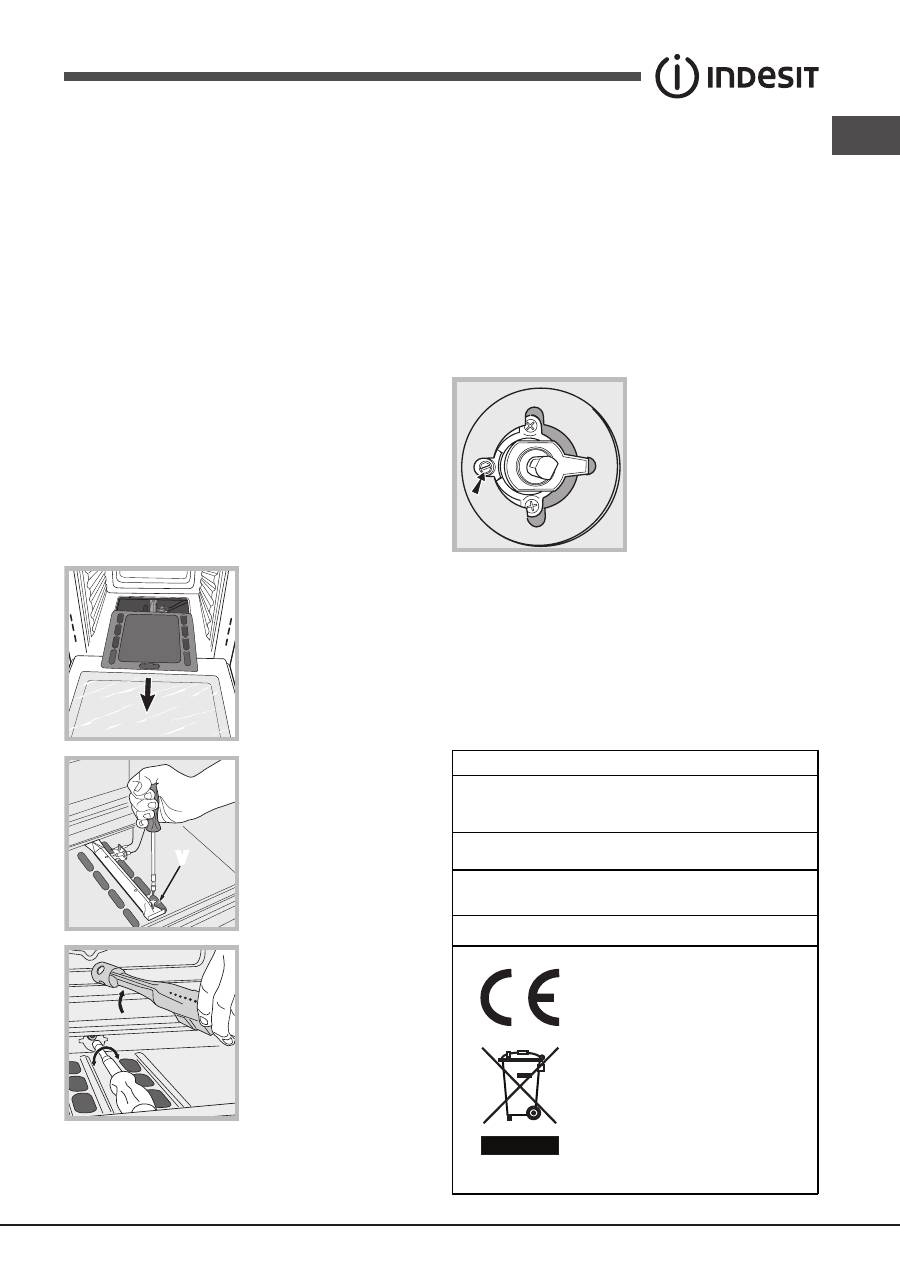

Adapting to different types of gas

In order to adapt the oven to a type of gas other than the

type for which it was manufactured (indicated on the label),

follow these simple steps:

• Replacing the oven burner nozzle

1. Open the oven door fully.

2. Slide out the bottom of the

oven.

V

3. Unscrew the burner

fastening screws.

4. Remove screw “

V

” and

then the oven burner.

5. Unscrew the oven burner

nozzle using the special

socket spanner for the

nozzles, or better still a 7 mm

socket spanner, and replace

it with a nozzle suited to the

new type of gas (see Table 1).

6. Replace all the parts, following the steps described above

in the reverse order.

!

Take particular care when handling the spark plug

wires and the thermocouple pipes.

• Primary air regulation for the oven burner

The burner was designed not to need any adjustments to

the primary air.

• Setting the oven burner to minimum

1. Turn the knob first to the Max setting for about 10 minutes

and then to Min.

2. Remove the knob.

3. Remove the disk fastened to the control panel.

4. Adjust the screw located outside the thermostat cock pin

until the flame is small but steady (the flame can be seen

through the slots on the oven bottom).

5. Make sure the burner does

not switch off when you turn

the knob from Max to Min

quickly, or when you open

and close the oven door

quickly.

!

If the appliance is connected to liquid gas, the regulation

screw must be fastened as tightly as possible.

!

Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used. This

sticker is available from any of our Service Centres.

!

If the gas pressure is different from the recommended

pressure, a suitable pressure regulator must be fitted to the

inlet pipe in accordance with current National Regulations.

DATA PLATE

Dimensions

width 43.5 cm

height 31 cm

depth 43.5 cm

Volume

58 l

Electrical

connections

see data plate

Gas features

see data plate

This appliance conforms to the

following European Economic

Community directives:

2006/95/EEC dated 12/12/06

(Low Voltage) and subsequent

amendments - 2004/108/EEC

dated 15/12/04 (Electromagnetic

compatibility) and subsequent

amendments - 93/68/EEC dated

22/07/93 and subsequent

amendments. 2009/142/EEC

dated 30/11/09 (Gas) and

subsequent amendments.

2012/19/EC and subsequent

amendments.

Оглавление

- Довідник користувача

- Avvertenze

- Advertencias

- Предупреждения

- Assistenza

- Assistência

- Descrizione dell’apparecchio

- Описание изделия

- Descrizione dell’apparecchio

- Installazione

- Avvio e utilizzo

- Programmi

- Precauzioni e consigli

- Installation

- Start-up and use

- Cooking modes

- Precautions and tips

- Instalación

- Puesta en funcionamiento y uso

- Programas

- Precauciones y consejos

- Instalação

- Início e utilização

- Programas

- Precauções e conselhos

- Установка

- Включение и эксплуатация

- Программы

- Предосторожности и рекомендации

- Техническое обслуживание и уход

- Установлення

- Запуск і використання

- Програми

- Запобіжні заходи та поради