Whirlpool AWG 259: INSTALLATION

INSTALLATION: Whirlpool AWG 259

•

As a result of quality control procedures, a certain amount of water

may remain in your machine. This is not harmful for your machine.

INSTALLATION

You must pay close attention to the following issues before using your

washing machine.

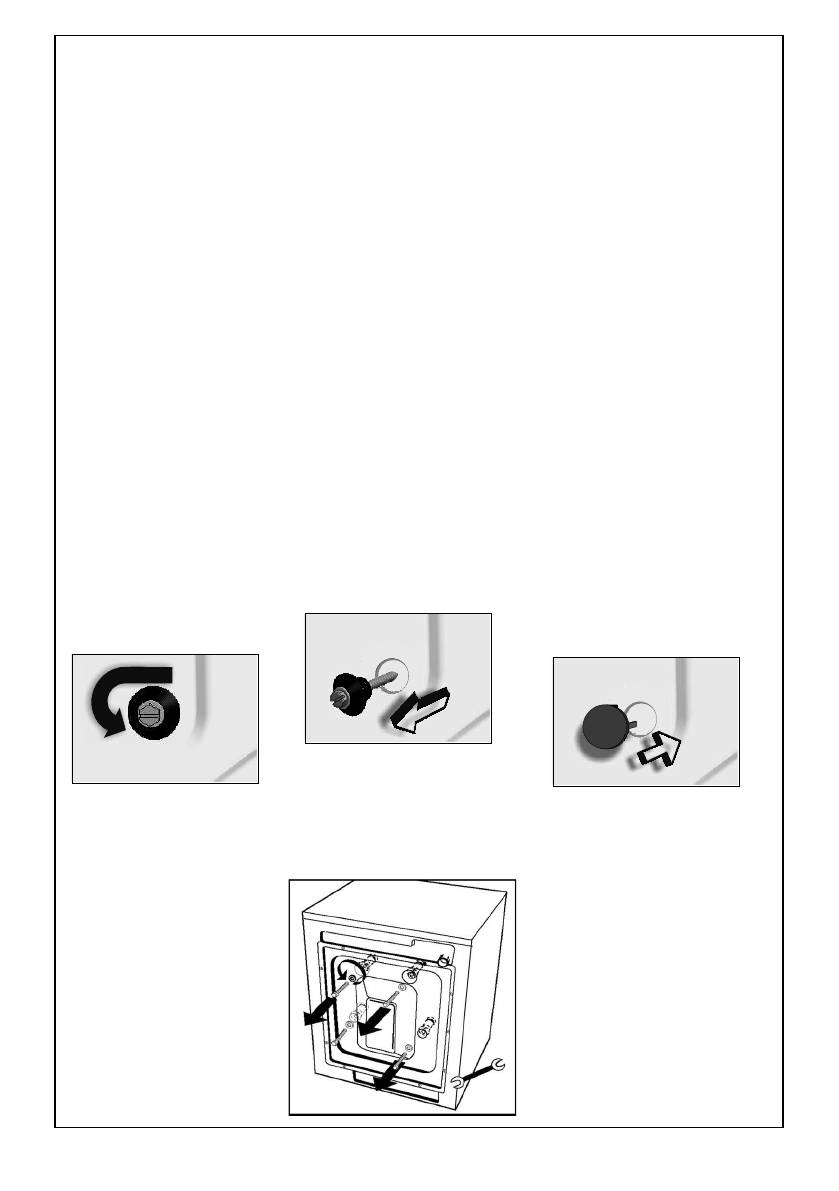

REMOVAL OF TRANSPORTATION SCREWS

•

Transportation screws, which are located at the rear side of the

machine, must be removed before running the machine.

•

Loosen the screws by rotating counter clockwise using a suitable

wrench. (DIAGRAM-1)

•

Remove the screws by pulling them.(DIAGRAM-2)

•

This will cause the plastic parts located in the interior part of your

machine to drop down under the appliance.

•

Lift the machine up slightly to pick up the plastic parts.

•

If all of the plastic parts from the screw groups have not dropped

down, open the door of your machine, move the drum until all plastic

parts drop down. Collect the parts that have fallen to the floor.

•

In the holes where the transport screws have been removed, insert

the plastic transport screw taps found in the accessories bag.

(DIAGRAM-3)

•

The transportation screws that have been removed from the machine

should be kept safe in the event of future transportation.

DIAGRAM-2

DIAGRAM-1 DIAGRAM-3

21

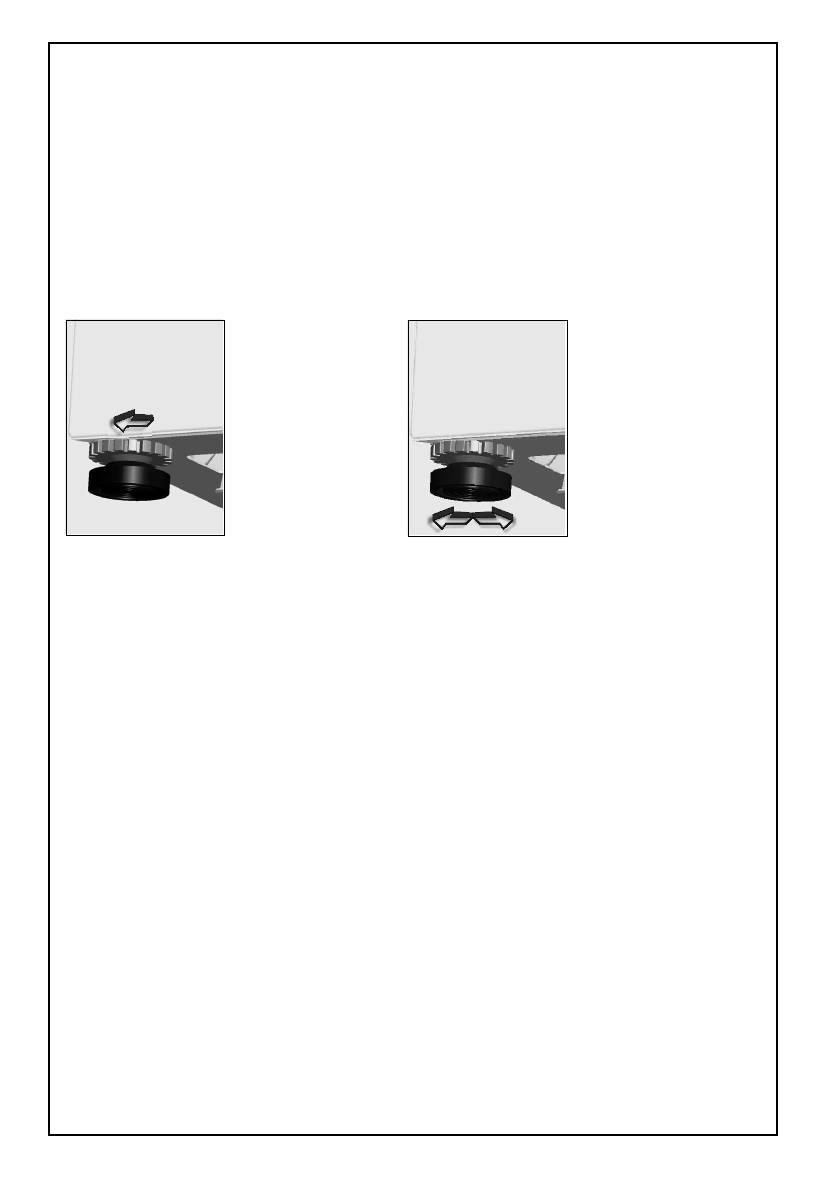

ADJUSTMENT OF FEET

•

Do not install your machine on rugs or similar surfaces.

•

For your machine to work silently and without vibrations, it should be

settled on a flat, non-slippery and tough surface.

•

You can adjust the balance of your machine from its feet.

•

First, loosen the plastic adjustment nut.

•

Adjust by rotating the feet upwards or downwards.

•

After balance has been achieved, tighten the plastic adjustment nut

again by rotating it upwards.

•

Never put cartons, wooden blocks or similar materials under the

machine to adjust the levelness of the machine with the ground.

ELECTRICAL CONNECTION

•

Your washing machine works with 220-240V and 50Hz.

•

A special grounded plug has been attached to the network cable of

your washing machine. This plug must be inserted to a grounded 10

amp socket. The currency rating of the attached electricity supply

should also be 10 amps. If you have no such sockets and fuses in

your house, the plug should be fitted by a qualified electrician.

•

Our company will not be held liable for any damage that may

occur as a result of usage without grounding.

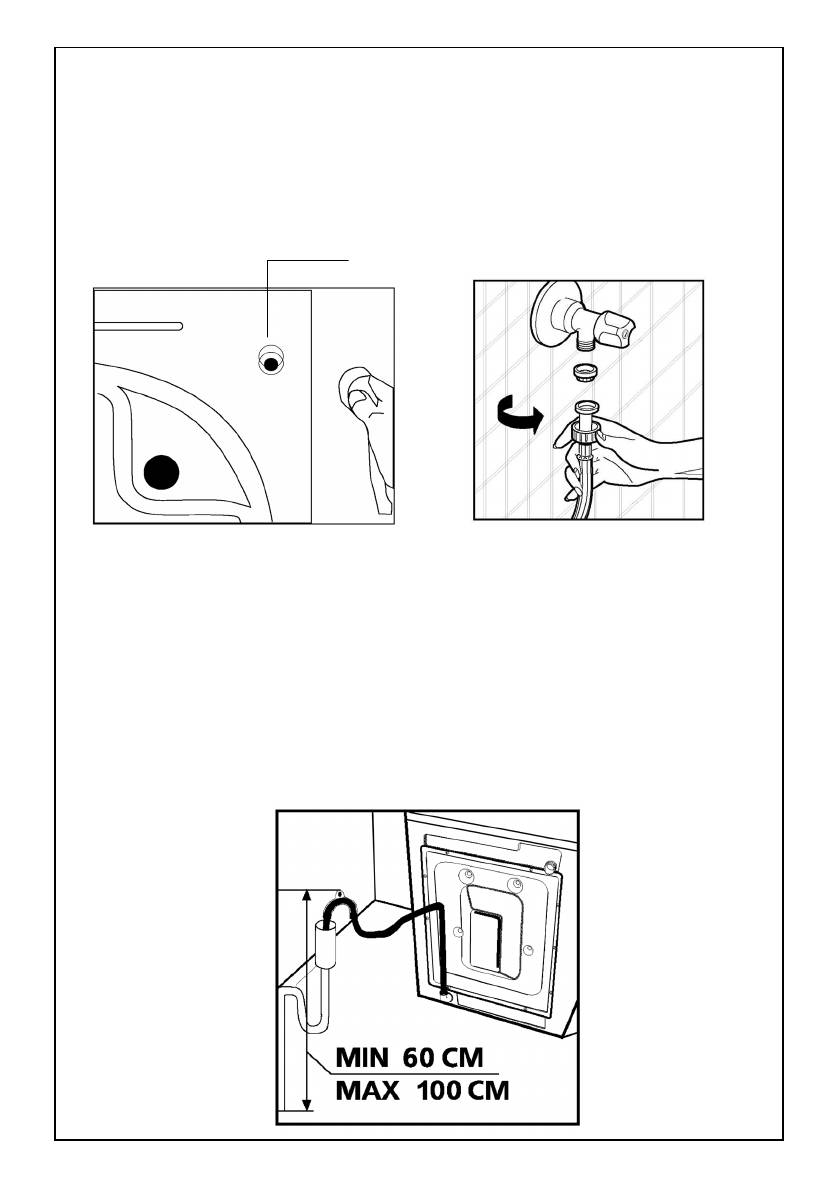

WATER SUPPLY CONNECTION

•

Depending on the specifications of your machine, it may be provided

with a single water inlet (cold) or double water inlet (cold/hot). The

white headed hose is for the cold water inlet and red headed hose is

for the hot water inlet (for machines with hot & cold water inlet).

•

To prevent leakage from the connection joints, 1 (valid for cold water

inlet) or 2 (valid for machines with hot & cold water inlet) seals are

included in the hose packaging. Fit these seals at the end of water

inlet hoses on the tap side.

•

Connect the white headed hose to the water inlet valve with white

filter and connect the red headed hose to the water inlet valve with

red filter (latter in the case of machines with hot & cold water inlet).

Manually tighten the connection parts. Please call a qualified plumber

for safer connections.

22

•

Water pressure of 1-10 bars from your tap will enable your machine

to work more efficiently (1 bar pressure means water flow of more

than 8 litres per minute from a fully opened tap).

•

After connections are secure, check for non-leakage of the

connection joints by turning on your tap fully.

•

Be sure that water inlet hoses are not folded, broken or crushed.

•

Mount the water inlet hoses to a 3”/4, geared water tap.

Cold water inlet (White filter valve)

WATER DRAIN CONNECTION

•

Be sure that water inlet hoses are not folded, twisted, crushed or

elongated by stretching.

•

Water drain hose should be mounted at a height of minimum 60 cm,

maximum 100 cm from the ground.

•

The end of the water drain hose may be directly fitted to the dirty

water outlet hole or a special apparatus mounted on the outlet

bracket of the wash-stand.

•

Never attempt to extend the water drain hose by adding extra parts.

23

Оглавление

- СОДЕРЖАНИЕ

- ПРЕЖДЕ ЧЕМ ПОЛЬЗОВАТЬСЯ СТИРАЛЬНОЙ МАШИНОЙ

- УСТАНОВКА

- ОПИСАНИЕ СТИРАЛЬНОЙ МАШИНЫ

- ПОДГОТОВКА К СТИРКЕ

- ОБСЛУЖИВАНИЕ И ЧИСТКА

- СЕРВИСНЫЙ ЦЕНТР

- CONTENTS

- BEFORE USING THE WASHING MACHINE

- INSTALLATION

- DESCRIPTION OF THE WASHING MACHINE

- PREPARATION OF THE WASHING

- MAINTENANCE AND CLEANING

- TROUBLESHOOTING GUIDE

- AFTER-SALES SERVICE