Whirlpool AWG 234: TROUBLESHOOTING GUIDE

TROUBLESHOOTING GUIDE: Whirlpool AWG 234

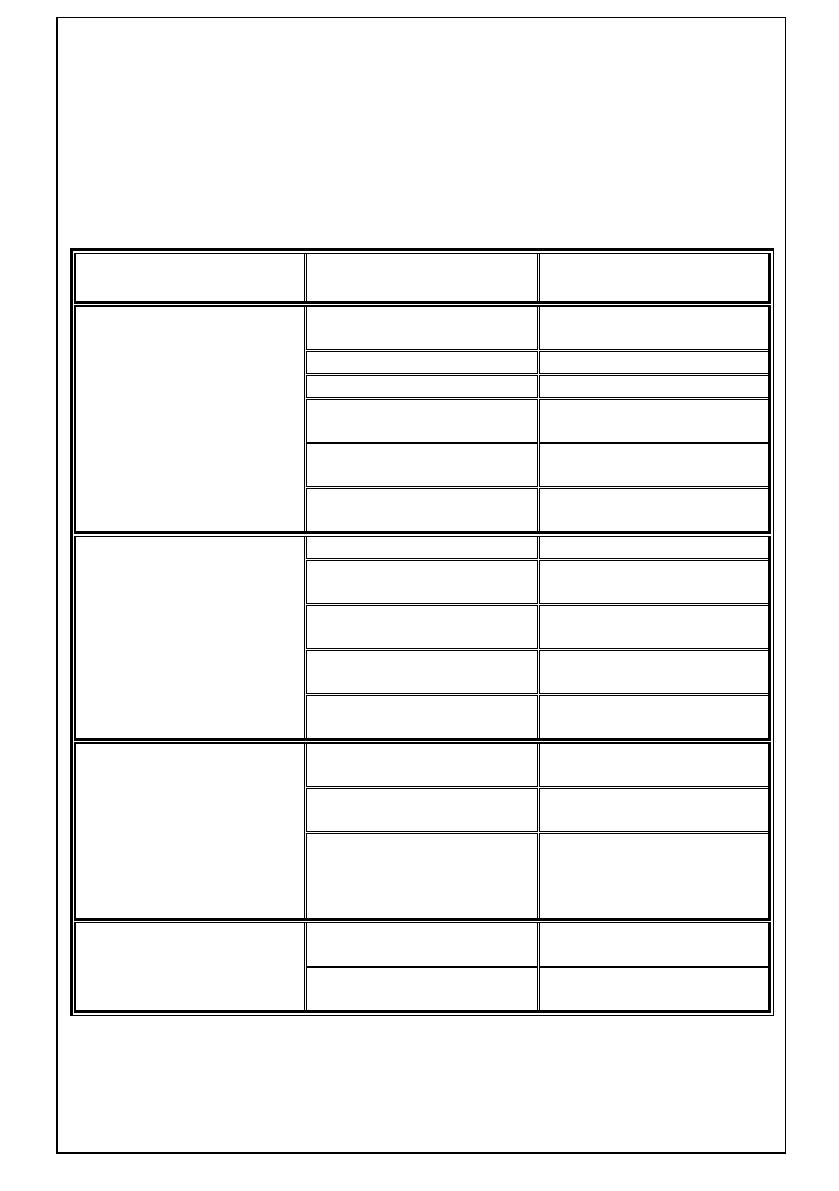

TROUBLESHOOTING GUIDE

All repairing which must be done on the machine should be performed by

authorized service personnel. When your machine requires repairs or you are

unable to eliminate the failure with the help of the information given below:

•

Unplug the machine.

•

Close the water tap.

•

Consult your nearest authorized service provider.

METHODS OF

FAILURE PROBABLE CAUSE

ELIMINATION

Insert the plug into the

It is unplugged.

socket.

Your fuse is defective. Change your fuse.

The electric power is off. Check the electric power.

Your machine does not

Start/pause button has

Press the start/pause

operate.

not been pressed.

button.

The programme knob is

Turn the programme knob

in O (off) mode.

to the desired mode.

The door is not shut

Shut the door properly.

properly.

You should hear it click.

Water tap is closed. Open water tap.

The water inlet hose may

Check the water inlet

be bent.

hose.

The water inlet hose is

Clean the filters of water

Your machine does not

obstructed.

inlet hose. (

*

)

receive water.

The valve inlet filter is

Clean the valve inlet

obstructed.

filters. (

*

)

The door is not shut

Shut the door properly.

properly.

You should hear it click.

The drain hose is

Check the drain hose.

obstructed or bent.

The pump filter is

Clean the pump filter. (

*

)

Your machine is not

obstructed.

draining water.

The clothes are not

Spread the clothes inside

placed inside the machine

the machine in an orderly

in an evenly-balanced

and evenly-balanced

manner.

manner.

The feet of your machine

Adjust the feet. (

**

)

are not adjusted.

Your machine is vibrating.

Transportation screws are

Remove transportation

not removed.

screws. (

**

)

(

*

) See the section concerning maintenance and cleaning of your

machine.

(

**

) See the section concerning installation of your machine.

31

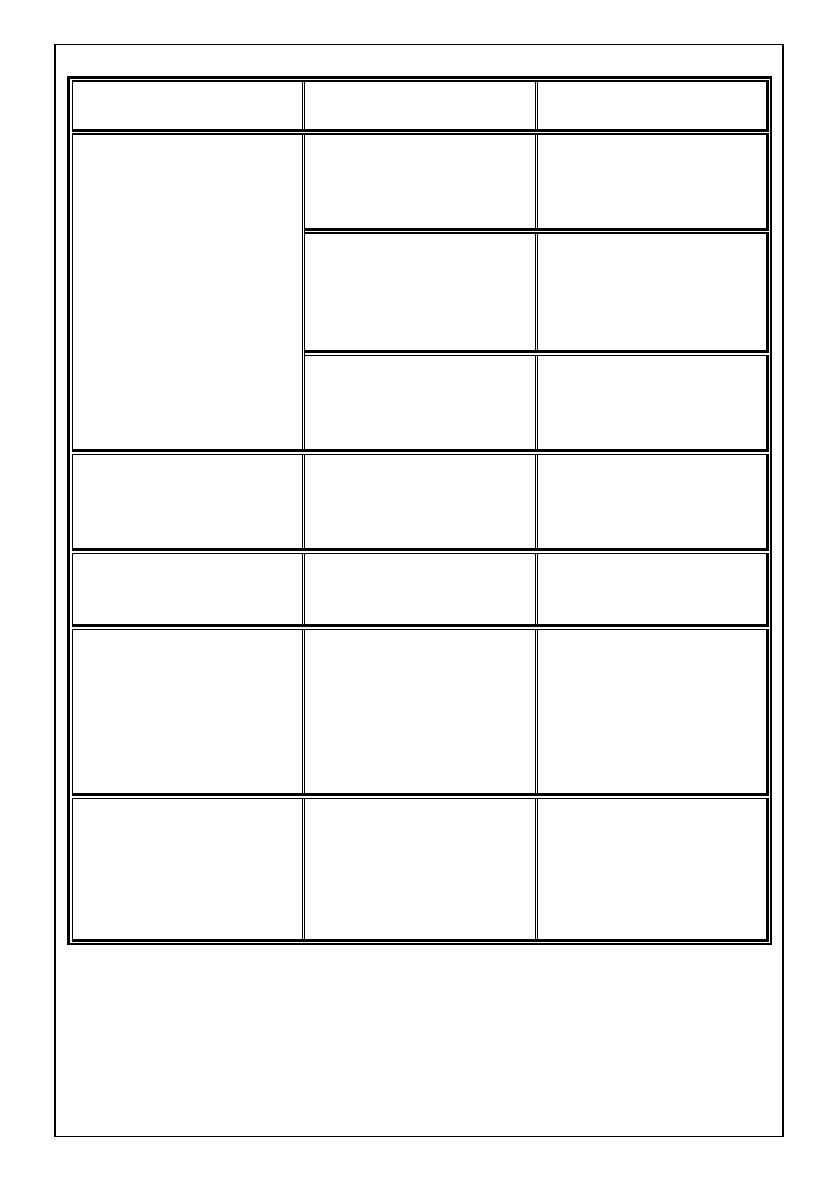

METHODS OF

FAILURE PROBABLE CAUSE

ELIMINATION

There is a small

It does not prevent

amount of clothes in

operation of the

the device.

machine.

Do not exceed the

Excessive amount of

recommended quantity

clothes are filled in the

Your machine is

of clothes and spread

machine or the clothes

vibrating.

your clothes in the

are not placed in a

machine in a well-

well-balanced manner.

balanced manner.

Prevent your

Your machine touches

machine’s leaning on a

a ripid object.

tough place .

Press the start/pause

button.In order to stop

the foam,dilute one

table-spoon of softener

in half liter of water and

pour it in the detergent

Too much detergent

drawer.Press the

has been used.

start/pause button after

Excessive foam in the

5-10 minutes. Arrange

detergent drawer.

the amount of the

detergent properly in

the next washing

process.

Use only the

Wrong detergent has

detergents produced

been used.

for full automatic

machines.

Your laundry too dirty

Select a suitable

for the program you

program. (see Table-1)

have selected.

The washing result is

bad.

The amount of

Use more detergent

detergent used is not

according to the

sufficient.

detergent.

32

METHODS OF

FAILURE PROBABLE CAUSE

ELIMINATION

Load clothes into your

Machine load exceeds

machine so as to avoid

maximum capacity.

exceeding its

maximum capacity.

Regulate the amount of

detergent used

Washing quality is

Your water may be

according to the

poor.

hard.

detergent producer's

guidelines.

Distribution of the

Spread the clothes

clothes in your

inside the machine in

machine is not evenly-

an orderly and evenly-

balanced.

balanced manner .

The end of the water

The water is drained

Place the water drain

drain hose is

from the machine as

hose at an appropriate

positioned too low in

soon as it is filled.

height.(**)

relation to the machine.

No failure. The water is

No water is seen in the

in the lower part of the

-

drum during washing.

drum.

By calibrating your

machine for “Rinsing”

Undissolved fragments

programme, run an

There is detergent

of certain detergents

additional rinse or

residue on the clothes.

may stick to your

eliminate stains after

clothes as white stains.

drying with the help of

a brush.

Use the maximum

detergent amount

These stains may be

There are grey stains

recommended by the

caused by oil, cream or

on the clothes.

detergent producer

ointment.

during the next

washing operation.

(**) See the section concerning installation of your machine.

33

METHODS OF

FAILURE PROBABLE CAUSE

ELIMINATION

The unbalanced load

control system will try

to distribute your

clothes in a

homogenous manner.

No failure. The

The spinning process

After your clothes are

unbalanced load

is not done or starts

distributed, the

control may operate in

with delay.

spinning process will

that way.

begin. For the next

wash, place your

clothes into the

machine in an evenly-

balanced manner.

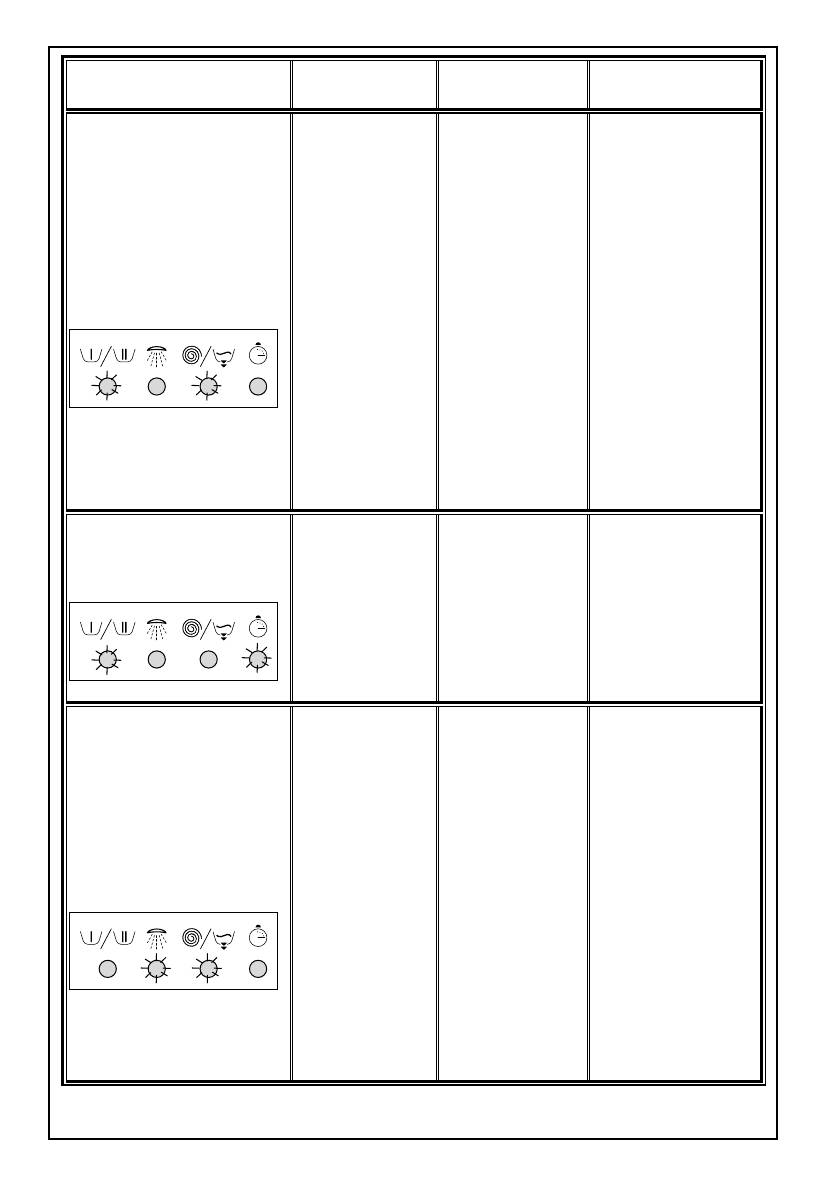

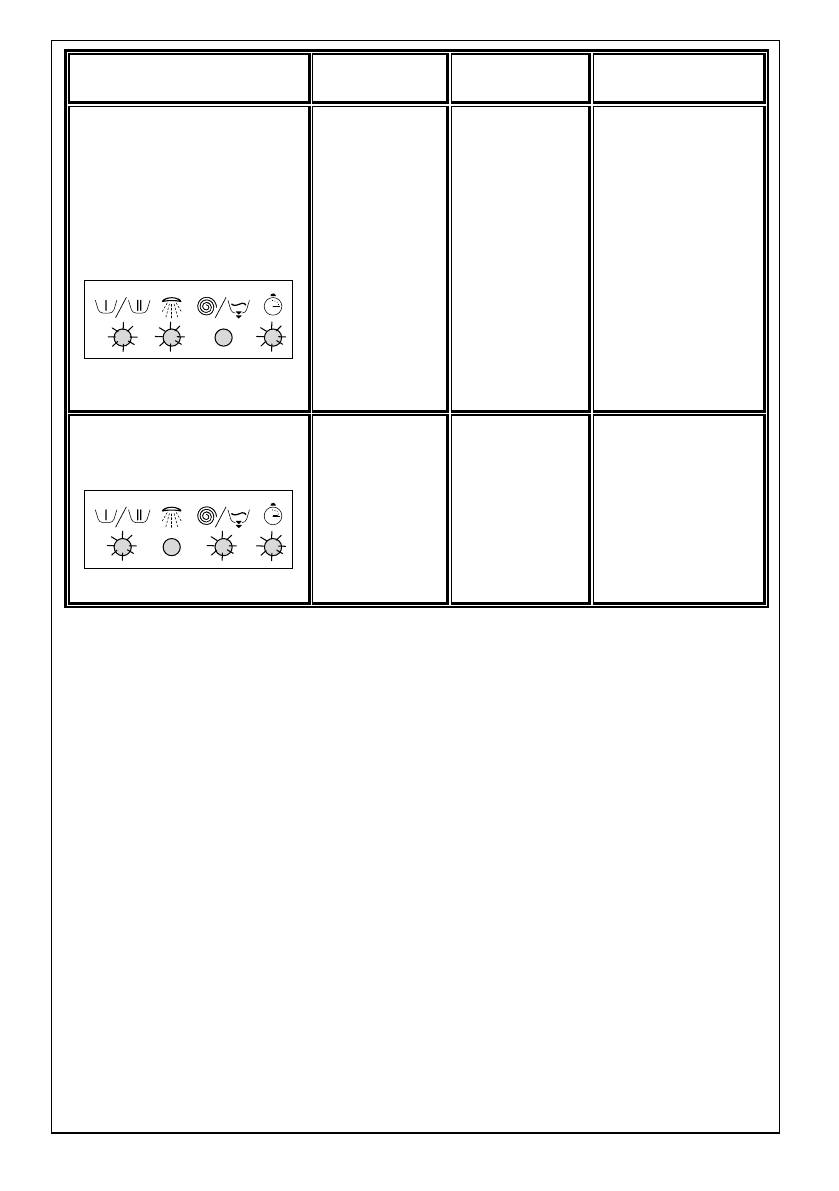

AUTOMATIC FAILURE DETECTION SYSTEM

Your machine is equipped with systems which will both take the necessary

precautions and warn you in case of any failure by continually monitoring the

washing processes.

FAILURE

PROBABLE

CORRECTIVE

FAILURE CODE

INDICATOR

FAILURE

MEASURES

Shut the door

properly so that

you hear it click.

If the problem

persists, turn off

The door is

Lights 1 and

the machine,

E01

not shut

2 blink.

unplug it and

properly.

consult your

nearest

authorized

service provider

immediately.

34

FAILURE

PROBABLE

CORRECTIVE

FAILURE CODE

INDICATOR

FAILURE

MEASURES

Turn on the tap

to the end.

Water supply

may be cut,

The water

check it. If the

level in your

problem still

machine is

exists, your

below heater.

machine will

Lights 1 and

E02

The pressure

automatically

3 blink.

of your water

stop after a

supply may

while. Unplug

be low or

your machine,

unstable.

turn off the tap

and consult your

nearest

authorized

service provider.

Clean the pump

filter. If the

E03

The pump

problem

Lights 1 and

has failed or

persists, consult

4 blink.

the pump filter

your nearest

is obstructed.

authorized

service

provider.(*)

Your machine

will automatically

drain the water.

After your

machine has

completed the

There is an

draining

excessive

Lights 2 and

process, shut

E04

amount of

3 blink.

down your

water in your

machine and

machine.

unplug. Close

the tap and

consult your

nearest

authorized

service provider.

(

*

)

See the section re

g

ardin

g

maintenance and cleanin

g

of

y

our machine.

35

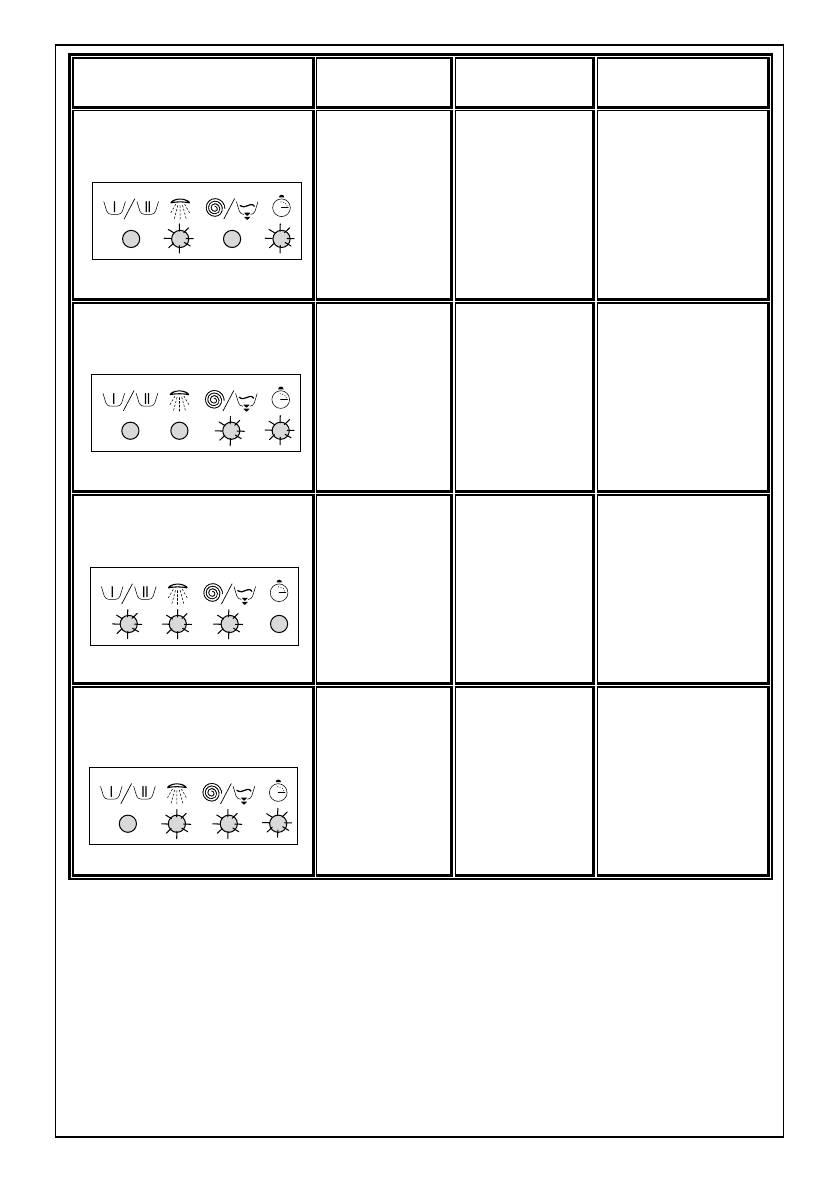

FAILURE

PROBABLE

CORRECTIVE

FAILURE CODE

INDICATOR

FAILURE

MEASURES

Shut down and

The heater

unplug your

E05

of your

machine. Turn

Lights 2 and

machine or

off your tap and

4 blink.

the heat

consult your

sensor has

nearest

failed.

authorized

service provider.

Shut down and

unplug your

E06

machine. Turn

Lights 3 and

The motor

off the tap and

4 blink.

has failed.

consult your

nearest

authorized

service provider.

Shut down and

unplug your

E07

machine. Turn

Electronic

Lights 1, 2

off the tap and

card has

and 3 blink.

consult your

failed.

nearest

authorized

service provider.

Shut down and

unplug your

E08

machine. Turn

Lights 2, 3

The motor

off the tap and

and 4 blink.

has failed.

consult your

nearest

authorized

service provider.

36

FAILURE

PROBABLE

CORRECTIVE

FAILURE CODE

INDICATOR

FAILURE

MEASURES

If the network

voltage is lower

than 150V or

higher than

260V, your

The network

machine will

Lights 1, 2

voltage is too

E09

automatically

and 4 blink.

high or too

stop. When the

low.

network voltage

is recovered,

your machine

will continue its

operation.

Shut down and

unplug your

E10

machine. Turn

Lights 1, 3

Communication

off the tap and

and 4 blink.

error

.

consult your

nearest

authorized

service provider.

37

Оглавление

- СОДЕРЖАНИЕ

- ПРЕЖДЕ ЧЕМ ПОЛЬЗОВАТЬСЯ СТИРАЛЬНОЙ МАШИНОЙ

- УСТАНОВКА

- ОПИСАНИЕ СТИРАЛЬНОЙ МАШИНЫ

- ПОДГОТОВКА К СТИРКЕ

- ОБСЛУЖИВАНИЕ И ЧИСТКА

- СЕРВИСНЫЙ ЦЕНТР

- CONTENTS

- BEFORE USING THE WASHING MACHINE

- INSTALLATION

- DESCRIPTION OF THE WASHING MACHINE

- PREPARATION OF THE WASHING

- MAINTENANCE AND CLEANING

- TROUBLESHOOTING GUIDE

- AFTER-SALES SERVICE

- NOTES