Whirlpool AWG 217 – страница 2

Инструкция к Стиральной Машине Whirlpool AWG 217

СЕРВИСНЫЙ ЦЕНТР

Прежде чем обращаться в сервисный центр:

1. Попробуйте устранить неисправность самостоятельно (см.

раздел "Поиск неисправностей").

2. Запустите программу еще раз, чтобы проверить, не устранилась

ли неисправность автоматически.

3. Если неисправность не исчезла, обратитесь в сервисный центр.

Сообщите:

•

Характер неисправности.

•

Модель стиральной машины.

•

Сервисный код (число после слова SERVICE).

Наклейка послереализационного обслуживания находится на

внутренней стороне дверцы.

•

Ваш полный адрес.

•

Ваш номер телефона и код города.

•

Номера телефонов и адреса мастерских послереализационного

обслуживания приведены в гарантийном талоне. В противном

случае обратитесь в магазин, где вы приобрели стиральную

машину.

ПЕРЕВОЗКА И ПЕРЕМЕЩЕНИЕ

При перемещении машины никогда не подымайте ее за

рабочую поверхность.

1. Выньте вилку из сети.

2. Закройте кран подачи воды.

3. Отсоедините наливной и сливной шланги.

4. Слейте всю воду из машины и шлангов (см. разделы "Снятие

фильтра", " Слив оставшейся воды").

5. Установите транспортировочные винты (обязательная операция).

19

CONTENTS

BEFORE USING THE WASHING MACHINE

•

Safety warning

•

Recommendations

INSTALLATION

•

Removal of transportation screws

•

Adjustment of feet

•

Electrical connection

•

Water supply connection

•

Water drain connection

DESCRIPTION OF THE WASHING MACHINE

WASH PREPARATION

•

First wash cycle

•

Sorting your laundry

•

Placing clothes into the machine

•

Filling detergent in the machine

MAINTENANCE AND CLEANING

•

Water inlet filters

•

Pump filter

•

Detergent drawer

•

Siphon plug

•

The cabinet

•

The drum

•

Removing lime from your machine

TROUBLESHOOTING GUIDE

•

Automatic failure detection system

AFTER-SALES SERVICE

TRANSPORT / HANDLING

20

BEFORE USING THE WASHING MACHINE

SAFETY WARNINGS

•

Do not use a multiple socket or extension cord.

•

Do not insert a plug with a damaged or broken cord into the socket.

•

If the cord is damaged, it should be replaced by the manufacturer or

appointed service agent in order to avoid a hazard.

•

Never remove the plug from the socket by pulling from the cord

section. Remove the plug by holding the head of the plug.

•

Do not plug the power supply with wet hands.

•

Never touch the machine with wet hands or feet.

•

Never open the detergent drawer while the device is running.

•

Never force open the door of the machine while the machine is

running.

•

Since the machine can reach high temperatures while running, do not

touch the drain hose or water during draining.

•

In case of any failure, first unplug the device and close the water tap.

Do not attempt to repair. Please consult your nearest authorized

service provider.

•

Do not forget that the packing material of your machine may be

hazardous for children.

•

Do not let your children play with the washing machine.

•

Keep your pet away from your machine.

•

Your machine should only be used by adults in accordance with the

instructions written in this manual.

•

Your machine is designed for use in a domestic environment.

Warranty will be invalid if machine is used for commercial purposes.

•

Never use or store flammable materials nearby the appliance.

•

To clean the appliance, do not use inflammable cleaning agents.

RECOMMENDATIONS

•

Detergent or softener which is in contact with air for a long time will

dry and stick to your detergent drawer. To avoid this, put your

detergent and softener into the detergent drawer just before washing.

•

It is recommended that you use pre-wash programme for only very

dirty clothes.

•

Please do not exceed the maximum load capacity.

•

If you do not intend to use your machine for a long time, unplug it, close

the water supply and leave the door open in order to keep the inside of the

machine dry and to prevent build-up of unpleasant odours.

21

•

As a result of quality control procedures, a certain amount of water

may remain in your machine. This is not harmful for your machine.

INSTALLATION

You must pay close attention to the following issues before using your

washing machine.

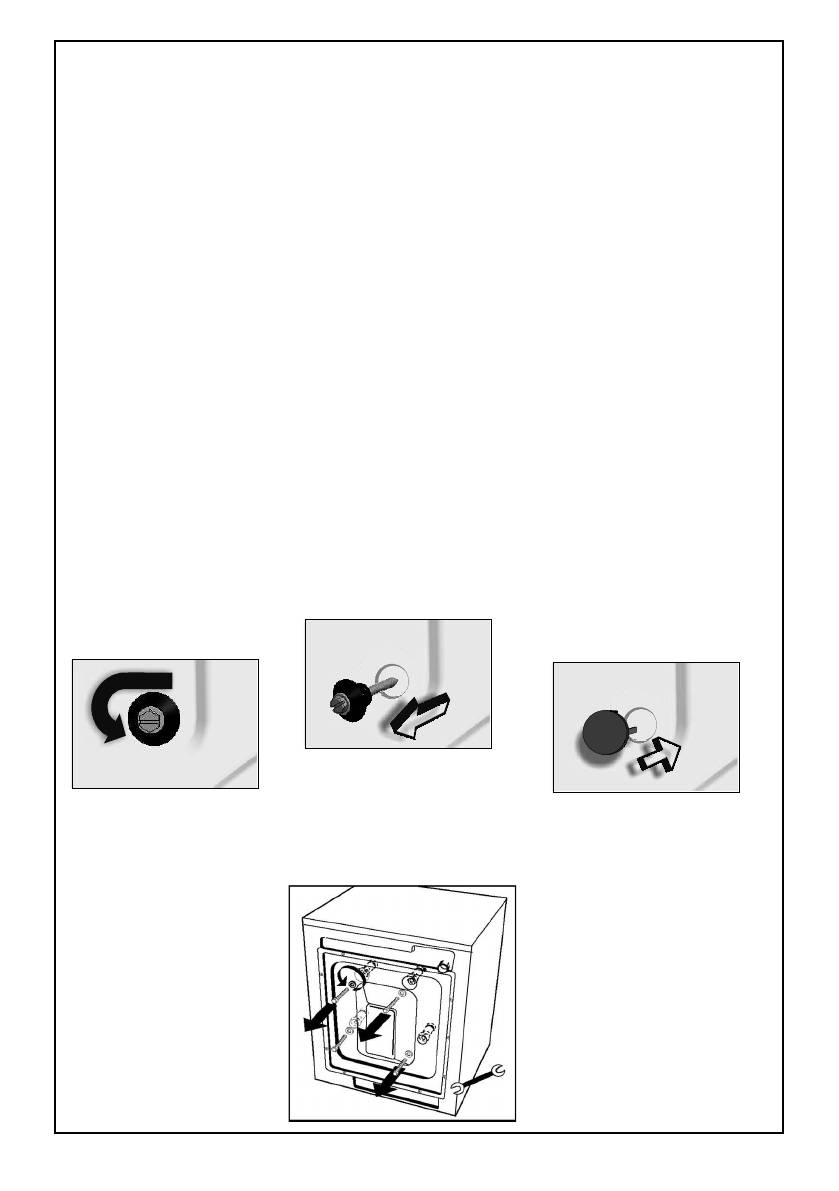

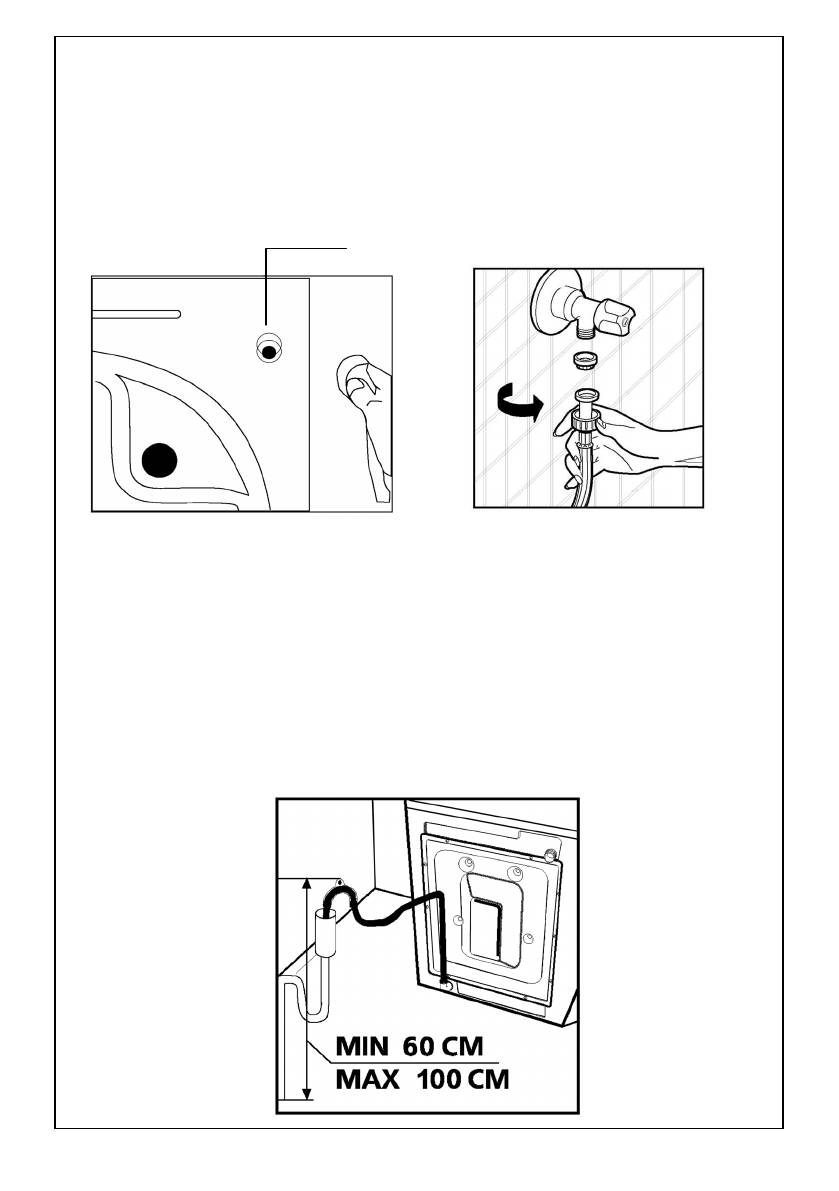

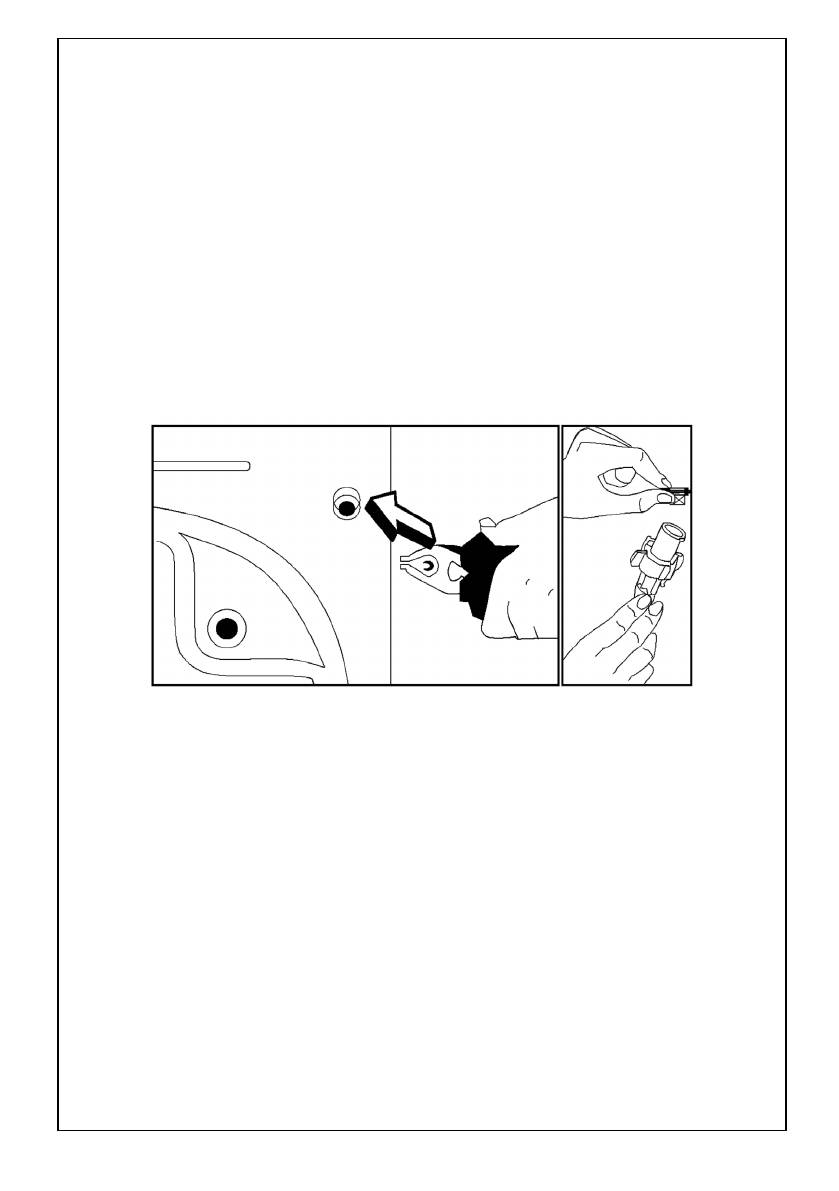

REMOVAL OF TRANSPORTATION SCREWS

•

Transportation screws, which are located at the rear side of the

machine, must be removed before running the machine.

•

Loosen the screws by rotating counter clockwise using a suitable

wrench. (DIAGRAM-1)

•

Remove the screws by pulling them.(DIAGRAM-2)

•

This will cause the plastic parts located in the interior part of your

machine to drop down under the appliance.

•

Lift the machine up slightly to pick up the plastic parts.

•

If all of the plastic parts from the screw groups have not dropped

down, open the door of your machine, move the drum until all plastic

parts drop down. Collect the parts that have fallen to the floor.

•

In the holes where the transport screws have been removed, insert

the plastic transport screw taps found in the accessories bag.

(DIAGRAM-3)

•

The transportation screws that have been removed from the machine

should be kept safe in the event of future transportation.

DIAGRAM-2

DIAGRAM-1 DIAGRAM-3

22

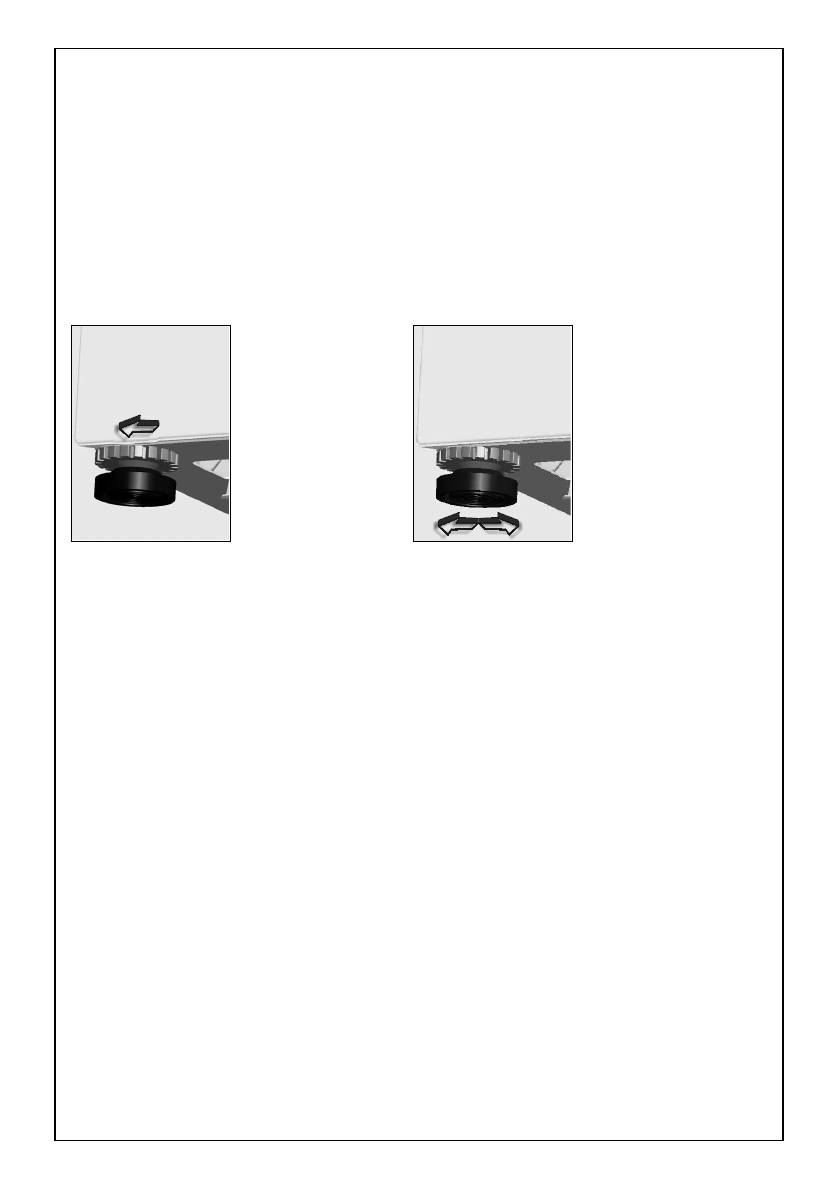

ADJUSTMENT OF FEET

•

Do not install your machine on rugs or similar surfaces.

•

For your machine to work silently and without vibrations, it should be

settled on a flat, non-slippery and tough surface.

•

You can adjust the balance of your machine from its feet.

•

First, loosen the plastic adjustment nut.

•

Adjust by rotating the feet upwards or downwards.

•

After balance has been achieved, tighten the plastic adjustment nut

again by rotating it upwards.

•

Never put cartons, wooden blocks or similar materials under the

machine to adjust the levelness of the machine with the ground.

ELECTRICAL CONNECTION

•

Your washing machine works with 220-240V and 50Hz.

•

A special grounded plug has been attached to the network cable of

your washing machine. This plug must be inserted to a grounded 10

amp socket. The currency rating of the attached electricity supply

should also be 10 amps. If you have no such sockets and fuses in

your house, the plug should be fitted by a qualified electrician.

•

Our company will not be held liable for any damage that may

occur as a result of usage without grounding.

WATER SUPPLY CONNECTION

•

Depending on the specifications of your machine, it may be provided

with a single water inlet (cold) or double water inlet (cold/hot). The

white headed hose is for the cold water inlet and red headed hose is

for the hot water inlet (for machines with hot & cold water inlet).

•

To prevent leakage from the connection joints, 1 (valid for cold water

inlet) or 2 (valid for machines with hot & cold water inlet) seals are

included in the hose packaging. Fit these seals at the end of water

inlet hoses on the tap side.

•

Connect the white headed hose to the water inlet valve with white

filter and connect the red headed hose to the water inlet valve with

red filter (latter in the case of machines with hot & cold water inlet).

Manually tighten the connection parts. Please call a qualified plumber

for safer connections.

23

•

Water pressure of 1-10 bars from your tap will enable your machine

to work more efficiently (1 bar pressure means water flow of more

than 8 litres per minute from a fully opened tap).

•

After connections are secure, check for non-leakage of the

connection joints by turning on your tap fully.

•

Be sure that water inlet hoses are not folded, broken or crushed.

•

Mount the water inlet hoses to a 3”/4, geared water tap.

Cold water inlet (White filter valve)

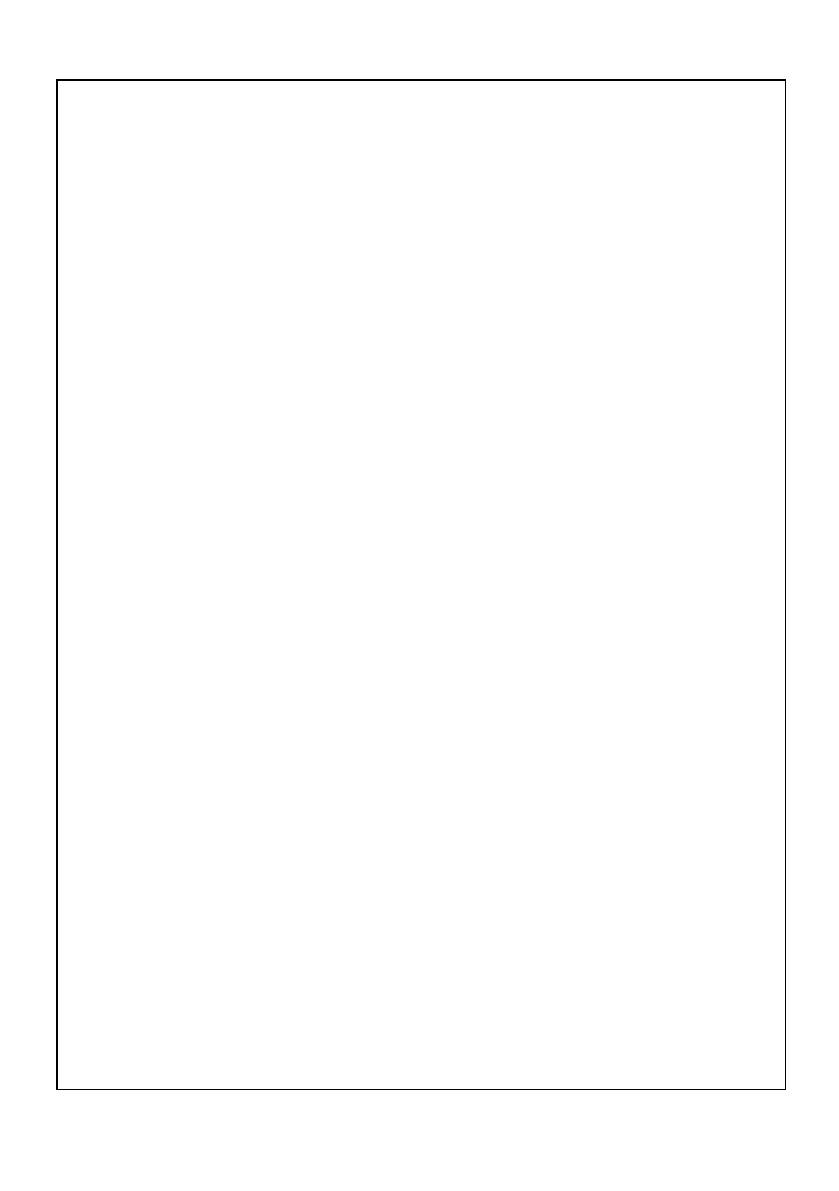

WATER DRAIN CONNECTION

•

Be sure that water inlet hoses are not folded, twisted, crushed or

elongated by stretching.

•

Water drain hose should be mounted at a height of minimum 60 cm,

maximum 100 cm from the ground.

•

The end of the water drain hose may be directly fitted to the dirty

water outlet hole or a special apparatus mounted on the outlet

bracket of the wash-stand.

•

Never attempt to extend the water drain hose by adding extra parts.

24

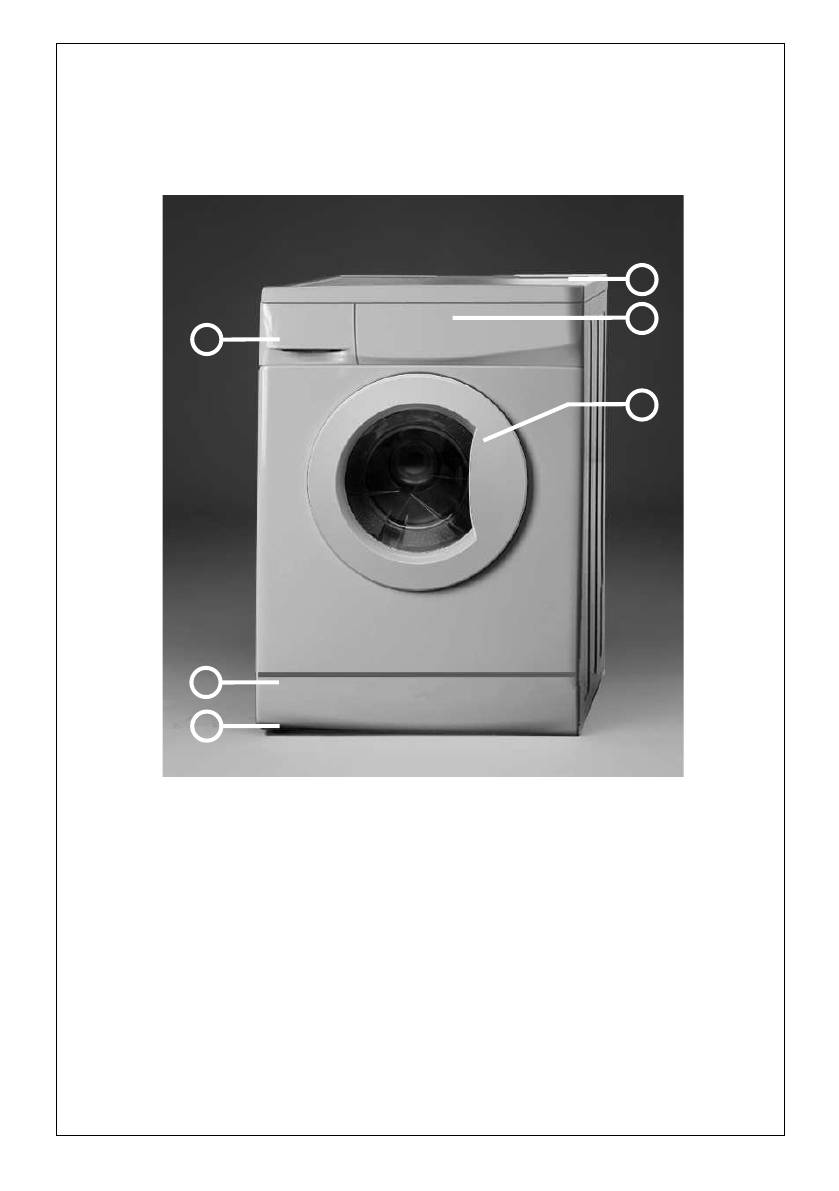

DESCRIPTION OF THE WASHING MACHINE

1

- Worktop

2

- Control panel

3

- Detergent dispenser

4

- Door

5

- Plinth covering pump access

6

- Adjustable feet

25

PREPARATION OF THE WASHING

•

Plug in the machine.

•

Open the water tap.

FIRST WASH CYCLE

There may be water left inside your machine after factory tests and trials. It is

recommended that the first wash cycle should be made without any laundry to

drain this water; pour half a measuring cup of normal all-purpose detergent

into compartment 2 and select cotton programme at 90°C.

SORTING YOUR LAUNDRY

•

Sort your clothes according to their types (cotton, synthetic, sensitive,

woollen, etc.), washing temperatures and level of dirtiness.

•

Never wash your white and coloured clothes together.

•

Since your new coloured clothes may shed dye on the first wash,

wash them separately.

•

Be careful that no metal pieces are found on or in the pockets of your

clothes, remove if necessary.

•

Zip and button your clothes.

•

Remove plastic or metal hooks from curtains and laces or place them

inside a washing bag and tie.

•

Turn textiles such as trousers, knitted fabrics, t-shirts and sweat shirts

inside out.

•

Wash small clothing items such as socks and handkerchiefs in a

washing bag.

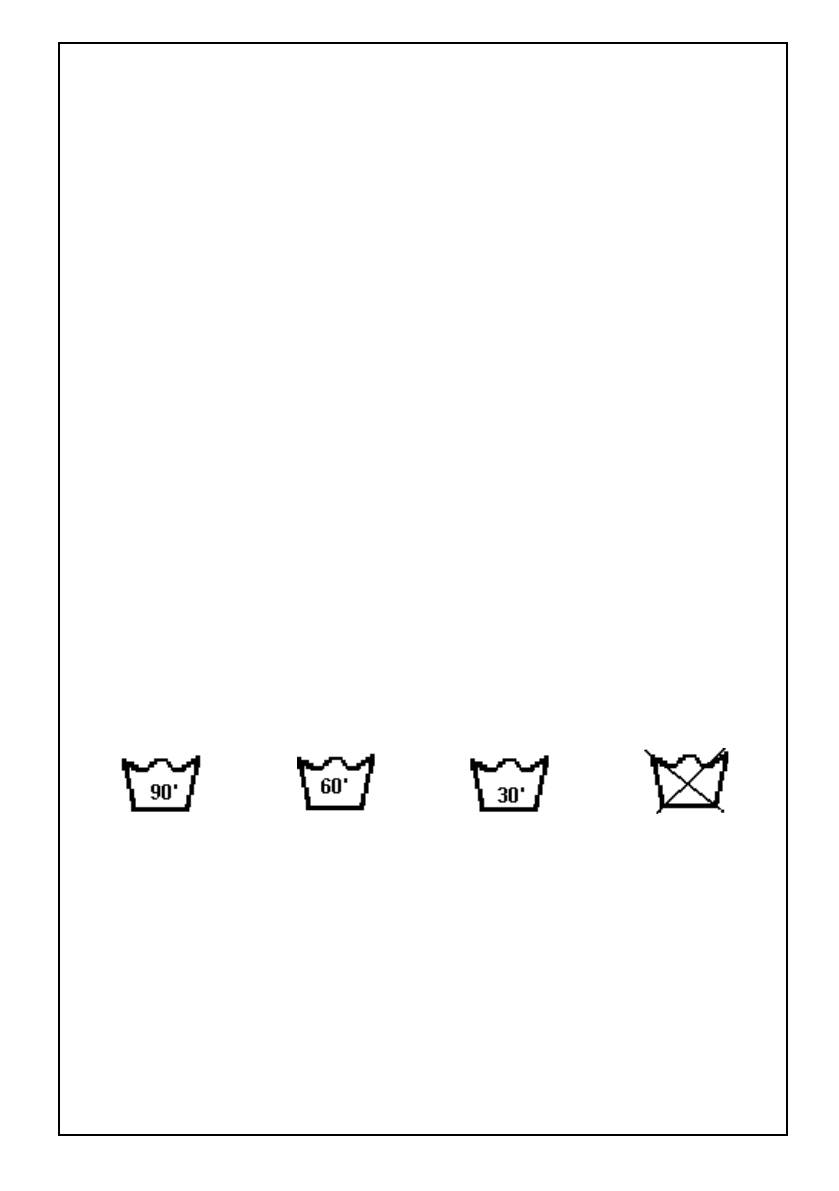

Wash up to 90

Û

C Wash up to 60 Û&:DVKXSWRÛ&1RWZDVKDEOHLQ

washing machine

PLACEMENT OF THE CLOTHES INTO THE MACHINE

•

Open the door of your machine.

•

Fill your clothes in your machine in an evenly-spread manner.

•

Place each clothing item into the machine separately.

•

When you shut the door of your machine, be careful that no clothing

item is jammed between the cover and the gasket.

•

Shut the door of your machine tightly otherwise your machine will not

begin the washing process.

26

FILLING DETERGENT IN THE MACHINE

The

quantity

of the detergent that you will fill in your machine depends on the

following criteria:

•

Your detergent consumption will change according to the level of

dirtiness of your clothes. For your slightly dirty clothes, do not pre-

wash and put a small amount of detergent in the compartment no.2

of the detergent drawer.

•

For your excessively dirty clothes, select a programme with pre-wash,

fill ¼ portion of the de tergent you will put in compartment 1 in the

detergent drawer and the remaining portion in compartment 2.

•

In your machine, use detergents developed especially for automatic

washing machines. The quantities that will be used for your clothes

are written on the packaging of the detergents.

•

As the hardness of your water increases, the amount of detergent to

be consumed will also increase.

•

As the amount of your clothes increases, the amount of detergent to

be consumed will also increase.

•

Pour your softener into the softener compartment of your detergent

drawer. Do not exceed the MAX level. Otherwise, the softener will

diffuse into the washing water via the siphon.

•

Concentrated softeners should be diluted with water before pouring

into the drawer. This is because concentrated softener obstructs the

siphon and prevents the flow of the softener.

•

You can use fluid detergents in all programmes without pre-

washing. For this, add the fluid detergent separator to the second

compartment of the detergent drawer and regulate the amount of

fluid detergent according to the levels on this plate.

WARNING!

In the event that power is cut off at any stage of the wash programmes and

then later reconnected, your machine will continue the programme from the

point it was interrupted at. Such a situation will not cause any harm to your

machine.

In the event that power is cut off during the wash operation, the door lock

mechanism will be released after two minutes. If there is water in the machine

do not open the door, in order to prevent water from pouring out. If you wish

to take out your laundry you can do so by draining the water inside the

machine.

27

MAINTENANCE AND CLEANING

•

Unplug your machine.

•

Close the water tap.

WATER INLET FILTERS

On the tap part of your machine’s water inlet hose and at the extremities of

the water inlet valves, there are filters to prevent entrance of dirt and foreign

bodies into the water to the machine. If the machine is unable to receive

sufficient water although your water tap is opened, these filters should be

cleaned.

•

Remove the water inlet hose.

•

Remove the filters found on the water inlet valves by using tweezers

or pliers and wash thoroughly with a brush.

•

Clean the filters of the water inlet hoses located on the tap side by

removing manually, together with the seal.

•

After cleaning the filters, they can be refitted by reversing the removal procedure.

PUMP FILTER

The pump filter system prolongs the life of your pump, which is used to drain

the dirty water. It prevents lint from entering the pump. Cleaning your pump

filter every 2-3 months is recommended. To clean your pump filter:

•

Remove the kickplate by pushing upwards with your hand from the

lower claws and pulling towards yourself.

•

Before opening the filter cover, place a cup in front of the filter cover

to prevent flow of the remaining water in the machine.

•

Loosen the filter cover by turning counter clockwise and drain the

water.

•

Remove the foreign bodies from the filter.

•

Check for the rotation of the pump manually.

•

After you have cleaned the pump, refit the filter cover by rotating

clockwise.

•

Refit the kickplate by holding from the claws and pushing it.

•

Do not forget that if the filter cover is not properly refitted, it will leak

water.

28

WARNING!

Danger of scalding!

Since the water inside the pump maybe hot, wait for it to cool.

DETERGENT DRAWER

Detergents may cause residue build-up in the detergent drawer and its slot

over time. Take out the detergent drawer periodically to clean away the

accumulated residue. To remove the drawer, proceed as follows:

•

Pull the drawer to its end (DIAGRAM-1).

•

Keep pulling by pressing on the siphon lid inside the drawer which is

fully pulled to its end, and remove the drawer from its place

(DIAGRAM-2).

•

Wash it by rinsing with water and cleaning with an old toothbrush.

•

Collect the residue inside the drawer slot without letting it drop into

the machine.

•

After thoroughly drying the drawer, refit by reversing the removal

procedure.

DIAGRAM-1 DIAGRAM-2

29

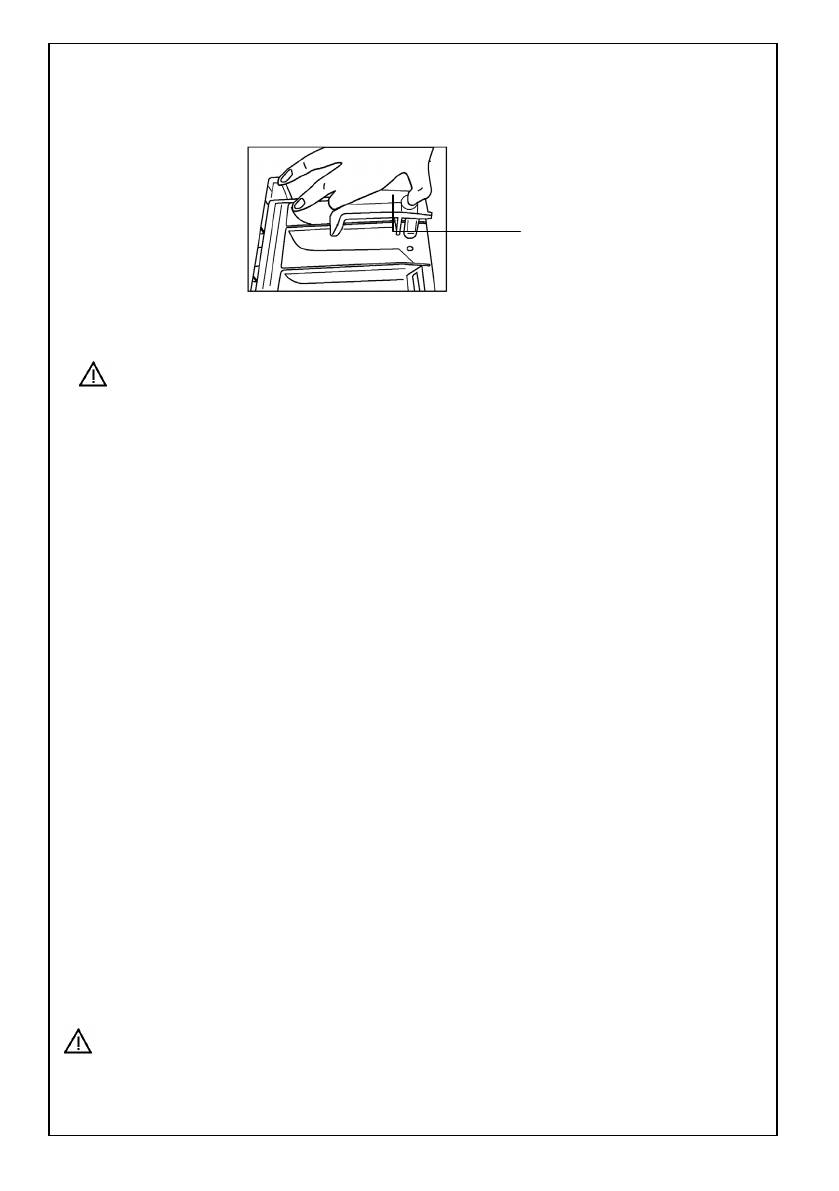

SIPHON PLUG

Pull out the detergent drawer. Remove the siphon plug and thoroughly clean

any softener residue. Refit the cleaned siphon plug back in its place. Check

that it is fitted properly.

Siphon plug

THE CABINET

To clean the outside of the appliance, use a neutral detergent and a damp

cloth. Please be careful not to use material that could damage the exterior

surface of your machine.

WARNING!

If the machine is installed in a location where the ambient temperature can fall

below 0 Û&SURFHHGDVIROORZVZKHQQRWLQXVH

•

Plug in the machine.

•

Close the water tap and pull out the water inlet hose or hoses from

the tap.

•

Place the ends of the water drain and water inlet hoses in a cup on

the ground.

•

Adjust the programme knob to “Draining” programme.

•

The programme ready light will be on.

•

Run the programme by pressing the start/pause button.

•

Unplug your machine when the programme is over (programme end

light is on).

When this process is completed, the remaining water inside the machine will

be drained and thus formation of ice in the machine will be prevented. When

you operate your machine again, be sure that the ambient temperature is

above 0 Û&

THE DRUM

Do not leave metal parts such as needles, staples or coins inside your

machine. These pieces cause rust stains to form inside the drum. To

eliminate these rust stains, use a non-chlorine cleaning agent and follow the

warnings of the cleaning agent producer. Never use dish-washing scourers or

similar abrasive objects to clean rust stains.

REMOVE OF LIME FROM YOUR MACHINE

If you regulate the amount of detergent used in your machine properly, there

will be no need for lime removal. However, if you desire to apply the removal

procedure, use lime protectors readily available on the market and pay

attention to their warnings.

WARNING!

The lime-eliminating substances contain acids and this may cause colour

modifications in your clothes along with an adverse effect on your machine.

30

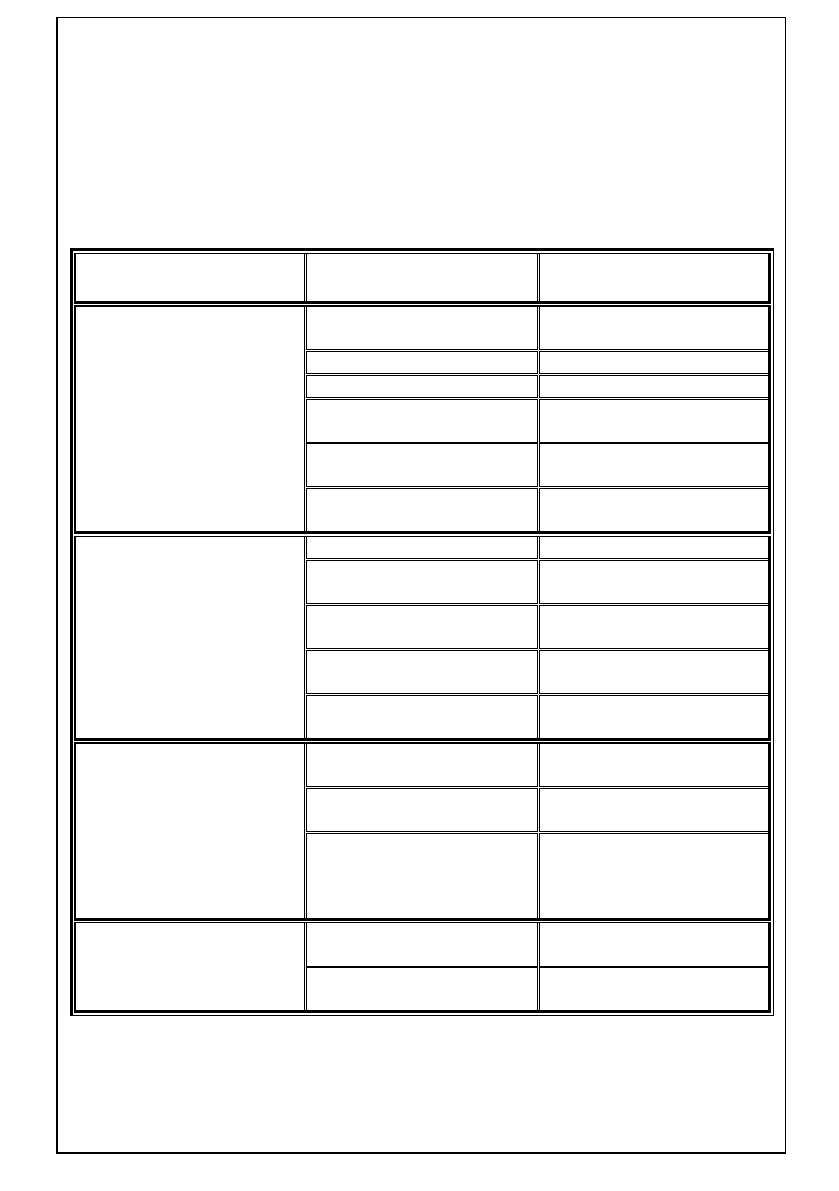

TROUBLESHOOTING GUIDE

All repairing which must be done on the machine should be performed by

authorized service personnel. When your machine requires repairs or you are

unable to eliminate the failure with the help of the information given below:

•

Unplug the machine.

•

Close the water tap.

•

Consult your nearest authorized service provider.

METHODS OF

FAILURE PROBABLE CAUSE

ELIMINATION

Insert the plug into the

It is unplugged.

socket.

Your fuse is defective. Change your fuse.

The electric power is off. Check the electric power.

Your machine does not

Start/pause button has

Press the start/pause

operate.

not been pressed.

button.

The programme knob is

Turn the programme knob

in O (off) mode.

to the desired mode.

The door is not shut

Shut the door properly.

properly.

You should hear it click.

Water tap is closed. Open water tap.

The water inlet hose may

Check the water inlet

be bent.

hose.

The water inlet hose is

Clean the filters of water

Your machine does not

obstructed.

inlet hose. (

*

)

receive water.

The valve inlet filter is

Clean the valve inlet

obstructed.

filters. (

*

)

The door is not shut

Shut the door properly.

properly.

You should hear it click.

The drain hose is

Check the drain hose.

obstructed or bent.

The pump filter is

Clean the pump filter. (

*

)

Your machine is not

obstructed.

draining water.

The clothes are not

Spread the clothes inside

placed inside the machine

the machine in an orderly

in an evenly-balanced

and evenly-balanced

manner.

manner.

The feet of your machine

Adjust the feet. (

**

)

are not adjusted.

Your machine is vibrating.

Transportation screws are

Remove transportation

not removed.

screws. (

**

)

(

*

) See the section concerning maintenance and cleaning of your

machine.

(

**

) See the section concerning installation of your machine.

31

METHODS OF

FAILURE PROBABLE CAUSE

ELIMINATION

There is a small

It does not prevent

amount of clothes in

operation of the

the device.

machine.

Do not exceed the

Excessive amount of

recommended quantity

clothes are filled in the

Your machine is

of clothes and spread

machine or the clothes

vibrating.

your clothes in the

are not placed in a

machine in a well-

well-balanced manner.

balanced manner.

Prevent your

Your machine touches

machine’s leaning on a

a ripid object.

tough place .

Press the start/pause

button.In order to stop

the foam,dilute one

table-spoon of softener

in half liter of water and

pour it in the detergent

Too much detergent

drawer.Press the

has been used.

start/pause button after

Excessive foam in the

5-10 minutes. Arrange

detergent drawer.

the amount of the

detergent properly in

the next washing

process.

Use only the

Wrong detergent has

detergents produced

been used.

for full automatic

machines.

Your laundry too dirty

Select a suitable

for the program you

program. (see Table-1)

have selected.

The washing result is

bad.

The amount of

Use more detergent

detergent used is not

according to the

sufficient.

detergent.

32

METHODS OF

FAILURE PROBABLE CAUSE

ELIMINATION

Load clothes into your

Machine load exceeds

machine so as to avoid

maximum capacity.

exceeding its

maximum capacity.

Regulate the amount of

detergent used

Washing quality is

Your water may be

according to the

poor.

hard.

detergent producer's

guidelines.

Distribution of the

Spread the clothes

clothes in your

inside the machine in

machine is not evenly-

an orderly and evenly-

balanced.

balanced manner .

The end of the water

The water is drained

Place the water drain

drain hose is

from the machine as

hose at an appropriate

positioned too low in

soon as it is filled.

height.(**)

relation to the machine.

No failure. The water is

No water is seen in the

in the lower part of the

-

drum during washing.

drum.

By calibrating your

machine for “Rinsing”

Undissolved fragments

programme, run an

There is detergent

of certain detergents

additional rinse or

residue on the clothes.

may stick to your

eliminate stains after

clothes as white stains.

drying with the help of

a brush.

Use the maximum

detergent amount

These stains may be

There are grey stains

recommended by the

caused by oil, cream or

on the clothes.

detergent producer

ointment.

during the next

washing operation.

(**) See the section concerning installation of your machine.

33

METHODS OF

FAILURE PROBABLE CAUSE

ELIMINATION

The unbalanced load

control system will try

to distribute your

clothes in a

homogenous manner.

No failure. The

The spinning process

After your clothes are

unbalanced load

is not done or starts

distributed, the

control may operate in

with delay.

spinning process will

that way.

begin. For the next

wash, place your

clothes into the

machine in an evenly-

balanced manner.

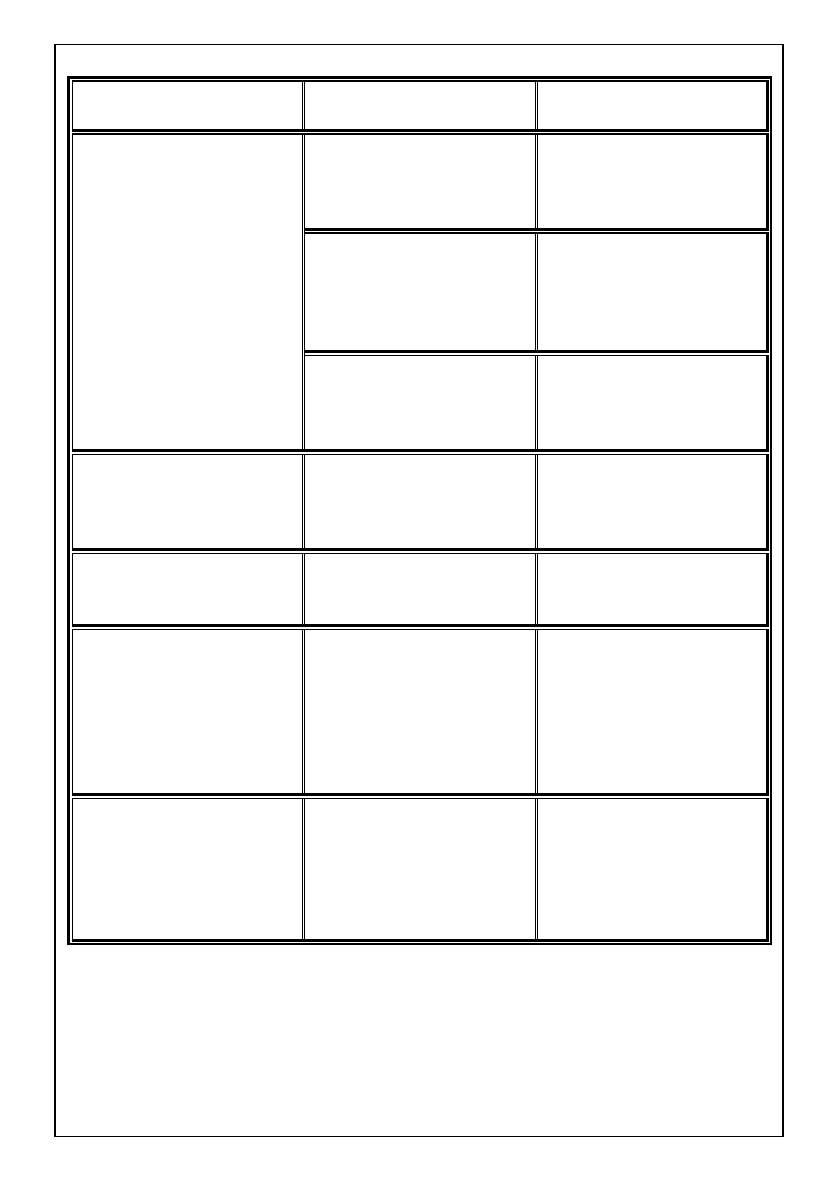

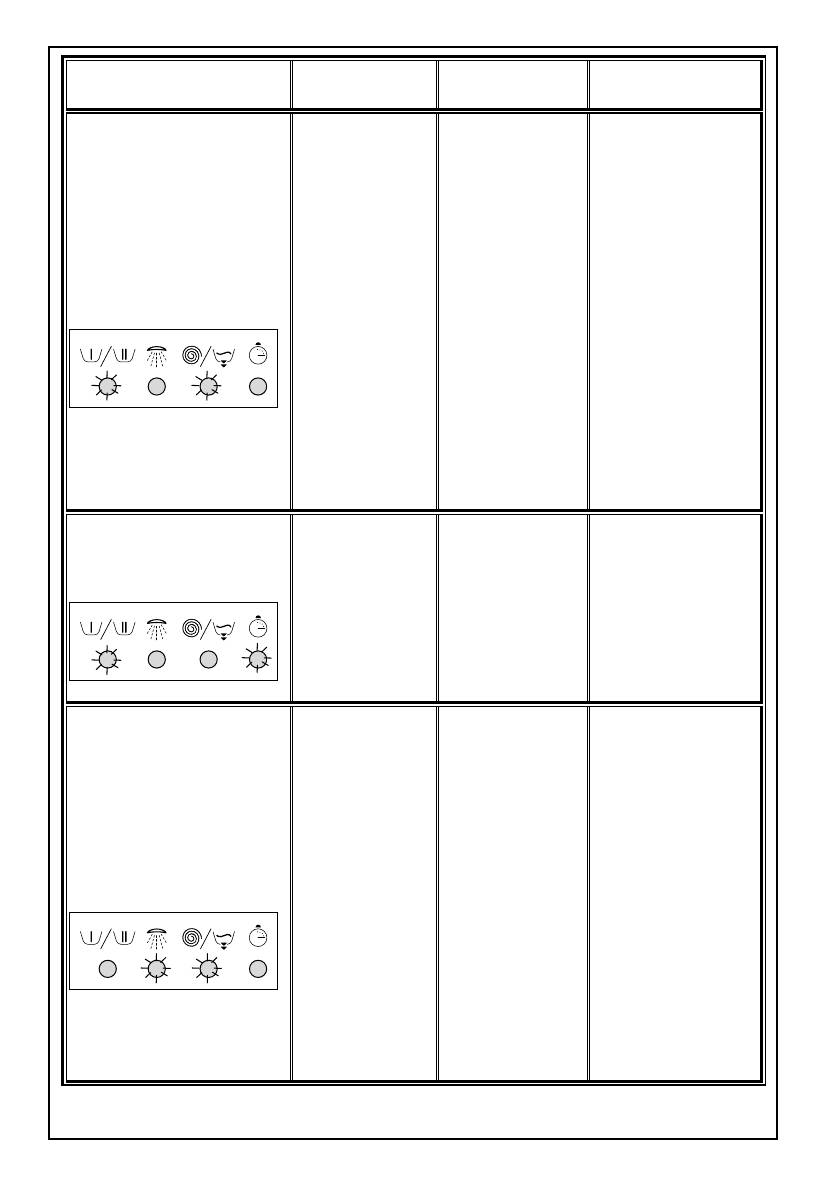

AUTOMATIC FAILURE DETECTION SYSTEM

Your machine is equipped with systems which will both take the necessary

precautions and warn you in case of any failure by continually monitoring the

washing processes.

FAILURE

PROBABLE

CORRECTIVE

FAILURE CODE

INDICATOR

FAILURE

MEASURES

Shut the door

properly so that

you hear it click.

If the problem

persists, turn off

The door is

Lights 1 and

the machine,

E01

not shut

2 blink.

unplug it and

properly.

consult your

nearest

authorized

service provider

immediately.

34

FAILURE

PROBABLE

CORRECTIVE

FAILURE CODE

INDICATOR

FAILURE

MEASURES

Turn on the tap

to the end.

Water supply

may be cut,

The water

check it. If the

level in your

problem still

machine is

exists, your

below heater.

machine will

Lights 1 and

E02

The pressure

automatically

3 blink.

of your water

stop after a

supply may

while. Unplug

be low or

your machine,

unstable.

turn off the tap

and consult your

nearest

authorized

service provider.

Clean the pump

filter. If the

E03

The pump

problem

Lights 1 and

has failed or

persists, consult

4 blink.

the pump filter

your nearest

is obstructed.

authorized

service

provider.(*)

Your machine

will automatically

drain the water.

After your

machine has

completed the

There is an

draining

excessive

Lights 2 and

process, shut

E04

amount of

3 blink.

down your

water in your

machine and

machine.

unplug. Close

the tap and

consult your

nearest

authorized

service provider.

(

*

)

See the section re

g

ardin

g

maintenance and cleanin

g

of

y

our machine.

35

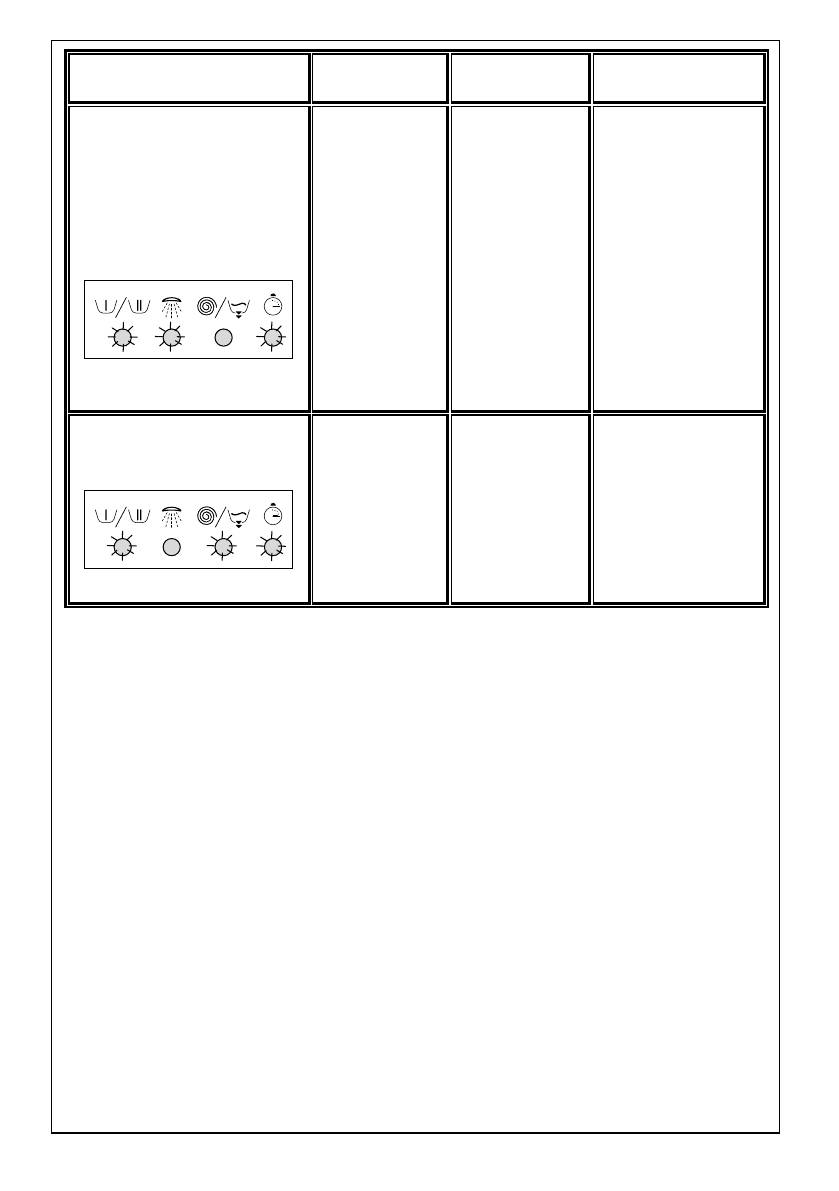

FAILURE

PROBABLE

CORRECTIVE

FAILURE CODE

INDICATOR

FAILURE

MEASURES

Shut down and

The heater

unplug your

E05

of your

machine. Turn

Lights 2 and

machine or

off your tap and

4 blink.

the heat

consult your

sensor has

nearest

failed.

authorized

service provider.

Shut down and

unplug your

E06

machine. Turn

Lights 3 and

The motor

off the tap and

4 blink.

has failed.

consult your

nearest

authorized

service provider.

Shut down and

unplug your

E07

machine. Turn

Electronic

Lights 1, 2

off the tap and

card has

and 3 blink.

consult your

failed.

nearest

authorized

service provider.

Shut down and

unplug your

E08

machine. Turn

Lights 2, 3

The motor

off the tap and

and 4 blink.

has failed.

consult your

nearest

authorized

service provider.

36

FAILURE

PROBABLE

CORRECTIVE

FAILURE CODE

INDICATOR

FAILURE

MEASURES

If the network

voltage is lower

than 150V or

higher than

260V, your

The network

machine will

Lights 1, 2

voltage is too

E09

automatically

and 4 blink.

high or too

stop. When the

low.

network voltage

is recovered,

your machine

will continue its

operation.

Shut down and

unplug your

E10

machine. Turn

Lights 1, 3

Communication

off the tap and

and 4 blink.

error

.

consult your

nearest

authorized

service provider.

37

AFTER-SALES SERVICE

Before contacting After-Sales Service:

1. Try to remedy the problem yourself (see “Troubleshooting Guide”).

2. Restart the programme to check whether the problem has solved itself.

3. If the washing machine continues to function incorrectly, call the After-

Sales Service.

Specify:

•

The nature of the problem.

•

The washing machine model.

•

The service code (number after the word SERVICE).

The After-Sales Service sticker can be found inside the door.

•

Your full address.

•

Your telephone number and area code.

•

After-Sales Service phone numbers and addresses are given on the

guarantee card. Alternatively, consult the dealer where you purchased

the appliance.

TRANSPORT / HANDLING

Never lift the appliance by the worktop when transporting.

1. Pull out the mains plug.

2. Turn off the tap.

3. Disconnect the inlet and drain hoses.

4. Drain all water from the hoses and from the appliance (see “Removing

the Filter”, “Draining Residual Water”).

5. Fit the transportation screws (obligatory).

38