Festool OF 2200 EB: WARNING

WARNING: Festool OF 2200 EB

15

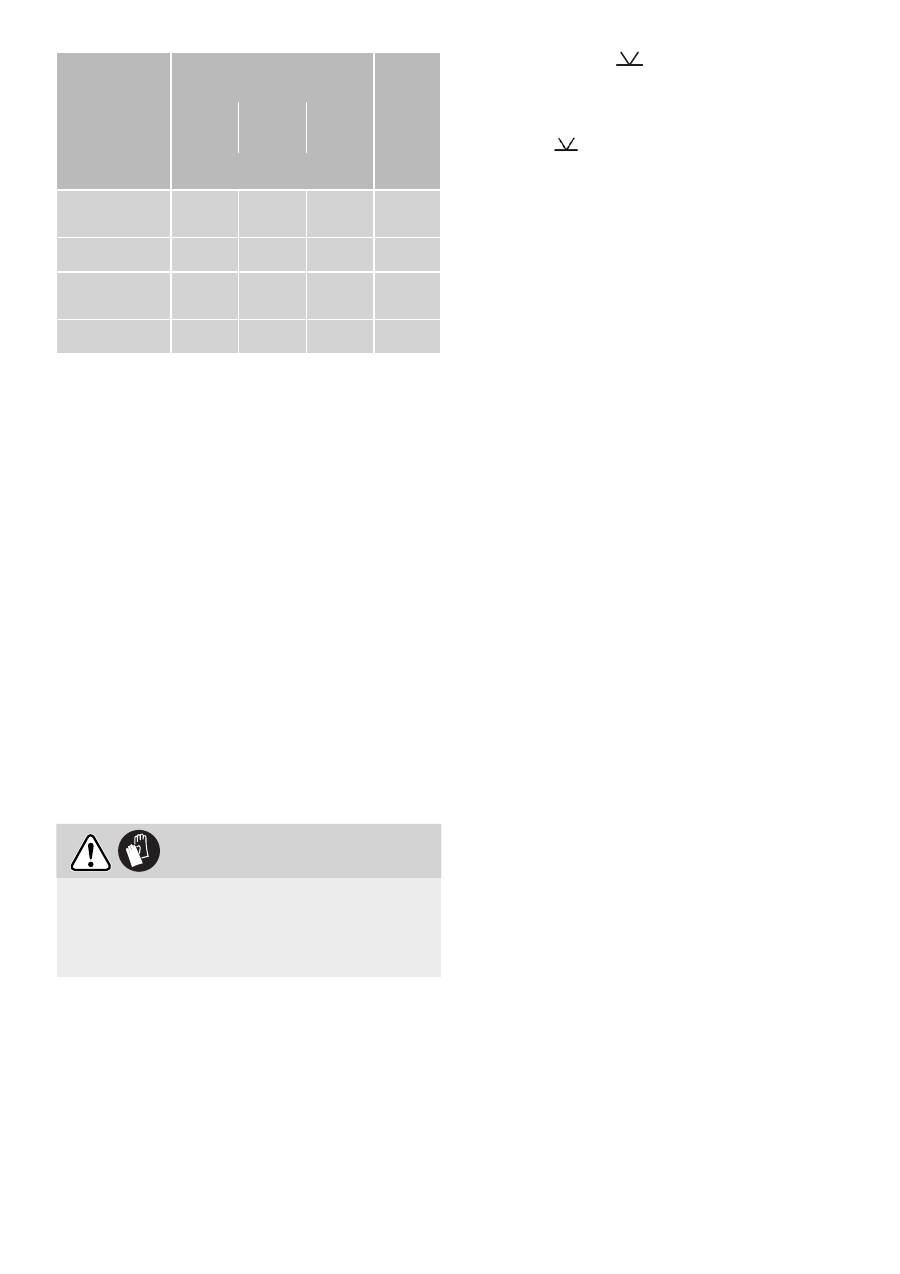

Routing tool diameter

[mm]

Rec

ommended

cutting mat

erial

Material

10 -30

30 - 50 50 - 89

Adjusting wheel setting

Chipboard,

coated

6 - 5

6 - 4

4 - 2

HW

Plastic

6 - 4

6 - 3

3 - 1

HW

Aluminium

3 - 1

3 - 1

2 - 1

HSS

(HW)

Plasterboard

2 - 1

1

1

HW

Constant speed

The preselected motor speed remains constant

through electronic control. This ensures a uni-

form cutting speed even when under strain.

Temperature cut-out

To protect against overheating (burning out of

motor), an electronic temperature monitoring

system has been installed. Prior to reaching a

critical motor temperature, the safety electronics

switches off the motor. After a cooling time of ap-

prox. 3-5 minutes, the machine can be operated

again at full load. The machine requires less time

to cool down if it is running, i.e. in neutral.

Brake

The OF 2200 EB has an electronic brake, which

stops the spindle within a few seconds of the ma-

chine switching off.

7.2 Changing tools

WARNING

Risk of accident - the routing tool may be hot

after use and has sharp edges.

Allow the tool to cool before changing.

Wear protective gloves when changing tools.

NOTE

Switch off the machine before pressing the rocker

for the spindle lock [3.1].

We recommend turning the machine on its side to

change the tool.

a) Inserting the tool

Insert the routing tool [3.4/3a.1]] into the open

clamping collet as far as possible, but at least

up to the mark

on the shank [3a.2]. If the

collet is not visible because it is blocked by the

union nut [3a.3], the milling tool must be insert-

ed into the collet at least far enough that the

marker

no longer overlaps with the union

nut.

Press the rocker [3.1] for the spindle lock to

side B.

Tighten the locking nut [3.3] using an open-end

wrench (size 24).

The rocker only blocks the motor spindle in

one direction of rotation at any one time.

Therefore when the locking nut is undone or

tightened, the wrench does not need to be

offset but can be moved back and forth like a

ratchet.

b) Removing the tool

Slide the chip guard [3.2] upwards until it en-

gages, if necessary.

Press the rocker [3.1] for the spindle lock to

side A.

Unscrew the locking nut [3.3] using an open-

end wrench (size 24) until you are able to re-

move the tool.

7.3 Changing the clamping collet

If necessary, slide the chip guard [4.2] upwards

until it engages.

Press the rocker [4.1] for the spindle lock to

side A.

Unscrew the locking nut [4.3] completely.

Remove the locking nut from the spindle to-

gether with the clamping collet [4.4]. Do not

separate the locking nut and clamping collet as

these form a single component.

Only insert a new clamping collet in the spin-

dle when the nut is attached and engaged, then

tighten the nut slightly. Do not tighten the lock-

ing nut until a router bit is inserted.

7.4 Adjusting the routing depth

The depth is adjusted in two steps:

a) Setting the zero point

Place the router on an even surface (reference

surface).

Open the clamping lever [5.2].

Unscrew the rotary knob [5.1].

Push the machine downwards until the router

bit rests on the surface (reference surface).

Оглавление

- VORSICHT

- WARNUNG

-

- VORSICHT

-

- WARNUNG

- CAUTION

- WARNING

-

- WARNING

-

- WARNING

- ATTENTION

- AVERTISSEMENT

-

- ATTENTION

-

- AVERTISSEMENT

- ATENCIÓN

- AVISO

-

- ATENCIÓN

-

- AVISO

- PRUDENZA

- AVVISO

-

- VOORZICHTIG

- WAARSCHUWING

-

- WAARSCHUWING

- VARNING

- VARNING!

-

- VARNING!

-

- VARO

- VAROITUS

-

- VAROITUS

-

- FORSIGTIG

- ADVARSEL

-

- ADVARSEL

-

- FORSIKTIG

- ADVARSEL!

-

- ADVARSEL!

-

- CUIDADO

- ADVERTÊNCIA

-

- ADVERTÊNCIA

- ВНИМАНИЕ

- ПРЕДУПРЕЖДЕНИЕ

-

- POZOR

- VÝSTRAHA

-

- VÝSTRAHA

-

- OSTROŻNIE

- OSTRZEŻENIE

-