Hotpoint-Ariston CAWD 129 EU: Installation

Installation: Hotpoint-Ariston CAWD 129 EU

16

GB

Installation

!

This instruction manual should be kept in a safe

place for future reference. If the washer dryer is

sold, transferred or moved, make sure that the

instruction manual remains with the machine so

that the new owner is able to familiarise himself/

herself with its operation and features.

!

Read these instructions carefully: they contain

vital information relating to the safe installation

and operation of the appliance.

Unpacking and levelling

Unpacking

1. Remove the washer dryer from its packaging.

2. Make sure that the washer dryer has not been

damaged during the transportation process. If it

has been damaged, contact the retailer and do not

proceed any further with the installation process.

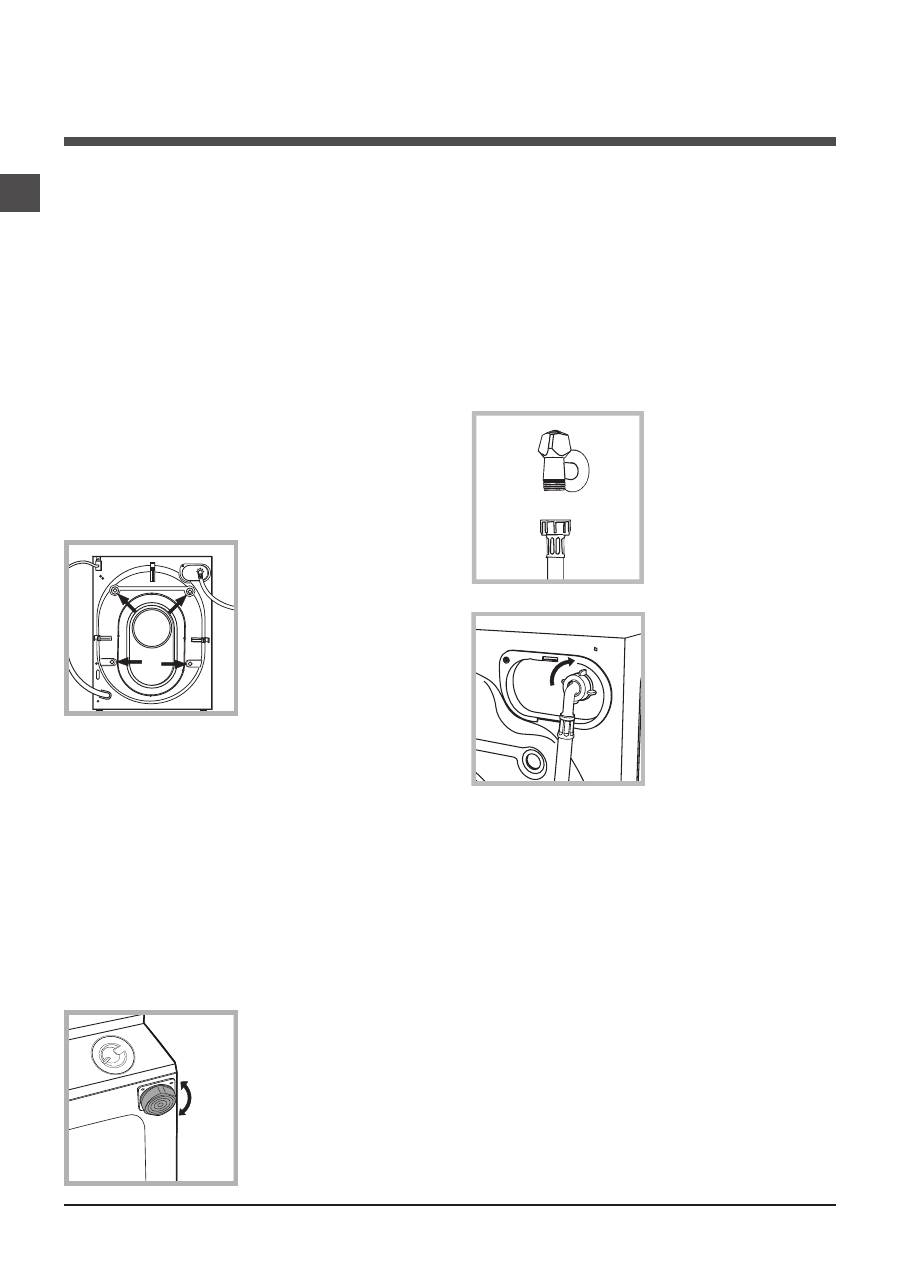

3. Remove the

4

pro-

tective screws (used

during transportation)

and the rubber washer

with the corresponding

spacer, located on the

rear part of the applian-

ce (

see figure

).

4. Close off the holes using the plastic plugs

provided.

5. Keep all the parts in a safe place: you will

need them again if the washer dryer needs to

be moved to another location.

!

Packaging materials should not be used as

toys for children.

Levelling

1. Install the washer dryer on a flat sturdy floor,

without resting it up against walls, furniture ca-

binets or anything else.

2. If the floor is not per-

fectly level, compensa-

te for any unevenness

by tightening or loo-

sening the adjustable

front feet (

see figure

);

the angle of inclination,

measured in relation to

the worktop, must not

exceed 2°.

Levelling the machine correctly will provide it with

stability, help to avoid vibrations and excessive

noise and prevent it from shifting while it is ope-

rating. If it is placed on carpet or a rug, adjust

the feet in such a way as to allow a sufficient

ventilation space underneath the washer dryer.

Connecting the electricity and wa-

ter supplies

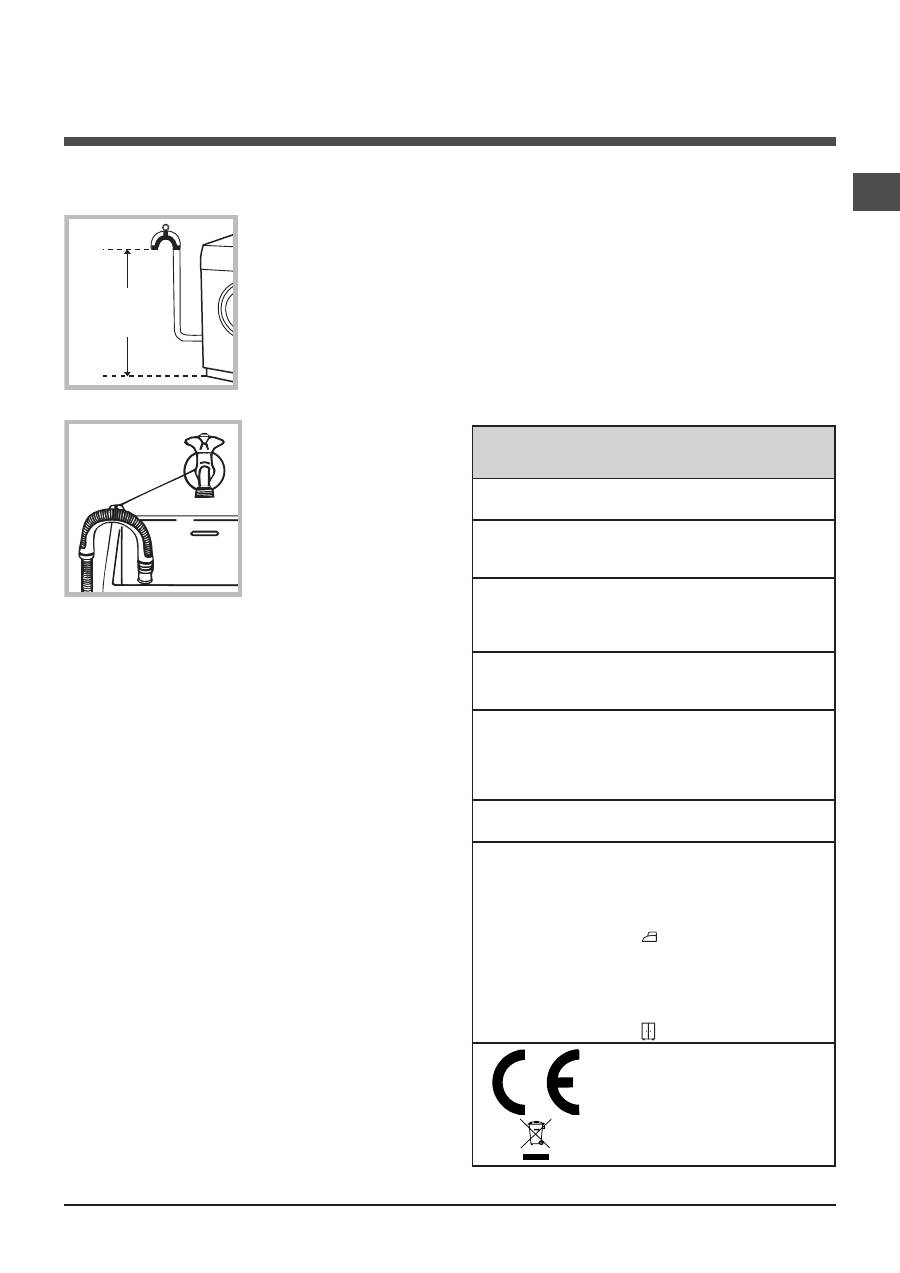

Connecting the water inlet hose

1. Connect the supply

pipe by screwing it to

a cold water tab using

a ¾ gas threaded con-

nection (see figure).

Before performing the

connection, allow the

water to run freely until

it is perfectly clear.

2. Connect the inlet

hose to the washer dr-

yer by screwing it onto

the corresponding wa-

ter inlet of the applian-

ce, which is situated on

the top right-hand side

of the rear part of the

appliance

(see figure)

.

3. Make sure that the hose is not folded over

or bent.

!

The water pressure at the tap must fall within

the values indicated in the Technical details table

(see next page).

!

If the inlet hose is not long enough, contact a

specialised shop or an authorised technician.

!

Never use second-hand hoses.

!

Use the ones supplied with the machine.

GB

17

65 - 100 cm

Connecting the drain hose

Connect the drain

hose, without bending

it, to a drainage duct or

a wall drain located at a

height between 65 and

100 cm from the floor;

alternatively, rest it on

the side of a washba-

sin or bathtub, faste-

ning the duct supplied

to the tap (

see figure

).

The free end of the

hose should not be

underwater.

!

We advise against the use of hose extensions;

if it is absolutely necessary, the extension must

have the same diameter as the original hose and

must not exceed 150 cm in length.

Electrical connections

Before plugging the appliance into the electricity

socket, make sure that:

• the socket is earthed and complies with all

applicable laws;

• the socket is able to withstand the maximum

power load of the appliance as indicated in the

Technical data table

(see opposite);

• the power supply voltage falls within the values

indicated in the Technical data table

(see opposite);

• the socket is compatible with the plug of the

washer dryer. If this is not the case, replace the

socket or the plug.

!

The washer dryer must not be installed ou-

tdoors, even in covered areas. It is extremely

dangerous to leave the appliance exposed to

rain, storms and other weather conditions.

!

When the washer dryer has been installed, the

electricity socket must be within easy reach.

!

Do not use extension cords or multiple sockets.

!

The cable should not be bent or compressed.

!

The power supply cable must only be replaced

by authorised technicians.

Warning! The company shall not be held responsible

in the event that these regulations are not respected.

The first wash cycle

Once the appliance has been installed, and before

you use it for the first time, run a wash cycle with

detergent and no laundry, using the wash cycle 1.

Technical data

Model

CAWD 129

Dimensions

width 59,5 cm

height 81,5 cm

depth 54,5 cm

Capacity

from 1 to 7 kg for the wash

programme

from 1 to 5 kg for the drying

programme

Electrical

connections

please refer to the technical

data plate fixed to the ma-

chine

Water con-

nections

maximum pressure 1 MPa

(10 bar)

minimum pressure 0.05

MPa (0.5 bar)

drum capacity 52 litres

Spin speed

up to 1200 rotations per

minute

Energy ra-

ted

programmes

according to

regulation

EN 50229

Wash:

programme 6; tem-

perature 60°C;

using a load of 7 kg.

Drying

: the smaller load

must be dried by selecting

the “ ” dryness level. The

load must consist of 2 she-

ets, 1 pillowcase and 1 hand

towel;

the remainder of the load

must be dried by selecting

the “ ” dryness level.

This appliance conforms to

the following EC Directives:

- 2004/108/EC (Electromagne-

tic Compatibility)

- 2006/95/EC (Low Voltage)

- 2002/96/EC

18

GB

A

B

C

D

E

Tur se

ite

Instructions for the fitter

Mounting the wooden panel onto the door

and inserting the machine into cabinets:

In the case where the machine must be shipped

for final installation after the wooden panel has

been mounted, we suggest leaving it in its ori-

ginal packaging. The packaging was designed

to make it possible to mount the wooden panel

onto the machine without removing it completely

(see figures below).

The wooden panel that covers the face of

the machine must not be less than

18 mm

in

thickness and can be hinged on either the right

or left. For the sake of practicality when using

the machine, we recommend that the panel be

hinged on the same side as the door for the

machine itself - the left.

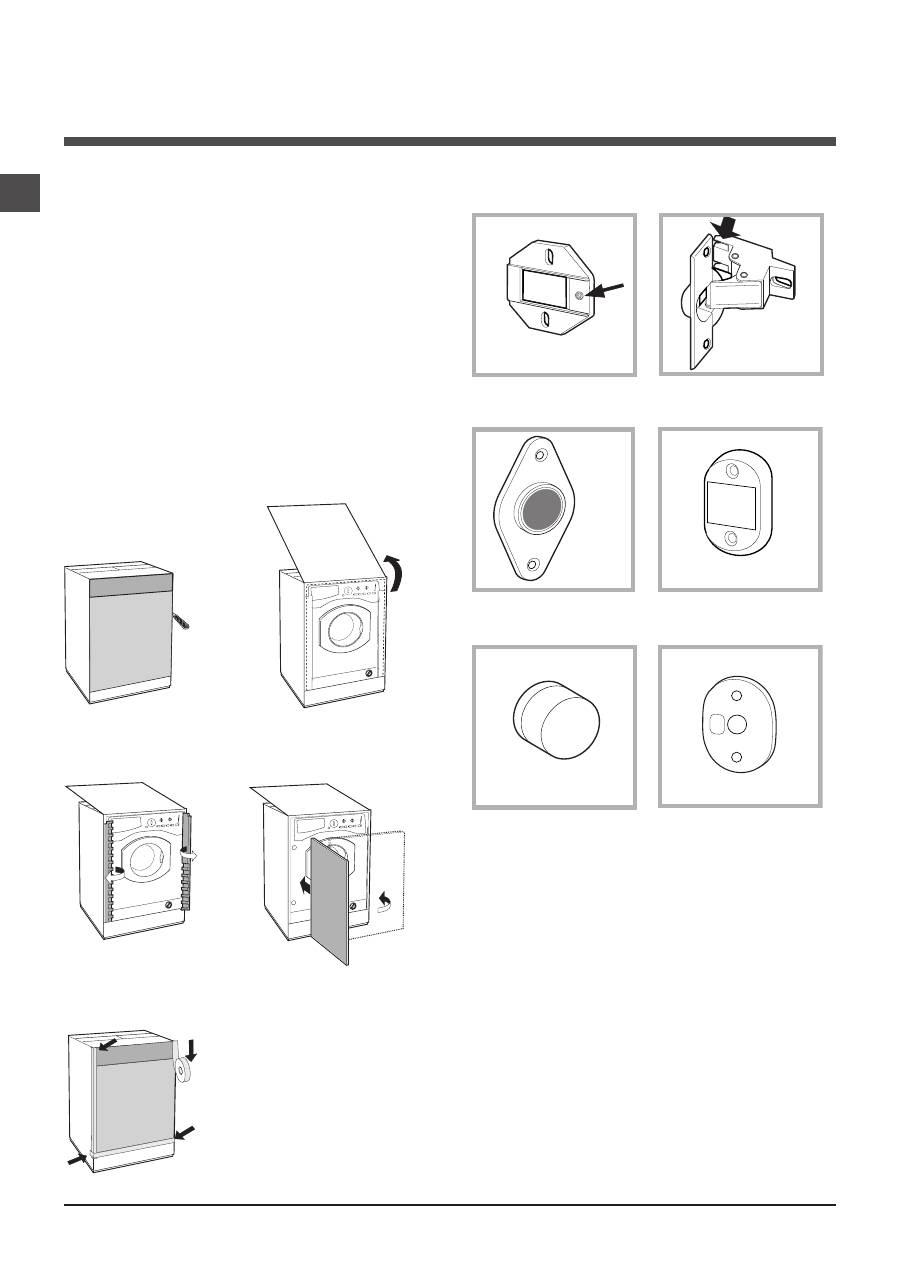

Door Mounting Accessories

(Fig. 1-2-3-4-5).

Fig. 1

N° 2 Hinges

N° 1 Magnet

N° 1 Magnet plate

N° 1 Rubber plug

N° 2 Hinge Supports

N° 4 Spacers

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 4/B

- No. 6 type

A

self-threading screws, l =13 mm.

- No. 2 type

B

metric, countersunk screws, l =25;

for fastening the magnet plate to the cabinet.

- No. 4 type

C

metric screws, l =15 mm; for

mounting the hinge supports to the cabinet.

- No. 4 type

D

metric screws, l =7 mm; for

mounting the hinges on the supports.

Mounting the Parts onto the Face of the

Machine.

- Fit the hinge supports to the appliance front

panel, positioning the hole marked with an arrow

in

fig. 1

so that it is on the inner side of the front

panel. Fit a spacer (

fig. 4/B)

between the surfa-

ces using type

C

screws.

- Fit the magnet plate at the top of the opposite

side, using type

B

screws to fix two spacers

(fig.

4/B)

between the plate and the surface.

GB

19

Using the Drilling Template.

- To trace the positions of the holes on the left-

hand side of the panel, align the drilling template

to the top left side of the panel using the lines

traced on the extremities as a reference.

- To trace the positions of the holes on the right-

hand side of the panel, align the drilling template

to the top right side of the panel.

- Use an appropriately sized router to mill the holes

for the two hinges, the rubber plug and the magnet.

Mounding the Parts onto the Wooden Panel

(Door).

- Insert the hinges into the holes (the movable part of

the hinge must be positioned facing away from the

panel) and fasten them with the 4 type

A

screws.

- Insert the magnet into the top hole on the op-

posite side of the hinges and fasten it with the

two type

B

screws.

- Insert the rubber plug into the bottom hole.

The panel is now ready to be mounted onto the

machine.

Mounting the Panel into the machine.

Insert the nib of the hinge (indicated by the arrow

in

fig. 2

) into the hole for the hinge and push the

panel towards the front of the machine. Fasten

the two hinges with the type

D

screws.

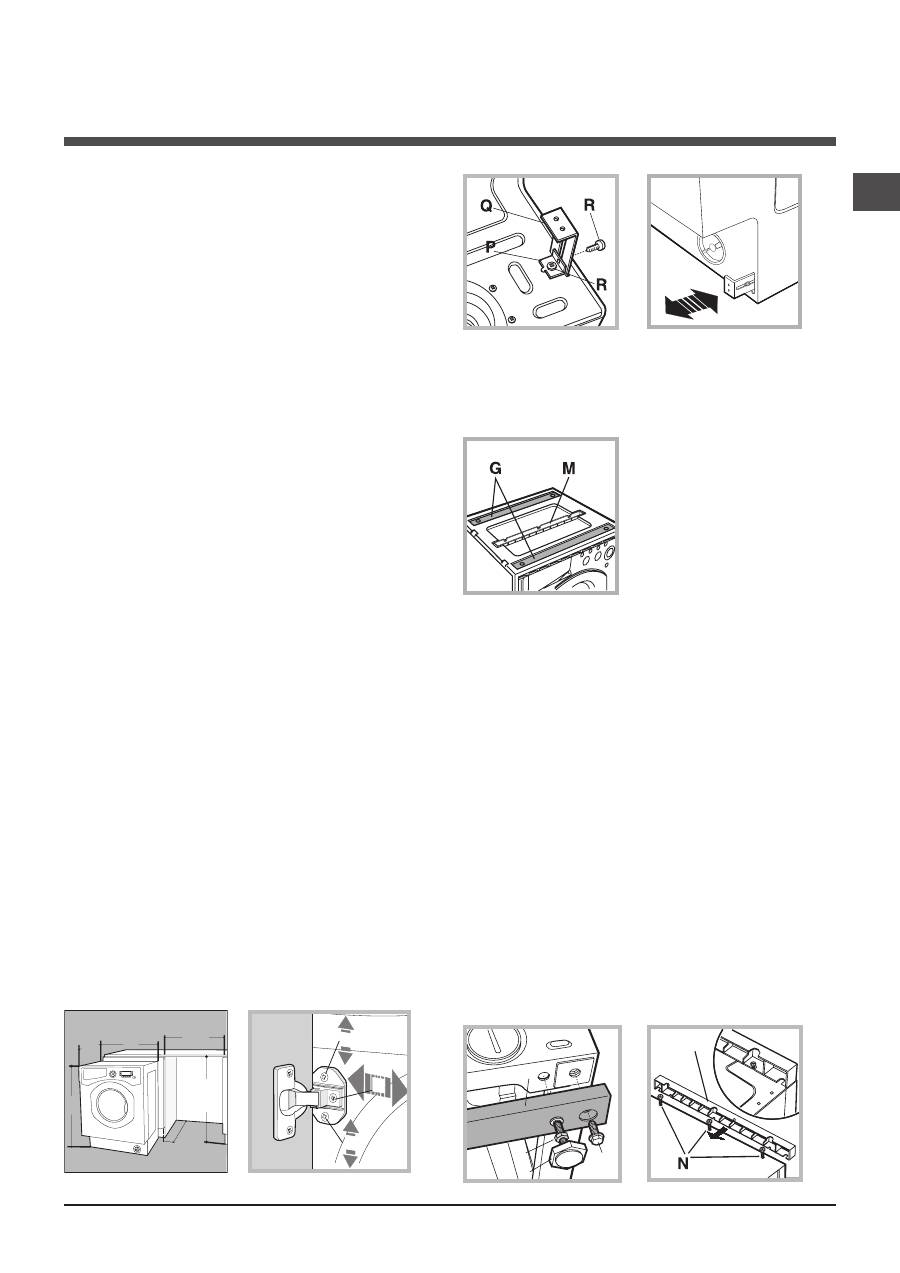

Fastening the plinth guide.

If the machine is installed at the end of a set of

modular cabinets, mount either one or both of

the guides for the base molding (as shown in

fig.

8

). Adjust them for depth based on the position

of the base molding, and, if necessary, fasten

the base to the guides

(fig. 9)

.

This is how to assemble the plinth guide

(fig. 8)

:

Fasten angle

P

using screw

R

, insert plinth guide

Q

into the special slot and once it is in the desired

position, lock it in place using angle

P

and screw

R

.

Inserting the machine into the Cabinet.

- Push the machine into the opening, aligning it

with the cabinets

(fig. 6)

.

- Regulate the adjustable feet to raise the ma-

chine to the appropriate height.

- To adjust the position of the wooden panel in

both the vertical and horizontal directions, use

the

C

and

D

screws, as shown in

fig. 7

.

Important:

close the lower part of the appliance

front by ensuring that the plinth rests against the floor.

Fig. 8

Fig. 9

Accessories provided for the height

adjustment.

The following can be found inside the polystyrene

lid

(fig. 10)

: 2 crossbars (

G

), 1 strip (

M

)

the following can be found

inside the appliance drum:

4 additional feet (

H

),

4 screws (

I

),

4 screws (

R

),

4 nuts (

L

),

2 plinth guides (

Q

)

Adjusting the appliance height.

The height of the appliance can be adjusted (from

815

mm to

835

mm), by turning the

4

feet.

Should you require the appliance to be placed

higher than the above height, you need to use the

following accessories to raise it to up to

870

mm:

The two crossbars (

G

); the 4 feet (

H

); the 4 screws (

I

); the

4 nuts (

L

) then perform the following operations

(fig. 11)

:

remove the

4

original feet, place a crossbar

G

at

the front of the appliance, fastening it in place

using screws

I

(screwing them in where the ori-

ginal feet were) then insert the new feet

H

.

Repeat the same operation at the back of the appliance.

Now adjust feet

H

to raise or lower the appliance

from

835

mm to

870

mm.

Once you have reached the desired height, lock

nuts

L

onto crossbar

G

.

To adjust the appliance to a height between

870

mm and

900

mm, you need to mount strip

M

,

adjusting feet

H

to the required height.

Insert the strip as follows:

loosen the three screws

N

situated at the front of

the Top cover of the appliance, insert strip

M

as

shown in

fig. 12

, then fasten screws

N

.

D

C

C

570

mi

n

81

5

540

595

820 ÷ 900

600 min

Fig. 6

Fig. 7

L

I

H

G

M

Fig. 11

Fig. 12

Fig. 10

Оглавление

- Installazione

- Manutenzione e cura

- Precauzioni e consigli

- Descrizione della lavasciuga e avviare un programma

- Programmi

- Personalizzazioni

- Detersivi e biancheria

- Anomalie e rimedi

- Assistenza

- Instructions for use

- Installation

- Care and maintenance

- Precautions and tips

- Description of the washer-dryer and starting a wash cycle

- Wash cycles

- Personalisation

- Detergents and laundry

- Troubleshooting

- Service

- Mode d’emploi

- Installation

- Entretien et soin

- Précautions et conseils

- Description du lavante-séchante et démarrage d’un programme

- Programmes

- Personnalisations

- Produits lessiviels et linge

- Anomalies et remèdes

- Assistance

- Bedienungsanleitungen

- Installation

- Reinigung und Pflege

- Vorsichtsmaßregeln und Hinweise

- Waschprogramme

- Personalisierungen

- Waschmittel und Wäsche

- Störungen und Abhilfe

- Kundendienst

- Руководство по эксплуатации

- Установка

- Описание стиральной машины и порядка запуска программы

- Программы

- Персонализированные настройки

- Моющие средства и типы белья

- Предосторожности и рекомендации

- Техническое обслуживание и уход

- Поиск неисправностей и методы их устранения

- Сервисное обслуживание