Festool Ti 15: WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury. Save all warnings and instructions for future reference.The term "power tool" in the warnings refers to your mains-operated (corded) powertool or battery-operated (cordless) power tool.

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury. Save all warnings and instructions for future reference.The term "power tool" in the warnings refers to your mains-operated (corded) powertool or battery-operated (cordless) power tool.: Festool Ti 15

12

TI 15

GB

Original operating manual 1 Safety instructions 1.1 General safety instructions

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury. Save all warnings and instructions for future reference. The term "power tool" in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1.2 Machine-related safety instructions

– Hold power tool by insulated gripping surfaces, when performing an operation where the cutting accessory or fastener may contact hidden wiring. Cutting acces- sory or fasteners contacting a "live" wire may make exposed metal parts of the pow- er tool "live" and could give the operator an electric shock. – This charger can be used by children of 8 years and upwards and persons with im- paired physical, sensory or mental abilities, or insufficient experience or knowl- edge, providing they are supervised or have been instructed in the proper use of the appliance and understand the risks involved. Children are not permitted to play with the appliance. Children must not carry out cleaning tasks or maintenance unless they are supervised. – Wear suitable protection: such as ear protection, safety goggles, a dust mask for work which generates dust, and protective gloves when working with raw materials and when changing tools. CAUTION! Rebound! Rotation: Switch off device immediately! – Do not lock the on/off switch permanently! – Do not open the battery pack or the charger! – Prevent metal parts (e.g. metal chips) or fluids from entering the charger! – Do not use battery packs or chargers from other manufacturers! – Protect the battery pack from excessive heat or constant heat sources such as sun- light or naked flames! – Never use water to extinguish burning li-ion battery packs! Use sand or a fire blan- ket. – Check the plug and the cable regularly and should either become damaged, in order to avoid a hazard, have them replaced by an authorised after-sales service workshop. – Always pull the mains plug out of the socket when the charger is not in use. – Only for AS/NZS: The tool shall always be supplied via residual current device with a rated residual current of 30 mA or less.

TI 15

13

GB

1.3

Emission levels

Levels determined in accordance with EN 60745 are

typically:

Vibration emission value a

h

(vector sum for three

directions) and uncertainty K measured in accor-

dance with EN 60745:

The specified emissions values (vibration, noise)

– are used to compare machines.

– They are also used for making preliminary esti-

mates regarding vibration and noise loads during

operation.

– They represent the primary applications of the

power tool.

Increase possible for other applications, with other

insertion tools or if not maintained adequately. Take

note of idling and downtimes of machine!

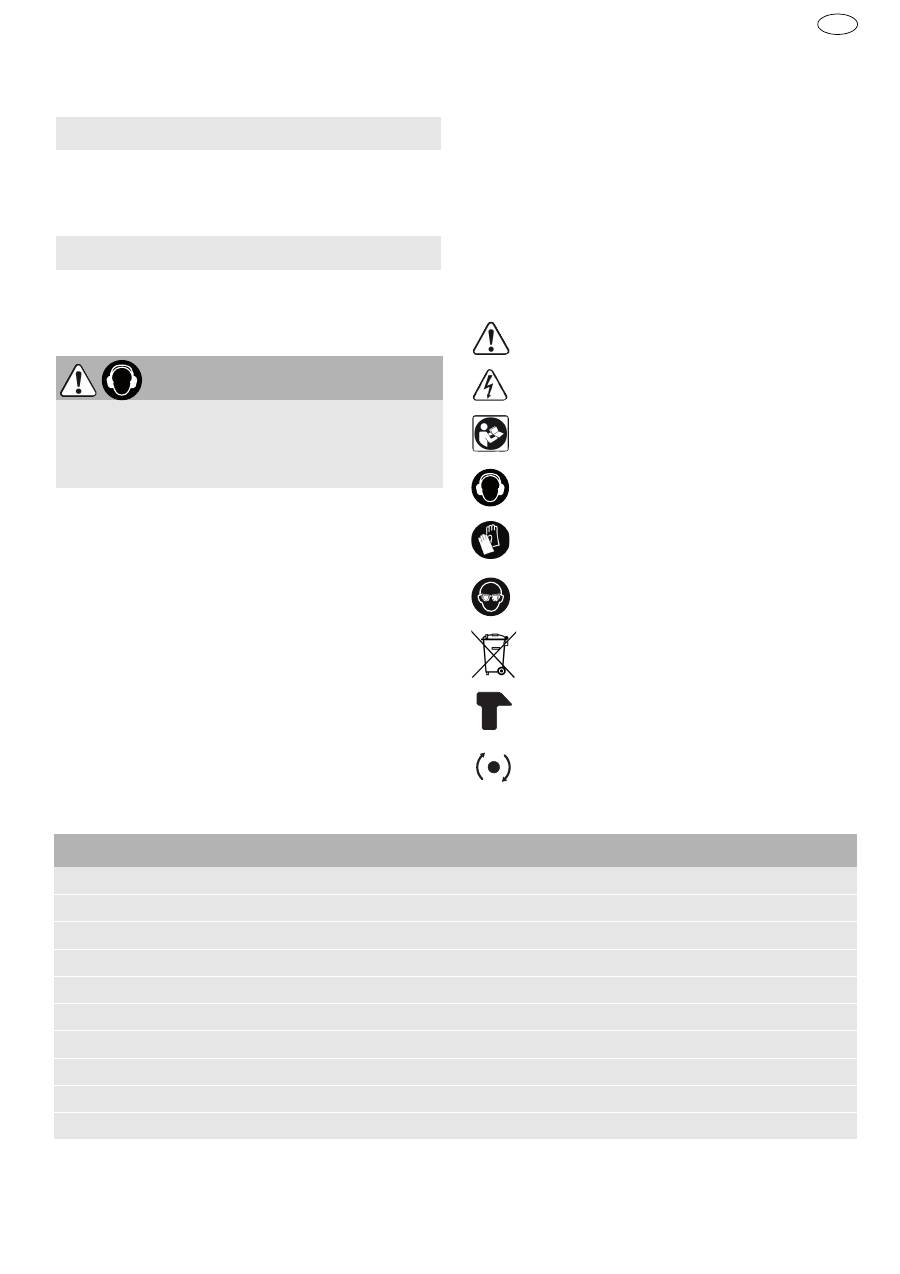

2 Symbols 3 Technical data

* electronically limited

Screwing with impact

Sound pressure level

L

PA

= 93 dB(A)

Noise level

L

WA

= 104 dB(A)

Uncertainty

K = 3 dB

Screwing and drilling without impact

Sound pressure level

L

PA

= 68 dB(A)

Noise level

L

WA

= 79 dB(A)

Uncertainty

K = 3 dB

CAUTION

When working with noise

Damage to hearing

Always use ear protection.

Drilling in metal

a

h

< 2,5 m/s

2

K = 1,5 m/s

2

Screwing

a

h

= 3,0 m/s

2

K = 1,5 m/s

2

Tightening screws and nuts

with maximum size

a

h

= 11,3 m/s

2

K = 3,0 m/s

2

Warning of general danger

Risk of electric shock

Read the Operating Instructions/Notes!

Wear ear protection.

Wear protective gloves.

Wear protective goggles.

Do not throw in the household waste.

Operating mode Impact screw driver

Operating mode Screwing/Drilling without

impact

Cordless impact screw driver

TI15

Motor voltage

14,4 V

Idling speed

0 - 2600 rpm

Impact rate

2400 - 3600 rpm

Max. torque

Hard material (metal)

100 Nm*

Chuck clamping range

1,5 - 13 mm

Drill diameter max.

Wood

13 mm

Metal

10 mm

Max. screw diameter in spruce

Up to 8x160 mm

Tool holder in drill spindle

1/4 ’’

Weight without battery pack with Centrotec

1,2 kg

14

TI 15

GB

4 Machine features

Accessories shown or described are sometimes not

included in the scope of delivery.

The specified illustrations appear at the beginning

of the Operating Instructions.

5 Intended use

Cordless impact screw driver is suitable

– for tightening screw fittings and screwing in

screws up to the maximum dimension range

stated

– drilling into metal, wood, plastics and similar

materials

– use with Festool batteries BPC and BPS of the

same voltage.

The device must

not

be used for applications which

require a precise/specific torque. When using the

device for applications which require a specific

torque or for which a maximum torque must not be

exceeded, there is the risk of overspeeding or dam-

age to the screw or the workpiece.

Charger TCL 3 suitable for

– charging Festool battery packs: BP, BPS and

BPC (NiMH, NiCd, li-ion are recognised automat-

ically.)

– indoor use only.

The user is liable for improper or non-in-

tended use; this also includes continuous in-

dustrial operation.

6 Operation

6.1

Charger cable holder[3-3]

Unwind the cable completely from the recess

before using the charger.

Charger

TCL 3

Mains voltage (input)

220 - 240 V ~

Mains frequency

50/60 Hz

Charging voltage (output)

10,8 - 18 V=

Rapid charging

max. 3 A

Conservation charging, intermittent (NiCd, NiMH)

approx. 0,06 A

Charging times for BP, BPS and BPC battery packs

Li-ion 1,5 Ah, 80 %/100 %

approx. 25/35 min.

Li-ion 3,0 Ah, 80 %/100 %

approx. 55/70 min.

Li-ion 4,2 Ah, 80 %/100 %

approx. 70/90 min.

Permitted operating temperature range

-5 °C to + 45 °C

Temperature monitoring

via NTC resistor

Safety class

/II

Battery pack

BPC 15 Li

Voltage

14,4 V

Capacity

4,2 Ah

Weight

0,58 kg

[1-1]

Bit store

[1-2]

On/Off switch

[1-3]

Right/left switch

[1-4]

LED lamp

[1-5]

CENTROTEC tool chuck

[1-6]

Thumbwheel Speed/Impact rate

[1-7]

Capacity display

[1-8]

Battery pack

[1-9]

Belt clip

[1-10]

Buttons for releasing the battery pack

[1-11]

Adapter for FastFix attachments

[1-12]

13 mm chuck

[1-13]

Elbow adapter

[3-1]

Charger

[3-2]

LED-Display

[3-3]

Cable holder

[3B]

Wall mount

TI 15

15

GB

6.2

Festool battery packs

Battery pack is ready for use immediately upon

delivery and can be charged at any time.

Changing the battery pack [2]

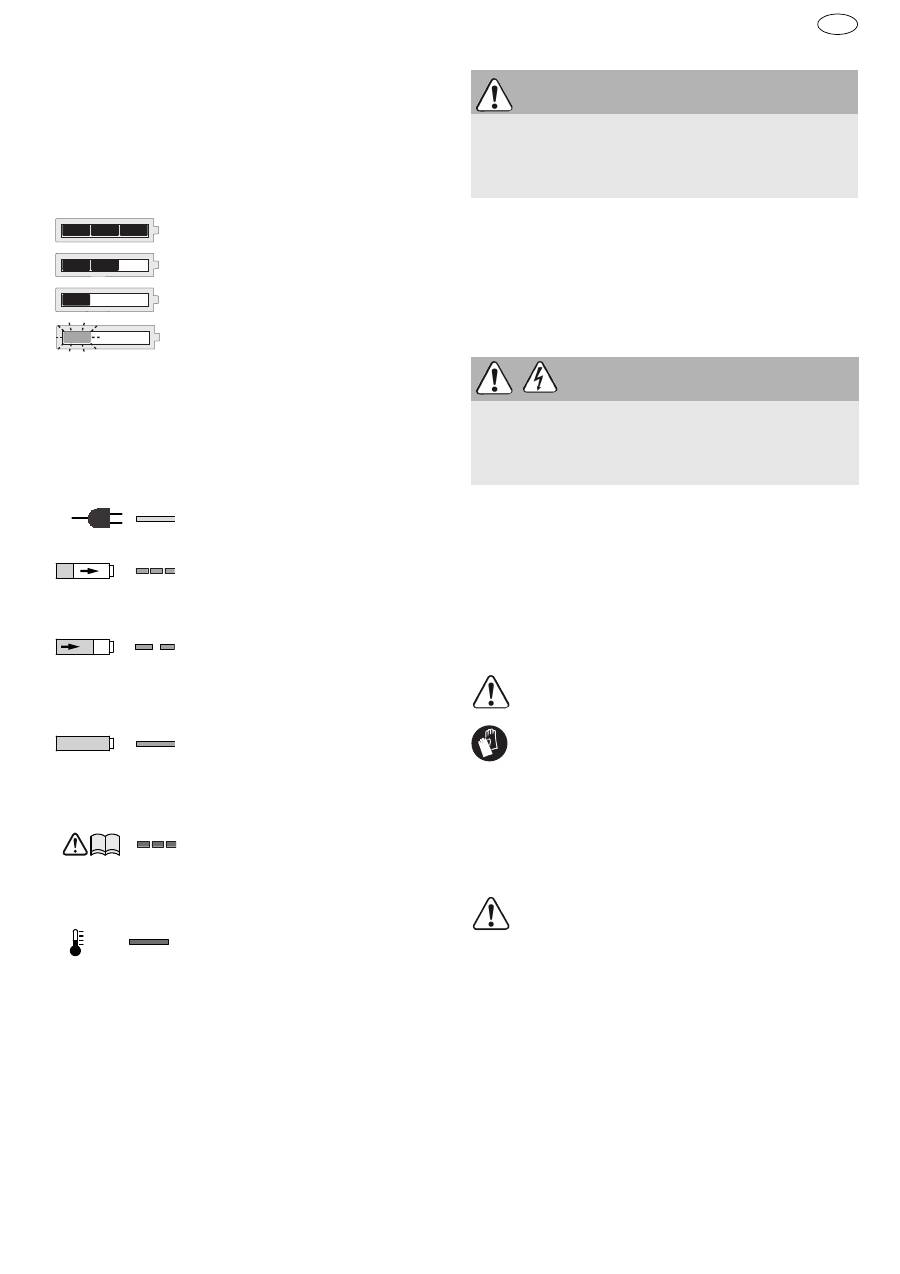

The capacity display

[1-7]

automatically displays

the charge state of the battery pack

[1-2]

when the

ON/OFF switch is actuated:

6.3

Festool charger

Charging the battery pack [3A]

The LED

[3-2]

on the charger indicates the respec-

tive operating status of the charger.

7 Settings

7.1

Changing direction of rotation [1-3]

• Switch to the left = clockwise rotation

• Switch to the right = counterclockwise rotation

7.2

Adjust speed/impact rate

Adjust the speed/impact rate at thumbwheel

[1-

6]

:

Setting 1 = low speed/impact rate

Setting 6 = high speed/impact rate

8 Tool holder, attachments

Festool offers attachments and tool holders for

various applications.

The order numbers of the accessories and tools can

be found in the Festool catalogue or on the Internet

under "www.festool.com".

8.1

CENTROTEC tool chuck [4]

Quick change of tools with CENTROTEC shaft

Only clamp CENTROTEC tools in CENTRO-

TEC tool chucks.

Wear gloves when replacing!

8.2

BF-TI 13 chuck [5]

Is used for clamping drill bits up to 13 mm and

shaft tools.

Impact mode is automatically switched off when

the chuck is inserted.

Clamp the tool centrally in the chuck.

Pull the sleeve back to clamp the drill bit and

turn this in a clockwise direction until it locks in.

8.3

TI-FX adapter [6]

makes possible the fitting of the following attach-

ments on the power tool (sometimes an accessory).

Impact mode is automatically switched off when

the adapter is inserted.

Place the three white points in a row when posi-

tioning the adapter. If necessary, the hexagon

socket holder must be turned manually so the

adapter can be fixed.

70 - 100 %

40 - 70 %

15 - 40 %

< 15 %

Recommendation:

Charge bat-

tery pack before further use.

LED yellow - lit continuously

Charger is ready to use.

LED green - flashes quickly

Battery pack is charged to maxi-

mum capacity.

LED green - flashes slowly

Battery pack is charged with

reduced current. Li-ion is

charged to 80 %.

LED green - lit continuously

Charging is complete or is not

restarted as current charge sta-

tus is greater than 80%.

LED red - flashes

General fault indication, e.g.

incomplete contact, short circuit,

defective battery pack, etc.

LED red - lit continuously

Battery temperature is outside

the permitted range.

CAUTION

Damage to screw and/or workpiece

Adjust the speed/impact rate and impact dura-

tion to the specific application.

WARNING

Risk of injury, electric shock

Always disconnect the battery pack before any

type of work on the machine!

16

TI 15

GB

Turn the clamping ring as far as the stop to se-

cure the adapter.

Angle attachment DD-AS [7]

Drilling and screwing at right angle to machine

(partly as an accessory).

Eccentric attachment DD-ES [8]

Screwdriving near edges with bits according to ISO

1173 (partly as accessory).

9 Working with the machine

9.1

Operating modes

Depending on the tool holder / adapter selected,

the machine is operated as follows:

9.2

On/Off switch [1-2]

Press = ON, release = OFF

Depending on the pressure applied to the ON/

OFF switch the speed/impact rate can be con-

trolled continuously.

The LED bulb

[1-4]

lights up when the ON/OFF

switch is pressed

[1-2]

.

9.3

Bit depot [1-1]

Magnetic, for storing bits and bit holders.

9.4

Belt clip [1-9]

For short-term fixing of the device to work attire:

can be moved to the right or left or can also be de-

tached from the battery pack.

9.5

Acoustic warning signals

Acoustic warning signals sound and the machine

switches off in the following operating states:

10 Service and maintenance

Customer service and repair

only

through manufacturer or service

workshops: Please find the nearest

address at:

www.festool.com/Service

Use only original Festool spare parts!

Order No. at:

www.festool.com/Service

Note the following information:

– Keep the ventilation slits on the machine free and

clean to ensure adequate cooling.

– Keep the contacts on the machine, charger and

battery pack clean.

Information on battery packs

– Store in a cool, dry place at a temperature be-

tween 5 °C and 25 °C.

– Protect battery packs from moisture, water and

heat.

– Do not leave flat battery packs in a charger dis-

connected from the mains power supply for lon-

ger than one month. Danger of deep discharge!

– If you intend to store li-ion battery packs for lon-

ger periods without use, you should charge them

to 40 % capacity (approx. 15 min charging time).

Screwing with impact

– WH-CE CENTROTEC tool chuck (see

Chapter CENTROTEC tool chuck [4])

Screwing and drilling without impact

– TI-FX adapter (see Chapter TI-FX adapter

[6])

• DD-AS elbow adapter

• DD-ES eccentric attachment

• DD-DC screwdriver attachment

– BF-TI 13 chuck (see Chapter BF-TI 13

chuck [5])

WARNING

Risk of injury

Only place the machine on the nut/screw when

switched off.

Battery flat or machine over-

loaded.

– Change the battery.

– Place the machine under reduced

stress.

Machine is overheating.

– You must allow the machine to

cool before using again.

LiIon battery pack is faulty or has

overheated.

– Once the battery pack has cooled,

perform a functional check using

the charger.

WARNING

Risk of injury, electric shock

Always disconnect the battery pack from the

machine before any maintenance or care work!

All maintenance and repair work which requires

the motor housing to be opened, must only be

carried out by an authorised service workshop.

EKAT

1

2

3

5

4

TI 15

17

GB

– To avoid short circuits the battery pack should be

stored in the packaging supplied.

– Significantly shorter operating times after each

charge indicate that the battery pack is worn and

should be replaced with a new one.

11 Environment

Do not dispose of the device in house-

hold waste!

Recycle devices, accesso-

ries and packaging. Observe applica-

ble country-specific regulations.

EU only:

European Directive 2002/96/

EC stipulates that used electric power tools must

be collected separately and disposed of at an envi-

ronmentally responsible recycling centre.

Return

used or faulty battery packs

to your local

specialist retailer, Festool after-sales service or a

designated public waste management facility. The

battery packs will then be recycled. (Observe the

regulations applicable in your country). The batter-

ies must be discharged on return.

EU only:

European Directive 91/157/EEC stipulates

that faulty or used battery packs/batteries must be

recycled.

Information on REACh:

www.festool.com/reach

12 Transport

A li-ion battery pack alone falls below the applica-

ble limit value and certified as per UN manual ST/

SG/ AC.10/11/rev. 3 part III, subsection 38.3. How-

ever, dangerous goods regulations may apply when

several battery packs are transported.

13 EU Declaration of Conformity

We declare under sole responsibility that this prod-

uct complies with all the relevant requirements in

the following Directives, standards and normative

documents:

2004/108/EC, 2006/95/EC, 2011/65/EU, EN 60745-

1, EN 60745-2-1, EN 60745-2-2, EN 55014-1, EN

55014-2.

We declare under sole responsibility that this prod-

uct complies with all the relevant requirements in

the following Directives, standards and normative

documents:

2004/108/EC, 2006/95/EC, 2011/65/EU, EN 60335-

1, EN 60335-2-29, EN 61000-3-2, EN 61000-3-3, EN

61204-3.

Festool Group GmbH & Co. KG

Wertstr. 20, D-73240 Wendlingen, Germany

Dr. Martin Zimmer

Head of Research, Development and Technical

Documentation

2013-05-22

Cordless impact screw driver

Serial no.

TI 15

496651

Year of CE mark: 2011

Charger

Serial no.

TCL 3

10002345, 10004911

Year of CE mark: 2013

Оглавление

- Warnung! Lesen Sie sämtliche Sicherheitshinweise und Anweisungen. Fehler bei der Einhaltung der Warnhinweise und Anweisungen können elektrischen Schlag, Brand und/oder schwere Verletzungen verursachen.Bewahren Sie alle Sicherheitshinweise und Anweisungen für die Zukunft auf.Der in den Sicherheitshinweisen verwendete Begriff „Elektrowerkzeug“ bezieht sichauf netzbetriebene Elektrowerkzeuge (mit Netzkabel) und auf akkubetriebene Elekt-rowerkzeuge (ohne Netzkabel).

- – Regelmäßig den Stecker und das Kabel prüfen um eine Gefährdung zu vermeiden, und diese bei Beschädigung von einer autorisierten Kundendienst-Werkstätte er-neuern lassen. – Bei Nicht-Gebrauch des Ladegeräts den Netzstecker aus der Steckdose ziehen.

- WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury. Save all warnings and instructions for future reference.The term "power tool" in the warnings refers to your mains-operated (corded) powertool or battery-operated (cordless) power tool.

- Avertissement ! Lire toutes les consignes de sécurité et instructions. Le non-res- pect des consignes d'avertissement et des instructions peut occasionner un choc électrique, un incendie et/ou des blessures graves.Conserver toutes les consignes de sécurité et instructions pour une référence future.Le terme "outil électrique" utilisé dans les consignes de sécurité se rapporte aux outilsélectriques fonctionnant sur secteur (avec cordon d'alimentation) et aux outils élec-triques fonctionnant sur accumulateurs (sans cordon d'alimentation).

- – Lorsque le chargeur n'est pas utilisé, débranchez systématiquement la fiche sec- teur de la prise de courant.

- Advertencia Lea todas las indicaciones de seguridad e instrucciones. Si no se cumplen debidamente las indicaciones de advertencia y las instrucciones puede producirse una descarga eléctrica, fuego y/o lesiones graves.Guarde todas las indicaciones de seguridad e instrucciones para que sirvan de fu-tura referencia.El término "herramienta eléctrica" empleado en las indicaciones de seguridad hacereferencia a herramientas eléctricas conectadas a la red eléctrica (con un cable dered) y a herramientas eléctricas alimentadas con batería (sin cable de red).

- Attenzione! Leggere tutte le avvertenze per la sicurezza e le istruzionid'uso. Eventuali errori nell'osservanza delle avvertenze e delle istruzioni d'uso pos- sono provocare scosse elettriche, incendi e/o gravi lesioni.Conservate tutte le avvertenze di sicurezza e le istruzioni d'uso per riferimenti futuri.Il termine “elettroutensile” usato nelle avvertenze di sicurezza indica gli elettroutensilicollegati alla rete elettrica (con cavo di rete) e gli elettroutensili azionati a batteria (senzacavo di rete).

- – Controllare periodicamente il cavo e la spina e accertarsi che non presentino dan- neggiamenti. All'occorrenza, incaricare della riparazione un centro di assistenzaclienti autorizzato. – Scollegare la spina del caricabatterie dalla presa di rete quando esso non è utiliz- zato.

- Waarschuwing! Lees alle veiligheidsvoorschriften en aanwijzingen. Wanneer men zich niet aan de waarschuwingen en aanwijzingen houdt, kan dit leiden tot elektri- sche schokken, brand en/of ernstig letsel.Bewaar alle veiligheidsinstructies en aanwijzingen om ze later te kunnen raadplegen.Het begrip „elektrisch gereedschap“ dat in de veiligheidsvoorschriften gebruikt wordt,heeft betrekking op elektrisch gereedschap met netvoeding (met netsnoer) en elek-trisch gereedschap met accuvoeding (zonder netsnoer).

- – Wanneer het oplaadapparaat niet wordt gebruikt, de stekker uit het stopcontact ha- len.

- Varning! Läs och följ alla säkerhetsanvisningar och instruktioner. Om man inte följer varningsmeddelanden och anvisningar kan det leda till elstötar, brand och/ eller svåra personskador. Spara alla säkerhetsanvisningar och andra anvisningar för framtida bruk.Med begreppet ”Elverktyg” som används i säkerhetsanvisningarna menas nätdrivnaelverktyg (med nätkabel) och batteridrivna elverktyg (utan nätkabel).

- Varoitus! Lue kaikki turva- ja käyttöohjeet. Varoitusten ja ohjeiden noudattami- sen laiminlyönti voi aiheuttaa sähköiskun, tulipalon ja/tai vakavia vammoja. Säilytä kaikki turvaohjeet ja käyttöohjeet myöhempää tarvetta varten.Turvaohjeissa käytetty termi "sähkötyökalu" tarkoittaa verkkokäyttöisiä sähkötyöka-luja (verkkojohdon kanssa) ja akkukäyttöisiä sähkötyökaluja (ilman verkkojohtoa).

- Advarsel! Læs alle sikkerhedsanvisninger og øvrige anvisninger. Overholdes anvisningerne ikke, er der risiko for elektrisk stød, brand og/eller alvorlige kvæ- stelser.Opbevar alle sikkerhedsanvisninger og vejledninger til senere brug.Med begrebet "elværktøj", som anvendes i sikkerhedsanvisningerne, menes led-ningsbåret elværktøj (med netkabel) og batteridrevet elværktøj (uden netkabel).

- Advarsel! Les alle sikkerhetsregler og anvisninger. Hvis advarslene og anvis- ningene ikke overholdes, kan det føre til elektrisk støt, brann og/eller alvorlige personskader.Oppbevar alle sikkerhetsmerknader og anvisninger for fremtidig bruk.Nedenfor brukes uttrykket "elektroverktøy". Det viser til nettdrevne elektroverktøy(med ledning) og batteridrevne elektroverktøy (uten ledning).

- Advertência! Leia todas as indicações de segurança e instruções. A não obser- vação das indicações de segurança e instruções pode dar origem a um choque eléctrico, um incêndio e/ou ferimentos graves.Guarde todas as indicações de segurança e instruções para futura referência.O termo "ferramenta eléctrica" utilizado nas indicação de segurança refere-se a fer-ramentas eléctricas utilizadas com ligação à rede (com cabo de rede) e com acumu-lador (sem cabo de rede).

- – Se não estiver a utilizar o carregador, retire a ficha da tomada.

- Внимание! Прочтите все указания по технике безопасности иинструкции. Неточное соблюдение инструкций и предупреждений может стать причиной удара электрическим током, пожара и/или тяжёлых травм.Сохраняйте все указания по технике безопасности и инструкции.Используемый в указаниях по технике безопасности термин«электроинструмент» относится к сетевым электроинструментам (с сетевымкабелем) и аккумуляторным электроинструментам (без сетевого кабеля).

- – Регулярно проверяйте штекер и кабель. В случае повреждения заменяйте их в авторизованных мастерских Сервисной службы. – Если зарядное устройство не используется, вынимайте вилку сетевого кабеля из розетки.

- Výstraha! Přečtěte si všechny bezpečnostní pokyny a instrukce. Chyba při dodr- žování varovných upozornění a instrukcí může způsobit zásah elektrickým prou- dem, požár a/nebo vážné zranění.Všechny bezpečnostní pokyny a instrukce uschovejte, abyste je mohli použíti v budoucnosti.Pojem „elektrické nářadí“, používaný v bezpečnostních pokynech, se vztahuje na síťo-vé elektrické nářadí (se síťovým kabelem) a na akumulátorové nářadí (bez síťovéhokabelu).

- – Pokud nabíječku nepoužíváte, vytáhněte zástrčku ze síťové zásuvky.

- Ostrzeżenie! Należy przeczytać wszystkie zalecenia bezpieczeństwa pracy i in-strukcje. Nieprzestrzeganie ostrzeżeń i instrukcji może spowodować porażenie elek- tryczne, pożar oraz/lub ciężkie obrażenia.Wszystkie zalecenia dotyczące bezpieczeństwa pracy i instrukcje należy zachować dowykorzystania w przyszłości.Używane w zaleceniach bezpieczeństwa pracy pojęcie „Narzędzie elektryczne“ odnosi siędo narzędzi elektrycznych zasilanych z sieci (z przewodem zasilającym) i do narzędzi elek-trycznych zasilanych z akumulatora (bez przewodu zasilającego).

- – Gdy ładowarka nie jest używana, wyłączyć wtyczkę przewodu zasilania z gniazda.