Hotpoint-Ariston C 34S G3 R/HA: I nstallation

I nstallation: Hotpoint-Ariston C 34S G3 R/HA

14

G

B

Before operating

y

our new appliance please read

this instruction booklet carefull

y

. It contains

important information concerning the safe installation

and operation of the appliance.

Please keep these operating instructions for future

reference. Make sure that the instructions are kept

with the appliance if it is sold, given awa

y

or moved.

The appliance must be installed b

y

a qualified

professional according to the instructions provided.

An

y

necessar

y

adjustment or maintenance must be

performed after the cooker has been disconnected

from the electricit

y

suppl

y

.

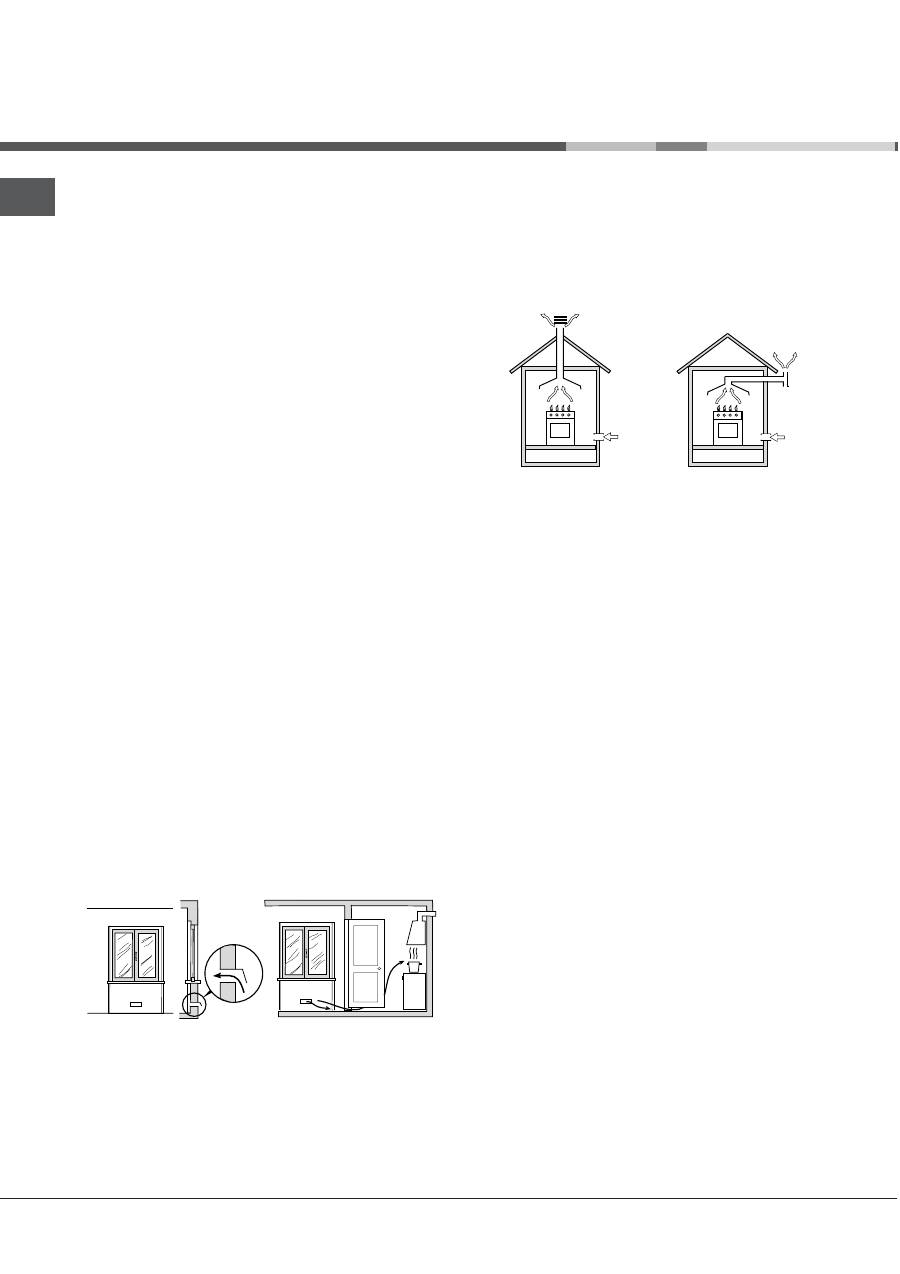

R

oom

venti

l

ation

The appliance ma

y

onl

y

be installed in permanentl

y

-

ventilated rooms, according to current national

legislation. The room in which the appliance is

installed must be ventilated adequatel

y

so as to

provide as much air as is needed b

y

the normal gas

combustion process (the flow of air must not be

lower than 2 m

3

/h per kW of installed power).

The air inlets, protected b

y

grilles, should have a

duct with an inner cross section of at least 100 cm

2

and should be positioned so that the

y

are not liable

to even partial obstruction (

see figure A

).

These inlets should be enlarged b

y

100% - with a

minimum of 200 cm

2

- whenever the surface of the

hob is not equipped with a flame failure safet

y

device. When the flow of air is provided in an

indirect manner from adjacent rooms (

see figure B

),

provided that these are not communal parts of a

building, areas with increased fire hazards or

bedrooms, the inlets should be fitted with a

ventilation duct leading outside as described above.

A

B

After prolonged use of the appliance, it is

advisable to open a window or increase the speed of

an

y

fans used.

Di

s

po

s

in

g

o

f

com

b

u

s

tion

f

ume

s

The disposal of combustion fumes should be

guaranteed using a hood connected to a safe and

efficient natural suction chimne

y

, or using an electric

fan that begins to operate automaticall

y

ever

y

time

the appliance is switched on (

see figure

).

The liquefied petroleum gases are heavier than air

and collect b

y

the floor, therefore all rooms

containing LPG c

y

linders must have openings

leading outside so that an

y

leaked gas can escape

easil

y

.

LPG c

y

linders, therefore, whether partiall

y

or

completel

y

full, must not be installed or stored in

rooms or storage areas that are below ground level

(cellars, etc.). Onl

y

the

c

y

linder being used should be stored in the room;

this should also be kept well awa

y

from sources

of heat (ovens, chimne

y

s, stoves) that ma

y

cause

the temperature of the c

y

linder to rise above 50°C.

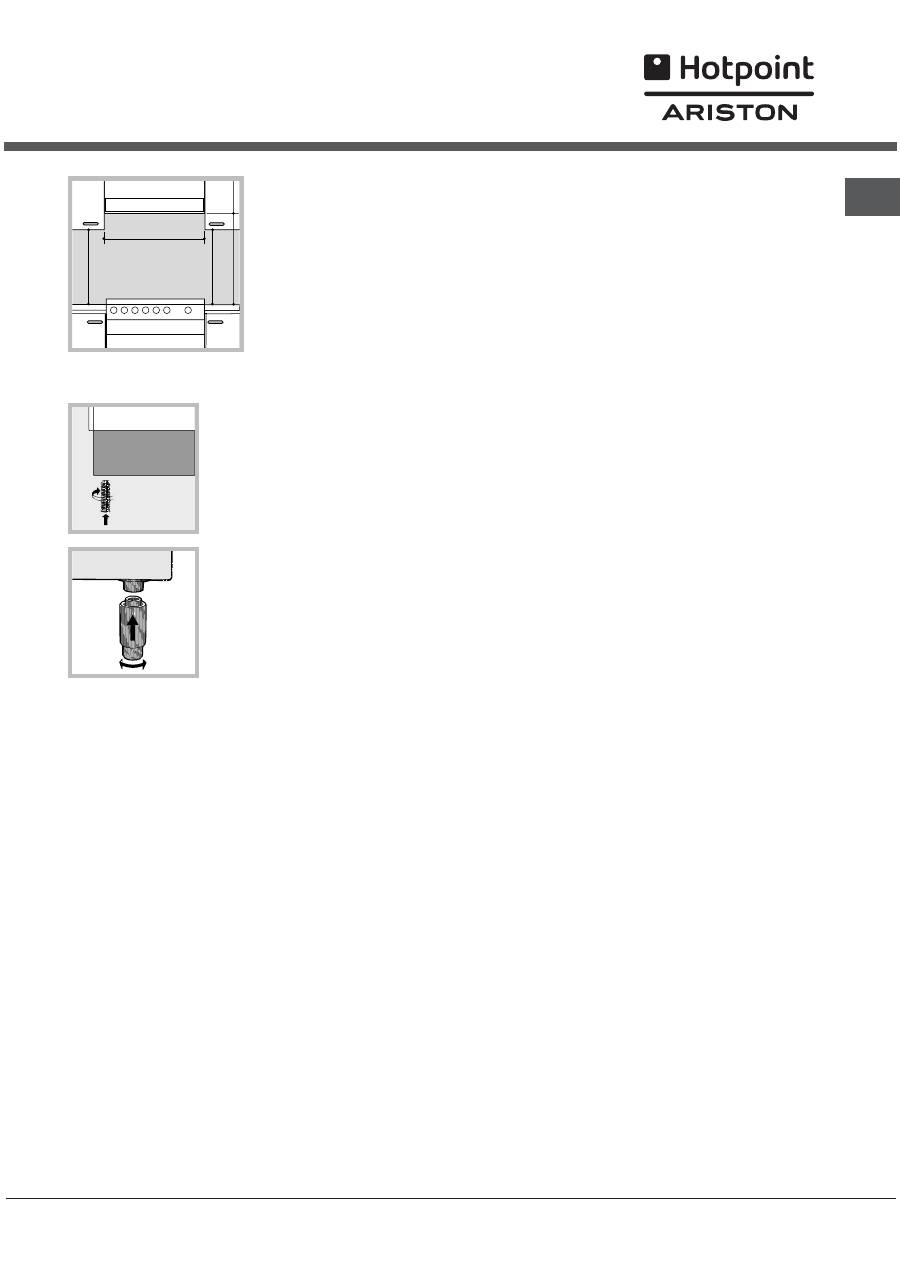

Positioning and levelling

It is possible to install the appliance alongside

cupboards whose height does not e

x

ceed that of the

hob surface.

Make sure that the wall in contact with the back of

the appliance is made from a non-flammable, heat-

resistant material (T 90°C).

To install the appliance correctl

y

:

Place it in the kitchen, dining room or the bed-sit

(not in the bathroom).

If the top of the hob is higher than the cupboards,

the appliance must be installed at least 200 mm

awa

y

from them.

If the cooker is installed underneath a wall cabinet,

there must be a minimum distance of 420 mm

between this cabinet and the top of the hob.

This distance should be increased to 700 mm if

the wall cabinets are flammable (

see figure

).

A

F

umes

channelled

through

a

chimney

or

branched

flue

system

reserved

for

cooking

appliances)

I nstallation

A

djacent

room

Room

requiring

ventilation

Ventilation

opening

for

comburent

air

Increase

in

the

gap

between

the

door

and

the

flooring

Fumes

channelled

straight

outside

15

G

B

Do not position

blinds behind the

cooker or less than 200

mm awa

y

from its

sides.

An

y

hoods must be

installed according to

the instructions listed in

the relevant operating

manual.

L

eve

ll

in

g

If it is necessar

y

to level the

appliance, screw the

adjustable feet into the places

provided on each corner of the

base of the cooker (

see

figure

).

The legs* fit into the slots on

the underside of the base of

the cooker.

E

lectrical connection

Install a standardised plug corresponding to the

load indicated on the appliance data plate (

see

Technical data table

).

The appliance must be directl

y

connected to the mains

using an omnipolar circuit-breaker with a minimum

contact opening of 3 mm installed between the

appliance and the mains. The circuit-breaker must be

suitable for the charge indicated and must compl

y

with

NFC 15-100 regulations (the earthing wire must not be

interrupted b

y

the circuit-breaker). The suppl

y

cable

must be positioned so that it does not come into

contact with temperatures higher than 50°C at an

y

point.

Before connecting the appliance to the power

suppl

y

, make sure that:

The appliance is earthed and the plug is compliant

with the law.

The socket can withstand the ma

x

imum power of

the appliance, which is indicated b

y

the data plate.

The voltage is in the range between the values

indicated on the data plate.

The socket is compatible with the plug of the

appliance. If the socket is incompatible with the

plug, ask an authorised technician to replace it.

Do not use e

x

tension cords or multiple sockets.

HOOD

420

Min.

min.

650

mm. with hood

min.

700

mm. without hood

mm.

600

Min.

mm.

420

Min.

mm.

* Onl

y

available in certain models

Once the appliance has been installed, the power

suppl

y

cable and the electrical socket must be

easil

y

accessible.

The cable must not be bent or compressed.

The cable must be checked regularl

y

and replaced

b

y

authorised technicians onl

y

.

T

h

e

manu

f

acturer

dec

l

ine

s

an

y

l

ia

b

i

l

it

y

s

h

ou

l

d

t

h

e

s

e

s

a

f

et

y

mea

s

ure

s

not

b

e

o

b

s

erved

.

G

a

s

connection

Connection to the gas network or to the gas c

y

linder

ma

y

be carried out using a fle

x

ible rubber or steel

hose, in accordance with current national legislation

and after making sure that the appliance is suited to

the t

y

pe of gas with which it will be supplied (see the

rating sticker on the cover: if this is not the case

see

below

). When using liquid gas from a c

y

linder, install a

pressure regulator which complies with current national

regulations. To make connection easier, the gas

suppl

y

ma

y

be turned sidewa

y

s*: reverse the position

of the hose holder with that of the cap and replace the

gasket that is supplied with the appliance.

Check that the pressure of the gas suppl

y

is

consistent with the values indicated in the Table of

burner and nozzle specifications (

see below

). This

will ensure the safe operation and durabilit

y

of

y

our

appliance while maintaining efficient energ

y

consumption.

G

a

s

connection

u

s

in

g

a

f

l

e

x

i

b

l

e

ru

bb

er

h

o

s

e

Make sure that the hose complies with current

national legislation. The internal diameter of the hose

must measure: 8 mm for liquid gas suppl

y

; 13 mm

for methane gas suppl

y

.

Once the connection has been performed, make

sure that the hose:

Does not come into contact with an

y

parts that

reach temperatures of over 50°C.

Is not subject to an

y

pulling or twisting forces and

that it is not kinked or bent.

Does not come into contact with blades, sharp

corners or moving parts and that it is not

compressed.

Is eas

y

to inspect along its whole length so that

its condition ma

y

be checked.

Is shorter than 1500 mm.

Fits firml

y

into place at both ends, where it will be

fi

x

ed using clamps that compl

y

with current

regulations.

16

G

B

A

V

If one or more of these conditions is not fulfilled or

if the cooker must be installed according to the

conditions listed for class 2 - subclass 1 appliances

(installed between two cupboards), the fle

x

ible steel

hose must be used instead (

see below

).

Connectin

g

a

f

l

e

x

i

b

l

e

j

oint

l

e

ss

s

tain

l

e

ss

s

tee

l

pipe

to

a

t

h

readed

attac

h

ment

Make sure that the hose and gaskets compl

y

with

current national legislation.

To begin using the hose, remove the hose holder on the

appliance (the gas suppl

y

inlet on the appliance is a

c

y

lindrical threaded 1/2 gas male attachment).

Perform the connection in such a wa

y

that the hose

length does not e

x

ceed a ma

x

imum of 2 metres,

making sure that the hose is not compressed and

does not come into contact with moving parts.

C

h

ec

k

in

g

t

h

e

connection

f

or

l

ea

k

s

When the installation process is complete, check

the hose fittings for leaks using a soap

y

solution.

Never use a flame.

A

dapting to di

ff

erent t

y

pes o

f

gas

It is possible to adapt the appliance to a t

y

pe of gas

other than the default t

y

pe (this is indicated on the

rating label on the cover).

A

daptin

g

t

h

e

h

o

b

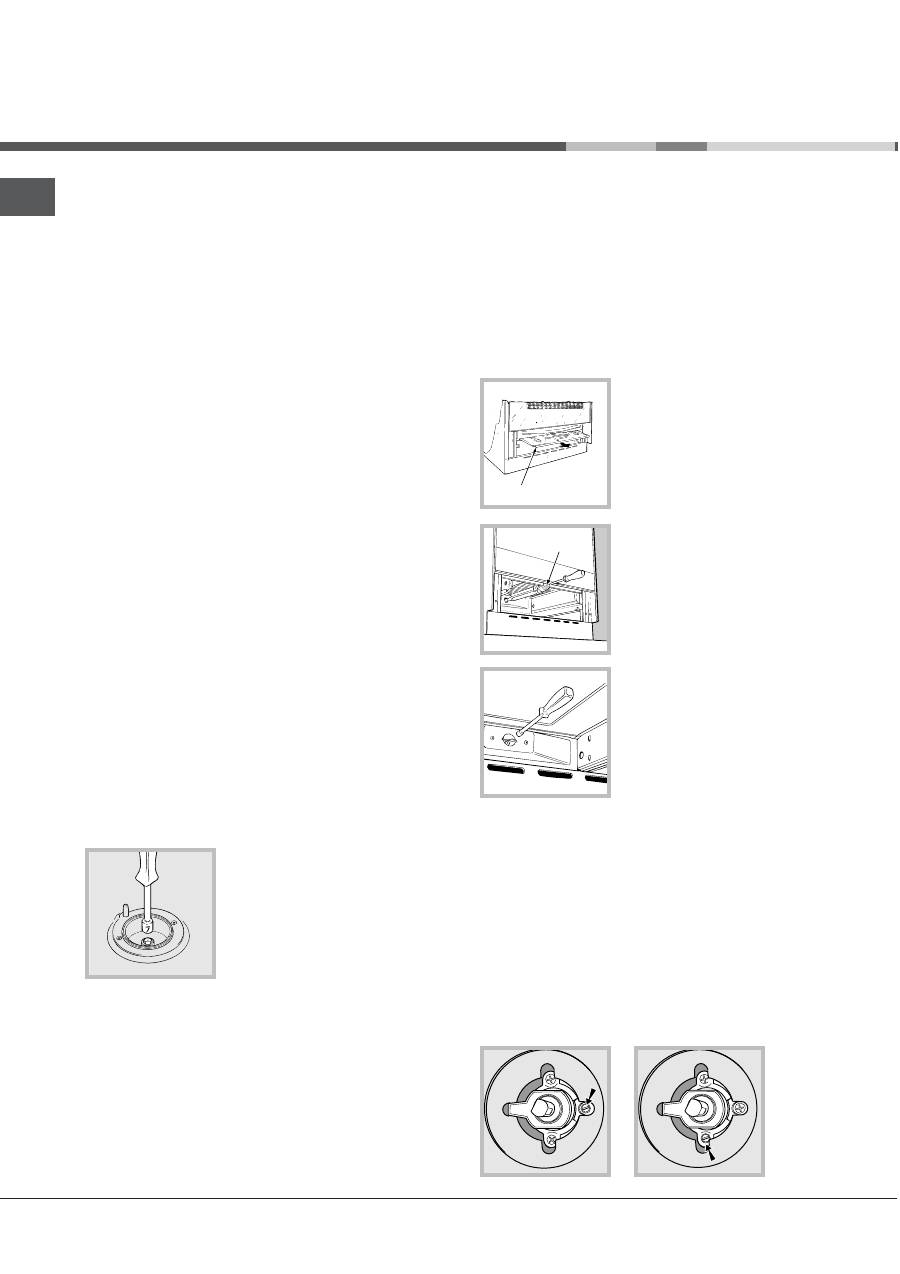

Replacing the nozzles for the hob burners:

1. Remove the hob grids and slide the burners off

their seats.

2. Unscrew the nozzles using a

7 mm socket spanner (

see

figure

), and replace them with

nozzles suited to the new t

y

pe

of gas(

see Burner and nozzle

specifications table

).

3. Replace all the components

b

y

following the above

instructions in reverse.

Adjusting the hob burners minimum setting:

1. Turn the tap to the minimum position.

2. Remove the knob and adjust the regulator

y

screw, which is positioned inside or ne

x

t to the tap

pin, until the flame is small but stead

y

.

If the appliance is connected to a liquid gas

suppl

y

, the regulator

y

screw must be fastened as

tightl

y

as possible.

3. While the burner is alight, quickl

y

change the position

of the knob from minimum to ma

x

imum and vice versa

several times, checking that the flame is not

e

x

tinguished.

The hob burners do not require primar

y

air adjustment.

A

daptin

g

t

h

e

oven

Replacing the oven burner nozzle:

1. Remove the oven compartment.

2. Slide out the protection

panel A

(

see diagram

).

3. Remove the oven burner

after unscrewing the screws V

(

see figure

).

The whole operation will be

made easier if the oven door

is removed.

4. Unscrew the nozzle using a

special nozzle socket spanner

(

see figure

) or with a 7 mm

socket spanner, and replace it

with a new nozzle that is

suited to the new t

y

pe of gas

(

see Burner and nozzle

specifications table

).

A

d

j

u

s

tin

g

t

h

e

g

a

s

oven

b

urner

s

minimum

s

ettin

g

:

1. Light the burner (

see Start-up and Use

).

2. Turn the knob to the minimum position (MIN) after

it has been in the ma

x

imum position (MAX) for

appro

x

imatel

y

10 minutes.

3. Remove the knob.

4. Tighten or loosen the adjustment screws on the

outside of the thermostat pin (

see figure

) until the

flame is small but stead

y

.

If the appliance is connected to liquid gas, the

adjustment screw must be fastened as tightl

y

as

possible.

17

G

B

C

34

S

G

1

R

/H

A

C

34

S

G3

R

/H

A

5. Turn the knob from the MAX position to the MIN

position quickl

y

or open and shut the oven door,

making sure that the burner is not e

x

tinguished.

A

daptin

g

t

h

e

g

ri

ll

Replacing the grill burner nozzle:

1. Remove the oven burner

after loosening screw V (

see

figure

).

2. Unscrew the grill burner

nozzle using a special nozzle

socket spanner (

see figure

) or

preferabl

y

with a 7 mm socket

spanner, and replace it with a

new nozzle that is suited to the

new t

y

pe of gas (

see Burner

and nozzle specifications table

).

Be careful of the spark plug wires and the

thermocouple tubes.

The oven and grill burners do not require primar

y

air adjustment.

After adjusting the appliance so it ma

y

be used

with a different t

y

pe of gas, replace the old rating

label with a new one that corresponds to the new

t

y

pe of gas (these labels are available from

Authorised Technical Assistance Centres).

Should the gas pressure used be different (or var

y

slightl

y

) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet hose in

accordance with current national regulations relating

to regulators for channelled gas.

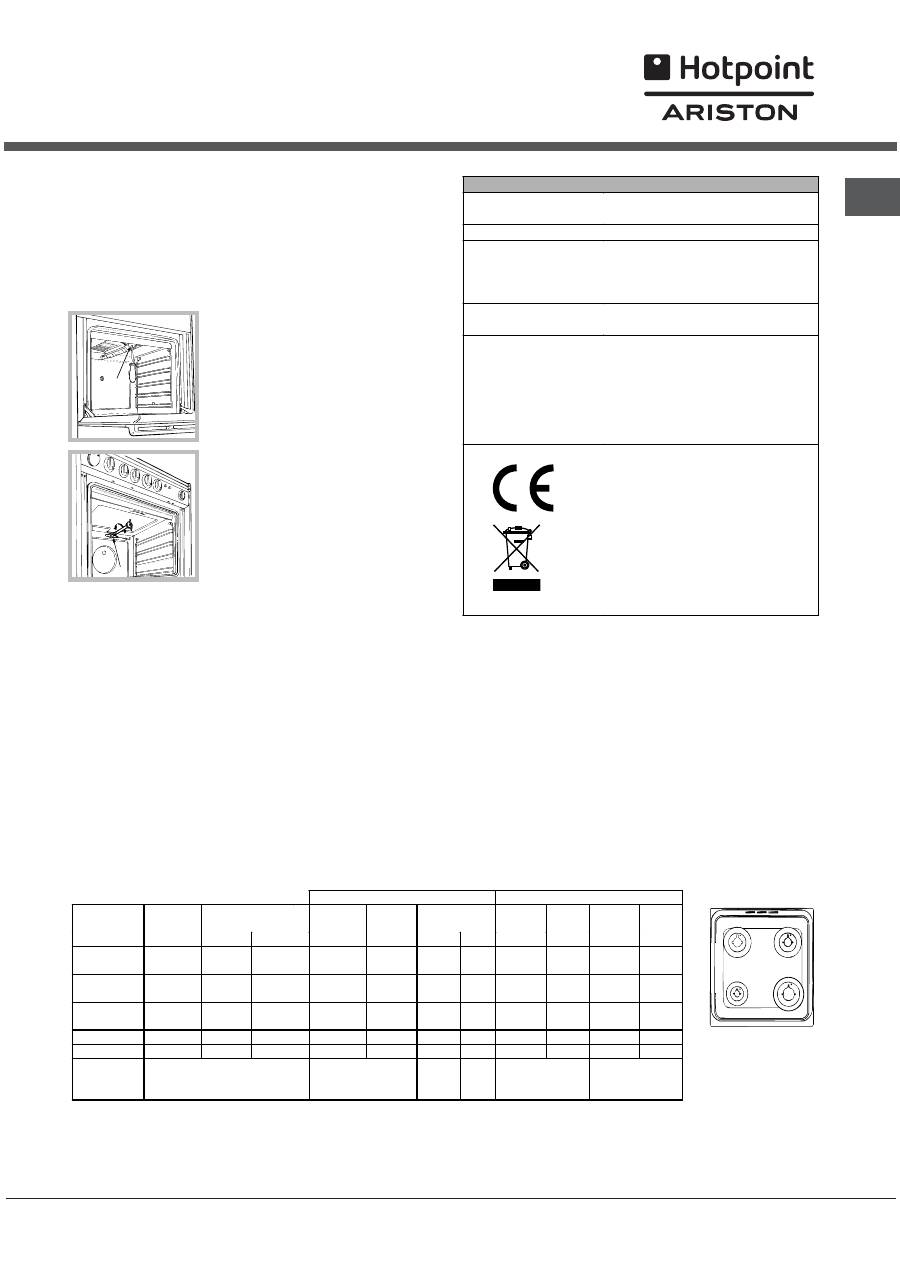

T

a

b

le o

f

b

urner and nozzle speci

f

ications

V

I

S S

R

A

TECHNICAL DATA

Oven dimensions

(HxWxD)

34x38x44 cm

Volume

57 l

Useful

measurements

relating to the oven

compartment

width 42 cm

depth 44 cm

height 17 cm

Power supply voltage

and frequency

see data plate

Burners

may be adapted for use with any

type of gas shown on the data

plate, which is located inside the

flap or, after the oven

compartment has been opened,

on the left-hand wall inside the

oven.

EC Directives: 73/23/EEC dated

19/02/73 (Low Voltage) and

subsequent amendments -

89/336/EEC dated 03/05/89

(Electromagnetic Compatibility)

and subsequent amendments -

90/369/EEC dated 29/06/90 (Gas)

and subsequent amendments -

93/68/EEC dated 22/07/93 and

subsequent amendments -

2002/96/EC.

T

able

1

Liquid

Gas

Natural

Gas

D

i

ameter

(mm)

Thermal

Power

kW

(p

.

c

.

s

.

*)

By

Pass

1/100

Nozzle

1/100

Flow*

g/h

Nozzle

1/100

Flow*

l/h

Nozzle

1/100

Flow*

l/h

Burner

Nominal

Reduced

(mm)

(mm)

***

**

(mm)

(mm)

Fast

(Large)(R)

100

3

.

00

0

.

7

41

87

218

214

128

286

143

286

Semi

Fast

(Medium)(S)

75

1

.

90

0

.

4

30

70

138

136

104

181

118

181

Auxiliary

(Small)(A)

51

1

.

00

0

.

4

30

52

73

71

76

95

80

95

Oven

-

3

.

10

1

.

0

46

85

225

221

132

295

148

288

Grill

-

2

.

50

-

-

80

182

179

122

238

139

227

Supply

Pressures

Nominal

(mbar)

Minimum

(mbar)

Maximum

(mbar)

28-30

20

35

37

25

45

20

17

25

13

6,5

18

*

At

15°C

1013

mbar-dry

gas

***

Butane

P

.

C

.

S

.

=

49,47

MJ/Kg

**

Propane

P

.

C

.

S

.

=

50,37

MJ/Kg

Natural

P

.

C

.

S

.

=

37,78

MJ/m³

Оглавление

- Installazione

- D escrizione dellapparecchio

- Avvio e utilizzo

- P recauzioni e con s i gl i

- M anutenzione e cura

- Ass i s tenza

- O perating I nstructions

- I nstallation

- Descriptiono f t h e appliance

- Start - up and use

- P recaution s and tip s

- Care and m aintenance

- Ð óêîâîäñòâî ïî ýêñïëóàòàöèè

- Ó ñ òàíî âê à

- Î ïè ñ àíèåè ç äåëèÿ

- Â ê ë þ÷ åíèå è ý êñ ïëóàòàöèÿ

- Ï ðåäî ñ òîðî æ íî ñ òè è ðå ê îìåíäàöèè

- Ò å õ íè ÷ å ñê îå î áñ ëó æ è â àíèå è ó õ îä

- ² í ñ òðó ê ö ³³ ç å êñ ïëóàòàö ³³

- Â ñ òàíî â ëåíí

- Î ïè ñ ïëèòè

- Â ê ë þ÷ åííÿ ³ â è ê îðè ñ òàííÿ

- Ç àïî á ³ æ í ³ ç à ñ î á è è ïîðàäè

- Ä î ã ëÿä i òå õ í ³ ÷ íå î áñ ëó ã î â ó â àííÿ

- I nstrucþiuni d e folosire

- Inst a l a re

- Descriereapa r a tului

- P ornire º i utili za re

- Pre c a uþii º i sf at u r i

- Î n tre þin ere º i cu rã þi re