Ridgid SeekTech ST-510: инструкция

Инструкция к Линейному Передатчику Ridgid SeekTech ST-510

®

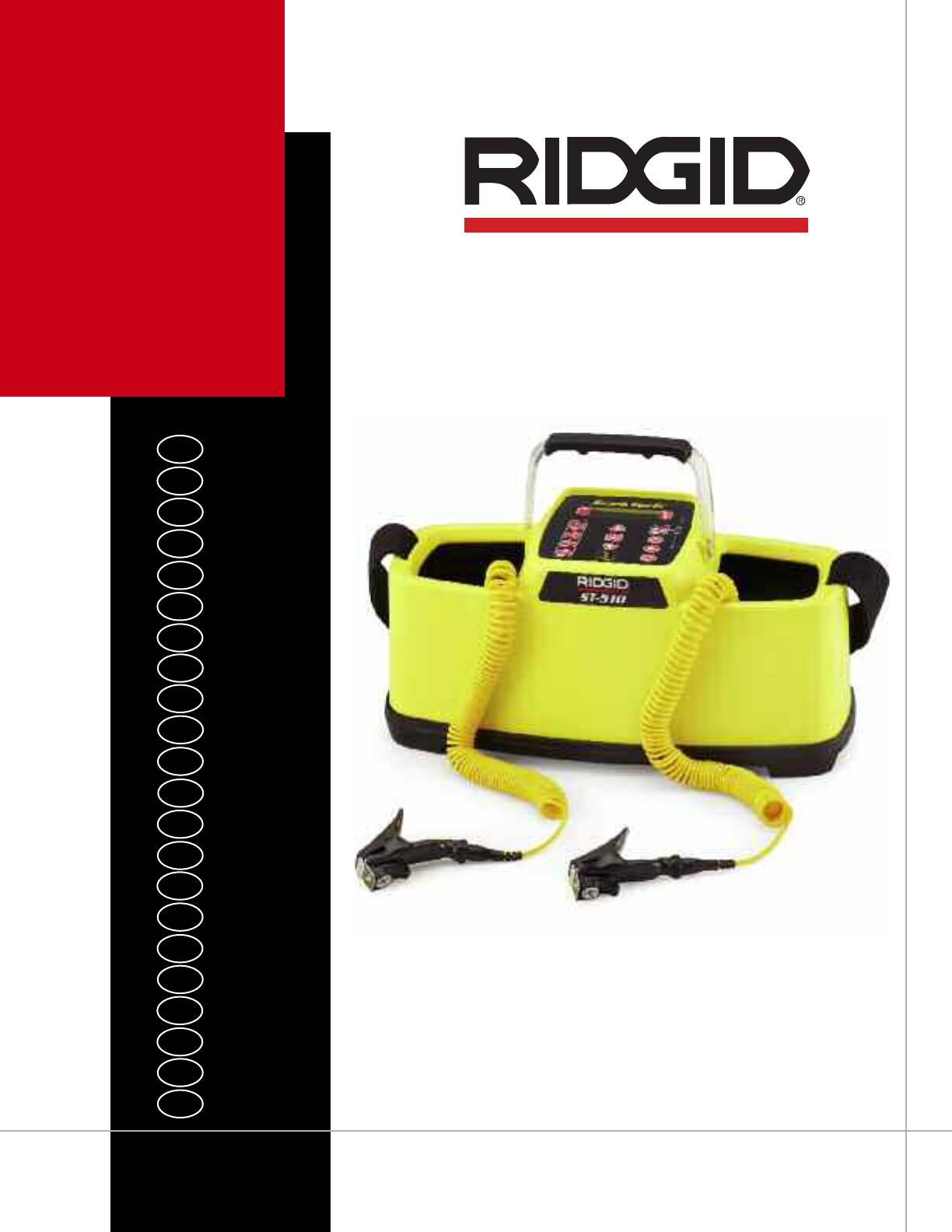

SeekTech

ST-510

GB p.1

FR p.19

ES p.39

DE p.59

NL p.77

PT p.95

IT p.113

SV p.131

DA p.149

FI p.167

NO p.185

HR p.203

PO p.221

RO p.239

CZ p.257

HU p.275

EL p.293

RU p.311

TR p.329

SL p.347

SK p.365

SB p.383

RIDGE TOOL COMPANY

®

SeekTech

ST-510 Line Transmitter

Table of Contents

Recording Form for Machine Serial Number..............................................................................................................1

Safety Symbols..............................................................................................................................................................2

General Safety Rules

Work Area ..................................................................................................................................................................2

Electrical Safety..........................................................................................................................................................2

Personal Safety ..........................................................................................................................................................2

Equipment Use and Care............................................................................................................................................3

Battery Use and Care ................................................................................................................................................3

Service........................................................................................................................................................................3

Specific Safety Information..........................................................................................................................................3

ST-510 Line Transmitter Safety..................................................................................................................................3

Description,Specifications and Standard Equipment

Description..................................................................................................................................................................4

Specifications..............................................................................................................................................................4

Standard Equipment ..................................................................................................................................................4

Transmitter Components..............................................................................................................................................5

Icon Legend ..................................................................................................................................................................5

Keypad ..........................................................................................................................................................................5

Display Screen ..............................................................................................................................................................6

Installing Batteries

Operation Time...........................................................................................................................................................6

Alternate Power Supply................................................................................................................................................6

Pre-Operating Inspection ............................................................................................................................................7

Set-Up and Operation

Direct-Connect Method ..............................................................................................................................................8

Inductive Clamp Method ............................................................................................................................................9

Inductive Mode............................................................................................................................................................9

Selecting A Frequency..............................................................................................................................................10

Check The Circuit ....................................................................................................................................................11

Adjust Current ..........................................................................................................................................................11

Main Menu................................................................................................................................................................12

Battery Saver Mode..................................................................................................................................................12

Auto Shut Off Adjustment ........................................................................................................................................12

Auto Back Light ........................................................................................................................................................13

Adjusting The LCD Screen Contrast ........................................................................................................................13

Cleaning Instructions..................................................................................................................................................13

Accessories ................................................................................................................................................................13

Transport And Storage ..............................................................................................................................................14

Service And Repair ....................................................................................................................................................14

Disposal ......................................................................................................................................................................14

Troubleshooting..........................................................................................................................................................15

Frequencies ................................................................................................................................................................16

Manufacturers Frequency Table ..........................................................................................................................16-17

ii

Ridge Tool Company

®

SeekTech

ST-510

10 Watt Pipe and Cable Line

Transmitter

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, fire and/or

serious personal injury.

®

SeekTech

ST-510 Line Transmitter

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

®

SeekTech

ST-510 Line Transmitter

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safety

information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains important

information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling or using this equipment to reduce

the risk of eye injury.

This symbol indicates the risk of electrical shock.

parts. Damaged or entangled cords increase the risk

General Safety Rules

of electric shock.

WARNING

• When operating equipment outdoors, use an ex-

Read all safety warnings and instructions. Failure to follow

tension cord suitable for outdoor use (marked “W-

the warnings and instructions may result in electric shock,

A” or “W”). Use of a cord suitable for outdoor use

fire and/or serious injury.

reduces the risk of electric shock.

SAVE THESE INSTRUCTIONS!

• If operating equipment in a damp location is un-

Work Area

avoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces

• Keep work area clean and well lit. Dark areas invite

the risk of electric shock.

accidents.

• Keep all electrical connections dry and off the

• Do not operate equipment in explosive atmo-

ground. Do not touch equipment or plugs with

spheres, such as in the presence of flammable

wet hands. This reduces the risk of electrical shock.

liquids, gases or dust. Equipment can create sparks

which may ignite the dust or fumes.

Personal Safety

• Keep children and by-standers away while oper-

• Stay alert, watch what you are doing and use com-

ating equipment. Distractions can cause you to lose

mon sense when operating equipment. Do not

control.

use equipment while you are tired or under the in-

fluence of drugs, alcohol or medication. A moment

Electrical Safety

of inattention while operating equipment may result in

• Avoid body contact with earthed or grounded sur-

serious personal injury.

faces such as pipes, radiators, ranges and refrig-

• Use personal protective equipment. Always wear

erators. There is an increased risk of electrical shock

eye protection. Protective equipment such as dust

if your body is earthed or grounded.

mask, non-skid heavy soled safety shoes, hard hat or

• Do not expose equipment to rain or wet condi-

hearing protection used for appropriate conditions will

tions. Water entering equipment will increase the risk

reduce personal injuries.

of electrical shock.

• Do not overreach. Keep proper footing and balance

• Do not abuse the cord. Never use the cord for car-

at all times. This enables better control of the equip-

rying, pulling or unplugging the equipment. Keep

ment in unexpected situations.

cord away from heat, oil, sharp edges or moving

2

Ridge Tool Company

®

SeekTech

ST-510 Line Transmitter

Equipment Use and Care

tions concerning battery disposal. Please follow all

applicable regulations.

• Do not force equipment. Use the correct equipment

for your application. The correctequipmentwilldo the

Service

job better and safer at the rate for which it is designed.

• Have your equipment serviced by a qualified repair

• Do not use equipment if the switch does not turn it

person using only identical replacement parts.

ON and OFF. Any equipment that cannot be con-

This will ensure that the safety of the power tool is

trolled with the switch is dangerous and must be re-

maintained.

paired.

• Disconnect the plug from the power source and/or

the battery pack from the equipment before making

Specific Safety Information

any adjustments, changing accessories or stor-

WARNING

ing. Such preventive safety measures reduce the risk

This section contains important safety information

of injury.

that is specific to this equipment.

• Store idle equipment out of the reach of children

Read these precautions carefully before using the

and do not allow persons unfamiliar with the equip-

®

SeekTech

ST-510 Line Transmitter to reduce the

ment or these instructions to operate the equip-

risk of electrical shock, fire or serious personal in-

ment. Equipment is dangerous in the handsofuntrained

jury.

users.

SAVE THESE INSTRUCTIONS!

• Maintain equipment. Check for misalignment or bind-

Keep thismanualwith the machineforuseby the operator.

ing of moving parts, missing parts, breakage of parts

and any other condition that may affect the equip-

If you have any question concerning this Ridge Tool

ment’s operation. If damaged, have the equipment

product:

repaired before use. Many accidents are caused by

– Contact your local RIDGID distributor.

poorly maintained equipment.

– Visit www.RIDGID.com or www.RIDGID.eu to find

• Use the equipment and accessories in accordance

your local Ridge Tool contact point.

with these instructions, taking into account the

– Contact Ridge Tool Technical Services Department at

working conditions and the work to be performed.

rtctechservices@emerson.com, or in the U.S. and

Use of the equipment for operations different from

Canada call (800) 519-3456.

those intended could result in a hazardous situation.

ST-510 Line Transmitter Safety

• Use only accessories that are recommended by

the manufacturer for your model. Accessories that

• Do not operate this equipment if operator or ma-

may be suitable for one piece of equipment may be-

chine is standing in water. Operating machine while

come hazardous when used with other equipment.

in water increases the risk of electrical shock.

• Keep handles dry and clean; free from oil and

• The ST-510 Line Transmitter is not water resis-

grease. Allows for better control of the equipment.

tant. Do not expose the equipment to water or

rain. This increases the risk of electrical shock.

Battery Use and Care

• Do not use where a danger of high voltage contact

• Recharge only with the charger specified by the

is present. Do not attach leads to high voltage

battery manufacturer. A charger that is suitable for

line. The equipment is not designed to provide high

one type of battery may create a risk of fire when

voltage protection and isolation. Use high voltage pre-

used with another battery.

cautions to carefully disconnect leads.

• Under abusive conditions, liquid may be ejected

• Always attach leads before turning unit on and

from the battery; avoid contact. If contact acciden-

turn unit off before disconnecting leads to reduce

tallyoccurs,flush withwater. If liquid contactseyes, ad-

the risk of electrical shock.

ditionally seek medical help. Liquid ejected from the

• Locating equipment uses electromagnetic fields

battery may cause irritation or burns.

that can be distorted and interfered with. More

• Properly dispose of batteries. Exposure to high

than one utility may be present in a given area.

temperatures can cause the batteries to explode, so do

Follow local guidelines and one call/call before

not dispose of in a fire. Some countries have regula-

you dig service procedures. Exposing the utility is

Ridge Tool Company

3

®

SeekTech

ST-510 Line Transmitter

the only way to verify its existence, location and

Dimensions:

depth.

Length .........................7.0" (17.8 cm)

• Avoid traffic. Pay close attention to moving vehicles

Width...........................15" (38.1 cm)

when using on or near roadways. Wear visible clothing

Height..........................6.5" (16.5 cm)

or reflector vests.

Cable Length...............48' Extended (14m); 46" con-

tracted (1.1m)

• Use equipment only as directed. Do not use the

transmitter and related equipment unless the operator’s

Output Power ................Nominal 10 watts max. 1 watt

manual has been read.

maximum if frequency is

NOTICE

Ridge Tool Company, its affiliates and sup-

above 45kHz. Maximum out-

pliers, will not be liable for any injury or any direct, indi-

put voltage 30V RMS; ~ 48V

rect, incidental or consequential damages sustained or

peak

incurred by reason of the use of the SeekTech ST-510

Power Settings:.............4 mA, 15 mA, 50 mA, 150 mA,

line transmitter.

600 mA

Default Settings:............60 Hz Mode, 2 Hr. Shutoff,

Description, Specifications

30V-RMS Maximum,

And Standard Equipment

SeekTech frequencies loaded

Description

FCC Limits.....................47 CFR 15.213 says that from

®

The RIDGID

SeekTech ST-510 line transmitter is part of

9kHz up to (but not including)

the RIDGID SeekTech cable and pipe locating system. The

45kHz, peak output power

ST-510 is used to generate an “active” signal on a metal-

shall not exceed 10 W. From

lic underground line so that it may be traced with a com-

45kHz to 490kHz, it must not

patible receiver such as the SeekTech SR-20 or SR-60.

exceed 1W.

This allows the line’s location to be correctly marked so it

can be exposed for repair or avoided during excavation.

Standard Equipment

TheST-510 linetransmitter canapply an active tracing sig-

• SeekTech ST-510 Transmitter

nal to a target conductor in three ways:

• Direct connect leads and clips

• Operator’s Manual

1. Direct Connect Method – The transmitter’s leads are

connected directly to the target conductor and a suit-

• 8 D-cell batteries (Alkaline)

able ground (See page 8).

• Grounding Stake

2. Inductive Clamp Method (optional accessory) –

The jaws of the inductive clamp encircle the target

conductor; there is no metal-to-metal contact (See

page 9).

3. Inductive Mode – The transmitter is placed over,

and in-line with, a conductor. Its internal antenna in-

duces a signal onto the target conductor (See page

9).

Specifications

Power Source................8 Alkaline or rechargeable

batteries.(D-Cells)

High Voltage Indicator

Features: AUTO Shut Off,

Battery Saver Mode,

AutoBack Light

Weight...........................4.75 lbs (2.15 kg) w/o batteries,

7.5 lbs (3.4 kg) w/batteries

4

Ridge Tool Company

®

SeekTech

ST-510 Line Transmitter

Transmitter Components

Icon Legend

Display Screen

High Voltage Present

Safety Alert

Keypad

Lead Clip

Handle

External Power

Coil Cord (48Ft.

Power ON/OFF

12-15VDC

(16m) Extended)

Shoulder

Inductive Clamp

Strap

Keypad

Display

Screen

Up/Down

Inductive

Arrows

Mode

On/Off

Figure 1 – Top View

Orientation

For

Inductive

Select

Mode

Main

menu

Sound

Frequency

On/Off

Selection

Power

Frequencies

On/Off

High Voltage

Indicator

128Hz

1kHz

Battery

Compartment/

Carriage

Jack For

Inductive

DC Power

8kHz

Clamp

Jack

Figure 2 – Back View

33kHz/

* Top frequency is 262 kHz on Cat. #21903

93kHz or 262kHz*

and 93 kHz on Cat. #21953

Figure 4 – Keypad

Serial Number

Label

Security

Cable Holes

(Can Be Used To Secure

Transmitter With Cable and Lock)

Grounding

Stake

Figure 3 – Bottom View

Ridge Tool Company

5

®

SeekTech

ST-510 Line Transmitter

clockwise to secure the holder in the case. The bat-

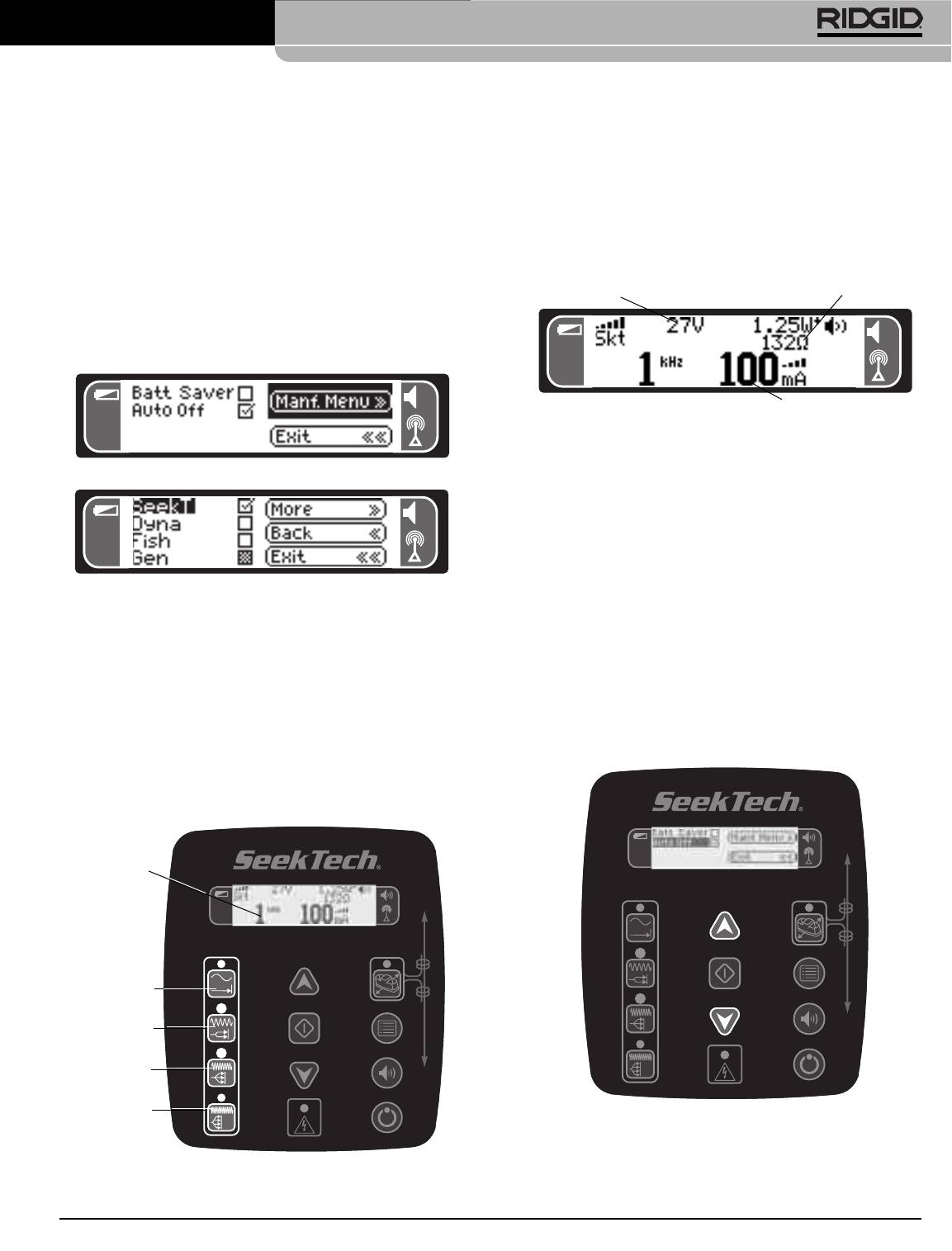

Display Screen

tery holder can be installed in either orientation.

Always remove batteries before shipping unit.

Operation Time

Typical operation time for transmitter with batteries

varies depending on battery type, transmitter settings

(load), backlight use, Battery Saver Mode use, operating

temperature and other factors. When using alkaline

batteries, under average conditions, the batteries will

supply about 12.5 hours of operation. See Estimated

• Battery Level – Shows remaining battery power in 5 steps.

Battery Operating Times Chart for more information.

• Manufacturer – Shows the manufacturer’s frequency set being

used (default is SeekTech).

Estimated Alkaline Battery Operating Times

• Voltage – Voltage that is applied to the leads. This may say MAX,

indicating the voltage is at its highest allowable point (~80 V peak-

Current Est. Time to Depletion

to-peak, ~30V RMS (square wave)).

400 mA 1.8 hours

• Current Strength – current flowing through the circuit in milliamps

200 mA 3.6 hours

(mA).

100 mA 7.25 hours

• Sound – Indicates if sound is ON or OFF.

• Ohms (resistance) – This shows the approximate resistance in

50 mA 14 hours

the circuit.

25 mA 28 hours

• Watts (Power) – Total power that the transmitter is putting out. In

Battery Saver mode, this is absent.

The ST-510 Line Transmitter also includes an auto shut-

• Frequency – Frequency being used.

off feature to help prevent batteries from running down if

the unit is left on inadvertently. Batteries used in high-cur-

rent applicationsmay recover and still be usable if allowed

Installing Batteries

to rest prior to being used again.

To install batteries in the ST-510 Line Transmitter, turn

the knob on the battery holder counter clockwise until the

Alternate Power Supply

holder is loose. Slide the holder straight back to re-

move from the transmitter. (See Figure 6.)

1. Using the transmitter with battery power provides the

highest level of electrical isolation and is the recom-

mended power source. However, the Transmitter can

be used with an external power source, such asa ve-

hicle power jack or a standard outlet. In those cases,

the following isolated adapters are recommended.

• Use only a power supply approved to IEC 61010-

1 or IEC 60950. Output must be isolated, SELV

and Limited-Energy Circuit per IEC 61010-1 or

LPS per IEC 60950, 12-15VDC, 30W minimum.

Output connection is standard barrel plug, 2.1mm

pin, tip positive.

NOTE: Adapters are sold separately.

Figure 6 – Removing Battery Holder

If used with an adapter, it is very important that the

above-specified adapter beusedto insure appropriate

Install eight “D” size batteries into the battery holder as

power is supplied to the transmitter. Be sure to read

indicated on the decal on the holder.

and keep the adapter instructions. Make sure the

Use batteries that are all of the same type

adapter cord has a clear, dry path without any poten-

(example – all Alkaline or all NiCd). Do not mix battery

tial source of damage. Use dry hands when plug-

types. Do not mix used and new batteries. Mixing bat-

ging cords in. Do not turn the transmitter on at

teries can cause over heating and battery leakage.

this time.

If the transmitter is used with an external

Fit the battery holder back into the transmitter case and

power source, you must make sure that the external

slide in. Push slightly on the holder and turn the knob

6

Ridge Tool Company

)

)

)

Battery

Voltage

Watts

Sound

Level

Manufacturer Frequency

Current

Ohms

Strength

(Resistance)

Figure 5 – Display Screen

NOTICE

WARNING

®

SeekTech

ST-510 Line Transmitter

power source is fully isolated from ground and power

Set-Up and Operation

mains. If the transmitter is not isolated, the transmitter is

not protected from connection to energized (live) power

WARNING

lines. This could cause electrical shock and damage the

transmitter. Do not use a non-isolated power supply

with the transmitter.

If using the transmitter with a 12V DC adapter from a ve-

hicle power jack on a power line, the vehicle is con-

nected to the power line. If that power line is energized

(live), the vehicle now is at the line voltage, and if the ve-

hicle is grounded, could cause electrical shock or property

Always wear eye protection to protect your eyes

damage to both the transmitter and vehicle.

against dirt and other foreign objects.

Set up and operate the transmitter and work area

according to these procedures to reduce the risk of

Pre-Operation Inspection

injury from electric shock, and other causes, and

prevent transmitter damage.

WARNING

1. Check for anappropriate work areaas indicated inthe

General Safety Section page 2.

2. Inspect the line to have a signal applied to it. The line

must be metal. If the line is not metallic, it will not be

able to be located with this equipment.

When using the transmitter on insulated conductors,

the target conductor should be grounded at each

Before each use, inspect your transmitter and cor-

rect any problems to reduce the risk of serious injury

end. Otherwise, the signal may not be strong enough

from electric shock and other causes and prevent

to locate.

transmitter damage.

The transmitter is not designed to provide high volt-

1. Make sure that the transmitter is unplugged and in-

age isolation and protection. Do not use where a

spect the cords and plug for damage or modification.

danger of high voltage contact is present.

2. Clean any oil, grease or dirt from equipment handles

3. Determine the correct equipment for the application.

and controls. This aids inspection.

Using incorrect equipment for an application can

3. Inspect the transmitter for any broken, worn, missing,

cause injury or damage the equipment.

mis-aligned or binding parts or any other condition

• Equipment for other applications can be found by

which may prevent safe and normal operation.

consulting the Ridge Tool Catalog, online at

www.RIDGID.com or www.RIDGID.eu.

4. Check that the warning label is present, firmly at-

tached and readable.

4. Make sure all equipment has been properly inspected.

5. If any issues are found during the inspection, do not

5. The ST-510 line transmitter can apply an active trac-

use the transmitter until it has been properly serviced.

ing signal to a conductor in three ways:

6. Inspect any other equipment being used per its in-

• Direct Connect – The transmitter’s leads are con-

structions to make sure it is in good usable condition.

nected directly to the target conductor and a suit-

able ground. This method is most commonly used

when the target utility is accessible. Direct con-

nect should not be used for energized (live) con-

ductors.

• Inductive Clamp (optional accessory) – the jaws of

the inductive clamp encircle the target conductor; if

the conductor is insulated, there is no metal to

metal contact. This method is commonly used

when the target utility is accessible but direct con-

nect is not possible on an insulated cable for ex-

ample. (See Page 9)

Ridge Tool Company

7

®

SeekTech

ST-510 Line Transmitter

• Inductive Mode – The transmitter generates a field,

4. Scrape away any dirt, paint, corrosion or other coat-

which in turn induces a current in the target con-

ings on the target conductor to insure good contact

ductor. There is no direct connection between the

with the cable lead. Again, this lowers the resistance

transmitter and the target conductor. The trans-

of the circuit and results in a stronger tracing signal.

mitter is placed over and inline with the target con-

Connect the other cable lead to the target conductor.

ductor. The transmitter’s internal antenna induces

(See Figure 8).

a signal onto the target conductor. This method is

most commonly used when the target utility is not

accessible. (See page 9).

Direct Connect Method

1. Confirm that the target conductor is NOT energized

(live). The transmitter is not designed to be con-

nected to energized (live) conductors.

2. Choose ground spike and target conductor connec-

tion locations. The cable leads extend up to 48 feet to

give flexibility in choosing connection points. The

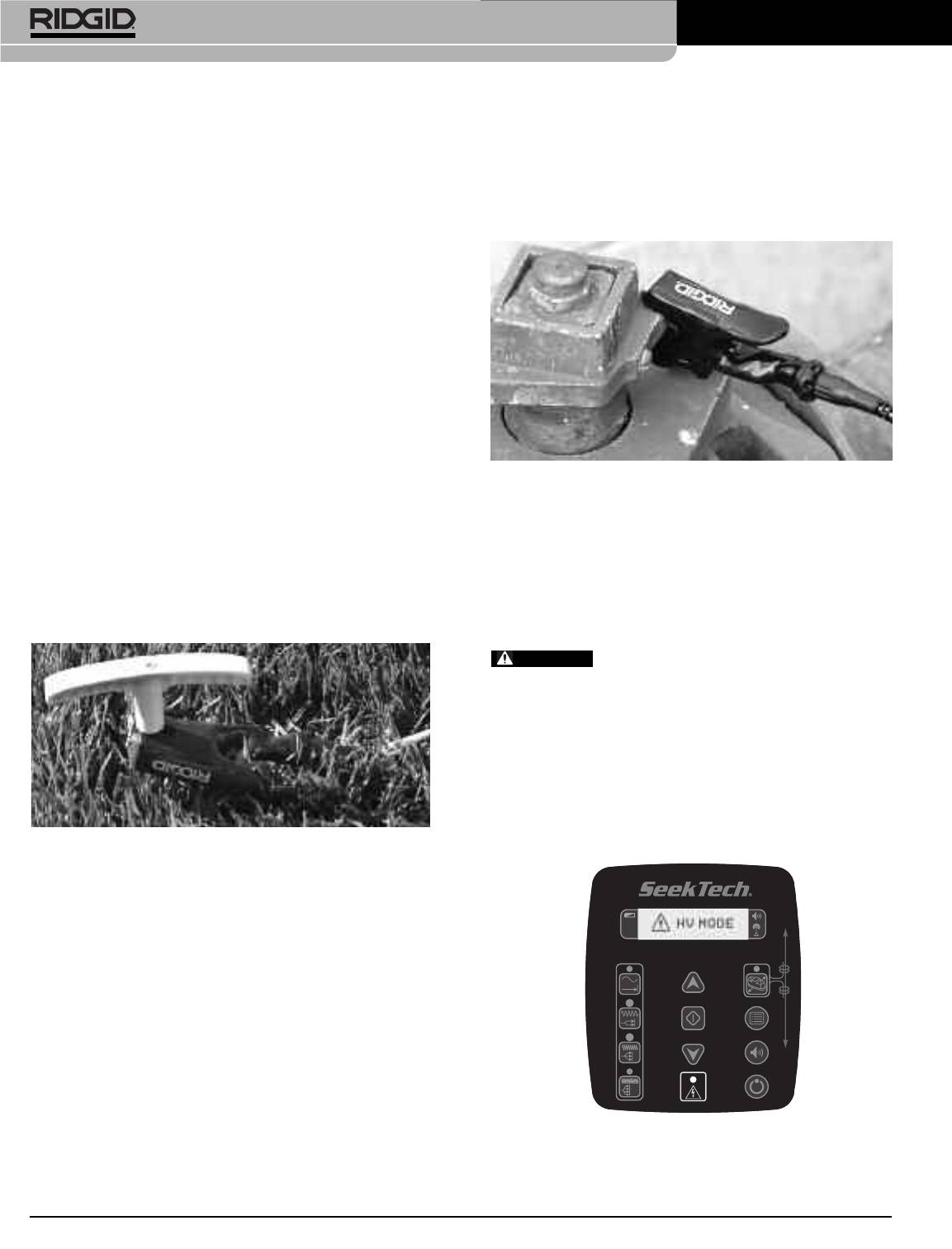

Figure 8 – Connecting Cable Lead To Target Conductor.

cords of the transmitter can act as antennas, and the

further they are extended, the more incidental signal

5. Press the POWER ON/OFF button on the keypad to

they can send out. The further the leads are ex-

turn the transmitter on. As the power comes on, the

tended, the further the receiver should be used from

transmitter will emit ascending beeps. The transmitter

the transmitter to avoid misleading signals from the

will pause to measure how much current is flowing

cords. If locating close to the transmitter, keep the

onto the target conductor. The faster the beeping, the

leads as short as possible with the excess in the

higher the detected current. To turn the beeping off,

transmitter’s side pockets.

press the sound key. (See Figure 4).

WARNING

The line transmitter is designed to with-

stand up to 240V AC between the two leads. The pro-

tection is NOT intended to be used continuously. If the

transmitter encounters a target conductor voltage higher

than approximately 42 volts (RMS), a red LED next to the

High Voltage Present Indicator will flash and the LCD

screen will display the safety alert symbol and “HV MODE”

(See Figure 9). If this happens, DO NOT TOUCH THE

TRANSMITTER, CORDS OR CONNECTIONS. The tar-

get conductorisenergized and there isthe risk of electrical

Figure 7 – Attaching Lead To Ground Stake

shock. Use high voltage precautions to disconnect.

3. Remove the ground spike from the bottom of the

transmitter and insert it into the earth. A good ground

results in a stronger tracing signal. To get a good

ground, insert the ground spike as far as possible into

the earth. Moist earth will give a better ground than

dry earth. Wetting the earth around the ground spike

can improve grounding. This lowers the resistance of

the circuit. Connect either cable lead to the ground

stake. Always connect to the ground first. Ifthe tar-

get conductor has an unknown voltage on it, this

may allow the current to be directed away from the

user. (See Figure 7).

Grounding can also be accomplished by attaching the

Figure 9 – High Voltage Indicator

cable lead to things like shovel blades or larger rods

sunk into the earth. These can improve grounding by

increasing area/depth in contact with the Earth.

8

Ridge Tool Company

®

SeekTech

ST-510 Line Transmitter

6. Select a frequency, check the circuit and adjust cur-

rent. See pages 10 and 11 for more information.

7. Turn onthe receiver/locator and follow the instructions

for the receiver. Make sure the receiver’s frequency is

set to match that on the transmitter. Confirm the re-

Figure 11 – Transmitter In Inductive Clamp Mode

ceiver is picking up the transmitted frequency by

holding it near the transmitter and observing the in-

5. Clamp the jaws of the inductive clamp around the tar-

crease in receiver signal.

get conductor. Make sure that the jaws of the clamp

are fully closed. (See Figure 12).

8 Once the locating is completed, press the POWER

ON/OFF button on the keypad to turn the transmitter

off. Always turn the unit off before disconnecting

the cable leads to reduce the risk of electrical

shock. Remove the cable lead from the target con-

ductor first. Always disconnect the cable lead fromthe

target conductor first before removing the cable lead

from the ground spike to reduce the risk of electrical

shock. Disconnect the cable lead from the ground

spike. Store the cables and ground spike for trans-

portation.

Inductive Clamp Method

Figure 12 – Inductive Clamp Attached to a Conductor

1. This method requires an inductive clamp that is not

supplied with the transmitter. Read and follow all in-

6. Turn the transmitter on and select a frequency for lo-

struction for the use of the inductive clamp.

cating, check the circuit and adjust current. (See

page 11). Be sure that the receiver is set to the same

2. Confirm that the target conductor is NOT energized

frequency. The inductive clamp typically works best

(live). The transmitter is not designed to be con-

with frequencies around 33 kHz.

nected to energized (live) conductors.

7. Once locating is complete, turn the transmitter power

3. Confirm that the transmitter is OFF. If needed, press

OFF before disconnecting the clamp.

the POWER ON/OFF button on the keypad to turn

thetransmitteroff.Never turn the transmitter onbefore

Inductive Mode

attaching the inductive clamp.

1. Properly place the transmitter relative to the target

4. Insert the plug of the inductive clamp into the jack on

conductor. On the top of the transmitter is an orien-

the transmitter (above the battery holder). When the

tation mark. The orientation mark needs to be aligned

inductive clamp plug isin place,the transmitter willau-

with the target conductor. (See Figure 13).

tomatically be in Inductive Clamp mode, the cable

leads will be disabled, and “Clamp” will be displayed

on the screen. (See Figure 11).

Figure 10 – ST-510 with Inductive Clamp

Target

Conductor

Figure 13 – Orientation to the Line – Inductive Mode

Ridge Tool Company

9

®

SeekTech

ST-510 Line Transmitter

2. Press the POWER ON/OFF button on the keypad to

at least 30 feet from the transmitter to prevent this.

turn the transmitter ON. As the power comes on, the

(See Figure 15).

transmitter will emit ascending beeps. Press the

One way to confirm that you are tracing the target

Inductive Mode Key. The display screen will read “IN-

conductor and not the transmitter field is to look for a

DUCTIVE MODE”. (See Figure 14). The transmitter

strong, stable proximity signal and a valid depth mea-

will make a short buzzing sound when shifting into

surement on the receiver. While directly over the en-

Inductive Mode, and after that,will make double beeps

ergized line you can also raise the receiver a set

during inductive mode operation. If desired turn the

distance off of the ground, and verify that the depth

beeping off by pressing the sound key (SeeFigure 4).

reading on the display equals the distance that you

Inductive Mode

Key

raised the receiver.

5. Once the locating is completed, press the inductive

mode key again toexit inductive mode, then pressthe

POWER ON/OFF button on the keypad to turn the

Orientation

transmitter OFF.

Mark

Selecting A Frequency

Select a frequency for locating by pressing a frequency

key on the keypad (See Figure 16). The frequency will be

shown in the display. For 262 kHz, press the 33 kHz key

twice. (In European versions, this will set the frequency to

Figure 14 – Inductive Mode Key

93 kHz.) The frequency selected will show on the display.

3. Select a frequency as described in thismanual. When

Frequency

using Inductive Mode, higher frequencies tend to get

Selected

a better signal at the receiver.

4. Turn on the receiver/locator and follow its instruc-

tions. Make sure to set the receiver to the same fre-

quency as the transmitter.

Transmitter

128Hz

Field

1kHz

Induced Field

On Target

Conductor

8kHz

33kHz/93kHz

or 262kHz

Figure 16 – Frequency Display

Target

Conductor

30 Feet Minimum

It is usually best to use the lowest frequency needed to in-

Figure 15 – In Inductive Mode, Locate At Least 30 Feet

duce a signal on the target conductor. Lower frequencies

From Transmitter To Insure Tracing Target

usually travel farther. Higher frequencies generally make

Conductor

it easier to induce a signal on the target conductor but are

more likely to cause signals on adjacent, non-target con-

When the transmitter is in inductive mode, itgenerates

ductors causing distortion and reducing accuracy.

a field around the transmitter. This field is in both

The default ST-510 frequency settings are for use with a

the ground (towards the target conductor) and into the

RIDGID receiver/locator. If using another manufacturer’s

air around the transmitter. When the receiver is within

receiver compatible frequencies will need to be loaded.

approximately 30 feet (10 meters) of the transmitter,

TheST-510 transmitter has theappropriate frequencies for

it will measure the field directly from the transmitter

a variety of other receiver/locator units available by using

and not the signal induced on the target conductor.

the manufacturer menu in the main menu. For available

This is called “Air Coupling”. Operate the receiver

10

Ridge Tool Company

manufacturers and frequencies, see the Manufacturers

Check The Circuit

Frequency Table on page 16. Consult your re-

Look at the resistance (Ω - ohms), the voltage (V) and

ceiver/locator operator’s manual or manufacturer for more

the current (mA) displayed on the screen (See Figure

information on those products.

20). Display numbers are approximate. Generally the

To load other manufacturers frequency information

lower the ohms (total resistance) the more efficiently

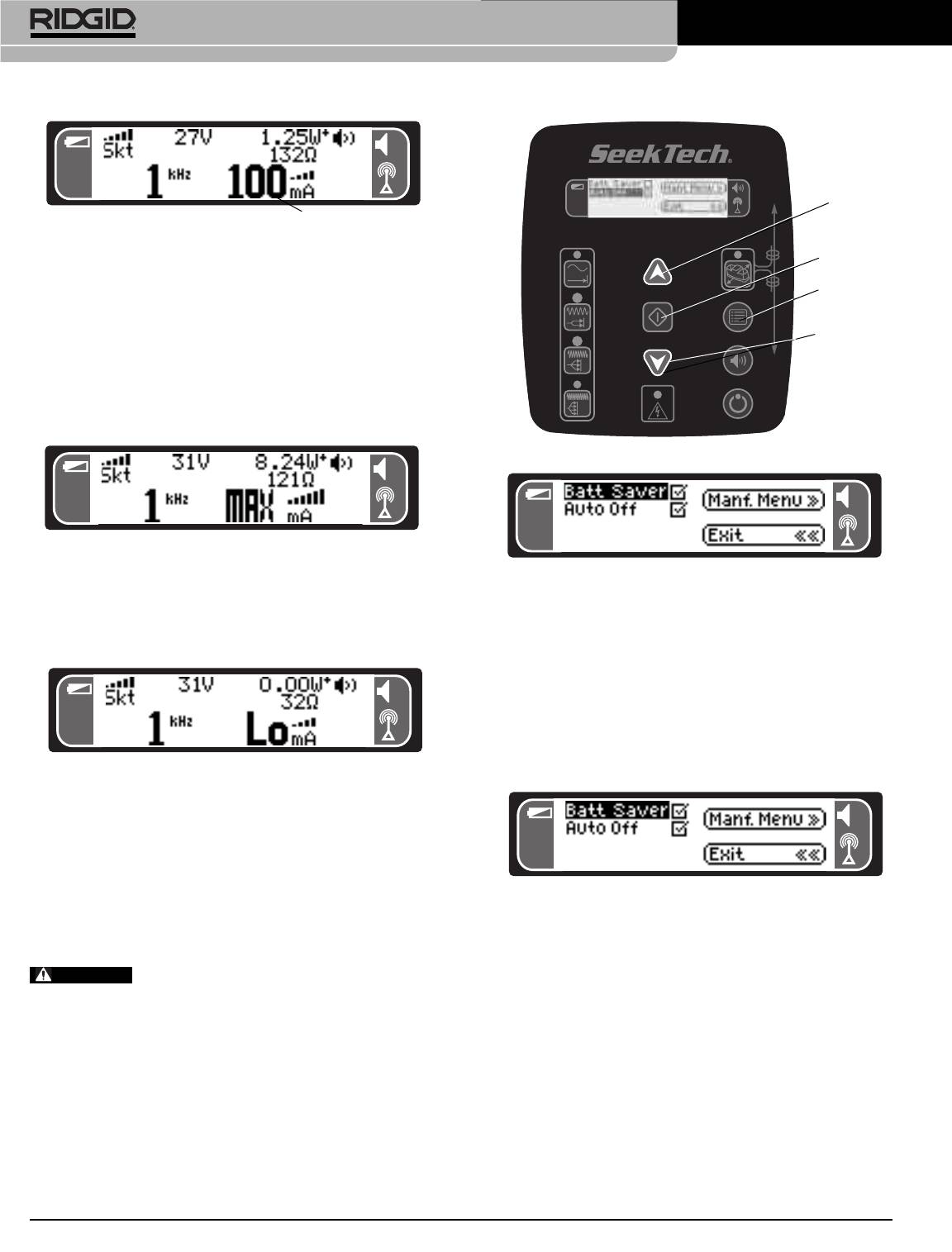

• Press the menu key (Figure 4).

current can be added. Lower total resistance indicates an

efficient circuit and requires less voltage to induce a

• Use the UP/DOWN keys to scroll to “Manf. Menu”

signal in the line.

and press the select key. This will bring up the list of

manufacturers. (Figure 17).

• Use the UP/DOWN keys to scroll to the appropriate op-

tion and press the select key. (Figure 18).

Figure 20 –Display Panel

The transmitter will beep faster if the resistance is lower

Figure 17 – Manufacturers Menu Selection

and slower if the resistance is higher.

Adjust Current

Use the up and down keys to adjust the amount of cur-

rent in milliamps (mA) (Figure 21).

More current gives a stronger signal. Less current pro-

Figure 18 – List of Manufacturers (First Screen)

longs battery life. Signal strength measured by the re-

ceiver is directly proportional to the amount of current on

When using the frequency keys while set up for a dif-

the line. More current means a stronger signal will be re-

ferent manufacturers receiver/locator, the lowest fre-

ceived by the receiver.

quency is controlled by the top (closest to the readout)

frequency key. The frequency moves higher with

To prolong battery life and reduce the chance of the sig-

each key further away from the readout. If there are

nal “bleeding over” onto adjacent lines, use the minimum

more than four frequencies, pushing the frequency

amount of current needed to get a clear reading on the

key furthest from the readout multiple times will in-

receiver.

crement the frequency to the next higher frequency.

(See Figure 19.) As always, the frequency selected is

displayed on the readout.

Figure 21 – Current Selection (Up and Down Keys)

There are 7 current levels that the user can choose

from: 5, 25, 50, 100, 200 or 400 mA.

Figure 19 – Frequency Buttons – Other Manufacturer

Receiver/Locator

))

))

))

))

))

))

Frequency

Selected

Low

Med Low

Med High

HIgh

))

))

))

®

SeekTech

ST-510 Line Transmitter

Resistance

Voltage

Current

Ridge Tool Company

11

Figure 22 – Current Selected

When a current level is chosen, the transmitter will adjust

the voltage to try and produce the selected current and

lock it in. If the transmitter cannot produce the current se-

lected, it will adjust down to the next level.

The transmitter’s maximum current output depends on

the amount of resistance in the circuit. When the trans-

mitter is putting out the maximum current possible for in-

ternal and external conditions, MAX will be displayed in

place of the current strength number.

Figure 25 – Menu, Up and Down and Select Keys

Figure 23 – MAX Current

Figure 26 – Main Menu Choices

MAX will also appear if the power output of the trans-

mitter is at its allowable limit.

To accept the highlighted choices, press the select key.

When the current drops below 5 mA, “LO” will appear in-

stead of a number.

Battery Saver Mode

This allows the user tolimit thepower output of the ST-510

line transmitter to approximately 1 watt in order to prolong

the life of the batteries. In many cases 1 watt of power is

all that is needed. Using the unit with up to 10 watts allows

for more power to be used, but consumes the batteries

Figure 24 – LO Current

much faster. Battery Saver is off by default.

If the desired current output cannot be produced, the volt-

age and ohms (resistance) readings can give useful in-

formation. For example, if the transmitter is putting out a

high voltage, the resistance of the circuit is probably

too high. If the voltage is lower (30V max) and the ohms

Figure 27 – Battery Saver and Auto-Off Options

(resistance) reading is also low, the line transmitter may

be constrained by power restrictions. (See FCC limits in-

Auto Shut Off Adjustment

formation on page 4.)

Check this box to have an automatic shut OFF of the

If the transmitter is showing low or no

transmitter. When checked, using the select key, the ST-

current, the signal may be too low to be detected by

510 will automatically shutdown to help conserve batter-

the receiver locator and inadequate for tracing.

ies. Shutdown time using this feature varies with current

draw. The approximate values are:

Main Menu

8 hrs 25mA output or less

To access the main menu, press the menu key (See

4 hrs 50-100mA

Figure 25). The Up and Down keys can be used to scroll

2 hrs 200-400mA

through the main menu choices (See Figure 26) in either

1hr >400mA

direction.

This feature prevents the batteries from running down if

the unit is inadvertently left on. Auto Shutoff is on by de-

fault. (See Figure 27).

))

))

))

))

))

))

Up Key

Down Key

))

))

))

Select Key

Menu Key

))

))

))

WARNING

))

))

))

®

SeekTech

ST-510 Line Transmitter

Current

12

Ridge Tool Company

®

SeekTech

ST-510 Line Transmitter

Auto Back Light

Cleaning Instructions

The SeekTech is equipped with an automatic LCD back-

light. Whenever a key is pressed, the backlight is acti-

WARNING

vated to aid viewing for 80 seconds.

Remove batteries before cleaning.

Adjusting the LCD Screen Contrast

1. Keep the ST-510 line transmitter clean with a damp

cloth and some mild detergent. Do not immerse in

LCD contrast is set at the factory and should not normally

water.

require adjustment. Optimal contrast is set when the

background remains white, while the black pixels are set

2. When cleaning, donot use scraping tools or abrasives

to be as dark as possible.The LCD can be adjusted to

as they may permanently scratch the display. NEVER

completely white or completely black, which will affect

USE SOLVENTS to clean any part of the system.

readability.

Substances like acetone and other harsh chemicals

can cause cracking of the case.

LCD contrast may change with extremes in tempera-

ture. When the screen is exposed to high heat from direct

sunlight it may darken. It is recommended that the screen

Accessories

be shaded if it is to beexposed to excessive sunlight. Use

the shoulder strap to cover the screen if needed.

WARNING

If the display appears too dark or too light when it is on, it

The following accessories have been designed to

function with the ST-510 line transmitter. Other ac-

is likely that the LCD contrast has become misadjusted.

cessories suitable for use with other equipment

First try powering the unit OFF and then back ON. If the

may become hazardous when used with the ST-

problem persists adjust the LCD contrast darker or lighter

510 line transmitter. To reduce the risk of serious in-

as needed.

jury, only use accessories specifically designed and

recommended for use with the ST-510 line trans-

To adjust the LCD Contrast:

mitter, such as those listed below.

1. Press and hold down the select key.

• Receivers: RIDGID SeekTech SR-20 (Cat#21893),

or SR-60 (Cat#22163)

2. Simultaneously press the up arrow key to lighten

• Inductive Clamp (Cat# 20973)

the display or press the down arrow key to darken the

display.

SR-20 SR-60

Inductive Clamp

Figure 28 – Adjusting LCD Contrast

Ridge Tool Company

13

®

SeekTech

ST-510 Line Transmitter

Replacement Parts

Disposal

Parts are available from your local RIDGID Distributor.

Parts of the SeekTech ST-510 Line Transmitter contain

A

CB

valuable materials and can be recycled. There are com-

panies that specialize in recycling that may be found lo-

cally. Dispose of the components in compliance with all

applicable regulations. Contact your local waste man-

agement authority for more information.

For EC countries: Do not dispose of elec-

trical equipment with household waste!

D

According to the European Guideline

2002/96/EC for Waste Electrical and

E

Electronic Equipment and its implemen-

tation into national legislation, electrical

equipment that is no longer usable must be collected

separately and disposed of in an environmentally correct

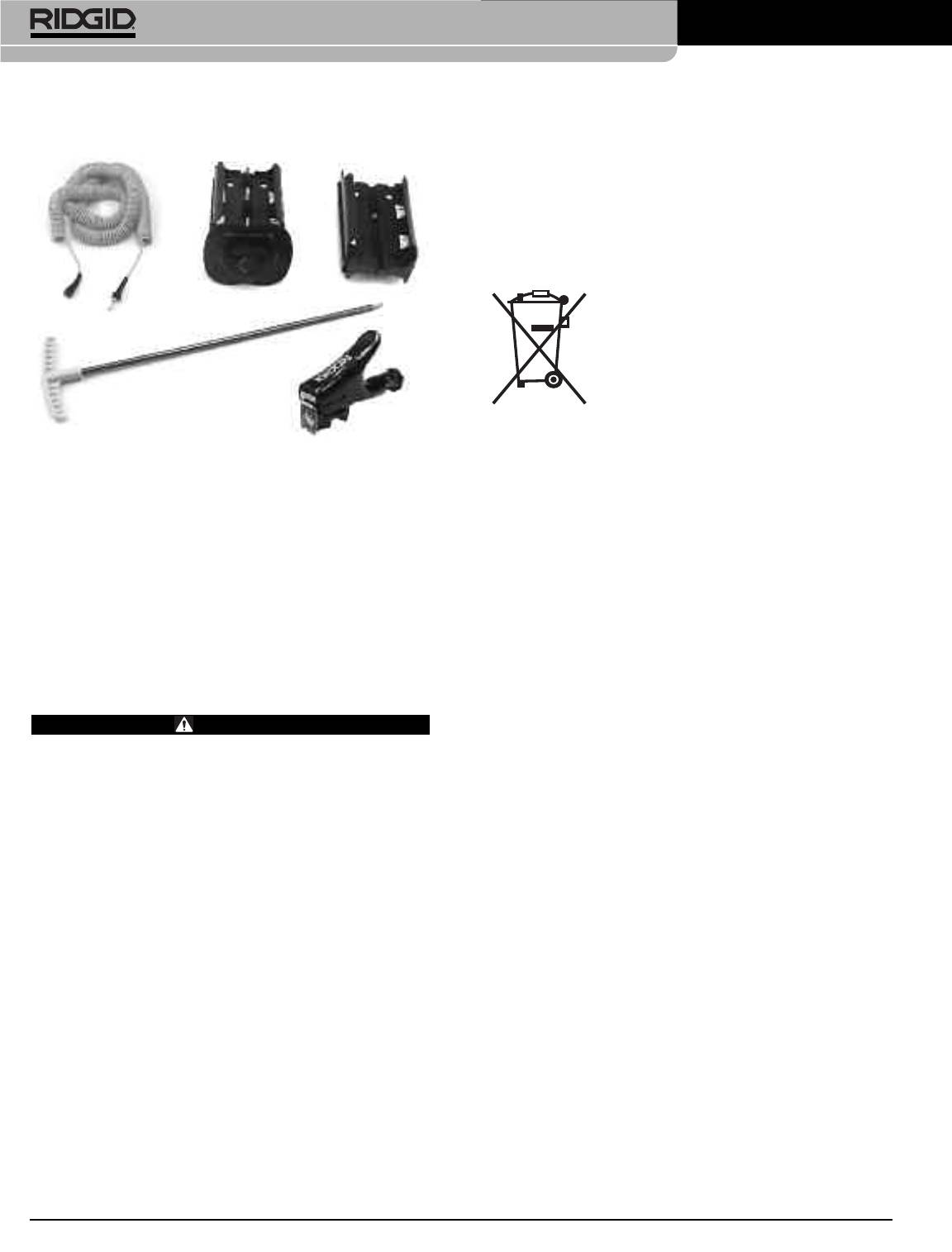

A. Direct Connect Lead(48ft./16m) (Cat. #18423)

manner.

B. Battery Holder Cover Assembly (Cat. #18428)

C. Battery Holder (Cat. #18433)

D. Ground Spike (Cat. #18438)

E. Direct Connect Lead Clip (Cat. #18443)

Transport And Storage

Remove batteries before shipping. Do not expose to

heavy shocks or impacts during transport. If storing for an

extended period, remove batteries. Store in environments

withintemperature range of14°Fto 158°F(-10°Cto 70°C).

Service And Repair

WARNING

Improper service or repair can make machine un-

safe to operate.

Service and repair of the SeekTech ST-510 must be per-

formed by a RIDGID Independent Authorized Service

Center.

For information on your nearest RIDGID Independent

Service Center or any service or repair questions:

• Contact your local RIDGID distributor.

• Visit www.RIDGID.com or www.RIDGID.eu to find

your local Ridge Tool contact point.

• Contact Ridge Tool Technical Services Department at

rtctechservices@emerson.com, or in the U.S. and

Canada call (800) 519-3456

14

Ridge Tool Company

®

SeekTech

ST-510 Line Transmitter

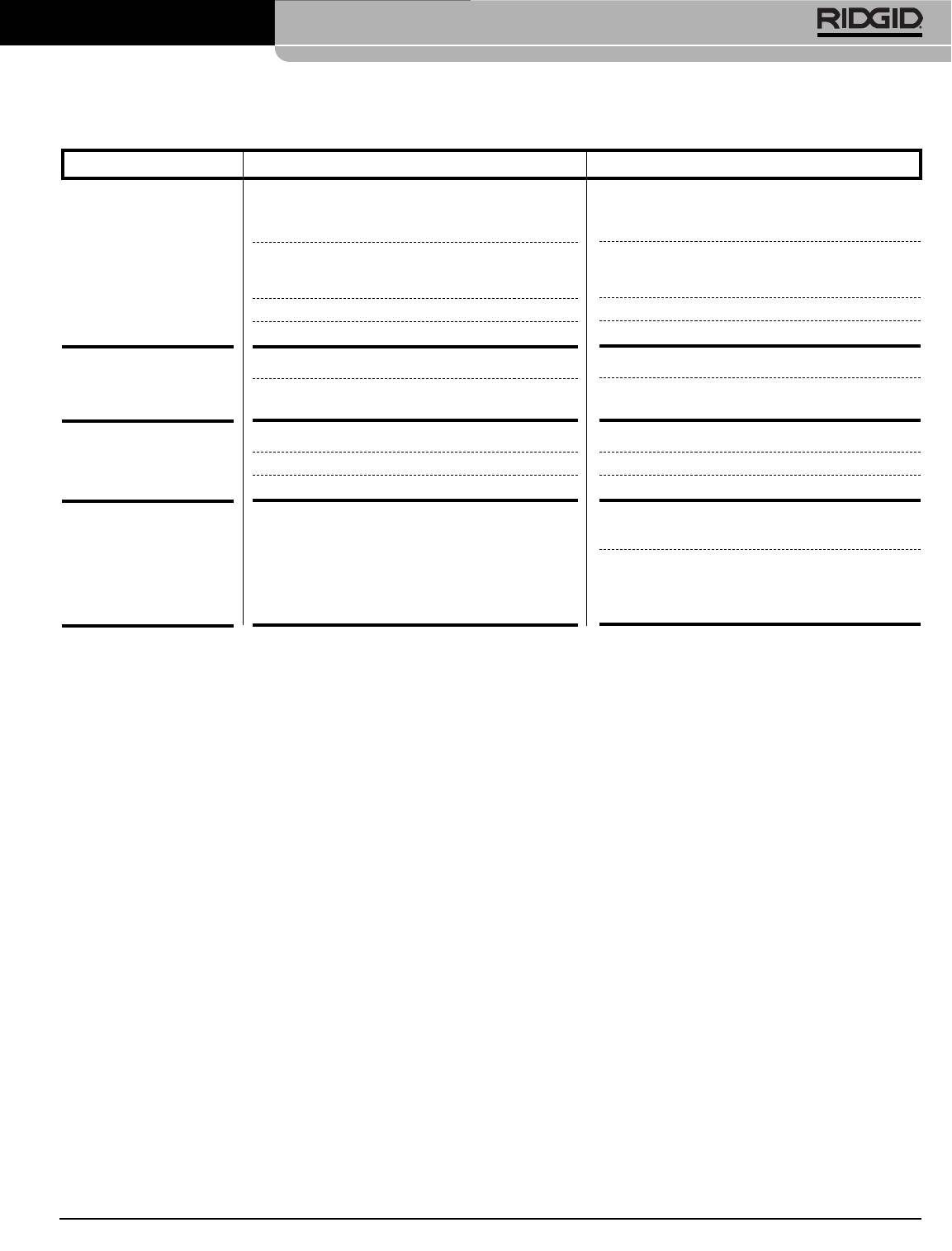

Chart 1 Troubleshooting

PROBLEM POSSIBLE REASONS SOLUTION

Receiver will not pick up

The Receiver and the Transmitter may not be on

Check that the correct frequency has been se-

the line transmitter’s

the same frequency.

lected on both units (See manual for the specific re-

signal.

ceiver). Higher or lower frequencies may be tried.

The receiver may not be in the correct mode.

Make sure that the proper functions are activated on

the receiver. e.g. activating the line trace function for

line tracing (See manual for the receiver).

Inadequate grounding.

Ensure grounding is adequate.

Power output may need to be increased.

Adjust power output upward if possible.

LCD appears completely

LCD may need to be reset.

Try Powering the unit OFF and then back ON.

dark, or completely light

Unit may be overheated.

Allow the unit to cool if it has been exposed to ex-

when unit is ON.

cessive heat from sunlight.

Unit will not turn ON.

Batteries may not be properly oriented.

Check orientation of batteries.

Batteries may be dead.

Check that the batteries are fresh or charged.

Battery Contacts may be broken or bent.

Inspect battery contacts.

93 kHz signal not

Receiver is not set to the correct 93kHz frequency.

Change transmitter frequency to 93696 Hz by se-

received.

lecting RIDGID-Old on manufactures menu.

Check that receiver is set to the actual 93kHz

frequency of 93,622.9 Hz. Some receivers use a

different frequency for 93 kHz (93,696). Update

SeekTech receiver software.

Ridge Tool Company

15

®

SeekTech

ST-510 Line Transmitter

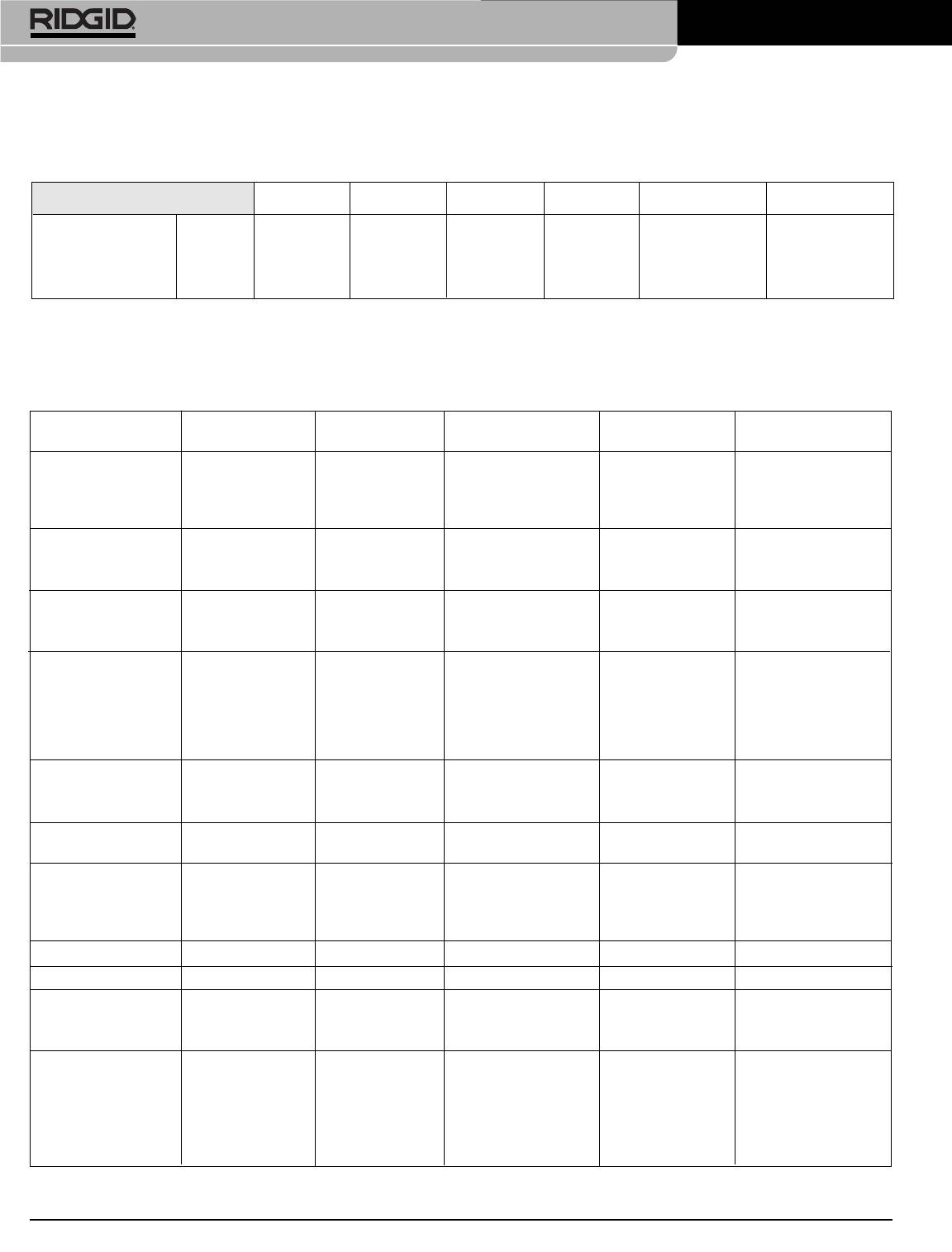

Frequencies

Exact Frequencies per Band (In Hz)

128 Hz 1kHz 8kHz 33kHz 93kHz* 262kHz

Default Line 128 1024 8192 32768 93623 262144

(SeekTech)

*(European

(European

Model Only)

Model Limited

To 93kHz)

Manufacturers Frequency Table

Displayed

Available

Exact

Company

Model

Notes

Manufacturer Frequencies Frequency (Hz)

577Hz 577

200 KHz not present

Dyna 3M Dynatel™ 8kHz 2273 8192

in European model of

33kHz 32768

the ST-510.

200kHz 200012

820Hz 821

Fish FISHER 8.2kHz TW-8800 8217

82kHz 82488

512Hz 512

Gen Gen-Eye™ 8kHz LCTX 512/8/65 8192

65kHz 65536

Not recommended for

use with the ST-510

transmitter.

Gold GOLDAK 117.5kHz 3300 117500

Not present in

European model of

the ST-510.

Heath 8.1kHz 8128

480 KHz not present

Heath Consultants 81kHz ALLPRO 81326

in European model of

Incorporated 480kHz 480323

the ST-510.

®

9.5kHz

9499

Made by Takachiho

McLau McLAUGHLIN

VERIFIER

38kHz 37997

Sanyo Co., Ltd.

982Hz 982

®

9.8kHz 9890 9820

Metro METROTECH

82kHz 810 for 83kHz 82488

83kHz 83080

MicroE Microengineering 76.8kHz Xmtr-101 76802

Mytan MyTana 76.8kHz PT20 76802

Not present in

Phorn PipeHorn 480kHz 479956

European model

of the ST-510.

512Hz 512

Radio Detection 8kHz

8192

(Same as

200 kHz not present in

(Same as 33kHz

32768

RD

LCTX 512/8/65

European model of the

Gen-Eye™ 65kHz

65536

above)

ST-510.

above) 82kHz 81865

200kHz 200000

16

Ridge Tool Company

®

SeekTech

ST-510 Line Transmitter

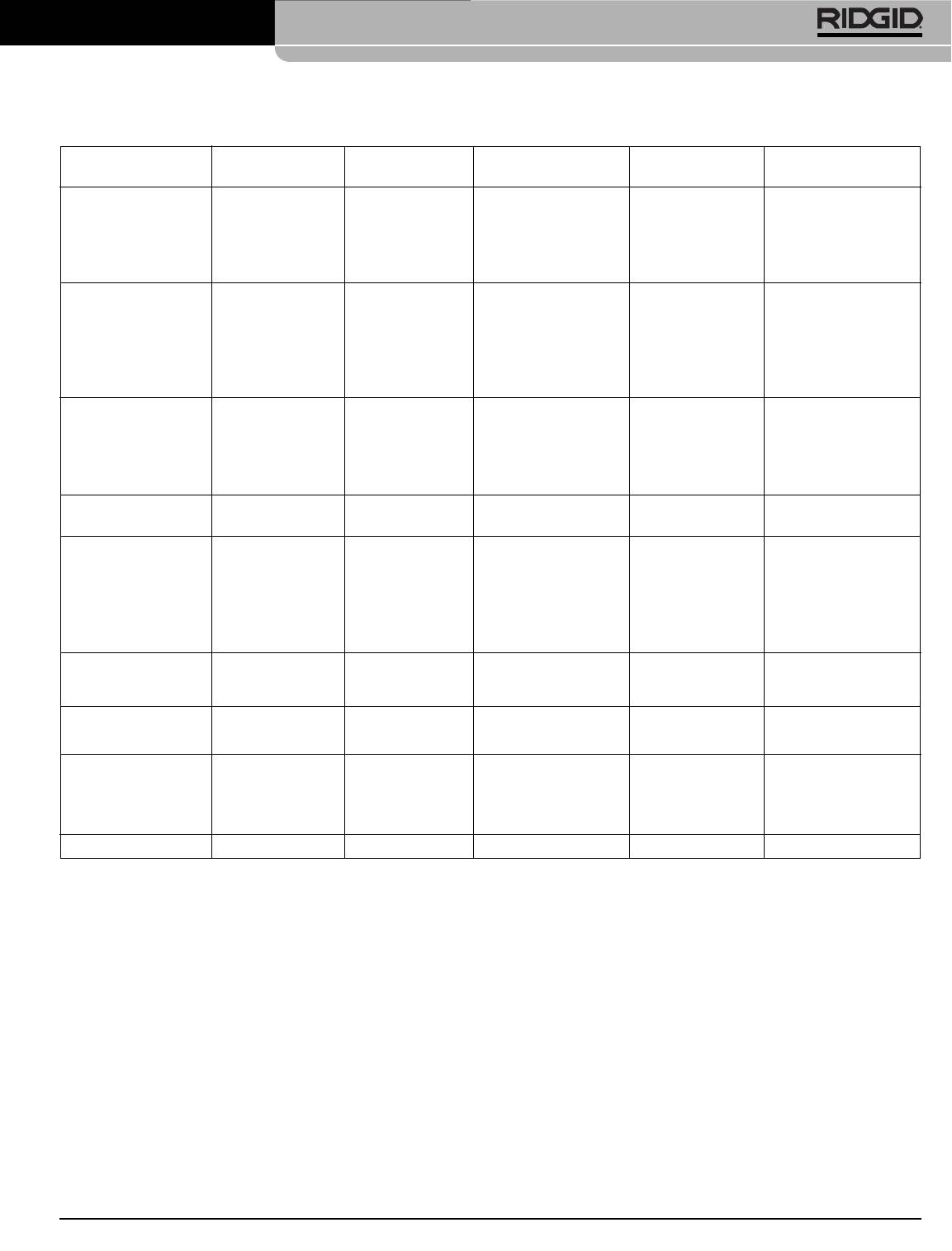

Manufacturers Frequency Table (continued)

Displayed

Available

Exact

Company

Model

Notes

Manufacturer Frequencies Frequency (Hz)

512 512

8kHz 8192

200k changed to

®

RIDGID

(Old) Ridge Tool Co. 33kHz 32768

93kHz in European

51kHz 51712

model of the ST-510.

200kHz 200000

128 Hz 128

1 kHz 1024

®

262k changed to

RIDGID

(New) Ridge Tool Co. 8 kHz 8192

93kHz in European

33 kHz 32768

model of the ST-510.

93 kHz 93623

262 kHz 262144

128 Hz 128

1 kHz 1024

RIDGID-B (New) Ridge Tool Co. 8 kHz 8192

33 kHz 32768

93 kHz 93696

815Hz

815

Ryco RYCOM

8876

82kHz 82318

SeekTech-B 128 Hz 128

1kHz 1024

8kHz 8192

33kHz 32768

93kHz* 93696

* 93 kHz on European

262kHz 262144

model Only

Schonstedt

Schon Instrument 575Hz TraceMaster 575

Company

8kHz

8055

Ssurf SubSurface

PL-2000

Made by FUJI TECOM

27kHz 26721

®

SubS SUBSITE

1kHz 1170

ELECTRONICS 8kHz 950 8009

Ditch Witch® 29kHz 29430

80kHz 80429

Telex 577Hz 577

Ridge Tool Company

17

®

SeekTech

ST-510 Line Transmitter

18

Ridge Tool Company