Ridgid Power-Spin: инструкция

Раздел: Электроинструменты

Тип:

Инструкция к Ridgid Power-Spin

Power-

Spin

EN

p. 1

FR

p. 9

ES

p. 17

DE

p. 25

NL

p. 33

IT

p. 41

PT

p. 49

SV

p. 57

DA

p. 65

NO

p. 73

FI

p. 81

PL

p. 89

CZ

p. 97

SK

p. 105

RO

p. 113

HU

p. 121

EL

p. 129

HR

p. 139

SL

p. 147

SR

p. 155

RU

p. 163

TR

p. 173

RIDGE TOOL COMPANY

Drain Cleaner

POWER-SPIN®

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

Power-Spin® Drain Cleaner

electrical shock, re and/or

Record Serial Number below and retain product serial number which is located on nameplate.

serious personal injury.

Serial

No.

POWER-SPIN® Drain Cleaner

Contents

Safety Symbols .................................................................................................................................................2

Specic Safety Information .......................................................................................................................3

Drain Cleaner Safety .................................................................................................................................... 3

Description and Specications ................................................................................................................ 3

Description ...................................................................................................................................................... 3

Specications ................................................................................................................................................. 4

Machine Inspection .......................................................................................................................................4

Machine and Work Area Set-Up ..............................................................................................................5

Operating Instructions ................................................................................................................................6

Maintenance Instructions ..........................................................................................................................8

Cleaning ...........................................................................................................................................................8

Installing Replacement Cable .................................................................................................................. 8

To Remove Cable From Drum .............................................................................................................8

To Install Replacement Cable ..............................................................................................................8

Troubleshooting .............................................................................................................................................. 8

Lifetime Warranty .......................................................................................................................Back Cover

*Original Instructions - English

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to

communicate important safety information. This section is provided to improve understand-

ing of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could result in mi-

nor or moderate injury.

NO TICE

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment.

The operator’s manual contains important information on the safe and proper operation

of the equipment.

This symbol means always wear safety glasses with side shields or goggles when han-

dling or using this equipment to reduce the risk of eye injury.

This symbol indicates the risk of hands, ngers or other body parts being caught,

wrapped or crushed in the drain cleaning cable.

2

POWER-SPIN® Drain Cleaner

operating or handling drain cleaning

Specific Safety

equipment. This will help prevent con-

Information

tamination with toxic or infectious mate-

rial.

WARNING

Do not operate this machine if opera-

This section contains important safety in-

tor or machine is standing in water.

formation that is specific to this tool.

Oper ating machine while in water in-

Read these precautions carefully before

creases the risk of electrical shock.

using the Power-Spin® Drain Cleaner to

Only use drain cleaner to clean drains

reduce the risk of electrical shock or other

of recommended sizes according to

serious personal injury.

these instructions. Other uses or modi-

fying the drain cleaning machine for

SAVE THESE INSTRUCTIONS!

other applications may increase the risk

of injury.

Drain Cleaner Safety

Read and understand these instruc-

Wear leather work gloves. Never grasp

tions, the battery drill instructions

the rotating cable with anything else,

and the instructions for any other

including cloth gloves or a rag. They

equipment used with this tool before

can become wrapped around the cable,

operating. Failure to follow all instruc-

causing hand injuries. Only wear latex or

tions may result in property damage

rubber gloves under leather work gloves.

and/or serious injury.

Do not use damaged gloves.

The EC Declaration of conformity (890-011-

Do not allow the end of cable to stop

320.10) will accompany this manual as a

turn ing while the machine is running.

separate booklet when required.

This can overstress the cable and may

If you have any question concerning this

cause twisting, kinking or breaking of

RIDGID® product:

the cable.

– Contact your local RIDGID distributor.

Position machine within 4" (100 mm)

– Visit www.RIDGID.com or www.ridgid.eu

of the drain inlet or properly support

to nd your local RIDGID contact point.

exposed cable when the distance ex-

ceeds 4" (100 mm). Greater dis tances

– Contact RIDGID Technical Services De-

can cause control problems leading to

part ment at rtctechservices@emer son.

twisting, kinking or breaking of the ca-

com, or in the U.S. and Canada call (800)

ble.

519-3456.

Do not wear loose clothing or jewelry.

Keep your hair and clothing away from

Description and

moving parts. Loose clothing, jewelry

Specifications

or hair can be caught in moving parts.

Always use appropriate personal pro-

Description

tective equipment while handling

The RIDGID® Power-Spin® Drain Cleaner will

and using drain cleaning equipment.

1

clean drain lines up to 1

/

2

" (40 mm) in di-

Drains may contain chemicals, bacte-

ameter and up to 25' (7,6 m) in length such

ria and other substances that may be

as bathroom and kitchen sinks, bathtub

toxic, infectious, cause burns or other

and shower drains. It features 25' (7,6 m) of

issues. Appropriate personal protec-

1

durable

/

4

" (6 mm) MAXCORE® cable that

tive equipment always includes safety

is positive ly retained in the drum to pre-

glasses and leather work gloves in

vent cable pullout. It is equipped with an

good condition, and may include equip-

AUTOFEED® that advances and retrieves

ment such as latex or rubber gloves, face

the cable with just the pull of a trigger. The

shields, goggles, protective clothing, res-

Power-Spin can be operated either manually

pirators and steel toed footwear.

or driven with a battery powered drill with a

Practice good hygiene. Use hot, soapy

maximum speed of 500 rpm.

water to wash hands and other body

The Power-Spin is not recommended for use

parts exposed to drain contents af-

with toilets.

ter handling or using drain cleaning

equipment. Do not eat or smoke while

3

POWER-SPIN® Drain Cleaner

Recommended Line

Machine Inspection

Cable Size

Size & Reach

WARNING

Line Size Reach

Before each use, inspect your drain clean-

1

1

/

4

" (6 mm) Cable Up to 1

/

2

"

25' (7,6 m)

ing machine and correct any problems to

reduce the risk of serious injury from elec-

(40 mm)

tric shock, twisted or broken cables, chemi-

cal burns, infections and other causes and

Specifications

prevent drain cleaner damage.

1

Drum Capacity......... 25' (7,6 m) of

/

4

"

1. Clean any oil, grease or dirt from all

(6 mm) Diameter

equipment, including handles and con-

MAXCORE Cable

trols. This aids inspection and helps

prevent the machine or control from

Drum Speed................ Maximum 500 RPM

slipping from your grip. Clean any debris

Weight.......................... 4.7 lbs. (2,1 kg)

from the cable and drum.

2. Inspect the drain cleaner for the follow-

NO TICE

ing items:

This machine is made to clean

drains. If properly used it will not damage a

drain that is in good condition and properly

designed, constructed and maintained. If the

binding parts

drain is in poor condition, or has not been

properly designed, constructed and main-

trigger and drum

tained, the drain cleaning process may not

be eective or could cause damage to the

-

drain. The best way to determine the condi-

ing label (see Figure 2.)

tion of a drain before cleaning is through vi-

If any problems are found, do not use

sual inspection with a camera. Improper use

the drain cleaner until the problems

of this drain cleaner can damage the drain

have been repaired.

cleaner and the drain. This machine may not

clear all blockages.

3. Inspect cable for wear and damage –

Look for:

the cable (cable is made from round

wire and prole should be round).

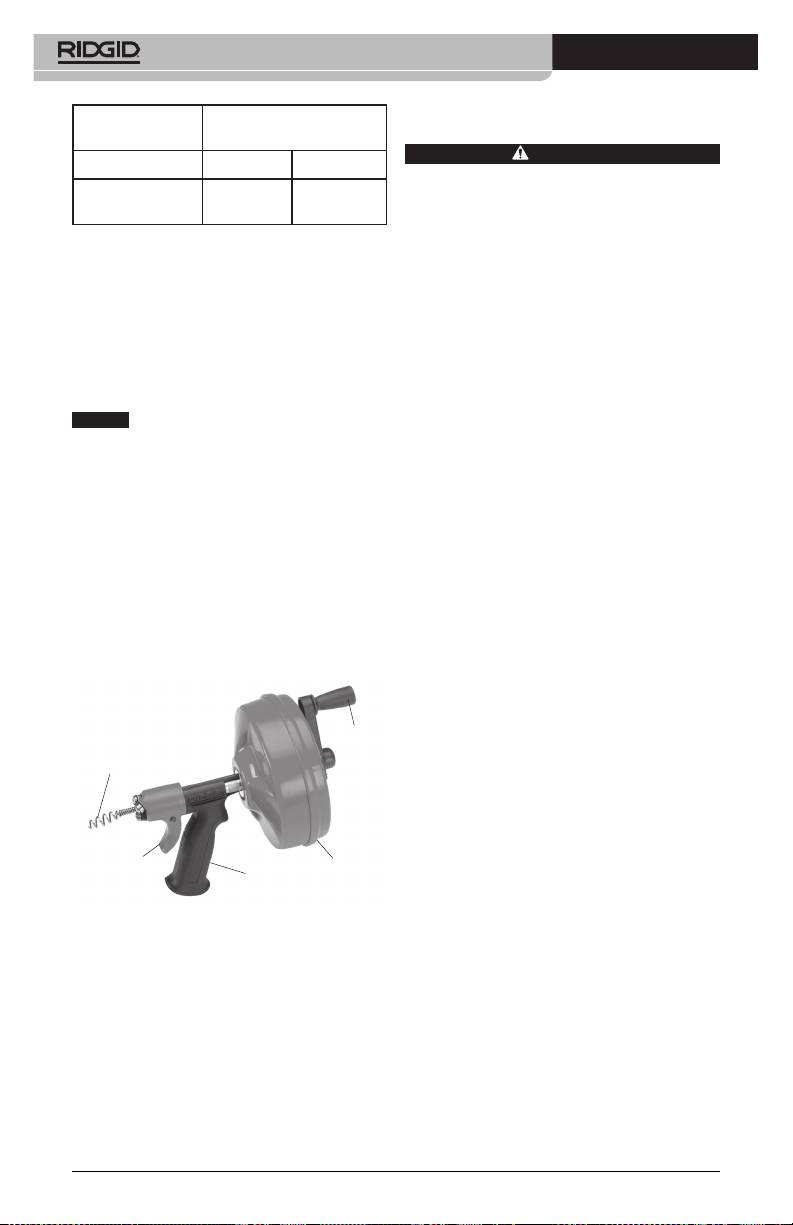

Crank

Cable End

(slight kinks up to 15 degrees can be

straightened).

-

ing the cable has been deformed by

stretch ing, kinking or run in REVERSE.

Trigger

Drum

Handle

or exposure to drain chemicals.

All of these forms of wear and damage

Figure 1 – Power-Spin

weaken the cable and make cable twist-

ing, kinking or breaking more likely dur-

ing use. Replace worn and damaged

cable before using drain cleaner.

4. If using the Power-Spin Drain Cleaner

with a Battery Power Drill, inspect the

drill per it’s instructions. Make sure that

the drill is in good operating condition

and the switch controls the drill opera-

tion. Conrm that the drill turns at less

than 500 rpm.

4

POWER-SPIN® Drain Cleaner

7. If using the Power-Spin with a battery

Machine and Work Area

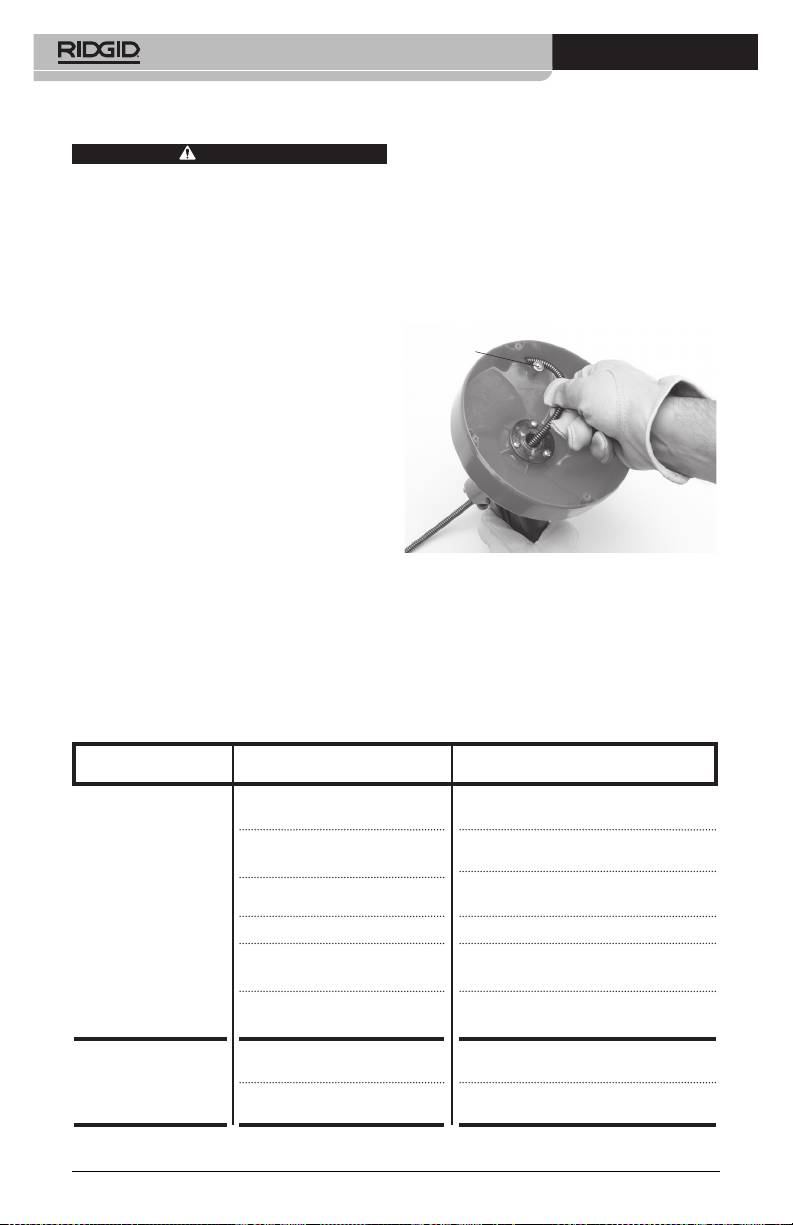

powered drill, remove the crank from the

Set-Up

back of the drum by pressing the tabs

on the either side (See Figure 2). Securely

WARNING

attach the chuck of the drill to the drum

Set up the drain cleaning machine and work

shaft.

area according to these procedures to re-

duce the risk of injury from electric shock,

twisted or broken cables, chemical burns,

Warning Label

infections and other causes, and prevent

drain cleaner damage.

Always wear safety glasses, leather gloves,

and other appropriate protective e quip-

ment when setting up your drain cleaner.

For extra protection from chemicals and

Drum Shaft

bacteria on the machine and in the work

area, wear latex, rubber or other liquid bar-

rier gloves under the leather gloves.

1. Check work area for:

Figure 2 – Removing Crank Handle From

Power-Spin

-

chine and operator. Do not use the

8. If needed, take appropriate steps to ac-

machine while standing in water. If

cess the drain to be cleaned.

needed, remove the water from the

work area.

threaded through the cross hairs in the

2. Inspect the drain to be cleaned. If pos-

drain (See Figure 3).

sible, determine the access point(s) to

the drain, the size(s) and length(s) of the

Remove lift rod and drain plug (See Fig-

drain, distance to mainlines, the nature

ure 4). Be sure to place a container un-

of the blockage, presence of drain clean-

der the clean out or trap to catch any

ing chemicals or other chemicals, etc. If

water that may come out.

chemicals are present in the drain, it is

important to understand the specic

safety measures required to work around

may need to be removed (See Figure

those chemicals. Contact the chemical

5.) Be sure to place a container under

manufacturer for required information.

the clean out or trap to catch any water

that may come out.

3. Determine the correct drain cleaning

equipment for the application. The Pow-

er-Spin is made for:

the drain, this will damage the cable.

1

/

2

"(40 mm) lines up to 25'

1

mechanism to access the drain (See Fi-

(7,6 m) long with

/

4

"(6 mm) cable.

gure 6).

can be found by consulting the Ridge

Tool Catalog, on line at www.RIDGID.

com or by calling RIDGID Tech nical

Services at 800-519-3456.

4. Make sure machine has been properly

inspected.

5. If needed, place protective covers in the

work area. The drain cleaning process

can be messy.

6. If using the Power-Spin by hand, make

sure that the crank is present and rmly

attached.

5

POWER-SPIN® Drain Cleaner

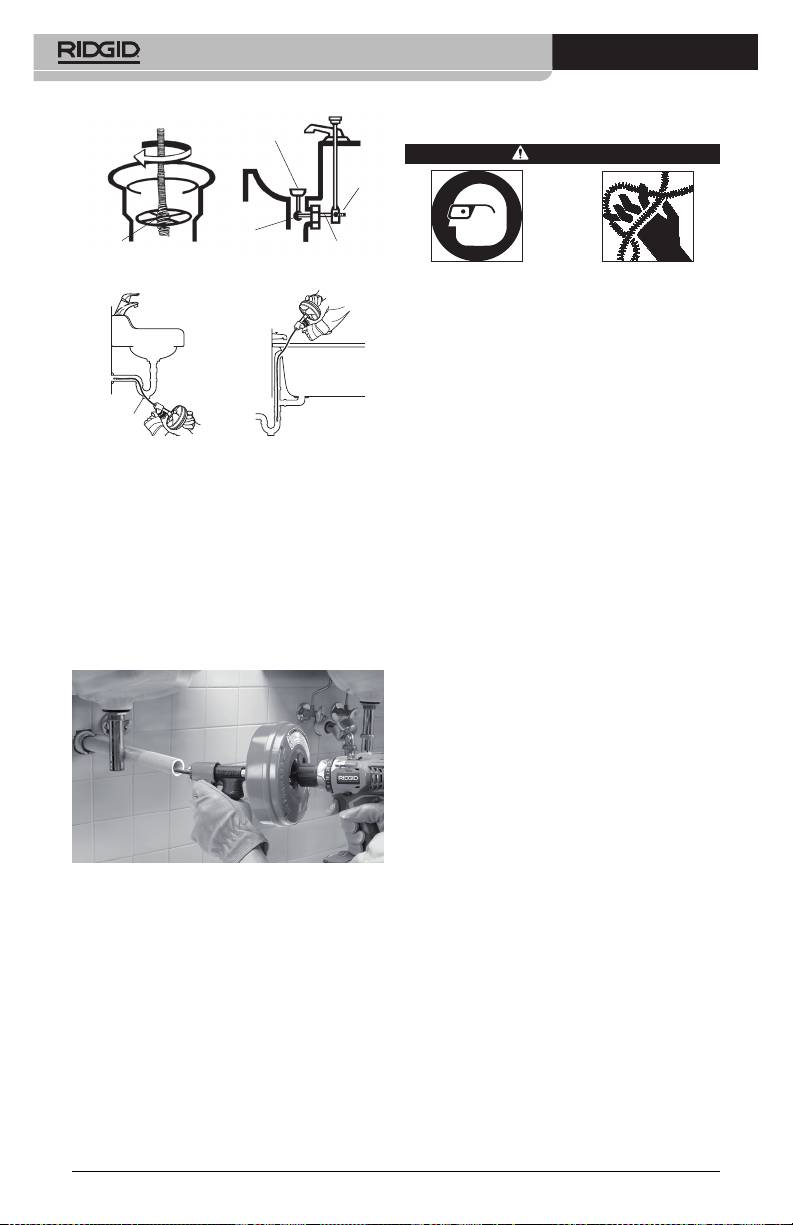

Drain Plug

Operating Instructions

WARNING

Set

Screw

Cap Nut

Cross

Hairs

Lift Rod

Figure 3

Figure 4

Always wear eye protection to protect your

eyes against dirt and other foreign objects.

When cleaning drains that might contain

hazardous chemicals or bacteria, wear ap-

propriate protective equipment, such as

goggles, face shields or respirators, to pre-

vent burns and infections. For extra protec-

Clean-out

tion from chemicals and bacteria on the

Plug

machine and in the work area, wear latex,

Figure 5 Figure 6

rubber or other liquid barrier gloves under

the leather gloves.

9. Determine if the Power-Spin can be

Follow operating instructions to reduce the

placed within 4" (100 mm) of the drain

risk of injury from twisted or broken cables,

opening. If not, the drain opening will

cable ends whipping around, machine tip-

need to be extended using similar size

ping, chemical burns, infections and other

pipe and ttings so that the Power-Spin

causes.

can be placed within 4" (100 mm) of the

1. Make sure that the work area is free of

drain opening (See Fi gure 7). Improper

bystanders and other distractions.

cable support can allow the cable to kink

or twist and damage the cable/xture or

2. Assume a proper operating position that

injure the operator.

will allow

over reaching.

used).

or less from the drain opening.

This will help maintain control of the

cable and machine.

3. Pull cable out of the drum and push into

drain as far as it will go. At least one foot

of cable must be in the drain so that the

Figure 7 – Example of Extending Drain

cable will not come out and whip around

to Within 4" (100 mm) of Drain

when the cable starts turning.

Opening

4. If using a battery powered drill, conrm

set to low speed (less than 500 rpm) and

with dry hands insert the battery, but do

not place you nger on the drill switch

yet.

5. Make sure that the drain cleaner is within

4" (100 mm) of the drain opening, and

maintain that distance throughout the

cleaning process. This helps to prevent

twisting and kinking of the cable.

6

POWER-SPIN® Drain Cleaner

6. Place one hand on the drain cleaner han-

8. Continue to advance the cable until the

dle with one or two ngers on the trig-

resistance is encountered. Carefully work

ger and the other hand on the drill grip

the cable through the blockage. Do not

or the crank.

force the cable – if the cable stops turn-

ing, it is not cleaning the drain. It may

7. Turn the drum clockwise (as marked with

be necessary to spin the cable without

an arrow on the back of the drum, see

advancing it, or advancing the cable

Figure 2) If using the Power-Spin manu-

very slowly. This will help to break up the

ally, use the crank (see Figure 8). If using

blockage.

a drill, operate it in the forward direction.

To feed the cable into the drain, squeeze

9. If the cable becomes stuck in the block-

the trigger rmly.

age, do not continue turning the drum.

Continuing to turn the drum may cause

the cable to twist and kink. It may be

necessary to back the cable out of the

blockage by turning the drum in reverse.

In some cases, it may be possible to pull

the cable and the blockage out of the

drain by hand. If this is done, be careful

to not damage the cable. Remove the

blockage from the cable, feed cable back

into the drum, and continue cleaning

the drain as detailed above.

10. Once the blockage is broken up and

drain.

11. Continue to clean the rest of the drain.

Figure 8 – Power-Spin Used By Hand

Pay attention to how far the cable has

gone. Do not overrun the cable into a

larger drain. This can cause the cable to

knot up or cause other damage.

12. Once the drain has been cleaned,

turn the drum counterclockwise while

squeezing the drain cleaner trigger to

retract the cable. Pay close attention, as

the cable may lodge in a blockage while

being retracted.

13. Release the drain cleaner trigger and

stop turning the drum when the end of

the cable nears the drain opening. Do

not pull the cable end from drain while

it is rotating. The cable can whip around

and could cause serious injury.

14. Several passes through a line are recom-

mended for complete cleaning. If need-

Figure 8A – Power-Spin Powered By Battery

ed, repeat the above procedure.

Drill

15. Pull any remaining cable from the line by

hand and push the cable into the drum.

7

POWER-SPIN® Drain Cleaner

2. To make cable installation easier, com-

Maintenance Instructions

pletely uncoil new cable before proceed-

ing. Use caution when removing the ca-

WARNING

ble from the package. The cable is under

Always wear safety glasses and leather

tension and could strike the user.

gloves when performing any maintenance.

3. Insert about 12" (0,3 m) of cable through

Drill should be removed from drain cleaner

the front rollers and guide tube into the

before any maintenance is performed.

drum.

4. Push end of cable into holder and under

Cleaning

clamp screw and washer. Tighten clamp

Cable, drum and AUTOFEED should be thor-

screw (see Figure 9).

prevent the damaging eects of chemicals

Clamp Screw

and sediment. Clean exterior as needed with

hot soapy water and/or disinfectants. Drain

drum by tipping forward after every use and

cleaning.

Installing Replacement Cable

To Remove Cable From Drum

1. Pull out excess cable from drum.

2. Remove 4 screws on back of drum.

3. Loosen clamp screw and pull end of old

cable from drum and discard.

Figure 9 – Installing Cable End Into Holder

To Install Replacement Cable

1

1. Replacement

/

4

" (6 mm) x 25' (7,6 m)

5. Replace drum back and retighten the 4

MAXCORE® cables are available under

screws.

catalog number 42163.

6. Feed cable into drum.

Troubleshooting

PROBLEM POSSIBLE REASONS SOLUTION

Cable kinking or

Cable is being forced Do Not Force Cable! Let the auger do

breaking.

the work.

1

Cable used in incorrect pipe

Do not use in lines over 1

/

2

" (40 mm).

diameter.

Use reverse only if cable gets caught in

Motor switched to reverse

pipe or to retract cable.

Cable exposed to acid. Clean cables routinely.

Cable worn out or damaged. If cable is worn or damaged, replace it.

Cable not properly supported. Support cable properly, see instructions.

Cable won’t feed. Cable bearings are dirty or

Clean cable and bearings with hot, soapy

greasy.

water.

AUTOFEED not fully engaged. Be aware and squeeze trigger harder.

8

Оглавление

- POWER-SPIN®

- Power-Spin

- Power-Spin®